Page 1

BIT 5X

BIT 5X-10X

Digital Night Vision Monoculars

OPERATION AND

MAINTENANCE MANUAL

Impor tant Export Rest rictions ! Com modities, produ cts, technologi es and ser vices of thi s manua l are contro lled b y the U.S.

Depar tment o f State Oce of D efense Trade Controls, in accordance with International Trac in Arms (ITAR), Title 22, Code of

Federal Regulati ons Part 120-130 and/or by the Expor t Administration Re gulations (EAR) of U.S. Depar tment of Commerce. At any

time whe n a license or a writ ten approval o f the U.S. Govern ment

is app licable to it, it is illegal and strict ly forbidd en to exp ort, intend to export, tr ansfer in any other manner whatsoever, sel l any

hardwar e or technical da ta, provide any a ssociated ser vice to any

non-U. S. re sident, beyond or within the United States territory,

until th e valid lice nse or writ ten approval has been issued by the

Depar tments of th e U.S. Gover nment h aving j urisdiction . Addi tionall y U.S. law prohibits the sale, transfer, o r export of items to

certai n restri cted parties, des tinations, and embar goed countries,

as iden tied on lis ts maintaine d by the U.S . Departm ent of State,

the U.S. Department of Commerce, and t he U.S. Depar tment o f

Treasury. It i s the responsib ility of the Customer to be awa re of

these lis ts. The sale, tra nsfer, transport ation, or shipme nt outside of the U.S. of any product prohibited o r restricte d for expor t

without complying with U.S. export control laws and re gulations,

includin g prope r expo rt licen sing, do cumentation or au thorization, is unlaw ful and may result in civil and/or cr iminal pe nalties

and/or constitute a fed eral cri me. Diver sion cont rary to U.S. law

is stric tly prohibited .

Page 2

2

SAFETY SUMMARY

Before operating this product, you must carefully study this Operation and Maintenance Manual.

The Armasight Bit Digital Night Vision Monocular is a precision electro-optical instrument and requires

careful handling. To avoid physical danger to the user and damage to the equipment, follow all WARNINGS, CAUTIONS and NOTES.

Below are denitions of the alerts that will appear throughout this Manual:

WARN ING – Identies clear danger to the person operating the equipment.

CAUTI ON – Identies risk of damage to the equipment.

NOTE – Highlights essential procedures, conditions, and statements, or conveys important instruc-

tional data to the user.

The information provided in this manual is for familiarization purposes only. The contents may undergo further

changes with no commitment by Armasight© to notif y customers of any updates.

Armasight© assumes no responsibility for any misprints or other errors that this manual may contain.

©2013 by Armasight. Al l rights reserved.

Page 3

3

WARNINGS:

This product contains natural rubber latex, which may cause allergic reactions! The FDA

has reported an increase in the number of deaths that are associated with an apparent sensitivity to natural latex proteins. If you are allergic to latex, it is a good idea to learn which products

contain it and strictly avoid exposure to those products.

CAUTION:

• Donotdismantletheequipment.

• Keeptheequipmentclean.Protectitfrommoisture,dramatictemperaturedrops,andelec-

trical shocks.

• DONOTforcetheequipmentcontrolspasttheirstoppingpoints.

• DONOTleavetheequipmentactivatedduringbreaksinoperation.

• DONOTstoretheequipmentwiththebatteriesinstalled.

• Thoroughlycleananddryeachitembeforeplacingthemintothestoragecase.

CAUTION:

Although the equipment is highly resistant to damage from light overload, DO NOT point it,

either powered or un-powered, directly at the sun or any other source of high intensity light

that the unprotected human eye cannot tolerate (such as welding arc). To prevent inadvertent

exposure to these light sources, never leave the equipment unsuper vised with the objective

lens cap removed.

NOTES:

• DONOTremovethebatteriesordisconnecttheexternalpowersourcewhiletheBitison.

• Inadvertentsundamageisnotconsideredadefectinmaterialorworkmanship,andisthere-

fore not covered in the product warranty.

Page 4

4

LIST OF CONTENTS

TITLE PAGE

Safety Summary 2

List of Contents 4

List of Figures 5

List of Tables 6

How to Use This Manual 6

1. INTRODUCTION 7

1.1 General Information 7

1.1.1 Type of Manual 7

1.1.2 Model Number and Equipment Name 7

1.1.3 Purpose of Equipment 7

1.1.4 Reporting Equipment Improvement Recommendations 8

1.2 Warranty Information and Registration 8

1.2.1 Warranty Information 8

1.2.2 Limitation of Liability 8

1.2.3 Product Warranty Registration 9

1.2.4 Obtaining Warranty Service 9

1.3 List of Abbreviations 10

2. DESCRIPTION AND DATA 11

2.1 System Description 11

2.2 Bit Specications 12

2.3 Standard Components 14

2.4 Optional Equipment 16

2.5 Key Features 17

3. OPERATING INSTRUCTIONS 18

3.1 Installation and Mounting 18

3.1.1 Battery Installation 18

3.1.2 Mounting a Platform Ring to the Bit 18

3.1.3 Fastening an Advanced Wireless Remote Control 19

3.1.4 Installing Additional Equipment on the Bit 19

3.1.5 Connecting Additional Equipment to the Bit 20

3.1.6 Installing an IR Illuminator on the Bit 21

3.1.7 Attaching an Afocal Doubler to the Bit 22

3.1.8 Installing the Bit on a Tripod 22

3.2 Controls and Display Indications 23

3.2.1 Bit Controls 23

3.2.2 IR Illuminator Controls 24

3.3 Operating Procedures 24

3.3.1 Operating the Bit 24

3.3.2 Operating an IR Illuminator 25

3.3.3 Bit Shut-Down 26

Page 5

5

4. PREVENTIVE MAINTENANCE AND TROUBLESHOOTING 27

4.1 Preventive Maintenance Checks and Services 27

4.1.1 Preventive Maintenance Checks and Services (PMCS) 27

4.2 Operator Troubleshooting 29

4.3 Maintenance 29

4.3.1 General 29

4.3.2 Cleaning Procedures 30

4.3.3 Battery Removal and Replacement 30

4.4 Return Instructions 31

APPENDIX 32

A List of Spare Parts 32

B Product Warranty Registration Card 33

LIST OF FIGURES

FIGURE TITLE PAGE

2-1 Bit Digital Night Vision Monoculars Appearance 11

2-2 Bit Digital Night Vision Monocular. System Description 12

2-3 Bit Standard Components 14

2-4 Optional Equipment 16

3-1 Battery Installation 18

3-2 The Bit Fully Assembled with the Platform Ring 19

3-3 Platform Ring 19

3-4 Advanced Wireless Remote Control 19

3-5 Armasight DT Digital Recorder Installation 20

3-6 Video Cable 20

3-7 IR Illuminator 21

3-8 IR Illuminator. Battery Installation 21

3-9 The Bit with the Afocal Doubler Attached 22

3-10 Bit Controls 23

3-11 IR Illuminator Controls 24

3-12 IR Illuminator Adjustment 25

4-1 Advanced Wireless Remote Control Battery Installation 30

A-1 Bit Spare Parts List 32

Page 6

LIST OF TABLES

TABLE TITLE PAGE

2-1 Bit System Description 12

2-2 System Data 12

2-3 Mechanical Data 13

2-4 Optical Data 13

2-5 Electrical Data 13

2-6 Environmental Data 14

2-7 IR850W Illuminator Data 14

2-8 Bit Standard Components 15

2-9 Optional Equipment 16

3-1 Controls and Indicators 23

3-2 IR Illuminator Controls 24

4-1 Preventive Maintenance Checks and Services 27

4-2 Operator Troubleshooting 29

A-1 Bit Spare Parts List 32

HOW TO USE THIS MANUAL

USAGE

You must familiarize yourself with the entire manual before operating the equipment. Read the entire

maintenance checklist before performing maintenance. Follow all WARNINGS, CAUTIONS, and NOTES.

MANUAL OVERVIEW

The Manual contains sections on operating and maintaining the Bit Digital Night Vision Monocular.

Throughout this Manual, the Bit Digital Night Vision Monocular will be referred to as the Bit or the

equipment.

A List of Spare Parts is in Appendix A.

The Product Warranty Registration Card is in Appendix B.

6

Page 7

7

1

INTRODUCTION

1.1 GENERAL INFORMATION

1.1.1 TYPE OF MANUAL

Operation and Maintenance (including a List of Spare Parts).

1.1.2 MODEL NUMBER AND EQUIPMENT NAME

Bit 5x Digital Night Vision Monocular.

Bit 5x-10x Digital Night Vision Monocular.

1.1.3 PURPOSE OF EQUIPMENT

The Bit is a professional grade, Digital Night Vision Monocular with optical 5x or 10x magnication, making

it the most powerful monocular in its class. Sensitive to both near-infrared and visible light, the high performance CCD imaging system of the Bit provides round-the-clock observation. The Bit is eective regardless

of light conditions - in daylight, in natural lighting, and at nighttime. The Bit is an ideal product for both

professional and amateur use, such as hunting, security, law enforcement, general nighttime observation,

and recording.

The Bit is available in two versions, with magnications of 5x and 10x. The magnication of the Bit 5x can be

changed to 10x by using an optional afocal lens attachment.

The Bit is powered by two CR 123A (2×3V) batteries. An external battery supply or 6 VDC/1A power source

can also be used to power the Bit.

The Bit can be controlled by a wireless remote control.

A detachable, long-range IR illuminator provides additional lighting and enables the use of the Bit in ex-

tremely low light conditions or total darkness.

The Bit is equipped with a standard NTSC/PAL video input/output function that makes it possible to con-

nect to an external video monitor, or to record images for eld documentation or training purposes. It also

allows the transmission of data from a remote display to that of the Bit.

The Bit can be used in conjunction with other Armasight equipment, such as the Recorder DT Digital Video

Recorder and External Battery Power Supply. The

Picatinny/Weaver rail or detachable platform ring.

Extremely reliable and versatile, the Bit is a valuable, multifunctional addition to any security or hunting.

additional equipment

can be mounted onto the Bit’s

Page 8

8

1.1.4 REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS

User recommendations for improvements to the device are encouraged.

Mail your comments to:

Armasight Inc.

815 Dubuque Avenue

South San Francisco, CA 94080

USA

Or, send an email to info@armasight.com.

1.2 WARRANTY INFORMATION AND REGISTRATION

1.2.1 WARRANTY INFORMATION

This product is guaranteed to be free from manufacturing defects in material and workmanship under

normal use for a period of two (2) years from the date of purchase. This warranty does not cover the

battery or damage caused by leaking batteries, nor does it protect against damage due to loss, misuse

or mishandling.

In the event a defect that is covered by the warranty occurs during the 2 year period stated above, Armasight, at its option, will either repair or replace the product, and such action on the part of Armasight

shall be the full extent of Armasight’s liability, and the Customer’s sole and exclusive remedy. This warranty does not cover a product (a) used in other than its normal and customary manner; (b) subjected

to misuse; (c) subjected to alterations, modications or repairs by the Customer or by any party other

than Armasight without prior written consent of Armasight; (d) special order or “close-out” merchandise or merchandise sold “as-is” by either Armasight or the Armasight dealer; or (e) merchandise that

has been discontinued by the manufacturer and either parts or replacement units are not available due

to reasons beyond the control of Armasight. Armasight shall not be responsible for any defects or damage that in, Armasight’s opinion, is a result from the mishandling, abuse, misuse, improper storage or

improper operation, including use in conjunction with equipment which is electrically or mechanically

incompatible with or of inferior quality to the product, as well as failure to maintain the environmental

conditions specied by the manufacturer.

This warranty is extended only to the original purchaser. Any breach of this warranty shall be waived

unless the customer noties Armasight at the address noted below within the applicable warranty

period.

The customer understands and agrees that except for the foregoing warranty, no other warranties

written or oral, statutory, expressed or implied, including any implied warranty of merchantability or

tness for a particular purpose, shall apply to the product. All such implied warranties are hereby and

expressly disclaimed.

1.2.2 LIMITATION OF LIABILITY

Armasight will not be liable for any claims, actions, suits, proceedings, costs, expenses, damages or

liabilities arising out of the use of this product. Operation and use of the product are the sole responsibility of the Customer. Armasight’s sole undertaking is limited to providing the products and services

outlined herein in accordance with the terms and conditions of this Agreement. The provision of products sold and services performed by Armasight to the Customer shall not be interpreted, construed,

or regarded, either expressly or implied, as being for the benet of or creating any obligation toward

any third party or legal entity outside Armasight and the Customer. Armasight’s obligations under this

Agreement extend solely to the Customer.

Armasight’s liability hereunder for damages, regardless of the form or action, shall not exceed the fees

or other charges paid to Armasight by the customer or customer’s dealer. Armasight shall not, in any

event, be liable for special, indirect, incidental, or consequential damages, including, but not limited to,

lost income, lost revenue, or lost prot, whether such damages were foreseeable or not at the time of

purchase, and whether or not such damages arise out of a breach of warranty, a breach of agreement,

negligence, strict liability or any other theory of liability.

Page 9

9

1.2.3 PRODUCT WARRANTY REGISTRATION

In order to validate the warranty on your product, Armasight must receive a completed Product Warranty Registration Card for each unit, or the Customer can complete a warranty registration on our

website at www.armasight.com. Please complete the included form (Appendix B) and immediately

mail it to our Service Center:

Armasight Inc.

815 Dubuque Avenue

South San Francisco, CA 94080

USA

1.2.4 OBTAINING WARRANTY SERVICE

To obtain warranty service on your unit, the End-user must notify the Armasight’s service depar tment

in order to receive a Return Merchandise Authorization number (RMA#). The customer can do this by

sending an email to service@armasight.com.

When returning any product, please take or send the product, postage paid, with a copy of your sales

receipt, to our service center, Armasight Inc. at the address noted above. All merchandise must be fully

insured with the correct postage; Armasight will not be responsible for improper postage or missing or

damaged merchandise during shipment.

When sending merchandise back, please write the RMA# clearly on the outside of the shipping box.

Please include a letter that indicates your RMA#, Name, Return Address, reason for service return, Contact information (such as a valid telephone number and/or e-mail address), as well as proof of your purchases that will help us to establish the valid start date of the warranty. Product merchandise returns

that do not have an RMA listed may be refused or be subject to a signicant delay in processing.

Estimated Warranty service time is 10-20 business days. The End-user/Customer is responsible for postage to Armasight for any warranty service. Armasight will cover return postage/shipping to continental

USA End-users/Customers after warranty repair only if product is covered by the aforementioned warranty. Armasight will return the product after warranty service via domestic ground service and/or domestic mail. The postage and shipping fees for any other requested, required or international shipping

methods will be the responsibility of the End-user/Customer.

Page 10

1.3 LIST OF ABBREVIATIONS

µm micrometer

AWREC Advanced Wireless Remote Control

C Celsius (Centigrade)

CCW counterclockwise

CW clockwise

F Fahrenheit

FL Focal Length

g gram

H Height

hr hour

in inch

inf. innity

kg kilogram

L Length

lbs pounds

m meter

mA milliampere

mil angular mil

min minute

mm millimeter

MOA Minute Of Angle

mrad milliradian

NO. Number

NTSC National Television Standards Committee

oz ounce

PAL Phase Alternating Line

PMCS Preventive Maintenance Checks and Services

RMA# Return Merchandise Authorization number

sec second

SEQ sequence

SOA Second Of Angle

SR Service Representative

V Volt

W Width

10

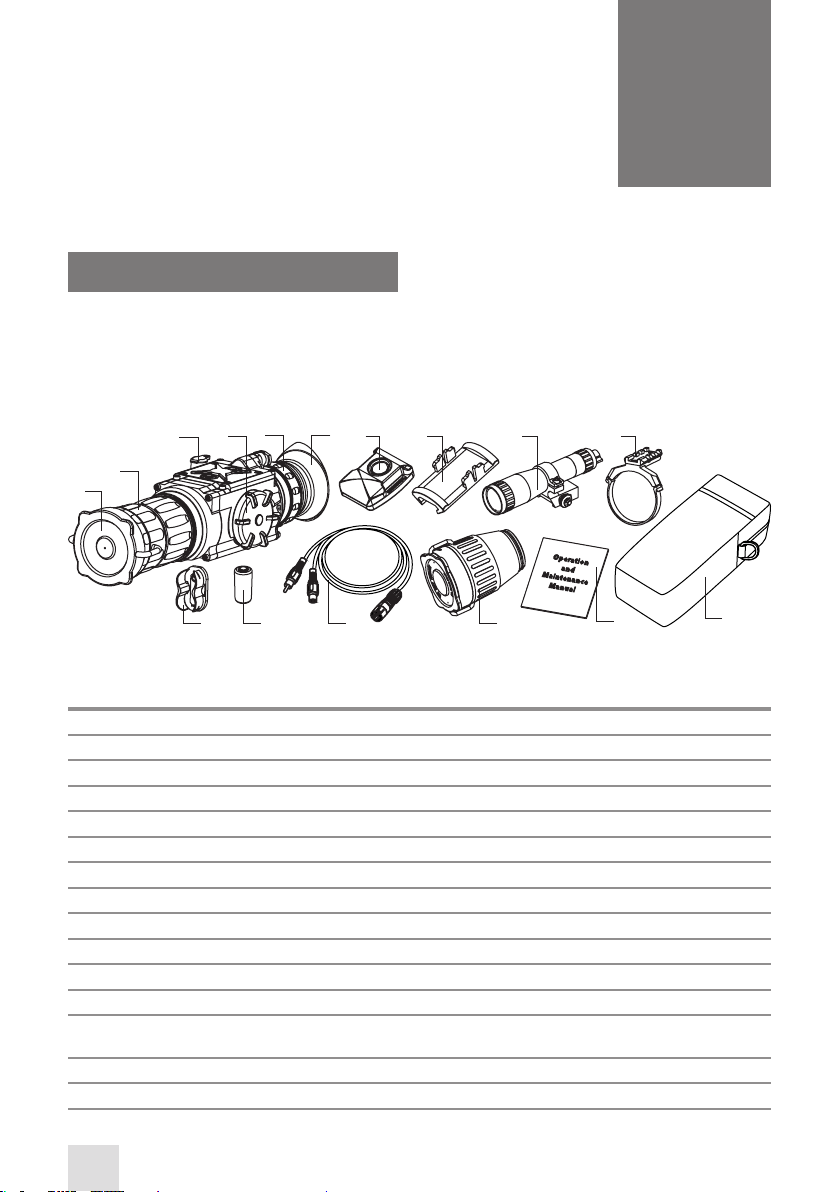

Page 11

11

2

DESCRIPTION AND DATA

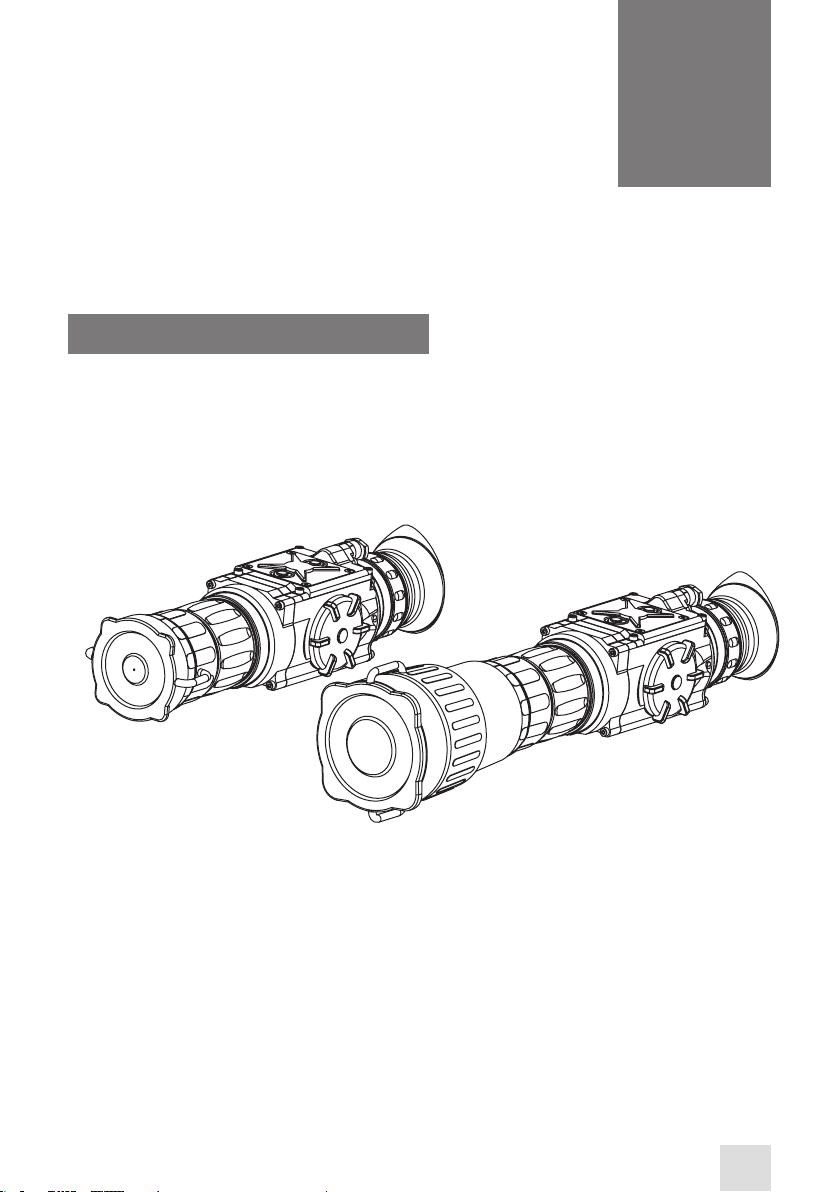

2.1 SYSTEM DESCRIPTION

The Bit consists of next primary parts: a body, a lens assembly and a eyepiece assembly. The equipment

comes as shown in Figure 2-1. The gure represents the both 5x and 5x-10x versions of the Bit.

The Bit is a highly light-sensitive device. The Bit sensor (CCD array) reacts to near-infrared and visible

light and converts the received light into electric charges. The controlling circuit converts the entire

contents of the two-dimensional array to a sequence of voltages that are processed into a continuous

analog signal. The Bit displays, as a result, a real-time images corresponding to the scene projected

onto the focal plane of the sensor.

BIT 5X

BIT 5X10X

FIGURE 21. BIT DIGITAL NIGHT VISION MONOCULARS APPEARANCE

The main optical-electronic components of the Bit include: an objective lens, an eyepiece, a CCD camera, a display, a control card, and a button control panel.

The Bit is equipped with a manually adjustable eyepiece, focusable objective lens, and a digitally controlled display brightness.

Information on the battery status is continuously displayed.

Manufactured for exceptional durability, the Bit has a lightweight and robust aluminum body.

A side Picatinny/Weaver rail allows for the installation of an optional Armasight DT Digital Video Re-

corder, extended battery supply, or other equipment.

A detachable Platform Ring makes it possible to mount an IR illuminator or other additional equipment

to the top of the device.

A detachable, long-range IR illuminator provides additional lighting and enables the use of the Bit in ex-

tremely low light conditions or total darkness.

Page 12

12

A standard NTSC/PAL video input/output connector enables an external video display (monitor, TV) or

video recorder to be connected to the Bit. An external battery power supply or 6 VDC/1A power source

can also be connected to the Bit.

The Bit is powered by two CR 123A (2×3V) batteries.

The Bit is shown in Figure 2-2. The ITEM NO. column of Table 2-1 indicates the number used to identify

items in Figure 2-2.

6

5

4

3

2

1

9

13

12

11

10

14

8

7

FIGURE 22. BIT DIGITAL NIGHT VISION MONOCULAR. SYSTEM DESCRIPTION

TABLE 21. BIT SYSTEM DESCRIPTION

ITEM DESCRIPTION ITEM DESCRIPTION

1 Objective Lens Cap 8 Eyepiece Focus Ring

2 Objective Lens 9 Eyecup

3 Objective Focus Ring 10 Turn-pull Switch

4 Body 11 Connector Cap

5 Button Control Panel

6 Battery Cap

7 Eyepiece

12

Connector

13

Side Picatinny/Weaver Rail

14

Tripod Socket

2.2 BIT SPECIFICATIONS

TABLE 22. SYSTEM DATA

ITEM

CCD Camera High-rate High Resolution Near-IR Hypersensitive CCD Camera

Pixel CCD Array Format 752×582

CCD Array Spectral Response 0.4 to 1.1 µm

Resolution 30 SOA 15 SOA

Display Type AMOLED SVGA 060

Pixel Display Format 800×600

BIT 5X BIT 5X10X

Page 13

13

TABLE 22. CONT INUED

ITEM

BIT 5X BIT 5X10X

Display Brightness Discretely Adjustable to 8 Levels

Turn-on Time, max 3 sec

Analog Input Format PAL/ NTSC

Analog Output Format PAL

PAL Output Resolution 768×574 pixels

TABLE 23. MECHANICAL DATA

ITEM

BIT 5X BIT 5X10X

Overall Dimensions 240×69×65mm (9.4”×2.7”×2.6“) 335×70×74mm (13.2”×2.8”×2.9“)

Weight (w/o Batteries) 0.74 kg (1.6 lbs) 1.07 kg (2.4 lbs)

TABLE 24. OPTICAL DATA

ITEM

Magnication 5x

BIT 5X BIT 5X10X

(10x with optional

Afocal Doubler)

5x or 10x

(10x with included

Afocal Doubler)

Field of View - ang. X degrees 5.7° 3.2° (with Afocal Doubler)

- ang. Y degrees 4.2° 2.3° (with Afocal Doubler)

Objective Focal Length 50mm 90mm (with Afocal Doubler)

Objective F-number 1:1. 2 1:1.4 (with Afocal Doubler)

Eyepiece Focal Length 25 mm

Entrance Pupil Diameter 42mm 65mm

Exit Pupil Diameter 10 mm

Eye Relief 45 mm

Focus Method Manual

Focusing Range 10m to innity 10m to innity

Diopter Adjustment Manual

Diopter Adjustment Range ±5 diopter

TABLE 25. ELECTRICAL DATA

ITEM DATA

Battery Two CR123A Lithium 3V or CR123 type

rechargeable batteries with voltage 3.2V

Current Consumption, maximum 500 mA

Battery Life at 20 °C (68 °F) up to 3 hr

External Battery Power Supply 1 Four AA Lithium batteries (1.5V) or AA recharge-

able batteries (1.2V) / Operational Time up to

3.5 hr

External Battery Power Supply 2 Two 18650 rechargeable batteries (3.7V) or four

CR123 type rechargeable batteries with voltage

3.7V max. / Operational Time up to 7 hr

External Power Supply 6 VDC / 1 А

Page 14

14

TABLE 26. ENVIRONMENTAL DATA

ITEM DATA

Operating Temperature -40 to +50°C (-40 to +122°F)

Storage Temperature -50 to +70°C (-58 to +158°F)

Recoil Resistance 700g

Immersion 10m for 30 min

TABLE 27. IR850W ILLUMINATOR DATA

ITEM DATA

IR Emitter Type LED

Power 500 mW

Peak Wavelength 850 nm

Illumination Range up to 500 m

Divergence 2 to 30°

Battery Single CR123А Lithium battery (3V) *

Battery Life at 20 °C (68 °F) From 1.5 hr (Full Power) to 10 hr (1/4 Power)

Overall Dimensions (with Mount) 120×42×38 mm (4.7”×1.6”×1.5”)

Weight (with Mount, without Battery) 102 g (3.6 oz)

Operating Temperature -30 to +50°С (-22 to 122°F)

Storage Temperature -50 to +70°С (-58 to 158°F)

Environmental Rating Water Resistant

* Any CR123 type rechargeable batteries with voltage from 3.0V to 3.7V can be used

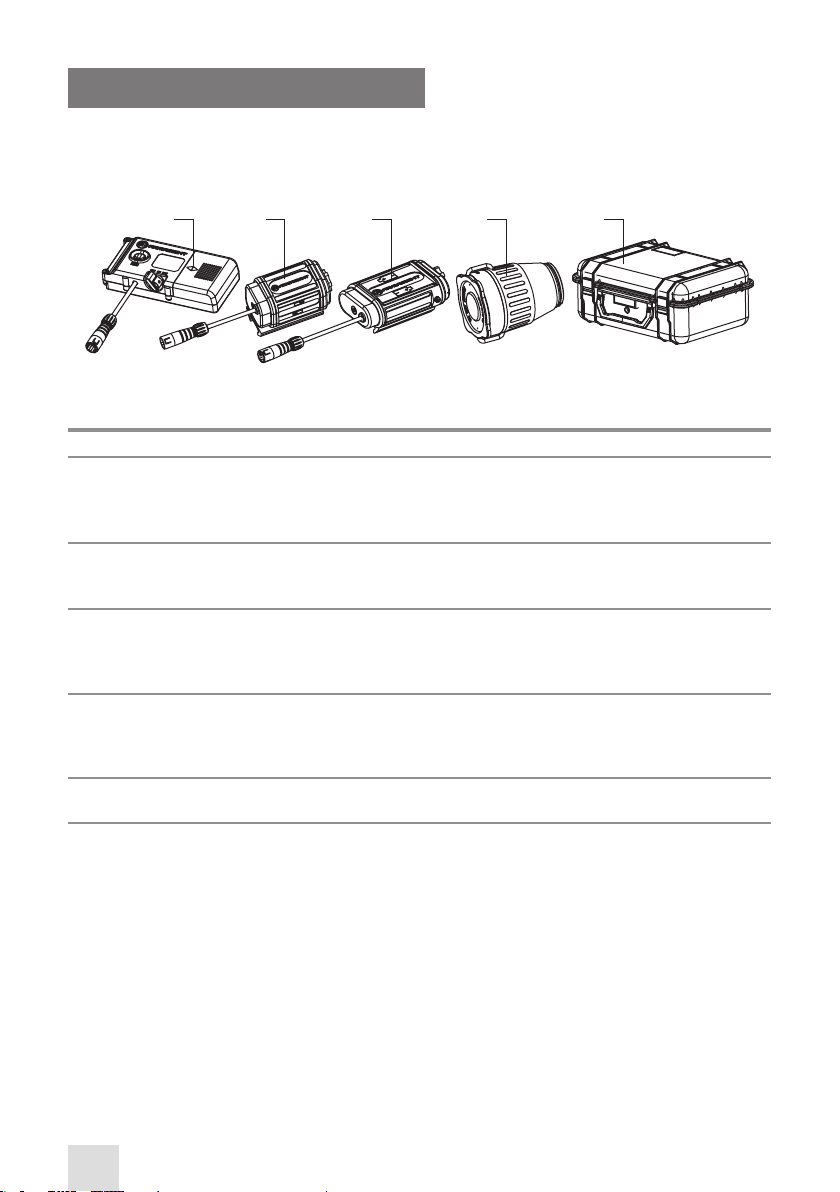

2.3 STANDARD COMPONENTS

The Bit standard components are shown in Figure 2-3 and listed in Table 2-8.

The ITEM NO. column indicates the number used to identify items in Figure 2-3.

1

2

3

54

6

10 11

7 8 9

FIGURE 23. BIT STANDARD COMPONENT

12

13

Page 15

15

TABLE 28. BIT STANDARD COMPONENTS

ITEM NO. DESCRIPTION QUANTITY

1 Armasight Bit Digital Night Vision Monocular

1

A Digital Night Vision device.

2 Objective Lens Cap

1

Protects the objective lens from dirt and mechanical damage, and provides protection

from light overload. Comes attached to the objective lens.

3 Eye-cup

1

A rubber cup used to protect the eyepiece as well as provide comfort for the operator.

Comes attached to the eyepiece.

4 Battery Cassette

2

Intended for the installation of two CR123 batteries in the battery compartment. The Bit

comes with two battery cassettes (includes one installed in the battery compartment

and one spare cassette).

5 CR123A Lithium Battery

2

Batteries are used to power the Bit.

6 Advanced Wireless Remote Control (AWREC)

1

Allows the user to operate the Bit in remote activation mode. Ensures quick and silent

activation/deactivation of the equipment. Comes with CR2032 (3V) battery installed.

7 Picatinny Adapter for Advanced Wireless Remote Control

1

Allows the advanced wireless remote control to be installed on a weapon’s Picatinny/

Weaver rail.

8 IR850W Detachable Wide Angle Adjustable X-Long Range Infrared Illuminator

1

A detachable LED long-range infrared illuminator with a wide, adjustable beam angle.

Compatible with night vision devices that rely on CCD or image intensier technology.

Should be used when there is little to no ambient light. Comes fully assembled with a

dedicated mount in order to be installed on a Picatinny/Weaver rail.

9 Platform Ring

1

A dedicated mount with a Picatinny/Weaver rail, used to install on the top of the Bit and

additional equipment, such as the Armasight MCS Miniature Collimating Sight.

10 Video Cable

1

A cable used to connect the analog video input/output of the Bit to external display

devices (a monitor, TV) or power sources. The cable plug A is used for video, the plug B

is used for external power surse connection.

11 Afocal Doubler (Bit 5X-10X only)

1

2x magnifying lens intended for long-range operation. Comes complete with an thread

adapter and three M2×3 screws that are required to mount the lens to the Bit.

12 Operation and Maintenance Manual

1

Provides safety information, equipment description, mounting procedures, operating

instructions, and preventive maintenance checks and services (including a List of Spare

Par ts).

13 Carrying Case

1

A textile bag used for the transportation and storage of the Bit and its accessories.

Page 16

16

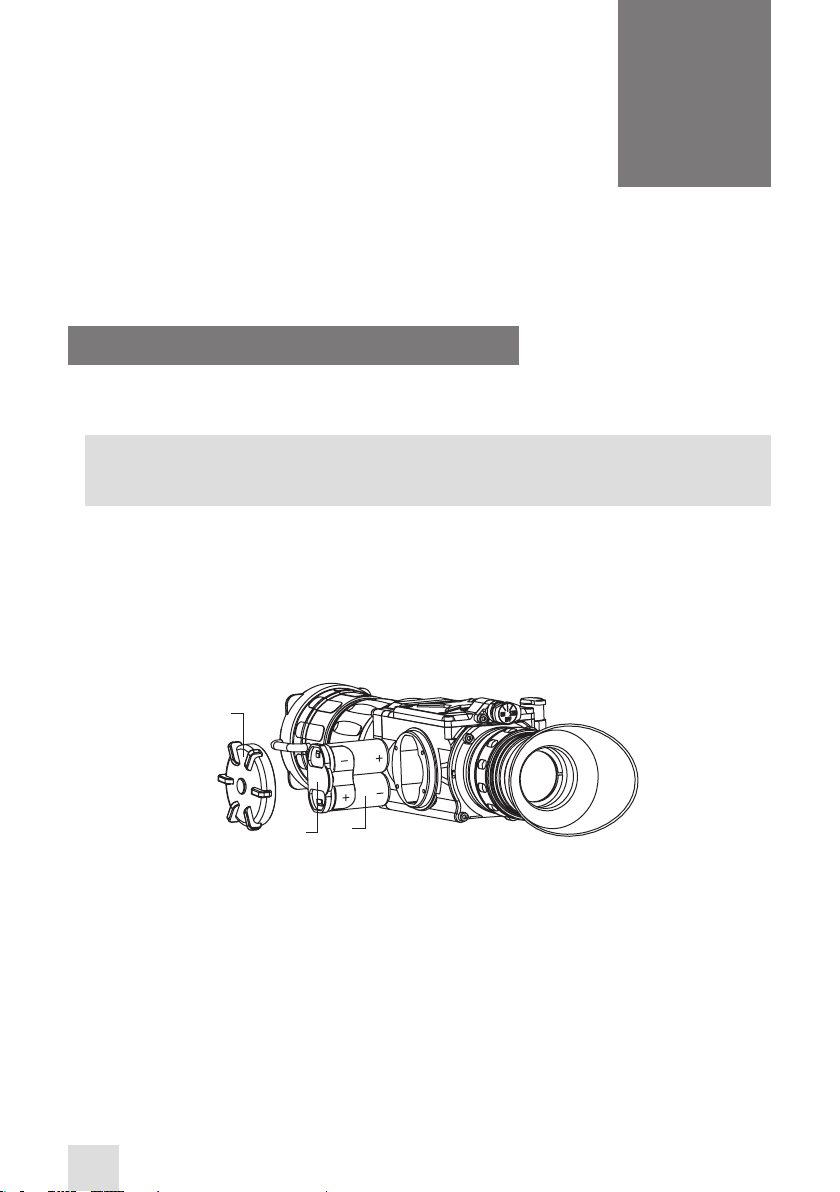

2.4 OPTIONAL EQUIPMENT

Optional items are shown in Figure 2-4 and listed in Table 2-9.

The ITEM NO. column indicates the number used to identify items in Figure 2-4.

The PART NO. column indicates the primary number used by the manufacturer, to identify an item.

1 2

3 4 5

FIGURE 24. OPTIONAL EQUIPMENT

TABLE 29. OPTIONAL EQUIPMENT

ITEM NO. DESCRIPTION PART NO.

1 Digital Video Recorder DT

ATAM000004

A compact digital video recorder used for video recording, storage and

playback. Can also serve as an external power source. Equipped with a remote

control.

2 External Battery Power Supply 1

ATAM000007

The power surce for extended operational time. Takes four AA batteries (1.5V)

or AA rechargeable batteries (1.2V).

3 External Battery Power Supply 2

ATAM000008

The power source for extended operational time. Takes four CR123A Lithium

batteries (1.5V) or CR123 type rechargeable batteries (3.2V or 3.7V) or two

18650 type rechargeable batteries (3.7V).

4 Afocal Doubler for Bit 5X

ANAF18X039

An accessory 2x magnifying lens intended for long-range operation. Comes

complete with an thread adapter and three M2×3 screws that are required to

mount the lens to the Bit 5X.

5 Hard Shipping/Storage Case

ANHC000004

A protective case used for the shipping/storage of the Bit and its accessories.

Page 17

17

2.5 KEY FEATURES

Available in two versions — with magnication of 5x and 10x

–

High-performance CCD camera

–

Bright-light tolerance

–

An eective regardless of light conditions - in daylight, in natural lighting, and at nighttime.

–

Lightweight and robust design

–

Easy to operate

–

Manually adjustable eyepiece and objective lens

–

Real-time display

–

Digitally controlled –display brightness

Indication of the battery status information on the display

–

Wireless remote control

–

Analog video input (NTSC/PAL) and output (PAL)

–

Powered by two standard CR123A batteries

–

Power input capability

–

Tripod mountable

–

Digital video recorder (optional)

–

Serviceability under severe conditions

–

Filled with dry nitrogen to prevent internal fogging

–

Waterproof

–

Limited two-year warranty

–

Page 18

18

3

OPERATING INSTRUCTIONS

3.1 INSTALLATION AND MOUNTING

3.1.1 BATTERY INSTALLATION

CAUTI ON:

Before installing a battery, verify that the equipment is o.

Install two CR123A batteries as follows (refer to Figure 3-1):

1. Unscrew the battery cap (A).

2. Remove the battery cassette (B).

3. Insert the batteries (C) into cassette. Align the polarity symbols on the batteries with the polarity

symbols on the cassette.

4. Insert the cassette with installed batteries to place.

5. Replace the battery cap.

A

C

B

FIGURE 31. BATTERY INSTALLATION

3.1.2 MOUNTING A PLATFORM RING TO THE BIT

Figure 3-2 shows the Bit with the Platform Ring adapter (A) installed.

To mount the Platform Ring on the Bit, do the following (refer to Figure 3-3):

1. Using a 1.5 hex key, unscrew the both clamp screws (C).

2. Place the clamps (B, D) onto the mounting tube (as in Figure 3-2). Screw the clamps together without

tightening the screws (C).

3. Adjust position of the Platform Ring until its rail (A) is level. Apply a small amount of thread lock to

the threads and tighten the screws (C).

Page 19

A

FIGURE 32. THE BIT FULLY ASSEMBLED WITH THE PLATFORM RING

A

C

B

C

D

FIGURE 33. PLATFORM RING

3.1.3 FASTENING AN ADVANCED WIRELESS REMOTE CONTROL

Using Velcro tape (A, Figure 3-4), fasten the remote control (B) in an easily accessible place.

If your equipment has a Picatinny or Weaver rail, you can use the Picatinny adaptor for the Advanced

Wireless Remote (C). Install the adaptor onto the rail (D). Insert the remote control unit into the adapter.

You can also install the Picatinny adaptor onto the Bit side rail or onto the platform ring.

B

A

B

C

D

FIGURE 34. ADVANCED WIRELESS REMOTE CONTROL

3.1.4 INSTALLING ADDITIONAL EQUIPMENT ON THE BIT

Use the side Picatinny/Weaver rail to install any additional equipment, such as the Armasight DT digital

video recorder (see Figure 3-5) or an external battery power supply.

Use the Platform Ring adapter to install any additional equipment, such as the long-range IR illuminator. For adapter mounting procedures, see Part 3.1.2.

19

Page 20

20

3.1.5 CONNECTING ADDITIONAL EQUIPMENT TO THE BIT

CAUTI ON:

Turn o the Bit before you begin connecting/disconnecting any external equipment and before removing the batteries.

Remove the batteries before you connect any external power source.

Remove the connector protective cap.

Connect a cable of Armasight DT digital video recorder or an external battery power supply to the Bit

connector.

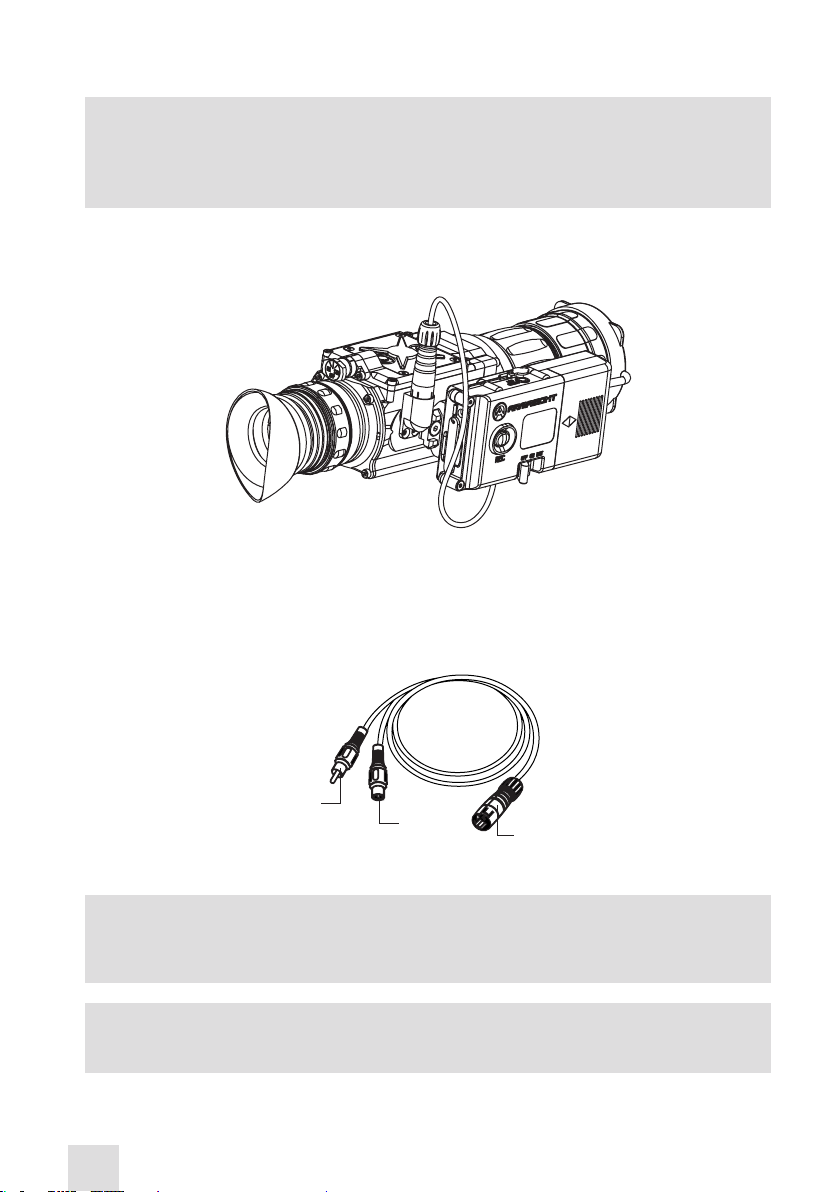

FIGURE 35. ARMASIGHT DT DIGITAL RECORDER INSTALLATION

Use the plug A of a video cable to connect an external video recorder/monitor/TV to the Bit. Connect

the plug C of a video cable to the Bit connector.

Use the plug B of a video cable to connect an external power source (6 VDC/1A) to the Bit. Connect the

plug C of a video cable to the Bit connector.

A

B

C

FIGURE 36. VIDEO CABLE

NOTE:

The external power supply must have a standard 6mm OD double-pole socket with a positive

center contact.

CAUTI ON:

After removing the cable, replace the protective cap over the connector.

Page 21

21

3.1.6 INSTALLING AN IR ILLUMINATOR ON THE BIT

Armasight long range IR illuminators are delivered fully assembled with a dedicated mount, to be installed on the side rail of the Bit or on the rail of the Platform Ring mounted to the Bit.

To mount an IR illuminator on a Picatinny/Weaver rail, do the following (refer to Figure 3-7):

1. With the nut (A) loosened, install the mount (B) on the Weaver rail so that the stop (C) slides into one

of the transverse slots of the rail.

2. Tighten the nut (A) using a screwdriver.

D

B

A

FIGURE 37. IR ILLUMINATOR

NOTE:

The mount clamp (D) has a spherical hinge that allows to tilt the IR illuminator mounted on the

rail.

Install the CR123A battery as follows (refer to Figure 3-8):

C

CAUTI ON:

Ensure that the IR Illuminator is o before installing the battery.

1. Unscrew the battery cap (A).

2. Install the battery (B) into the battery compartment. Align the polarity symbols on the battery with

those on the cap face.

3. Replace the battery cap (A).

B

A

FIGURE 38. IR ILLUMINATOR. BATTERY INSTALLATION

Page 22

22

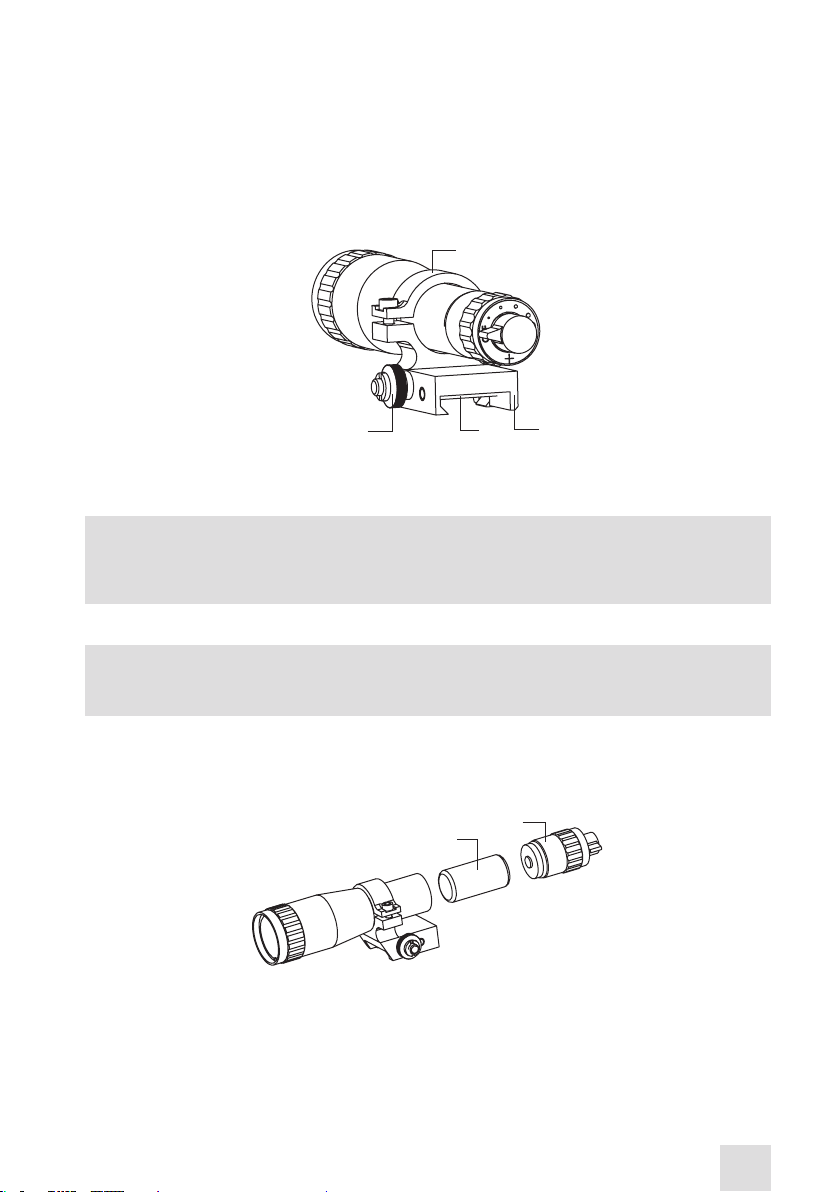

3.1.7 ATTACHING AN AFOCAL DOUBLER TO THE BIT

Figure 3-9 shows the Bit with an accessory Afocal Doubler lens attached.

Attach the magnifying lens to the Bit as follows:

1. Remove the Bit objective lens cap and place it over the lens housing.

2. Screw the Afocal Doubler (A) into the threading of the Bit objective lens (B) housing. Be careful not

to over-tighten the lens.

A

B

C

FIGURE 39. THE BIT WITH THE AFOCAL DOUBLER ATTACHED

NOTE:

The adapter (C, Figure 3-9) is used for mounting the Afocal Doubler to the Bit. The adapter is

screwed to the threaded portion of the doubler housing and xed with three M2×3 screws using a 0.9 hex key. The thread adapter switches between M48×1 and M51×1 thread sizes.

NOTE:

With the magnifying lens in place, magnication value changes as well as other parameters,

such as system resolution, eld of view, focusing range, etc.

NOTE:

The caution notice DO NOT REMOVE IN DAYLIGHT on the front lens cap of this universal magnifying lens is not applicable when using it on the Bit.

3.1.8 INSTALLING THE BIT ON A TRIPOD

The Bit can be installed to a tripod. To mount the tripod with the Bit device, screw the tripod into the

1/4’’ threaded socket located on the Bit’s bottom side.

CAUTI ON:

The unit may be badly damaged if the tripod collapses or falls over. Remove the unit from the

tripod if it is not within your reach.

Page 23

23

3.2 CONTROLS AND DISPLAY INDICATIONS

3.2.1 BIT CONTROLS

The Bit controls are shown in Figure 3-10 and are dened in Table 3-1. The ITEM NO. columns of the

tables indicate the number used to identify items in the gures.

4

3

2

1

5

6

FIGURE 310. BIT CONTROLS

CAUTI ON:

DO NOT force the equipment controls past their stopping points.

TABLE 31. CONTROLS AND INDICATORS

ITEM NO. CONTROL/INDICATOR FUNCTION

1 Eyepiece Focus Ring Adjusts the eyepiece diopter. The total diopter adjustment range is

covered with 2 turns of the ring.

2 Turn-pull Switch Activates the Bit when turned to ON.

NOTE:

You must pull the knob before turning in order to activate either

ON or STB.

Activates standby mode when turned to STB (see note above).

Deactivates the Bit when turned to OFF.

3 Display Brightness

Push the button (3) to decrease the screen brightness.

Decrease Button

4 Display Brightness

Push the button (4) to increase the screen brightness.

Increase Button

5 Objective Focus Ring Focuses the objective lens. Adjusts for sharpest view of the scene.

The total focus range is covered with three quarter turns of the lens.

6 Remote Control Button Activates/deactivates the Bit in standby mode. To turn the unit on,

press button once, to turn it o – press button again.

— Battery Status Indicator

(a battery icon on the

the display) *

The light gray bar in the battery icon indicates the current power

level of the internal battery, or remaining battery life.

The totally shaded battery icon indicates the fully charged battery.

The ashing transparent battery icon indicates a low battery.

* The Battery Status Indicator not show a correct power level when the external battery or power supply is

used.

Page 24

24

3.2.2 IR ILLUMINATOR CONTROLS

The controls of the optional IR illuminators are shown in Figure 3-11 and dened in Table 3-2. The ITEM

NO. column indicates the number used to identify items in Figure 3-14.

2

FIGURE 311. IR ILLUMINATOR CONTROLS

TABLE 32. IR ILLUMINATOR CONTROLS

ITEM NO. CONTROL FUNCTION

Switches the IR illuminator on/o and adjusts for radiated power.

1

2

POWER SWITCH

LENS FOCUS

Four ON positions are located between the two OFF positions, and

are each marked with a dierent-sized spot. The larger the spot, the

greater the radiated power.

Adjusts for IR beam divergence. Adjustment range is covered with

approximately one turn of the lens.

1

3.3 OPERATING PROCEDURES

3.3.1 OPERATING THE BIT

CAUTI ON:

DO NOT force the equipment controls past their stopping points.

CAUTI ON:

Although the Bit is highly resistant to damage from light overload, DO NOT point it, either powered or un-powered, directly at the sun or any other source of high intensity light that the unprotected human eye cannot tolerate (such as welding arc). To prevent exposure to these types

of sources, never leave the equipment unsuper vised with the objective lens cap removed.

Operating procedures are as follows:

1. Remove the Bit from the carrying case.

2. Remove the objective lens cap.

3. Point the equipment at an object.

4. Activate the Bit by turning the turn-pull switch to the ON position. Af ter approximately 3 sec, video

of the scene should appear.

5. Adjust the Bit for your eyesight by turning the eyepiece focus ring CW up to the stop, and then CCW

until the display and symbols are as clear as possible. Bring the object into focus by turning the objective focus ring (CW for long-range focus, CCW for close-range focus).

Page 25

25

NOTE:

The total diopter adjustment range is covered with 2 turns of the eyepiece focus ring.

The total focus range is covered with 3/4 turn of the objective focus ring.

6. Using the buttons on the control panel, adjust the brightness of the display for your comfort. Momentarily push the brightness adjustment buttons to increase/decrease the display brightness by

one level at a time until you reach your desired brightness level.

7. To operate the Bit with remote control, turn the switch to the STB position (standby mode). To activate the Bit, press the remote control button once. Press the remote control button again to deactivate the Bit.

CAUTI ON:

DO NOT leave the equipment activated when it is not in use.

3.3.2 OPERATING AN IR ILLUMINATOR

Use an IR illuminator when there is little to no ambient light.

CAUTI ON:

IR illuminator infrared light will be invisible to the naked eye. However, the light can be detected by other night vision devices.

CAUTI ON:

DO NOT leave the IR illuminator activated if it is not being used.

Operate the IR illuminator as follows:

1. Turn on the IR illuminator by rotating the power switch (A) from OFF position.

2. To change the radiated power level, turn the power switch to one of the spots between the two OFF

positions.

3. To adjust IR beam divergence, turn the lens (B).

4. To adjust the IR spot position in the eld of view, loosen the clamp screw (C) and tilt the IR illuminator

as required in the spherical clamp hinge. Tighten the screw using a 2.5 mm hex key.

B

C

A

FIGURE 312. IR ILLUMINATOR ADJUSTMENT

Page 26

3.3.3 BIT SHUTDOWN

NOTE:

Shut down the Bit properly to avoid losing unsaved settings and data.

Shut-down the Bit as follows:

1. Turn o the Bit.

2. Replace the cap on the objective lens.

3. Disconnect the cable (if applicable).

4. Place the cap on the connector.

5. Remove the batteries.

CAUTI ON:

Do not store the Bit with the batteries still installed.

6. Store the Bit and all accessories in the carrying case.

26

Page 27

27

4

PREVENTIVE MAINTENANCE AND

TROUBLESHOOTING

4.1 PREVENTIVE MAINTENANCE CHECKS AND SERVICES

4.1.1 PREVENTIVE MAINTENANCE CHECKS AND SERVICES PMCS

Table 4-1 Preventive Maintenance Checks and Services (PMCS) has been provided so that you can keep

your equipment in good operating condition.

Perform functional tests in the order listed in Table 4-1.

Operating procedures are detailed in Chapter 3.

Explanation of Table Entries:

SEQ NO. column. Sequence numbers are for reference and appear in the order required to perform

checks and services.

LOCATION/ITEM TO CHECK/SERVICE column. Indicates the location and the item to be checked or

serviced.

PROCEDURE column. Details the check/ service procedure.

NOT FULLY MISSION CAPABLE IF ... column. Indicates what faults will prevent your equipment from

operating successfully.

TABLE 41. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

SEQ

LOCATION ITEM TO

NO.

CHECK/SERVICE

1 Completeness Open storage /carr ying ca se and i nventory items by

2 Soft Carrying Case Shake out loos e dirt or foreign material. Inspect for tears,

3 Body Inspect for cracks or damage. Scratches and gouges are

4 Objective Lens

Cap

5 Eyecup Inspec t for cut s, tears and dirt . Inspect for torn, bent or

comparin g them with the data sp ecied in this manual .

cuts, excess wear or damage.

OKifoperationisnotaec ted.Inspec tformissingpar ts.

Clean as required.

Inspec t for cuts, tears and d irt.

Clean as required.

imprope rly tting eyecup.

Clean as required.

PROCEDURE

PRE-OPERATIONCHECKS

NOT FULLY MISSION

CAPABLE IF ...

Missing ite ms.

Cracked or d amaged. Missing parts.

Cap is torn or cut. Cap is not secured to

the housin g of the lens.

Cup is torn or cu t.

Page 28

28

TABLE 41. CONTIN UED

SEQ

LOCATION ITEM TO

NO.

CHECK/SERVICE

6 Batter y Compart-

ment, Cap, a nd,

Cassette

7 Lenses Inspec t for cleanliness, s cratches, chips or cr acks.

8 Objective Focus

Ring

9 Eyepiece Fo cus

Ring

10 Turn-pull Switch Check for operation (w ithout batterie s). Switch is inoperati ve.

11 Connector Inspe ct for corrosion, moisture, and corro ded or defec-

12 Remote Control

Unit

13 Long Range IR

Illuminator

14 Platform Rin g Inspe ct for damage, corrosion , or missing parts. Check

15 Video Cabl e Inspec t for damage. In spect the cab le connector f or cor-

16 Afocal Doubl er Inspect the Afocal D oubler l ens optic al surfaces for

Inspec t for corros ion, moisture , and corrod ed or defective contacts. Insp ect for cap damaged or reta iner

breaks . Inspect rubbe r gasket for damage.

Clean as required.

Rotate obje ctive focus ring to ensure it is not too tight or

too loose . Range is approximately 3/4 turns.

Rotate eyepiece fo cus ring t o ensure th e ring is not too

tight or too l oose. Range is appro ximately 2 turns.

tive cont acts. Inspe ct for cap dam age or retaine r breaks.

Check for d amage and missing par ts.

Check Velcro tape for wear.

Inspec t the body of the IR illuminator and mount for

damage an d missing parts.

Check IR Ill uminator Power Switch fo r proper operation.

Check IR Illumina tor B attery Cap and O-ring for dam-

age.

Inspec t IR Illuminator lens for cleanliness, scratche s, chips

or cracks . Clean as requir ed. Check to ensure there is free

rotation t hrough the full range of travel (one turn).

for proper operation. Clean as require d.

rosion, moisture, and corr oded or defect ive contacts.

Clean as required.

cleanlin ess, scratches, chi ps or cracks. Clean as required.

Inspec t the front cap for cut s, tears and dirt. I nspect

the rear cap for ease of installation and dir t. Cl ean a s

required.

Check ease of attaching and removal of the lens. Clean

as required.

PROCEDURE

NOT FULLY MISSION

CAPABLE IF ...

Contact s are da maged or corrod ed.

Retaine r is broken. Cap or rubbe r gasket is damag ed.

Chipped or cracked. Scratches hinder

visibility.

Ring get s stuck, is too loose, o r adversely aect s the user’s ability to

properly focus the obje ctive lens.

Ring get s stuck, is too loos e, or

adverse ly aects the use r’s ability to

properly adjust the diop ter.

Contact s are damaged or corr oded.

Cap is damag ed. Retainer is broken.

Damaged . Missing parts.

Damaged.

Missing pa rts.

Switch is inop erative.

O-rin g is damaged or missin g.

Lens is chipped or cra cked. Lens is

stickin g or too loose when tu rned.

Damaged . Missing parts.

Damaged.

Chipped or cracked. Scratches hinder

vision thr ough the equipment .

The fron t cap i s torn or cut , or is not se cured to the housing of the lens. The

rear cap is da maged.

Damaged.

OPERATIONALCHECKS

17 Turn-pull Switch I nstall the bat teries. Rem ove the o bjective l ens cap.

18 Control Board Ensure the Bit is r esponsive to control b uttons. Unresponsive buttons.

19 Remote Control Turn the equipment to standby. Point the equipme nt at

20 Video Ca ble Connect an external monitor to the Bit. Point the equip-

21 Lon g Range IR

Illuminator

Point the equipment at an object. Turn the equ ipment

on. Loo k for an image on the display. Loo k for a ashing

batter y icon in the eyepiec e viewing area.

an ob ject. Press the remote contr ol button. Look fo r an

image on the display. Press the button again. Turn o the

equipment.

ment o n an objec t. Turn the equipment o n. Look fo r an

image on th e monitor. Turn o the Bit. Disconnect the

monitor.

Insert the battery. M ount the IR illu minator onto the Bit.

Turn the IR i lluminator on. D irect the rad iated beam at a

wall fro m a distance of about 5 m. Lo ok through the Bit.

A square of li ght should appear on t he wall.

No i mage. Bat tery icon is ashin g (indicates a low battery).

No image.

No image.

No light app ears on the wall.

POST-CHECKPROCEDURES

Turn o the equip ment.

Replace th e objective lens c ap.

Remove the b atteries.

Return the equipment and al l accessor ies to the c arrying case.

Page 29

29

4.2 OPERATOR TROUBLESHOOTING

The purpose of troubleshooting is to identify the most frequent equipment malfunctions, probable

causes, and corrective actions required.

Table 4-2 lists the common malfunctions that may be found during the operation or maintenance of

the Bit. Perform the tests/inspections and corrective actions in the order listed.

This table does not list all of the malfunctions that may occur with your device, or all of the tests

and corrective actions that may be necessary. If you experience an equipment malfunction that is

not listed, or is not xed by the corrective actions listed in the table, please contact Armasight’s Customer Service center.

TABLE 42. OPERATOR TROUBLESHOOTING

MALFUNCTION PROBABLE CAUSE / TEST/I NSPECTION CORRECTIVE ACTION

The Bit fa ils to activate. Bat teries are m issing o r impro perly in-

The Bit i s not res ponsive to

control bu ttons.

Remote control do es no t

work.

Poor image q uality. Check objective lens and eyepie ce fo-

No image Vi deo cable is damage d. Replace the vi deo cable with a new one. Please

Hindere d rotation of the

batter y cap.

Light is v isible arou nd eyecup. C heck eyecup resilie nce. If the eyecup is defec tive, pleas e contact Cus-

stalled.

Batter ies are dead. Replace the batterie s.

Batter ies, surf aces or contacts are dir ty

or corroded.

Remote control unit is damaged. Please cont act Customer Supp ort.

Remote control batter y is dead. Replace the b attery as per Par t 4.3.4.

The equipment is damaged. Please cont act Customer Supp ort.

The equipment is damaged. Please cont act Customer Supp ort.

Batter y is missing or impr operly in stalled.

Batter y is dead. Replace th e battery.

Batter y surfaces or contacts are dirty or

corroded.

Remote control unit is damaged. Please cont act Customer Supp ort.

cus.

Check for fogging or dirt on objective

lens and eye piece.

The equipment is damaged. Please cont act Customer Supp ort.

The equipment is damaged. Please cont act Customer Supp ort.

Dirt y cap thread. Clean the th read.

Damaged cap thread. Replace the cap wit h a new one. Please contac t

Insert b atteries or inst all correctly.

Clean the contact surfaces with a pencil eraser

and/or alcoh ol and cotton swabs .

Insert b attery or inst all correctly.

Clean the contact surfaces with a pencil eraser

and/or alcoh ol and cotton swabs .

Refocus.

Clean the le nses as detailed in Pa rt 4.3.2.

contact Cu stomer Suppor t.

Customer Support.

tomer Support.

4.3 MAINTENANCE

4.3.1 GENERAL

The Bit operator maintenance consists of operational tests, inspections for unit serviceability, cleaning

and mounting procedures, corrective actions (troubleshooting and replacement of a limited number

of parts). Maintenance instructions covered elsewhere in this manual (PMCS, troubleshooting, etc.) are

not repeated in this section.

Page 30

30

CAUTI ON:

The Bit is a precision electro-optical instrument and must be handled carefully at all times to

prevent damage.

CAUTI ON:

DO NOT dismantle the equipment.

4.3.2 CLEANING PROCEDURES

Clean the Bit and optional items as follows:

1. Gently brush o any dirt from the equipment using only a clean, soft cloth.

2. Moisten the cloth with fresh water and gently wipe the external surfaces (except for optical surfaces).

3. Dry any wet surfaces (except for optical surfaces) with another clean, dry soft cloth.

4. Using a lens brush, carefully remove all loose dirt from optical surfaces (objective lens and eyepiece).

5. Slightly dampen a cotton swab with ethanol and lightly and slowly wipe optical surfaces. Clean optical surfaces using circular movements, starting from the center and moving out towards the edge,

not touching the lens holder and changing the cotton swab after each circular stroke. Repeat until

the optical surface is clean.

6. Clean the batter y contact surfaces and contact springs with a pencil eraser and/or alcohol and cotton swabs.

CAUTI ON:

Thoroughly dry each item before replacing into the storage/carrying case.

4.3.4 BATTERY REMOVAL AND REPLACEMENT

Refer to Part 3.1.1 for battery installation procedures.

Refer to Part 3.1.6 for IR illuminator battery installation procedure.

Replace the remote control battery as follows:

1. Using a screwdriver, unscrew the four screws (A, Figure 4-1) that secure the cover to the bottom of

the unit. Remove the cover.

2. Replace the battery with new one (CR2032, 3V). Install the battery, aligning it polarity markings (+/-)

with those embossed on the compartment.

3. Replace the cover and tighten the screws (A).

A

FIGURE 41. ADVANCED WIRELESS REMOTE CONTROL BATTERY INSTALLATION

Page 31

31

4.4 RETURN INSTRUCTIONS

For service, repair or replacement, please email: service@arm as ig ht .com.

To assist the Service Representative (SR) with determining if the item is repairable, please provide the

following information:

1. Serial Number of the defective item (engraved on bottom of the equipment).

2. Thorough description of the malfunction, defect or damage.

3. An explanation of how the malfunction, defect or damage occurred, if known.

If the SR determines that the item is under warranty or should be returned for repair, a Return Material

Authorization number (RMA#) will be provided.

When returning the Bit for service or repair, the following procedures should be followed to prevent

any additional damage:

1. Make sure the Bit is free of all contaminants such as dirt or any other foreign material.

2. Remove the batteries.

3. Place the cap over the objective lens.

4. Place the Bit and accessories in the carrying case.

Place the Bit and a copy of the test report or detailed description of the failure in a suitable packing/

shipping container. Mark the package with the RMA#. Ship the fastest, traceable, prepaid means to:

Armasight Inc.

815 Dubuque Avenue

South San Francisco, CA 94080

USA

Page 32

32

APPENDIx

A. LIST OF SPARE PARTS

The parts authorized by this list of spare parts are required for operator maintenance. The list includes

parts that must be removed before replacing authorized parts.

The PART NO. column indicates the primary number used by the manufacturer, which controls the design and characteristics of the item in terms of its engineering drawings, specications, standards, and

inspection requirement, to identify an item.

4

3

2

1

5

6

10 11 12 13

98

14 15

16

FIGURE 23. BIT STANDARD COMPONENT

TABLE A1. BIT SPARE PARTS LIST

ITEM NO. DESCRIPTION PART NO.

1 Objective Lens Cap ABPSOLC

2 Objective Lens Assembly ABPSOLA

3 Connector Cap ABCCP

4 Battery Cap ABPSBC

5 Eyepiece Assembly ABPSEPA

6 Eyecup ABPSEC

7 Side Picatinny/Weaver Rail (not shown) ABPSPRL

8 Battery Cassette ABBTCS

9 CR 123A Lithium Battery ALT

10 Advanced Wireless Remote Control ANVR000001

11 Picatinny Adapter for Advanced Wireless Remote Control ANRA000002

12 IR850W Detachable Wide Angle Adjustable X-Long-Range

IAIR850IR000002

Infrared Illuminator

13 Platform Ring ATAM000003

14 Video Cable ATCA000004

17

Page 33

TABLE A1. CONTINU ED

ARMASIGHT PRODUCT WARRANTY REGISTRATION CARD

PRODUCT INFORMATION

CUSTOMER INFORMATION

Product Name

Purchase Date

Name

Purchased From

Product Serial #

Address

City

Day Phone #

E-mail address

Country Zip

Home Phone #

Customer Signature Required

ITEM NO. DESCRIPTION PART NO.

15 Afocal Doubler ANAF18X039

16 Operation and Maintenance Manual ABOMM

17 Carrying Case ABCRCS

B. PRODUCT WARRANTY REGISTRATION CARD

In order to validate the warranty on your product, Armasight must receive a completed Product Warranty Registration Card for each unit, or the user must complete warranty registration on our website

(www.armasight.com). Please complete the included form and immediately mail it to our Service Center:

Armasight Inc.

815 Dubuque Avenue

South San Francisco, CA 94080

USA

33

Page 34

34

Page 35

35

v1-2 01403 26

Page 36

Armasight Inc.

815 Dubuque Avenue

South San Francisco

CA 94080, USA

Phone: (888)959-2259

Fax: (888)959-2260

Intl Phone/Fax: (650)492-7755

info@armasight.com

CAUTI ON:

This product contains natural rubber latex

which may cause allergic reactions! The FDA

has reported an increase in the number of deaths

that are associated with an apparent sensitivity

to natural latex proteins. If you are allergic to

latex, it is a good idea to learn which products

contain it and strictly avoid exposure to those

products.

www.armasight.com

2014.03.05

Loading...

Loading...