Aries Automotive 3062-2 User Manual

1

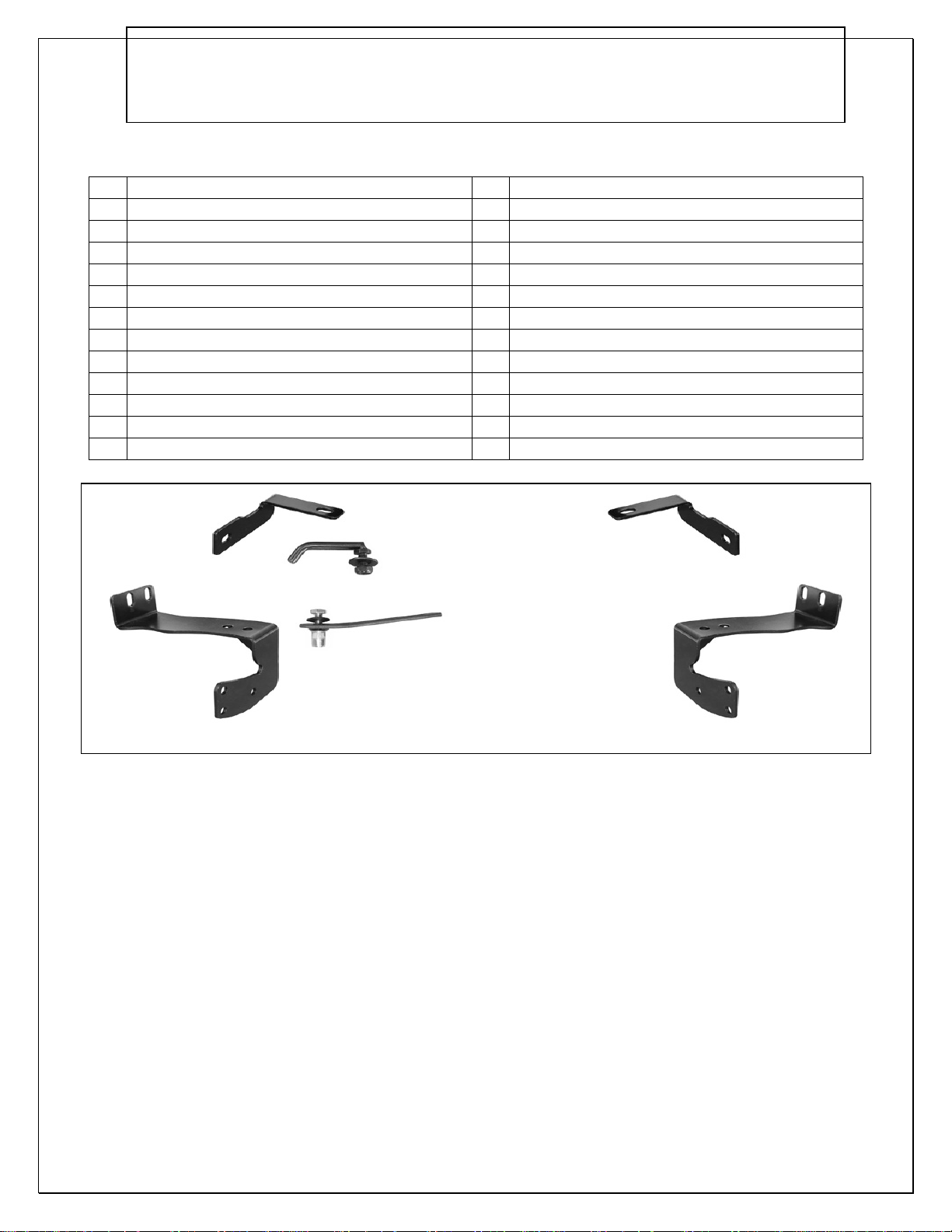

Grille Guard

4

10-1.50mm x 30mm Hex Bolts

1

Driver/Left Frame Mounting Bracket

4

10mm Lock Washers

1

Passenger/Right Frame Mounting Bracket

6

10mm x 27mm OD x 3mm Flat Washers

1

Driver/Left Top Bracket

4

10mm x 20mm OD x 2mm Flat Washers

1

Passenger/Right Top Bracket

4

10mm Nylon Lock Nuts

2

10-1.5mm x 25mm Rod Bolt

4

8-1.25mm x 30mm Hex Bolts

2

8-1.25mm x 25mm Bolt Plate

4

8mm Lock Washers

1

8mm Insert Tool

6

8mm x 24mm OD x 2mm Flat Washers

4

8-1.25mm Threaded Inserts

2

8mm Nylon Lock Nut

6

12-1.75mm x 30mm Hex Head Bolts

2

6-1.0mm x 30mm Phillips Screw

12

12mm ID x 24mm OD x 2.5mm Flat Washers

2

6mm Lock Washer

6

12mm Nylon Lock Nuts

2

6mm x 12mm OD x 1.6mm Flat Washer

2

10-1.50mm x 25mm Button Head Bolts

INSTALLATIO N IN S T R UCTIONS

Passenger/

Passenger/

Driver/Left

Driver/Left

Bracket

8mm Threaded Insert Tool

10mm Rod Bolt (pictured

10mm Nylon Lock Nut)

PARTS LIST:

PROCEDURE:

Right side

Top Bracket

Right Side

Frame

Mounting

Bracket

1. REMOVE CONTENTS FROM BOX. VERIFY ALL PARTS ARE PRESENT. READ INSTRUCTIO NS

CAREFULLY BEFORE STARTING INSTALLATION. DO NOT ATTEMPT INSTALLATION ALONE;

PERSONAL INJURY OR DAMAGE TO THE VEHICLE MAY RESULT. CUTTING IS REQUIRED.

2. Starting from under the front of the vehicle, remove the front factory plastic shroud and the air dam and

place them on a clean, stable working surface. Pay close attention to the location of the factory

hardware for easy reassembly.

3. Locate the three factory holes in the bottom of the passenger side of the cross member. Insert (1)

10mm x 25mm Rod Bolt in and through the factory holes as shown in Figure 1.

4. Next, locate the two factory holes on the upright end of the front cross member.

On 2008 Models: These two factory holes will be threaded. Continue on to Step 5.

On 2009-2012 Models: These two factory holes are not threaded, (Figure 2). Select the 8mm

Threaded Insert Tool, (1) 8mm Threaded Insert, (1) 8mm Flat Washer and (1) 8mm x 30mm Hex Bolt.

Assemble the tool as per Figure 3A & 3B. Insert assembly into the factory hole, hold tool handle and

assembly up tight against the cross member and tighten hex bolt until insert is fully expanded into hole,

(Figure 4). NOTE: Do not over tighten or a pull out may occur. Once Metal Insert is fully compressed,

GRILLE GUARD

08-12 FORD ESCAPE

w/10mm Flat Washer and

(pictured w/insert, 8mm Hex

Bolt and 8mm Flat Washer)

Page 1 of 5 10/29/13

Side Top

Side

Frame

Mounting

Bracket

remove the bolt and tool from the Metal Insert. Repeat this step for second hole and for installation of

the remaining Threaded Metal Inserts for the driver side Mounting Bracket installation. NOTE: It is not

necessary but to make installation of the Threaded Inserts easier, remove the plastic bumper cover.

5. Position the passenger side Mounting Bracket up to the cross member and over the previously installed

Rod Bolt. Se cure Mounting Bracket to Rod Bolt with (1) 10mm Flat Washer and (1) 10mm Nylon Lock

Nut, (Figure 6). Do not tighten hardware at this time.

6. Attach the Mounting Bracket to the (2) threaded holes in the end of the cross member.

2008 Models: Use (2) 10mm x 30mm Hex Bolts, (2) 10mm Lock Washers and (2) 10mm Flat Washers,

(Figure 5 & 6). Do not tighten hardware at this time.

2009-2012 Models: Insert (2) 8mm x 30mm Hex Bolts, (2) 8mm Lock Washers and (2) 8mm Flat

Washers into the threaded inserts installed in Step 4, (Figure 5 & 6). Do not tighten hardware at this

time.

7. Move up to the passenger side of the grille opening. Locate and remove the fastener at the top-left

hand corner of the grille opening, (Figure 7). Insert (1) 8mm x 25mm Bolt Plate into and down through

the factory hole left by the plastic fastener, (Figure 8).

8. Select the passenger side Top Bracket and hang it from the previously installed Bolt Plate with ( 1 ) 8m m

Flat Washer and (1) 8mm Nylon lock Nut, (Figure 9). Do not tighten at this time.

9. Repeat steps 3 - 8 for the driver side Bracket installation.

10. With assistance, position the Grille Guard up to the outside of the Mounting Brackets and Top Brackets.

Attach Grille Guard to Mounting Brackets using (6) 12mm x 30mm Hex Bolts, (12) 12mm Flat Washers

and (6) 12mm Nylon Lock Nuts, (Figure 10). Do not tighten at this time.

11. Attach Grille Guard to the Top Brackets with (2) 10mm x 25mm Button Head Bolts, (4) 10mm Flat

Washers and (2) 10mm Nylon Lock Nuts, (Figure 11). Do not tighten at this time

12. Level and adjust Grille Guard and tighten all hardware at this time.

13. One at a time, hold each of the splash guards and the spoiler up into position to determine the area that

will need to be removed to clear the Mounting Brackets. To maintain strength, only remove the

minimum amount of material to clear the Mounting Brackets. Using a hacksaw, cut out 3/4” wide slot on

each marked location on the air dam shown in Figure 12A & 12B. NOTE: The air dam will be in three

pieces when re-installed.

14. Cut out a 1-1/4” x 4” wide slot in each marked location on both plastic splash guards as shown in

Figure 12A & 12B. Once the air dam and plastic shroud are cut re-install them using the factory screws

removed in Step 2. NOTE: (2) longer 6mm x 30mm Screws, (2) 6mm Lock Washers and (2) 6mm Flat

Washers have been included to go through the Mounting Brackets for the Grille Guard, the spoiler and

the splash guards, (Figure 12A & 12B).

15. Do periodic inspections to the installation to make sure that all hardware is secure and tight.

To protect your investment, wax this product after installing. Regular waxing is recommended to add a

protective layer over the finish. Do not use any type of polish or wax that may contain abrasives that could

damage the finish.

For stainless steel: Aluminum polish may be used to polish small scratches and scuffs on the finish. Mild

soap may be used also to clean the Grille Guard.

For gloss black finishes: Mild soap may be used to clean the Grille Guard.

Page 2 of 5 10/29/13

Loading...

Loading...