Armstrong FLO-RITE-TEMP 8120, FLO-RITE-TEMP 415, FLO-RITE-TEMP 415DW, FLO-RITE-TEMP 535DW, FLO-RITE-TEMP 665DW Installation And Adjustment Instructions

...

Bulletin No. AY-780-K

FLO-RITE-TEMP

INSTANTANEOUS WATER HEATER

INSTALLATION AND ADJUSTMENT INSTRUCTIONS

FOR SINGLE AND DOUBLE WALL UNITS

This bulletin should be used by experienced personnel as a guide to the installation of the

FLO-RITE-TEMP Instantaneous Water heater. Selection or installation of equipment should always

be accompanied by competent technical assistance. You are encouraged to contact Armstrong

International, Inc. or its local sales representative for additional information.

FLO-RITE-TEMP

INSTANTANEOUS WATER HEATER

INSTALLATION AND ADJUSTMENT INSTRUCTIONS

NOTICE

No water heater will work satisfactorily if improperly installed and operated. These instructions contain

important information for the installation and adjustment of the FLO-RITE-TEMP Water Heaters. Read

these instructions carefully before installing this unit. FAILURE TO ADHERE TO THESE

INSTRUCTIONS COULD RESULT IN SERIOUS BODILY INJURY OR PROPERTY DAMAGE.

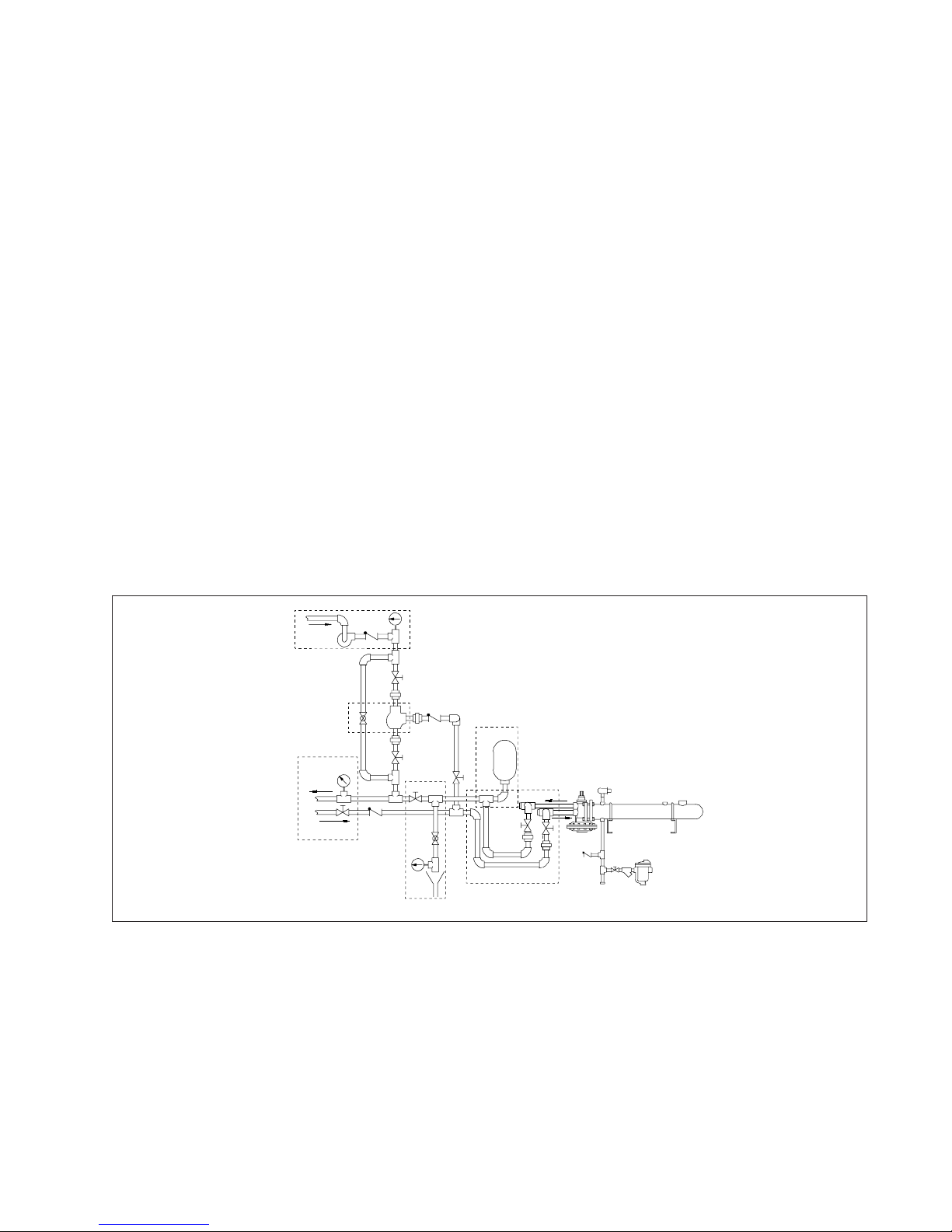

STEAM PIPING INSTALLATION OF A SINGLE UNIT

Single and Double Wall

Steam

In

Armstrong Pressure

Reducing Valve (If Req'd)

Armstrong

I.B. Trap

Armstrong Thermostatic

GP-2000

Air Vent

2-15 psig Steam

in the Shell

Vacuum Breaker

Pressure

Gauge

Gate

Valve

Safety Relief

Valve

Armstrong

I.B. Trap

NOTE: FLO-RITE TEMP is provided with (1) one Armstrong Steam Trap and Thermostatic

Air Vent (shaded). All other items shown not included.

Fig. 2-1

NOTE: units may be piped in parallel for larger capacity requirements. See Fig. 15-1 for an example of

parallel unit installation.

The unit includes the mixing valve mounted to the heat exchanger, channel iron and U-bolts mounted,

thermostatic air vent installed on the heat exchanger, a water pressure pop off valve integral to the unit control

valve and a separate Armstrong Inverted Bucket Steam Trap.

STEAM SIDE INSTALLATION

(Refer to Fig. 2-1)

1. Install the FLO-RITE-TEMP with adequate room to allow for tube bundle removal when cleaning is

required. See Table 12-1 for specific dimensions.

2. If 2-15 psig of steam is available a pressure reducing valve is NOT required. If a pressure reducing valve is

required, an Armstrong Inverted Bucket Steam Trap is recommended to drain condensate at the inlet of the

pressure reducing valve.

October 31, 2002 @ 3:15 pm

2

3. An Armstrong Y-strainer should be installed

before the pressure reducing valve to reduce the

chance of dirt fouling.

4. If an externally piloted pressure reducing valve is

used, the control pipe should be pitched away

from the PRV and installed at the pressure gauge

on the shell of the heat exchanger.

5. A steam safety relief valve should be used prior to

the heat exchanger if either or both of the

following conditions exist. (1) If the maximum

steam pressure could exceed the minimum water

pressure in the tubes, or (2) The maximum steam

pressure could exceed 150 psig (the maximum

steam pressure rating of the shell).

IMPORTANT -Steam supply pipe size

coming to the heat exchanger should NOT be

smaller than the steam connection supplied on

the heater, otherwise steam flow could be

restricted. If a pressure reducing valve is used,

installation should be as close as possible to the

Flo-Rite-Temp. Downstream piping from the

Pressure Reducing Valve should be expanded

immediately after the PRV to accomodate the

expanded volume of steam.

6. To vent start-up air, an Armstrong Thermostatic

Air Vent is included and installed on the top

connection, opposite the trap drain connection of

the heat exchanger. This discharge can be piped

to drain or the floor if preferred.

7. Install a vacuum breaker in the piping between the

heat exchanger drain connection and the steam

trap. This will prevent improper draining of the

heat exchanger caused by a possible vacuum

forming when the steam is shut off.

8. Install a suitable steam pressure gauge in the 1/4"

coupler located in the top mid section of the heat

exchanger shell. This gauge will help diagnose

pressure problems should they occur. This port

may also be used for a PRV external control pipe

if a PRV is required.

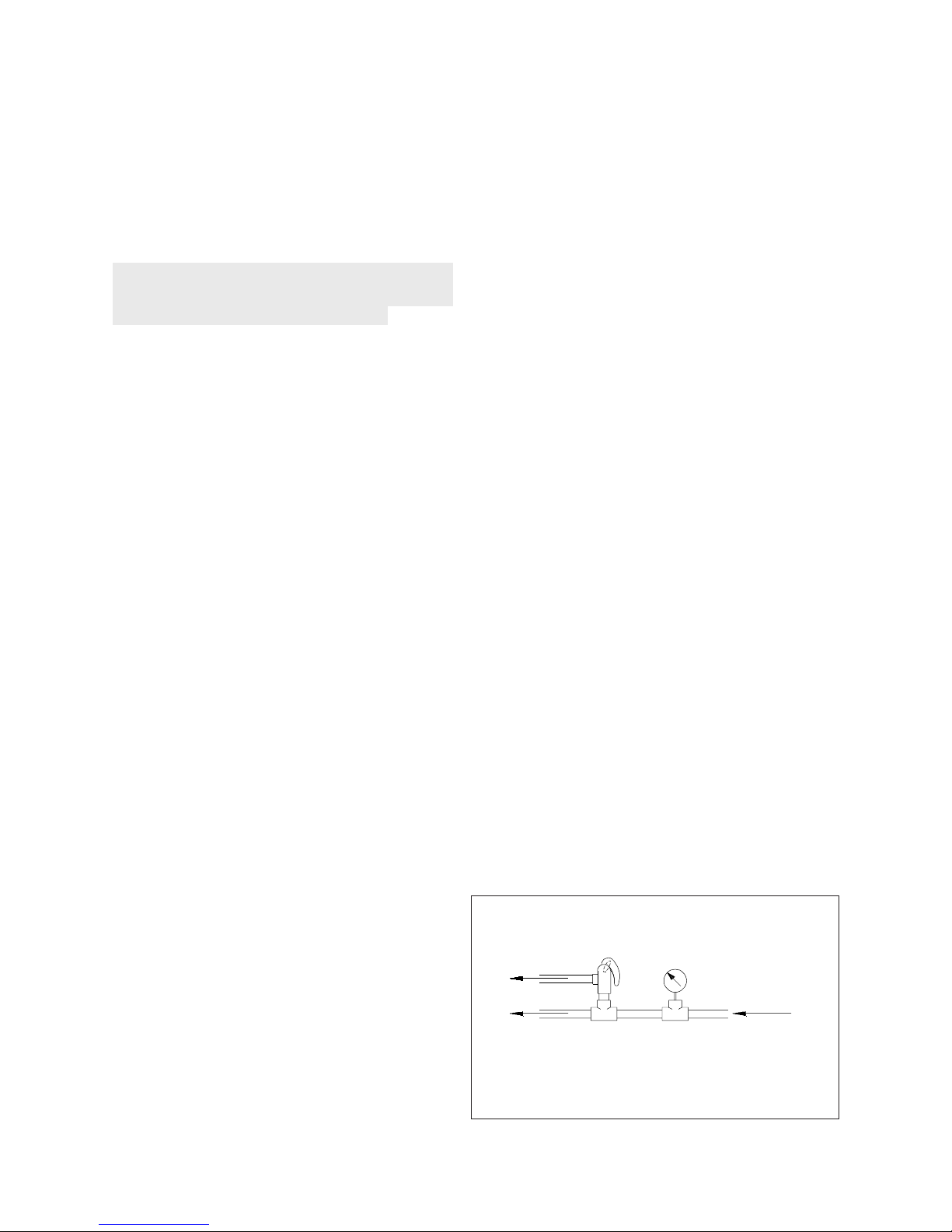

WATER PIPING INSTALLATION

(Follow same plumbing for DW units)

D

A

C

E

B

C

B

1. An 18 inch minimum thermal loop should be piped into the water inlet and outlet of the FLO-RITE-TEMP

and should be located as close to the mixing valve as possible (See Fig. 3-1A). These loops will act as a

thermal check valve or heat trap to prevent the conduction of heat through the water from the unit during

inactive times.

F

A

Fig. 3-1

2. Isolation valves and hose connections added to both the inlet and outlet water supplies will allow for

Clean-In-Place equipment to be utilized.

3. Use pipe unions on both the water inlet and outlet to allow ease of water heater mixing valve removal for

maintenance and removal of the tube bundle for cleaning (See Fig. 3-1A).

4. For adjusting the unit, an isolation valve and hot water by-pass to drain should be installed close to the unit

October 31, 2002 @ 3:15 pm

3

down stream from the thermal loops and prior to

the recirculation loop (if one is used) (See Fig.

3-1B). This allows for quick and easy setting of

the FLO-RITE-TEMP by one person. By isolating

the unit from the hot water system, flow can be

controlled to drain through the globe valve while

monitoring outlet water temperature during low

and high flow adjustments on the water heaters

mixing valve.

Minimum line sizes to drain should be as

follows: model 415 = 3/4", model 535 = 1",

model 665 = 1-1/4", model 8120 = 2". Line

sizes smaller than these will not allow sufficient

flow for making high flow settings on the mixing

valve.

5. A water temperature gauge should be installed

directly after the by-pass drain valve. This

thermometer is only used for inital temperature

adjustments of the Flo-Rite-Temp or

troubleshooting the unit. (See Fig. 3-1B)

6. If a recirculation system is used with a

FLO-RITE-TEMP, a small diverting valve must

be piped into the loop return downstream of the

recirculating pump (See Fig. 3-1C). This device is

used to divert recirculated water back to the

heater for reheating if the temperature of the

water drops too low due to no hot water demand

from the system plus piping radiation losses (See

page 9 for operation explanation). Be sure to pipe

in unions and isolation valves to facilitate diverting

valve removal required when element replacement

is needed. A throttling type valve should be

installed in a full return line size bypass around the

diverting valve in order to balance the flow to the

diverting valve. This is especially needed when

recirculating pumps are large or oversized.

7. For a recirculated system, a small constant running

pump should be piped in on the return side of the

loop (See Fig.3-1D). This pump should be sized to

move approximately 10% of the maximum rated

gpm of the FLO-RITE-TEMP in the system with

enough head to overcome the head encountered in

the loop.

NOTE: A thermometer should be installed in

the outgoing loop to monitor system temperature

(Fig. 3-1E). A thermometer may also be

installed on the loop return to monitor

temperature drop through the loop or to help

troubleshoot the diverting valve (Fig. 3-1D). The

thermometer referred to in point #4 and Fig. 3-1B

should only be used to set the FLO-RITE-TEMP

and never used to monitor system temperature.

NOTE: Expansion tanks should be used in on/

off demand applications where there is a short

duration of time from high flow to no flow of

water, i.e., a shut off time of 10 seconds or less.

(See Fig. 3-1F)

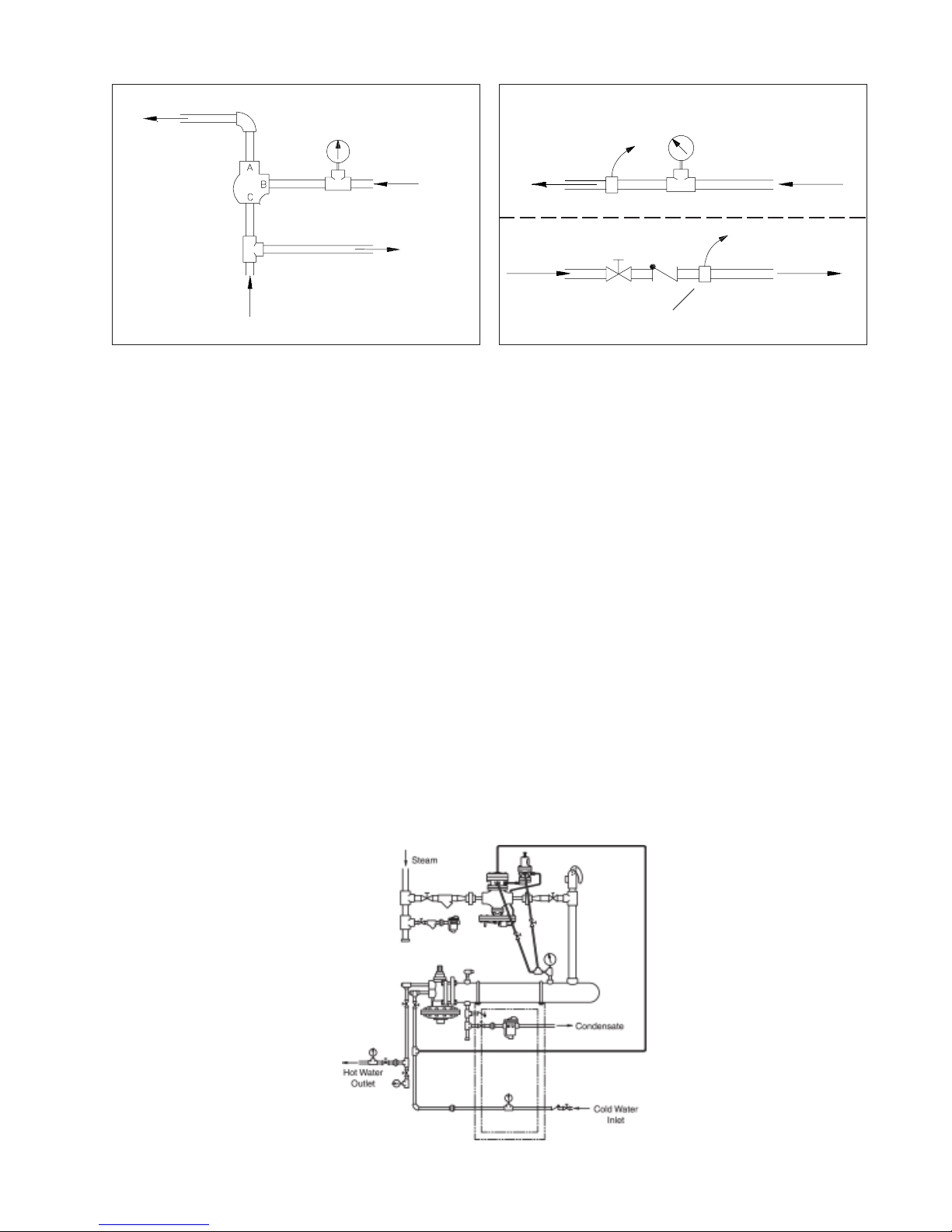

OPTIONAL SAFETY EQUIPMENT

See Fig. 3-1E for location of each option within the system. All options would be installed downstream of

the water heater in the outgoing recirculation loop, if one is present, or downstream of the hot water thermal

loop if recirculation is not used but always before the first hot water take off from the system.

Option #1 A temperature relief valve set at roughly 15-30 degrees above that of the FLO-RITE-TEMP

will help prevent any chance of overheated water reaching the faucets. (NOTE: Normally unit will fail closed

and either no water or only cold water will flow from the unit.)

Option #2 A 3-way blending valve with a set

point 10-30 degrees above that of the FLO-RITETEMP will help prevent the chance of overheated

water reaching the faucets in the event of unit failure.

Under normal operating conditions the hot water flows

straight through the blending valve from Port B to Port

A. But in the event of an overheated situation, the

blending valve will open Port C to add sufficient cold

water to maintain a constant temperature . (NOTE:

The blending valve should be sized to handle the

maximum flow of the system).

October 31, 2002 @ 3:15 pm

Temperature

Relief Valve

Option #1

4

Loop or System

Thermometer

Hot Water from

Flo-Rite-Temp

3-Way

Thermostatic

Valve

Loop or System

Thermometer

To Flo-Rite-Temp

Cold Water Supply

Option 3A

Temperature

Switch

Hot Water from

Flo-Rite-Temp

Option 3B

Pressure Switch

Loop or System

Thermometer

To steam

shut-off valve

Option #3Option #2

Hot Water Supply From

Flo-Rite-Temp

To Steam

Shut-Off Valve

!

Cold Water Supply to

Flo-Rite-Temp

Option #3 A temperature switch installed well downstream of the Flo-Rite-Temp outlet on a non-recirculated

system or just into the outgoing recirculated system loop on a recirculated system, with a set point 15-30

degrees above that of the FLO-RITE-TEMP will help prevent the chance of overheated water reaching the

faucets in the event of system problems. This switch can be used to turn off the steam supply to the heater in

the event of overheating. The most economical way to accomplish this is with a solenoid on the PRV. A full

ported motorized valve on the steam supply line may also be used. Option 3B. Along these same lines, a

pressure switch installed in the inlet water line would shut down the supply steam on the heat exchanger in the

event of water pressure loss, preventing thermal shock and water hammer to the unit.

Option #4 (Available only when a pressure reducing station is installed on the Flo-Rite-Temp). Using the

Model GP-2000W1P system, when piped as shown in the Option 4 drawing, will provide a safe dependable

shut down of the main steam valve when the water pressure fails or drops rapidly on the Flo-Rite-Temp.

Unlike a solenoid application, which shuts the steam down when the water pressure drops below a pre-set

point, the GP-2000W1P offers another benefit that it allows the system to keep producing hot water even

when the water pressure is below the set pressure. The GP-2000W1P Combination valve essentially lets the

steam pressure modulate below the water pressure by 2 or 3 pounds, allowing a water heater to supply hot

water even when water pressure is low.

Incoming cold water is piped into the hot water heater with a sample line piped to the W-1 Pilot of

GP-2000W1P. At the same time the cold water is supplying the water heater, its pressure it is also supplying

the W-1 Pilot. When the pressure of the incoming cold water decreases, the W-1 Pilot modulates down the

supply of steam to the pressure pilot controlling the main steam valve, acting as a non-electric self-controlled

shutdown device. Ultimately, this valve eliminates the use of any electricity and gives the customer safe

control of their hot water supply when water pressure loss or fluctuating water pressure conditions exist.

October 31, 2002 @ 3:15 pm

Option #4

5

Loading...

Loading...