Aries Automotive 35700-2 User Manual

(6) 10mm Nut Plates

INSTALLATION INSTRUCTIONS

r

r

PARTS LIST:

Qty Description Qty Description

1 Driver/Left Side Bar 4 10mm x 25mm Hex Bolt

1 Passenger/Right Side Bar 4 10mm ID x 30mm OD Flat Washer

1 Driver/Left Front Mounting Bracket 12 10mm ID x 23mm OD Flat Washer

1 Passenger/Right Front Mounting Bracket 16 10mm Lock Washer

1 Driver/Left Middle Mounting Bracket 2 8mm x 35mm Hex Bolt

1 Passenger/ Middle Mounting Brace Bracket 2 8mm ID x 24mm OD Flat Washer

1 Driver/Left Rear Mounting Bracket 2 8mm Lock Washer

1 Passenger/ Rear Mounting Bracket 12 6mm Lock Nuts

6 10mm Nut Plates 12 6mm x 25mm Button Head Cap Bolts

12 10mm x 30mm Hex Bolt 24 6mm ID x 18mm OD Flat Washers

1 4mm Allen wrench

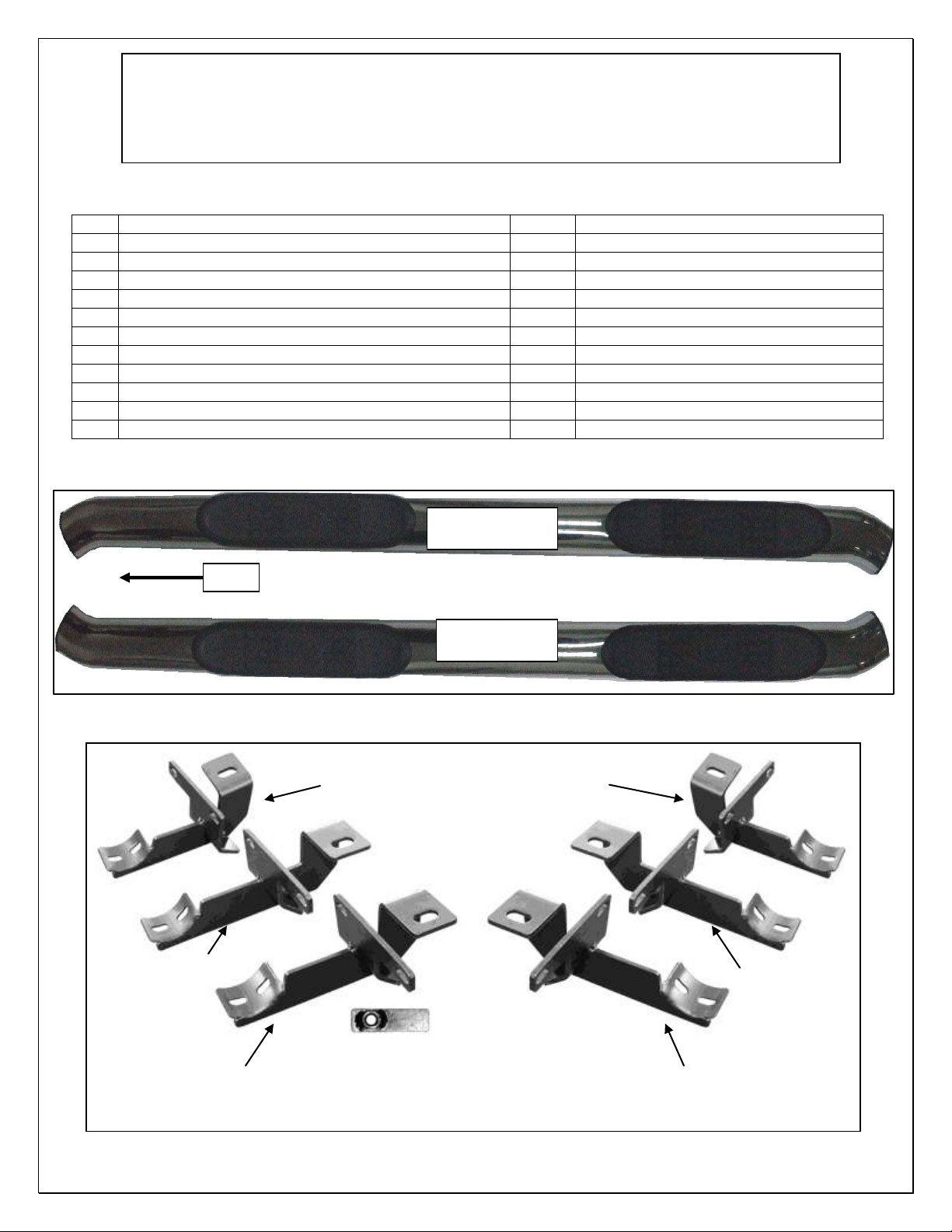

2007-12 WRANGLER 4DR (will not fit with factory rocker)

Part # 35700 / 35700-2

Front

Passenger/Right

Side ba

Driver/Left side

Side ba

Passenger Side Rear

Mounting Bracket (short)

Driver Side Rear Mounting

Bracket (short)

Passenger Side

Center (long)

Mounting

Bracket

Passenger Side Front (mid

length) Mounting Bracket

Page 1 of

Driver Side

Center (long)

Mounting

4

Driver Side Front (mid

length) Mounting Bracket

Bracket

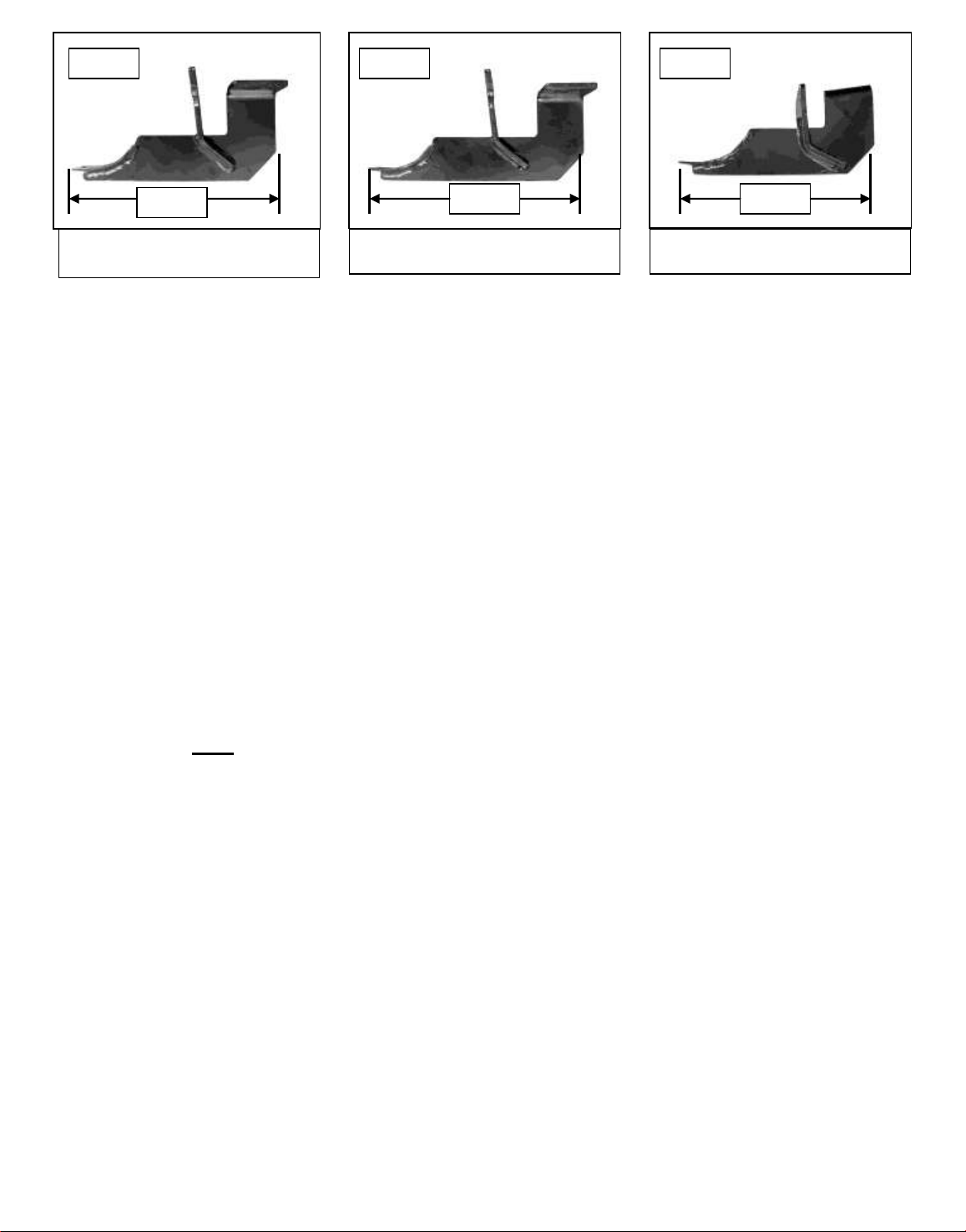

Fig 3B Fig 3D

3/8"3/

9 3/8"

Fig 3C

10 1/8"

10 1/8"

8 3/4"

8 3/4"

Passenger side "mid-length"

front Bracket pictured

(Fig 3A) Passenger side "long"

center Bracket pictured

Passenger side "short" rear

Bracket pictured

PROCEDURE:

1. REMOVE CONTENTS FROM BOX. VERIFY ALL PARTS ARE PRESENT. READ INSTRUCTIONS

CAREFULLY BEFORE STARTING INSTALLATION. FACTORY INSTALLED OR AFTERMARKET

"ROCK RAILS," SIDE STEPS OR RUNNING BOARDS MUST BE REMOVED.

2. Start installation toward the front of the passenger side of the vehicle. Determine if the vehicle has an

open floor panel or a threaded hole in the floor panel for the top tab on the Bracket, 1 - 2).

(Fig

Remove any insulation that may be covering the mounting locations.

3. Select the passenger side front Bracket. VERY IMPORTANT: The 6 Mounting Brackets look very

similar. Use the instructions to properly identify the front, center and rear Brackets for either side of the

vehicle. Each bracket has been designed for a specific location for proper installation.

a. Vehicles with open mounting location: Insert (1) 10mm Nut Plate into the large square

opening in the floor panel. Line up the threaded nut with the small hole in line with the tab on the

Bracket, 1). Bolt the Bracket to the Nut Plate with (1) 10mm x 35mm Hex Bolt, (1)

10mm Lock Washer and (1) 10mm Flat Washer, 3A). Do not tighten hardware.

(Fig

(Fig

b. Vehicles with factory threaded hole in floor panel: Bolt the tab on the Bracket to the

threaded hole in the floor panel with (1) 8mm x 35mm Hex Bolt, (1) 8mm Lock Washer and (1)

8mm Washer, 2 & 3A). Do not tighten hardware.

x 24mm OD Large Flat

(Fig

4. Line up the mounting plate on the Bracket with the (2) factory holes in the pinch weld. Bolt the Mounting

Bracket to the back

6mm Flat Washers, ( Flat Washers ,

(inside against the bracket), and (2) 6mm Nylon Lock Nuts, 3A). Leave loose at this time.

of the pinch weld using the included (2) 6mm x 25mm Button Head Allen Bolts, (2)

against pinch weld), (2) 6mm x 18mm ODx 18mm

(Fig

5. Repeat Steps 2 – 4 for Center and Rear Mounting Bracket installation. Use the instructions to correctly

identify the Brackets, 3B, 3C, 3D & 4).

(Fig

6. Once all three Mounting Brackets are securely in position, place the passenger Sidebar onto the

Mounting Brackets and secure it with the included ( ,(6) mm Lock Washers

and (6) mm Flat Washers, . NOTE: Mounting cradles on Brackets should be inline and

(Fig 5)10

6)

10,(10mm x 30mm Hex Bolts

pointing toward the rear of the vehicle for proper installation. Snug all hardware but do not tighten at

this time.

7. Adjust and level the Sidebar and tighten all hardware.

8. Repeat Steps 2 - 7 for /left Sidebar installation.

Driver

9. Do periodic inspections to the installation to make sure that all hardware is secure and tight.

To protect your investment, wax this product after installing. Regular waxing is recommended to add a protective layer

over the finish. Do not use any type of polish or wax that may contain abrasives that could damage the finish.

For stainless steel: Aluminum polish may be used to polish small scratches and scuffs on the finish. Mild soap may be

used also to clean the Sidebar.

For gloss black finishes: Mild soap may be used to clean Sidebar.

2

4Page of

Loading...

Loading...