Aries Filterworks AF-10-4010-BB, AF-10-4010, AF-20-4011-BB, AF-20-4010, AF-20-4020 Data Sheet

...

KEY FEATURES

•

RESINTECH® MIXED BED HIGH CAPACITY MEDIA

•

ABILITY TO PRODUCE RESISTIVIT Y >18 MEGOHM FOR POLISHING

•

LTOC RESIN AVAILABLE FOR ULTRA HIGH PURITY APPLICATIONS

HIGH PURITY DEIONIZATION CARTRIDGES

®

Aries FilterWorks cartridges uses ResinTech

mixed bed resins to ensure high

purity, demineralized water. These resins, combined with the cartridge manufacturing of Aries FilterWorks, provide consistent high purity water quality with

the backing of a strict quality control program. Mixed bed resins are available

in various grades depending upon the applications requirements. Aside from

the standard characteristic of demineralization, resin options include low odor

(for humidification), and low TOC (for sensitivity to organics). These cartridges

are ideal for processes requiring high purity water for washing, rinsing, scale

control, or “final polishing”.

APPLICATIONS

COMMERCIAL USE -

Mixed bed deionization cartridges are a great choice for low flow applications

that require high purity water. Resins can be matched to specific application

needs. Standard resins are used for make up supply, rinsing and washing, cooling loops, battery filling, hydrogen generation, and fuel cell. Low odor resins are

preferred on misting and humidification applications while low TOC resins are

used in specialty systems where organics can cause interferences.

LABORATORY USE -

It is important to effectively match the purification technique to the application. Ultra High Purity water > 18 Megohm is required in most pharmaceutical,

research and clinical laboratories. Deionizers are most commonly used when

reverse osmosis (RO) alone cannot be relied upon to produce water of acceptable quality. Mixed bed cartridges may be placed downstream of the RO unit,

completing the purification process. This quality water is used in making up

reagents, preparing buffers, and diluting various solutions.

LABORATORY • COMMERCIAL • RESIDENTIAL

AF SERIES

HIGH PURITY DEIONIZATION

ABOUT HIGH PURITY DEIONIZATION

The process used for removal of all dissolved salts from water is referred to as deionization or demineralization. Deionizers (DI) remove both cations

and anions, releasing hydrogen ions (H+) in exchange for the former, and hydroxyl ions (OH-) for the latter. The hydrogen and hydroxyl ions subsequently combine to form pure water. Mixed-bed deionizers produce water containing the lowest ionic concentrations. Dual-bed deionizers produce

water of lesser quality, generally unacceptable for specialized medical purposes. Custom mixes of almost any kind as well as separate component are

used for different applications. These combinations are most useful at the final polishing stage of the effluent.

FEATURES & BENEFITS

• PREMIUM MEDIA FOR LONG-LASTING SERVICE LIFE

ResinTech® MBD-10 or MBD-20 mixed bed resin with resistivities of 14 -18 MΩ-cm

• RESIN AND CARTRIDGE MANUFACTURER ALL-IN-ONE

Quality is built into every cartridge ensuring user confidence and performance

• FITS STANDARD RESIDENTIAL AND INDUSTRIAL SIZE HOUSING

AF Series cartridges are double-open end cartridges that fit standard residential and industrial housings

• OVERSIZED CARTRIDGE FOR MAXIMUM MEDIA FILL

AF Series cartridges have up to 50% higher capacity and extend cartridge life, due to the use of larger cartridges

• QUALITY PRODUCED AND MADE IN THE USA

Cartridges are produced by Aries FilterWorks, a division of ResinTech®. Strict quality control over all aspects of cartridge and media production

allows complete traceability of every filter

160 Cooper Road • Building #2, Suite A • West Berlin, NJ 08091-9243, USA • p: 856.626.1550 • f: 856.626.1551 • info@ariesfilterworks.com • ariesfilterworks.com

A Division of ResinTech • Innovations in Ion Exchange

AF SERIES - HIGH PURITY DEIONIZATION

10

1

2

TECHNICAL DATA

10” SLIM 20” SLIM 10” SUPER BLUE 20” SUPER BLUE

Diameter (in.) 3.0” 2.9” 4.6” 4.6”

3

Length (in.) 9.9” 20.0” 10.0” 20.0”

Temperature (˚F.)

Min. 40˚ 40˚ 40˚ 40˚

Max 100˚ 100˚ 100˚ 100˚

Pressure (psi)

Min. 20 20 20 20

Max. 125 125 125 125

Micron Rating (µ) 25 25 25 25

Materials of Construction

1. Gasket TPE TPE TPE TPE

2. End Caps PP ABS ABS ABS

3. Pads PE PE PE PE

4. Body / Tube PP ABS ABS ABS

5. Media*

PP Polypropylene

ABS Acrylonitrile Butadiene Styrene

ResinTech

®

Mixed Bed Resin

PE Polyester

TPE Thermoplastic Elastomer

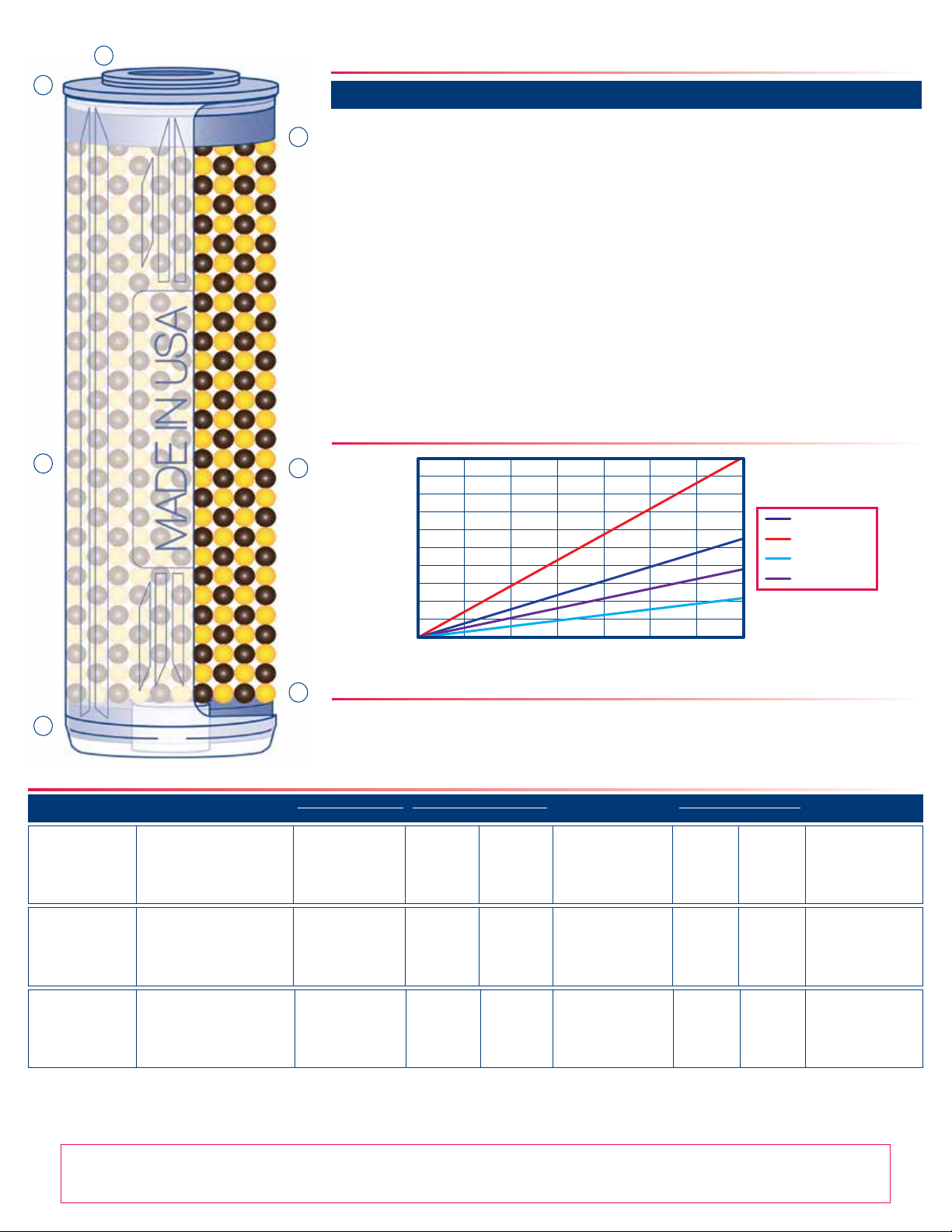

MIXED BED DELTA P

4

5

9

8

7

6

5

4

3

Delta P (psi)

2

1

0

00.2 0.40.6

0.81.0

1.21.4

Flow (gpm)

MEDIA

3

As a division of ResinTech, Inc.®, Aries FilterWorks is the only integrated water filtration media and

2

cartridge manufacturer providing a premium product at the most competitive cost. Aries builds

technology and knowledge of ion exchange and specialty adsorbents into each cartridge. Strict

quality control over all aspects of cartridge production allows complete traceability of every filter.

ORDERING GUIDE

MEDIAPART NUMBER TYPICAL EFFLUENT**

STANDARD HOUSING

DIAMETER X LENGTH

FLOW RATE (GPM)

OPERATING

MAXIMUM

TOTAL CAPACITY*

(GRAINS AS CaCO

ESTIMATED GALLONS

200 PPM 5 PPM

)

3

AF-10-4010 2.5” x 10” 0.2 0.3 450 33 1,320

AF-20-4010 2.5” x 20” 0.2 0.6 900 66 2,640

AF-10-4010-BB 4.5” x 10” 0.5 0.8 1,050 75 3,000

High-Purity

ResinTech

®

MBD-10-SC

Mixed Bed Resin

AF-20-4010-BB 4.5” x 20” 0.5 1.5 2,350 170 6,800

AF-10-4011 2.5” x 10” 0.2 0.3 450 33 1,320

AF-20-4011 2.5” x 20” 0.2 0.6 900 66 2,640

AF-10-4011-BB 4.5” x 10” 0.5 0.8 1,050 75 3,000

Ultra High-Purity / LTOC

ResinTech

®

MBD-10-LTOC

Mixed Bed Resin

AF-20-4011-BB 4.5” x 20” 0.5 1.5 2,350 170 6,800

AF-10-4020 2.5” x 10” 0.2 0.3 450 33 1,320

AF-20-4020 2.5” x 20” 0.2 0.6 900 66 2,640

AF-10-4020-BB 4.5” x 10” 0.5 0.8 1,050 75 3,000

Ultra Purity / Low-Odor

ResinTech

®

MBD-20

Mixed Bed Resin

AF-20-4020-BB 4.5” x 20” 0.5 1.5 2,350 170 6,800

* Through-put based upon capacity. Specific feed contaminants can effect capacity.

** Effluent based upon flow rate and 200 ppm feed water. Specific feed water contaminants can effect effluent water quality.

Notes: Ordering information subject to change without notice. Please verify all specifications prior to ordering.

To place an order call (856) 626-1550 or e-mail ariescs@ariesfilterworks.com

The following is made in lieu of all other warranties expressed or implied. Manufacturer’s and Seller’s only obligation shall be to issue credit against the purchase or replacement of the equipment proved to be defective in material or workmanship. Neither Manufacturer nor Seller

shall be liable for any injury, loss or damage, direct or indirect, special or consequential, arising out of the use of, misuse, or the inability to use such product. The information contained herein is based on technical data and tests which we believe to be reliable and is intended for

use by persons having technical skill at their discretion and risk. Since conditions of use are outside ResinTech’s control, we can assume no liabilit y whatsoever for results obtained or damages incurred through the application of the data presented. This information is not intended

as a license to operate under, or a recommendation to infringe upon, any patent of ResinTech’s or others covering any material or use. The foregoing may not be altered except by written agreement signed by officers of the manufacturer.

IMPORTANT NOTICE TO USER:

AF-10-4010

AF-20-4010

AF-10-4010-BB

AF-20-4010-BB

(RESISTIVITY)

14 -18 MΩ-cm

14 -18 MΩ-cm

>14 MΩ-cm

DS-AFHighPurity-rev1.4

Loading...

Loading...