Page 1

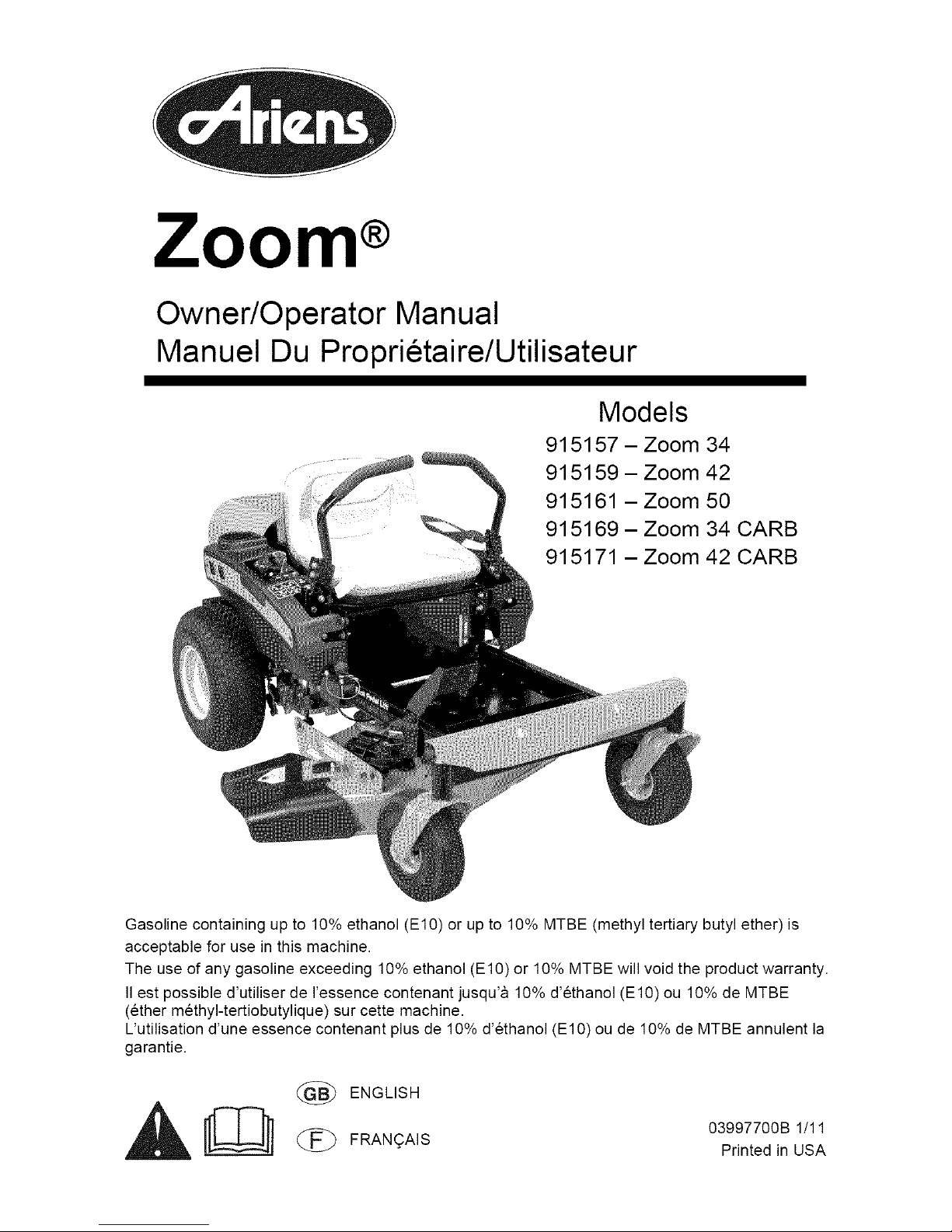

Zoom ®

Owner/Operator Manual

Manuel Du Proprietaire/Utilisateur

Models

915157 - Zoom 34

915159 - Zoom 42

915161 - Zoom 50

915169 - Zoom 34 CARB

915171 - Zoom 42 CARB

Gasoline containing up to 10% ethanol (El0) or up to 10% MTBE (methyl tertiary butyl ether)is

acceptable for use in this machine.

The use of any gasoline exceeding 10% ethanol (El0) or 10% MTBE will void the product warranty.

II est possible d'utiliser de I'essence contenant jusqu'a 10% d'ethanol (El0) ou 10% de MTBE

(ether methyl-tertiobutylique) sur cette machine.

L'utilisation d'une essence contenant plus de 10% d'ethanol (El0) ou de 10% de MTBE annulent la

garantie.

ENGLISH

,_ _ (_ FRAN(_AIS 03997700B1/11

Printed in USA

Page 2

/ Y.*_:] i _ [o]_ _[o] _/ / _ _/ _

SAFETY .......................... 4

ASSEMBLY ....................... 9

CONTROLS AND FEATURES ....... 11

OPERATION ..................... 12

MAINTENANCE SCHEDULE ........ 16

SERVICE AND ADJUSTMENTS ..... 17

STORAGE ....................... 24

TROUBLESHOOTING ............. 25

SERVICE PARTS ................. 26

ACCESSORIES ................... 26

SPECIFICATIONS ................. 27

WARRANTY ..................... 29

II_liill={o]_lr_]ilKo] _I

NON-ENGLISH MANUALS

Manuals in languages other than

English may be obtained from your

Dealer. Visit your dealer or

www.ariens.com for a list of

languages available for your

equipment.

Manuals printed in languages other

than English are also available as a

free download on our website:

http://www.ariens.com

MANUALES EN IDIOMAS

DIFERENTES DEL INGLES

Puede obtener manuales en

idiomas diferentes del ingles en su

distribuidor. Visite a su distribuidor

o vaya a www.ariens.com para

obtener una lista de idiomas

-_ disponibles para su equipo.

Tambien puede imprimir manuales

en idiomas diferentes del ingles

descargandolos gratuitamente de

nuestra pagina Web:

http://www.ariens.com

MANUELS NON ANGLAIS

Des manuels dans differentes

langues sont disponibles chez

votre revendeur. Rendez-vous

chez votre revendeur ou allez sur

-_ le site www.ariens.com pour

consulter la liste des langues

disponibles pour votre equipement.

Les manuels imprimes dans des

langues differentes de I'anglais

sont egalement disponibles en

telechargement gratuit sur notre

site Web:

http://www.ariens.com

THE MANUAL

Before operation of unit, carefully and

completely read your manuals. The contents

will provide you with an understanding of

safety instructions and controls during normal

operation and maintenance.

All reference to left, right, front, or rear are

given from operator seated in operation

position and facing the direction of forward

travel.

ENGINE MANUAL

The engine on this unit is covered by a

separate manual specific to the engine. This

manual is included in the literature package

that shipped with the unit. Refer to this

manual for engine service recommendations.

If the engine manual is not available, contact

the engine manufacturer for a replacement

manual.

MODEL AND SERIAL NUMBERS

When ordering replacement parts or making

service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product

registration form in the unit literature

package. They are printed on a serial number

label, located on the frame of your unit under

the seat (figure 1).

GB-2

Page 3

UnitSerialNumberLabel

NOTE:AcompletePartsmanualmaybe

downloadfromwww.ariens.comonthe

internet.

DELIVERY

Customer Note: If you have purchased this

product without complete assembly and

instruction by your retailer, it is your

responsibility to:

Read and understand all assembly

instructions in this manual. If you do

not understand or have difficulty

following the instructions, contact your

nearest Ariens Dealer for assistance.

NOTE: To locate your nearest Ariens Dealer,

go to www.ariens.com on the internet.

Figure 1

Record Unit Model and Serial

numbers here.

Record Engine Model and Serial

numbers here.

PRODUCT REGISTRATION

The Ariens dealer must register the product

at the time of purchase. Registering the

product will help the company process

warranty claims or contact you with the latest

service information. All claims meeting

requirements during the limited warranty

period will be honored, whether or not the

product registration card is returned. Keep a

proof of purchase if you do not register your

unit.

Customer Note: If the Dealer does not

register your product, please fill out, sign and

return the product registration card to Ariens

or go to www.ariens.com on the internet.

,_ WARNING: Improper assembly

or adjustments can cause serious

injury.

Before Attempting to Operate Your

Unit:

1. Make sure all assembly has been

properly completed.

2. Understand all Safety Precautions

provided in the manuals.

3. Review control functions and operation

of the unit. Do not operate the unit

unless all controls function as described

in this manual.

4. Review recommended lubrication,

maintenance and adjustments.

5. Review Limited Warranty Policy.

6. Fill out a product registration card and

return the card to the Ariens Company or

go to www.ariens.com.

DISCLAIMER

Ariens reserves the right to discontinue,

change, and improve its products at any time

without notice or obligation to the purchaser.

The descriptions and specifications contained

in this manual were in effect at printing.

Equipment described within this manual may

be optional. Some illustrations may not be

applicable to your unit.

UNAUTHORIZED REPLACEMENT

PARTS

Use only Ariens replacement parts. The

replacement of any part on this unit with

anything other than an Ariens authorized

replacement part may adversely affect the

performance, durability, and safety of this unit

and may void the warranty. Ariens disclaims

liability for any claims or damages, whether

warranty, property damage, personal injury or

death arising out of the use of unauthorized

replacement parts.

GB-3

Page 4

[,:'Y-'1al=1i'I

WARNING: This cutting machine

is capable of amputating hands

and feet and throwing objects.

Failure to observe the safety

instructions in the manuals and on

decals could result in serious

injury or death.

Slopes are a major factor related

to loss-of-control and tip-over

accidents. Operation on all slopes

requires extra caution.

Tragic accidents can occur if the

operator is not alert to the

presence of children. Never

assume that children will remain

where you last saw them.

Gasoline is extremely flammable

and the vapors are explosive,

handle with care.

Disengage attachment, stop unit

and engine, remove key, engage

parking brake, and allow moving

parts to stop before leaving

operator's position.

SAFETY ALERTS

Look for these symbols to point

out important safety

precautions. They mean:

Attention!

Personal Safety Is

Involved!

Become Alert!

Obey The Message!

The safety alert symbol is used in decals and

with this manual. Understand the safety

message. It contains important information

about personal safety.

,_ WARNING: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, COULD RESULT in

death or serious injury.

_ DANGER: IMMINENTLY

HAZARDOUS SITUATION! If not

avoided, WILL RESULT in death

or serious injury.

A AUTION: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, MAY RESULT in minor

or moderate injury. It may also be

used to alert against unsafe

practices.

NOTATIONS

NOTE: General reference information for

proper operation and maintenance practices.

IMPORTANT: Specific procedures or

information required to prevent damage to

unit or attachment.

SAFETY DECALS AND

LOCATIONS

ALWAYS replace missing or damaged Safety

Decals. Refer to figure 2 for Safety Decal

locations.

GB-4

Page 5

5

1.DANGER!

Figure2

&DANGER!

Avoid injury - Stay clear of

rotating parts.

OL1816

2.CAUTION

No smoking.

IMPORTANT: DO NOT overfill.

(_ illfuel tank to below bottom of

filler neck (see FILLING FUEL

TANK on page 13).

,_ WARNING: Over Filling may cause

severe damage to evaporative

system !

Never fill fuel tank when engine is

running, hot or unit is indoors. Never

overfill fuel tank.

Replace fuel cap securely and clean

up spilled fuel.

3L q.

OL1809

Always keep feet and hands

away from rotating parts.

Always stand clear of discharge

area. Do not direct discharge

toward other people.

D_-_L_ Keep people away from unit

while operating.

OL1812

Shut off engine, remove key,

and read manual before you

adjust or repair unit.

NO STEP! Always keep feet

away from rotating parts.

OL1813

GB-5

Page 6

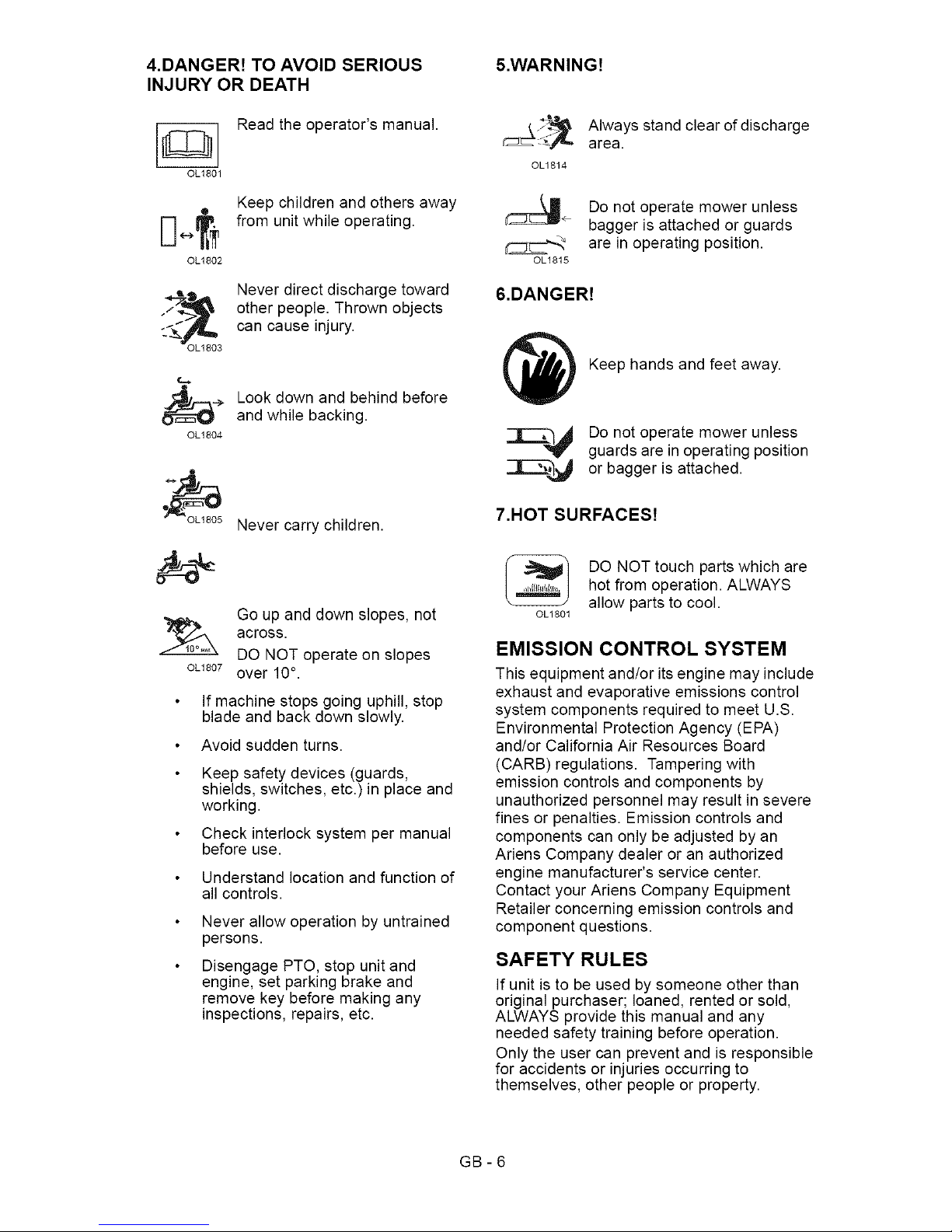

4.DANGER! TO AVOID SERIOUS

INJURY OR DEATH

Read the operator's manual.

OL1801

Keep children and others away

D [ from unit while operating.

OL1802

Never direct discharge toward

_-_=_, other people. Thrown objects

_-_>__ can cause injury.

OL1803

_.> Look down and behind before

and while backing.

OL1804

Never carry children.

Go up and down slopes, not

across.

DO NOT operate on slopes

OL1807over 10°.

If machine stops going uphill, stop

blade and back down slowly.

Avoid sudden turns.

Keep safety devices (guards,

shields, switches, etc.) in place and

working.

Check interlock system per manual

before use.

Understand location and function of

all controls.

Never allow operation by untrained

persons.

Disengage PTO, stop unit and

engine, set parking brake and

remove key before making any

inspections, repairs, etc.

&WARNING!

OL1814

OL1815

Always stand clear of discharge

area.

Do not operate mower unless

bagger is attached or guards

are in operating position.

&DANGER!

Keep hands and feet away.

_r------_--_ Do not operate mower unless

guards are in operating position

--[-_,_]_ or bagger is attached.

7.HOT SURFACES!

OL1801

DO NOT touch parts which are

hot from operation. ALWAYS

allow parts to cool.

EMISSION CONTROL SYSTEM

This equipment and/or its engine may include

exhaust and evaporative emissions control

system components required to meet U.S.

Environmental Protection Agency (EPA)

and!or California Air Resources Board

(CARB) regulations. Tampering with

emission controls and components by

unauthorized personnel may result in severe

fines or penalties. Emission controls and

components can only be adjusted by an

Ariens Company dealer or an authorized

engine manufacturer's service center.

Contact your Ariens Company Equipment

Retailer concerning emission controls and

component questions.

SAFETY RULES

If unit is to be used by someone other than

original purchaser; loaned, rented or sold,

ALWAYS provide this manual and any

needed safety training before operation.

Only the user can prevent and is responsible

for accidents or injuries occurring to

themselves, other people or property.

GB-6

Page 7

Read,understand,andfollowallsafety

practicesinOwner/OperatorManualbefore

assembling,usingorworkingonthismower.

ALWAYSremovekeyfromignitionandwire

fromsparkplugbeforeassembly,orworking

onthisunit.

Inspectunitbeforeeachusefor:missingor

damageddecalsandshields,correctly

operatingsafetyinterlocksystem,and

deteriorationofgrasscatchers.Replaceor

repairasneeded.

ALWAYScheckoverheadandside

clearancescarefullybeforeoperation.

ALWAYSbeawareoftrafficwhencrossingor

operatingalongstreetsorcurbs.

Keepchildren,people,andpetsaway.Be

alertandshutoffunitifanyoneenterswork

area.Keepchildrenunderwatchfulcareofa

responsibleadult.

NEVERallowchildrentooperateorplayon

ornearunit.

Keepareaofoperationclearofalltoys,and

debris.Thrownobjectscancauseinjury.

Stayalertforhiddenhazards,holes,andruts.

Avoidunevenorroughterrain.DONOT

operateneardrop-offs,ditches,or

embankments.Unitcansuddenlyturnoverif

awheelisovertheedgeofaclifforditch,orif

anedgecavesin.

Dust,fog,etc.canreducevisionandcause

anaccident.Operateunitonlywhenthereis

goodvisibilityandlight.

Dataindicatesthatoperators,age60and

above,areinvolvedinalargerpercentageof

ridingmowerrelatedinjuries.These

operatorsshouldevaluatetheirabilityto

operatetheridingmowersafelyenoughto

protectthemselvesandothersfromserious

injury.

Onlytrainedadultsmayoperateunit.Training

includesbeingfamiliarwithcontrolsand

actualoperation.

NEVERoperateunitafterorduringtheuseof

medication,drugsoralcohol.

NEVERallowanyonetooperatethisunit

whentheiralertnessorcoordinationis

impaired.

Wearadequatesafetygear,sturdyshoes,

andprotectivegloves.

DONOTwearlooseclothingorjewelryand

tiebackhairthatmaygetcaughtinrotating

parts.

Protecteyes,faceandheadfromobjectsthat

maybethrownfromunit.Wearappropriate

hearingprotection.Alwayswearsafety

gogglesorsafetyglasseswithsideshields

whenoperatingmower.

Avoidsharpedges.Sharpedgescancut.

Movingpartscancutofffingersorahand.

ALWAYSkeephandsandfeetawayfromall

rotatingpartsduringoperation.Rotatingparts

cancutoffbodyparts.

ALWAYSkeephandsawayfromallpinch

points.

Startandoperateunitonlywhenseatedin

operator'sposition.Steeringcontrollevers

mustbeinneutral,PTOdisengagedand

parkingbrakesetwhenstartingengine.

ALWAYSkeepbodyandhandsawayfrom

pinholesornozzleswhichejecthydraulic

fluidunderpressure.

DONOTtouchunitpartswhichmightbehot

fromoperation.Allowpartstocoolbefore

attemptingtomaintain,adjustorservice.

NEVERplaceyourhandsoranypartofyour

bodyorclothinginsideornearanymoving

partwhileunitisrunning.

NEVERdirectdischargetowardspersonsor

property.Thrownobjectsmayricochetback

towardsoperator.ALWAYSstandclearofthe

dischargearea.

ALWAYSdisengageattachment,stopunit

andengine,placecontrolleversinneutral,

removekey,engageparkingbrake,andallow

movingpartstostopbeforeleaving

operator'sposition.

Useextremecautionongravelsurfaces.

DisengagePTOwhenattachmentisnotin

useandwhencrossinggravelsurfaces.

DONOToperateunitifsafetyinterlock

systemisdamagedordisabled.Checksafety

interlockbeforeeachuse.

ALWAYSremovekeytopreventunauthorized

use.

DO NOT operate at too fast a rate. Slow

down before turning.

Stop engine before removing grass catcher or

unclogging chute.

DO NOT mow on wet grass. Reduced

traction could cause sliding.

DO NOT try to stabilize the machine by

putting your foot on the ground.

Know the weight of loads. Limit loads to those

you can safely control and the unit can safely

handle.

ALWAYS keep protective structures, guards

and panels in good repair, in place and

securely fastened.

Do not operate without either entire grass

catcher or the discharge guard in place.

DO NOT operate in reverse unless absolutely

necessary. ALWAYS look down and behind

before and while backing; especially for

children.

Follow the manufacturer's recommendations

for wheel weights or counterweights to

improve stability when using attachments.

NEVER carry passengers-especially

children-even with blades off.

Use extra care when approaching blind

corners or objects that may obscure vision of

hidden obstacles and children.

If you cannot back up a slope or you feel

uneasy on it, do not mow it.

Operation on slopes may lead to loss of

steering control. When operating on slopes

be prepared to react to an emergency

situation:

GB-7

Page 8

Returnsteeringleverstoneutral

position.

Immediatelysetparkingbrake.

TurnoffPTOandengine.

Mowupanddownslopes,notacrossthem.

Useslowspeedonanyslope.Tiresmaylose

tractiononslopeseventhoughthebrakesare

functioningproperly.

Keepallmovementsontheslopeslow and

gradual, DO NOT make sudden changes in

speed or direction.

Use extra care while operating machines with

grass catcher or other attachments. They can

affect stability of the machine.

Avoid starting, stopping, or turning on a

slope. If tires lose traction, disengage the

blades and proceed slowly straight down the

slope.

DO NOT operate on slopes over 10°.

DO NOT park on slopes unless necessary. If

unit is parked on a slope, ALWAYS chock or

block wheels and set parking brake.

DO NOT disengage or bypass transmission

and coast downhill.

Tow only with a machine that has a hitch

designed for towing. Do not attach towed

equipment except at the hitch point.

Follow the manufacturer's recommendations

for weight limits for towed equipment and

towing on slopes.

Maximum Tongue weight: 30 Ibs.

Maximum Trailer weight: 300 Ibs.

Do not use hitch with bagger attached.

Do not use on steep hills or slopes.

Do not park on hills when trailer is attached.

Do not use with any ground engaging

equipment.

NEVER allow children or others in or on

towed equipment.

On slopes, the weight of the towed equipment

may cause loss of traction and loss of control.

Travel slowly and allow extra distance to stop.

Use extra care when loading or unloading

unit onto trailer or truck.

Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that

could be damaged.

DO NOT transport machine while engine is

running.

ALWAYS turn off power to attachment and

properly drain fuel when transporting unit.

Keep unit free of grass clippings, leaves, and

other debris. Clean up oil or fuel spills.

This product is equipped with an internal

combustion type engine. DO NOT use unit on

or near any unimproved, forest-covered or

brush covered land unless exhaust system is

equipped with a spark arrester meeting

applicable local, state or federal laws. A spark

arrester, if it is used, must be maintained in

effective working order by operator.

Fuel is highly flammable and its vapors are

explosive. Handle with care. Use only an

approved gasoline container with an

appropriately sized dispensing spout.

NO smoking, NO sparks, NO flames.

ALWAYS allow engine to cool before

servicing.

NEVER fill fuel tank when engine is running

or hot from operation.

NEVER fill or drain fuel tank indoors.

NEVER overfill fuel tank.

Properly remove fuel before tipping unit.

Replace fuel cap securely and clean up

spilled fuel.

NEVER fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always

place containers on the ground away from

your vehicle before filling.

When practical, remove gas-powered

equipment from the truck or trailer and refuel

it on the ground. If this is not possible, then

refuel such equipment on a trailer with a

portable container, rather than from a

gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until

fueling is complete. Do not use a nozzle lock-

open device.

If fuel is spilled on clothing, change clothing

immediately.

Avoid Electric Shock. Objects contacting both

battery terminals at the same time may result

in injury and unit damage. DO NOT reverse

battery connections.

Explosive Gases from battery can cause

death or serious injury. Poisonous battery

fluid contains sulfuric acid and its contact with

skin, eyes or clothing can cause severe

chemical burns.

NO flames, NO sparks, NO smoking near

battery.

ALWAYS wear safety glasses and protective

gear near battery. Use insulated tools.

DO NOT TIP battery beyond a 45° angle in

any direction.

ALWAYS keep batteries out of reach of

children.

Battery posts, terminals and related

accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and reproductive

harm. Wash hands after handling.

Reverse connections may result in sparks

which can cause serious injury. Always

connect positive (+) lead of charger to

positive (+) terminal, and negative (-) lead to

negative (-) terminal.

ALWAYS disconnect negative (-) cable FIRST

and positive (+) cable SECOND. ALWAYS

connect positive (+) cable FIRST, and

negative (-) cable SECOND.

GB-8

Page 9

A frozen battery can explode and result in

death or serious injury. DO NOT charge or

jump start a battery containing frozen fluid.

Thaw the battery before putting on a charger

or jump starting.

ALWAYS keep protective structures, guards,

and panels in good repair, in place and

securely fastened. NEVER modify or remove

safety devices.

DO NOT change engine governor settings or

over-speed engine.

Fumes from engine exhaust can cause injury

or death. DO NOT run engine in an enclosed

area. Always provide good ventilation.

ALWAYS maintain unit in safe operating

condition. Damaged or worn out muffler can

cause fire or explosion.

Stop and inspect equipment if you strike an

object or if there is an unusual vibration.

Repair, if necessary, before restarting. Never

make adjustments or repairs with the engine

running.

Mower blades are sharp and can cut you.

Wrap the blade(s) or wear gloves, and use

extra caution when servicing them. NEVER

weld or straighten mower blades.

Rotation of one blade may cause rotation of

the other blades.

Check brake operation frequently. Adjust and

service as required.

Keep all hardware properly tightened.

Stored energy in springs can cause injury.

Maintain or replace safety and instruction

labels, as necessary.

Never store the machine or fuel container

inside a building where there is an open

flame, such as a water heater.

Shut off fuel (if provided) and allow engine to

cool completely before storing in closed area

or covering unit.

Clean grass and debris from unit, especially

from around muffler and engine, to help

prevent fires.

For extended storage, clean unit thoroughly.

See storage section and Engine Manual for

proper storage.

Use only attachments or accessories

designed for your unit.

Check attachment components frequently. If

worn or damaged, replace with

manufacturer's recommended parts.

V_,_,.$1=1_v_I:]t'i

WARNING: AVOID INJURY.

Read and understand the entire

Safety section before proceeding.

Tools Required

Adjustable wrench

Petroleum jelly or dielectric grease.

Unpack Unit

Remove unit and all other components from

the shipping container. Engage transmission

bypass lever (see MOVING UNIT

MANUALLYon page 15). Push unit from

container onto a level surface. Disengage

transmission bypass lever.

Connect Battery

See Battery Removal and Installation on

page 20 and perform steps 2 and 3 in the

installation section.

Place Unit in Operating Position

(Figure 3)

NOTE: The seat is shipped with the seat

positioned as far back as possible.

1. Push steering levers aside and tip seat

up.

2. Adjust the seat as needed (see SEAT

ADJUSTMENT on page 17).

3. Remove hardware from top hole of the

steering lever (Figure 3). Slide steering

lever back to align slot with hole at the

top of the steering pivot arm.

NOTE: Do not tighten hardware before

reviewing ADJUSTING STEERING LEVERS

on page 22. If no adjustment is desired

tighten hardware.

4. Adjust steering levers (see ADJUSTING

STEERING LEVERS on page 22).

1

3

2

1. Steering Lever 3. Steering Lever

2. Steering Pivot Hardware

Arm

Figure 3

Check Engine Oil Level

Refer to Engine Manual.

GB-9

Page 10

Check Tire Pressure

CAUTION: Avoid injury!

Explosive separation of tire and

rim parts is possible when they

are serviced incorrectly:

Do not attempt to mount a tire

without the proper equipment

and experience to perform the

job.

Do not inflate the tires above

the recommended pressure.

Do not weld or heat a wheel

and tire assembly. Heat can

cause an increase in air

pressure resulting in an

explosion. Welding can

structurally weaken or deform

the wheel.

Do not stand in front or over

the tire assembly when

inflating. Use a clip-on chuck

and extension hose long

enough to allow you to stand

to one side.

See SPECIFICATIONS on page 27.

Level Mower Deck

See LEVELLING AND ADJUSTING PITCH

OF MOWER DECK on page 18.

Fill Fuel Tank

Fill fuel tank. DO NOT OVERFILL! See

FILLING FUEL TANK on page 13.

Check Safety Interlock System

A ARNING: Safety interlockfailure and improper operation of

unit can result in death or serious

injury. Check system before each

use to make sure it is functioning

properly.

See Safety Interlock System on page 12.

Check function of all controls

See OPERATION on page 12.

GB - 10

Page 11

[_o]_ij_o_ r-'__Im]I_1_i uL_"]

3

\

10

915157,169

13

915159,161,171

11

1 2

Figure 4

1. ignition Switch

2. PTO Switch

3. Seat

4. Fuel Level

5. Steering Levers

6. Fuel Tank

7. Mower Lift Pedal

8. Mower Deck

9. Discharge Chute

10. Parking Brake

11. Choke (915159, 161, 171)

12. Throttle (915159, 161, 171)

13. Throttle/Choke Lever (915157, 169)

GB- 11

Page 12

[e]_:1;l.*t / [e]_

WARNING: AVOID INJURY.

Read and understand the entire

Safety section before proceeding.

CONTROLS AND FEATURES

See figure 4 for all controls and features

locations.

Safety Interlock System

WARNING: Safety interlock failure

and improper operation of unit can

result in death or serious injury.

Check system before each use to

make sure it is functioning

properly.

Test Steering Lever PTO

1 Neutral Position Off

2 Neutral Position On

3 Neutral Position Off

4*+ Out of Neutral Position Off

5*+ Neutral Position On

Test with engine running.

+ Operator lifts off seat.

Perform the following tests to ensure the

safety interlock system is working properly. If

the unit does not perform as stated contact

your Ariens dealer for repairs.

Ignition Switch

1

Operate ignition switch

with a removable key.

Ignition switch has three

positions: Stop (1),

Run (2), Start (3). See

STARTING AND

SHUTTING OFF

ENGINE on page 14 for

detailed instructions on

how to start engine.

Parking Brake

Engaged

Engaged

Disengaged

Disengaged

Engaged

Engine

Starts

Doesn't Start

Doesn't Start

Shuts Off

Shuts Off

Throttle/Choke Lever (915157, 169)

Choke (1) - Use to start a cold

engine.

i\ll

J

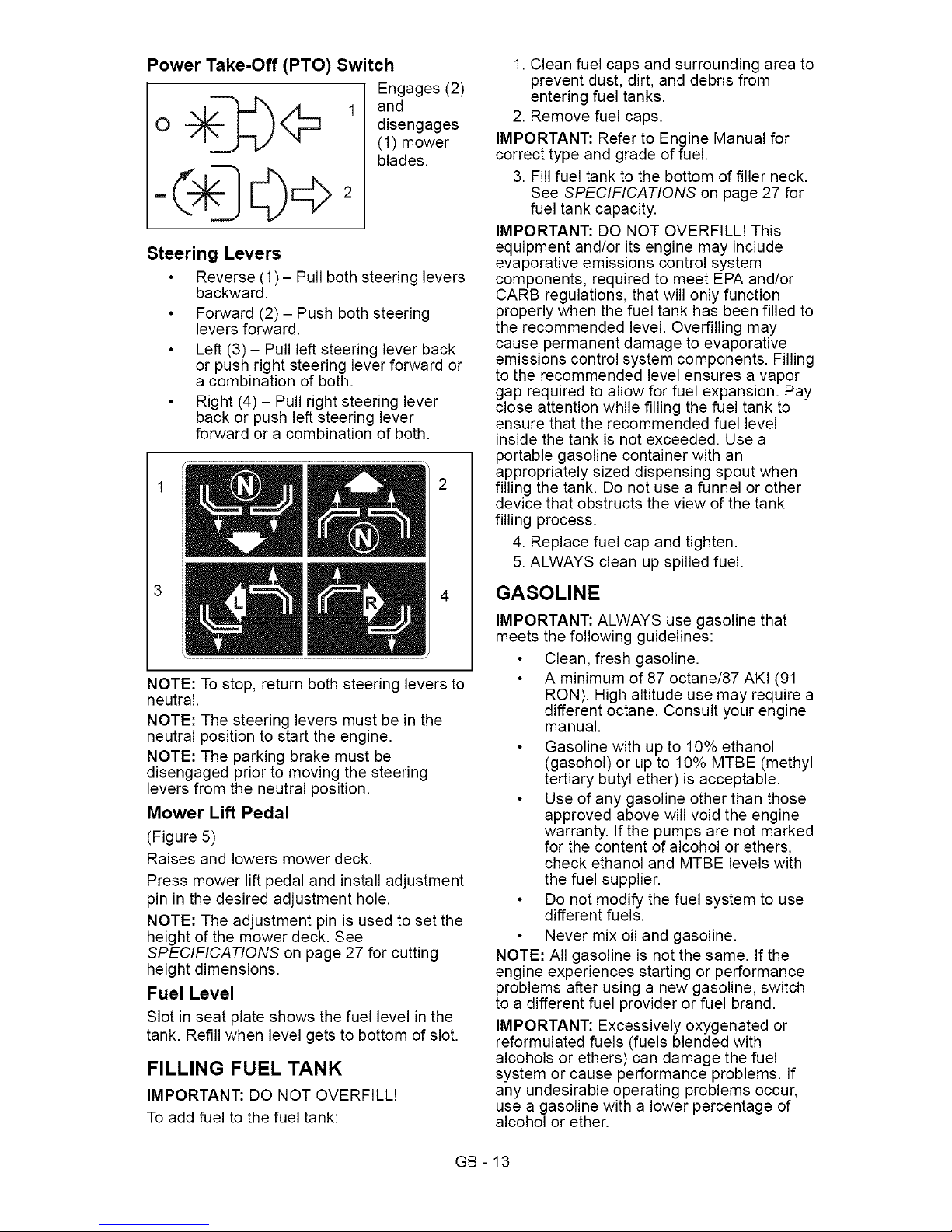

Power Take-Off (PTO) Switch

o

Engages (2)

and

disengages

(1) mower

blades.

Steering Levers

Reverse (1)- Pull both steering levers

backward.

Forward (2) - Push both steering

levers forward.

Left (3) - Pull left steering lever back

or push right steering lever forward or

a combination of both.

Right (4) - Pull right steering lever

back or push left steering lever

forward or a combination of both.

NOTE: To stop, return both steering levers to

neutral.

NOTE: The steering levers must be in the

neutral position to start the engine.

NOTE: The parking brake must be

disengaged prior to moving the steering

levers from the neutral position.

Mower Lift Pedal

(Figure 5)

Raises and lowers mower deck.

Press mower lift pedal and install adjustment

pin in the desired adjustment hole.

NOTE: The adjustment pin is used to set the

height of the mower deck. See

SPECIFICATIONS on page 27 for cutting

height dimensions.

Fuel Level

Slot in seat plate shows the fuel level in the

tank. Refill when level gets to bottom of slot.

FILLING FUEL TANK

IMPORTANT: DO NOT OVERFILL!

To add fuel to the fuel tank:

1. Clean fuel caps and surrounding area to

prevent dust, dirt, and debris from

entering fuel tanks.

2. Remove fuel caps.

IMPORTANT: Refer to Engine Manual for

correct type and grade of fuel.

3. Fill fuel tank to the bottom of filler neck.

See SPECIFICATIONS on page 27 for

fuel tank capacity.

IMPORTANT: DO NOT OVERFILL! This

equipment and/or its engine may include

evaporative emissions control system

components, required to meet EPA and/or

CARB regulations, that will only function

properly when the fuel tank has been filled to

the recommended level. Overfilling may

cause permanent damage to evaporative

emissions control system components. Filling

to the recommended level ensures a vapor

gap required to allow for fuel expansion. Pay

close attention while filling the fuel tank to

ensure that the recommended fuel level

inside the tank is not exceeded. Use a

portable gasoline container with an

appropriately sized dispensing spout when

filling the tank. Do not use a funnel or other

device that obstructs the view of the tank

filling process.

4. Replace fuel cap and tighten.

5. ALWAYS clean up spilled fuel.

GASOLINE

IMPORTANT: ALWAYS use gasoline that

meets the following guidelines:

Clean, fresh gasoline.

A minimum of 87 octane/87 AKI (91

IRON). High altitude use may require a

different octane. Consult your engine

manual.

Gasoline with up to 10% ethanol

(gasohol) or up to 10% MTBE (methyl

tertiary butyl ether) is acceptable.

Use of any gasoline other than those

approved above will void the engine

warranty. If the pumps are not marked

for the content of alcohol or ethers,

check ethanol and MTBE levels with

the fuel supplier.

Do not modify the fuel system to use

different fuels.

Never mix oil and gasoline.

NOTE: All gasoline is not the same. If the

engine experiences starting or performance

problems after using a new gasoline, switch

to a different fuel provider or fuel brand.

IMPORTANT: Excessively oxygenated or

reformulated fuels (fuels blended with

alcohols or ethers) can damage the fuel

system or cause performance problems. If

any undesirable operating problems occur,

use a gasoline with a lower percentage of

alcohol or ether.

GB - 13

Page 14

Fuel Stabilizer

Gasoline left in the fuel system for extended

periods without a stabilizer will deteriorate,

resulting in gum deposits in the system.

These deposits can damage the carburetor

and the fuel hoses, filter and tank. Prevent

deposits from forming in the fuel system

during storage by adding a quality fuel

stabilizer to the fuel. Follow the

recommended mix ratio found on the fuel

stabilizer container.

STOPPING IN AN EMERGENCY

WARNING: Operating unit on

slopes may lead to loss of

steering control. When operating

on slopes be prepared to react to

an emergency situation.

1. Return steering levers to neutral position

2. Immediately set parking brake

3. Turn off PTO and engine

NOTE: This unit is not equipped with the

return to neutral function. The control arms

must be manually brought back to neutral

from the forward position.

STARTING AND SHUTTING OFF

ENGINE

Starting the Engine

NOTE: Disengage the PTO, place the

steering levers in neutral, and engage the

parking brake prior to starting the engine.

1. If the engine is cold, move the choke

control to the On position. If the engine

is warm or hot, do not use choke.

IMPORTANT: DO NOT operate starter for

more than 10 seconds per minute as damage

can occur.

2. Put the ignition key in the switch and

turn it to the Start position.

3. As soon as the engine starts, release the

key.

4. Move the choke control to the Off

position from the Choke position. Wait

until the engine is running smoothly

before operation.

IMPORTANT: Let the engine warm up

several seconds to several minutes

depending on outside temperature.

Stopping the Engine

1. Stop unit.

2. Disengage PTO.

3. Set throttle lever to slow.

4. Turn ignition switch to off position and

remove key.

5. Set parking brake.

OPERATING MOWER

1. Start engine.

2. Set throttle lever to fast.

IMPORTANT: Never engage PTO if mower is

plugged with grass or other material.

3. Engage PTO to start mower blades. It

will take 2-3 seconds for the blades to

engage.

NOTE: The parking brake must be

disengaged prior to moving the steering

levers from the neutral lockout position.

4. Release parking brake.

5. Use steering levers to move the unit.

6. Disengage PTO to stop mower blades.

TRANSPORTING UNIT

ALWAYS shut off engine, set parking brake,

remove key, and properly remove fuel when

transporting unit on a truck or trailer. Tie unit

down securely. Do not tie down by linkages,

guards, cables or other parts that may be

damaged.

GB - 14

Page 15

FOR BEST PERFORMANCE

Cut grass when it is dry.

Keep mower blades sharp.

Keep mower deck properly leveled.

Do not set height of cut too low. For very tall

grass, mow twice.

Do not travel too fast.

Mow with the engine set at full throttle.

When mulching, only remove one-third of

grass length per cutting.

Discharge clippings into areas already cut.

Vary cutting pattern with each mowing.

Do not allow grass or debris to collect inside

of mower deck. Clean after each use.

MOVING UNIT MANUALLY

WARNING: DO NOT disengageor bypass transmission and coast

downhill.

Pull the bypass lever out and lock it in place,

and then release the parking brake to push

the unit by hand.

Push the bypass lever in to drive the unit

normally.

NOTE: There are two bypass levers; one on

each side of the unit.

1. Bypass lever pulled out to push

the unit by hand.

2. Bypass lever pushed in to drive

the unit.

Figure 5

GB- 15

Page 16

_l,]_i __Jl:l

,_ WARNING: AVOID INJURY. Readand understand the entire Safety

section before proceeding.

IMPORTANT: Proper maintenance can

prolong the life of unit. The following chart

shows the recommended service schedule.

Refer to the maintenance instructions in the

Engine Manual for additional information.

NOTE: To have full access to the engine, the

seat must be tipped forward (see TIPPING

SEAT FORWARD on page 17) and the hood

opened (see MOWER DECK REMOVAL

AND INSTALLATION on page 18).

Interval Task _,ction

Check

Safety ,_

Interlock

System

WARNING: Safety interlock system failure and improper

operation of unit can result in death or serious injury. Test

this system each time the unit is operated. If this system

does not function as described, do not operate until repairs

are made (see Safety Interlock System on page 12).

Check Engage parking brake and engage transmission bypass lever (see

Parking MOVING UNIT MANUALLY on page 15). Push unit. If unit rolls, contact

Brake your Ariens Dealer.

Clean Unit Clean engine, battery, seat, mower deck, etc. of all dirt and debris. Do

not use solvents, hard cleaners, or abrasives.

NOTE: Protect painted surfaces with automotive type wax.

IMPORTANT: Do not spray the unit with water, especially when the unit

is warm from operation. Water can seep into bearings and damage

them.

Check

Tires

See SPECIFICATIONS on page 27 for correct tire pressure.

Each Use

CAUTION: Avoid injury! Explosive separation of tire and rim

parts is possible when they are serviced incorrectly:

•Do not attempt to mount a tire without the proper equipment

and experience to perform the job.

Do not inflate the tires above the recommended pressure.

Do not weld or heat a wheel and tire assembly. Heat can cause

an increase in air pressure resulting in an explosion. Welding

can structurally weaken or deform the wheel.

Do not stand in front or over the tire assembly when inflating.

Use a clip-on chuck and extension hose long enough to allow

you to stand to one side.

Check Check for worn or damaged mower blades (see SHARPENING

Mower MOWER BLADE on page 20).

Blades

Follow

Engine

Manual

Mainten-

ance

Schedule

Perform scheduled engine maintenance.

Refer to Engine Manual for detailed

instructions.

NOTE: To drain the oil, remove oil drain

cap and attach the oil drain hose,

supplied in the lit pack, to the drain plug.

Rotate the drain to the left to allow oil to

drain. Turn the drain to the right to close.

Oil Drain Plug

GB - 16

Page 17

Interval Task _,ction

25 Hours

or Every

Season

50 Hours

or Every

Season

100 Hours

or Every

Season

Check

Battery

Keep battery and battery terminals clean (see Cleaning Battery and

Battery Cables on page 21).

UnitLubricatefrontApplygreaset°zerk (1)oneachwheel _ 1

Check Check mower blade mounting hardware and all other fasteners.

Fasteners Replace fasteners that are missing or damaged. Tighten all nuts and

bolts to the correct torque values.

Check All

Belts

Replace worn or deteriorated belts.

Check hydrostatic belt (see REPLACING HYDROSTATIC BELT

on page 24 for hydrostatic belt location).

Check PTO belt (see REPLACING PTO BELT on page 23 for

PTO belt location).

Check All Replace worn or improperly functioning PTO cables.

Cables

[,._o]=l r_,1#Im]r_,1m]l[l_ll / tv_I=1#III[€]

WARNING: AVOID INJURY.

Read and understand the entire

Safety section before proceeding.

TIPPING SEAT FORWARD

Put steering levers up and tip seat forward

(figure 6).

1. Seat Tipped Forward

2. Mounting Hardware

Figure 6

SEAT ADJUSTMENT

1. Tip the seat forward.

2. Loosen mounting hardware and slide

seat forward or backward to desired

position. Tighten mounting hardware

(figure 6).

3. Tip seat back.

GB - 17

Page 18

MOWER DECK REMOVAL AND

INSTALLATION

Remove

(Figure 7)

1. Remove PTO belt from the engine drive

pulley (see REPLACING PTO BELT on

page 23).

NOTE: Perform step 2 and 3 for the right and

left side of unit.

2. Disconnect drag link from the front deck

bracket.

3. Disconnect front and rear trunnions from

the lift arms.

4. Slide mower deck out from under unit.

Install

(Figure 7)

1. Slide mower deck under unit.

NOTE: Perform step 2 and 3 for the right and

left side of unit.

2. Connect drag link to front deck bracket.

3. Connect front and rear trunnions to lift

arms.

4. Install PTO belt on the engine drive

pulley (see REPLACING PTO BELT on

page 23).

5. Level and adjust pitch of mower deck

(see LEVELLING AND ADJUSTING

PITCH OF MOWER DECK on page 18).

5 4

1. Rear Trunnion

2. PTO Belt

3. Mower Deck

3

4.

5.

6.

Figure 7

2

Drag Link

Front Trunnion

Lift Arms

LEVELLING AND ADJUSTING

PITCH OF MOWER DECK

NOTE: Adjust on a level surface, with the

tires inflated to the correct air pressure (see

SPECIFICATIONS on page 27).

Three measurements are required to level

and adjust the pitch of the mower deck.

1. The distance from the mower blades to

the ground.

2. The forward pitch of the mower blades.

3. The pitch of the mower blades from

side-to-side.

The Distance From The Mower

Blades To The Ground

(Figure 8)

In the lowest cutting position should be

1 in. + 1/4 in. (2.54 cm + 0.64 cm).

In the highest cutting position should

be4 in. + 1/4 in. (10.16 cm +0.64 cm).

Lowest Cutting Position

3 1 2

\, / /

\ U /f-q

..

1 in. + 1/4 in. (2.54 cm + 0.64 cm)

Highest Cutting Position

3 1 2

k / /

fl I! " />-ql]

4 in. + 1/4 in. (10.16 cm +0.64 cm)

1. Mower Deck 3. Ground

2. Mower Blade

Figure 8

GB - 18

Page 19

The Forward Pitch Of The Mower

Blades

(Figure 9)

Should be 0.0 in. (0.0 mm) to 1/4 in.

(6.35 mm) pitched forward.

NOTE: This measurement must be taken

when the mower blades ends point forward.

Forward Pitch of Mower Blades

3 1 2

\ / /

1

Front of

Mower Deck

1. Mower Deck 3. Ground

2. Mower Blade

Figure 9

The Pitch Of The Mower Blades From

Side-To-Side

(Figure 10)

Should be within 1/4 in. (6.35 mm) as

measured on each side of the mower

deck.

NOTE: This measurement must be taken

when the mower blade ends point left and

right.

Side-To-Side Pitch

1

2

3 / /

\ /

ti / J---ll)

1/4-in. (6.35 mm) from Side-To-Side

1. Mower Deck 3. Ground

2. Mower Blade

Figure 10

Adjusting The Mower Deck To Adjust

Mower Blade Height And Pitch

(Figure 11)

NOTE: Adjusting the mower deck will adjust

the height and pitch of the mower blades.

1. Adjust the trunnions first and re-take the

three measurements required to level

and adjust the pitch of the mower deck.

These measurements are:

a. The distance from the mower

blades to the ground.

b. The forward pitch of the mower

blades.

c. The pitch of the mower blades

from side-to-side.

2. Repeat step 1 as needed until all three

measurements are within the tolerances

specified.

1. Trunnion 2. Mower Deck

Figure 11

REPLACING MOWER BLADE

Remove

(Figure 12)

CAUTION: Mower blades are

sharp and can cut you. Wrap

the blades or wear gloves, and

use extra caution when

servicing them.

1. Block mower blades to prevent rotation.

2. Remove mounting hardware and mower

blades from spindles.

Install

(Figure 12)

1. Install mower blades on spindles with

mounting hardware.

2. Torque 5/8-inch nut to 92 to 130 Ibf-ft

(125 to 176 N°m).

GB - 19

Page 20

j4

1.Spindle

2. Blade

3. Washer

4. 5/8in.Nut

Figure12

SHARPENING MOWER BLADE

CAUTION: DO NOT sharpen

mower blade while on unit. An

unbalanced mower blade will

cause excessive vibration and

eventual damage to unit. Check

mower blade balance prior to

reinstalling mower blades.

NEVER weld or straighten mower

blades.

1. Remove mower blade from unit (see

REPLACING MOWER BLADE on

page 19).

Ariens recommends having mower blades

sharpened by a professional. Contact your

Ariens dealer.

Discard mower blade if (figure 13):

more than 1/2 in. (1.27 cm) of metal is

removed.

the air lift erosion area is eroded.

the mower blade is bent or broken.

Do not change angle of cutting edge or round

the corner at the end of mower blade.

2. Sharpen mower blade by removing an

equal amount of material from each end

of mower blade.

3. Check mower blade balance by sliding

mower blade on an unthreaded bolt. If

blade is balanced, it should remain in a

horizontal position. If either end of

mower blade moves downward, sharpen

the heavy end until mower blade is

balanced.

4. Install mower blade on unit (see

REPLACING MOWER BLADE on

page 19).

DO NOT Sharpen to this Pattern

Sharpen to this Pattern

1/2 in. /

(1/27 cm) 2

1

1. Air Lift Erosion

2. Cutting Edge

Figure 13

SERVICING THE BATTERY

NOTE: Unit comes equipped with a

maintenance-free battery that requires no

regular maintenance except cleaning the

terminals.

,_ WARNING: Battery posts,

terminals and related accessories

contain lead and lead

compounds, chemicals known to

the State of California to cause

cancer and reproductive harm.

Wash hands after handling.

Battery Removal and Installation

Remove

(Figure 14)

1. Tip seat forward (see TIPPING SEAT

FORWARD on page 17).

2. Disconnect negative (-) cable first, then

positive (+) cable.

3. Remove battery hold-down bracket and

battery from unit.

GB - 20

Page 21

Install

(Figure 14)

1. Install battery on the unit with battery

hold-down bracket.

2. Connect positive (+) cable first, then

negative (-) cable.

3. Apply petroleum jelly or dielectric grease

to battery cable ends and terminals.

4. Tip seat back (see TIPPING SEAT

FORWARD on page 17).

2 3 4

1. Positive (+) Terminal

2. Positive (+) Cable

3. Battery Hold-Down Bracket

4. Battery

5. Negative (-) Terminal

6. Negative (-) Cable

Figure 14

Cleaning Battery and Battery Cables

(Figure 14)

1. Tip seat forward (see TIPPING SEAT

FORWARD on page 17).

2. Disconnect negative (-) cable first, then

positive (+) cable.

3. Clean battery cable ends, negative (-)

terminal, and positive (+) terminal with a

wire brush and rinse with a weak baking

soda solution.

4. Connect positive (+) cable first, then

negative (-) cable.

5. Apply petroleum jelly or dielectric grease

to battery cable ends and terminals.

6. Tip seat back (see TIPPING SEAT

FORWARD on page 17).

Charging the Battery

(Figure 14)

WARNING: FROZEN

BATTERIES CAN EXPLODE and

result in death or serious injury.

DO NOT charge a frozen battery.

Let the battery thaw before

charging.

Follow First Aid directions for contact with

battery fluid.

External Contact: Flush with water.

Eyes: Flush with water for at least 15

minutes and get medical attention

immediately!

Internal Contact: Drink large quantities

of water. Follow with Milk of Magnesia,

beaten egg or vegetable oil. Get

medical attention immediately!

In case of internal contact, DO NOT

induce vomiting!

IMPORTANT: DO NOT fast charge. Charging

at a higher rate will damage or destroy

battery.

IMPORTANT: ALWAYS follow information

provided on battery and battery charger.

Contact battery and battery charger

manufacturers' for detailed instructions.

1. Remove battery from unit (see Battery

Removal and Installation on page 20).

2. Place battery in a well-ventilated area.

3. Connect positive (+) lead of charger to

positive (+) terminal, and negative (-)

lead of charger to negative (-) terminal.

4. Charge battery according to battery

charger and battery manufacturers'

instructions.

5. Install battery on unit (see Battery

Removal and Installation on page 20).

Jump-Starting

Ariens does not recommend jump-starting

your unit. Jump-starting can damage engine

and electrical system components. See your

engine manual for more detailed information.

GB - 21

Page 22

ADJUSTING STEERING LEVERS

(Figure 15)

Adjustment 3 Adjustment 1

Adjustment 2

1. Handlebar

2. Upper Control Arm

3. Adjustment Holes

4. Eccentric Spacer

5. Mounting Hardware

6. Lower Control Arm

Figure 15

IMPORTANT: Adjust each steering lever

equally.

NOTE: When adjusting steering levers for the

first time it is recommended that you make

adjustments in the following order.

1. Adjust Steering Lever Height

1. Remove mounting hardware that

attaches the handlebars to the upper

control arm. Move handlebar up or down

until the handlebar mounting holes are

aligned with the prefered adjustment

holes.

2. Install mounting hardware and tighten.

2. Adjust Steering Lever Width

1. Loosen hardware at the base of the

lower control arm item 5.

2. Rotate eccentric spacer to move the

levers away from or closer to the

operators position (figure 16).

Rotate this end away from the the operator

position to move the steering levers in.

Rotate this end away from the operator

position to move the steering levers out.

Figure 16

3. Adjust Steering Lever Forward or

Backward

1. Loosen, do not remove, the bolts

securing the handlebar to the upper

control arm.

2. Slide steering lever forward or backward

to desired position and tighten bolts.

NOTE: Tigthen upper bolt first.

Forward Speed Adjustment

(Figure 17)

NOTE: Reverse speed cannot be adjusted. If

unit tracks excessively left or right in reverse,

see your Dealer for repair.

IMPORTANT: The unit should track within

2 feet (0.61 m) of a straight line for 30 feet

(9.14 m).

The travel of the steering levers may need

adjustment if the unit turns to the right or left

when both steering levers are pushed as far

forward as possible.

NOTE: The side the unit turns toward

indicates that the wheel on that side is turning

slower than the other wheel. Either the wheel

that is turning faster needs to slow down or

the wheel that is turning slower needs to

speed up to allow the unit to travel in a

straight line.

1. Determine which way the unit turns.

2. Loosen jam nut on the adjustment bolt.

3. Adjust speed by:

Turning adjustment bolt clockwise to

decrease steering lever travel.

Turning adjustment bolt

counterclockwise to increase steering

lever travel.

4. Tighten the jam nut.

GB - 22

Page 23

1

1. ForwardTravelAdjustmentBolt

2. LowerControlArm

Figure17

REPLACING PTO BELT

Remove

(Figure 18)

1. Lower mower deck to the ground.

2. Remove belt covers from mower deck.

CAUTION: Use care when

releasing idler spring tension.

Keep body parts well away from

idler when performing this

operation.

3. Pull idler arm towards outside of unit

until tension is removed from PTO belt.

4. Remove PTO belt from left mower deck

pulley.

5. Slowly release idler arm until tension is

removed from idler spring.

6. Remove PTO belt from mower deck and

engine drive pulley.

915157,169

1

1. Deck Spindle

2. Engine Drive Pulley

3. Deck Idler

4. PTO Belt

Figure 18

915159, 161,171

4

1. Deck Spindle

2. Engine Drive Pulley

3. Deck Idler

4. PTO Belt

Figure 19

Install

(Figure 18)

NOTE: Do not install PTO belt on left mower

deck pulley in step 1.

1. Install PTO belt on engine drive pulley

and mower deck.

2. Pull idler arm towards outside of unit

until PTO belt can be routed around left

mower deck pulley.

GB - 23

Page 24

3.Slowlyreleaseidlerarmuntilidlerpulley

restsfirmlyagainstPTObelt.

4.Installbeltcoversonmowerdeck.

NOTE:Ensurethatbeltisstillpositionedin

thegrooveofthesheaveafterbeltcoversare

installed.

REPLACING HYDROSTATIC BELT

Remove

(Figure 20)

1. Remove PTO belt (see REPLACING

PTO BELT on page 23).

CAUTION: Use care when

releasing idler spring tension.

Keep body parts well away from

idler when performing this

operation.

2. Disconnect idler spring.

3. Remove hydrostatic belt from

hydrostatic transmission pulleys, drive

pulley, and idler.

Install

(Figure 20)

1. Install hydrostatic belt on idler, drive

pulley, and hydrostatic transmission

pulleys.

2. Connect idler spring.

3. Install PTO belt (see REPLACING PTO

BELT on page 23).

4

1

\

1. Hydrostatic Belt 3. Idler

2. Hydrostatic 4. Idler Spring

Transmission

Pulley

Figure 20

[,,,,"]i_o_e-] :1

Short Term Storage

IMPORTANT: NEVER clean unit with high-

pressure water or store unit outdoors.

Remove all dirt, grease, leaves, etc. Store in

a clean dry area.

Inspect unit for signs of wear or damage.

Ensure all fasteners are properly tightened.

Long Term Storage

Follow all instructions under Short Term

Storage,

Remove and fully charge battery. Store in a

clean dry area.

Refer to Engine Manual for the proper engine

storage procedures.

Touch up all scratched or chipped paint

surfaces.

Fuel System

Gasoline left in the fuel system for extended

periods without a stabilizer will deteriorate,

resulting in gum deposits in the system.

These deposits can damage the carburetor

and the fuel hoses, filter and tank. Prevent

deposits from forming in the fuel system

during storage by adding a quality fuel

stabilizer to the fuel. Follow the

recommended mix ratio found on the fuel

stabilizer container.

To treat the fuel system for storage:

1. Add fuel stabilizer according to

manufacturers's instructions.

2. Run engine for at least 10 minutes after

adding stabilizer to allow it to reach the

carburetor.

NEVER store the engine with fuel in the fuel

tank inside of a building with potential

sources of ignition.

GB - 24

Page 25

PROBLEM PROBABLE CORRECTION

CAUSE

Enginewill not 1. 1.

crank/start.

Engine runs

rough.

Unit does not

move with

engine running

when using

steering levers.

PTO or mower

blades do not

engage or shut

off.

Engine

overheats.

Safety interlock

system is not

engaged or is

faulty.

2. Fuel tank is

empty.

3. Discharged

battery.

4. Poor connection

between battery

and battery

cables.

5.

Spark plug wire(s)

loose or spark

plug(s) faulty.

6. Faulty electrical

system.

7.

1.

2.

3.

1.

2.

3.

1.

2.

3.

4.

1.

2.

3.

Faulty engine.

Choke engaged.

Airfiltercartridge

plugged.

Faulty engine.

The transmission

bypassleveris

engaged.

Faulty hydrostatic

belt.

Faulty

transmission.

Operator

presence switch

not depressed.

Faulty operator

presence switch.

Faulty PTO belt.

Faulty PTO

switch, wires,

connectors, or

clutch.

Engine oil level

low.

Cooling system

plugged.

Faulty engine.

2.

3.

4.

5.

Check safety interlock system (see Safety

Interlock System on page 12).

Fill fuel tank (see FILLING FUEL TANK on

page 13).

Charge battery (see Charging the Battery

on page 21 ).

Tighten battery cables and/or clean battery

and battery cables (see Cleaning Battery

and Battery Cables on page 21).

Connect spark plug wire(s) or replace spark

plug(s). Refer to Engine Manual for detailed

instructions.

6. Contact your Ariens Dealer.

7. Contact your Ariens Dealer.

1. Disengage choke.

2. Clean or replace air filter cartridge. Refer to

Engine Manual for detailed instructions.

3. Contact your Ariens Dealer.

1. Disengage transmission bypass lever (see

MOVING UNIT MANUALLY on page 15).

2.

3.

1.

2.

3.

4.

1.

2.

3.

Replace hydrostatic belt (see REPLACING

HYDROSTATIC BELT on page 24).

Contact your Ariens Dealer.

Depress operator presence switch by sitting

on seat.

Contact your Ariens Dealer.

Replace PTO belt (see REPLACING PTO

BELT on page 23).

Contact your Ariens Dealer.

Add engine oil. Refer to Engine Manual for

detailed instructions.

Clean cooling system. Refer to Engine

Manual for detailed instructions.

Contact your Ariens Dealer.

GB - 25

Page 26

PROBLEM

Unit moves with

engine off and

parking brake

engaged.

Unit does not

travel in a

straight line.

Unit creeps with

steering levers

in neutral

position.

Poor cutting

quality.

2.

1.

2.

3.

2.

PROBABLE

CAUSE

The parking brake

needs

adjustment.

Faulty parking

brake.

Incorrect tire

pressure.

Steering levers

need adjustment.

Hydrostatic

transmission

and/or linkage

needs

adjustment.

Hydrostatic

transmission

and/or linkage

needs

adjustment.

Mower deck not

level or mower

pitch is incorrect.

Dull or faulty

mower blades.

CORRECTION

1. Contact your Ariens Dealer.

2. Contact your Ariens Dealer.

1.

2.

3.

Check tire pressure (see SPECIFICATIONS

on page 27).

Adjust steering levers (see Forward Speed

Adjustment on page 22)

Contact your Ariens Dealer.

1. Contact your Ariens Dealer.

2.

Level and adjust pitch of mower deck (see

LEVELLING AND ADJUSTING PITCH OF

MOWER DECK on page 18).

Sharpen mower blades (see SHARPENING

MOWER BLADE on page 20) or replace

mower blades (see REPLACING MOWER

BLADE on page 19).

[.,,-._o,]:11 _7__I_ K,,,.-_ P_'T__o];_[_,,,,_

Be sure to always use genuine Ariens

parts to kee your unit running like new.

Part No. Description

51519500 34- and 50-Inch Spindle

Assembly

51520900 42-Inch Spindle Assembly

07100801 Front Wheel (Tread)

07100124 Front Wheel (Smooth)

07200116 34-Inch Deck Belt

07200010 HA Raw Laminated Belt -

Hydraulic Drive

03971900 34-Inch Mower Blade

03797300 34-Inch Mulching Blade

04265400 42-Inch Mower Blade

07200523 42-Inch Deck Belt

03971900 50-Inch Mower Blade

07200524 50-Inch Deck Belt

See your authorized Ariens dealer to add

these optional accessories to your unit.

Part No. Description

71503300 36-Inch Roller

71503400 48-Inch Dethatcher

71503600 Spreader

71508200 48-Inch Aerator

71510800 34-Inch Mulch Kit

71510900 Trailer Hitch Kit

81503700 34-Inch Non-Powered Bagger

81503800 42-Inch Non-Powered Bagger

81503900 50-Inch Non-Powered Bagger

71512000 42-Inch Mulch Kit

71511900 50-Inch Mulch Kit

GB - 26

Page 27

[,,,,___o]_,,,_

915157 915159 915161

Zoom 34 Zoom 42 Zoom 50

Model Number

Model

Engine

Type

Engine Displacement in.3 (cc)

Governed RPM (May be different

from maximum RPM)

Drive

Forward Max. - m.p.h (km/h)

Reverse Max. - m.p.h (km/h)

Briggs & Stratton Kohler Kohler

30.51 (500) 44 (725) 44 (725)

3600 + 0

3600 - 100

6.0 (9.6)

3.0 (4.8)

Turning Radius Zero

Brakes Internal Transmission

Transmission Hydrostatic Drive

Electrical

Starter Electric

Battery 12V Maintenance Free SLI U1B 275

PTO (Power Take-Off) Electric Clutch

Fuel

Fuel Type Refer to Engine Manual

Fuel Tank Capacity - gal. (L) 1.97 (7.49)

Size and Weight

Length - in. (cm) 65 (165.1)

Width -in. (cm) 45 (114.3) 54 (137.2) 62 (157.5)

Weight -Ibs (kg) 405 (183.7) 415 (188.2) 490 (222.3)

Height- in. (cm) 40 (102) 42 (106.7)

Tires

Front Tire Size - in. 4 x 11

Rear Tire Size - in. 18x6.5x8 18xS.5x8 18x9.5x8

Front Tire Pressure- psi (kPa) 46 (317)

Rear Tire Pressure - psi (kPa) 10 (68.95)

Mower Deck

Cutting Height- in. (cm) 1-4 (2.54- 10.16)

Cutting width -in. (cm) 34 (86) 42 (106.7) 50 (127)

Max. Towing Capacity- Ibs (kg) 300 (136)

Max. Tongue Weight - Ibs (kg) 30 (13.6)

GB - 27

Page 28

[,,,,___o]_,,,_

Model Number

Model

Engine

Type

Engine Displacement in.3 (cc)

Governed RPM (May be different

from maximum RPM)

Drive

Forward Max. - m.p.h (km/h)

Reverse Max. - m.p.h (km/h)

Turning Radius

Brakes

Transmission

Electrical

Starter

Battery

915169

Zoom 34 CARB

915171

Zoom 42 CARE}

Briggs & Stratton Kohler

30.51 (500) 44 (725)

3600 + 0

3600 - 100

6.0 (9.6)

3.0 (4.8)

Zero

Internal Transmission

Hydrostatic Drive

Electric

12V Maintenance Free

SLI U1B 275

PTO (Power Take-Off) Electric Clutch

Fuel

Fuel Type Refer to Engine Manual

Fuel Tank Capacity - gal. (L) 1.97 (7.49)

Size and Weight

Length - in. (cm) 65 (165.1)

Width -in. (cm) 45 (114.3) 54 (137.2)

Weight -Ibs (kg) 405 (183.7) 415 (188.2)

Height - in. (cm) 40 (102)

Tires

Front Tire Size - in. 4 x 11

Rear Tire Size - in. 18 x 6.5 x 8 18 x 8.5 x 8

Front Tire Pressure - psi (kPa) 46 (317)

Rear Tire Pressure - psi (kPa) 10 (68.95)

Mower Deck

Cutting Height - in. (cm) 1.5 - 4.5 1 - 4 (2.54 - 10.16)

(3.8- 11.4)

Cutting width - in. (cm) 34 (86) 42 (106.7)

Max. Towing Capacity- Ibs (kg) 300 (136)

Max. Tongue Weight - Ibs (kg) 30 (13.6)

GB - 28

Page 29

COMPANY

Two-Year Limited Lawn and

Garden Consumer Ride-On

Warranty

Ariens Company warrants to the original purchaser that Ariens, Gravely and Countax brand consumer

products manufactured and sold by Ariens Company will be free from defects in material and workmanship

for a period of two years after the date of purchase. An authorized Ariens dealer (Ariens brand products),

Gravely dealer (Gravely brand products), or Countax dealer (Countax brand products) will repair any defect

in material or workmanship, and repair or replace any defective part, subject to the conditions, limitations and

exclusions set forth herein. Such repair or replacement will be free of charge (labor and parts) to the original

purchaser except as noted below.

Five-Year Limited Warranty on Mower Deck Shell

The deck shell on zero-turn riding mowers is warranted to the original purchaser for five years from

the date of purchase. Any defect in material or workmanship of the deck shell will be repaired free of

charge (parts and labor) to the original purchaser for two years after the date of purchase. For the third

through fifth year from the date of purchase, the parts required to repair a defect in material or work-

manship of the deck shell, not the labor, will be provided free of charge.

Five-Year Limited Warranty on Main Frame

The main frame on zero-turn riding mowers is warranted to the original purchaser for five years from

the date of purchase. Any defect in material or workmanship of the main frame will be repaired free of

charge (parts and labor) to the original purchaser for two years after the date of purchase. For the third

through fifth year from the date of purchase, the parts required to repair a defect in material or work-

manship of the main frame, not the labor, will be provided free of charge.

Two-Year Limited Warranty on AMP TM Series Battery Packs and Subassembfies

The battery pack and/or battery subassemblies on AMP series electric riding mowers is/are warranted to the

original purchaser for two years from the date of purchase. Ariens Company will replace, free of charge to

the original purchaser, any battery pack and/or battery subassembly that fails due to defect in material or

workmanship for one year after the date of purchase. For the next 12 months, Ariens Company will cover the

prorated cost of replacing a battery pack and/or battery subassembly that fails due to defect in material or

workmanship. This warranty does not apply to battery packs or battery subassemblies that fail due to acci-

dent, neglect, abuse, improper maintenance, improper storage or improper charging procedures.

90-Day Limited Warranty on Service Parts and Accessories

Genuine Ariens, Gravely or Countax brand service parts and accessories are warranted to be free from

defects in material and workmanship for a period of 90 days after the date of purchase. An authorized

Ariens, Gravely or Countax dealer will repair or replace any such part or accessory free of charge,

except for labor, during that period.

The duration of all warranties herein applies only if the product is put to personal use around a household or

residence. If the product is put to any business use, agricultural, commercial, or industrial, then the duration

of these warranties shall be 90 days after the date of purchase. For Ariens Max Zoom and Gravely ZT HD

models put to commercial use, the duration of these warranties, except for service parts and accessories, is

one year from the date of purchase.

If any product is rented or leased, then the duration of these warranties shall be 90 days after the date of

purchase,

Exceptions, Limitations, Exclusions

Customer Responsibilities

Register the product immediately at the time of sale. If the dealer does not register the product, the

customer must complete the product registration card in the literature package and return it to the Ariens

Company, or register the unit online at wwv.ariens.com, www.gravely.com, wv_v.countax.com.

To obtain warranty service, the original purchaser must:

Perform the maintenance and minor adjustments explained in the owner's manual.

Promptly notify Ariens Company or an authorized Ariens, Gravely or Countax service representative of

the need for warranty service.

Transport the product to and from the place of warranty service.

Have the warranty service performed by an authorized Ariens, Gravely or Countax service

representative.

_,_'/_ Con_Ride_2011

Company 29

Page 30

To find an Ariens or Gravely authorized service representative, contact Ariens in the United States, Canada

or Mexico at:

655 W. Ryan Street

Brillion, WI 54110

(g20) 756- 4688

www.ariens.com

www.gravely.com

To find a Countax authorized service representative, contact Countax in Europe or Australia at:

Countax Ltd

Countax House

Great Haseley

Oxfordshire

OX44 7PF

0800 597 7777

www.countax.com

Exceptions and Limitations

Batteries are warranted only for a period of 12 months after date of purchase, on a prorated basis. For

the first 90 days of the warranty period, a defective battery will be replaced free of charge. If the

applicable warranty period is more than 90 days, Ariens Company will cover the prorated cost of any

defective battery, for up to 12 months after the date of purchase. This battery limited warranty does not

apply to the battery packs on AMP series products.

Exclusions - Items Not Covered by This Warranty

Engines and engine accessories are covered only by the engine manufacturer's warranty and are not

covered by this warranty.

Parts that are not genuine Ariens, Gravely or Countax service parts are not covered by this warranty.

The following maintenance, service and replacement items are not covered by this warranty unless

they are noted in the Limitations section above: lubricants, spark plugs, oil, oil filters, air filters, fuel

filters, brake linings, brake arms, brake shoes, runners, scraper blades, shear bolts, mower blades,

mower vanes, headlights, light bulbs, knives, cutters.

Any misuse, alteration, improper assembly, improper adjustment, neglect, or accident which requires

repair is not covered by this warranty.

Disclaimer

Ariens Company may from time to time change the design of its products. Nothing contained in this warranty

shall be construed as obligating the Ariens Company to incorporate such design changes into previously

manufactured products, nor shall such changes be construed as an admission that previous designs were

defective.

LIMITATION OF REMED Y A ND DAMA GES

Ariens Company's liability under this warranty, and under any implied warranty that may exist, is limited to

repair of any defect in workmanship, and repair or replacement of any defective part. Ariens Company shall

not be liable for incidental, special, or consequential damages (including lost profits). Some states do not

allow the exclusion of incidental or consequential damages, so the above limitation or exclusion may not

apply to you.

DISCLAIMER OF FURTHER WARRANTY

Ariens Company makes no warranty, express or implied, other than what is expressly made in this

warranty. If the law of your state provides that an implied warranty of merchantability, or an implied

warranty of fitness for particular purpose, or any other implied warranty, applies to Ariens Company,

then any such implied warranty is limited to the duration of this warranty. Some states do not allow

limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which

vary from region to region.

__ Con_Ride_2011

Company 3o

Page 31

CALIFORNIA AND EPA (UNITED STATES ENVIRONMENTAL

PROTECTION AGENCY) EVAPORATIVE EMISSION CONTROL

WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The CARB (California Air Resources Board), the EPA, and Ariens Company are pleased to explain the

evaporative emission control system's warranty on your 2011 model year small off-road equipment. In

California, new equipment that uses small off-road engines must be designed, built, and equipped to

meet the State's stringent anti-smog standards. Ariens Company must warrant the evaporative

emission control system on your small off-road equipment for the period listed below provided there

has been no abuse, neglect or improper maintenance of your equipment.

Your evaporative emission control system may include parts such as: fuel tanks, fuel lines, fuel caps,

valves, canisters, filters, vapor hoses, clamps, connectors, and other associated components.

MANUFACTURER'S WARRANTY COVERAGE:

This evaporative emission control system is warranted for two years. If any evaporative

emission-related part on your equipment is defective, the part will be repaired or replaced by Ariens

Company.

OWNER'S WARRANTY RESPONSIBILITIES:

• As the small off-road equipment owner, you are responsible for the performance of the required

maintenance listed in your Owner's Manual. Ariens Company recommends that you retain all

receipts covering maintenance on your small off-road equipment, but Ariens Company cannot deny

warranty solely for the lack of receipts.

• As the small off-road equipment owner, you should however be aware that the Ariens Company may

deny you warranty coverage if your evaporative emission control system part has failed due to

abuse, neglect, or improper maintenance or unapproved modifications.

• You are responsible for presenting your small off-road equipment to an authorized Ariens, Gravely,

or Parker service representative as soon as the problem exists. The warranty repairs should be

completed in a reasonable amount of time, not to exceed 30 days. If you have a question regarding

your warranty coverage, you should contact Ariens Company Technical Service Center at

1-920-756-4688.

DEFECTS WARRANTY REQUIREMENTS:

(a.) The warranty period begins on the date the small off-road equipment is delivered to an ultimate

purchaser.

(b.) General Evaporative Emissions Warranty Coverage. Ariens Company warrants to the ultimate

purchaser and any subsequent owner that the evaporative emission control system when

installed was:

(1.) Designed, built, and equipped so as to conform with all applicable EPA and CARB

regulations; and

(2.) Free from defects in materials and workmanship that causes the failure of a warranted part

for a period of two years.

(c.) The warranty on evaporative emissions-related parts will be interpreted as follows:

(1.) Any warranted part that is not scheduled for replacement as required maintenance in the

written instructions must be warranted for the warranty period defined in subsection (b)(2).

If any such part fails during the period of warranty coverage, it must be repaired or replaced

by the Ariens Company. Any such part repaired or replaced under the warranty must be

warranted for a time not less than the remaining warranty period.

(2.) Any warranted part that is scheduled only for regular inspection in the written instructions

must be warranted for the warranty period defined in subsection (b)(2). A statement in such

written instructions to the effect of "repair or replace as necessary" will not reduce the

period of warranty coverage. Any such part repaired or replaced under warranty must be

warranted for a time not less than the remaining warranty period.

(3.) Any warranted part that is scheduled for replacement as required maintenance in the

written instructions must be warranted for the period of time prior to the first scheduled

replacement point for that part. If the part fails prior to the first scheduled replacement, the

part must be repaired or replaced by the Ariens Company. Any such part repaired or

replaced under warranty must be warranted for a time not less than the remainder of the

period prior to the first scheduled replacement point for the part.