Page 1

NATURAL OPTIONS

™

linoleum

luxury vinyl tile

commercial hardwood

vct

specialty flooring

accessories

sheet

Stone Wood & Rustico Metal & Chrome Metrics Borders & Ornaments

LVT

Page 2

Visit armstrong.com/flooring Call 1 877 ARMSTRONG

DID YOU KNOW...

Armstrong has almost 650 products that can contribute to LEED credits? Our LVT flooring can earn points in the

LEED-NC and LEED CI categories in two sections: Environmental Quality 4.3 and in Materials and Resources

1.3. Plus, our LVT, like all Armstrong

™

resilient floors, is FloorScore™certified. Products with the FloorScore

seal are in compliance with California Section 1350 for low VOC emissions and are recognized as

contributing to good indoor air quality. Find out more at armstrong.com/flooring/environmental.

76109

oak light

76116

rustic oak

medium

T1000

maple light

T1020

rustic beech

light

76118

teak red

brown

T1011

stained wood

sahara beige

T1014

stained wood

sand gray

T1003

antique wood

smoke gray

76105

oak medium

76117

rustic oak

dark

T1006

maple

medium

T1021

rustic beech

medium

T1016

walnut mid

brown

T1012

stained wood

smoke blue

76106

oak dark

T1005

antique wood

rust brown

76113

beech dark

T1019

cherry

natural

T1017

walnut black

brown

T1013

stained wood

chestnut

brown

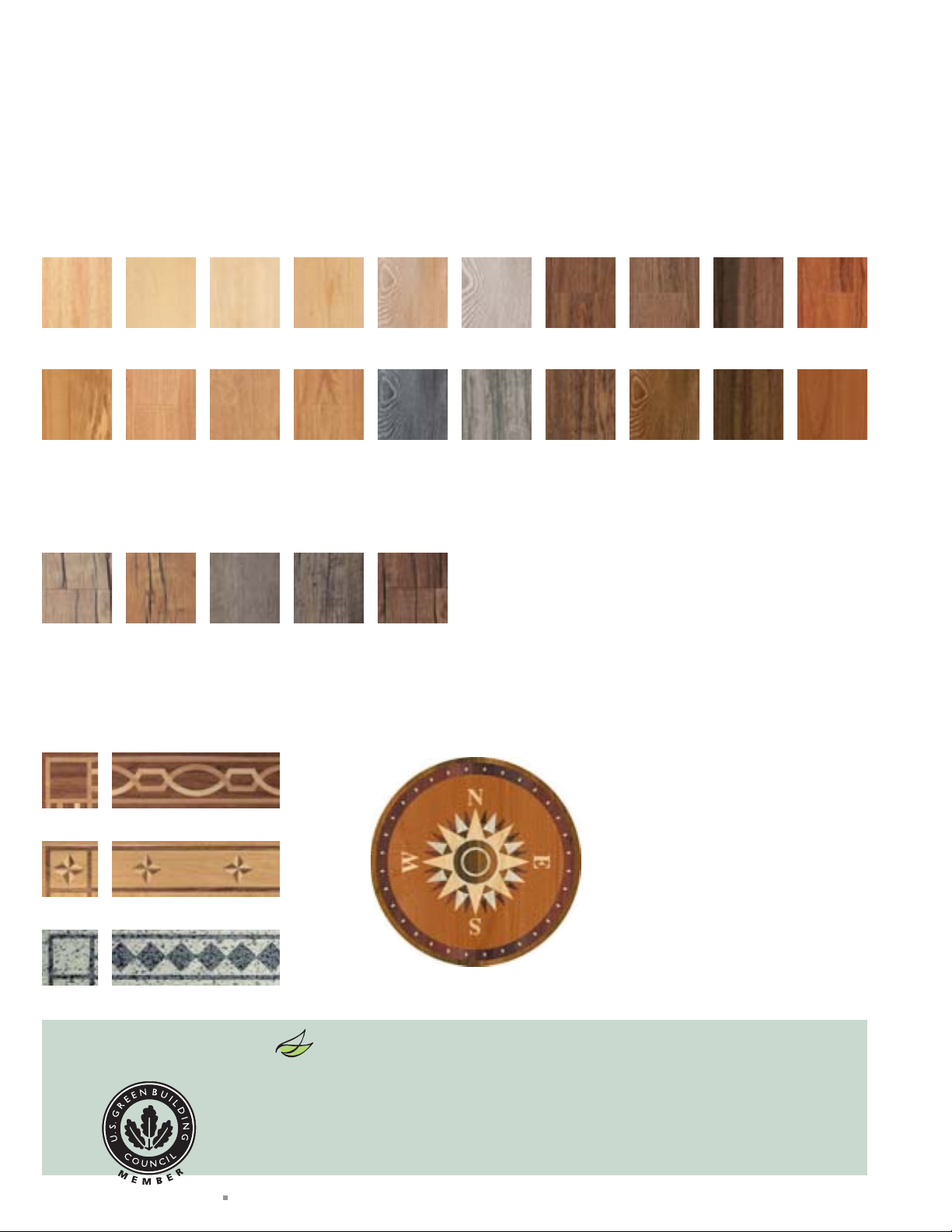

NATURAL OPTIONS Wood

PLANK: 3 in. (76.2 mm) x 36 in. (914.4 mm), 6 in. (152.4 mm) x 36 in. (914.4 mm)

GAUGE: 0.100 in. (2.5 mm) (overall), 0.040 in. (1.0 mm) (wear layer)

76120

sand

76121

medium

brown

76123

pacific coast

gray brown

76122

red brown

76124

mountain

lodge khaki

NATURAL OPTIONS Rustico

PLANK: 7.09 in. (180 mm) x 35.44 in. (900 mm)

GAUGE: 0.100 in. (2.5 mm) (overall), 0.040 in. (1.0 mm) (wear layer)

76174 loop I

76176 star I

76179 cube II

NATURAL OPTIONS Borders and Cornerstones

BORDER: 3 in. (76.2 mm) x 36 in. (914.4 mm)

CORNERSTONE: 3 in. (76.2 mm) x 3 in. (76.2 mm), 6 in. (152.4 mm) x 6 in. (152.4 mm)

GAUGE: 0.100 in. (2.5 mm) (overall), 0.040 in. (1.0 mm) (wear layer)

T1510 windrose cherry wood

INSET: 39.37 in. (1000 mm)

NATURAL OPTIONS

™

• Naturally influenced designs with the performance advantages of resilient flooring.

• Flexible and easy installation with low costs and excellent maintainability.

•

Interpretive patterns and colors look stunning in full field installations and extraordinary in cross-product and

multiple color combinations.

Page 3

Visit armstrong.com/flooring Call 1 877 ARMSTRONG

T1206

metal plate

steel blue

T1205

metal granite

silver gray

T1207

metal plate

silver

T1213

metal tile

silver

T1208

metal plate

copper

T1203

shiny cloud

deep silver

NATURAL OPTIONS Metal

TILE: 12 in. (304.8 mm) x 12 in. (304.8 mm), 18 in. (457.2 mm) x 18 in. (457.2 mm), 24 in. (609.6 mm) x 24 in. (609.6 mm)

GAUGE: 0.100 in. (2.5 mm) (overall), 0.040 in. (1.0 mm) (wear layer)

T1301

chrome

crackle gold

T1303

chrome

granite gold

T1300

chrome

crackle silver

T1305

pearl shell

T1302

chrome

granite silver

T1304

pearl solid

shell

NATURAL OPTIONS Chrome Metrics

TILE: 18 in. (457.2 mm) x 18 in. (457.2 mm)

GAUGE: 0.100 in. (2.5 mm) (overall), 0.040 in. (1.0 mm) (wear layer)

T1116

stratum gold

brown

T1113

terrazzo

beige

T1119

camaro

pebble gray

76132

limbara

granite gray

76141

carrara

marble beige

76142

carrara

marble gray

T1122

granite

white

T1118

camaro

sand beige

T1117

camaro

ivory

T1121

marble

white

T1120

metal

marble black

T1111

granite black

T1107

terracotta

dark

76150

arabico

terracotta

slate

NATURAL OPTIONS™Stone

TILE: 12 in. (304.8 mm) x 12 in. (304.8 mm), 12 in. (304.8 mm) x 24 in. (609.6 mm), 18 in. (457.2 mm) x 18 in. (457.2 mm),

24 in. (609.6 mm) x 24 in. (609.6 mm)

GAUGE: 0.100 in. (2.5 mm) (overall), 0.040 in. (1.0 mm) (wear layer)

stocked

Product Availability 3 in. x 36 in. 6 in. x 36 in. 12 in. x 12 in. 18 in. x 18 in. 24 in. x 24 in.

7.09 in. x

35.44 in.

Sizes

NATURAL OPTIONS

Wood

Rustico

Stone

Metal

Chrome Metrics

Page 4

COMMERCIAL FLOORING

[

Between us, ideas become reality.

]

®

ARMSTRONG FLOOR PRODUCTS

Armstrong World Industries, Inc.

P.O. Box 3001

Lancaster, PA 17604 U.S.A.

Armstrong World Industries Canada Ltd.

6911 Decarie Blvd.

Montreal, Quebec H3W 3E5 Canada

1. PRODUCT NAME

Armstrong NATURAL OPTIONS luxury solid vinyl flooring

Wood & Rustico

Stone

Metal & Chrome Metrics

Borders & Ornaments

2. PRODUCT DESCRIPTION

Material

A tough, clear, polyurethane-coated unfilled wear layer composed

of polyvinyl chloride resins, plasticizers, stabilizers and processing

aids on a filled vinyl backing.

Pattern and Colors

The overall visuals are created by a print between the wear layer

and intermediate color layer. The clear wear layer is embossed

with different textures to enhance each of the printed visuals.

Color pigments are insoluble in water and resistant to cleaning

agents and light.

Size

Wood

3 in. x 36 in. (76.2 mm x 914.4 mm)

6 in. x 36 in. (152.4 mm x 914.4 mm)

Rustico

7.09 in. x 35.44 in. (180 mm x 900 mm)

Stone

12 in. x 12 in. (304.8 mm x 304.8 mm)

12 in. x 24 in. (304.8 mm x 609.6 mm)

18 in. x 18 in. (457.2 mm x 457.2 mm)

24 in. x 24 in. (609.6 mm x 609.6 mm)

Metal

12 in. x 12 in. (304.8 mm x 304.8 mm)

18 in. x 18 in. (457.2 mm x 457.2 mm)

24 in. x 24 in. (609.6 mm x 609.6 mm)

Chrome Metrics

18 in. x 18 in. (457.2 mm x 457.2 mm)

Borders

3 in. x 36 in. (76.2 mm x 914.4 mm)

6 in. x 36 in. (152.4 mm x 914.4 mm)

Borders Cornerstones

3 in. x 3 in. (76.2 mm x 76.2 mm)

6 in. x 6 in. (152.4 mm x 152.4 mm)

Ornaments

39.37 in. (1000 mm)

Gauge (nominal thickness)

0.100 in. (2.5 mm) overall (nominal)

0.040 in. (1.0 mm) wear layer (nominal)

Limitations

These products should not be used in the following areas:

Hospital operating rooms.

Heavy industrial and exterior areas.

Commercial kitchens and commercial food processing areas.

Where pointed spikes such as golf or track shoes will be used.

Where the floor will be subjected to unusually

concentrated static or dynamic loads.

NOTE: Concentrated static and dynamic loads such as

hospital beds, roll-out bleachers, portable x-ray machines, etc.,

may visibly damage resilient as well as other types of floor

coverings. For questions regarding product suitability and

detailed instructions for floor preparation and installation in

these applications, please contact Armstrong.

Suitable for Application Over

Concrete, terrazzo, and other dry, structurally sound

monolithic subfloors, which are suspended or on grade.

Suspended wood subfloor construction with approved wood

underlayments, and a minimum of 18 in. (45.7 cm) well-ventilated

air space below.

Certain metals.

Radiant-heated subfloors with a maximum surface

temperature of 85˚ F (29˚ C).

Existing resilient flooring.

Unsuitable for Application Over

Subfloors where excessive moisture or alkali is present.

On-grade or below-grade sleeper-constructed wood

subfloors.

Lightweight aggregate concrete subfloors having a density of

less than 90 lbs. per cu. ft. (1441 kg/m3) or cellular

concrete having a plastic (wet) density less than 100 lbs. per

cu. ft. (1602 kg/m3) [94 lbs. per cu. ft. (1506 kg/m3) dry

weight], or concrete having a compressive strength of less

than 3500 psi (24 MPa). Concrete slabs with heavy static

and/or dynamic loads should have higher design strengths

and densities calculated to accommodate such loads.

Concrete curing agents, sealers, hardeners, or parting

agents should be removed.

3. TECHNICAL DATA

Shipping Weight

Wood, Rustico, Stone, Metal and Chrome Metrics: 7.1 lbs./yd.

2

(3.8 kg/m2)

Rustico: 8.5 lbs./yd2(4.6 kg/m2)

Gloss (typical value)

60 degrees specular: approximately 2-15

Reference Specifications

Wood, Stone, Metal, Chrome Metrics

ASTM F 1700, Class III, Type B — Embossed Surface

Meets requirements for composition, size, thickness, squareness,

flexibility, dimensional stability, resistance to chemicals and

resistance to heat and light.

Rustico

ASTM F 1700, Class III, Type B — Embossed Surface

Meets requirements for composition, size, thickness, squareness,

flexibility, residual indentation and resistance to chemicals and

resistance to heat and light.

Static Load Limit

250 lbs./sq. in. (17.6 kg/cm2)

ASTM F 970

NOTE: High-heeled traffic [1000 psi (70.3 kg/cm2) or more] may

visibly damage wood, resilient and other floor coverings.

Comparative Subjective Property Ratings

Durability – Very Good

Maintainability – Excellent

Resilience – Excellent

Subjective ratings (excellent, very good, good, fair) are in relation to other Armstrong commercial resilient floors. Ratings are

not directly related to any one test. They are broadly based on

tests and experience of Armstrong Research and Development

under varying conditions and circumstances. These ratings

should not be used for comparison to ratings used by other

manufacturers to rank their own products.

Fire Test Data

ASTM E 648 Flooring Radiant Panel Critical Radiant Flux –

0.45 watts/cm2or more – Class I

ASTM E 662 Smoke Chamber Specific Optical Smoke Density

– 450 or less

Numerical flammability ratings alone may not define the

performance of the product under actual fire conditions. These

ratings are provided only for use in the selection of products to

meet the specified limits.

4. INSTALLATION

Job Conditions

Subfloors/underlayments shall be dry, clean, and smooth.

They shall be free from paint, varnish, solvents, wax, oil, existing adhesive residue, or other foreign matter.

For more detailed requirements of concrete, wood and

metal subfloors, as well as wood and trowelable underlayments, refer to Armstrong Guaranteed Installation Systems

manual, F-5061. Calcium Chloride Tests for moisture must be

conducted. Armstrong offers a guideline of a maximum

acceptable moisture emission level of 3.0 lbs. per 1000 sq. ft.

per 24 hours. Bond Tests should also be conducted for compatibility with the substrate. When testing for alkalinity, the

allowable readings for the installation of Armstrong flooring are

5 to 9 on the pH scale.

Temperature shall be maintained at a minimum of 65˚ F

(18˚ C) and a maximum of 100˚ F (38˚ C) for 48 hours prior to

installation, during installation and 48 hours after completion

when using S-599 Adhesive. When using S-240 Epoxy

Adhesive, the temperature shall be maintained at a minimum of

65˚ F (18˚ C) and a maximum of 85˚ F (29˚ C) for 48 hours prior

to and during installation and for 48 hours after completion. A

minimum temperature of 55˚ F (13˚ C) shall be maintained

thereafter. Condition all flooring materials and adhesives to

room temperature at least 48 hours prior to starting installation.

Protect all materials from the direct flow of heat from hot-air

registers, radiators, or other heating fixtures and appliances.

Procedure

Armstrong NATURAL OPTIONS should be installed using

Armstrong S-599 Adhesive full spread. NATURAL OPTIONS

installed in areas subjected to topical moisture or heavy rolling

loads must be installed with Armstrong S-240 Epoxy Adhesive.

Note: All Rustico patterns must be installed with Armstrong

S-240 Epoxy Adhesive. Detailed instructions may be found in

Armstrong Guaranteed Installation Systems manual, F-5061.

5. MAINTENANCE

NATURAL OPTIONS is designed to be maintained by

traditional resilient flooring maintenance methods. This floor

may be maintained by polishing, spray-buffing or dry buffing.

The urethane protective finish can make initial maintenance

easier, as well as reduce ongoing maintenance procedures.

Initial Maintenance Immediately After Installation

Sweep or vacuum thoroughly.

Damp mop with a dilute neutral detergent solution such as

Armstrong S-485 Floor Cleaner. Do not wash the floor for at

least four or five days after installation. Black marks and dirty

spots can be treated by spot scrubbing (use nothing more

abrasive than a 3M blue or green pad or equal).

If maintaining Natural Options with polish, as a temporary

measure, apply a minimum of two coats of high-quality

commercial floor polish such as Armstrong S-480 Floor

Polish to protect the floor until regular maintenance

procedures can be started.

Preparation for Commercial Use

For specific, ongoing maintenance procedures see Armstrong

Maintenance Recommendations & Procedures for Commercial

Resilient Flooring booklet, F-8663.

6. WARRANTIES

Armstrong warrants its regular (first quality) commercial floors

and wall base to be free from manufacturing defects and warrants the installation integrity for five years from the date of

purchase, if installed according to the Armstrong Guaranteed

Installation Systems manual, F-5061. This warranty extends

only to the original end-user. See Armstrong Commercial Floor

Warranty, F-3349 or visit armstrong.com for warranty details,

limitations and exclusions.

EXISTING IN-PLACE RESILIENT FLOOR COVERING AND

ASPHALTIC ADHESIVES. DO NOT SAND, DRY SWEEP, DRY

SCRAPE, DRILL, SAW, BEADBLAST, OR MECHANICALLY

CHIP OR PULVERIZE EXISTING RESILIENT FLOORING,

BACKING, LINING FELT, ASPHALTIC “CUTBACK”

ADHESIVE, OR OTHER ADHESIVE.

These existing in-place products may contain asbestos

fibers and/or crystalline silica.

Avoid creating dust. Inhalation of such dust is a cancer and

respiratory tract hazard.

Smoking by individuals exposed to asbestos fibers greatly

increases the risk of serious bodily harm.

Unless positively certain that the existing in-place product is a

non-asbestos-containing material, you must presume it contains asbestos. Regulations may require that the material be

tested to determine asbestos content and may govern removal

and disposal of material.

See current edition of the Resilient Floor Covering Institute

(RFCI) publication Recommended Work Practices for Removal

of Resilient Floor Coverings for instructions on removing all

resilient floor covering structures or contact your retailer or

Armstrong World Industries, Inc. 1 800 233 3823.

The floor covering or adhesive in this package does NOT

contain asbestos.

Specification Data

NATURAL OPTIONS

™

Stone Wood & Rustico Metal & Chrome Metrics Borders & Ornaments

The Armstrong logo is a registered trademark in the United States and Canada.

[Between us, ideas become reality.]®is registered in the United States only.

Printed in United States of America

© 2006 AWI Licensing Company

FloorScore is a trademark of Resilient Floor Covering Institute.

All other trademarks owned by AWI Licensing Company

F-7134-1206

For more information, visit

www.armstrong.com/floorscore

luxury vinyl tile

The knowledge and technical support you need

to bring your vision to life.

Visit armstrong.com/flooring

Call 1 877 ARMSTRONG (276 7876 )

TechLine Flooring Expert: options 2, 3 and 3

Armstrong Flooring Representative: options 2 and 2

Samples: Visit armstrong.com/flooring

Call 1 877 276 7876, options 2 and 1

Loading...

Loading...