Page 1

Models

991158 – Zenith 60

(SN 095000 +)

991159 – Apex 52

(SN 095000 +)

991161 – Apex 48

(SN 095000 +)

991163 – Apex 60

(SN 095000 +)

Apex

Zenith

Operator’s Manual

Manuel du Utilisateur

E10

ENGLISH

FRANÇAIS

09740300A • 9/22

Printed in USA

Page 2

TABLE OF CONTENTS

WELCOME . . . . . . . . . . . . . . . . . . . . . . 1

Register Your Product!. . . . . . . . . . . . . . 1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . 2

Practices & Laws . . . . . . . . . . . . . . . . . . 2

Emission Control System. . . . . . . . . . . . 2

Required Operator Training . . . . . . . . . . 2

Safety Alert Symbol . . . . . . . . . . . . . . . . 2

Signal Words . . . . . . . . . . . . . . . . . . . . . 2

Safety Decals. . . . . . . . . . . . . . . . . . . . . 3

Safety Instructions . . . . . . . . . . . . . . . . . 7

CONTROLS AND FEATURES . . . . . . . 10

Ignition Key . . . . . . . . . . . . . . . . . . . . . . 12

Choke Control Knob. . . . . . . . . . . . . . . . 12

Throttle Control Lever . . . . . . . . . . . . . . 12

Power-Take-Off (PTO) Knob . . . . . . . . . 12

Hour Meter. . . . . . . . . . . . . . . . . . . . . . . 12

Height-of-Cut Adjustment System . . . . . 12

Transport Lock Release Lever . . . . . . . . 13

Deck Lift Pedal. . . . . . . . . . . . . . . . . . . . 13

Seat Adjustment Lever. . . . . . . . . . . . . . 13

Rollover Protection Structure (ROPS) . . 13

Parking Brake Lever . . . . . . . . . . . . . . . 13

Safety Interlock System . . . . . . . . . . . . . 13

Steering Levers . . . . . . . . . . . . . . . . . . . 13

Transaxle Bypass Levers. . . . . . . . . . . . 13

Anti-scalp Wheel . . . . . . . . . . . . . . . . . . 13

OPERATION . . . . . . . . . . . . . . . . . . . . . 14

Emergency Stopping . . . . . . . . . . . . . . . 14

Before Operating Unit . . . . . . . . . . . . . . 14

Position ROPS. . . . . . . . . . . . . . . . . . . . 15

Start the Engine. . . . . . . . . . . . . . . . . . . 16

Operate Unit. . . . . . . . . . . . . . . . . . . . . . 16

Stop the Engine . . . . . . . . . . . . . . . . . . . 17

Move Unit Manually . . . . . . . . . . . . . . . . 17

Transport Unit . . . . . . . . . . . . . . . . . . . . 17

Release Transport Lock. . . . . . . . . . . . . 17

MAINTENANCE . . . . . . . . . . . . . . . . . . 18

Maintenance Schedule . . . . . . . . . . . . . 18

Service Parts . . . . . . . . . . . . . . . . . . . . . 18

Service Position. . . . . . . . . . . . . . . . . . . 19

Check Safety Interlock System . . . . . . . 19

Check Parking Brake. . . . . . . . . . . . . . . 20

Check Engine Oil. . . . . . . . . . . . . . . . . . 20

Check Tire Pressure . . . . . . . . . . . . . . . 20

Check Fasteners . . . . . . . . . . . . . . . . . . 20

Lubricate Unit. . . . . . . . . . . . . . . . . . . . . 20

Check Mower Blades . . . . . . . . . . . . . . . 20

Check Battery . . . . . . . . . . . . . . . . . . . . 21

Check Mower Belts . . . . . . . . . . . . . . . . 21

Check Hydraulic System . . . . . . . . . . . . 21

ADJUSTMENTS . . . . . . . . . . . . . . . . . . 23

Adjust Seat . . . . . . . . . . . . . . . . . . . . . . 23

Adjust Steering Levers. . . . . . . . . . . . . . 23

Adjust Unit to Drive Straight. . . . . . . . . . 24

ELECTRICAL SERVICE . . . . . . . . . . . . 25

TROUBLESHOOTING . . . . . . . . . . . . . 26

STORAGE . . . . . . . . . . . . . . . . . . . . . . . 28

Short-Term Storage. . . . . . . . . . . . . . . . 28

Long-Term Storage . . . . . . . . . . . . . . . . 28

Start-of-Season Preparation . . . . . . . . . 28

ACCESSORIES. . . . . . . . . . . . . . . . . . . 28

SPECIFICATIONS. . . . . . . . . . . . . . . . . 29

WARRANTY . . . . . . . . . . . . . . . . . . . . . 30

Page 3

WELCOME

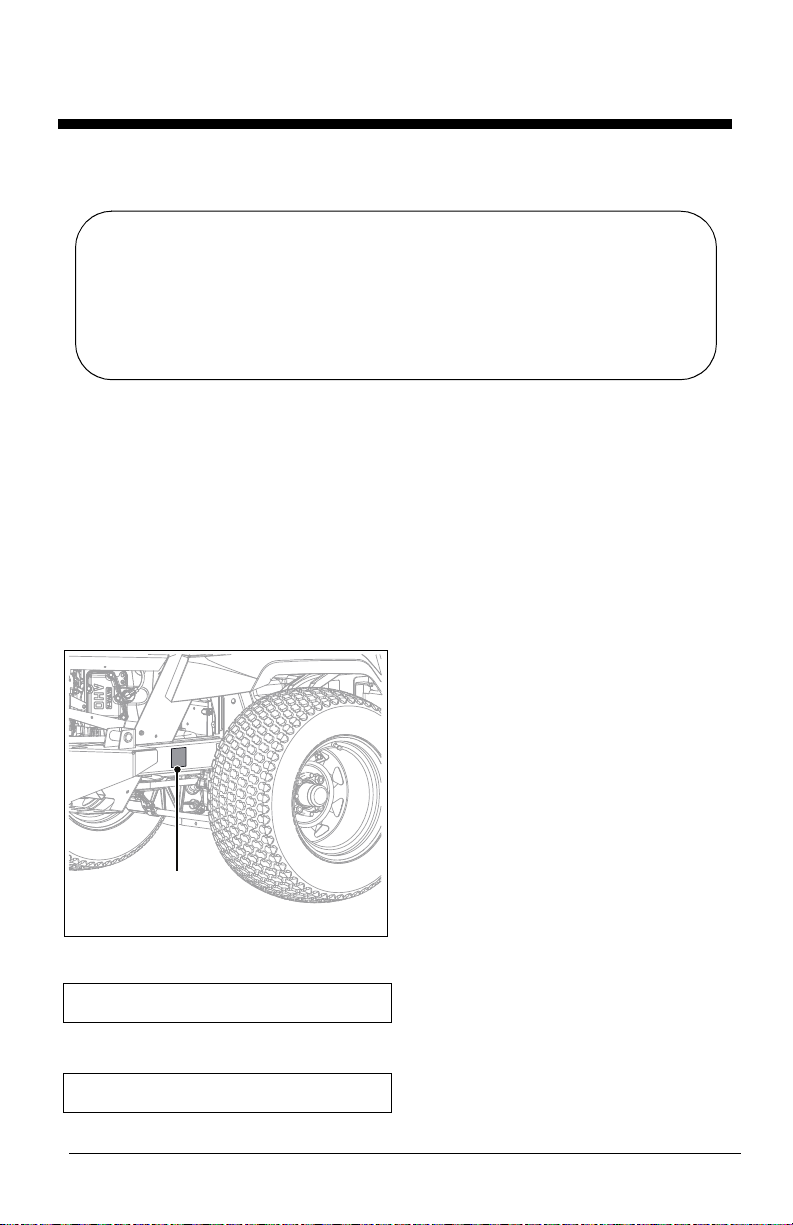

Figure 1

Model & Serial Number

Label

Congratulations on your purchase and welcome to the Ariens family! Every machine in the

Ariens lineup is designed for long-lasting and unsurpassed performance. We are confident your

machine will be part of your family for many years to come.

Have Questions or Need Assistance?

www.ariens.com

A service manual and parts manual for your unit are available for free download

or purchase at www.ariens.com.

REGISTER YOUR PRODUCT!

It is extremely important to register your

product at time of purchase. Product

registration activates the warranty and

establishes a communication link from

AriensCo.

Locate the model and serial number decal on

your unit and register those numbers online at

www.ariens.com. See Figure 1 for decal

location. Be aware that the original selling

dealer may have already completed product

registration on behalf of the original

purchaser.

Record model number here.

MANUALS

Before operating or servicing the unit, carefully

and completely read the manuals provided with

the unit. They contain safety instructions and

important information about unit controls.

The engine on this unit is covered by a

separate manual. Refer to the engine manual

for engine service recommendations. Contact

the engine manufacturer for a replacement

manual if necessary.

Your dealer must review important information

in this manual with you before or upon delivery

of the unit. It is your responsibility to read and

understand all safety precautions and

instructions in the manuals. If you do not

understand or have difficulty following the

instructions, contact your Ariens dealer for

assistance. To locate your nearest Ariens

dealer, go to www.ariens.com.

DISCLAIMER

Ariens reserves the right to discontinue, make

changes to, and add improvements upon its

products at any time without public notice or

obligation. The descriptions and specifications

contained in this manual were in effect at

printing. Equipment described in this manual

may be optional. Some illustrations may not be

applicable to your unit.

Record serial number here.

© 2022 • AriensCo • Brillion, WI 54110

EN - 1

Page 4

SAFETY

Read these safety rules and follow them

closely. Failure to follow these rules could

lead to loss of control of unit, severe personal

injury or death to you or bystanders, or result

in damage to property or the machine.

PRACTICES & LAWS

Practice usual and customary safe working

precautions. Learn applicable rules and laws

in your area. Always follow the practices set

forth in this manual.

EMISSION CONTROL SYSTEM

This equipment and/or its engine may include

exhaust and evaporative emissions control

system components required to meet U.S.

Environmental Protection Agency (EPA)

and/or California Air Resources Board

(CARB) regulations. Tampering with emission

controls and components by unauthorized

personnel may result in severe fines or

penalties. Emission controls and components

can only be adjusted by an Ariens dealer or

an authorized engine manufacturer's service

center. Contact your Ariens Equipment

Retailer concerning emission controls and

component questions.

REQUIRED OPERATOR TRAINING

Read and understand the

Operator's Manual and decals

on the unit. This information is

for your safety and the proper

use of your equipment.

Failure to follow these

instructions and warnings may cause death

or serious injury. If you have purchased this

product from an Ariens dealer, the dealer can

provide you with training.

Familiarize yourself and any other operators

with all controls and the safe use of the

features of this unit. If you loan, rent or sell

this product to others, provide them with all

manuals.

If you have any questions, please call our

customer support line at 920-756-4688 or

contact us at www.ariens.com. Do not use

this equipment if, after reading the Operator's

Manual and the on-board decals, you have

any questions about the safe use of this

product.

WARNING: AVOID INJURY.

This cutting machine is capable

of amputating hands and feet

and throwing objects. Failure to

observe the safety instructions

in the manuals and on decals

could result in serious injury or

death.

SAFETY ALERT SYMBOL

This is the safety alert symbol. It

means:

• ATTENTION!

• YOUR SAFETY IS

INVOLVED!

When you see this symbol:

• BECOME ALERT!

• OBEY THE MESSAGE!

SIGNAL WORDS

The safety alert symbol above and signal

words below are used on decals and in this

manual. Read and understand all safety

messages.

1. Danger

DANGER: Indicates an

IMMINENTLY HAZARDOUS

SITUATION! If not avoided,

WILL RESULT in death or

serious injury.

2. Warning

WARNING: Indicates a

POTENTIALLY HAZARDOUS

SITUATION! If not avoided,

COULD RESULT in death or

serious injury.

3. Caution

CAUTION: Indicates a

POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY

RESULT in minor or moderate injury. It may also be used to alert

against unsafe practices.

4. Notice

NOTICE: Indicates information or procedures

that are considered important but not hazard

related. If not avoided property damage could

result.

EN - 2

Page 5

5. Important

KEEP HANDS and FEET AWAY

02

9

8

81

0

0

07800537

P

07800820

MAX. FILL

07801836

07801836

07801735

07801735

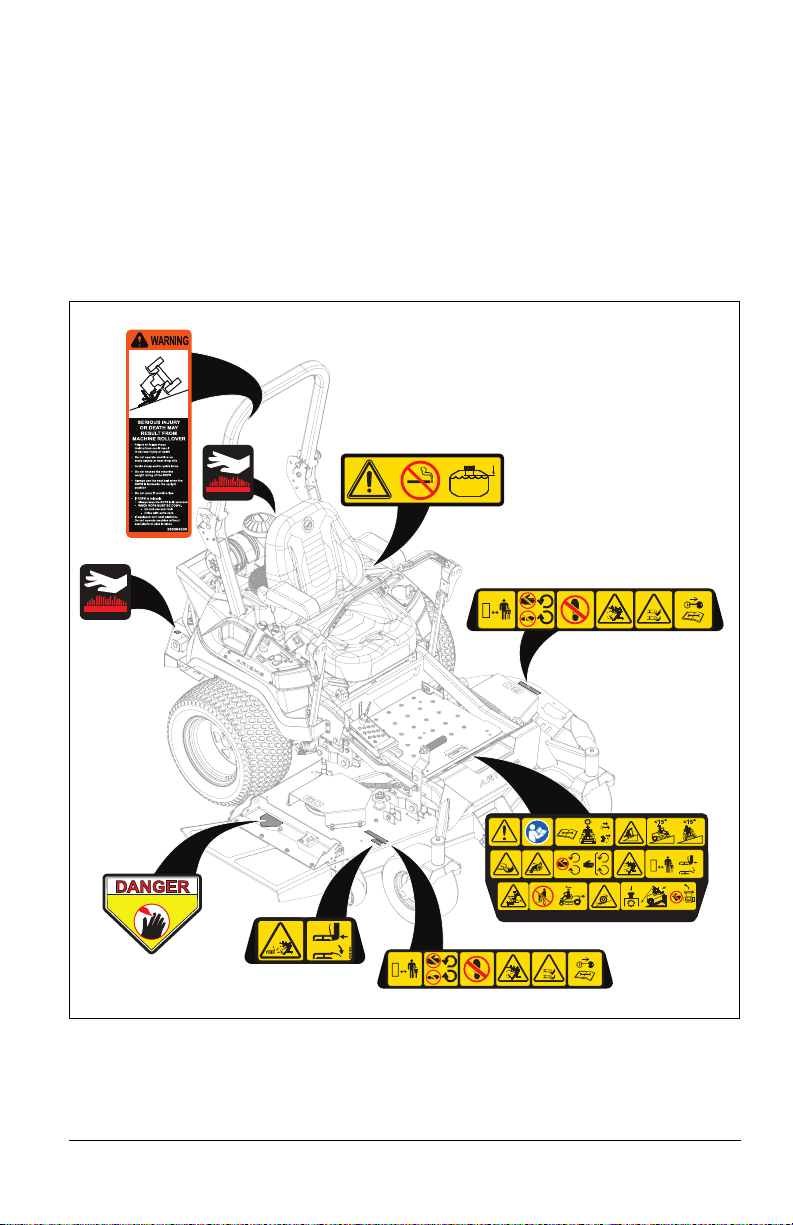

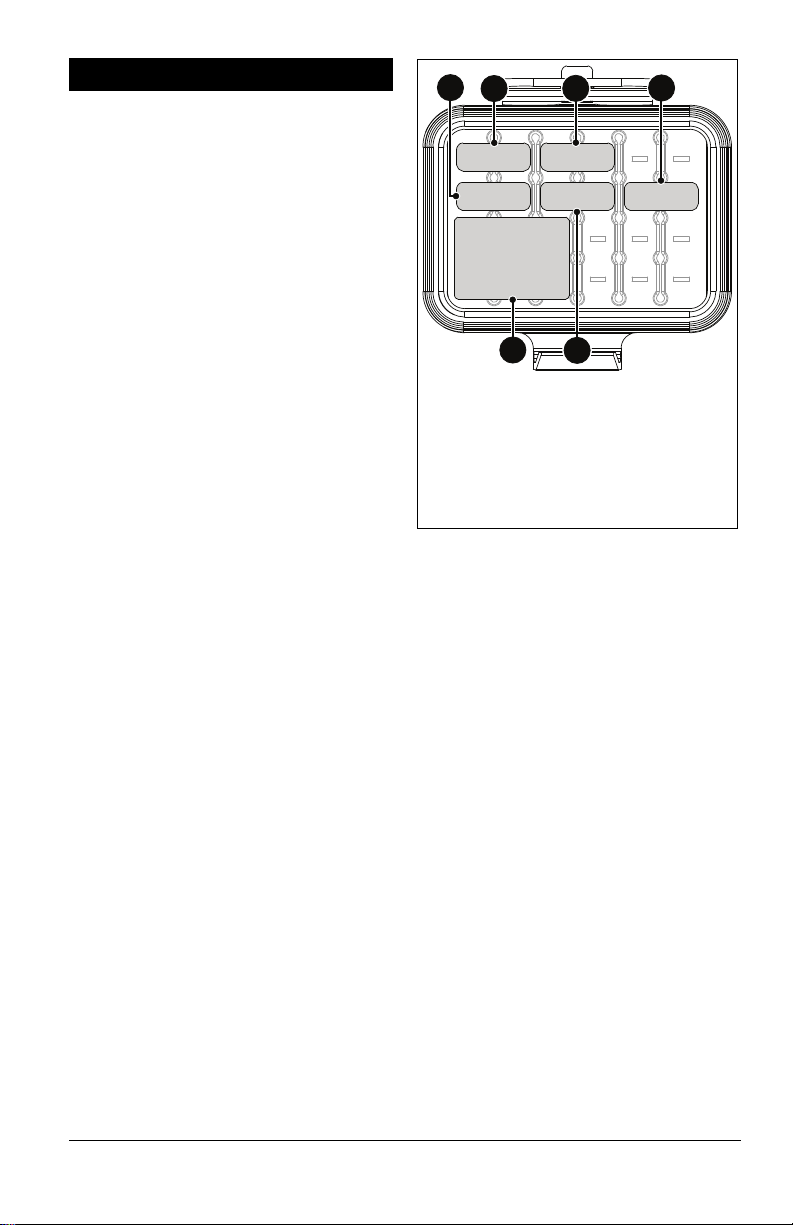

Figure 2

1

4

5

5

6

3

2

2

7

(Model 991158)

IMPORTANT: Indicates general reference

information worthy of special attention.

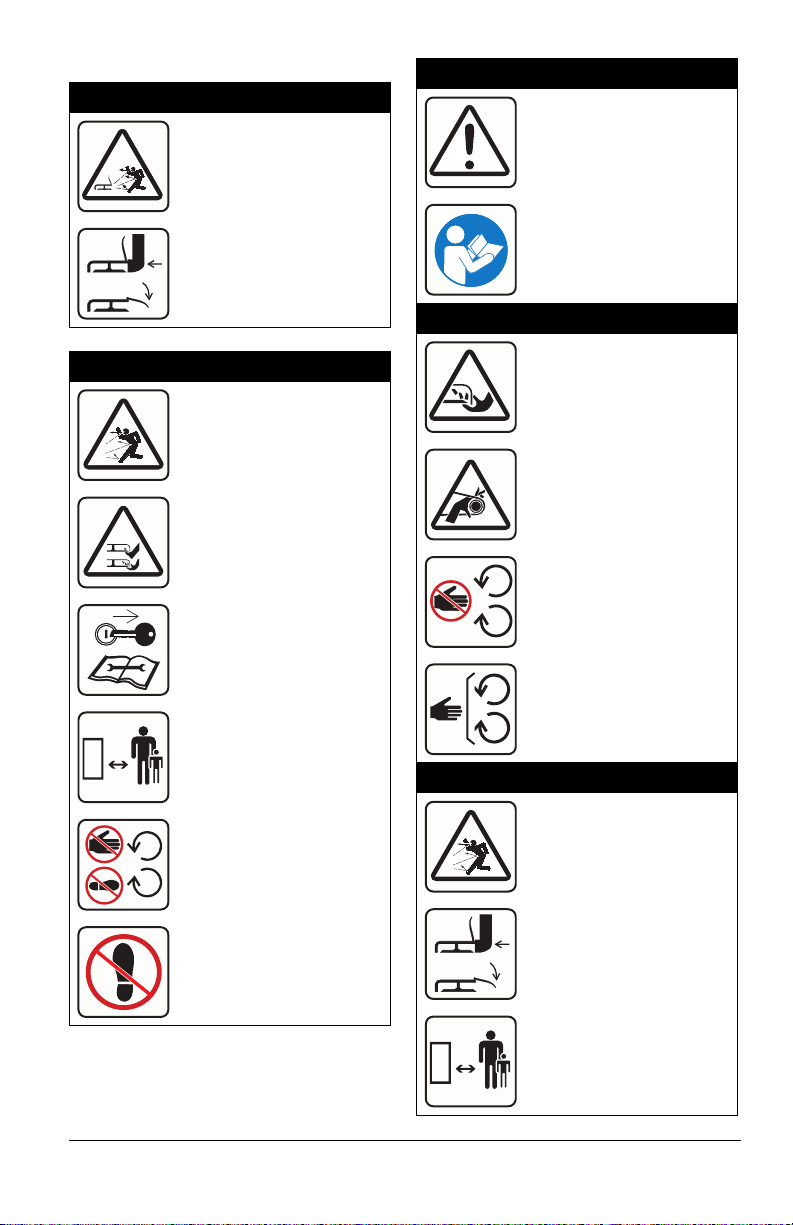

SAFETY DECALS

The safety decals on your machine are visual

reminders of the important safety information

in this manual. All messages on your unit

must be fully understood and carefully

followed. Safety decals on the machine are

explained below.

Safety Decal Locations

ALWAYS replace missing or damaged safety

decals. Replacement decal part numbers are

found in the parts manual for your machine

and may be ordered from your dealer.

See Figure 2 for safety decal locations.

EN - 3

Page 6

Safety Decal Descriptions

1. DANGER!

Discharge Hazard NEVER operate unit

without discharge chute in

operating position. Thrown

objects can cause injury or

damage.

DO NOT operate mower

unless all guards are in

operating position or

bagger is attached.

3. DANGER!

DANGER!

Read and understand the

operator’s manual before

operating unit.

3. Amputation Hazard

2. DANGER!

Discharge Hazard - NEVER

direct discharge toward

people, pets or property.

Thrown objects can cause

injury or damage.

Amputation Hazard NEVER stick hands or feet

under deck or shielded

areas.

Shut off engine, remove key,

and read manual before

servicing or making

adjustments to unit.

Keep children and others

away from unit while unit is

in operation.

Keep feet and hands away

from all rotating or moving

parts.

DO NOT step or stand in

this area.

To avoid amputation hazard

DO NOT put hands near

rotating blades.

To avoid amputation hazard

DO NOT put hands near

moving belts.

Keep hands away from all

rotating or moving parts.

Keep all guards and shields

in place.

3. Discharge Hazard

Discharge Hazard - NEVER

direct discharge toward

people, pets or property.

Thrown objects can cause

injury or damage.

DO NOT operate mower

unless all guards are in

operating position or bagger

is attached.

EN - 4

Keep children and others

away from unit while unit is

in operation.

Page 7

3. Tipping Hazard

Avoid tipping hazard.

Look behind when operating

the unit in reverse.

3. Loss of Traction Hazard

15

DO NOT operate on slopes

over 15°.

15

DO NOT operate on slopes

over 15°.

3. Service Hazard

Before servicing unit do the

following:

Read owners manual before

servicing or making

adjustments to unit.

P

Set parking brake.

Remove key and disconnect

spark plug before servicing

or making adjustments to

unit.

3. Bystander Hazard

If loss of traction is

experienced do the

following:

Disengage PTO.

Proceed off slope slowly.

DO NOT try to turn or speed

up.

4. DANGER!

ALWAYS keep hands and

feet away from discharge

chute.

5. HOT PARTS!

DO NOT touch parts which

are hot from operation.

ALWAYS allow parts to cool.

DO NOT operate the unit in

the presence of bystanders.

DO NOT carry passengers.

EN - 5

Page 8

6. DANGER!

7. WARNING! (MODEL 991158)

DANGER!

No smoking.

MAX. FILL

IMPORTANT: DO NOT

overfill. Fill fuel tank to

below bottom of filler neck.

WARNING: Overfilling may cause severe

damage to evaporative system!

• NEVER fill fuel tank when engine is

running, hot or unit is indoors. NEVER

overfill fuel tank.

• Replace fuel cap securely and clean up

spilled fuel.

SERIOUS INJURY OR

DEATH may result from

machine rollover.

• Failure to follow these instructions could

result in serious injury or death.

• DO NOT operate machine on steep

slopes or near drop offs.

• Avoid sharp and/or quick turns.

• DO NOT exceed the machine weight

rating of the ROPS.

• ALWAYS use the seat belt when the

ROPS is locked in the upright position.

• DO NOT jump if machine tips.

• If ROPS is foldable:

— ALWAYS keep the ROPS fully

extended.

— WHEN ROPS MUST BE DOWN:

- DO NOT use seat belt.

- Drive with extra care.

• If equipped with seat platform:

— DO NOT operate machine without

seat platform pins in place or locks

engaged.

ROLLOVER PROTECTIVE STRUCTURE

To maintain operator protection and roll bar

certification:

• Replace a damaged roll bar, DO NOT

attempt to repair or modify.

• Any alteration of the roll bar must be

approved by the manufacturer.

• DO NOT exceed the machine weight

rating of the roll bar.

EN - 6

Page 9

SAFETY INSTRUCTIONS

The following safety instructions are based

on the B71.1 specifications of the American

National Standards Institute and ISO 5395 in

effect at the time of production.

Safe Practices for Ride-On Mowers

If used improperly, this machine is capable of

amputating hands and feet and throwing

objects. Failure to observe the following

safety instructions could result in serious

injury or death. Use only for purposes

intended as set forth in the Operator's

Manual. Other use is improper and may

cause serious injury or death.

General Information

Read, understand, and follow instructions

and warnings in this manual and on the

machine, engine and attachments.

Only allow operators, who are responsible,

trained, familiar with the instructions, and

physically capable to operate the machine.

DO NOT carry passengers and keep people

or pets away from the mowing area.

DO NOT operate the machine while

physically or mentally impaired, feeling tired,

ill or under the influence of alcohol or drugs.

Follow the manufacturer’s recommendation

for wheel weights or counterweights.

DO NOT touch parts which are hot. Allow

parts to cool.

Preparation Before Operating

Inspect unit before each use for missing or

damaged decals and shields, correctly

operating safety interlock system, ROPS

and deterioration of grass catchers. Replace

or repair as needed.

Clear the operating area of all objects which

could be thrown by or interfere with

operation of the machine.

Keep the area of operation clear of all

bystanders, particularly small children. Stop

the machine and attachment(s) if anyone

enters the area.

DO NOT operate the machine without the

entire grass catcher, discharge chute, or

other safety devices in place and functioning

properly. Check frequently for signs of

damage, wear or deterioration and replace

as needed.

NEVER tamper with safety devices. Check

their proper operation regularly. NEVER do

anything to interfere with the intended

function of a safety device or to reduce the

protection provided by the safety device.

Check parking brake operation frequently.

Adjust and service as required.

Wear appropriate personal protective

equipment such as safety glasses, hearing

protection, and substantial footwear. DO

NOT mow barefoot or while wearing

sandals.

Operating

Improper use of power equipment can cause

serious permanent injury or death to the

operator or a bystander. Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an emergency

• Braking and steering characteristics

• Turning radius and clearances

If the operator or the mechanic cannot read

the manual, it is the owner’s responsibility to

explain it to them.Manuals are available in

other languages at www.ariens.com.

Only run the engine in well ventilated areas.

Exhaust gases contain carbon monoxide, an

odorless deadly poison.

Only operate the machine in daylight or

good artificial light.

Avoid holes, ruts, bumps, rocks and other

hazards. Uneven terrain could overturn the

machine, or cause operator to lose their

balance, footing and/or control of the mower.

DO NOT put hands or feet near rotating

parts or under the machine. Keep clear of

the discharge opening at all times.

Avoid slippery surfaces. ALWAYS be sure of

your footing.

Stop engine before removing grass catcher

or unclogging chute.

DO NOT direct discharge material toward

anyone. Avoid discharging material against

a wall or obstruction. Material may ricochet

back toward the operator. Stop the blade(s)

when crossing gravel surfaces. DO NOT

mow into roads or across sidewalks.

EN - 7

Page 10

DO NOT leave a running machine

unattended. ALWAYS park on level ground,

disengage the attachment, set parking

brake, stop engine and remove key (if

applicable) before leaving the operator's

position.

DO NOT mow in reverse unless absolutely

necessary. ALWAYS look down and behind

before and while backing.

Lightning can cause severe injury or death.

If lightning is seen or thunder is heard in the

area, DO NOT operate the machine; seek

shelter.

If you strike a foreign object, stop and

inspect the machine. Repair, if necessary,

before restarting.

ALWAYS check overhead and side

clearances carefully before operation. Keep

in mind that your mower deck may be wider

than your track width.

Children Specific

Tragic accidents can occur if the operator is

not alert to the presence of children.

Children are often attracted to the machine

and the mowing activity. NEVER assume

that children will remain where you last saw

them.

Keep children out of the operating area and

under the watchful care of a responsible

adult other than the operator.

Do not carry children, even with the blade(s)

shut off. Children could fall off and be

seriously injured or interfere with safe

machine operation. Children who have been

given rides in the past could suddenly

appear in the mowing area for another ride

and be run over or backed over.

DO NOT allow children under the age of 18

to operate any outdoor power equipment.

Slope Specific

Slopes are a major factor related to

accidents. Operation on slopes requires

extra caution. If you feel uneasy on a slope

DO NOT mow it. Use the parking brake for

emergency stops.

DO Not operate on slopes of more than 15°.

Do not mow within 1.2 M (4 feet) of a drop

off. Do not mow within 1.2 M (4 feet) of a

pond or other waterway.

The primary hazard of slope operation is

loss of control and/or roll over.

Mow up and down slopes, NEVER across.

Exercise caution when changing direction

on slopes. Use caution while operating near

dropoffs.

Avoid mowing wet grass. Wet surfaces can

cause a loss of traction and control.

DO NOT operate machine under any

condition where traction, steering, or stability

is in question. Tires could slide even if the

wheels are stopped.

Always keep the machine in gear when

going down slopes. Do not coast downhill.

Avoid starting and stopping on slopes. Avoid

making sudden changes in speed or

direction. Make turns slowly and gradually.

Use extra care while operating machine with

a grass catcher or other attachment(s). They

can affect the stability of the machine.

Fire and Fuel Specific

Extinguish all cigarettes, cigars, pipes and

other sources of ignition.

Use only an approved fuel container.

DO NOT remove fuel cap or add fuel with

the engine running or while hot.

DO NOT refuel indoors or in enclosed

spaces.

DO NOT store the machine or fuel container,

or refuel, where there is an open flame,

spark, or pilot light such as on a water

heater or other appliance.

If fuel is spilled, DO NOT attempt to start the

engine and avoid creating any source of

ignition until fuel vapors have dissipated.

To help prevent fires: keep machine free of

grass, leaves, or other debris build up; clean

up oil or fuel spillage and remove any fuel

soaked debris; allow engine to cool before

storing.

Use extra care in handling gasoline and

other fuels. They are flammable and vapors

are explosive.

Hauling

Use a single full-width ramp for loading and

unloading a machine for transport. Secure

with appropriate straps.

Towing

Follow the manufacturer’s recommendation

for weight limits for towed equipment and

towing on slopes.

EN - 8

Page 11

ROPS (Model 991158)

The ROPS is an integral safety device. Do

not remove or alter the ROPS.

Keep a folding ROPS in the raised and

locked position and use the seat belt when

operating the machine.

Lower a folding ROPS temporarily only

when absolutely necessary. Do not wear the

seat belt when folded down. There is no

rollover protection when a folding ROPS is

in the down position.

Frequently inspect the ROPS and the

seatbelt for damage. Replace a damaged

ROPS. Do not repair or alter.

Service

Keep machine in good working order.

Replace worn or damaged parts.

Use caution when servicing blades. Wrap

the blade(s) or wear gloves. Replace

damaged blades. DO NOT repair or alter

blade(s).

Disconnect spark plug wire(s) and the

negative battery cable before making any

repairs.

Use only attachments recommended by

AriensCo that are appropriate to your use

and can be used safely in your application.

The use of non-genuine replacement parts

or accessories could adversely affect

machine operation and safety.

DO NOT change engine governor setting or

overspeed the engine.

EN - 9

Page 12

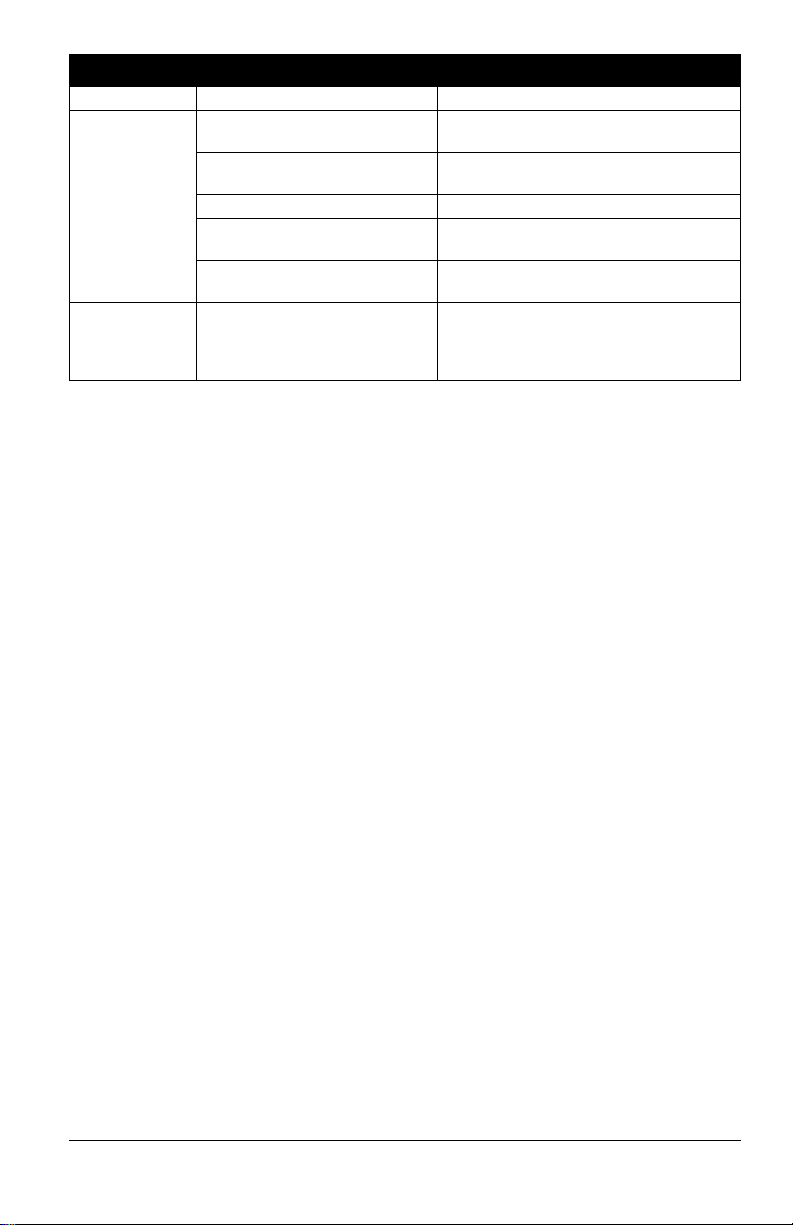

CONTROLS AND FEATURES

Figure 3

12

15

10

18

3

20

4

21

5

19

11

1

9

14

25

6

23

7

8

24

2

17

13

Model 991158

3

4

5

6

22

Model 991161

Models 991159, 991163

3

4

5

6

16

26

EN - 10

Page 13

1. Fuel Tank and Cap

2. Fuel Level Window

3. Oil Filter

4. Oil Drain

5. Engine Oil Dipstick

6. Air Filter

7. Ignition Key

8. Choke Control Knob

9. Throttle Control Lever

10. Power Take-off (PTO) Knob

11. Hour Meter

12. Height-of-Cut Adjustment System

13. Transport Lock Release Lever

14. Deck Lift Pedal

15. Seat Adjustment Lever

16. Seat Latch (Model 991158)

17. Parking Brake Lever

18. Belt Cover (2)

19. Steering Lever (2)

20. Discharge Chute

21. Anti-Scalp Wheel (6)

22. Transaxle Bypass Lever (2)

23. Battery (Under Seat)

24. Fuse Box

25. Hydraulic Oil Expansion Tank (2)

26. Rollover Protection Structure (ROPS)

(Model 991158)

EN - 11

Page 14

WAR NING: AVOID INJURY.

Figure 4

Off

Start

On

Figure 5

Choke On

Choke Off

Figure 6

Fast

Slow

Figure 7

Blades Off

Blades On

Read and understand the

entire Safety section before

proceeding.

See Figure 3 for all controls and features

locations.

IGNITION KEY

See Figure 4.

Controls power to the engine. The key cannot

be removed when in run position.

CHOKE CONTROL KNOB

See Figure 5.

Controls airflow to the engine.

THROTTLE CONTROL LEVER

See Figure 6.

Controls engine speed.

POWER-TAKE-OFF (PTO) KNOB

See Figure 7.

Controls power to mower blades. The engine

will not start with the PTO knob in the on

position.

WARNING: AVOID INJURY.

Blades will not immediately

stop after pushing PTO knob

down to off position.

HOUR METER

Measures engine runtime and cannot be

reset.

HEIGHT-OF-CUT ADJUSTMENT SYSTEM

Sets the height of cut.

EN - 12

Page 15

TRANSPORT LOCK RELEASE

Figure 8

Figure 9

Parking Brake

Engaged (On)

Brake Released

(Off)

LEVER

See Figure 8.

Releases deck from transport lock position.

DECK LIFT PEDAL

Raises mower deck to change height-of-cut

setting.

SEAT ADJUSTMENT LEVER

Unlocks seat to allow operator to move seat

forward or backward and then lock in desired

position.

PARKING BRAKE LEVER

See Figure 9.

Controls the parking brake. The engine will

not start with brake in the off position.

ROLLOVER PROTECTION STRUCTURE (ROPS)

Help protect operator that is wearing their

seatbelt in the event of a rollover. DO NOT

wear seatbelt when operating with ROPS in

the lowered position.

SAFETY INTERLOCK SYSTEM

Monitors the interaction of various unit

features for operator safety.

STEERING LEVERS

Control the direction and speed of unit. To

stop unit, return both steering levers to

neutral.

TRANSAXLE BYPASS LEVERS

Control the transaxles so unit may be moved

with the engine off.

ANTI-SCALP WHEEL

Help prevent the deck from contacting the

ground and scalping the lawn when passing

over a high spot.

EN - 13

Page 16

OPERATION

Figure 10

1. Deck Lift Pedal

2. Height-of-Cut Adjustment System

1

2

WAR NING: AVOID INJURY.

Read and understand the

Safety section before

proceeding.

IMPORTANT: All references to left, right, front

or rear are given from the perspective of

operator in operator’s position, facing the

direction of forward travel.

EMERGENCY STOPPING

1. Move steering levers to neutral position.

2. Engage parking brake.

3. Push PTO knob down to off position.

4. Turn ignition key to off position and

remove key from ignition.

BEFORE OPERATING UNIT

1. Check fuel level and add fuel if needed.

IMPORTANT: Use fresh unleaded fuel with

an octane rating of at least 87. DO NOT use

E85 blended fuels; the engine is not E20 /

E30 / E85 compatible. The maximum

recommended ethanol content is 10%. Ariens

recommends using a quality fuel stabilizer in

all fuel. See Short-Term Storage on page 28.

2. Check engine oil level and add oil if

needed. Refer to engine manual.

3. Check condition of air cleaner. Refer to

engine manual.

4. Check function of the Safety Interlock

System by performing the tests in Check

Safety Interlock System on page 19.

Contact your Ariens dealer for repair if

any of the tests fail.

5. Set cutting height. See Figure 10.

a. Push mower lift pedal forward until

transport lock engages.

b. Insert adjustment pin through desired

setting in height-of-cut adjustment

system.

c. Push mower lift pedal slightly forward,

release transport lock and slowly

release pedal until it contacts

adjustment pin and stops.

EN - 14

Page 17

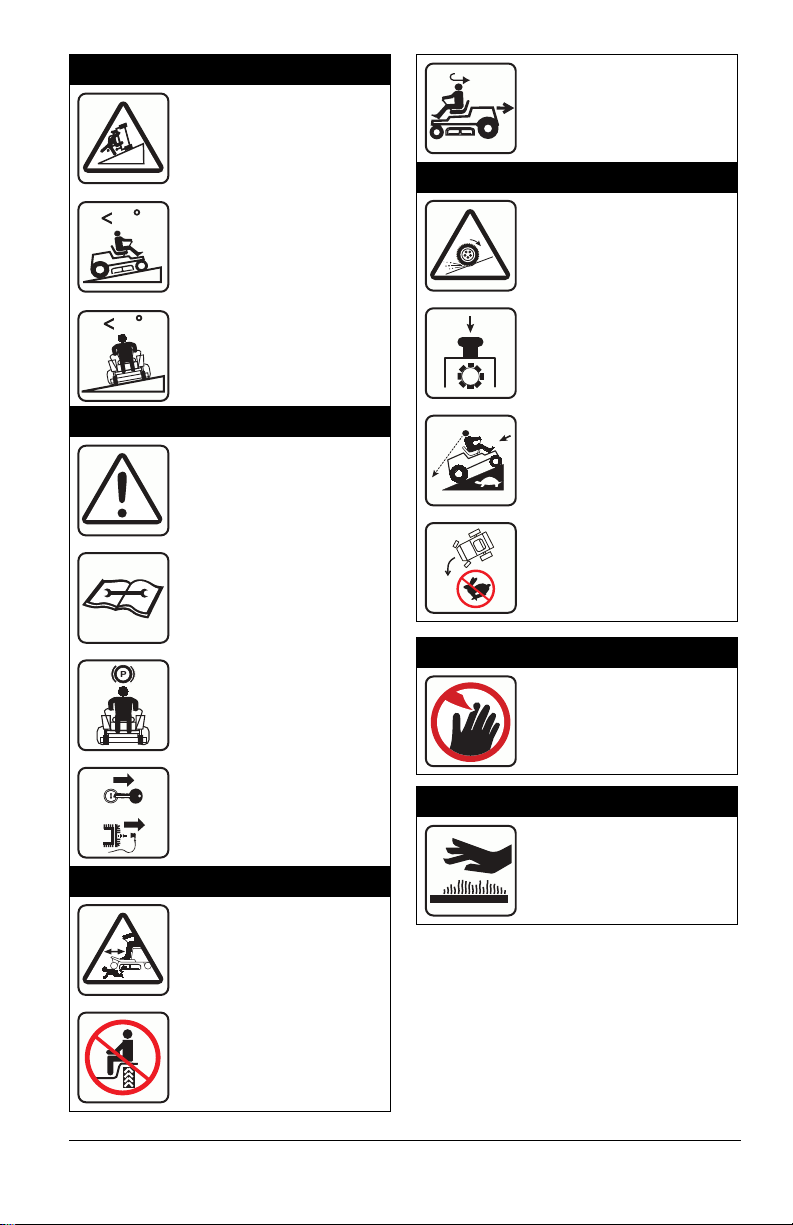

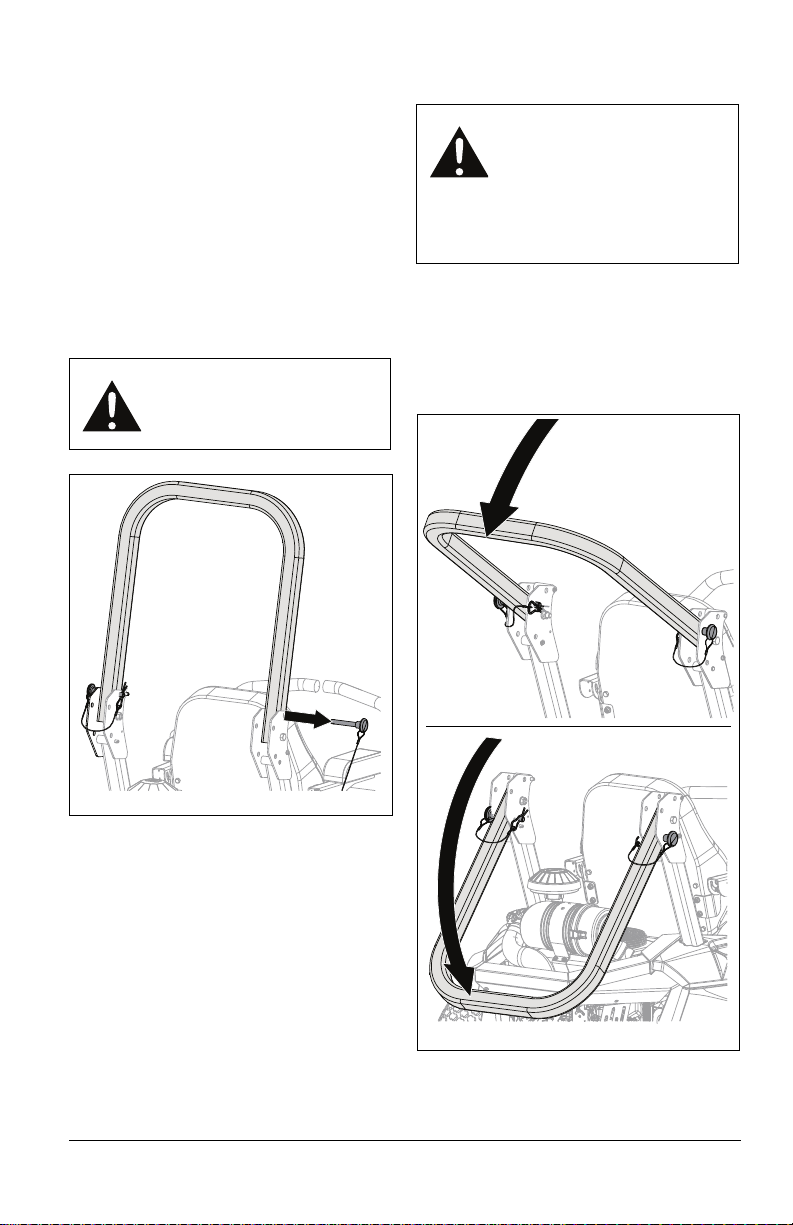

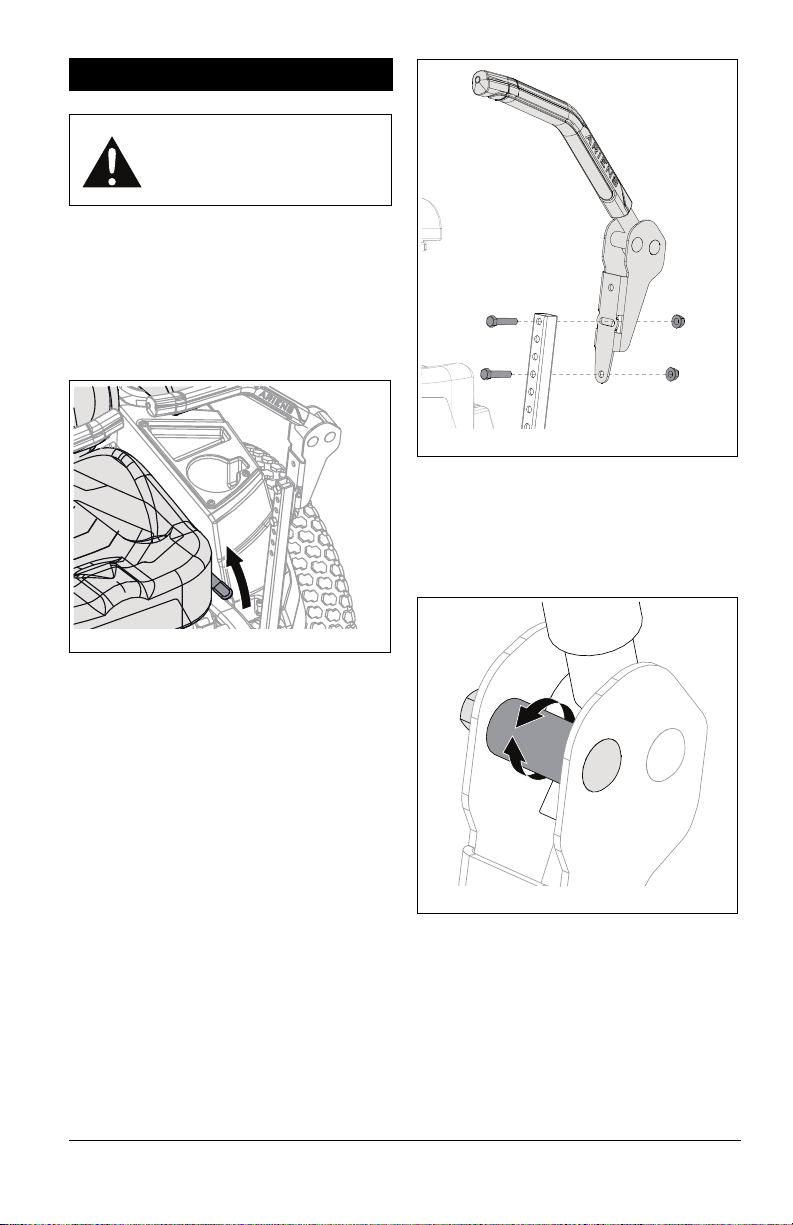

POSITION ROPS

Figure 11

Figure 12

Lowered Position With

Bagger Installed

Lowered Position With

No Bagger Installed

Model 991158

IMPORTANT: Models 991159, 991161,

991163: An optional rollover protection

structure (ROPS) is available for this unit.

See Accessories on page 28.

IMPORTANT: Inspect ROPS and seatbelt for

damage and loose or missing hardware.

Raise Center Bar

See Figure 11.

1. Remove hairpins from lock pins and

remove lock pins from hinge plate.

2. Raise center bar and secure with lock

pins and hairpins.

WAR NING: AVOID INJURY.

Seatbelt MUST be worn when

operating with center bar

raised.

Lower Center Bar

See Figure 12.

WARNING: AVOID INJURY.

Lower the center bar only

when needed to drive under

an object. There is no rollover

protection with the center bar

in the lowered position. DO

NOT wear seatbelt when

ROPS is in lowered position.

1. Remove hairpins from lock pins and

remove lock pins from hinge plate.

2. Lower center bar and secure with lock

pins and hairpins.

IMPORTANT: Return center bar to the raised

position when clear of obstacles.

EN - 15

Page 18

START THE ENGINE

1. Push PTO knob down to off position.

2. Move steering levers to neutral position.

3. Engage parking brake.

4. If engine is cold, pull choke knob up to on

position. If engine is warm or hot, turn

choke off.

5. Set throttle to slow speed.

6. Insert ignition key and turn to start

position. Release key when engine starts.

IMPORTANT: Do not operate the starter for

more than 10 seconds at a time. If the engine

does not start, allow a 60-second cool down

period between starting attempts.

7. If choke is on, wait a few seconds after

engine starts and then push choke knob

down to off position.

IMPORTANT: Make sure choke is completely

off. Engine will not run smoothly using partial

choke.

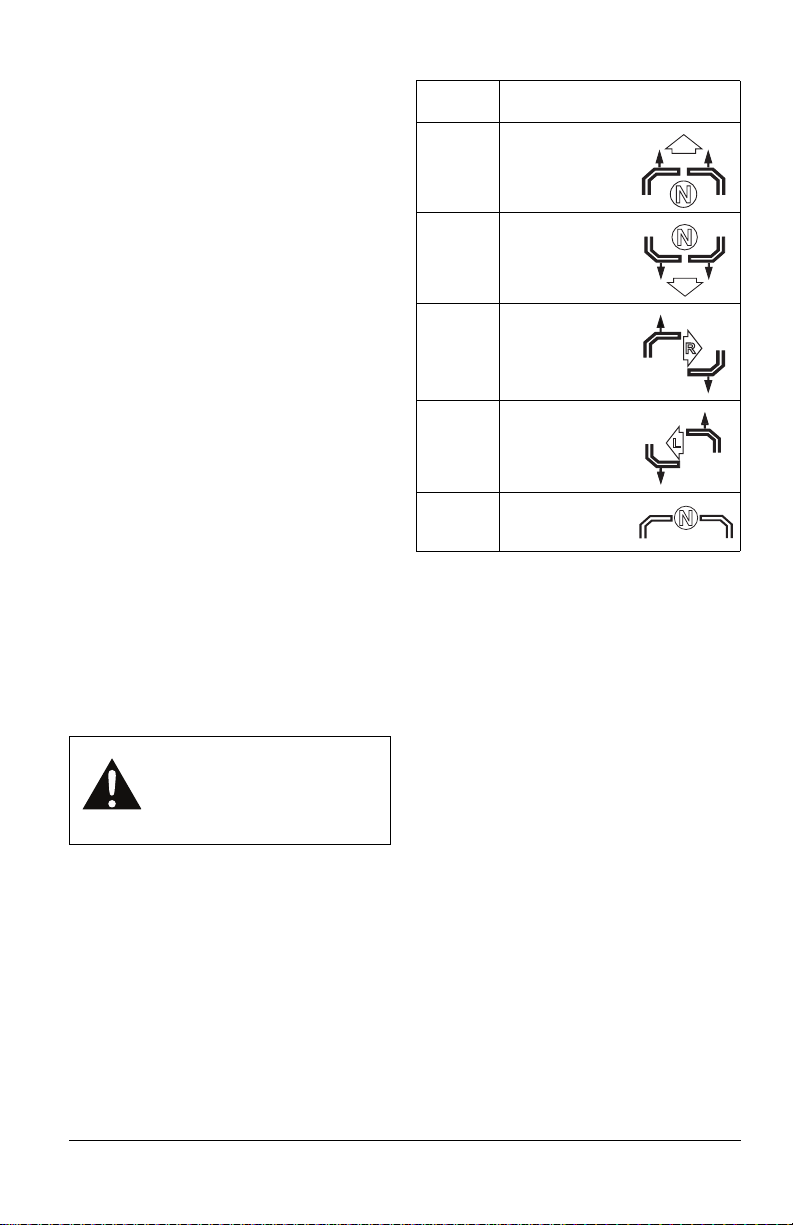

4. Move steering levers to begin mowing.

Direction

of Travel

Forward Push both levers

Reverse Pull both levers

Right Turn Push left lever

Left Turn Push right lever

Lever Position

forward from

neutral position.

backward from

neutral position.

farther forward

than the right

lever.

farther forward

than the left lever.

OPERATE UNIT

1. Release parking brake.

2. Set throttle control lever to fast position.

IMPORTANT: Engaging the PTO knob with

the throttle lever set lower than fast position

can cause excessive belt wear. ALWAYS use

fast position when engaging the PTO.

3. Pull PTO knob up to on position.

IMPORTANT: Never engage the PTO if the

mower is plugged with grass or other

material. This may cause damage to the

electric clutch.

WAR NING: AVOID INJURY.

Move the steering levers

slowly and keep the throttle at

slow speed until you learn how

to operate the unit.

Stop Return both

levers to neutral

position.

IMPORTANT: Aggressive turning can scuff or

damage lawns. Always keep both wheels

rotating when making sharp turns. DO NOT

make turns with inside wheel completely

stopped. For minimum turning radius, slowly

reverse inside wheel while moving outside

wheel slowly forward.

For Best Mowing Results

• Cut grass when it is dry.

• Keep mower blades sharp.

• Keep mower deck properly leveled.

• Do not set height of cut too low. For very

tall grass, mow twice.

• Do not travel too fast.

• Mow with the engine set at full throttle.

• When mulching, only remove 1/3 of grass

length per cutting. Do not cut more than

2.5 cm (1") at any one time.

• Discharge clippings into areas already cut.

• Vary cutting pattern with each mowing.

• Do not allow grass or debris to collect

inside of mower deck. Clean after each

use.

EN - 16

Page 19

STOP THE ENGINE

Figure 13

Figure 14

WAR NING: AVOID INJURY.

Wait for all moving parts to

stop before leaving operator’s

position.

1. Move steering levers to neutral position

and rotate outward.

2. Engage parking brake.

3. Push PTO knob down to off position.

4. Set throttle to slow speed.

5. Turn ignition key to off position and

remove key from ignition.

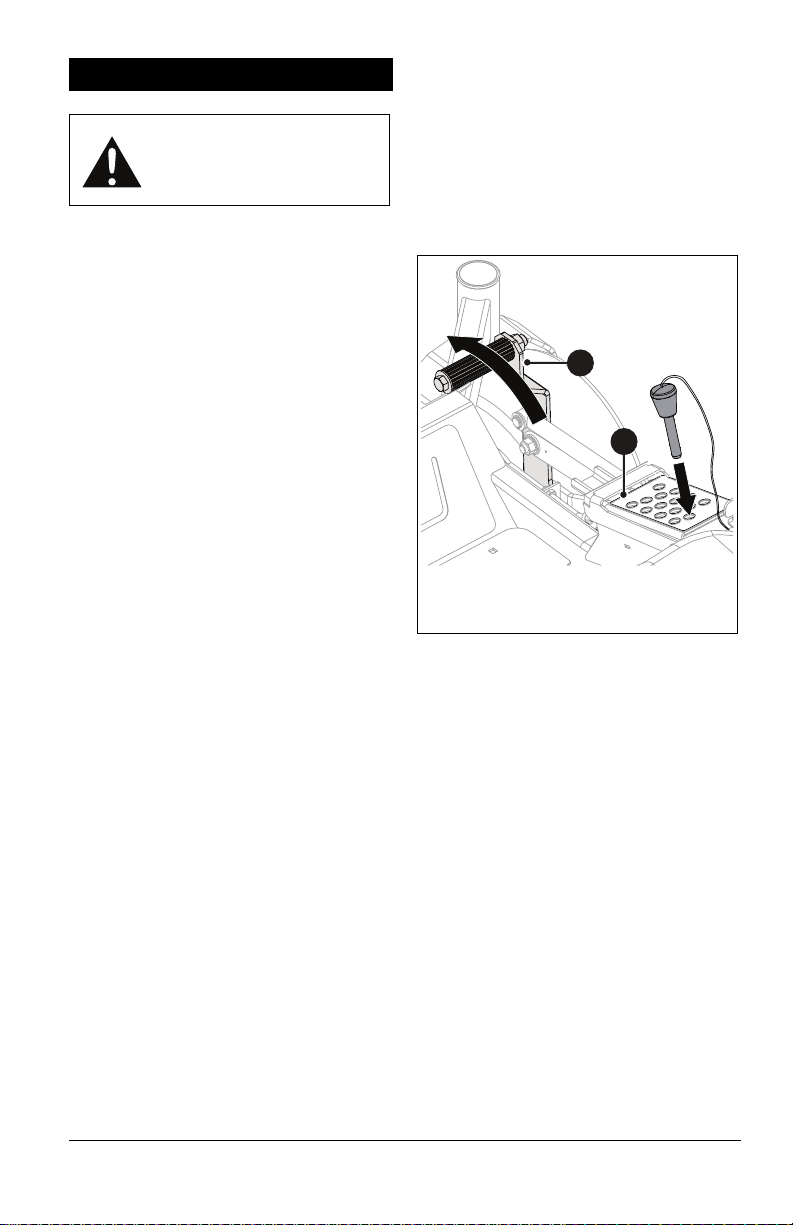

MOVE UNIT MANUALLY

Bypass the transaxles to move the unit with

the engine off.

IMPORTANT: There is one transaxle bypass

lever on each side of unit. Ensure that both

levers are fully in front or rear position.

1. Stop engine, remove key and wait for

moving parts to stop and for hot parts to

cool.

2. Pull both transaxle bypass levers out into

bypass position. See Figure 13.

3. Release parking brake and push unit to

desired location.

4. Engage parking brake.

5. Return transaxle bypass levers to

operating position. See Figure 14.

TRANSPORT UNIT

1. Push deck lift pedal completely forward to

engage transport lock. Release pedal.

2. Move unit to transport vehicle.

3. Stop engine, engage parking brake and

remove key from ignition.

4. Secure mower frame to transport vehicle.

NOTICE: NEVER secure unit to vehicle from

rods or linkages that could be damaged.

RELEASE TRANSPORT LOCK

1. Push deck lift pedal forward and lift

transport lock release lever.

2. Slowly return mower lift pedal to resting

position.

EN - 17

Page 20

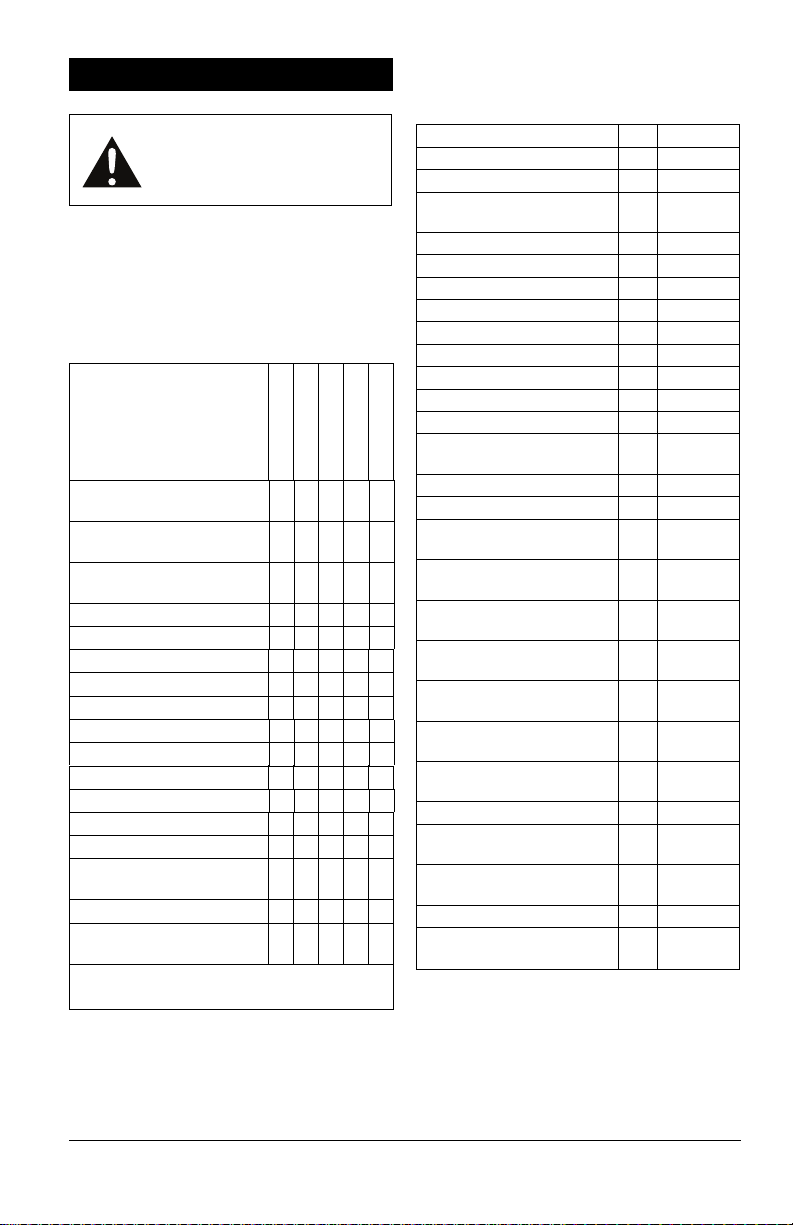

MAINTENANCE

WAR NING: AVOID INJURY.

Read and understand the

Safety section before

proceeding.

Your Ariens dealer can provide service and

adjustments to keep your unit operating at

peak efficiency.

Contact an authorized engine manufacturer’s

service center for engine service.

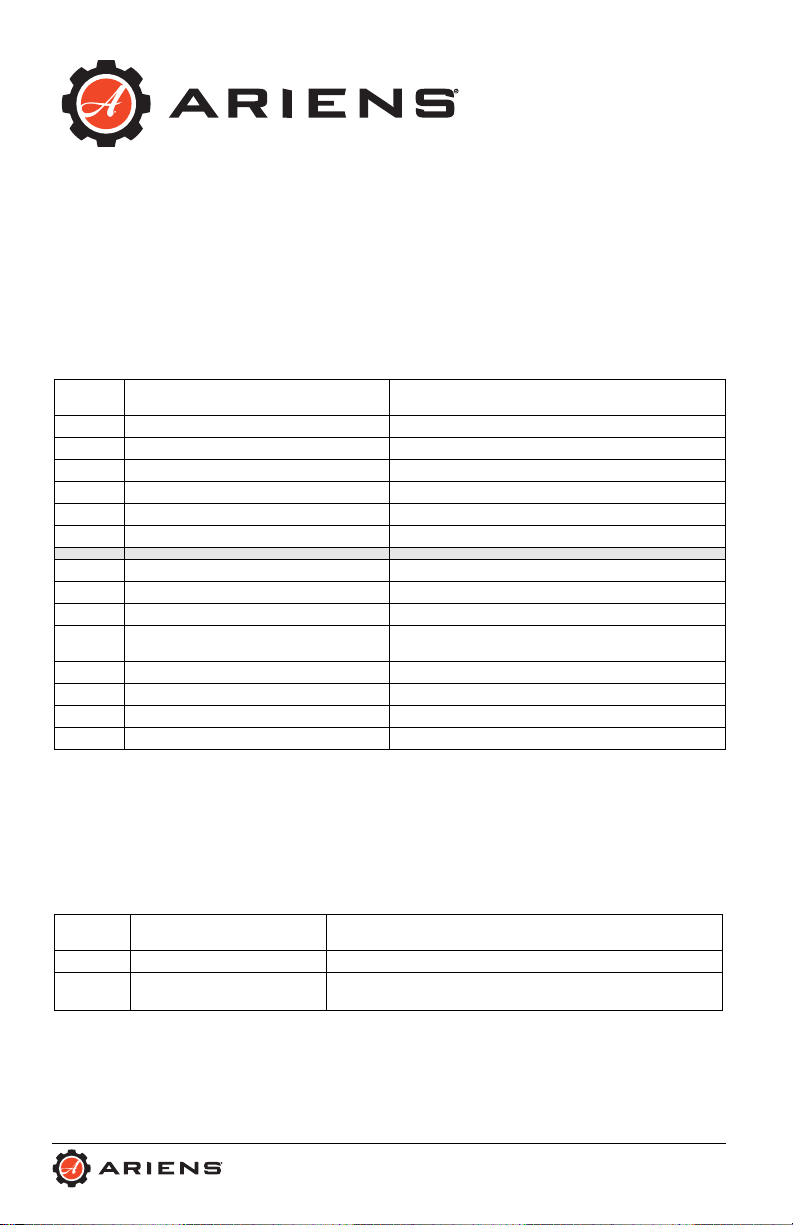

MAINTENANCE SCHEDULE

Service Performed

Clean Engine of Any Grass

or Debris

Clean Mower Deck of Any

Grass or Debris

Check Safety Interlock

System

Check Hydraulic System •

Check Parking Brake •

Check Engine Oil * •

Change Engine Oil *

Check Tire Pressure •

Check Mower Blades •

Check Battery •

Clean Battery •

Check Air Filter * •

Check Fasteners •

Lubricate Unit •

Clean Engine Cooling

System*

Check Belts •

Change Hydraulic Oil and

Filter **

* Refer to engine manual for instructions

** Change after first 75 hours of operation

Each Use

•

•

•

Every 25 hrs.

Every 50 hrs.

Every 100 hrs.

•

SERVICE PARTS

See your Ariens dealer to purchase service

parts for your unit.

Description Qty. Part No.

Transaxle Drive Belt 1 07225600

Mower Belt – Left 44" 1 07200814

Mower Belt – Right

44" & 48"

Mower Belt – Left 48" 1 07200815

Mower Belt – Left 52" 1 07200816

Mower Belt – Right 52" 1 07200806

Mower Belt – Left 60" 1 07200817

Mower Belt – Right 60" 1 07200807

Mower Blade – 44" & 48" 3 00450200

Mower Blade – 52" 3 03253800

Mower Blade – 60" 3 03253900

Seat Switch 1 03654200

Hydraulic Oil – 32 oz

(1 Qt.)

Every 400 hrs.

Hydraulic Oil Filter 2 21545100

Fuel Filter (Model 991161) 1 21541500

Fuel Filter (Models 991158,

991159, 991163)

Engine Oil Filter (Model

991158)

Engine Oil Filter (Model

991161)

Engine Oil Filter (Models

991159, 991163)

Pre-Cleaner (Model

991161)

Air Filter – Inner Element

(Model 991158)

Air Filter – Outer Element

(Model 991158)

Air Filter (Model 991161) 1 21555500

Muffler Gasket (Models

991158, 991159, 991163)

Muffler Gasket (Model

991161)

Relay 1 04438400

Fuel Stabilizer – 118 ml

•

(4 oz.)

1 07200805

AR 00057100

1 21548101

1 21549800

1 20715100

1 21548100

1 21564900

1 21548700

1 21548800

1 00191627

1 05600505

AR 04730400

EN - 18

Page 21

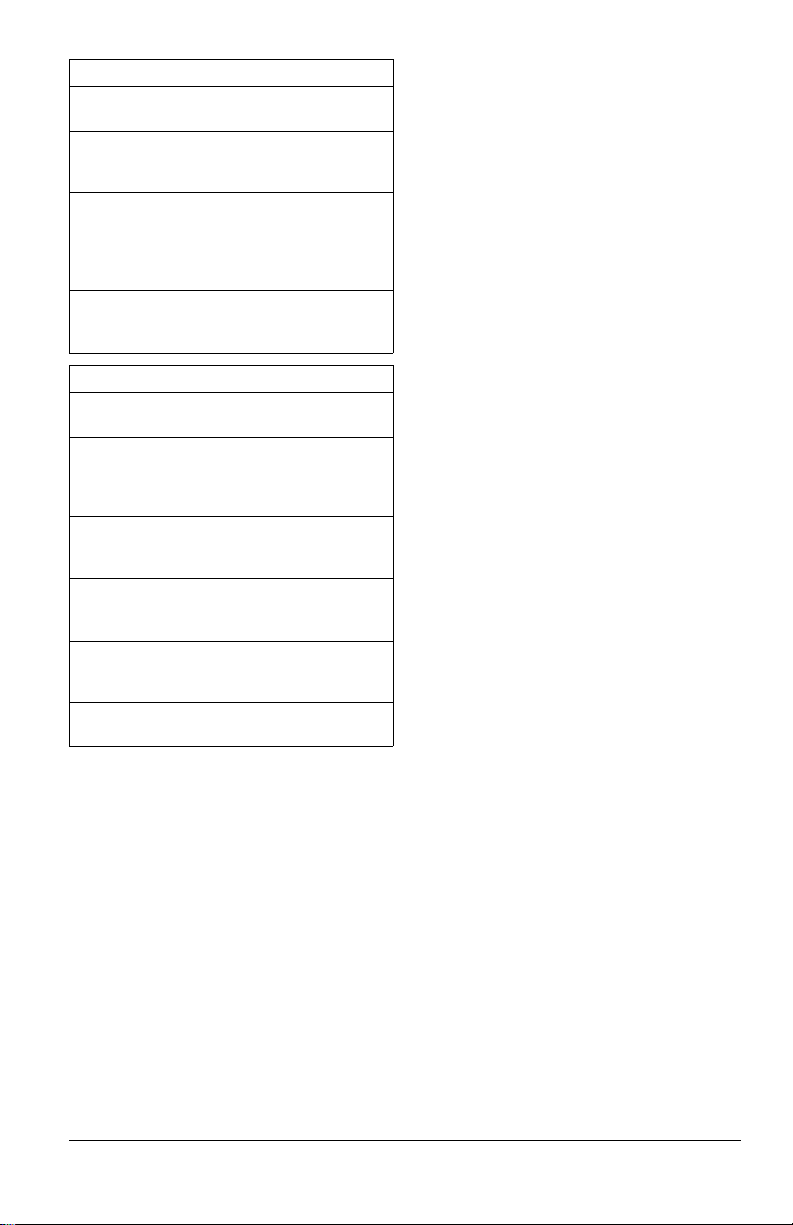

SERVICE POSITION

Figure 15

Figure 16

Before starting any of the following

maintenance procedures:

1. Park unit on a flat, level surface.

2. Stop engine, remove key and wait for all

moving parts to stop and for hot parts to

cool.

3. Engage parking brake.

4. Chock wheels. Strap and clamp unit onto

lift, if used.

5. Place steering levers in neutral position

and rotate outward.

6. Models 991159, 991161, 991163: Rotate

seat forward. See Figure 15.

7. Model 991158: Pull seat latch and rotate

seat forward. See Figure 16.

IMPORTANT: Reconnect spark plug wires

after maintenance.

CHECK SAFETY INTERLOCK SYSTEM

Check function of the Safety Interlock System

by performing the tests below. Contact your

Ariens dealer for repair if any of the tests fail.

Test Steering

Levers

1 Neutral Off On

Forward,

2

Neutral,

Reverse

Forward,

3

Neutral,

Reverse

Operating Interlock (Engine On)

Forward,

4 *

Neutral,

Reverse

Forward,

5 *

Neutral,

Reverse

* When operator lifts off seat.

PTO Parking

Brake

Starting Interlock

On or

On

Off

On

or

Off

Off

On or

On

Off

On

or

Off

Off

Result

Engine

starts.

Engine does

not start.

Engine does

not start.

Engine

shuts off.

Engine

shuts off.

EN - 19

Page 22

CHECK PARKING BRAKE

Figure 17

1. Place unit in service position. See

Service Position on page 19.

2. Bypass transaxles. See Move Unit

Manually on page 17.

3. Push unit forward.

• If unit does not move forward, no further

action is needed.

• If unit easily moves forward, adjust the

brake lever. Refer to your unit’s Service

Manual.

CHECK ENGINE OIL

NOTICE: Engine oil level must be maintained

at correct level or engine damage may occur.

Refer to engine manual.

CHECK TIRE PRESSURE

See Specifications on page 29 for

recommended tire pressure.

WAR NING: AVOID INJURY.

Explosive separation of tire

and rim parts is possible.

• DO NOT inflate tires above

the recommended pressure.

• DO NOT inflate tires with a

compressor; use a hand

pump.

• DO NOT stand in front of

tire assembly when

inflating. Use a clip-on

chuck and extension hose

long enough to allow you to

stand to one side.

CHECK FASTENERS

Check for loose or missing hardware.

Lubricate Seat

See Figure 17.

1. Place unit in service position.

2. Apply grease to seat tracks through slots

under seat plate.

3. Return seat to operating position and

slide seat back and forth to spread

grease along tracks.

CHECK MOWER BLADES

Check blades for wear and damage. Replace

or sharpen as needed.

CAUTION: AVOID INJURY. Use

sturdy gloves or padding to

protect hands when working with

mower blades.

Rotation of one blade rotates the

other blades.

LUBRICATE UNIT

1. Apply oil to all pivot points and pin

connections.

CAUTION: Unbalanced blades

cause excessive vibration and

eventual damage to unit.

Balance blades before

reinstalling on unit.

NEVER weld or straighten

blades.

EN - 20

Page 23

CHECK BATTERY

Figure 18

1. Cold Fill Line

1

WARNING: Battery posts,

terminals and related

accessories contain lead. Wash

hands after handling.

Clean Battery

CAUTION: AVOID DAMAGE.

DO NOT allow tools to contact

metal surfaces when removing

positive battery cable.

1. Disconnect battery cables, negative cable

first.

2. Clean terminals and battery cable ends

with a wire brush.

3. Coat terminals with dielectric grease or

petroleum jelly.

4. Reinstall battery cables, positive first.

CHECK MOWER BELTS

Check belts for wear and replace as needed.

CAUTION: Keep body parts

away from idler when

releasing idler spring tension.

CHECK HYDRAULIC SYSTEM

Check Hydraulic Oil Level

1. Place unit in service position. See

Service Position on page 19.

2. Check oil level in expansion tanks. Oil

should reach the cold fill indicator mark.

See Figure 18.

IMPORTANT: Engine should be cold when

checking initial oil level.

3. Operate engine for 1 minute and recheck

oil levels.

4. Add hydraulic oil, if needed.

a. Remove expansion tank caps.

b. Fill expansion tanks with 15W-50 Full-

Synthetic Hydraulic Fluid until oil

reaches the cold fill indicator mark.

See Figure 18.

c. Reinstall expansion tank caps.

Change Hydraulic Oil and Filter

1. Operate unit for a few minutes to warm

hydraulic oil.

2. Stop engine, remove key and wait for all

moving parts to stop and for hot parts to

cool.

3. Position container under oil filter to catch

used oil.

EN - 21

Page 24

See Figure 19.

Figure 19

4. Remove filter guard and oil filter from

transaxle.

5. Remove the vent / fill plug from the fill

port and allow transaxle to drain

completely.

6. Wipe filter-mounting surface clean.

7. Lubricate rubber gasket on new oil filter

with clean hydraulic oil.

8. Spin filter onto filter housing until it makes

contact, and then turn filter 3/4 turn to

tighten.

9. Reinstall filter guard and torque to 7.3

N•m (65 lb-in). DO NOT overtighten.

10. Add 15W-50 Full-Synthetic Hydraulic

Fluid until oil appears at the bottom of the

fill port (1892.7 mL (64 fl. ounces) per

transaxle).

11. Reinstall the vent / fill plug and torque to

20.3 N•m (180 lb-in).

12. Add hydraulic oil to expansion tank until

oil reaches cold fill indicator mark.

13. Repeat steps 3 – 12 for other transaxle.

14. Purge hydraulic system. See Purge

Hydraulic System on page 22.

Purge Hydraulic System

Purge air from hydraulic system after draining

oil or changing the filter.

WARNING: AVOID INJURY.

This adjustment requires

operating the engine. Use

extreme care to avoid contact

with moving parts and hot

surfaces. Be sure rear of unit

is well supported and secure

before starting engine.

1. Park unit facing a wall or chock wheels.

2. Release parking brake.

3. Support unit so drive wheels are off the

ground.

4. Bypass transaxles. See Move Unit

Manually on page 17.

5. Start the engine and slowly move steering

levers forward and backward 5 or 6 times.

6. Return transaxle bypass levers to

operating position. See Move Unit

Manually on page 17.

7. Slowly move steering levers forward and

backward 5 or 6 times.

8. Stop engine, lower unit to ground and

check oil level. Add oil if needed.

9. Repeat steps 1 – 8 until transaxles

operate smoothly in forward and reverse

at normal speed without excessive noise.

EN - 22

Page 25

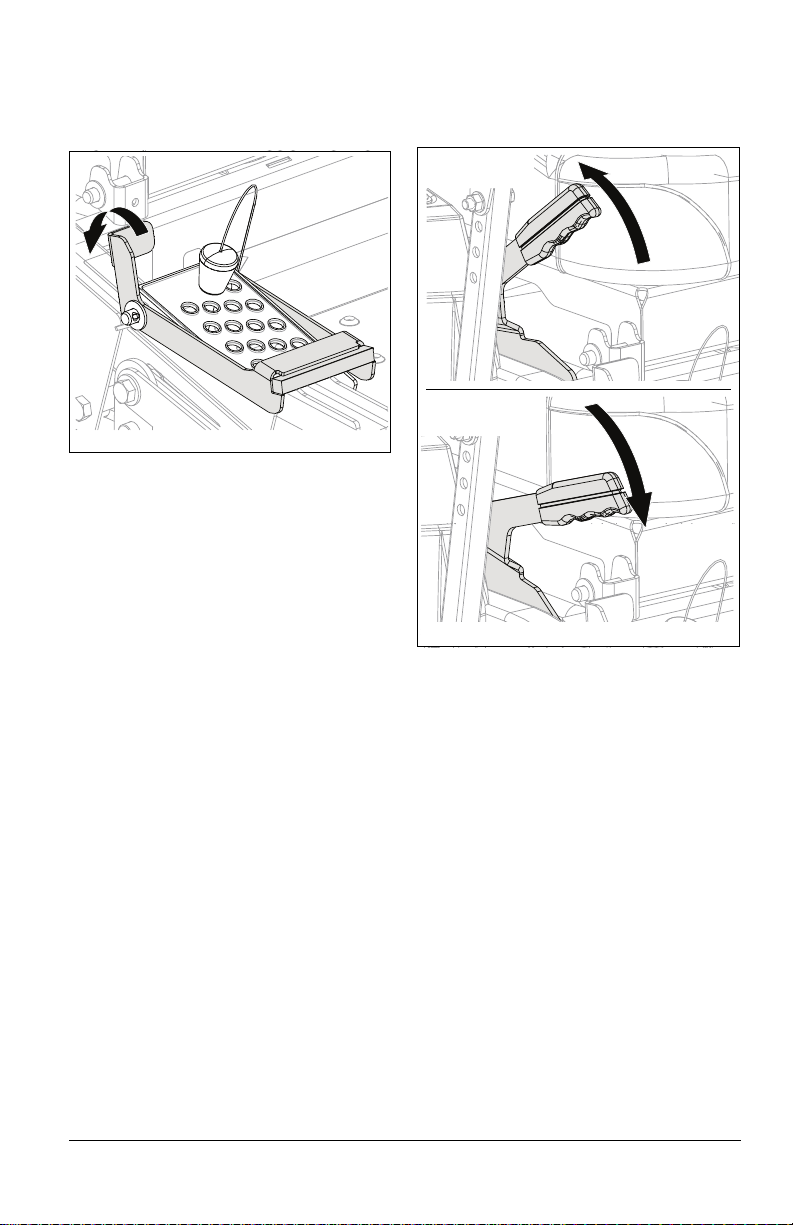

ADJUSTMENTS

Figure 20

Figure 21

Figure 22

WAR NING: AVOID INJURY.

Read and understand the

Safety section before

proceeding.

ADJUST SEAT

See Figure 20.

1. Pull seat adjustment lever up to unlock

seat.

2. Move seat to desired position.

3. Release seat adjustment lever to lock

seat in place.

4. Adjust steering lever position. See Adjust

Steering Levers on page 23.

5. Turn eccentric spacer so levers are at the

same height and have a 1.3 cm – 2.5 cm

(1/2" – 1") gap between lever ends. See

Figure 22.

ADJUST STEERING LEVERS

Adjust Height

The steering lever height may be adjusted for

operator comfort. See Figure 21.

1. Stop engine, remove key and wait for

moving parts to stop and for hot parts to

cool.

2. Remove steering lever hardware and

remove steering lever from lower control

arm.

3. Position steering lever at desired height

and align with lower control arm. Secure

with original hardware.

If there is more than 3.2 mm (1/8") between

the horizontal alignment of the steering

levers, align the levers.

6. Stop engine, remove key and wait for

moving parts to stop and for hot parts to

cool.

7. Engage parking brake.

EN - 23

Page 26

8. Loosen mounting hardware, align levers

Figure 23

Figure 24

and tighten hardware. See Figure 23.

Adjust Forward Position

The steering lever forward position may be

adjusted for operator comfort.

1. Stop engine, remove key and wait for

moving parts to stop and for hot parts to

cool.

2. Loosen mounting hardware on steering

lever assemblies.

3. Place steering levers in desired position:

• Gently push levers forward for greater

distance from operator.

• Gently pull levers back for closer

distance to operator.

4. Tighten hardware.

ADJUST UNIT TO DRIVE STRAIGHT

Adjust Tire Pressure

1. Place unit in service position. See

Service Position on page 19.

2. Check tire pressures. If needed, adjust to

recommended pressures. See

Specifications on page 29.

3. Check tracking.

• If unit does not track straight, increase

tire pressure to the drive wheel of the

side it moves toward.

IMPORTANT: DO NOT exceed maximum tire

pressure listed on tire sidewall.

• If increasing tire pressure does not

correct tracking, adjust the limiter bolts

as directed below.

Adjust Limiter Bolts

See Figure 24.

Limiter bolts can be adjusted to increase or

decrease drive wheel speeds. To adjust:

1. Loosen jam nut.

• Turn limiter bolt counterclockwise to

increase maximum drive wheel speed

on that side.

• Turn limiter bolt clockwise to reduce

maximum drive wheel speed on that

side.

2. Tighten jam nut.

3. Align steering levers. See Adjust Steering

Levers on page 23.

EN - 24

Page 27

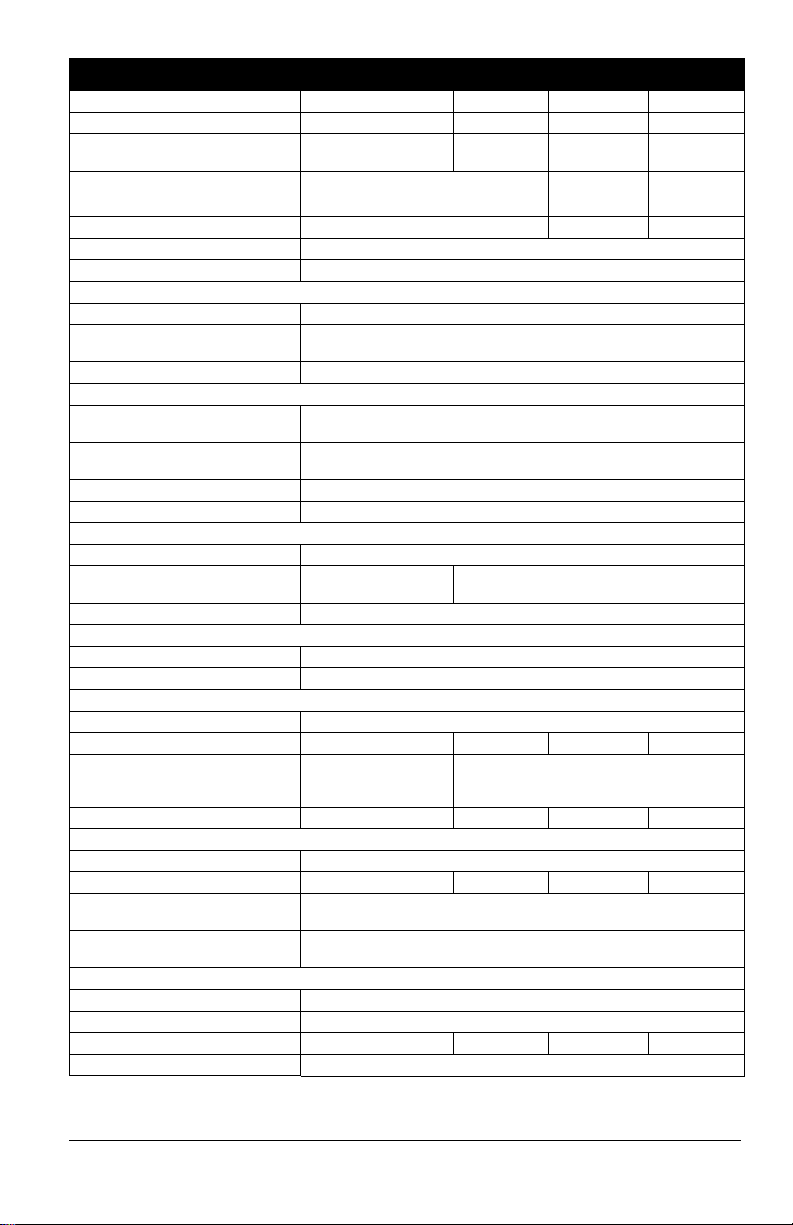

ELECTRICAL SERVICE

20

510

5

15

5

Figure 25

1. Regulator Fuse 20A

2. Controls Fuse 5A

3. PTO Fuse 10A

4. Starter Fuse 5A

5. Auxiliary Fuse 15A

6. Run Relay

1

2

3

4

5

6

See Controls and Features on page 10 for

fuse box location.

See Figure 25.

Replace Fuse

IMPORTANT: To avoid damaging the circuit,

replace fuses with fuses of the same

amperage rating. Determine the cause of

electrical failure and repair before replacing

failed electrical components.

1. Place unit in service position. See

Service Position on page 19.

2. Remove fuse box cover.

3. Remove defective fuse.

4. Determine cause of fuse failure and

repair condition.

5. Install new fuse.

6. Replace fuse box cover. Ensure cover

snaps tightly in position.

Replace Relay

NOTICE: Relays are interchangeable. Use

only quality replacement parts. See Service

Parts on page 18.

1. Place unit in service position. See

Service Position on page 19.

2. Remove fuse box cover.

3. Remove defective relay.

4. Determine cause of relay failure and

repair condition.

5. Install new relay.

6. Replace fuse box cover. Ensure cover

snaps tightly in position.

EN - 25

Page 28

TROUBLESHOOTING

Problem Probable Cause Correction

Engine does

not start.

Engine runs

rough.

Engine

overheats.

Unit does not

drive.

PTO

malfunctions.

Unit moves

with engine off

and parking

brake engaged.

Unit does not

drive straight.

Unit creeps

when steering

levers are in

neutral

position.

Safety Interlock System is not

engaged or is faulty.

Fuel tank is empty. Fill fuel tank. See Before Operating Unit

Fuel supply is contaminated. Replace with clean fuel.

Battery is discharged. Charge battery. Refer to your unit’s

Connection between battery and

battery cables is poor.

Spark plug wire(s) are loose or

spark plug(s) are faulty.

Electrical system is faulty. Contact your Ariens dealer.

Engine is faulty. Contact your Ariens dealer.

Choke control knob is in on

position.

Air filter cartridge is plugged. Clean or replace air filter cartridge. Refer

Engine is faulty. Contact your Ariens dealer.

Engine oil level is low. Add engine oil. Refer to engine manual.

Cooling fins are plugged. Clean engine. Refer to engine manual.

Engine is faulty. Contact your Ariens dealer.

The transaxles are bypassed. Engage levers. See Move Unit Manually

Transaxle drive belt is faulty. Contact your Ariens dealer.

Transaxles are faulty. Contact your Ariens dealer.

Operator presence switch is not

engaged.

Operator presence switch is

faulty.

PTO belt is faulty. Replace belt. Refer to your unit’s Service

PTO switch, wiring, connectors

or clutch are faulty.

Parking brake needs adjustment. Adjust parking brake lever. Refer to your

Parking brake is faulty. Contact your Ariens dealer.

Tire pressure is incorrect. Check tire pressure. See Specifications

Steering levers need adjustment. See Adjust Steering Levers on page 23.

Transmission and/or linkage

need adjustment.

Check Safety Interlock System. See

Check Safety Interlock System on

page 19.

on page 14.

Service Manual.

Tighten and/or clean battery and battery

cables. See Clean Battery on page 21.

Connect spark plug wire(s) or replace

spark plug(s). Refer to engine manual.

Move knob to off position.

to engine manual.

on page 17.

Activate switch by sitting on operator

seat.

Contact your Ariens dealer.

Manual.

Contact your Ariens dealer.

unit’s Service Manual.

on page 29.

Contact your Ariens dealer.

EN - 26

Page 29

TROUBLESHOOTING

Problem Probable Cause Correction

Poor cutting

quality.

Blades do not

stop within 5

seconds.

Mower blades not level or mower

deck pitch is incorrect.

Mower blades are dull or faulty. Sharpen or replace mower blades. Refer

Mowing speed is too fast. Drive slower when cutting grass.

Belt tension or condition is poor. Replace mower belts. Refer to your unit’s

Cutting height is too low. Do not set height of cut too low. For very

Clutch brake plates worn. Reverse clutch brake plates. If clutch

Level and adjust pitch of mower deck.

Refer to your unit’s Service Manual.

to your unit’s Service Manual.

Service Manual.

tall grass, mow twice.

brake plates have already been reversed,

replace clutch. Refer to your unit’s

Service Manual.

EN - 27

Page 30

STORAGE ACCESSORIES

SHORT-TERM STORAGE

IMPORTANT: NEVER wash unit with high-

pressure water or store outdoors.

1. Allow unit to cool and clean with mild

soap and water.

2. Tighten all hardware to correct

specifications.

3. Inspect unit for visible signs of wear or

damage. Repair as needed.

4. Prepare fuel system for storage.

NOTICE: Ariens recommends using a quality

fuel stabilizer in all fuel. Gasoline left in the

fuel system without a stabilizer, even for short

periods of time, deteriorates and leaves

gummy deposits in the system that may

damage the carburetor and fuel hoses, filter

and tank. For the best effectiveness, add

stabilizer to all fuel containers whenever

purchasing fuel. Add the stabilizer to the

container before adding fuel.

a. Add fuel stabilizer (see Service Parts

on page 18) or equivalent according

to manufacturer's instructions to the

fuel tank and any fuel containers with

remaining fuel.

b. Run engine outdoors for at least

5 minutes to allow stabilizer to reach

the carburetor.

5. Turn ignition key to off position and

remove from ignition.

6. Store unit in a cool, dry, protected area.

DO NOT store unit outdoors.

LONG-TERM STORAGE

1. Perform short-term storage procedures.

2. Lubricate as directed in Maintenance on

page 18.

3. Touch-up all scratched painted surfaces.

4. Remove and charge battery. Refer to

your unit’s Service Manual. Store battery

in a cool, dry, protected area.

5. Store unit in a cool, dry, protected area.

Do not store unit outdoors.

See your Ariens dealer for a complete list of

compatible accessories and attachments for

your unit.

Description Part No.

Mulch Kit – 60" 79109800

Hitch Kit 70764300

Headlight Kit 70764400

Light Operator Seat Spring Kit 79107000

Flex Fork Suspension Kit 79109000

Striper Kit 79206700

Operator Controlled

Discharge Baffle Kit

22" Rear Tweel Kit 79109900

79110000

Apex Models Only

Description Part No.

Mulch Kit – 48" 79109600

Mulch Kit – 52" 79220200

Rollover Protection Structure

(ROPS) Kit

Seat Isolator Kit 79110500

Bagger Attachment Kit 79107800

Bagger Kits*

Base Kit 89100800

• Kit for 48" Decks 79109200

• Kit for 52" Decks 79109300

• Kit for 60" Decks 79109400

* Bagger kits are ordered in two parts.

Complete baggers require Base Kit

89100800

size of the unit.

plus the kit matching the deck

89101100

START-OF-SEASON PREPARATION

1. Before adding fuel for the first time after

long-term storage, add fresh, stabilizertreated fuel to fuel tank and any fuel

containers with remaining fuel.

2. Charge and install the battery.

EN - 28

Page 31

SPECIFICATIONS

Model Number 991158 991159 991161 991163

Description Zenith 60 Apex 52 Apex 48 Apex 60

Engine

Engine Displacement – cm3

(in3)

Maximum RPM – No Load 3600 ± 100 3600 ± 75 3600 ± 100

Oil Capacity Refer to engine manual.

Liquid or Air Cooled Air

Transmission

Type Hydrostatic Drive

Oil 15W-50 Full-Synthetic Hydraulic Fluid (P/N 00057100)

Hydraulic Oil Filter Yes

Drive

Forward Maximum – km/h

(mph)

Reverse Maximum – km/h

(mph)

Turning Radius Zero

Brakes Parking

Electrical

Starter Electric

Battery 300 CCA (U1

PTO (Power Take-off) Electric PTO Clutch / Brake

Fuel

Fuel Tank Capacity – Liter (gal) 19.3 (5.1)

Type See Engine Manual

Size and Weight

Length – cm (in) 200.7 (79)

Width – cm (in) 190.5 (75) 170.2 (67) 160 (63) 190.5 (75)

Height – cm (in)

• with ROPS extended

• with ROPS folded

Weight – kg (lbs) 421.8 (930) 370.1 (816) 352.9 (778) 376.5 (830)

Tires

Front Tire Size – in 13 x 6.5-6

Rear Tire Size – in 22 x 12-12 22 x 10.5-12 22 x 10-12 22 x 12-12

Recommended Front Tire

Pressure – kPa (psi)

Recommended Rear Tire

Pressure – kPa (psi)

Mower Deck

Cutting Height – cm (in) 3.8 – 12.7 (1.5 – 5.0)

Cutting Height Increments 0.635 (0.25)

Cutting Width – cm (in) 152.4 (60) 132.1 (52) 121.9 (48) 152.4 (60)

Mower Deck Lift Mechanical Pin Lock

Kawasaki FX 730V

726 (44.3) 725.0 (44.2) 726 (44.3)

Replaceable)

184.2 (72.5)

124.5 (49.0)

Kawasaki FRKohler 7000

or equivalent

12.9 (8)

6.4 (4)

12 Volt 12A-190 CCA (U1 Replaceable)

137.9 – 172.4 (20 – 25)

82.7 – 103.4 (12 – 15)

Pro

119.4 (47)

N/A

N/A

Kawasaki

FR

EN - 29

Page 32

Warran

ty

Outdoor Power

Equipment

Limited Warranty

AriensCo warrants to the original purchaser that Ariens brand products purchased on or after 1/1/2022 will

be free from defects in material and workmanship for the time period noted in the chart below. Equipment put

to personal use around a single household or residence is considered “Residential Use.” Equipment put to

any business use (agricultural, commercial, or industrial) or used at multiple locations is considered

“Commercial Use.” If any product is rented or leased, then the duration of these warranties shall be 90 days

after the date of purchase.

An authorized Ariens dealer will repair any defect in material or workmanship, and repair or replace any

defective part, subject to the conditions, limitations and exclusions set forth herein. Such repair or

replacement will be free of charge (labor and parts) to the original purchaser; except as noted below. Pick-up

and delivery are at the owner’s expense.

The warranty code is found on the model and serial number identification label on the unit.

Warranty

Code

AA Serialized Attachments 1 Year.

CH, CQ Zenith Mowers 4 Years or 750 Hours.*

HD LM-Series Walk-Behind Mowers 3 Years Residential Use. 90 Days Commercial Use.

HE Edge Mowers 2 Years or 150 Hours.*

HF Ikon-XD Mowers 3 Years or 300 Hours.*

HH Apex Mowers 4 Years or 500 Hours.*

PA 921-Series Brushes 3 Years Residential Use. 90 Days Commercial Use.

PB 926-Series Brushes 3 Years Residential Use. 1 Year Commercial Use.

SA Professional Sno-Thro 3 Years Residential Use. 1 Year Commercial Use.

Compact, Deluxe and Platinum Sno-Thro

SB

and Path-Pro

SC S18 2 Years Residential Use. 90 Days Commercial Use.

SD Deluxe and Platinum EFI Sno-Thro 3 Years Residential Use. 90 Days Commercial Use.

SE 920-Series Classic Sno-Thro, Crossover 3 Years Residential Use. 90 Days Commercial Use.

SF Mammoth Tractor 2 Years or 500 Hours.*

* Whichever comes first.

Product Group Warranty Period

3 Years Residential Use. 90 Days Commercial Use.

Special Extensions

The chart below details special extensions to warranty terms. Warranty terms are total time periods

covered. If any product is rented or leased, there are no extensions to the 90-day warranty.

Warranty

SB, SD Cast Iron Auger Gear Case

Warranty Term Extension Warranty Period

Code

SA Cast Iron Auger Gear Case 5 Years.

5 Years Residential Use.

1 Year Commercial Use.

EN - 30

9/22 • 05299800I

Page 33

Exclusions and Limitations

The charts below detail special exclusions and limitations to this warranty.

Warranty Term Exclusions Warranty Period

Air filters, auger paddles, brake arms, brake linings, brake shoes,

brushes, cutters, fuel filters, halogen headlights, knives, halogen light

bulbs, lubricants, mower blades, oil, oil filters, spark plugs, scraper

blades, shear bolts and skid shoes.

Hydro-Gear Transaxle Limitation

See Hydro-Gear warranty. The warranty is administrated by AriensCo. Refer to www.ariens.com for

warranty statement.

Warranty Term Limitations Warranty Period

Cloth, Plastic and Rubber Components.

Mufflers, Tires and Belts.

Parker Actuators 1 Year.

Exclusions – Items Not Covered by This Warranty

• Parts that are not genuine Ariens service parts are not covered by this warranty and may void the warranty if the parts result in premature wear or damage to the product.

• Damages resulting from the installation or use of any part, accessory, or attachment which is not approved

by AriensCo for use with product(s) identified herein are not covered by this warranty.

• Any misuse, alteration, improper assembly, improper adjustment, neglect, or accident which requires

repair is not covered by this warranty.

• Repairs or adjustments required due to failure to use fresh fuel or failure to properly prepare the unit for

periods of non-use.

• Use of gasoline blends exceeding 10% ethanol voids any and all warranties.

• Any tampering with the hour meter voids any and all warranties.

• Products are designed to the specifications in the area that the product was originally distributed. Different areas may have significantly different legal and design requirements. This warranty is limited to the

requirements in the area in which the unit was originally distributed. AriensCo does not warrant this product to the requirements of any other area. Warranty service is limited to service within the area originally

distributed.

• In countries other than the United States and Canada, contact the AriensCo dealer for

warranty policies that govern within your country. Rights may vary from country to country and within any

one country.

Evaporative Emissions Control Warranty Exception

As required by the California Air Resources Board (CARB) and the US Environmental Protection Agency

(EPA) the evaporative emissions control system is warranted to the ultimate purchaser, and any subsequent

owner, for two years.

The CARB and EPA evaporative emissions control system warranty is described in a separate evaporative

emission control warranty statement.

Components are covered for manufacturer’s defect only, not

Components are not covered

under warranty.

wear.

Battery Warranty

Battery warranty is one year. Units used for rental or lease have no exceptions to the 90-day warranty. Total

battery claim reimbursement will not exceed 45.00 USD.

EN - 31

9/22 • 05299800I

Page 34

Engines

The chart below details engine warranty information. Engine warranty terms may vary from the specific terms

of this warranty. If inconsistent, the terms of the engine warranty shall apply to the engine and its component

parts.

Engine Manufacturer Detail

Ariens AX

Briggs & Stratton, Kawasaki, Kohler

Ariens-branded engines are warranted by the manufacturer

and the warranty is administrated by AriensCo

engine manual or www.ariens.com for warranty statements.

Covered by the engine manufacturer’s warranty.

Refer to the engine manufacturer’s warranty statements.

. Refer to the

Parts and Accessories

Service replacement parts and non-serialized accessories are warranted for 90 days from date of purchase.

Labor is not included.

Customer Responsibilities

Register the product immediately at the time of sale. If the dealer does not register the product, the

customer must register the unit on-line at www.ariens.com.

To obtain warranty service, the original purchaser must:

• Ensure that the maintenance and adjustments explained in the Operator’s Manual are routinely

completed.

• Promptly notify AriensCo or an authorized Ariens service representative of the need for warranty service.

• Transport the product to and from the place of warranty service at owner’s expense.

• Have the warranty service performed by an authorized Ariens service representative.

To find an authorized dealer use the dealer locator on our websites, or contact us by mail or phone.

Globally (Except Australia or

New Zealand):

AriensCo

655 W. Ryan Street

Brillion, WI 54110

Phone: (920) 756 - 4688

www.ariensco.com

Australia: New Zealand:

Masport Australia Pty Ltd

27 Commercial Drive

Dandenong South

Victoria 3175

Australia

Phone: 1300 366 225

www.masport.com.au

Masport Ltd

320 Ti Rakau Drive

East Tamaki

Auckland 2013

New Zealand

Phone: 0800 627 7678

www.masport.co.nz

EN - 32

9/22 • 05299800I

Page 35

Disclaimer

AriensCo may from time to time change the design of its products. Nothing contained in this warranty shall be

construed as obligating the AriensCo to incorporate such design changes into previously manufactured

products, nor shall such changes be construed as an admission that previous designs were defective.

Limitation of Remedy and Damages

AriensCo liability under this warranty, and under any implied warranty that may exist, is limited to repair of

any defect in workmanship, and repair or replacement of any defective part. AriensCo shall not be liable for

incidental, special, or consequential damages (including lost profits). Some states do not allow the exclusion

of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

AriensCo shall not be held liable for damages, including premature wear and tear, or injuries caused by

installation of unauthorized parts and accessories or for parts and accessories not installed by an authorized

Ariens dealer.

Australian Consumer Law

The following applies solely to warranties subject to Subsection 102(1) of the Australian Consumer Law: Our

goods come with guarantees that cannot be excluded by the Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or

damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable

quality and failure does not amount to a major failure.

Disclaimer of Further Warranty

AriensCo makes no warranty, express or implied, other than what is expressly made in this warranty. If the

law of your state provides that an implied warranty of merchantability, or an implied warranty of fitness for

particular purpose, or any other implied warranty, applies to AriensCo, then any such implied warranty is

limited to the duration of this warranty. Some states do not allow limitations on how long an implied warranty

lasts, so the above limitation may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from region to

region.

EN - 33

9/22 • 05299800I

Page 36

P

R

I

N

T

E

D

655 West Ryan Street

Brillion, WI 54110

www.ariens.com

parts.ariens.com

Loading...

Loading...