Arista DCS-7260QX-64, DCS-7050TX-128, DCS-7050SX2-128, DCS-7250QX-64, DCS-7260CX-64 Quick Start Manual

...Page 1

Quick Start Guide

7000 Series 2 RU

Data Center Switches

Arista Networks

www.arista.com

PDOC-00039-10

Page 2

Headquarters

5453 Great America Parkway

Santa Clara, CA 95054

USA

408 547-5500

www.arista.com

© Copyright 2017 Arista Networks, Inc. The information contained herein is subject to change without notice. Arista Networks

and the Arista logo are trademarks of Arista Networks, Inc in the United States and other countries. Other product or service

names may be trademarks or service marks of others.

ii Quick Start Guide: 7000 Series 2 RU Data Center Switches

Support

408 547-5502

866 476-0000

support@arista.com

Sales

408 547-5501

866 497-0000

sales@arista.com

Page 3

Overview

1.1 Scope

This guide is intended for properly trained service personnel and technicians who need to install the

following Arista Networks Data Center Switches:

Chapter 1

• DCS-7050SX-128 • DCS-7250QX-64 • DCS-7280CR-48

• DCS-7050TX-128 • DCS-7260QX-64 • DCS-7280CR2-60

• DCS-7050SX2-128 • DCS-7260CX-64 • DCS-7280CR2A-60

• DCS-7050TX2-128 • DCS-7260CX3-64 • DCS-7280CR2K-60

Important! Only qualified personnel should install, service, or replace this equipment.

Seul le personnel qualifié doit installer, service, ou remplacer cet équipement.

1.2 Receiving and Inspecting the Equipment

Upon receiving the switch, inspect the shipping boxes and record any external damage. Retain packing

materials if you suspect that part of the shipment is damaged; the carrier may need to inspect them.

If the boxes were not damaged in transit, unpack them carefully. Ensure that you do not discard any

accessories that may be packaged in the same box as the main unit.

Inspect the packing list and confirm that you received all listed items. Compare the packing list with

your purchase order. Appendix B provides a list of components included with the switch.

1.3 Installation Process

The following tasks are required to install and use the switch:

Step 1 Select and prepare the installation site (Section 2.1).

Step 2 Assemble the installation tools listed in Section 2.2.

Step 3 Attach the mounting brackets and install the switch in an equipment rack (Chapter 3).

Step 4 Connect the switch to the power source and network devices (Chapter 4).

Step 5 Configure the switch (Chapter 5).

Quick Start Guide: 7000 Series 2 RU Data Center Switches 1

Page 4

Safety Information Chapter 1: Overview

Important! Class 1 Laser Product: This product has provisions to install Class 1 laser transceivers which provide

optical coupling to the communication network. Once a Class 1 laser product is installed, the

equipment is a Class 1 Laser Product (Appareil à Laser de Classe 1). The customer is responsible for

selecting and installing the Class 1 laser transceiver and for insuring that the Class 1 AEL (Allowable

Emission Limit) per EN/IEC 60825, CSA E60825-1, and Code of Federal Regulations 21 CFR 1040 is

not exceeded after the laser transceiver have been installed. Do not install laser products whose class

rating is greater than 1. Refer to all safety instructions that accompanied the transceiver prior to

installation. Only Class 1 laser devices, certified for use in the country of installation by the cognizant

agency are to be utilized in this product.

Appareil à laser de classe 1 Cet appareil comporte des dispositions permettant d'installer des

émetteurs-récepteurs fournissant un couplage optique au réseau de communication. Une fois

l'appareil à laser de classe 1 installé, l'équipement devient un appareil à laser de classe 1. Le client est

responsable du choix et de l'installation de l'émetteur-récepteur à laser de classe 1 et il doit s'assurer

que les limites d'émission admissibles pour la classe 1 régulées par les normes EN/IEC 60825 et

CAN/CSA E60825-1 et par le Code of Federal Regulations 21 CFR 1040 ne soient pas dépassées

après l'installation de l'émetteur-récepteur à laser. N'installez pas d'appareils à laser dont la

classification est supérieure à 1. Avant l'installation, lisez attentivement les instructions de sécurité

fournies avec l'émetteur-récepteur. Seuls les appareils à laser de classe 1 qui ont été certifiés par

l'autorité agréée pour une utilisation dans le pays d'installation peuvent être utilisés dans ce produit.

Important! Ultimate disposal of this product should be in accordance with all applicable laws and regulations.

Élimination définitive de ce produit devrait être en conformité avec toutes les lois et règlements

applicables.

1.4 Safety Information

Refer to the Arista Networks document Safety Information and Translated Safety Warnings available at:

www.arista.com/support/docs/eos

1.5 Obtaining Technical Assistance

Any customer, partner, reseller or distributor holding a valid Arista Service Contract can obtain

technical support in any of the following ways:

• Email: support@arista.com. This is the easiest way to create a new service request.

Include a detailed description of the problem and the output of “show tech-support”.

• Web: www.arista.com/support.

A support case may be created through the support portal on our website. You may also download

the most current software and documentation, as well as view FAQs, Knowledge Base articles,

Security Advisories, and Field Notices.

• Phone: 866-476-0000 or 408-547-5502.

Important! No user serviceable parts inside. Refer all servicing to qualified service personnel.

Aucune pièce réparable par l'utilisateur à l'intérieur. Confiez toute réparation à un technicien qualifié.

2 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 5

Chapter 1: Overview Specifications

1.6 Specifications

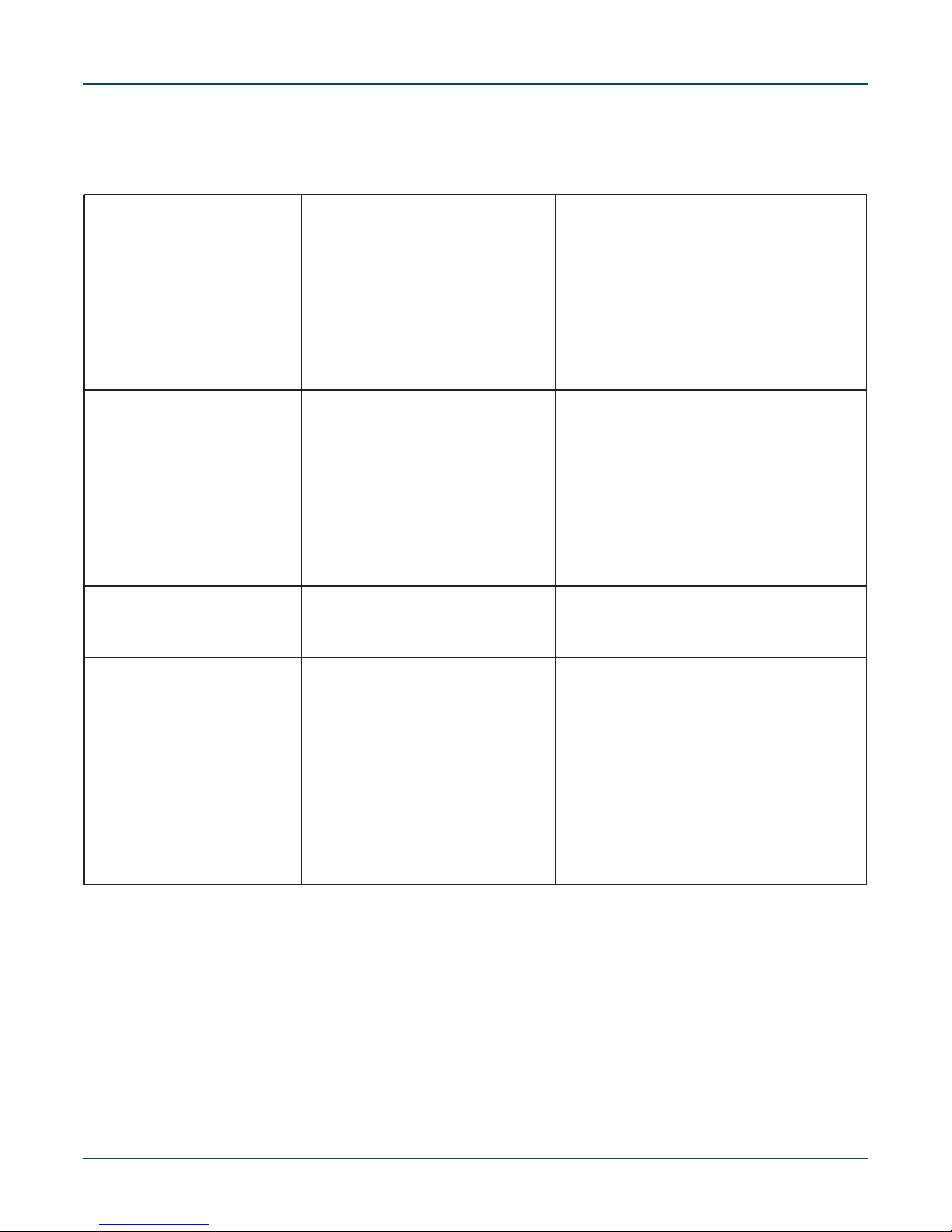

Table 1-1 lists the specifications of Arista Data Center switches covered by this guide.

Table 1-1 Switch Specifications

Size (WxHxD) DCS-7050SX-128

Weight DCS-7050SX-128

Operating Temperature

Storage Temperature

Operating Altitude

Relative Humidity

Power Input (AC Power) DCS-7050SX-128 / PWR-500AC

DCS-7050TX-128

DCS-7050SX2-128

DCS-7050TX2-128

DCS-7250QX-64

DCS-7260QX-64

DCS-7260CX-64

DCS-7260CX3-64

DCS-7280CR-48

DCS-7280CR2-60

DCS-7280CR2A-60

DCS-7280CR2K-60

DCS-7050TX-128

DCS-7050SX2-128

DCS-7050TX2-128

DCS-7250QX-64

DCS-7260QX-64

DCS-7260CX-64

DCS-7260CX3-64

DCS-7280CR-48

DCS-7280CR2-60

DCS-7280CR2A-60

DCS-7280CR2K-60

all

all

all

all

DCS-7050SX-128 / PWR-750AC

DCS-7050TX-128 / PWR-745AC

DCS-7050SX2-128 / PWR-500AC

DCS-7050TX2-128 / PWR-745AC

DCS-7250QX-64 / PWR-1100AC

DCS-7260QX-64 / PWR-1100AC

DCS-7260CX-64 / PWR-1900AC

DCS-7260CX3-64 / PWR-745AC

DCS-7260CX3-64 / PWR-1900AC

DCS-7280CR-48 / PWR-1900AC

DCS-7280CR2-60 / PWR-1900AC

DCS-7280CR2A-60 / PWR-1900AC

DCS-7280CR2K-60 / PWR-1900AC

48.3 x 8.8 x 45.9 cm (19 x 3.5 x 18.1 inches)

48.3 x 8.8 x 45.9 cm (19 x 3.5 x 18.1 inches)

48.3 x 8.8 x 45.9 cm (19 x 3.5 x 18.1 inches)

48.3 x 8.8 x 45.9 cm (19 x 3.5 x 18.1 inches)

44.5 x 8.8 x 55.3 cm (19 x 3.5 x 21.8 inches)

44.5 x 8.8 x 45.7 cm (19 x 3.5 x 18.0 inches)

44.5 x 8.8 x 45.7 cm (19 x 3.5 x 18.0 inches)

44.5 x 8.8 x 45.4 cm (19 x 3.5 x 17.9 inches)

44.5 x 8.9 x 56.3 cm (19 x 3.5 x 22.2 inches)

44.5 x 8.8 x 64.0 cm (19 x 3.5 x 25.2 inches)

44.5 x 8.8 x 64.0 cm (19 x 3.5 x 25.2 inches)

44.5 x 8.8 x 64.0 cm (19 x 3.5 x 25.2 inches)

15.1 kg (33 pounds)

15.6 kg (34 pounds)

15.1 kg (33 pounds)

15.6 kg (34 pounds)

19.2 kg (42 pounds)

16.1 kg (35.5 pounds)

21.3 kg (47 pounds)

15.6 kg (34 pounds)

21.2 kg (47 pounds)

24.9 kg (54.8 pounds)

24.9 kg (54.8 pounds)

24.9 kg (54.8 pounds)

0° to 40°C (32° to 104°F)

-25° to 70°C (-13° to 158°F)

0 to 3,000 meters (0 to 10,000 feet)

5to90%

100 - 240 VAC, 5.7-2.4 A, 50/60 Hz

100 - 240 VAC, 5.7-2.4 A, 50/60 Hz

100 - 240 VAC, 10-5 A, 50/60 Hz

100 - 240 VAC, 5.7-2.4 A, 50/60 Hz

100 - 240 VAC, 10-5 A, 50/60 Hz

200 - 240 VAC, 6.5 A, 50/60 Hz

200 - 240 VAC, 6.5 A, 50/60 Hz

200 - 240 VAC, 11.5 A, 50/60 Hz

100 - 240 VAC, 10-5 A, 50/60 Hz

100 - 240 VAC, 10-5 A, 50/60 Hz

200 - 240 VAC, 11.5 A, 50/60 Hz

200 - 240 VAC, 11.5 A, 50/60 Hz

200 - 240 VAC, 11.5 A, 50/60 Hz

200 - 240 VAC, 11.5 A, 50/60 Hz

Quick Start Guide: 7000 Series 2 RU Data Center Switches 3

Page 6

Specifications Chapter 1: Overview

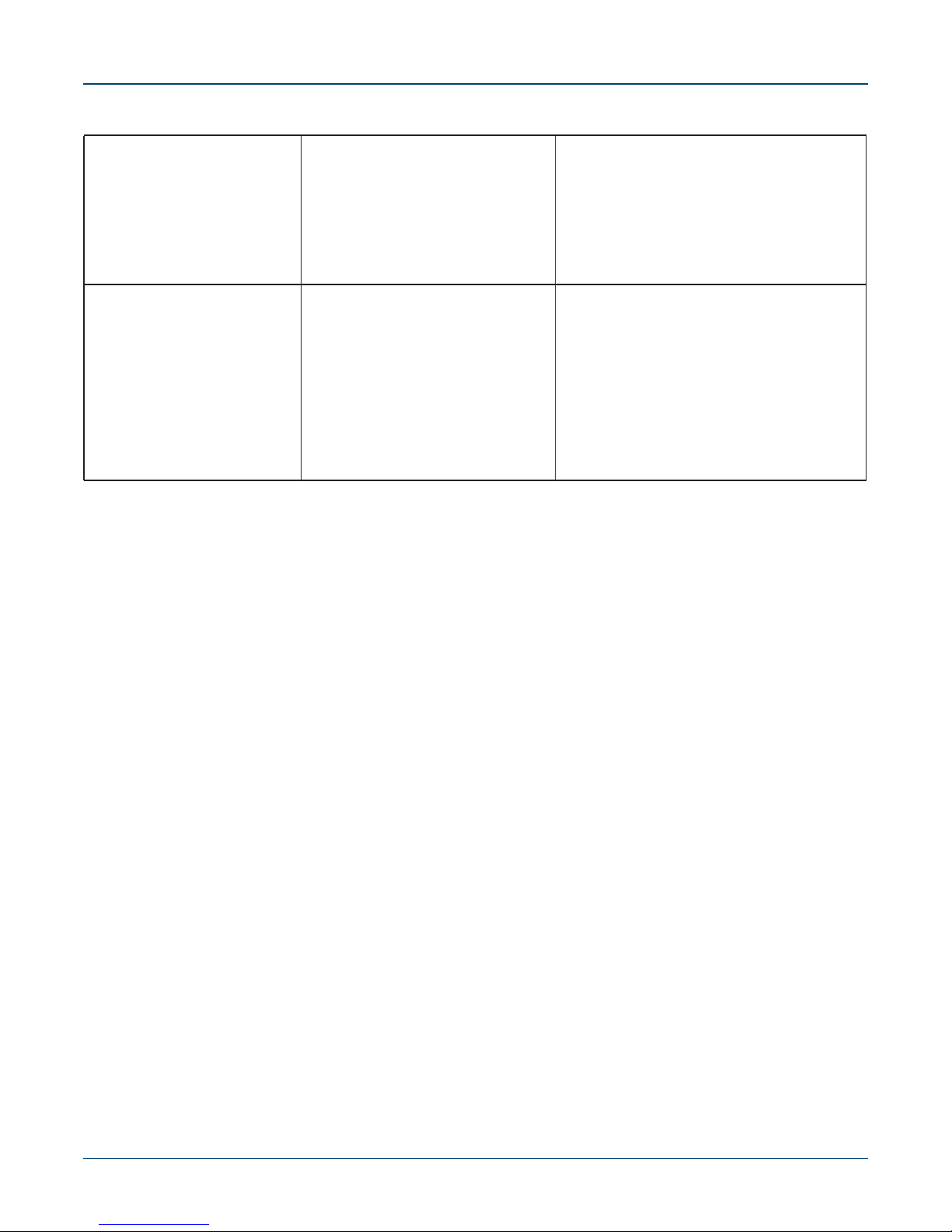

Table 1-1 Switch Specifications (Continued)

Power Input (DC Power) DCS-7050SX-128 / PWR-500DC

DCS-7050TX-128 /PWR-1900DC

DCS-7250QX-64 / PWR-1900DC

DCS-7260CX-64 / PWR-1900DC

DCS-7260CX3-64 / PWR-1900DC

DCS-7280CR-48 / PWR-1900DC

DCS-7280CR2-60 / PWR-1900DC

DCS-7280CR2A-60 / PWR-1900DC

DCS-7280CR2K-60 / PWR-1900DC

Power Draw

(Typical / Maximum)

DCS-7050SX-128

DCS-7050TX-128

DCS-7050SX2-128

DCS-7050TX2-128

DCS-7250QX-64

DCS-7260QX-64

DCS-7260CX-64

DCS-7260CX3-64

DCS-7280CR-48

DCS-7280CR2-60

DCS-7280CR2A-60

DCS-7280CR2K-60

-48 - 60VDC, 15 A

-48 - 60VDC, 32 A

-48 - 60VDC, 32 A

-48 - 60VDC, 46 A

-48 - 60VDC, 32 A

-48 - 60VDC, 52 A

-48 - 60VDC, 52 A

-48 - 60VDC, 52 A

-48 - 60VDC, 52 A

235 W / 415 W

570 W / 740 W

220 W / 395 W

430 W / 580 W

622 W / 946 W

315 W / 850 W

1672 W / 2090 W

340 W / 660 W

1363 W / 1710 W

1660 W / 1850 W

1760 W / 1950 W

1760 W / 1950 W

4 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 7

Chapter 2

Preparation

2.1 Site Selection

The following criteria should be considered when selecting a site to install the switch:

• Temperature and Ventilation: For proper ventilation, install the switch where there is ample

airflow to the front and back of the switch. The ambient temperature should not go below 0° or

exceed 40°C.

Important! To prevent the switch from overheating, do not operate it in an area where the ambient temperature

exceeds 40°C (104°F).

Pour empêcher l'interrupteur de surchauffe, ne pas utiliser il dans une zone où la température ambiante

est supérieure à 40°C (104°F).

• Airflow Orientation: Determine airflow direction of the four fan modules and two power supply

modules on the rear panel. Fan and power supply module handles indicate airflow direction:

• Blue Handle: Air Inlet module.

• Red Handle: Air Exit module.

Figure 2-1 on page 6 displays fan and power supply module locations on the rear panel. Their red

handles indicate that they are air exit modules. Verify that each module has the same airflow

direction. Base the switch orientation on the airflow direction of the modules to assure the air inlet

is always oriented toward the cool aisle:

• Air Exit modules: orient the rear panel toward the hot aisle.

• Air Inlet modules: orient the rear panel toward the cool aisle.

If the airflow direction is not compatible with the installation site, contact your sales representative

to obtain modules that circulate air in the opposite direction.

Quick Start Guide: 7000 Series 2 RU Data Center Switches 5

Page 8

Site Selection Chapter 2: Preparation

Figure 2-1: Fan and Power Supply (Air Exit) Modules

• Rack Space: Install the switch in a 19" rack or cabinet. The switch height is 2 RU. The accessory

kit provides mounting brackets for four-post racks. Contact your sales representative to obtain

two-post mounting brackets.

When mounting the switch in a partially filled rack, load the rack from bottom to top, with the

heaviest equipment at the bottom. Load the switch at the bottom if it is the only item in the rack.

• Power Requirements: Power requirements vary by switch and power supply model. Refer to

Table 1-1 for information regarding your specific system.

Two circuits provide redundancy protection. Section 4.1 describes power cable requirements.

Important! The power input plug-socket combination must be accessible at all times; it provides the primary

method of disconnecting power from the system.

La combinaison de la puissance-prise d'entrée doit être accessible en tout temps ; Il fournit le principal

moyen de coupure d'alimentation du système.

• Other Requirements: Select a site where liquids or objects cannot fall onto the equipment and

foreign objects are not drawn into the ventilation holes. Verify these guidelines are met:

• Clearance areas to the front and rear panels allow for unrestricted cabling.

• All front and rear panel indicators can be easily read.

• Power cords can reach from the power outlet to the connector on the rear panel.

Important! All power connections must be removed to de-energize the unit.

Toutes les connexions d'alimentation doivent être enlevées pour hors tension l'appareil.

Important! This unit is intended for installation in restricted access areas.

Cet appareil est prévu pour une installation dans les zones d'accès restreintes.

6 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 9

Chapter 2: Preparation Tools and Parts Required for Installation

2.2 Tools and Parts Required for Installation

The following tools and equipment are required to install the switch:

Two-Post Rack

• Screws or rack mounting nuts and bolts.

• Screwdriver

Four-Post Rack (Toolless)

No additional equipment required.

Accessory kit does not include screws for attaching the switch to the equipment rack. When installing

the switch into an equipment rack with unthreaded post holes, nuts are also required to secure the

switch to the rack posts.

2.3 Electrostatic Discharge (ESD) Precautions

Observe these guidelines to avoid ESD damage when installing or servicing the switch.

• Assemble or disassemble equipment only in a static-free work area.

• Use a conductive work surface (such as an anti-static mat) to dissipate static charge.

• Wear a conductive wrist strap to dissipate static charge accumulation.

• Minimize handling of assemblies and components.

• Keep replacement parts in their original static-free packaging.

• Remove all plastic, foam, vinyl, paper, and other static-generating materials from the work area.

• Use tools that do not create ESD.

Quick Start Guide: 7000 Series 2 RU Data Center Switches 7

Page 10

Electrostatic Discharge (ESD) Precautions Chapter 2: Preparation

8 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 11

Chapter 3

Rack Mounting the Switch

Important! The rack mounting procedure is identical for all switches covered by this guide. Illustrations in this

chapter depict the mounting of a DCS-7050SX-128 switch.

Les procédure de montage du bâti est identique pour tous les commutateurs visés par ce guide.

Illustrations dans ce chapitre montrent le montage d'un interrupteur de DCS-7050SX-128.

• Section 3.1 provides instructions for mounting the switch in a two-post rack.

• Section 3.2 provides instructions for mounting the switch in a four-post rack.

After completing the instructions for your rack type, proceed to Chapter 4.

3.1 Two-Post Rack Mount

To mount the switch onto a two-post rack, assemble the mounting brackets to the chassis, then attach

the brackets to the rack posts. Two-post accessory kits includes 2 three-hole mounting brackets.

Each chassis side has attachment pins that align with bracket holes; the number of pins (six or seven)

varies by switch model. Pin orientation is symmetric and equidistant, supporting bracket placement

where the flange is either flush with the front and rear panels, or not flush with the panels. Each bracket

hole includes a key-opening for placing the bracket flush with the chassis and then locking it into place.

Important! Attachment pins must engage all three upper bracket holes.

Goupilles de fixation doivent s’engager tous les trois trous de la bride supérieure..

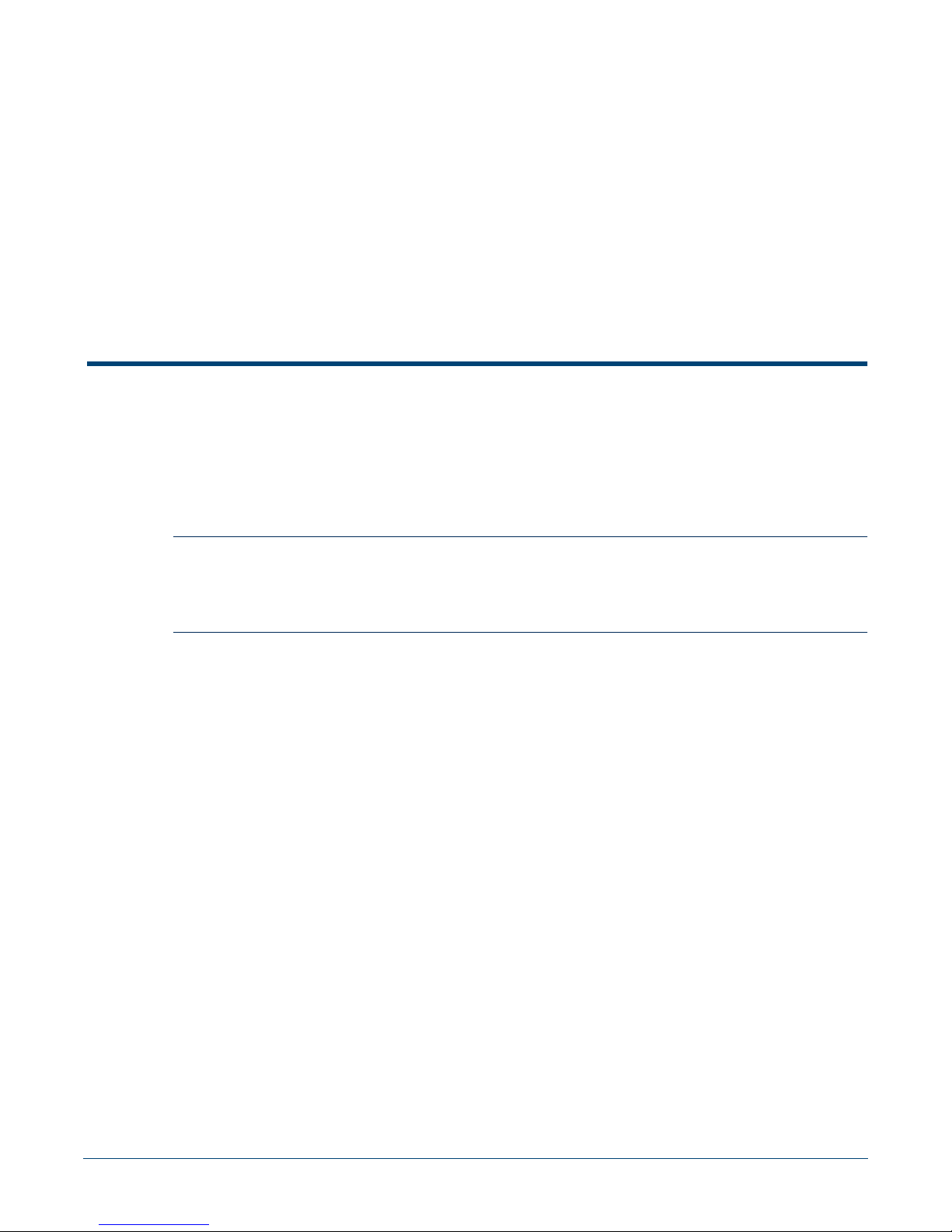

Figure 3-1 displays proper bracket mount configuration examples. Figure 3-2 on page 10 displays

improper bracket mount configuration examples.

Figure 3-1: Bracket Mount Examples for Two-Post Rack Mount

Quick Start Guide: 7000 Series 2 RU Data Center Switches 9

Page 12

Two-Post Rack Mount Chapter 3: Rack Mounting the Switch

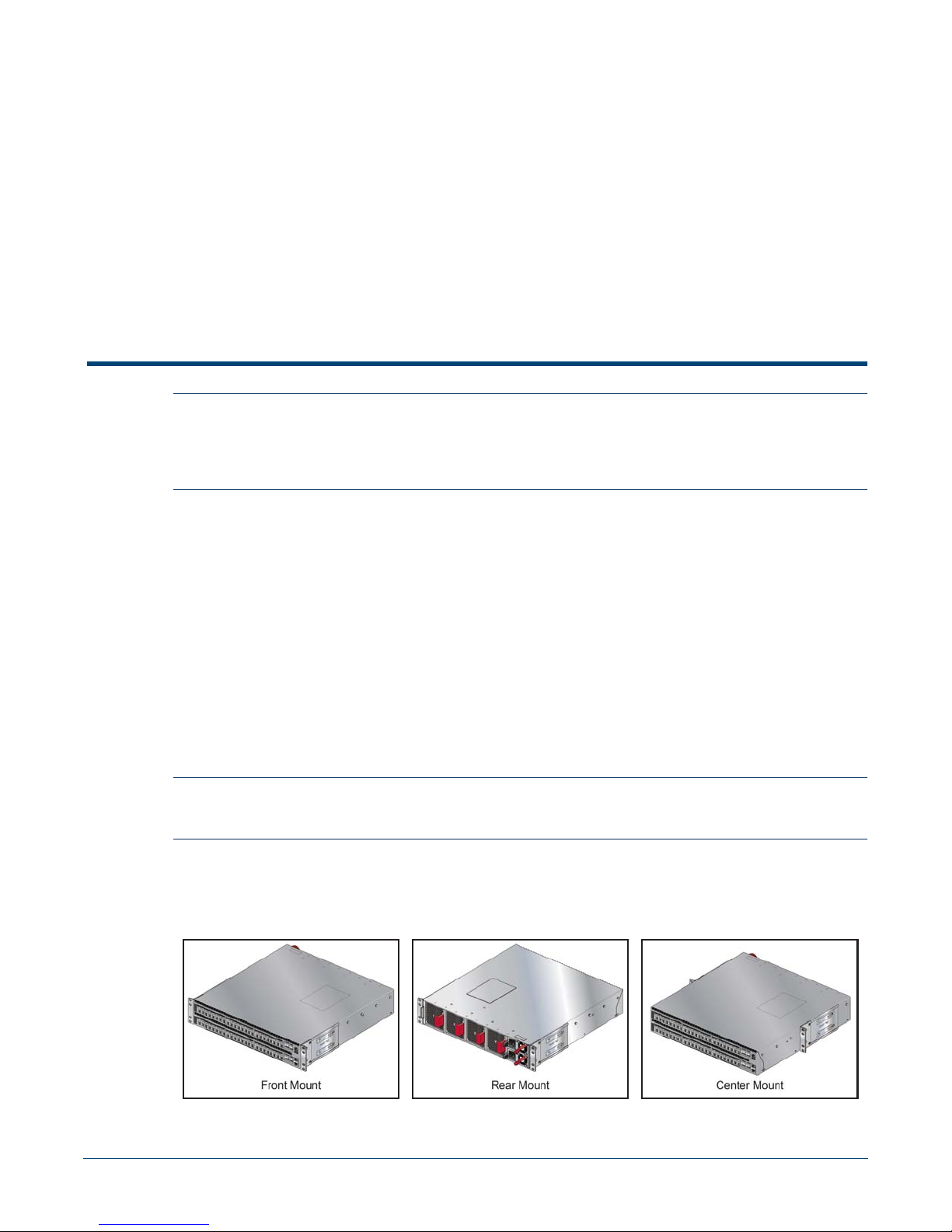

Figure 3-2: Improper Bracket Mount Examples for Two-Post Rack Mount

3.1.1 Attaching Mounting Brackets to the Chassis

This procedure attaches mounting brackets to the switch chassis (Figure 3-3).

Step 1 Align the mounting brackets with the attachment pins to obtain the desired mounting position.

Step 2 Place the bracket flush on the chassis with attachment pins protruding through key-openings.

Step 3 Slide the bracket toward the front flange until the bracket clip locks with an audible click.

Figure 3-3: Attaching the Mounting Brackets to the Switch Chassis

To remove the mounting bracket from the chassis, lift the front edge of the mounting bracket clip

with a flathead screwdriver and slide the bracket away from the front flange (opposite from the

installation direction).

3.1.2 Inserting the Switch into the Rack

This procedure attaches the switch to the rack (Figure 3-4 on page 11).

Step 1 Lift the chassis into the rack. Position the flanges against the rack posts.

10 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 13

Chapter 3: Rack Mounting the Switch Four-Post Rack Mount

Figure 3-4: Inserting the Switch into the Rack

Step 2 Select mounting screws that fit your equipment rack.

Step 3 Attach the bracket flanges to the rack posts.

After completing the two-post rack mount, proceed to Chapter 4.

3.2 Four-Post Rack Mount

The switch is mounted onto a four-post rack by assembling two rails onto the rear posts, sliding the

switch onto the rails, then securing the switch to the front posts.

The installation kit provides two bracket-rail assemblies. The following four-post mounting parts are

extracted from each assembly:

• Six-hole mounting bracket

• Rail

Each chassis side has attachment pins that align with bracket holes; the number of pins (six or seven)

varies by switch model. Pin orientation is symmetric and equidistant, supporting bracket placement

where the flange is either flush with the front and rear panels, or not flush with the panels. Each bracket

hole includes a key-opening for placing the bracket flush with the chassis and then locking it into place.

Important! Attachment pins must engage all six bracket holes.

Goupilles de fixation doivent s’engager tous les trous de support six.

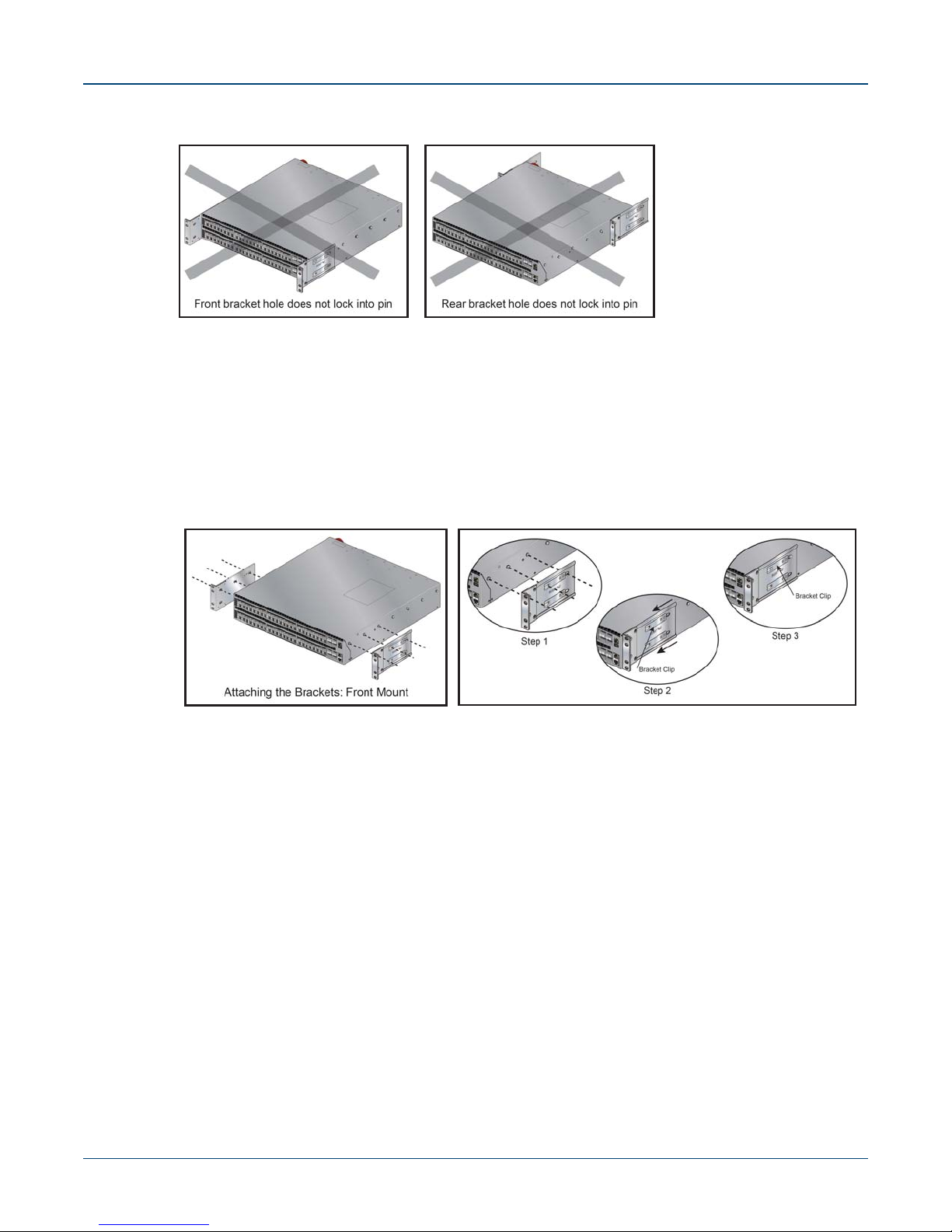

Figure 3-5 on page 12 displays proper bracket mount configuration examples. Figure 3-6 on page 12

displays an improper bracket mount configuration examples.

Quick Start Guide: 7000 Series 2 RU Data Center Switches 11

Page 14

Four-Post Rack Mount Chapter 3: Rack Mounting the Switch

Figure 3-5: Bracket Mount Examples for Four-Post Rack Mount

Figure 3-6: Improper Bracket Mount Example for Four-Post Rack Mount

Off-set mount is always an improper bracket mount configuration on switches that have six attachment

pins on each side.

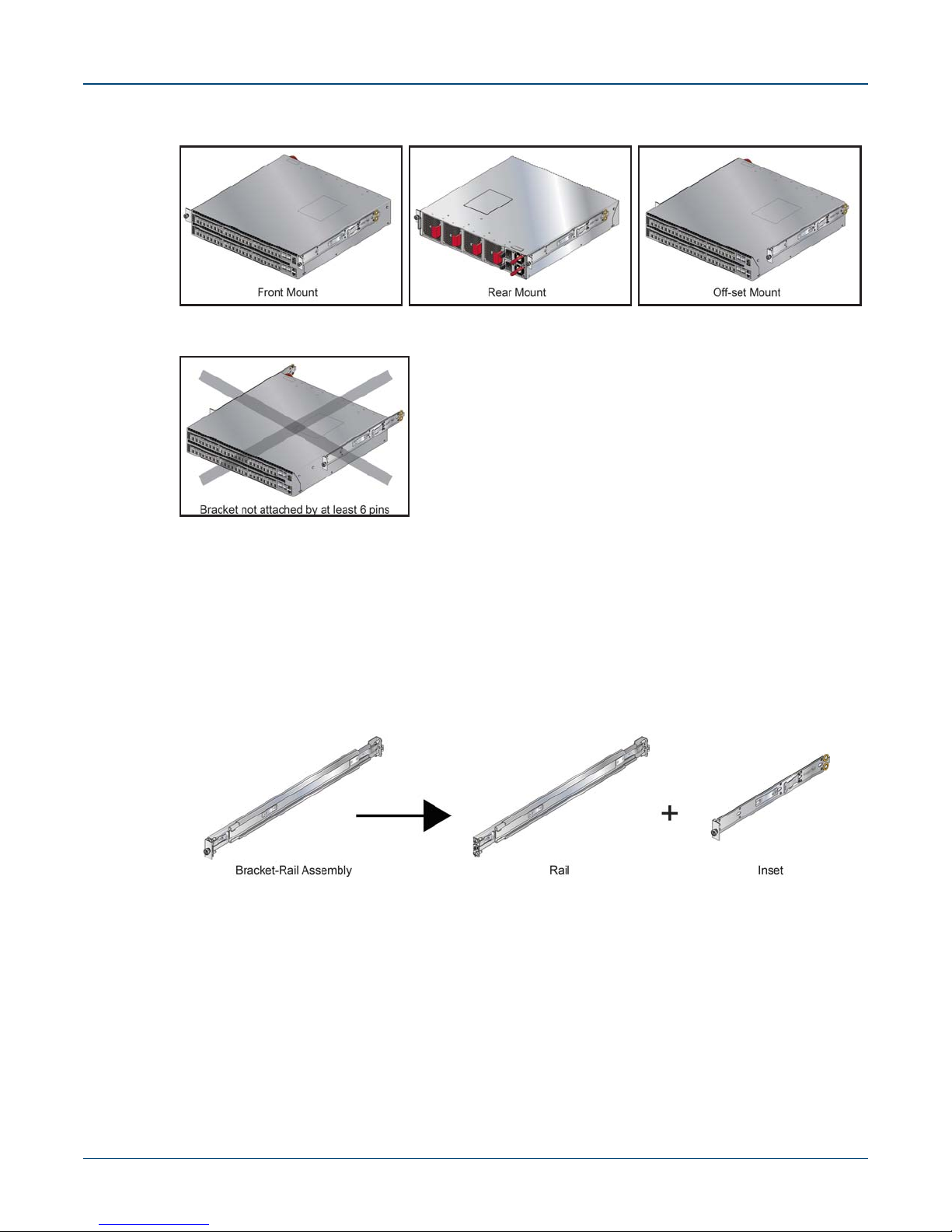

3.2.1 Extracting the Brackets and the Rails

Figure 3-7 displays a bracket-rail assembly and the component pieces (bracket and rail) that are

extracted from the assembly. Each assembly must be separated into its component pieces before

mounting the switch into a four-post rack. The two assemblies supplied with the switch are identical.

Figure 3-7: Bracket-Rail Assembly – Before and After Extraction

This procedure separates a bracket-rail assembly into its component pieces.

Step 1 Grip the rail with your right hand, as shown in Figure 3-8-left. Pull the bracket flange away from

the rail flange with your left hand until the bracket clip catches on the rail (Figure 3-8-Right).

If the bracket flange resists initially, verify the thumb screw on the bracket flange is not attached

to the rail flange.

12 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 15

Chapter 3: Rack Mounting the Switch Four-Post Rack Mount

Figure 3-8: Extracting the Bracket-Rail Assembly

Step 2 While pressing the locking clip on the bracket (Figure 3-8-Right), resume pulling the bracket

from the rail until the separation is complete.

Step 3 Repeat the procedure for the other assembly.

3.2.2 Attaching Mounting Brackets to the Chassis

Figure 3-9 displays the front bracket alignment for mounting the switch into a four-post rack.

This procedure attaches mounting brackets to the switch chassis as depicted by Figure 3-10 on page

14.

Step 1 Align the mounting brackets with the attachment pins to obtain the desired mounting position.

Step 2 Place the bracket flush on the chassis with attachment pins protruding through key-openings.

Step 3 Slide the bracket toward the front flange until the bracket clip locks with an audible click.

Figure 3-9: Front Bracket Alignment

To remove the mounting bracket from the chassis, lift the front edge of the mounting bracket clip

with a flathead screwdriver and slide the bracket away from the front flange (opposite from the

installation direction).

Quick Start Guide: 7000 Series 2 RU Data Center Switches 13

Page 16

Four-Post Rack Mount Chapter 3: Rack Mounting the Switch

Figure 3-10: Attaching the Mounting Brackets to the Switch Chassis

3.2.3 Expanding the Rails

The rail is a two-piece mechanism. The rail length is adjusted by sliding the rail-rod inside the rail-slide.

The rail clip prevent extension of the rail beyond the maximum supported distance between front and

rear rack posts. When the rail is contracted, the rail clip is closest to the slide end.

The rail is initially contracted and must be expanded to attach onto the rack. This procedure expands

the rails from their contracted state:

Step 1 Grip the slide end with your left hand and the rod end with your right hand (Figure 3-11-left).

Step 2 Pull the ends apart until the rail-clip makes an audible click (Figure 3-11-right).

Figure 3-11: Expanding the Rails

3.2.4 Assembling the Rails onto the Equipment Rack

A rail connects a front post to a rear post. Each end has two rack plugs (Figure 3-11-Right, Inset A).

Rails are installed into a rack by inserting the plugs into rack slots. To install rails into posts with

threaded or rounded holes, remove all plugs on both sides of the rails, then install the rails with bolts

that fit the rack. This procedure attaches the rails to a four-post rack:

Step 1 Attach rail to the right rear rack post by inserting rod-end rack plugs into post slots

(Figure 3-12-Right, Inset A). The slide assembly must be inside the right posts, relative to the

left rack posts.

If the rack plugs were previously removed, use bolts to attach the rail to the rack.

14 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 17

Chapter 3: Rack Mounting the Switch Four-Post Rack Mount

Step 2 Attach the slide end of the rail to the front post by extending the rail end past the post, then

contracting the rail while guiding the rack plugs into the post (Figure 3-12, Inset B).

Step 3 Repeat step 1 through step 2 for the left posts. Ensure the rails are on the same horizontal

level.

Figure 3-12: Attaching the Rails

3.2.5 Attaching the Switch to the Rack

After the rails are installed, the switch slides on the rails into the rack. Each bracket includes a thumb

screw that attaches the switch to the rail.

Step 1 Lift the switch into the rack and insert the mounting brackets into the slide rails.

Step 2 Slide the switch on the rails, toward the rear posts, until the mounting bracket flanges are flush

with the rail flanges attached to the rack posts.

Figure 3-13: Inserting the Switch onto the Rails

Quick Start Guide: 7000 Series 2 RU Data Center Switches 15

Page 18

Four-Post Rack Mount Chapter 3: Rack Mounting the Switch

Step 3 Attach the bracket flanges to the rack post using the quick-release thumb screws supplied with

the brackets.

Figure 3-14: Attaching the Switch to the Rack Posts

After completing the four-post rack mount, proceed to Chapter 4.

16 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 19

Chapter 4

Cabling the Switch

4.1 Connecting Power Cables

Important! Installation of this equipment must comply with local and national electrical codes. If necessary, consult

with the appropriate regulatory agencies and inspection authorities to ensure compliance.

Installation de cet équipement doit être conformes aux codes électriques locaux et nationaux. Si

nécessaire, consulter les organismes de réglementation appropriés et des autorités de contrôle pour

assurer la conformité.

The switch operates with two installed power supplies. At least one power supply must connect to a

power source. Two circuits provide redundancy protection.

Appendix D displays the location of the power supplies on the rear panel of the switch.

Important! Read all installation instructions before connecting the system to the power source.

Lire toutes les instructions d'installation avant de brancher le système à la source d'alimentation.

• Non-Redundant Configuration: Connect power to either of the two power supplies.

• Redundant Power Supply Configuration: Connect power to both power supplies.

• Power down the Switch: Remove all power cords and wires from the power supplies.

Important! This equipment must be grounded. Never defeat the ground conductor.

Cet équipement doit être mis à la terre. Ne jamais modifier le conducteur de terre.

Important! This unit requires overcurrent protection.

Cet appareil requiert une protection contre les surintensités.

Quick Start Guide: 7000 Series 2 RU Data Center Switches 17

Page 20

Connecting Power Cables Chapter 4: Cabling the Switch

4.1.1 AC Power Supplies

Four power supply models (in each air flow direction) are available for 7000 Series 2 RU switches. The

power supply model number is located on the module between the power socket and the fan

(Figure 4-1). Model number of available power supplies include:

• PWR-500AC • PWR-1900AC

• PWR-745AC • PWR-1100AC

Power requirements vary by switch. Refer to Table 1-1 for information regarding your specific system.

The AC power supply connects to a circuit that provides the required power.

Figure 4-1 displays an AC power supply, including the power socket on the left side of the module.

Figure 4-1: AC Power Supply

The accessory kit provides two IEC-320 C13 to C14 power cables, each two meters long for 500W/

750W/ 1100W power supplies. Systems with 1900W power supplies come with C19 to C20 power

cables.

4.1.2 DC Power Supplies

The following two power supplies are supported.

• PWR-1900DC

• PWR-500DC

Figure 4-2: Supported DC power supplies

Important! A disconnect device must be provided as part of the installation .

Un dispositif de sectionnement doit être fourni dans le cadre de l'installation.

18 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 21

Chapter 4: Cabling the Switch Connecting Power Cables

Important! Ensure power is removed from DC circuits before performing any installation actions. Locate the

disconnect device, circuit breakers or fuses on DC power lines servicing the circuits.

Turn off the power line circuits or remove the fuses.

Pouvoir assurer qu'il est retiré de circuits DC avant d'effectuer des actions d'installation . Localiser les

disjoncteurs ou des fusibles sur les lignes de courant continu desservant les circuits.

Coupez les circuits de lignes d'alimentation ou retirer les fusibles.

Important! Wire size must comply with local and national requirements and electrical codes.

Use only copper wire.

Le calibre du fil doit être conforme aux exigences locales et nationales et les codes électriques.

Utiliser du fil de cuivre.

Important! Apply ground connection to the switch first during installation and remove last when removing power.

Appliquer connexion à la terre à l'interrupteur premier lors de l'installation et de supprimer la dernière

alimentation lors du débranchement.

4.1.2.1 Wire and Lug Preparation

Before performing any installation actions, ensure power is removed from DC circuits by turning off the

power line servicing the circuits. Prepare the stranded wiring before you begin a DC power installation.

Step 1 Attach an ESD grounding strap.

Step 2 Stranded copper wiring is required.

• Commercially available 2 to 4 AWG wire for PWR-1900DC and 10 AWG wire for

PWR-500DC is recommended for installations in the U.S.

• Wire size should meet local and national installation requirements.

• Grounding wires and grounding lugs are not supplied.

• Strip the wires to the appropriate length for the lugs.

The wires connecting the DC power supply to the power source must meet the following

requirements:

• DC Input Wire Size: 2 – 4 AWG (26.7 mm2to 21.2 mm2) for PWR-1900DC.

• DC Input Wire Size: 10 AWG (5.26 mm2) for PWR-500DC.

• Tightening Torque: 2.7 N-m (24 in. lbs.)

• Primary Ground Wire Size: 2 – 4 AWG (26.7 mm2to 21.2 mm2) per power supply.

• The conductors are copper.

Step 3 Use agency-approved compression (pressure) lugs for wiring terminations.

Step 4 Slip on heat-shrink tubing on the wire ends before assembling the lugs on to the wire.

• The lugs must be crimped with the proper tool.

• The tubing should extend over the lugs barrel and the wire's insulator.

Step 5 Shrink the tubing with a heat gun.

Quick Start Guide: 7000 Series 2 RU Data Center Switches 19

Page 22

Connecting Power Cables Chapter 4: Cabling the Switch

4.1.2.2 1900W DC Power Supply

Figure 4-3: 1900W DC power supply

To connect a DC power supply to power source:

Step 1 Prepare the stranded wiring, see Section 4.1.2.1, Wire and Lug Preparation, on page

19.

Step 2 Attach the appropriate lugs to the source DC wires.

Step 3 Use DC cables with either insulated crimp-on spade lugs or insulated crimp-on ring

connectors.

Step 4 Connect the DC-input wires:

• Ground wire to the Protective Earth (PE ) terminal.

• Negative source DC cable to the negative (- / -48V) terminal.

• Positive (+) source DC cable to the positive (+ / Rtn) terminal.

4.1.2.3 PWR-500DC Power Supply

The 500W DC power supply connects to a circuit that provides -48Vto -60V and 15A. Figure 4-4

displays the DC power supply.

Figure 4-4: 500W DC Power Supply

Step 1 Prepare the stranded wiring, see Section 4.1.2.1, Wire and Lug Preparation, on page

19.

Figure 4-5: Attaching the DC Wires

20 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 23

Chapter 4: Cabling the Switch Connecting Serial and Management Cables

Step 2 Attach the appropriate lugs to the source DC wires.

Step 3 Use DC cables with either insulated crimp-on spade lugs or insulated crimp-on ring

connectors.

Step 4 Connect the DC-input wires to the terminal block in this order:

• Ground wire to the Protective Earth (PE ) terminal.

• Negative source DC cable to the negative (- / -48V) terminal.

• Positive (+) source DC cable to the positive (+ / RTN) terminal.

4.2 Connecting Serial and Management Cables

The accessory kit includes the following cables:

• RJ-45 to DB-9 serial adapter cable.

• RJ-45 Ethernet cable.

Table 4-1 lists the pin connections of the RJ-45 to DB-9 adapter cable.

Table 4-1 RJ-45 to DB-9 Connections

RJ-45 DB-9 RJ-45 DB-9

RTS 1 8 CTS

DTR 2 6 DSR

TXD 3 2 RXD

GND 4 5 GND

GND 5 5 GND

RXD 6 3 TXD

DSR 7 4 DTR

CTS 8 7 RTS

The front panel contains the console, management, and USB ports. Figure 4-6 displays the ports on

the DCS-7050SX-128 switch. Appendix C displays the front panel of all switches covered by this guide.

Figure 4-6: Front Panel Ports

Connect the front panel ports as follows:

• Console (Serial) Port: Connect to a PC with the RJ-45 to DB-9 serial adapter cable.

The switch uses the following default settings:

• 9600 baud

• No flow control

• 1 stop bit

Quick Start Guide: 7000 Series 2 RU Data Center Switches 21

Page 24

Connecting Serial and Management Cables Chapter 4: Cabling the Switch

• No parity bits

• 8 data bits

• Ethernet Management Port: Connect to 10/100/1000 management network with RJ-45 Ethernet

cable.

• USB Port: The USB port may be used for software or configuration updates.

Caution Excessive bending can damage interface cables, especially optical cables.

Flexion excessive peut endommager les câbles d'interface, notamment des câbles optiques.

22 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 25

Configuring the Switch

Arista switches ship from the factory in Zero Touch Provisioning (ZTP) mode. ZTP configures the switch

without user intervention by downloading a startup configuration file or a boot script from a location

specified by a DHCP server. To manually configure a switch, ZTP is bypassed. The initial configuration

provides one username (admin) accessible only through the console port because it has no password.

When bypassing ZTP, initial switch access requires logging in as admin, with no password, through the

console port. Then you can configure an admin password and other password protected usernames.

This manual configuration procedure cancels ZTP mode, logs into the switch, assigns a password to

admin, assigns an IP address to the management port, and defines a default route to a network

gateway.

Chapter 5

Step 1 Provide power to the switch (Section 4.1).

Step 2 Connect the console port to a PC (Section 4.2).

As the switch boots without a startup-config file, it displays the following through the console:

The device is in Zero Touch Provisioning mode and is attempting to

download the startup-config from a remote system. The device will not

be fully functional until either a valid startup-config is downloaded

from a remote system or Zero Touch Provisioning is cancelled. To cancel

Zero Touch Provisioning, login as admin and type 'zerotouch cancel'

at the CLI.

localhost login:

Step 3 Log into the switch by typing admin at the login prompt.

localhost login:admin

Step 4 Cancel ZTP mode by typing zerotouch cancel. IMPORTANT: This step initiates a switch

reboot.

localhost>zerotouch cancel

Step 5 After the switch boots, log into the switch again by typing admin at the login prompt.

Arista EOS

localhost login:admin

Last login: Fri Mar 15 13:17:13 on console

Step 6 Enter global configuration mode.

localhost>enable

localhost#config

Quick Start Guide: 7000 Series 2 RU Data Center Switches 23

Page 26

Chapter 5: Configuring the Switch

Step 7 Assign a password to the admin username with the username secret command.

localhost(config)#username admin secret pxq123

Step 8 Configure a default route to the network gateway.

localhost(config)#ip route 0.0.0.0/0 192.0.2.1

Step 9 Assign an IP address (192.0.2.8/24 in this example) to an Ethernet management port.

localhost(config)#interface management 1

localhost(config-if-Ma1/1)#ip address 192.0.2.8/24

Step 10 Save the configuration by typing write memory or copy running-config startup-config.

localhost#copy running-config startup-config

When the management port IP address is configured, use this command to access the switch from a

host, using the address configured in step 9:

ssh admin@192.0.2.8

Refer to the Arista Networks User Manual for complete switch configuration information.

24 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 27

Status Indicators

A.1 Front Indicators

A.1.1 Switch Indicators

Front panel LEDs are located on the right side of the chassis and display system, fan, and power supply

status. Appendix C displays the front panels of all switches covered by this guide.

Figure A-1 displays the DCS-7050SX-128 front panel LEDs.

Figure A-1: System Status Indicators

Appendix A

Quick Start Guide: 7000 Series 2 RU Data Center Switches 25

Page 28

Front Indicators Appendix A: Status Indicators

Table A-1 Switch Indicators LED States

LED Name LED State Device Status

System Status Blinking Green System powering up.

Green All power supplies and fans are operating normally.

Blue The locator function is active.

Red A power supply or fan is missing or in a failed state.

Fan Status Green All fans are operating normally.

Red One or more fans are not inserted or have failed.

Power Supply 1 Status

Power Supply 2 Status

A.1.2 Port Indicators

Port LEDs, located in the vicinity of their corresponding ports, provide link and operational status.

Figure A-2 displays the Port LED location on the DCS-7050SX-128 switch. Appendix C displays the

port LED locations of all switches covered by this guide.

Figure A-2: Port LEDs

Off Power supply is not inserted or is not powered.

Green Power supply operating normally.

Red Power supply has failed.

26 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 29

Appendix A: Status Indicators Rear Status Indicators

Table A-2 provides status conditions that correspond to port LED states. Port LED behavior for QSFP+

and SFP+ ports is consistent.

Table A-2 Port LED States

LED State Status

Off Port link is down.

Green Port link is up.

Yellow Port is software disabled.

Flashing Yellow Port failed diagnostics.

A.2 Rear Status Indicators

Fan and power supply modules are accessed from the rear panel. Each fan and power supply module

contains an LED that reports the module status. Appendix D displays the rear panel of all switches

covered by this guide.

Fan Status LEDs are on the fan modules, as displayed in Figure A-3.

Figure A-3: Fan Status LED

The module installation indicator is green when the fan module is properly installed or red when the

module is not fully installed. Table A-3 provides status conditions that correspond to fan status LED

states.

Table A-3 Fan Status LED States

LED State Status

Off The fan module is inserted but not receiving power – it may not be properly seated.

Green The fan is operating normally.

Red The fan has failed.

Quick Start Guide: 7000 Series 2 RU Data Center Switches 27

Page 30

Rear Status Indicators Appendix A: Status Indicators

The Power Supply Status LEDs are on the power supply modules, as displayed in Figure A-4.

Figure A-4: Power Supply Status LED

Table A-4 provides status conditions that correspond to power supply status LED states.

Table A-4 Power Supply Status LED States

LED State Status

Off Power supply not connected to AC power or not inserted fully.

Green Power supply operating normally.

Amber Power supply has overheated or failed.

28 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 31

Parts List

Each switch provides an accessory kit that contains parts that are required to install the switch. This

appendix lists the installation parts contained in the switch accessory kit.

B.1 Rack Mount Parts

Four-post rack mount parts are provided in the accessory kit. Two-post rack mount parts are available

through your sales representative.

B.1.1 Four-Post Rack Mount Parts

Figure B-1: Four-Post Rack Mount Parts

Appendix B

B.1.2 Two-Post Rack Mount Parts

Figure B-2: Two-Post Rack Mount Parts

Quick Start Guide: 7000 Series 2 RU Data Center Switches 29

Page 32

Cables Appendix B: Parts List

B.2 Cables

Quantity Description

2 Power cables: IEC-320/C13-C14, 13 A, 250 V, 2 meter

1 RJ-45 Patch Panel Cable, 2 meter

1 RJ-45 to DB9 Adapter Cable, 2 meter

Warning All provided power cables are for use only with Arista products.

30 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 33

Front Panel

This appendix displays the front panel of all switches covered by this guide.

Figure C-1: DCS-7050SX-128

Appendix C

Figure C-2: DCS-7050TX-128

Quick Start Guide: 7000 Series 2 RU Data Center Switches 31

Page 34

Figure C-3: DCS-7050SX2-128

Figure C-4: DCS-7050TX2-128

Appendix C: Front Panel

Figure C-5: DCS-7250QX-64

32 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 35

Appendix C: Front Panel

Figure C-6: DCS-7260QX-64

Figure C-7: DCS-7260CX-64

Power Supply 2 Status LED

Power Supply 1 Status LED

FAN Tray Status LED

System Status LED

7260CX-64

6 7 85 10 11 129 14 15 1613 18 19 2017 22 23 2421 26 27 2825 30 31 32292 3 41

38 39 4037 42 43 4441 46 47 4845 50 51 5249 54 55 5653 58 59 6057 62 63 646134 35 3633

Figure C-8: DCS-7260CX3-64

Ethernet Management Port

Console (Serial) Port

USB Flash Port

65 66

QSFP

100

1

PS

2

Quick Start Guide: 7000 Series 2 RU Data Center Switches 33

Page 36

Figure C-9: DCS-7280CR-48

7280CR-48

215049 43 109 1615 18171413 2221 24232019 525165

26255453 2827 3433 4039 42413837 4645 48474443 56553029 36353231

Figure C-10: DCS-7280CR2-60

Appendix C: Front Panel

Power Supply 2 Status LED

Power Supply 1 Status LED

FAN Tray Status LED

System Status LED

Ethernet Management Port

87

1211

QSFP

100G

1

PS

2

Console (Serial) Port

USB Flash Port

Figure C-11: DCS-7280CR2A-60

34 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 37

Appendix C: Front Panel

Figure C-12: DCS-7280CR2K-60

Quick Start Guide: 7000 Series 2 RU Data Center Switches 35

Page 38

Appendix C: Front Panel

36 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 39

Rear Panel

This appendix displays the rear panel of all switches covered by this guide. Depending on the power

supply modules installed, the rear panel on your switch may appear slightly different.

All Models

Appendix D

Quick Start Guide: 7000 Series 2 RU Data Center Switches 37

Page 40

Appendix D: Rear Panel

38 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 41

Regulatory Model Numbers

This appendix lists the regulatory model numbers (RMNs) for the product models for the switches

described in this document.

Table E-1 Regulatory Model Numbers and Product Numbers

Regulatory Model Number (RMN) Product Name(s)

N/A DCS-7050SX-128

N/A DCS-7050TX-128

Appendix E

N/A DCS-7050SX2-128

N/A DCS-7050TX2-128

N/A DCS-7250QX-64

N/A DCS-7260QX-64

AN1509 DCS-7260CX-64

AN1619 DCS7260CX3-64

AN1510 DCS-7280CR-48

AN1617 DCS-7280CR2-60, DCS-7280CR2A-60, DCS-7280CR2K-60

Quick Start Guide: 7000 Series 2 RU Data Center Switches 39

Page 42

Appendix E: Regulatory Model Numbers

40 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Page 43

Taiwan RoHS Information

This appendix provides Taiwan RoHS information for switches covered by this guide.

For Taiwan BSMI RoHS Table, go to https://www.arista.com/assets/data/pdf/AristaBSMIRoHS.pdf.

Appendix F

Quick Start Guide: 7000 Series 2 RU Data Center Switches 41

Page 44

Appendix F: Taiwan RoHS Information

42 Quick Start Guide: 7000 Series 2 RU Data Center Switches

Loading...

Loading...