Page 1

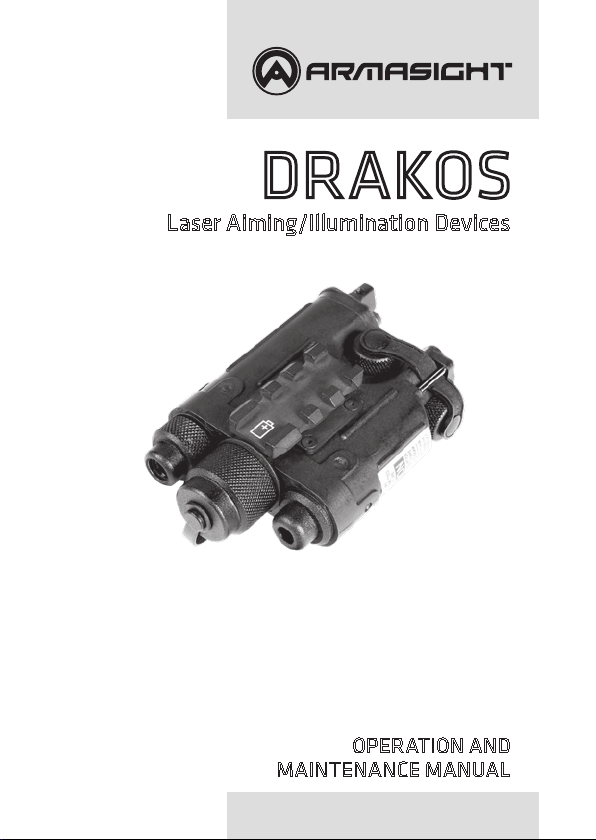

DRAKOS

Laser Aiming/Illumination Devices

DRAKOS IR LASER POINTER

DRAKOSI IR LASER POINTER & IR LED ILLUMINATOR

DRAKOSII IR LASER POINTER & VISIBLE RED LASER POINTER

OPERATION AND

MAINTENANCE MANUAL

Page 2

SAFETY SUMMARY

Before operating this product, carefully study this Operation and

Maintenance Manual.

The Drakos Laser Aiming Device (LAD) is a precision electro-optical instrument, and requires careful handling. To avoid physical danger or equipment

damage when operating the Drakos, follow all WARNINGS, CAUTIONS and

NOTES.

Below you will nd denitions of the following alerts that appear throughout this manual:

WARN ING — Identies a clear danger to the person operating the equipment.

CAUTI ON — Identies risk of damage to the equipment.

NOTE — Serves to highlight essential procedures, conditions, state-

ments, or convey important instructional data to the user.

We provide the informatio n in this manual for introductor y and instruc tional purposes

only; the conte nts may undergo fur ther changes with no comm itment by Armasight

to notif y customers of those c hanges.

Armasight assumes no res ponsibility f or any misprints or other mist akes that may be

containe d in this manual.

©2013 Armasight. All rights rese rved.

2

Page 3

WARNING:

Remember to reinstall the safet y lock screw after you have complet-•

ed operation.

The light from the equipment’s IR laser emitter(s) is invisible to the •

naked eye. However, the light can be detected by all night vision devices (NVD). To reduce the risk of detection, avoid prolonged activation of the IR laser(s).

The IR light is more detectable by other NVDs when used in smoke, •

fog and rain. Avoid prolonged activation of the IR laser(s) in these

conditions.

WARNING:

When installing the equipment on a weapon, be sure the weapon is •

CLEAR and that the SAFETY is on before proceeding.

Take note of the laser safety warning label sticker located near the •

laser emission aperture. NEVER REMOVE this sticker, which identies

laser wavelengths, laser output power sources, and the safety class

of the equipment according to the IEC 60825-1:2007 standard.

NEVER LOOK INTO THE LASER BEAM.•

DO NOT leave the Drakos activated when not in active use.•

When adjusting the equipment boresight, beware of reections •

from optical surfaces.

CAUTION:

Do not dismantle the equipment.•

Keep the equipment clean. Protect it from moisture, dramatic tem-•

perature changes, and electric shocks.

DO NOT drop or hit the equipment.•

DO NOT force the equipment controls past their stopping points.•

Do not store the equipment with the battery still installed.•

Thoroughly clean and dry each item before replacing them in the •

storage carton.

3

Page 4

NOTES:

Remember to zero your weapon prior to installing the Drakos or ad-•

justing the boresight.

To operate the Drakos’ IR channel(s), you will need to wear night vi-•

sion goggles (NVG).

4

Page 5

LIST OF CONTENTS

TITLE PAGE

Safety Summary 2

List of Contents 5

List of Figures 6

List of Tables 7

How to Use This Manual 7

Chapter 1. INTRODUCTION 8

1.1 General Information 8

1.1.1 Type of Manual 8

1.1.2 Equipment Name and Let ter Designation 8

1.1.3 Purpose of Equipment 8

1.1.4 Reporting Equipment Improvement Recommendations 9

1.2 Warranty Information and Registration 9

1.3 List of Abbreviations 12

Chapter 2. DESCRIPTION AND DATA 13

2.1 System Description 13

2.2 Specications 16

2.3 Standard Components 17

2.4 Key Features 18

Chapter 3. OPERATING INSTRUCTIONS 19

3.1 Installation and Mounting 19

3.1.1 Battery Installation 19

3.1.2 Mounting the LAD on a Picatinny/Weaver Weapon Rail 20

3.1.3 Clamping Device Adjustment 21

3.1.4 Fastening a Remote Control Unit to a Weapon 21

3.2 Controls 22

3.3 Operating Procedures 24

3.3.1 Boresight Adjustment Procedure 24

3.3.2 Operating Procedure 25

3.3.3 LAD Shut-Down 26

5

Page 6

Chapter 4. PREVENTIVE MAINTENANCE AND TROUBLESHOOTING 27

4.1 Preventive Maintenance Checks and Services 27

4.2 Operator Troubleshooting 30

4.3 Maintenance 31

4.3.1 General 31

4.3.2 Cleaning Procedures 31

4.3.3 Boresight Testing 32

4.3.4 Battery Removal and Replacement 32

APPENDIX A. Product Warranty Registration Card 34

APPENDIX B. List of Spare Parts 35

LIST OF FIGURES

FIGURE TI TLE PAGE

2-1a Laser Aiming Device. Drakos 14

2-1b Laser Aiming Device. Drakos-I 14

2-1c Laser Aiming Device. Drakos-II 14

2-1d Laser Aiming Device 15

2-2 Standard Components 17

3-1 Battery Installation 19

3-2 Positions of the Adapter in the Bat tery Cap 19

3-3 LAD Installed on a Picatinny Weapon Rail 20

3-4 Mount. Cam Lever 20

3-5 Mount. Underside View 21

3-6 Remote Control Unit 21

3-7 Controls 22

4-1 Remote Control Unit. Battery Installation 32

B-1 Spare Parts 35

6

Page 7

LIST OF TABLES

TABLE TITLE PAGE

1-1 Drakos Series. Function Denition 8

2-1 System Description 15

2-2 Mechanical Data 16

2-3 Optical Data 16

2-4 Electrical Data 17

2-5 Environmental Data 17

2-6 Standard Components 18

3-1 Controls 22

3-2 Operation Modes 23

4-1 Preventive Maintenance Checks and Services 28

4-2 Operator Troubleshooting 30

B-1 Spare Parts List 35

HOW TO USE THIS MANUAL

USAGE

You must familiarize yourself with the entire manual before operating the

equipment. Before performing any kind of maintenance on your device,

read the section on maintenance in its entirety. Follow all WARNINGS, CAUTIONS, and NOTES.

MANUAL OVERVIEW

This manual contains sections on operating and maintaining the Drakos series laser aiming devices.

Throughout this manual, the Drakos Laser Aiming Device will be referred to

as the LAD, “the device” or “the equipment”.

The Product Warranty Registration Card is located in Appendix A.

The List of Spare Parts appears in Appendix B.

7

Page 8

1

INTRODUCTION

1.1 GENERAL INFORMATION

1.1.1 TYPE OF MANUAL

Operation and Maintenance (including a List of Spare Par ts).

1.1.2 MODEL NUMBER AND EQUIPMENT NAME

Drakos Laser Aiming Device. IR Laser Pointer Class I with Quick-Release

Mount (QRM) and Wireless Remote Control.

Drakos-I Laser Aiming Device. Dual Channel: IR 850 Laser Pointer Class I &

IR LED 850 Illuminator with QRM and Wireless Remote Control.

Drakos-II Laser Aiming Device. Dual Channel: IR 850 Laser Pointer Class I &

Visible Red Laser Pointer Class II with QRM and Wireless Remote Control.

1.1.3 PURPOSE OF EQUIPMENT

The Drakos series LAD is a versatile laser aiming system intended for using on

weapons equipped with a Picatinny MIL-STD-1913 or Weaver rail.

The equipment is available with a red or infrared aiming laser, as well as in

two-channel versions that combine two aiming lasers or an aiming laser with

an IR illuminator. For a detailed list of the LAD’s functions, see Table 1-1.

TABLE 11. DRAKOS SER IES. FUNCTIO N DEFINITION

MODEL

Drakos 1 IR Laser Pointer (4 output levels)

Drakos-I 2

Drakos-II 2

NUMBER O F

LASER CHANNELS

1 - IR Laser Pointer (2 output levels)

2 - IR LED Illuminator (2 output levels)

1 - IR Laser Pointer (2 output levels)

2 - Visible Red Laser Pointer (2 output levels)

FUNCTION

8

Page 9

The adjustable laser output ensures easy and accurate aiming in a wide

range of ambient light.

The IR aiming channel is intended for use at night (under moonlight, starlight conditions, etc.), in poor visibilit y, and in changing light conditions. The

long-range IR illuminator should be used when there is little-to-no ambient

light.

Night vision goggles are required when using the IR channels.

The LAD is adjustable for elevation and windage and may be removed and

reinstalled on the weapon without readjusting the boresight.

The device is powered by a single AA or CR123A battery and equipped with

a wireless remote control.

1.1.4 REPORTING EQUIPMENT IMPROVEMENT

RECOMMENDATIONS

Recommendations from the user for improvements to the device are encouraged.

Mail your comments to:

Armasight Inc.

815 Dubuque Avenue

South San Francisco, CA 94080, USA.

Or, send an email to service@armasight.com.

1.2 WARRANTY INFORMATION AND

REGISTRATION

1.2.1 WARRANTY INFORMATION

This product is guaranteed to be free from manufacturing defects in material and workmanship under normal use for a period of two (2) years from

the date of purchase. In the event that a defect covered by the below warranty occurs during the applicable period stated above, Armasight, at its

discretion, will either repair or replace the product; such action on the part

of A rmasi ght sh all b e the f ull ex tent of Arm asigh t’s li abil ity, a nd the Custo mer’s sole and exclusive reparation. This warranty does not cover a product if

it has (a) been used in ways other than its normal and customar y manner;

(b) subjected to misuse; (c) subjected to alterations, modications or repairs

by the Customer or by any party other than Armasight without prior written

consent of Armasight; (d) special order or “close-out” merchandise or mercha ndise sold “a s-is” by eit her Ar masig ht or the A rmasi ght de aler; or (e) me r-

9

Page 10

chandise that has been discontinued by the manufacturer and either parts

or replacement units are not available due to reasons beyond the control of

Armasight. Armasight shall not be responsible for any defects or damage

that in Armasight’s view are a result from the mishandling, abuse, misuse,

improper storage or improper operation of the device, including use in

conjunction with equipment that is electrically or mechanically incompatible with, or of inferior quality to, the product, as well as failure to maintain

the environmental conditions specied by the manufacturer. CUSTOMER IS

HEREBY NOTIFIED THAT OPERATION OF THE EQUIPMENT DURING DAYLIGHT

HOURS OR UNDER ANY EXCESSIVE LIGHT CONDITIONS MAY PERMANENTLY

DAMAGE THE INTERNAL COMPONENTS OF THE UNIT AND SAID DAMAGE

WILL NOT BE COVERED UNDER THIS WARRANTY. This warranty is extended

only to the original purchaser. Any breach of this warranty shall be enforced

unless the Customer noties Armasight at the address noted below within

the applicable warranty period.

The Customer understands and agrees that except for the foregoing warranty, no other warranties written or oral, statutory, expressed or implied,

including any implied warranty of merchantability or tness for a particular

purpose, shall apply to the product. All such implied warranties are hereby

and expressly disclaimed.

1.2.2 LIMITATION OF LIABILITY

Armasight will not be liable for any claims, actions, suits, proceedings, costs,

expenses, damages or liabilities arising out of the use of this product. Operation and use of the product are the sole responsibility of the Customer.

Armasight’s sole undertaking is limited to providing the products and services outlined herein in accordance with the terms and conditions of this

Agreement. The provision of products sold and services performed by Armasight to the Customer shall not be interpreted, construed, or regarded,

ei the r ex pres sly or i mpl ied , as b ein g fo r the ben et of o r cre ati ng a ny ob lig ation toward any third party of legal entity outside Armasight and the Customer; Armasight’s obligations under this Agreement extend solely to the

Customer. Armasight’s liability hereunder for damages, regardless of the

form or action, shall not exceed the fees or other charges paid to Armasight

by the Customer or Customer’s dealer. Armasight shall not, in any event, be

liable for special, indirect, incidental, or consequential damages, including,

but not limited to, lost income, lost revenue, or lost prot, whether such

damages were foreseeable or not at the time of purchase, and whether or

not such damages arise out of a breach of warranty, a breach of agreement,

negligence, strict liability or any other theory of liability.

10

Page 11

1.2.3 PRODUCT WARRANTY REGISTRATION

In order to validate the warranty on your product, Armasight must receive a

co mple ted Pro duc t War rant y Re gis tra tio n Car d fo r eac h uni t, o r the Cus tom er can complete a warranty registration on our website, at www.armasight.

com. Please complete the included form (Appendix C) and immediately mail

it to our Service Center:

Armasight Inc.

815 Dubuque Avenue

South San Francisco, CA 94080

USA

1.2.4 OBTAINING WARRANTY SERVICE

To obtain warranty service on your unit, the End-user (Customer) must notify the Armasight service department via email. Send any requests to service@armasight.com to receive a Return Merchandise Authorization number (RMA). When returning any device, please take in the product to your

retailer, or send the product, postage paid and with a copy of your sales receipt, to Armasight Corporation’s service center at the address listed above.

All merchandise must be fully insured with the correct postage; Armasight

will not be responsible for improper postage or merchandise that becomes

lost or damaged during shipment. When sending product back, please

clearly write the RMA# on the outside of the shipping box. Please include

a letter that indicates your RMA#, the Customer’s Name, a Return Address,

reason for the return, Contact information (valid telephone numbers and/

or an e-mail address), and proof of purchase that will help us to establish

the valid start date of the warranty. Product merchandise returns that do

not have an RMA# listed may be refused, or a signicant delay in processing

may occur. Estimated Warranty service time is 10-20 business days. The Enduser/ Customer is responsible for postage to Armasight for any warranty

service. Armasight will cover return postage/ shipping after warranty repair

to the End-user/ Customer only if the product is covered by the aforementioned warranty. Armasight will return the product after warranty service

by domestic UPS Ground service and/ or domestic mail. Should any other

requested, required or international shipping methods be necessar y, the

postage/ shipping fee will be the responsibility of the End-user/ Customer.

11

Page 12

1.3 LIST OF ABBREVIATIONS

C Celsius (Centigrade)

cm centimeter

CW clockwise

CCW counterclockwise

F Fahrenheit

H Height

hr hour

Illum Illumination

kg kilogram

L Length

LAD Laser Aiming Device

m meter

max maximum

mils milliradians

min minimum

mm millimeter

MOA Minute Of Angle

MPI Mean Point of Impact

mW milliwatt

nm nanometer

NO. Number

NVD Night Vision Device

NVG Night Vision Goggles

PMCS Preventive Maintenance Checks and Services

SEQ sequence

V Vo lt

W Width

12

Page 13

2

DESCRIPTION AND DATA

2 .1. SYSTEM DESCRIPTION

The LAD is a weapon aiming system that uses a laser to indicate the point

of impact. The equipment is available in ve functionally dierent versions,

which are presented in Table 1-1 of this manual.

The LAD uses continuous diode lasers, which produce both visible and invisible radiation; both are potentially hazardous to your eyes. You will nd

the laser safety classication of your device on the warning label(s) near the

laser emission aperture(s).

The laser(s) and boresight adjustment mechanisms are mounted in a lightweight but durable, high-impact plastic body.

The LAD mount system is designed to t any Picatinny MIL-STD-1913 or

Weaver weapon rail. Manufactured from aluminum alloy, it is lightweight

and robust. An adjustable lever-cam clamping device ensures quick, easy,

and reliable mounting and disassembly.

Figure 2-1a shows a single-channel LAD (Drakos).

Figure 2-1b shows a two-channel LAD with an IR LED illuminator (Drakos- I).

Figure 2-1c shows the LAD with two aiming channels (Drakos-II).

These gures indicate the design dierences that exist between the vari-

ous LADs. To learn which individual features these devices share, see Figure

2-1d .

The ITEM NO. column in Table 2-1 indicates the number used to identify

items in Figures 2-1 (a-d).

13

Page 14

2

FIGURE 2-1a. LASER AIMING DEVICE. DRAKOS

4

3

FIGURE 2-1b. LASER AIMING DEVICE. DRAKOSI

1

2

1

1

5

14

FIGURE 2-1c. LASER AIMING DEVICE. DRAKOSII

Page 15

6 7 8

91610 12

11

1314

FIGURE 2-1d. LASER AIMING DEVICE

TABLE 21. SYSTEM DES CRIPTION

ITEM

NO.

Output Aperture of IR Aiming Laser

1

(closed with a Cap)

DESCRIPTION NOTE

15

2 Battery Cap with Adapter Drakos and Drakos-II

3 Battery Cap Drakos-I only

Output Aperture of IR LED Illuminator (closed

4

with a Cap)

Output Aperture of Visible Red Aiming Laser

5

(closed with a Cap)

Drakos-I only

Drakos-II only

6 Windage Adjustment Screw (closed with a Cap)

7 ON Button

8 Elevation Adjustment Screw (closed with a Cap)

9 Safety Lock Screw

10 Mode Select Switch

11 Picatinny/Weaver Rail

12 Plastic Body

13 Cam Lever

14 Lever Holder

15 Clamp

16 Mount

15

Page 16

2.2 SPECIFICATIONS

TABLE 22. MECH ANICAL DATA

ITEM

Elevation/Windage Adjustment

Range (MOA, min)

Elevation/Windage Adjustment

Increment (mils)

Boresight Accuracy af ter 1000

Shots Fired from a Weapon (mils)

DRAKOS DRAKOSI DRAKOSII

±90 ±90 ±90

0.5±0.05 (5cm

at a distance

of 100m)

0.5* 0. 5* 0. 5*

Boresight Accuracy af ter 100

Reinstallations of the L AD on

1.0 * 1.0 * 1. 0*

a Picatinny Rail (mils)

Overall Dimensions (mm)

110 × 67 ×4 3 104×67×43 110 ×6 7 ×4 3

Weight without Batter y (g) 19 8 210 220

Weapon Mount Type

* Reference data

Wavelength

(nm)

Output Power

(mW, max)

Operating Distance

(m)

TABLE 23. OPT ICAL DATA

ITEM

Red Dot — — 650

IR Dot 850 850 850

IR Illum — 850 —

Red Dot — — 0.9

IR Dot 0.7 0.7 0.7

IR Illum — 250 —

Red Dot — — 200

IR Dot 800 800 800

Picatinny MIL STD 1913 / Weaver Rail

Red Dot (mils) — — 0.5

Divergence

IR Dot (mils) 0.5 0.5 0.5

IR Illum (°, min) — 22 —

Aiming Dot Size

IR Illuminator Eective

Range in Total Darkness

DATA

0.5±0.05 (5cm

at a distance

of 100m)

DRAKOS DRAKOSI DR AKOSII

0.5±0.05 (5cm

at a distance of

100 m)

DATA

25mm at a distance of 50m

50mm at a distance of 100m

— 100 m —

16

Page 17

TABLE 24. E LECTRICAL DATA

ITEM

Battery

Batter y Life at 20°C/

68°F (hr, min)

DRAKOS DRAKOSI DRAKOSII

Single CR123A

Lithium (3V) or A A

Alkaline (1.5V)*

42 2 27

DATA

Single CR123A

Lithium (3V)**

Single CR123A

Lithium (3V) or A A

Alkaline (1.5V)*

* Any AA or CR123 type rechargeable batteries with voltage from 1.2V to 3.2V can

be used

** Any CR123 type rechargeable batteries with voltage 3.2V can be used

TABLE 25. EN VIRONMENTAL DATA

ITEM DATA

Operating Temperature -20 to +40°C (-4 to +104°F)

Storage Temperature - 40 to +55°C (-40 to +131°F)

Immersion

10m for 2 hr

2.3 STANDARD COMPONENTS

LAD standard components are shown in Figure 2-2 and listed in Table 2-6.

The ITEM NO. column indicates the number used to identify items in Figure

2-2.

1 2 3 4

FIGURE 2-2. STANDARD COMPONENTS

17

Page 18

TABLE 26. STANDARD COMP ONENTS

ITEM

NO.

Laser Aiming Device

A laser aiming system equipped with a Picatinny quick-detach

1

mount.

CR123A Lithium Bat tery

2

A single, CR123A (3V) batter y used to power the LAD.

Remote Control Unit

Wireless control used to operate the LAD in short-time activation

3

mode. Ensures quick and silent activation/deactivation of the

device. Delivered with CR2032 (3 V) battery installed.

Operation and Maintenance Manual

Provides safety information, equipment description, mounting

4

procedures, operating instructions, and preventive maintenance

checks and services (including a List of Spare Parts).

Carton

Packing box used for storage/transportation of the L AD and its

accessories.

2.4 KEY FEATURES

Fast and easy target acquisition

–

No need to close one eye

–

Operational versatility

–

Lightweight but durable high-impact plastic body

–

Adjustable laser output

–

IR LED illuminator (only in Drakos-I version)

–

Clicking mechanisms for boresight adjustment

–

Wireless remote control

–

Powered by a single AA or CR123A battery

–

Fits any Picatinny MIL-STD-1913 and Weaver rail with an adjustable

–

quick-detach mount

Waterproof

DESCRIPTION QTY

–

1

1

1

1

1

18

Page 19

3

OPERATING INSTRUCTIONS

3.1. INSTALLATION AND MOUNTING

3.1.1 BATTERY INSTALLATION

CAUTION:

Verify that the device is OFF before installing a battery.

Install the battery as follows (refer to Figure 3-1):

1. Unscrew the battery cap (A).

2. Check the position of the adapter (B) (only Drakos and Drakos-II). See

Figure 3-2 for the correct positioning of the threaded adapter, which

changes depending on the battery being installed. If necessary, change

the adapter position in the cap.

3. Install the battery (C) into the battery compar tment (D). Align the battery

with the battery symbols (E).

4. Replace the battery cap (A).

E

D

C

B

A

BATTERY CAP

ADAPTER

FIGURE 3-1.

BATTERY INSTALL ATION

FIGURE 3-2.

POSITIONS OF THE ADAPTER

IN THE BATTERY CAP

19

Page 20

3.1.2 MOUNTING THE LAD ON A PICATINNY/WEAVER

WEAPON RAIL

NOTE:

Remember to zero your weapon prior to installing the LAD or adjusting the boresight.

WARNING:

When installing the equipment on a weapon, be sure the weapon is

CLEAR and that the SAFETY is on before proceeding.

Figure 3-3 shows a single-channel LAD installed on a Picatinny weapon rail.

FIGURE 3-3. LAD INSTALLED ON A PICATINNY WEAPON RAIL

Install the LAD on a Picatinny/ Weaver rail as follows (refer to Figure 3- 4):

1. Unlock the LAD mount’s clamping device by pushing down on the dog

(A) and turning the cam lever (B) towards the arrow (backwards).

2. Install the LAD on the Picatinny/ Weaver rail so that the stop (B, see Figure

3-5) slides into one of the rail’s transverse slots.

3. Ax the LAD to the rail by locking the clamping device.

4. Verify that the clamping device is rmly holding the LAD. If necessary,

adjust the clamping device as detailed in Part 3.1.3: Clamping Device Adjustment.

20

A B

FIGURE 3-4. MOUNT. CAM LEVER

Page 21

B

A

FIGURE 3-5. MOUNT. UNDERSIDE VIEW

C

3.1.3 CLAMPING DEVICE ADJUSTMENT

Adjust the mount clamping device as follows (refer to Figure 3-5):

1. Unlock the clamping device and remove the LAD from the weapon.

2. To tighten/loosen the clamping device, push the cam (C) towards the arrow (which will cause the nut (A) to slide out of the hole) and turn the

nut (A) CW/CCW, respectively, in one-two increments (see note below).

Much like when the cam (C) is released, the backward-moving springs

will cause the nut (A) to slide back into the hole.

NOTE:

The eight-sided nut of the clamping device must be turned in increments equal to the turn angle of 360o/8 in order to properly t into

the hole.

3. Verify that the adjusted clamping device is rmly holding the LAD.

3.1.4 FASTENING A REMOTE CONTROL UNIT TO A WEAPON

Using Velcro tape, fasten the remote control unit (Figure 3-6) to your weapon in an easily accessible place (e.g., on the front of the rie stock).

FIGURE 3-6. REMOTE CONTROL UNIT

21

Page 22

3.2. CONTROLS

The LAD controls are shown in Figure 3-7 and dened in Table 3-1. The ITEM

NO. column indicates the number used to identify items in Figure 3-7.

2 3

1

FIGURE 3-7. CONTROLS

TABLE 31. CONTROLS

ITEM

CONTROL FUNCTION

NO.

Activates the laser(s) after the required operation

1 ON Button

mode has been selec ted with the switch.

When the LAD is activated, this activates standby

mode.

Mode Select

2

Switch

Switches between the four dened operation modes:

“Low 1”, “Low 2”, “Hi 1”, and “Hi 2”.

For operating parameters, see Table 3-2.

When turned OFF, deactivates the LAD as shown in

Figure 3-7.

Prevents the mode select switch from being inad-

vertently turned to high-power positions (“Hi 1” and

Safety Lock

Screw

3

(with redcolored head)

“Hi 2”).

NOTE:

The both “Hi 1” and “Hi 2” positions can only be

entered when the switch is unlocked. You will

need to unscrew the lock screw to operate with

high-power levels.

4

5

22

Page 23

TABLE 31. CONTINU ED

ITEM

CONTROL FUNCTION

NO.

Elevation

4

Adjustment

Screws

Windage

5

Adjustment

Screws

Remote Control

Button

MODEL

DRAKOS

DRAKOSI

DRAKOSII

OFF

Turned o

Turned o

Turned o

Adjust the laser(s) boresight.

NOTE:

When turning the screws, adjustment mechanisms

click in increments corresponding to the minimum

boresight correction value 0.5 mils (5cm at a

distance of 100m).

The circular scales are indexed in 0.5 mils adjustment

increments.

Elevation and windage adjustment ranges are covered in approximately 4 turns of the screws.

NOTE:

If using one of the two-channel devices, remember

that the screws adjust the boresight of both lasers

concurrently.

Activates/deactivates the laser(s) in standby when

held down/released.

TABLE 32. OPER ATION MO DES

OPERATING PARAMETERS

LOWPOW ER OPERATION H IGHPOWE R OPERATION

“LOW 1” “ LOW 2” “HI 1” “H I 2”

IR Dot

Level 1

0.1 mW

IR Dot

Level 1

0.2 mW

IR Dot

Level 1

0.1 mW

IR Dot

Level 2

0.2 mW

IR Dot

Level 1

0.2 mW &

IR Illum

Level 1

125 mW

Red Dot

Level 1

0.3 mW

IR Dot

Level 3

0.3 mW

IR Dot

Level 2

0.9 mW

IR Dot

Level 2

0.6 mW

IR Dot

Level 4

0.7 mW

IR Dot

Level 2

0.9 mW &

IR Illum

Level 2

250 mW

Red Dot

Level 2

0.9 mW

23

Page 24

3.3. OPERATING PROCEDURES

NOTE:

When operating the LAD’s IR channel(s), you must wear night vision

goggles.

CAUTION:

DO NOT force the equipment controls past their stopping points.

3.3.1 BORESIGHT ADJUSTMENT PROCEDURE

NOTE:

Bef ore adju sting th e LAD bo resight for the rst tim e, re ap proxima tely 10 shots from the weapon with the device installed, in order to stabilize the adjustment mechanisms under applied shocks.

NOTE:

When adjusting the equipment boresight, beware of reections from

optical surfaces.

To adjust the boresight:

1. Locate a target at the re adjustment range (100m).

2. Take aim at the center of the target using the weapon’s iron sight; secure

the weapon in the aiming rest.

3. Unscrew the caps from the adjustment screws.

4. Remove the cap from the output aperture of the aiming laser.

5. Turn the switch to the required position, and activate the LAD (push

ON).

6. Using a screwdriver

To shift the aiming dot to the right, turn the windage adjustment screw

CCW. To shift it to the left, turn the screw CW.

To shift the aiming dot down, turn the elevation adjustment screw

CCW. To shift it up, turn the screw CW.

7. Fire a series of shots.

24

Page 25

8. Work out the values of the elevation and windage corrections required

to compensate for the measured deviation of the mean point of impact

(MPI) from the center of the target. The minimum correction value of 0.5

mils (5 cm at a distance of 100 m) corresponds to one click of the adjustment mechanisms.

9. Adjust the equipment boresight by turning the adjustment screws and

counting out a denite number of clicks (or reading the scales).

NOTE:

To shift the MPI to the right, turn the windage adjustment screw CW.

To shift the MPI to the left, turn the screw CCW.

To shift the MPI down, turn the elevation adjustment screw CW. To

shift the MPI up, turn the screw CCW.

10. To check the equipment boresight, use the laser dot to take aim at the

center of the target and re a series of shots.

11. After completing the boresight adjustment procedure, turn the device

OFF and re place th e cap(s) on the l aser out put ape rture(s) and the a djustment screws.

3.3.2 OPERATING PROCEDURE

To operate the LAD:

1. If you are operating the device using high-power levels, use a 2mm hex

key to unscrew the safety lock.

2. Remove the cap(s) from the laser output aper ture(s).

3. Turn the switch to the required position.

4. Activate the LAD (push ON).

5. To go to standby, push ON a second time. To activate/deactivate the LAD

while in standby mode, hold down/release the remote control button.

6. To align the barrel of the weapon, center the aiming dot on the desired

target. To allow for the bullet travel (i.e. bullet drop, windage, distance

between the direction of the beam and the axis of the barrel and the target mobility), use the clicking adjustment mechanisms.

WARNING:

DO NOT leave the LAD activated when it ’s not in use.

25

Page 26

WARNING:

The IR light from the equipment’s IR laser(s) is invisible to the naked

eye. However, the light can be detected by all night vision devices.

To reduce the risk of detection, avoid prolonged activation of the IR

laser(s).

NOTE:

To switch the ac tivated equipment to another operation mode, turn

the switch to the desired position and reactivate the laser(s) by pushing ON.

3.3.3 LAD SHUTDOWN

To shut down the LAD:

1. Turn the switch to OFF.

2. Replace the cap(s) on the laser output aper ture(s).

3. Remove the equipment from the weapon rail.

4. Reinstall the safety lock screw (if removed).

WARNING:

Remember to reinstall the safety lock screw after you have completed

any high-output operation.

5. Remove the battery.

CAUTION:

Do not store the equipment with the battery still installed.

6. Store the LAD and all accessories in the carton.

26

Page 27

4

PREVENTIVE

MAINTENANCE AND

TROUBLESHOOTING

4.1. PREVENTIVE MAINTENANCE CHECKS

AND SERVICES PMCS

Table 4-1: Preventive Maintenance Checks and Services has been provided

so that you can keep your equipment operable and in good condition.

Perform all functional tests in the order listed in Table 4-1.

Operating Procedures are detailed in Chapter 3.

Always obser ve any WARNINGS and CAUTIONS that appear in the table.

Explanation of Table Entries:

— SEQ NO. column. Sequence numbers are for reference and appear in the

order required to perform checks and ser vices.

— LOCATION/ ITEM TO INSPECTION/ CHECK/ SERVICE column. Indicates

the location and the item to be checked or serviced.

— PROCEDURE column. Details the checking/ servicing procedure.

— NOT FULLY MISSION CAPABLE IF… column. Indicates what faults will

prevent your equipment from operating successfully.

27

Page 28

TABLE 41. PREVE NTIVE MAINTEN ANCE CHECKS AND S ERVICES

LOCATION/

SEQ

NO.

INSPEC T/ CHECK/

ITEM TO

SERVICE

PROCEDURE

BEFORE OPERATION CHECKS

Inventory items by comparing

1 Completeness

them with the data specied in this

manual.

Inspect for dirt, cracks, or damage.

Scratches and gouges are OK if

2 Body

operation is not aected. Inspect

for missing parts (safety lock screw,

caps, etc.).

Clean as required.

Laser Aperture

3

Cap(s)

Inspect for dirt or damage. Inspect

for retainer breaks.

Clean as required.

Verify that the batter y adapter

and O-ring are present. Inspect for

Batter y Com-

4

partment/ Cap

with Adapter

corrosion, moisture, corroded or

defective contacts. Inspect for cap

damage or retaining loop breaks.

Inspect O-ring for cuts or damage.

Clean as required.

Adjustment

5

Screw Caps

Mode Select

6

Switch

Laser Aperture

7

Protective

Glass(es)

Remote Control

8

Unit

Inspect for dirt, damage. Inspect for

retaining strap break s.

Clean as required.

Check for operation (without battery).

Inspect for cleanliness, scratches,

chips, or cracks.

Clean as required.

Check for damage.

Check Velcro tape for wear.

Inspect for dirt, damage, corrosion,

9 Mount

or missing parts. Check for proper

operation.

Clean as required.

NOT FULLY MISSI ON

CAPABLE IF...

Items are missing.

Cracked or damaged. Missing

parts.

Cap is damaged.

Retainer is broken.

Contacts are damaged or corroded.

Retaining loop

is broken. Cap,

O-ring or adapter

is damaged or

missing.

Caps are damaged.

Retaining strap is

broken.

Switch is inoperative.

Scratches, chips or

cracks are present.

Damaged. Unit or

tape is missing.

Mount is damaged.

Missing par ts.

Clamping device is

inoperative.

28

Page 29

TABLE 41. CONTINUED

SEQ

NO.

INSPEC T/ CHECK/

LOCATION/

ITEM TO

SERVICE

PROCEDURE

NOT FULLY MISSI ON

CAPABLE IF...

OPERATIONAL CHECKS

WARN INGS:

NEVER LOOK INTO THE LASER BEAM.

When per forming operational checks, beware of reections from optical

surfaces.

NOTE:

You must wear NVG when checking IR channel(s).

Install the battery. Turn the switch

to the position corresponding

to the minimum laser output of

the aiming channel. Push the ON

10 Aiming Laser(s)

button down to activate the laser.

Direct the radiated beam at a wall

No aiming dot.

from a distance of about 5m. A red

(infrared) dot should appear on the

wall. To see an infrared dot, look

through the NVG.

Push the ON but ton down again to

Remote

11

Control Unit

actuate standby mode. Push the

remote control button down to activate the laser. A red (infrared) dot

No aiming dot.

should appear on the wall.

Turn the switch to the position

corresponding to the minimum

12 IR Illuminator

laser output of the IR illuminator.

Activate the laser. Direct the radiated beam at a wall from a distance

No light appears

on the wall.

of about 5m. Look through the NVG.

A spot of light should appear on

the wall.

13 Boresight

Perform boresight testing as per

Part 4.3.3.

Adjustment

mechanisms are

inoperative.

29

Page 30

TABLE 41. CONTINUED

SEQ

NO.

INSPEC T/ CHECK/

LOCATION/

ITEM TO

SERVICE

PROCEDURE

NOT FULLY MISSI ON

CAPABLE IF...

AFTER CHECKING PROCEDURES

Turn the switch to OFF.

Replace the cap(s) on the laser

output aperture(s).

14

Remove the battery.

Return the equipment and all accessories to the storage/carrying

carton.

4.2. OPERATOR TROUBLESHOOTING

The purpose of troubleshooting is to identify the most commonly occurring

equipment malfunctions, their probable causes, and the corrective actions

required to x them.

Table 4-2 lists common malfunctions that may occur during the operation

or maintenance of the LAD. Per form the tests, inspections, and corrective

actions in the order listed in the table.

This table cannot list all of the malfunctions that may occur with your LAD,

or a ll of th e test s and corr ecti ve act ions that may b e nece ssar y. If yo u expe rience an equipment malfunction that is not listed, or is not xed by the corrective actions listed in the table, please contact the

TABLE 42. OPE RATOR TROUBLESH OOTING

MALFUNCTION

PROBABLE C AUSE/ TEST/

INSPECTION

Batter y is dead, missing or

improperly installed.

LAD fails to activate

(no aiming dot, no IR

illumination).

Batter y contact surfaces or

contact springs are dir ty or

corroded.

Laser diode is faulty.

Boresight adjustment

screws do not adjust for

aiming dot position.

Adjustment mechanisms

are faulty.

Customer Support.

CORREC TIVE ACTION

Replace battery or

install it correctly.

Clean as per Part 4.3. 2.

Please contact the

Customer Support.

Please contact the

Customer Support.

30

Page 31

TABLE 42. CONT INUED

MALFUNCTION

Remote control does

not work.

PROBABLE C AUSE/ TEST/

INSPECTION

Batter y is missing or improperly installed.

CORREC TIVE ACTION

Insert battery or install

correctly.

Batter y is dead. Replace the battery.

Batter y surfaces or contacts

are dirty or corroded.

Clean the contact

surfaces with a pencil

eraser and/or alcohol

and cotton swabs.

Batter y adapter dicult

to remove (Drakos and

Drakos-II only).

Hindered rotation of

the battery cap.

Remote control unit is

damaged.

Inspect for damaged battery adapter and battery

cap.

Dirty cap thread. Clean the thread.

Damaged cap thread. Please contact the

Please contact Cus-

tomer Support.

Please contact the

Customer Support.

Customer Support.

4.3. MAINTENANCE

4.3.1 GENERAL

The LAD operator maintenance consists of operational tests, inspections

for the equipment serviceability, cleaning and mounting procedures, corrective actions (troubleshooting and replacement of a limited number of

parts). Maintenance instructions covered elsewhere in this manual (PMCS,

troubleshooting, etc.) are not repeated in this section.

CAUTION:

The LAD is a precision electro-optical instrument and must be handled

carefully at all times to prevent damage.

CAUTION:

DO NOT dismantle the equipment.

31

Page 32

4.3.2 CLEANING PROCEDURES

Clean the LAD as follows:

1. Gently brush o any dirt from the equipment using a clean, soft cloth.

2. Moisten the cloth with fresh water and gently wipe down the external

surfaces (except for glass surfaces).

3. Dry any wet sur faces (except for glass surfaces) with another dry, clean,

soft cloth.

4. Using a lens brush, carefully remove all loose dirt from the surface(s) of

the laser aperture protective glass(es).

5. Slightly dampen a cotton swab with ethanol and gently, slowly wipe

down the glass surface(s). Clean the glass surface(s) using circular movements. Change the cotton swab after each circular stroke. Repeat until

the glass surfaces are clean.

6. Clean the battery contact surfaces and contacts in the battery compartment with a pencil eraser and/or alcohol-dampened cotton swabs.

CAUTION:

Thoroughly dry each item before placing them into the storage carton.

4.3.3 BORESIGHT TESTING

Perform boresight testing:

— When the LAD is mounted to a weapon for the rst time;

— After repair of the LAD/weapon;

— As the need arises (in case of systematic inaccuracy or missing the tar-

get).

Test the LAD boresight as per Part 3.3.1.

4.3.4 BATTERY REMOVAL AND REPLACEMENT

Refer to Part 3.1.1 for the LAD battery installation procedure.

Replace the remote control battery as follows:

1. Using a screwdriver, unscrew the four screws (A, Figure 4 -1) that ax the

cover to the bottom of the unit. Remove the cover.

2. Replace the battery with new one (CR2032, 3V). Inser t the batter y in

alignment with the positive (+)/negative (-) symbols.

3. Replace the cover and retighten the screws (A).

32

Page 33

A

FIGURE 4-1. REMOTE CONTROL UNIT. BATTERY INSTALLATION

33

Page 34

APPENDIX A

ARMASIGHT PRODUCT WARRANTY REGISTRATION CARD

PRODUCT INFORMATION

CUSTOMER INFORMATION

Product Name

Purchase Date

Name

Purchased Form

Product Serial #

Address

City

Day Phone #

E-mail address

Country Zip

Home Phone #

Customer Signature Required

PRODUCT WARRANTY REGISTRATION CARD

In order to validate the warranty on your product, Armasight must receive

a completed Product Warranty Registration Card for each unit, or the user

must complete a warranty registration form, which can be found on our

website at www.armasight.com. Please complete the included form and immediately mail it to our Ser vice Center:

Armasight Inc.

815 Dubuque Avenue

South San Francisco, CA 94080

USA

34

Page 35

APPENDIX B

LIST OF SPARE PARTS

The parts authorized in the below list of spare parts, common to all versions

of the LAD, are required for operator maintenance. This list includes parts

that must be removed in order to replace any authorized parts.

The ITEM NO. column in Table B-1 indicates the number used to identify

items in Figure B-1.

The PART NO. column indicates the primary number used by the manufacturer to identify an item.

11

6

5

8

10

3

1

3

4

2

FIGURE B-1. SPARE PARTS

TABLE B1. SPARE PARTS LIST

ITEM NO. DESCRIPTION PART NO.

9

7

5

1 Battery Cap OH-2.01.35.000

2 Battery Adapter O H-2.01.35.002

3 Laser Output Aperture Cap PL-03.01.00.015

4 Retaining Loop MH-01.01.05.003

5 Adjustment Screw Cap PL-03.01.00.006

6 Safety Lock Screw DIN912 M3x4

7 Retaining Strap PL-03.01.00.014

8 Switch PL-03.01.00.017

9 ON Button Pusher PL-03.01.50.002

10 ON Button PL-03.01.00.013

11 Picatinny/Weaver Rail PL-03.01.00.016

V42 0140 42 8

35

Page 36

Armasight Inc.

815 Dubuque Avenue

South San Francisco, CA 94080

Phone: (888)959-2259

Fax: (888)959-2260

Intl Phone/Fax: (650)492-7755

info@armasight.com

www.armasight.com

Loading...

Loading...