Analytical Reference Materials International • 276 Abby Road • Manchester, NH 03103

MBH-83X PR12 B-F

Telephone (603) 935-4100 • www.ARMI.com • ARMI@LGCgroup.com

9/17/2020

1 / 2

ZZ

ZZ

Description and Intended Use

This Certified Reference Material is covered under the scope of accreditation to ISO 17034 by LGC Standards - Manchester, NH. As an ISO 17034 certified reference

material, appropriate use of this material will fulfill the certified reference material and traceability requirements for use in ISO 17025 certified laboratories. This CRM may

come in the form of a solid disk or chips. The intended use of this CRM may include, but is not limited to, the calibration of instruments and the validation of analytical

methods.

Instructions for Use

1.

2.

3.

4.

The test surface is on the opposite side of the labeled surface, which includes the material identification. The entire thickness of the unit is certified. However, the user is

cautioned not to measure disks less than 2 mm thick when using X-ray fluorescence spectrometry. Each packaged disk has been prepared by finishing the test surface

using a lathe. The user must determine the correct surface preparation procedure for each analytical technique. The user is cautioned to use care when either resurfacing

the disk or performing additional polishing, as these processes may contaminate the surface.

The minimum sample size for chips should be individually evaluated based on the analytical technique used; this would typically be greater than 0.1 grams.

The material should be stored in a cool, dry location when not in use.

Chips are not recommended for gas analysis.

ZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZSe

(5)Tl(100)

ZZ

ZZ

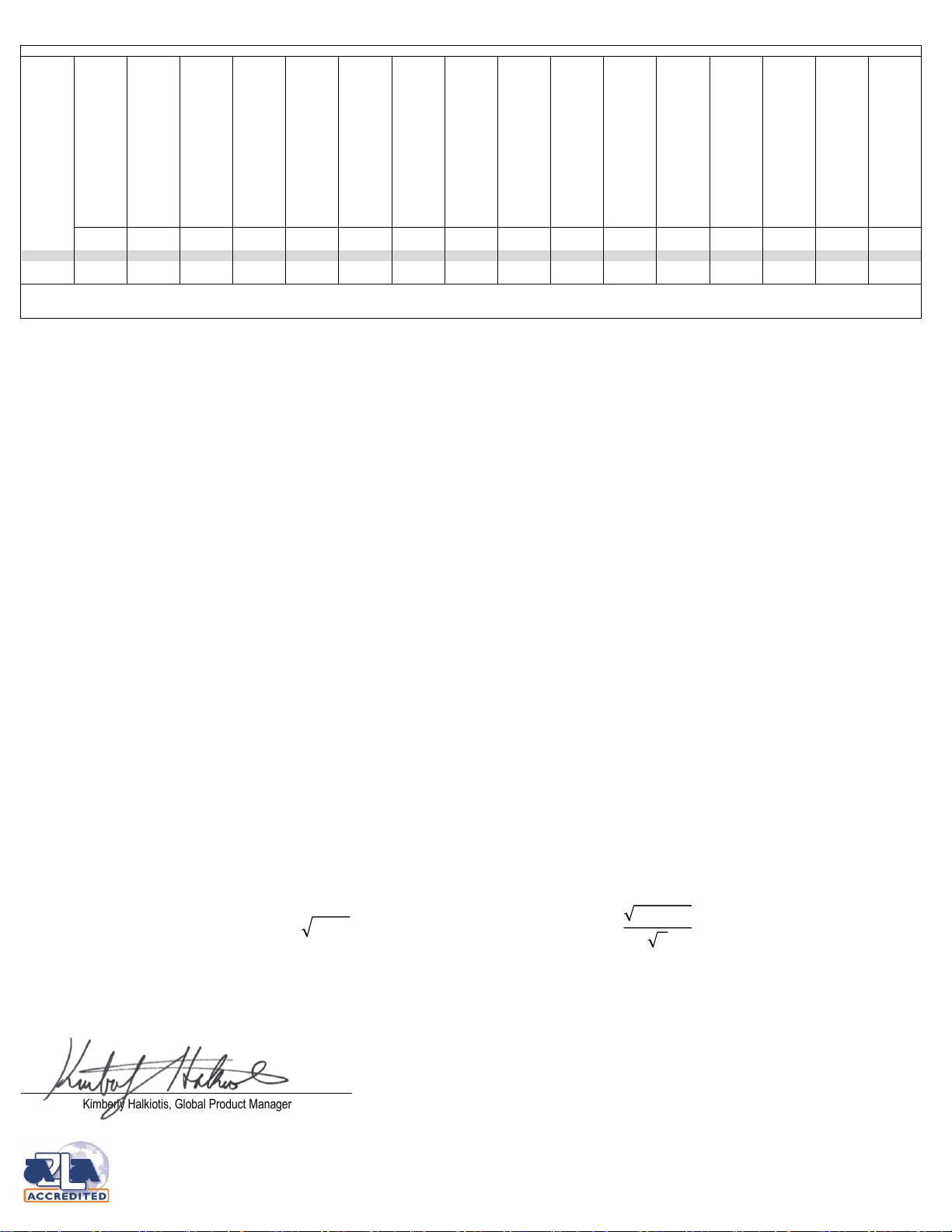

Indicative Values listed in ppm

As

(5)S(<10)

Sb

(9)

0.0002

Sn

0.0007

±

0.0003

0.036

±

0.001

Fe

0.0007

±

0.0003

Ni

0.0009

±

0.0005

Cd

0.00104

±

0.00008

Cu

Lead with Impurities (Cast)

Certified Reference Material

Certified Values listed in wt.% with associated uncertainties

Ag

0.0021

±

0.0004

Bi

0.0116

±

ISO Certified · 9001 · 17025 · 17043 · 17034

Certificate of Analysis

MBH-83X PR12 B

Universal Scientific Laboratory PTY LTD NSW, Australia Siec Badawcza Lukasiewicz Poland

Sheffield Analytical Services

Sheffield, UK

Anchorcert Analytical Birmingham, England

I.M.N.R. Pantelimon, Romania Tec-Eurolab Campogalliano, Italy

Genitest Inc. Montreal, QC AMG Superalloys UK Ltd. Rotherham, England

1. 2.

Telephone (603) 935-4100 • www.ARMI.com • ARMI@LGCgroup.com

9/17/2020

2 / 2

Analytical Reference Materials International • 276 Abby Road • Manchester, NH 03103

MBH-83X PR12 B-F

ARMI | MBH - LGC Standards Industrial Sector

Kimberly Halkiotis, Global Product Manager

The certification of this material is valid indefinitely, within the uncertainty specified, provided the material is handled and stored in accordance with the instructions stated on this certificate.

The certification is nullified if the material is damaged, contaminated, otherwise modified, or used in a manner for which it was not intended.

Expiration

"Uncertainty" values, as reported adjacent to certified concentration values, are based on a 95% Confidence Interval. These estimated uncertainties include the combined effects of method

imprecision, material inhomogeneity, and any bias between methods. Homogeneity data from experimental spark OES results are reflected in both the overall statistics and certified data.

Homogeneity samples are selected by a systematic sampling procedure. The number of samples may be determined by equation 1, where Nprod is the number of units produced and Nmin

is the number of samples used for homogeneity testing. These samples are arranged in a simple randomized design such that each sample is analyzed multiple times by spark OES.

Homogeneity may also be determined within sample using an applied version of ASTM E826. A single factor ANOVA is used to calculated uncertainty due to inhomogeneity (Uhom).

Uncertainty of the material is calculated by equation 2, where H=Uhom, S= Standard deviation, t= t-value at 95% CI, and n= number of observations.

Homogeneity and Uncertainty

Legend: W = Classical, C = Combustion, F = Fusion, A = AA or GFAA, I = ICP or DCP, IM=ICP-MS, D = DC Arc, O = AES, X = XRF, G = GDAES or GDMS, H = Hollow Cathode AES

Certification Laboratories

Much of the analytical work performed to assess this material has been carried out by laboratories with proven competence, as indicated by their accreditation to ISO 17025. It is an implicit

requirement for this accreditation that analytical work should be performed with due traceability, via an unbroken chain of comparisons, each with stated uncertainty, to primary standards

such as the mole, or to nationally- or internationally-recognised reference materials. Of the individual results herein, some have traceability (to the mole) via primary analytical methods.

Some are traceable to substances of known stoichiometry. Most have traceability via commercial solutions. Furthermore, some results have additional traceability to NIST standards, as

part of the analytical calibration or process control.

A,IIA,I

A,I

A,I

C,I

A,I

A,I

Methods

A,I

A,I

A,I

A,I

0.0003

0.0002

0.0003

U

CRM

0.0004

0.0005

0.00008

0.001

0.0007

(0.01)

0.036

0.0007

0.0009

(0.001)

(0.0009)

(0.0005)

0.0140

Certified

0.0021

(0.0005)

0.0116

0.00104

0.0004

0.0002

0.0005

0.0006

0.0006

0.0003

STDV.

0.0006

0.0003

0.0006

0.0001

0.0015

0.00069

0.01093

0.03643

0.00065

0.00088

0.00089

0.00091

0.00045

Mean

0.00210

0.00045

0.01163

0.00104151413121110

<0.0005

9

0.00290

0.00120

0.03850

0.03760

0.00130

8

0.00280

0.01230

0.00115

0.00120

0.00090

<0.001

<0.0005

7

0.00242

<0.001

0.01210

0.00110

0.03710

0.00110

<0.005

0.03670

0.00090

0.00090

<0.0005

<0.0005

0.03580

6

0.00240

<0.0005

0.01185

0.00103

0.00080

0.00090

0.00170

<0.0005

0.00090

5

0.00200

<0.0005

0.01180

0.00100

0.03660

0.00080

0.00730

0.03648

0.00070

0.00090

<0.001

0.00133

0.00130

0.00470

4

0.00180

0.00090

0.01180

0.00100

0.00057

0.00082

0.00150

0.00056

0.00020

0.00057

3

0.00180

0.00050

0.01160

0.00100

0.03620

0.00073

0.00067

0.00050

0.00020

0.00046

0.00430

2

0.00163

0.00020

0.01080

0.00100

0.03570

0.00030

0.00050

0.00045

0.00010

0.00030

0.00255

ZZ

ZZ

1

0.00115

0.00020

0.01077

0.00085

0.03303

0.00010

0.00058

SbSeSnTlZZ

ZZ

The following data represents all pertinent information reported as it applies to the chemical characterization of this material.

AgAsBiCdCuFeNi

S

𝑈

𝐶𝑅𝑀

=

𝐻2+ 𝑆

2

𝑛

∗ 𝑡

𝑁

𝑚𝑖𝑛

= max(10,3𝑁

𝑝𝑟𝑜𝑑

)

Loading...

Loading...