Promaster 144Z

Owner/Operator Manual-- Manuel du proprietaire/utilisateur- Betriebsanlei-

tung -- Eigenaars/gebruikshandleiding- Instruktionsbog -- Manuale d'uso/

del proprietario -- Manual del propietario/operador- Brukerhandboken -

Instruktionsboken -- Omistajan/kuljettajan k_ytt6ohjekirja --Instrukcj¢

obsfugi/operatora -- PyKOBOACTBO BnaAenbL_a/nonb3OBaTen,q -- Navod k

obsluze/pro obsluhu -- Manual do Operador / Proprietario

992312 21HP 144Z

',_' ENGLISH

'__' FRAN(_AIS

(._D_' DEUTSCH

_', NEDERLANDS

',_* DANSK

'_ ITALIANO

'_-_' ESPANOL

',_._N_'NORSK

'_' SVENSKA

'_) SUOMI

'._L_, POLSKI

,'_ PYCCKVIH R3blK

,--_'_j (_ESKY

,_, PORTUGUESE

00678500 10/06

Printed in USA

AriensCompany

655WestRyanStreet

RO.Box157

Brillion,Wisconsin54110-0157

USA

Telephone(920)756-2141

Facsimile(920)756-2407

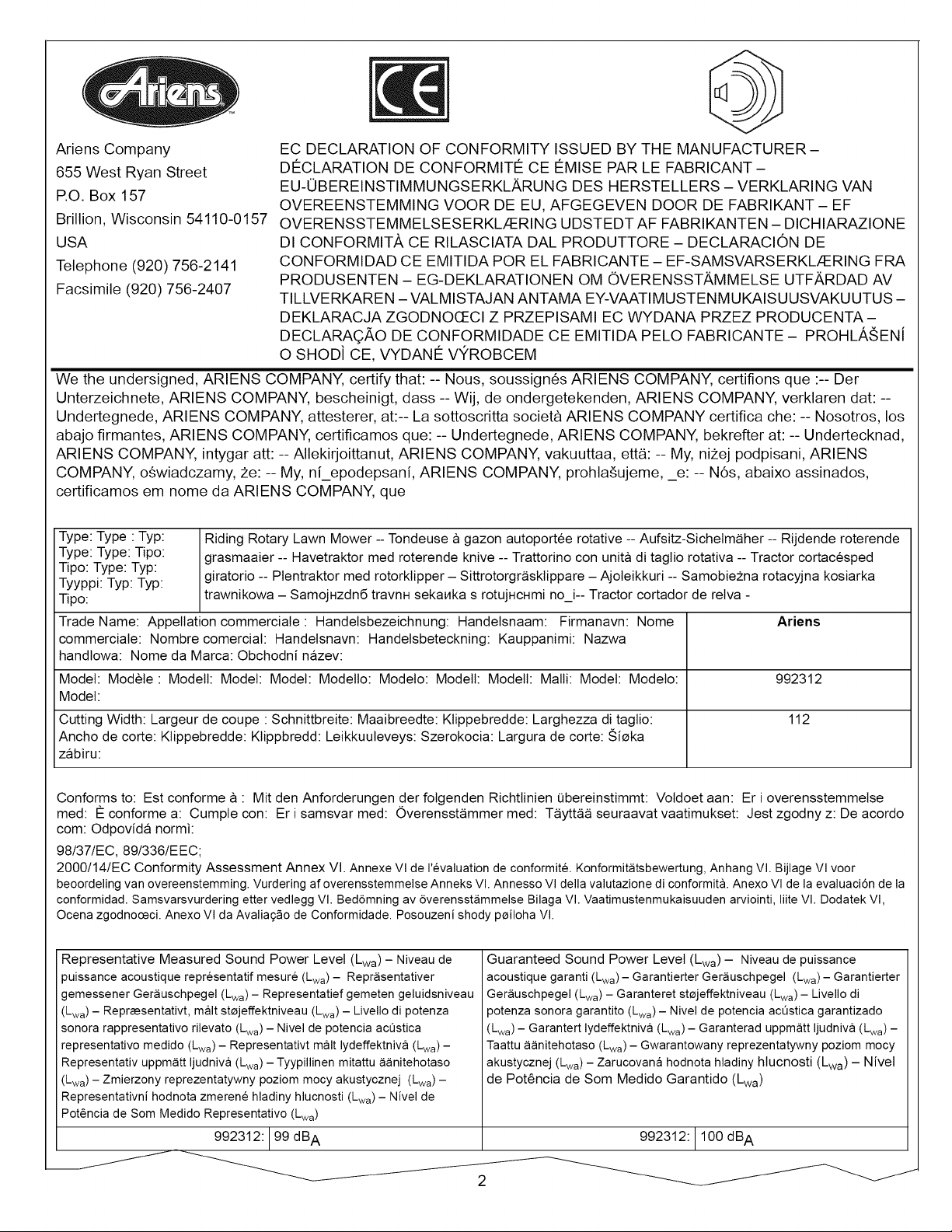

ECDECLARATIONOFCONFORMITYISSUEDBYTHEMANUFACTURER-

Dt_CLARATIONDECONFORMITI_ CE I_MISE PAR LE FABRICANT-

EU-0BEREINSTIMMUNGSERKL_,RUNG DES HERSTELLERS - VERKLARING VAN

OVEREENSTEMMING VOOR DE EU, AFGEGEVEN DOOR DE FABRIKANT- EF

OVERENSSTEMMELSESERKL,ZERING UDSTEDT AF FABRIKANTEN - DICHIARAZlONE

DI CONFORMITA CE RILASCIATA DAL PRODUTTORE - DECLARACION DE

CONFORMIDAD CE EMITIDA POR EL FABRICANTE - EF-SAMSVARSERKL/ERING FRA

PRODUSENTEN - EG-DEKLARATIONEN OM OVERENSST_,MMELSE UTF_,RDAD AV

TILLVERKAREN -VALMISTAJAN ANTAMA EY-VAATIMUSTENMUKAISUUSVAKUUTUS -

DEKLARACJA ZGODNOCECI Z PRZEPISAMI EC WYDANA PRZEZ PRODUCENTA -

DECLARA(_,O DE CONFORMIDADE CE EMITIDA PELO FABRICANTE - PROHL/_,SENi

O SHODi CE, VYDANI _ V"/ROBCEM

We the undersigned, ARIENS COMPANY, certify that: -- Nous, soussign6s ARIENS COMPANY, certifions que :-- Der

Unterzeichnete, ARIENS COMPANY, bescheinigt, dass -- Wij, de ondergetekenden, ARIENS COMPANY, verklaren dat: --

Undertegnede, ARIENS COMPANY, attesterer, at:-- La sottoscritta societ_ ARIENS COMPANY certifica che: -- Nosotros, los

abajo firmantes, ARIENS COMPANY, certificamos que: -- Undertegnede, ARIENS COMPANY, bekrefter at: -- Undertecknad,

ARIENS COMPANY, intygar att: -- Allekirjoittanut, ARIENS COMPANY, vakuuttaa, ett_: -- My, ni_'ej podpisani, ARIENS

COMPANY, ogwiadczamy, _'e: -- My, nLepodepsani, ARIENS COMPANY, prohla_ujeme, _e: -- N6s, abaixo assinados,

certificamos em nome da ARIENS COMPANY, que

Type: Type : Typ:

Type: Type: Tipo:

Tipo: Type: Typ:

Tyyppi: Typ: Typ:

Tipo: trawnikowa - SamojHzdn5 travnH seka_4kas rotujHcHmi no_i-- Tractor cortador de relva -

Trade Name: Appellation commerciale : Handelsbezeichnung: Handelsnaam: Firmanavn: Nome Ariens

commerciale: Nombre comercial: Handelsnavn: Handelsbeteckning: Kauppanimi: Nazwa

handlowa: Nome da Marca: Obchodni nazev:

Model: Modele: Modell: Model: Model: Modello: Modelo: Modell: Modell: Malli: Model: Modelo: 992312

Model:

Cutting Width: Largeur de coupe : Schnittbreite: Maaibreedte: Ktippebredde: Larghezza di tagtio: 112

Ancho de corte: Klippebredde: Klippbredd: Leikkuuleveys: Szerokocia: Largura de corte: Sieka

zabiru:

Conforms to: Est conforme & : Mit den Anforderungen der folgenden Richtlinien 0bereinstimmt: Voldoet aan: Er i overensstemmelse

med: €: conforme a: Cumpte con: Er i samsvar med: Overensst&mmer med: T&ytt&& seuraavat vaatimukset: Jest zgodny z: De acordo

com: Odpovida normi:

98/37/EC, 89/336/EEC;

2000/14/EC Conformity Assessment Annex VI. AnnexeVI de I'evaluation de conformit& Konformit_tsbewertung,Anhang Vl. BijlageVI voor

beoordeling vanovereenstemming.Vurdering afoverensstemmelse Anneks VI. AnnessoVI dellavalutazione di conformit& Anexo VI de laevaluaci6n de la

conformidad. Samsvarsvurdering ettervedlegg Vl. Bed6mning av 6verensst_mmelse Bilaga Vl. Vaatimustenmukaisuudenarviointi, liite Vl. DodatekVl,

Ocena zgodnooeci.Anexo VI da Avalia9_ode Conformidade. Posouzeni shody p_iloha VI.

Representative Measured Sound Power Level (Lwa) - Niveau de

puissance acoustique representatif mesure (Lwa) - Repr_sentativer

gemessener Ger_uschpegel (Lwa)- Representatief gemeten geluidsniveau

(Lwa) - Repraesentativt, malt st_jeffektniveau (Lwa) - Livello di potenza

sonora rappresentativo rilevato (Lwa) - Nivel de potencia acQstica

representativo medido (Lwa) - Representativt malt lydeffektniva (Lwa) -

Representativ uppm_tt Ijudniva (Lwa) - Tyypillinen mitattu _nitehotaso

(Lwa) - Zmierzony reprezentatywny poziom mocy akustycznej (Lwa) -

Representativni hodnota zmerene hladiny hlucnosti (Lwa) - Nivel de

Pot6ncia de Som Medido Representativo (Lwa)

Riding Rotary Lawn Mower -- Tondeuse a gazon autoportee rotative -- Aufsitz-Sichelm_her -- Rijdende roterende

grasmaaier -- Havetraktor med roterende knive -- Trattorino con unita di taglio rotativa -- Tractor cortacesped

giratorio -- Plentraktor med rotorklipper - Sittrotorgr_sklippare - Ajoleikkuri -- Samobie_:na rotacyjna kosiarka

Guaranteed Sound Power Level (Lwa) - Niveau de puissance

acoustique garanti (Lwa) - Garantierter Ger_uschpegel (Lwa) - Garantierter

Ger_uschpegel (Lwa) - Garanteret st_jeffektniveau (Lwa) - Livello di

potenza sonora garantito (Lwa) - Nivel de potencia acQstica garantizado

(Lwa) - Garantert lydeffektniva (Lwa) - Garanterad uppm_tt Ijudniva (Lwa) -

Taattu _nitehotaso (Lwa) - Gwarantowany reprezentatywny poziom mocy

akustycznej (Lwa) - Zarucovana hodnota hladiny hlucnosti (Lwa) - Nivel

de Pot_ncia de Som Medido Garantido (Lwa)

992312:99 dBA

992312: 100dB A

2

J

jJ

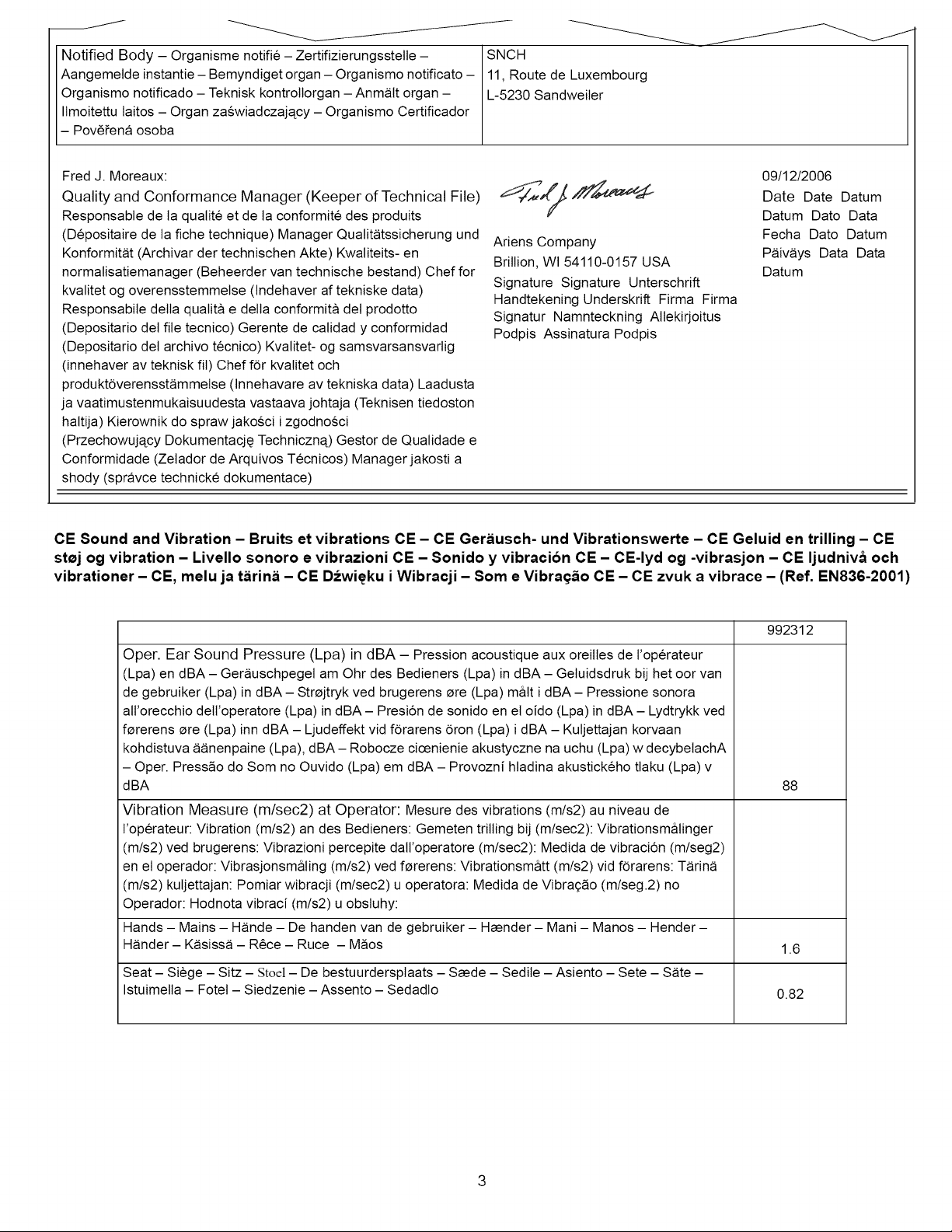

Notified Body - Organisme notifie - Zertifizierungsstelle -

Aangemelde instantie - Bemyndiget organ - Organismo notificato -

Organismo notificado - Teknisk kontrollorgan - AnmNt organ -

Ilmoitettu laitos - Organ za_wiadczajatcy - Organismo Certificador

- Pov_fena osoba

Fred J. Moreaux:

Quality and Conformance Manager (Keeper of Technical File)

Responsable de ta qualite et de ta conformite des produits

(Depositaire de la fiche technique) Manager Qualit&tssicherung und

Konformit&t (Archivar der technischen Akte) Kwaliteits- en

normalisatiemanager (Beheerder van technische bestand) Chef for

kvalitet og overensstemmelse (Indehaver af tekniske data)

Responsabite della qualit& e della conformit& del prodotto

(Depositario del file tecnico) Gerente de calidad y conformidad

(Depositario del archivo tecnico) Kvalitet- og samsvarsansvarlig

(innehaver av teknisk ill) Chef for kvalitet och

produktOverensst&mmelse (Innehavare av tekniska data) Laadusta

ja vaatimustenmukaisuudesta vastaava johtaja (Teknisen tiedoston

haltija) Kierownik do spraw jako_ci i zgodno_ci

(Przechowuja_cy Dokumentacj_ Techniczna) Gestor de Qualidade e

Conformidade (Zelador de Arquivos Tecnicos) Manager jakosti a

shody (spravce technicke dokumentace)

SNCH

11, Route de Luxembourg

L-5230 Sandweiler

Ariens Company

Brillion, WI 54110-0157 USA

Signature Signature Unterschrift

Handtekening Underskrift Firma Firma

Signatur Namnteckning Altekirjoitus

Podpis Assinatura Podpis

09/12/2006

Date Date Datum

Datum Dato Data

Fecha Dato Datum

PNv_ys Data Data

Datum

CE Sound and Vibration - Bruits et vibrations CE - CE Ger_iusch- und Vibrationswerte - CE Geluid en trilling - CE

stoj og vibration - Livello sonoro e vibrazioni CE - Sonido y vibracion CE - CE-lyd og -vibrasjon - CE Ijudniv& och

vibrationer - CE, melu ja t_irin_i- CE D:_wi_pkui Wibracji - Som e Vibrag_o CE - CE zvuk a vibrace - (Ref. EN836-2001)

992312

Oper. Ear Sound Pressure (Lpa) in dBA - Pression acoustique aux oreittes de t'operateur

(Lpa) en dBA - Ger&uschpegel am Ohr des Bedieners (Lpa) in dBA - Geluidsdruk bij het oor van

de gebruiker (Lpa) in dBA - Strejtryk ved brugerens ere (Lpa) m&It i dBA - Pressione sonora

alt'orecchio delt'operatore (Lpa) in dBA - Presi6n de sonido en el oido (Lpa) in dBA - Lydtrykk ved

fererens ere (Lpa) inn dBA - Ljudeffekt vid f5rarens Oron (Lpa) i dBA - Kuljettajan korvaan

kohdistuva &&nenpaine (Lpa), dBA-Robocze cicenienie akustyczne na uchu (Lpa)w decybelachA

- Oper. Press_o do Som no Ouvido (Lpa) em dBA - Provozni hladina akustickeho tlaku (Lpa) v

dBA

Vibration Measure (m/sec2) at Operator: Mesure des vibrations (m/s2) au niveau de

l'operateur: Vibration (m/s2) an des Bedieners: Gemeten trilling bij (m/sec2): Vibrationsm&linger

(m/s2) ved brugerens: Vibrazioni percepite dalt'operatore (m/sec2): Medida de vibraci6n (m/seg2)

en el operador: Vibrasjonsm&ling (m/s2) ved f_rerens: Vibrationsm&tt (m/s2) vid f_rarens: T_rin_

(m/s2) kuljettajan: Pomiar wibracji (m/sec2) u operatora: Medida de Vibrag_o (m/seg.2) no

Operador: Hodnota vibraci (m/s2) u obsluhy:

Hands - Mains - H_nde - De handen van de gebruiker - Haender- Mani- Manos - Hender-

H_nder- K_siss_ - R6ce - Ruce - M_os

Seat - Siege - Sitz - Stoel - De bestuurdersplaats - Saede - Sedile - Asiento - Sete - S_te -

Istuimella - Fotel - Siedzenie - Assento - Sedadlo 0.82

88

1.6

Safety ....................................... 5

Assembly .................................... 10

Controls and Features .......................... 11

Operation .................................... 12

Maintenance Schedule ......................... 16

Service and Adjustments ....................... 17

Storage ...................................... 25

Troubleshooting .............................. 26

Accessories .................................. 27

Service Parts ................................. 27

Specifications ................................ 28

THE MANUAL

Before operation of unit, carefully and completely read your

manuals. The contents will provide you with an

understanding of safety instructions and controls during

normal operation and maintenance.

All reference to left, right, front, or rear are given from

operator sitting in the operation position and facing the

direction of forward travel.

SERVICE AND REPLACEMENT PARTS

"1 When ordering publications, replacement

I model &

I serial

I number

I label from

product

I registration

I here.

L

parts, or making service inquiries, know the

Model and Serial numbers of your unit and

engine.

Numbers are located on the product

registration form in the literature package.

They are printed on a serial number label,

located on the frame of your unit (Figure 1).

PRODUCT REGISTRATION

The Ariens dealer must register the product at the time of

purchase. Registering the product will help the company

process warranty claims or contact you with the latest

service information. All claims meeting requirements during

the limited warranty period will be honored, whether or not

the product registration card is returned. Keep a proof of

purchase if you do not register your unit.

Customer Note: If dealer does not register your product,

please fill out, sign and return the product registration card to

Ariens or go to www.ariens.com on the internet.

UNAUTHORIZED REPLACEMENT PARTS

Use only Ariens replacement parts. The replacement of any

part on this equipment with anything other than an Ariens

authorized replacement part may adversely affect the

performance, durability, and safety of this unit and may void

the warranty. Ariens disclaims liability for any claims or

damages, whether regarding warranty, property damage,

personal injury or death arising out of the use of

unauthorized replacement parts.

NOTE: To locate your nearest Ariens dealer, go to

www.ariens.com on the internet.

Figure 1

• Record Unit Model and Serial numbers here.

• Record Engine Model and Serial numbers here.

OF3510

DISCLAIMER

Ariens reserves the right to discontinue, change, and

improve its products at any time without public notice or

obligation to the purchaser. The descriptions and

specifications contained in this manual were in effect at

printing. Equipment described within this manual may be

optional. Some illustrations may not be applicable to your

unit.

DEALER DELIVERY

Dealer should:

1. Test brakes after unit is assembled to be sure

adjustment has not been disturbed in shipment (See

Adjust the Parking Brake on page 22). Wheel brakes

are properly adjusted at factory.

GB - 4 Copyright 2006 Ariens Company

2.Checkthesafetyinterlocksystemtomakesurethatit

isfunctioningproperly.Withoperatoronseat,unitmust

notstartunlessthesteeringleversareinneutral(N),

theparkingbrakeengaged,andthePowerTakeoff

(PTO)isdisengaged(Off).Enginemuststopif

operatorleavesseatwhensteeringleversareinany

drivepositionorPTOisengaged(On).SeeSafety

Interlock System on page 12.

3. Fill out Original Purchaser Registration Card and

return the card to Ariens.

4. Explain Ariens Limited Warranty Policy.

5. Explain recommended lubrication and maintenance.

Advise customer on adjustments. Instruct customer on

controls and operation of unit. Discuss and emphasize

the Safety Precautions. Give customer

Owner/Operator, Parts, and Engine Manuals. Advise

customer to thoroughly read and understand them.

Customer Note: Your Dealer has been provided complete

setup and preparation instructions which must be completed

prior to you taking delivery of this unit. The dealer is required

to review important information in this manual with you

before or upon delivery of the unit or attachment.

WARNING: This cutting machine is capable of

amputating hands and feet and throwing objects.

Failure to observe the safety instructions in the

manuals and on decals could result in serious injury

or death.

Slopes are a major factor related to loss-of-control

and tip-over accidents. Operation on all slopes

requires extra caution.

Tragic accidents can occur if the operator is not

alert to the presence of children. Never assume that

children will remain where you last saw them.

Gasoline is extremely flammable and the vapors

are explosive, handle with care.

Disengage attachment, stop unit and engine,

remove key, engage parking brake, and allow

moving parts to stop before leaving operator's

position.

SAFETY ALERT SYMBOL

These are safety alert symbols. They mean:

-ATTENTION!

OLI253 1

•YOUR SAFETY IS INVOLVED!

When you see this symbol:

•BECOME ALERT!

•OBEY THE MESSAGE!

OL3900

SIGNAL WORDS

The safety alert symbols above and signal words below are

used on decals and in this manual.

Read and understand all safety messages.

_ ANGER: IMMINENTLY HAZARDOUS

SITUATION! If not avoided, WILL RESULT in death

or serious injury.

_ WARNING: POTENTIALLY HAZARDOUS

SITUATION[ If not avoided, COULD RESULT in

death or serious injury.

CAUTION: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY RESULT in minor

or moderate injury. It may also be used to alert

against unsafe practices.

NOTATIONS

NOTE: General reference information for proper operation

and maintenance practices.

IMPORTANT: Specific procedures or information required to

prevent damage to unit or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working precautions, for

the benefit of yourself and others. Understand and follow all

safety messages. Be alert to unsafe conditions and the

possibility of minor, moderate, or serious injury or death.

Learn applicable rules and laws in your area, including those

that may restrict the age of the operator.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the seller on

safe and proper operation. If unit is to be used by someone

other than original purchaser (loaned, rented or sold),

ALWAYS provide this manual and any needed safety

training before operation.

GB - 5

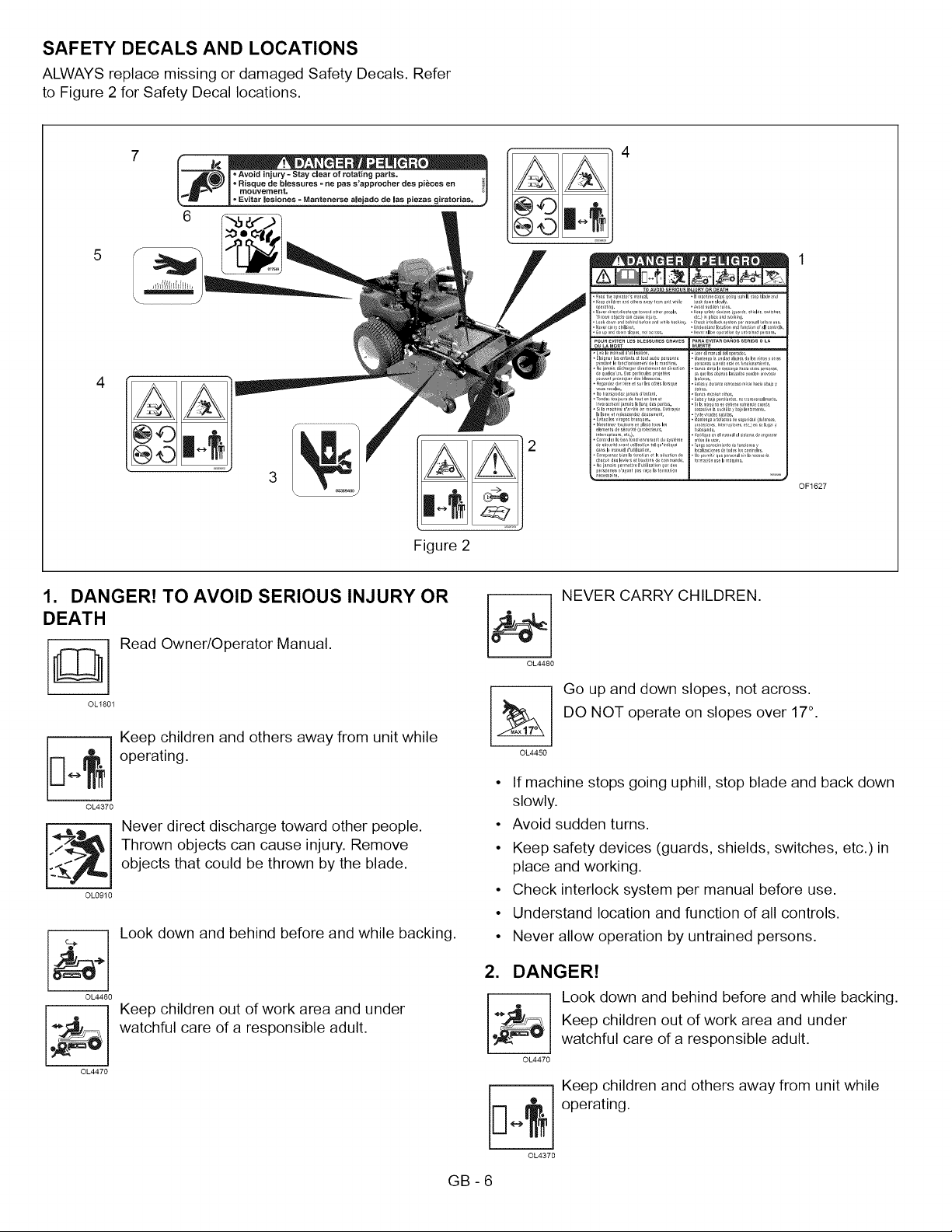

SAFETY DECALS AND LOCATIONS

ALWAYS replace missing or damaged Safety Decals. Refer

to Figure 2 for Safety Decal locations.

@©

@o

OF1627

Figure 2

1. DANGER!TO AVOID SERIOUSINJURY OR

DEATH

Read Owner/Operator Manual.

OLI801

Keep children and others away from unit while

operating.

0L4370

Never direct discharge toward other people.

Thrown objects can cause injury. Remove

objects that could be thrown by the blade.

OL0910

Look down and behind before and while backing.

OL4460

Keep children out of work area and under

watchful care of a responsible adult.

01_4470

NEVER CARRY CHILDREN.

OL4480

Go up and down slopes, not across.

DO NOT operate on slopes over 17°.

OL4450

• If machine stops going uphill, stop blade and back down

slowly.

• Avoid sudden turns.

• Keep safety devices (guards, shields, switches, etc.) in

place and working.

• Check interlock system per manual before use.

• Understand location and function of all controls.

• Never allow operation by untrained persons.

2. DANGER!

Look down and behind before and while backing.

Keep children out of work area and under

watchful care of a responsible adult.

OL4470

Keep children and others away from unit while

operating.

GB-6

0L4370

L_Shut offengine,removekey,readmanualbefore

makinganyrepairsoradjustments.-->

3. PINCH POINT

_ Avoid pinch points.

4. DANGER! ROTATING PARTS

Always keep feet and hands away from rotating

_ parts.

OL3030

Always stand clear of discharge area. Do not

direct discharge toward other people.

OL0910

_ Keep people away from unit while operating.

OL3292

/z'&'%_

(.r'_ _" NO STEP! Always keep feet away from rotating

.... parts.

0L4420

_ AVOID INJURY. Stay clear of rotating parts.

5. HOT SURFACES!

operation. ALWAYS allow parts to cool.

i ,,. -_ DO NOT touch parts which are hot from

OS073I

6. ROTATING PARTS

_ AVOID INJURY. Stay clear of rotating parts.

OF3450

7. DANGER!

AVOID INJURY. Stay clear of rotating parts.

OL4730

SAFETY RULES

Read, understand, and follow all safety practices in

Owner/Operator Manual before beginning assembly. Failure

to follow instructions could result in personal injury and/or

damage to unit.

ALWAYS remove key and/or wire from spark plug before

assembly. Unintentional engine start up can cause death or

serious injury.

Complete a walk around inspection of unit and work area to

understand:

• Work area • Your unit •All safety decals

Determine which attachments are needed and can be used

safely.

Inspect unit before each use for: missing or damaged decals

and shields, correctly operating safety interlock system, and

deterioration of grass catchers. Replace or repair as

needed.

ALWAYS check overhead and side clearances carefully

before operation. ALWAYS be aware of traffic when

operating along streets or curbs.

Keep children and people away.

Keep children out of work area and under watchful care of a

responsible adult.

Keep area of operation clear of all toys, pets, and debris.

Thrown objects can cause injury.

Check for weak spots on docks, ramps or floors. Avoid

uneven work areas and rough terrain. Stay alert for hidden

hazards or traffic.

DO NOT operate near drop-offs, ditches, or embankments.

Unit can suddenly turn over if a wheel is over the edge of a

cliff or ditch, or if an edge caves in.

Data indicates that operators, age 60 and above, are

involved in a larger percentage of riding mower related

injuries. These operators should evaluate their ability to

operate the riding mower safely enough to protect

themselves and others from serious injury.

Read the entire Owner/Operator manual and other training

material. If the operator or the mechanic cannot read the

manual, it is the owner's responsibility to explain it to them.

Only the user can prevent and is responsible for accidents or

injuries occurring to themselves, other people or property.

Only trained adults may operate or service unit. Training

includes actual operation.

Local regulations may restrict the age of the operator.

NEVER allow children to operate or play on or near unit. Be

alert and shut off unit if children enter area.

NEVER operate unit after or during the use of medication,

drugs or alcohol. Safe operation requires your complete and

unimpaired attention at all times.

DO NOT wear loose clothing or jewelry and tie back hair that

may get caught in rotating parts.

Wear adequate outer garments.

NEVER wear open sandals or canvas shoes during

operation. Wear adequate safety gear, protective gloves and

footwear.

Wear proper footwear to improve footing on slippery

surfaces.

Always wear safety goggles or safety glasses with side

shields when operating mower.

GB - 7

Movingpartscancutoramputatefingersorahand.Wrap

blade(s)orwearglovestoservice.Onmultiblademowers,

rotationofonebladewillcauseallbladestorotate.

NEVERplaceyourhandsoranypartofyourbodyor

clothinginsideornearanymovingpartwhileunitisrunning.

ALWAYSkeephandsandfeetawayfromallrotatingparts

duringoperation.Rotatingpartscancutoffbodyparts.

ALWAYSkeepbodyandhandsawayfrompinholesor

nozzleswhichejecthydraulicfluidunderpressure.

DONOTtouchpartswhicharehot.Allowpartstocool.

ALWAYSkeephandsandfeetawayfromallpinchpoints.

Fumesfromtheengineexhaustcancausedeathorserious

injury.DONOTrunengineinanenclosedarea.Always

providegoodventilation.

Read,understand,andfollowallinstructionsinthemanual

andonthemachinebeforestarting.

Understand:

• Howtooperateallcontrols

• Thefunctionsofallcontrols

• HowtoSTOPinanEmergency

• Brakingandsteeringcharacteristics

• Turningradiusandclearances

Keepsafetydevicesorguardsinplaceandfunctioning

properly.NEVERmodifyorremovesafetydevices.

Do not operate without either entire grass catcher or the

discharge guard in place.

Stop engine before removing grass catcher or unclogging

chute.

Ensure Safety Interlock System is functioning properly. DO

NOT operate unit if safety interlock is damaged or disabled.

Start and operate unit only when seated in operator's

position. Steering control levers must be in neutral, PTO

disengaged and parking brake set when starting engine.

Use care when approaching blind corners, shrubs, trees or

other objects that may obscure vision.

Dust, smoke, fog, etc. can reduce vision and cause an

accident. Mow only in daylight or good artificial light.

Avoid slippery surfaces. Always be sure of your footing.

DO NOT mow on wet grass. Reduced traction could cause

sliding and effect the machine's stability.

Watch for traffic when operating near or crossing roadways.

Never carry passengers.

DO NOT try to stabilize the machine by putting your foot on

the ground.

Never direct discharge towards persons or property that may

be injured or damaged by thrown objects. Use extreme

caution on gravel surfaces.

Always stand clear of the discharge area.

ALWAYS disengage PTO, stop unit and engine, remove key,

engage parking brake and allow moving parts to stop before

leaving operator's position.

Never engage PTO while raising attachment or when

attachment is in raised position.

DO NOT operate at too fast a rate. DO NOT change engine

governor settings or over-speed engine. Slow down before

turning.

DO NOT operate in reverse unless absolutely necessary.

ALWAYS look down and behind before and while backing.

Stop and inspect equipment if you strike an object or if there

is an unusual vibration. Repair, if necessary, before

restarting. Never make adjustments or repairs with the

engine running.

Mower blades are sharp and can cut you. Wrap the blade(s)

or wear gloves, and use extra caution when servicing them.

NEVER weld or straighten mower blades.

Rotation of one blade may cause rotation of the other

blades.

Take all possible precautions when leaving unit unattended.

Shut off engine. Remove wire from spark plug and secure it

away from spark plug.

ALWAYS remove key to prevent unauthorized use.

Know the weight of loads. Limit loads to those you can

safely control and the unit can safely handle.

Disengage PTO when attachment is not in use. ALWAYS

turn off power to attachment when travelling, crossing

driveways, etc.

Mow up and down slopes, not across them.

DO NOT operate on slopes of more than 17 degrees.

Use of a Rollover Protection System (ROPS) is

recommended for slope operation. See Attachments and

Accessories.

Always wear a seat belt when operating unit using a

Rollover Protection System (ROPS).

Keep all movements on the slope slow and gradual. Do not

make sudden changes in speed or direction.

Avoid starting or stopping on the slope. If tires lose traction,

disengage the blades and proceed slowly straight down the

slope.

If you cannot back up a slope or you feel uneasy on it, do not

mow it.

DO NOT park on slopes unless necessary. When parking on

slope always chock or block wheels. Always set parking

brake.

Use a slow speed. Tires may lose traction on slopes even

though the brakes are functioning properly.

Do not bypass transmission when on a slope.

Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the hitch

point.

Follow the manufacturer's recommendations for weight

limits for towed equipment and towing on slopes.

NEVER allow children or others in or on towed equipment.

On slopes, the weight of the towed equipment may cause

loss of control.

Travel slowly and allow extra distance to stop.

GB-8

Useextracarewhenloadingorunloadingunitontotraileror

truck.

Secureunitchassistotransportvehicle.NEVERsecure

fromrodsorlinkagesthatcouldbedamaged.

DONOTtransportmachinewhileengineisrunning.

ALWAYSturnoffpowertoattachmentandshutofffuelwhen

transportingunit.

Keepunitfreeofdebris.Cleanupoilorfuelspills.

Thisproductisequippedwithaninternalcombustiontype

engine.DONOTuseunitonornearanyunimproved,

forest-coveredorbrushcoveredlandunlessexhaustsystem

isequippedwithasparkarrestermeetingapplicablelocal,

stateorfederallaws.Asparkarrester,ifitisused,mustbe

maintainedineffectiveworkingorderbyoperator.

Fuelishighlyflammableanditsvaporsareexplosive.

Handlewithcare.Useanapprovedfuelcontainer.

NOsmoking,NOsparks,NOflames.ALWAYSallowengine

tocoolbeforeservicing.

NEVERfillfueltankwhenengineisrunningorhotfrom

operation.

NEVERfillordrainfueltankindoors.

Replacefuelcapsecurelyandcleanupspilledfuel.

Neverfillcontainersinsideavehicleoronatruckortrailer

bedwithaplasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

Whenpractical,removegas-poweredequipmentfromthe

truckortrailerandrefuelitontheground.Ifthisisnot

possible,thenrefuelsuchequipmentonatrailerwitha

portablecontainer,ratherthanfromagasolinedispenser

nozzle.

Keepthenozzleincontactwiththerimofthefueltankor

containeropeningatalltimesuntilfuelingiscomplete.Do

notusea nozzlelock-opendevice.

Iffuelisspilledonclothing,changeclothingimmediately.

AvoidElectricShock.Objectscontactingbothbattery

terminalsatthesametimemayresultininjuryandunit

damage.DONOTreversebatteryconnections.

Reverseconnectionsmayresultinsparkswhichcancause

seriousinjury.Alwaysconnectpositive(+)leadofchargerto

positive(+)terminal,andnegative(-)leadtonegative(-)

terminal.

ALWAYSdisconnectnegative(-)cableFIRSTandpositive

(+)cableSECOND.ALWAYSconnectpositive(+)cable

FIRST,andnegative(-)cableSECOND.

ExplosiveGasesfrombatterycancausedeathorserious

injury.Poisonousbatteryfluidcontainssulfuricacidandits

contactwithskin,eyesorclothingcancausesevere

chemicalburns.

Noflames,Nosparks,Nosmokingnearbattery.

ALWAYSwearsafetyglassesandprotectivegearnear

battery.Useinsulatedtools.

DONOTTIPbatterybeyonda45° angleinanydirection.

ALWAYSkeepbatteriesoutofreachofchildren.

Batteryposts,terminalsandrelatedaccessoriescontain

leadandleadcompounds,chemicalsknowntotheStateof

Californiatocausecancerandreproductiveharm.Wash

handsafterhandling.

ALWAYSblockwheelsandknowalljackstandsarestrong

andsecureandwillholdweightofunitduringmaintenance.

Releasepressureslowlyfromcomponentswithstored

energy.

NEVERattempttomakeanyadjustmentstounitwhile

engineisrunning(exceptwherespecificallyrecommended).

Stopengine,removekeyorsparkplugwireandwaitforall

movingpartstostopbeforeservicingorcleaning.

Checkparkingbrakeoperationfrequently.Adjustand

serviceasrequired.

ALWAYSmaintainunitinsafeoperatingcondition.Damaged

orwornoutmufflercancausefireorexplosion.

Maintainorreplacesafetyandinstructionlabels,as

necessary.

NEVERstoreunitwithfuelinfueltank,insideabuilding

whereanyignitionsourcesarepresent.

Shutofffuelandallowenginetocoolcompletelybefore

storinginclosedareaorcoveringunit.

Cleangrassanddebrisfromunit,especiallyfromaround

mufflerandengine,to helppreventfires.

Forextendedstorage,shutofffuelandcleanunitthoroughly.

Seeenginemanualforproperstorage.

Lowercuttingdeckunlessapositivemechanicallockis

used.

Useonlyattachmentsoraccessoriesdesignedforyourunit.

Checkallhardwareatregularintervals,especiallyblade

attachmentbolts.Keepallhardwareproperlytightened.

Checkattachmentcomponentsfrequently.Ifwornor

damaged,replacewithmanufacturer'srecommendedparts.

GB- 9

_ ARNING: AVOID INJURY. Read and understand

entire Safety section before proceeding.

UNIT ASSEMBLY

Package Contents:

Unit, Mower Deck and Literature Pack

Unpack Unit

Remove unit and all other components from shipping

container. Open bypass valves (see MOVING THE UNIT

WITH THE ENGINE OFF on page 15). Push unit from

container onto a level surface. Close bypass valves.

Check Tire Pressure

See SPECIFICATIONS on page 28.

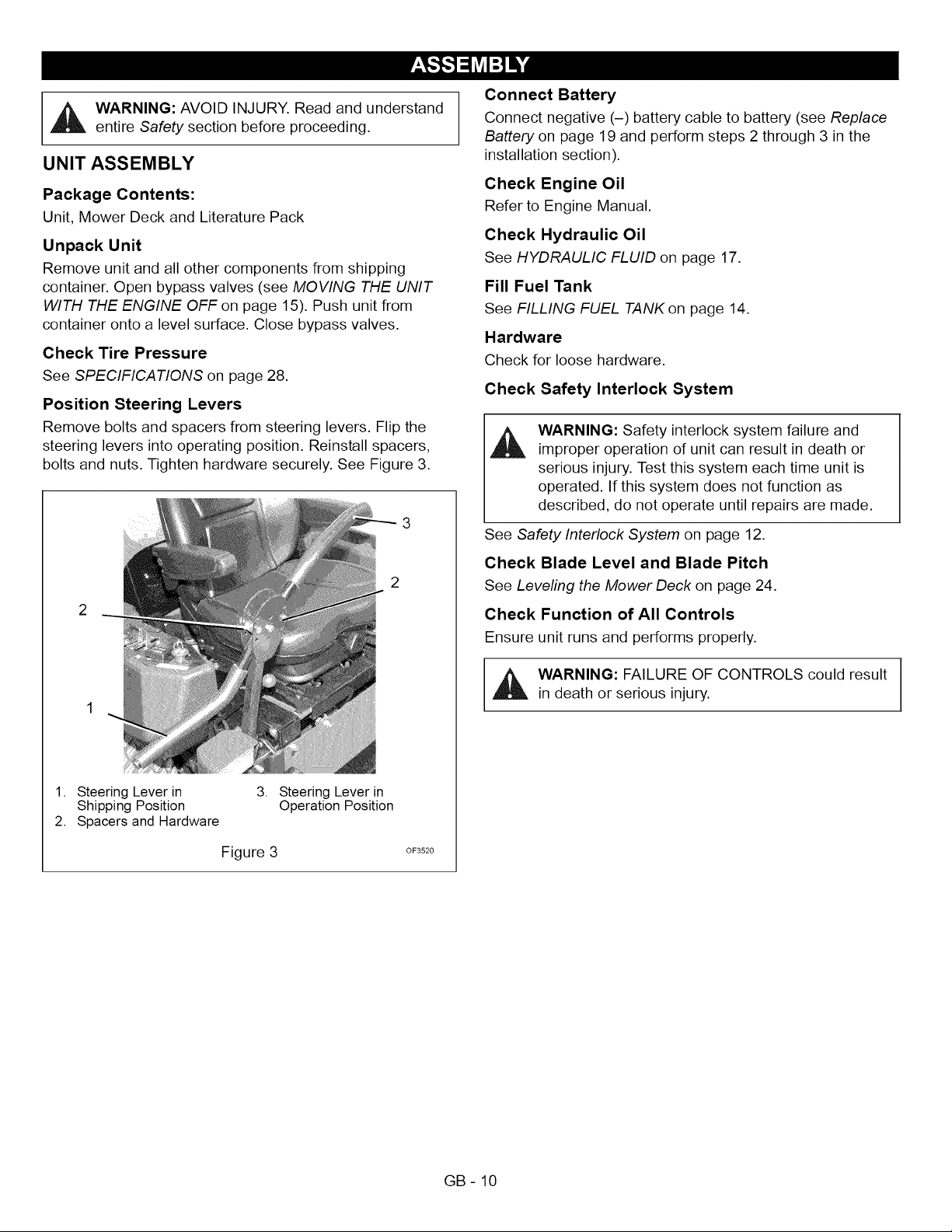

Position Steering Levers

Remove bolts and spacers from steering levers. Flip the

steering levers into operating position. Reinstall spacers,

bolts and nuts. Tighten hardware securely. See Figure 3.

3

Connect Battery

Connect negative (-) battery cable to battery (see Replace

Battery on page 19 and perform steps 2 through 3 in the

installation section).

Check Engine Oil

Refer to Engine Manual.

Check Hydraulic Oil

See HYDRAULIC FLUID on page 17.

Fill Fuel Tank

See FILLING FUEL TANK on page 14.

Hardware

Check for loose hardware.

Check Safety Interlock System

WARNING: Safety interlock system failure and

improper operation of unit can result in death or

serious injury. Test this system each time unit is

operated. If this system does not function as

described, do not operate until repairs are made.

See Safety Interlock System on page 12.

Check Blade Level and Blade Pitch

See Leveling the Mower Deck on page 24.

Check Function of All Controls

Ensure unit runs and performs properly.

1. Steering Lever in

Shipping Position

2. Spacers and Hardware

3. Steering Lever in

Operation Position

Figure 3

OF3520

_ ARNING: FAILURE OF CONTROLS could result

in death or serious injury.

GB- 10

15

17

18

16

13

12

2O

11

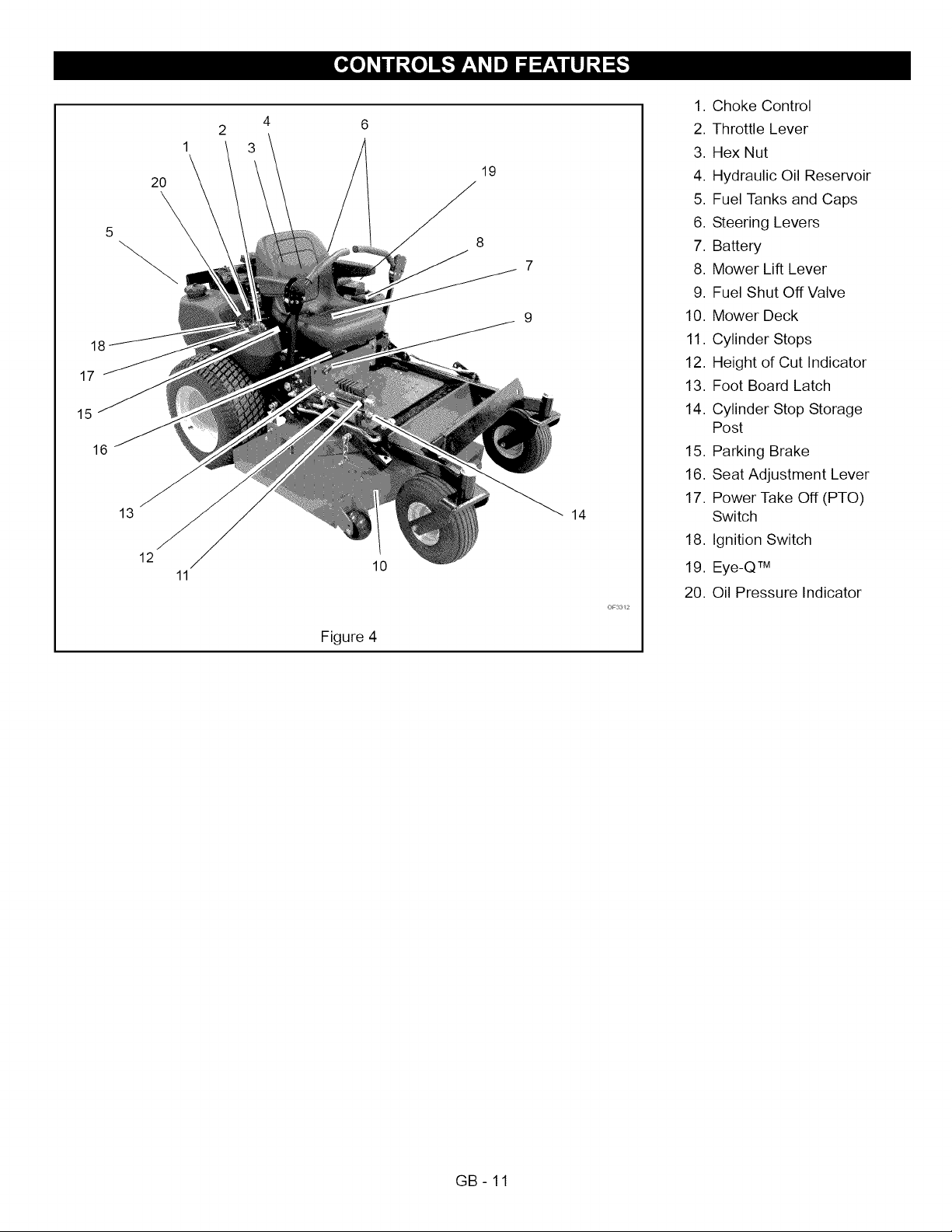

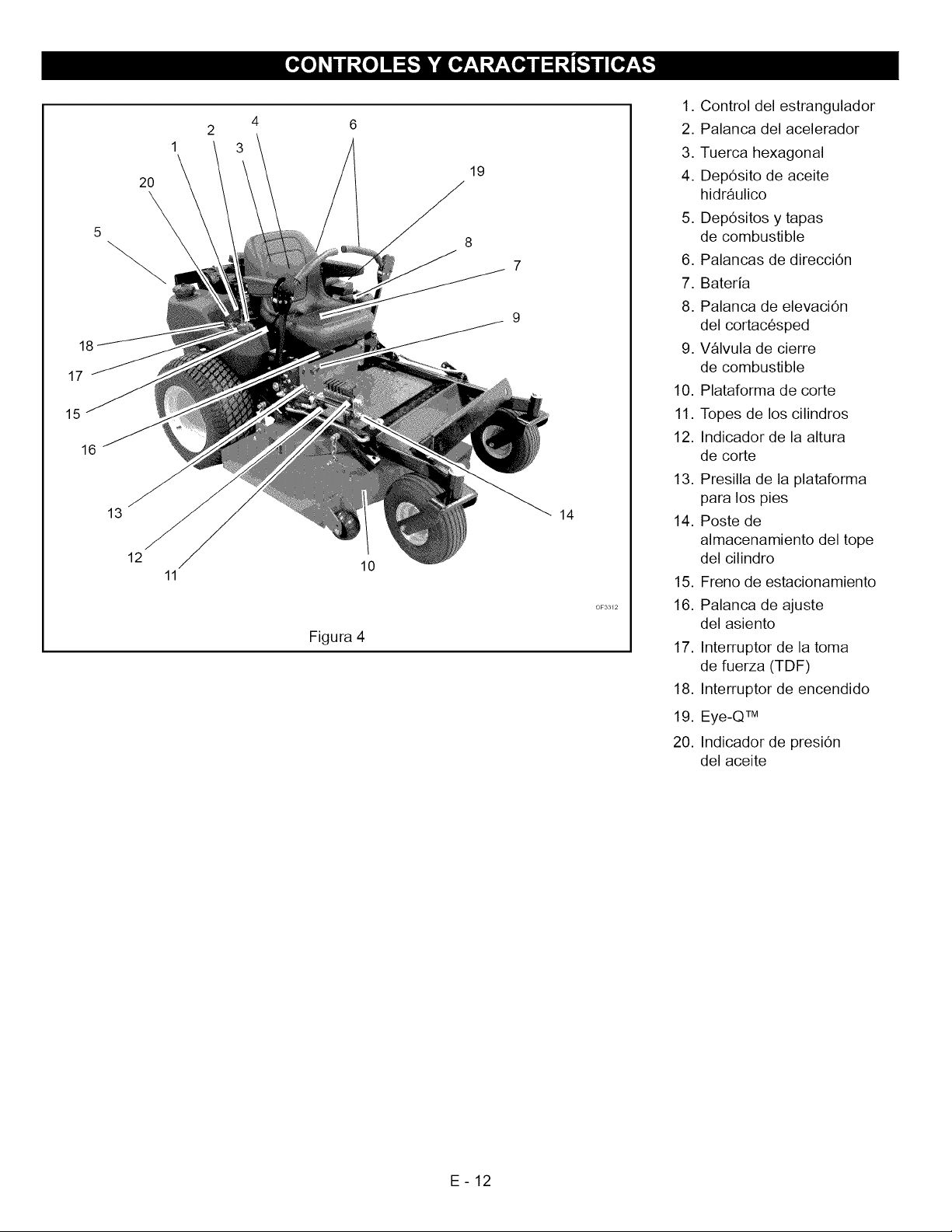

1. Choke Control

6

2. Throttle Lever

3. Hex Nut

19

4. Hydraulic Oil Reservoir

5. Fuel Tanks and Caps

6. Steering Levers

7. Battery

8. Mower Lift Lever

9. Fuel Shut Off Valve

10. Mower Deck

11. Cylinder Stops

12. Height of Cut Indicator

13. Foot Board Latch

14. Cylinder Stop Storage

Post

15. Parking Brake

16. Seat Adjustment Lever

17. Power Take Off (PTO)

14

Switch

18. Ignition Switch

10

19. Eye-QTM

20. Oil Pressure Indicator

Figure 4

GB-11

_ ARNING: AVOID INJURY. Read and understand

entire Safety section before proceeding.

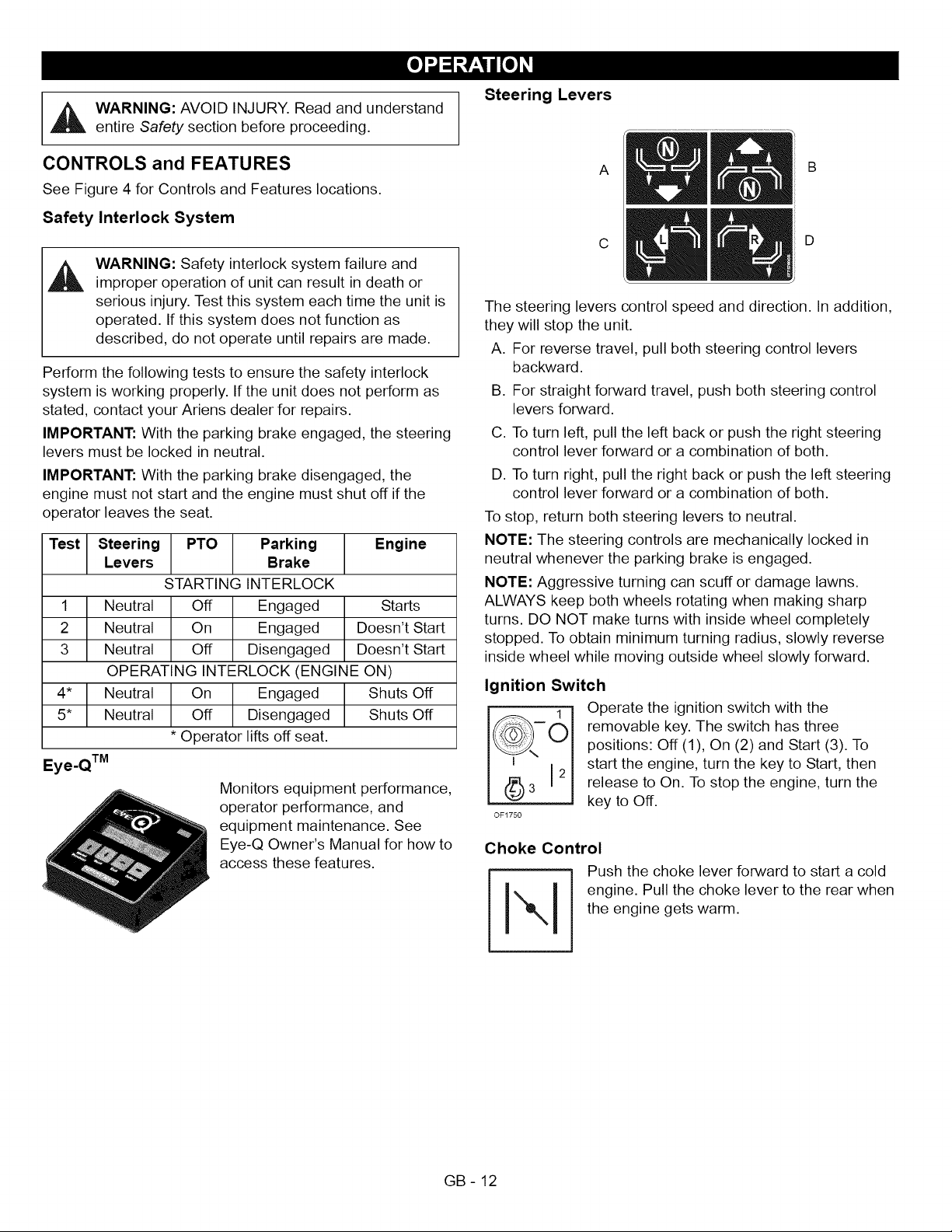

Steering Levers

CONTROLS and FEATURES

See Figure 4 for Controls and Features locations.

Safety Interlock System

WARNING: Safety interlock system failure and

improper operation of unit can result in death or

serious injury. Test this system each time the unit is

operated. If this system does not function as

described, do not operate until repairs are made.

Perform the following tests to ensure the safety interlock

system is working properly. If the unit does not perform as

stated, contact your Ariens dealer for repairs.

IMPORTANT: With the parking brake engaged, the steering

levers must be locked in neutral.

IMPORTANT: With the parking brake disengaged, the

engine must not start and the engine must shut off if the

operator leaves the seat.

Test Steering PTO Parking Engine

Levers Brake

STARTING INTERLOCK

1

2

3

5*

Eye.Q TM

Neutral Off Engaged

Neutral On Engaged

Neutral Off Disengaged

OPERATING INTERLOCK (ENGINE ON)

Neutral On Engaged Shuts Off

Neutral Off Disengaged Shuts Off

* Operator lifts off seat.

Monitors equipment performance,

operator performance, and

equipment maintenance. See

Eye-Q Owner's Manual for how to

access these features.

Starts

Doesn't Start

Doesn't Start

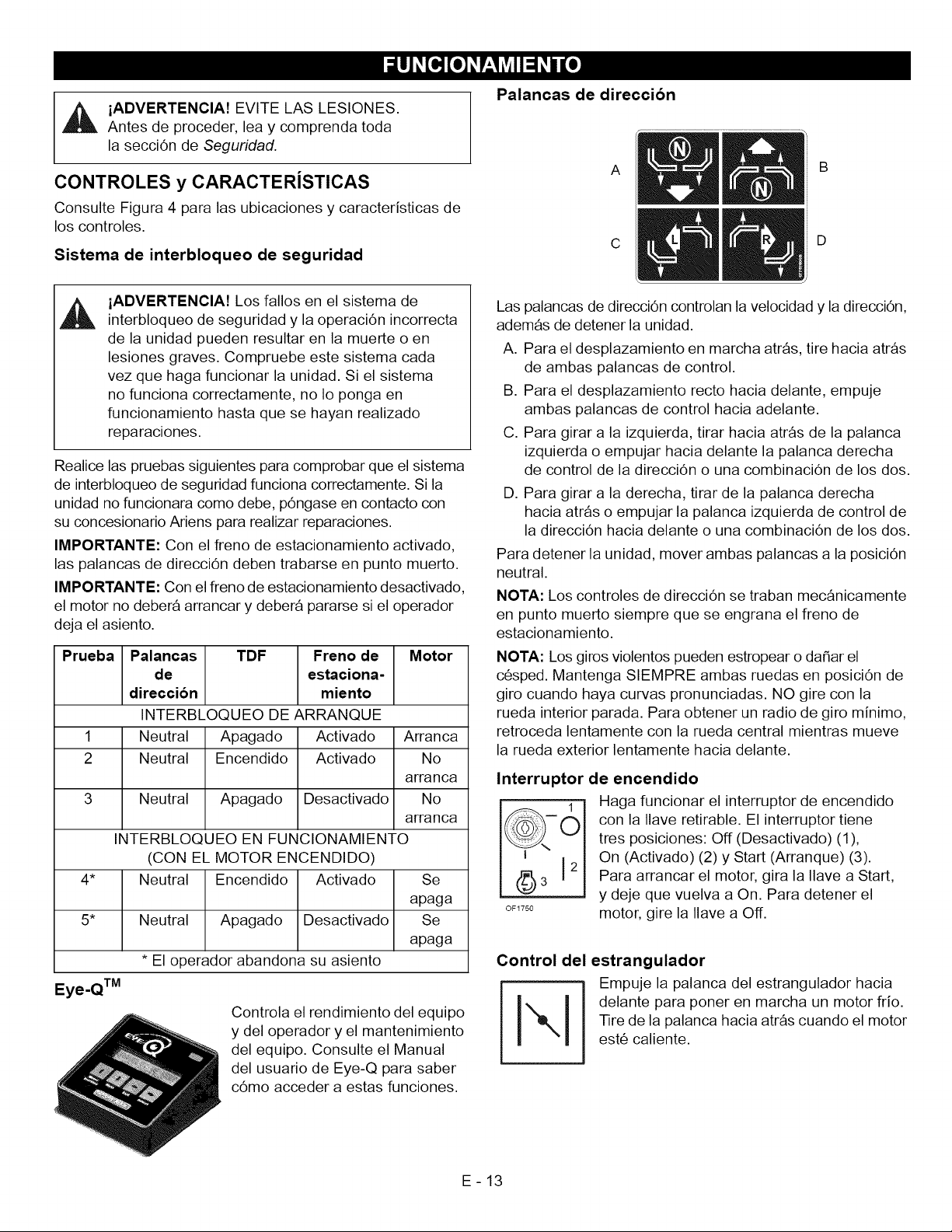

A

C

The steering levers control speed and direction. In addition,

they will stop the unit.

A. For reverse travel, pull both steering control levers

backward.

B. For straight forward travel, push both steering control

levers forward.

C. To turn left, pull the left back or push the right steering

control lever forward or a combination of both.

D. To turn right, pull the right back or push the left steering

control lever forward or a combination of both.

To stop, return both steering levers to neutral.

NOTE: The steering controls are mechanically locked in

neutral whenever the parking brake is engaged.

NOTE: Aggressive turning can scuff or damage lawns.

ALWAYS keep both wheels rotating when making sharp

turns. DO NOT make turns with inside wheel completely

stopped. To obtain minimum turning radius, slowly reverse

inside wheel while moving outside wheel slowly forward.

Ignition Switch

Operate the ignition switch with the

removable key. The switch has three

positions: Off (1), On (2) and Start (3). To

start the engine, turn the key to Start, then

release to On. To stop the engine, turn the

OF1750

Choke Control

key to Off.

Push the choke lever forward to start a cold

B

D

GB- 12

I N,_ _ engine. Pull the choke lever to the rear when

the engine gets warm.

i

Throttle Lever

1

Changes the engine speed.

Fast (1) -Increases engine speed.

Fuel Shut-Off Valve

Control fuel flow from left or right fuel tank.

Open the valve to operate the engine. Turn

the valve to Off when storing or transporting

the unit.

OF1881

Parking Brake Lever

1. Pull lever up to engage parking brake.

Slow (2) - Decreases engine speed.

Power Take

Off (PTO) 8witch

Power take off (PTO) switch engages and

disengages the mower blades.

Pull the power take off (PTO) switch to On

position to engage mower blades (1).

Push the power take off (PTO) switch to Off

position to disengage mower blades (2).

NOTE: The engine will not start unless the

steering control levers are in the neutral posi-

tion, the PTO switch is in the Off position and

OE0261

parking brake is set.

Mower Lift Lever

To lower (1)- Move mower lift lever forward.

Raises and lowers the mower deck.

t"

t"

$

To raise (2) - Move mower lift lever rearward.

Release lever to hold the mower deck in

t OF1700

selected position.

,_(Q)_, 2. Push lever down to disengage parking

÷(Q)÷ brake.

"_'OF1740

Seat Adjustments

_ WARNING: Make all seat adjustments with unit

stationary, parking brake on and engine shut off.

To adjust seat forward or backward:

1. While seated, pull seat adjustment lever outward and

slide seat into desired position.

2. Release lever and slide seat forward or back to lock

seat into position.

Engine Oil Pressure Indicator

Refer to engine manual.

i ndicator lights up Red if the oil pressure is

low. Check oil level and add if necessary.

I

Hour Meter

Records total number of hours the engine

has been run.

IMPORTANT: Keep a record of Hour Meter

readings for recommended Lubrication and

Maintenance intervals.

NOTE: For accurate readings be sure Igni-

tion Switch is OFF when unit is not in opera-

tion.

Cylinder Stops

,_ CAUTION: AVOID PINCH POINTS. Always use the

T-portion of the cylinder stop when removing or

installing the cylinder stops.

Ensure the same cutting height after raising the deck to clear

an obstacle. Store the stops on the post behind the hydraulic

lift cylinder. The stops come in two (2) sizes, 11/32 in.

(8.73 mm) and 11/16 in. (17.5 mm).

1. Remove the cylinder stops from the post and snap

onto the lift cylinder rod.

2. Push the lift lever forward until the cylinder rests

against the cylinder stops.

GB- 13

FILLING FUEL TANK STARTING AND SHUT OFF

CAUTION: Read entire Owner/Operator Manual,

WARNING: AVOID INJURY. Read and understand

entire Safety section before proceeding.

Clutch Manual, and Engine Manual first. DO NOT

attempt to start engine at this time.

Add fuel to Fuel Tank as needed. See your Engine Manual

for correct type and grade of fuel.

To add fuel to the fuel tank:

1. Place unit in an open or well-ventilated open area.

2. Stop the engine.

3. Clean the fuel cap and the area around the fuel cap to

prevent dirt from entering the fuel tank. Remove the

cap from the fuel tank.

4. Fill the fuel tank to within 1 in. (25 mm) below bottom of

filler neck.

5. Replace fuel cap and tighten.

6. Clean up any spilled fuel.

PRE-START

,i_ CAUTION: Make sure all hardware is tight, all

safety devices are in place and all adjustments are

made correctly.

1. Check Safety Interlock System

If this system does not function as described do not operate

until repairs are made.

2. Check Air Cleaner

Check air filter for dirt. Clean as required. Follow Engine

Manual Maintenance Schedule.

NOTE: DO NOT operate starter more than 15 seconds per

minute, as overheating and damage can occur. If engine will

not start, see TROUBLESHOOTING on page 26 or refer to

Engine Manual.

NOTE: The engine will not start unless the steering control

levers are in the neutral position, the PTO switch is in the off

position, and parking brake is engaged.

To start:

1. If the engine is cold, move the choke control to the On

position. If the engine is warm or hot, do not use

choke.

,

Move the throttle to 3/4 Fast position. See Engine

Manual for detailed instructions.

3.

Put the ignition key in the switch and turn it to the Start

position.

4.

As soon as the engine starts, release the key.

5.

Move the choke control to the Off position from the

Choke position. Wait until the engine is running

smoothly before operation.

To shut off:

1. Bring the steering levers to neutral. Disengage the

PTO and engage the parking brake.

2. Move the throttle lever to the Slow position.

3. Turn the ignition key to the Off position.

3. Check Engine Fuel and Crankcase Oil

Check and add fuel if required. Check that engine crankcase

oil is full. Follow Engine Manual Maintenance Schedule.

4. Check Tire Pressure

5. Check Hydraulic Fluid Level

6. Adjust Seat

Be sure all controls can be reached safely from operator's

position.

7. Set Cutting Height

Make sure the deck is set to the correct cutting height.

STOPPING IN AN EMERGENCY

The unit can be stopped immediately at any time by turning

the ignition key to the Off position.

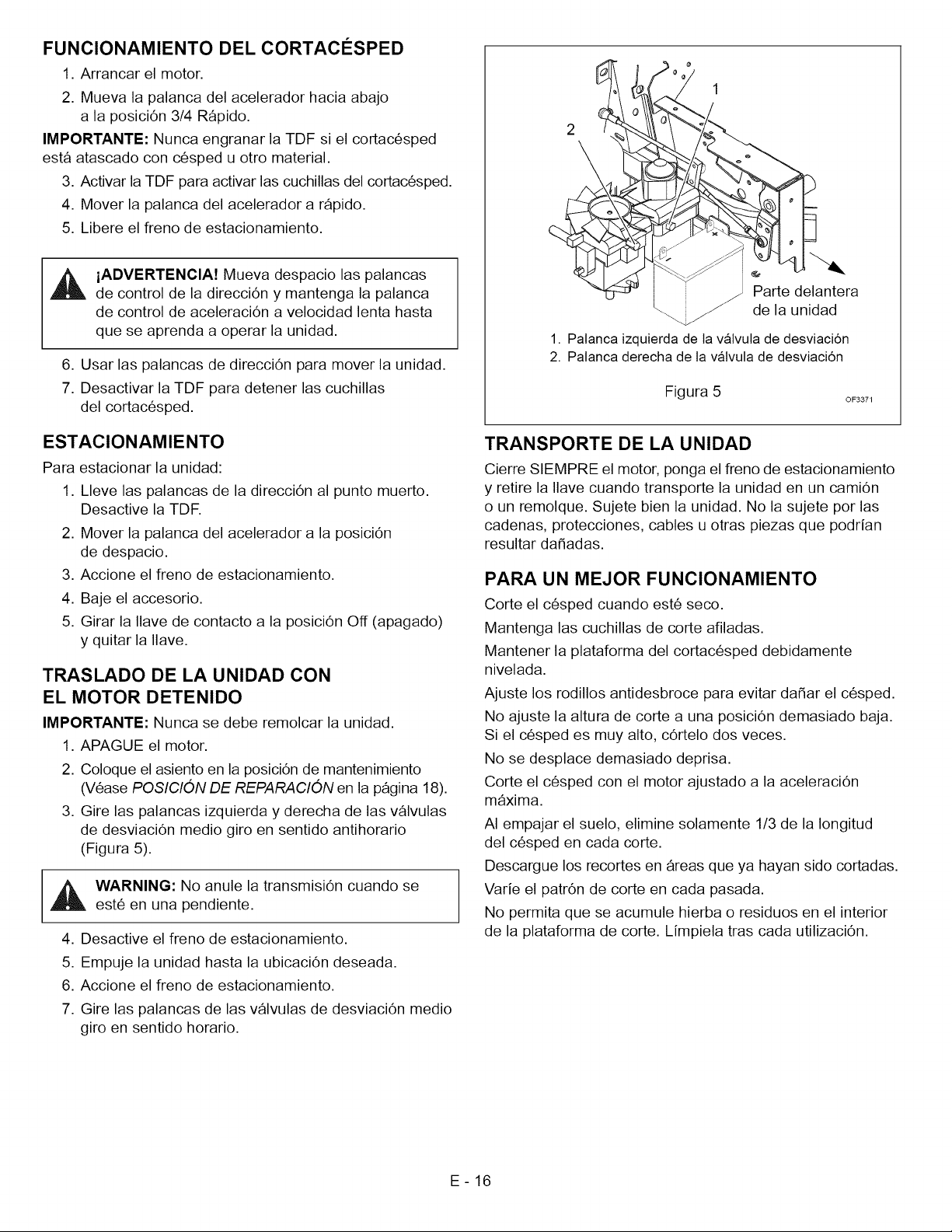

OPERATING MOWER

1. Start engine.

2. Move throttle lever 3/4 Fast position.

IMPORTANT: Never engage the PTO if the mower is

plugged with grass or other material.

3. Engage PTO to engage mower blades.

4. Move throttle lever to fast.

5. Release parking brake.

,i_ WARNING: Move the steering control levers slowly

and keep the throttle control lever at slow speed

until you learn how to operate the unit.

6. Use steering levers to move the unit.

7. Disengage PTO to stop mower blades.

GB- 14

PARKING

To park the unit:

1. Bring the steering levers to neutral. Turn off PTO.

2. Move the throttle lever to the Slow position.

3. Engage the parking brake.

4. Lower the attachment.

5. Turn the ignition key to the Off position and remove the

key.

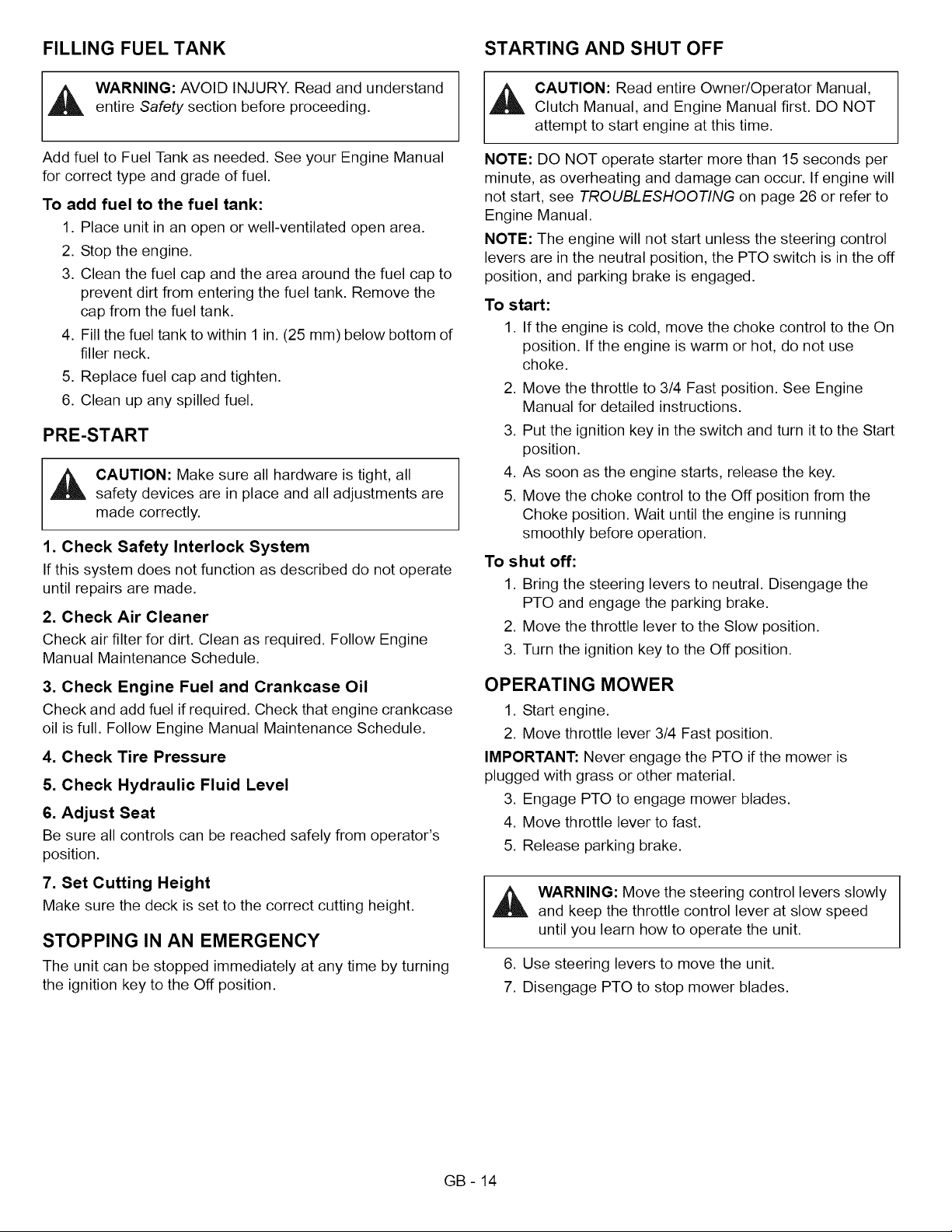

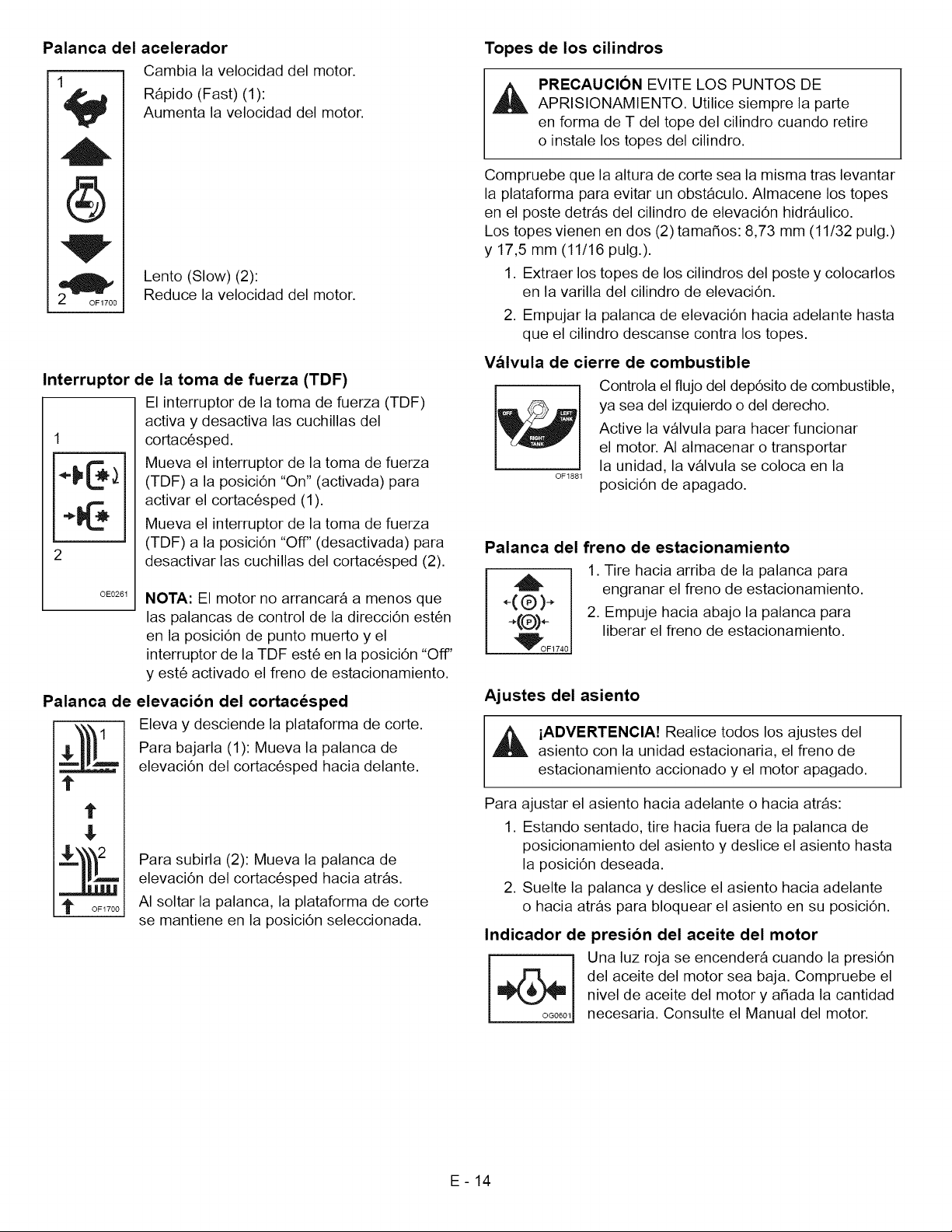

MOVING THE UNIT WITH THE ENGINE OFF

IMPORTANT: Never tow unit.

1. Shut OFF engine.

2. Place seat in the service position (See SERVICE

POSITION on page 17).

3. Turn right and left bypass valve levers

counterclockwise 1/2 turn (Figure 5).

_ ARNING: Do not bypass transmission when on a

slope.

4. Disengage parking brake.

5. Push unit to desired location.

6. Engage parking brake.

7. Turn bypass valve levers clockwise 1/2 turn.

TRANSPORTING UNIT

ALWAYS shut off engine, set parking brake, and remove key

when transporting unit on a truck or trailer. Tie unit down

securely. Do not tie down by linkages, guards, cables or

other parts that may be damaged.

FOR BEST PERFORMANCE

Cut grass when it is dry.

Keep mower blades sharp.

Keep mower deck properly leveled.

Adjust anti-scalp rollers to prevent scalping.

Do not set height of cut too low. For very tall grass, mow

twice.

Do not travel too fast.

Mow with the engine set at full throttle.

When mulching, only remove 1/3 of grass length per cutting.

Discharge clippings into areas already cut.

Vary cutting pattern with each mowing.

Do not allow grass or debris to collect inside of mower deck.

Clean after each use.

2

1. Left Bypass Valve Lever

2. Right Bypass Valve Lever

Figure 5

Front of unit

OF3371

GB- 15

WARNING: AVOID INJURY. Read and understand

entire Safety section before proceeding.

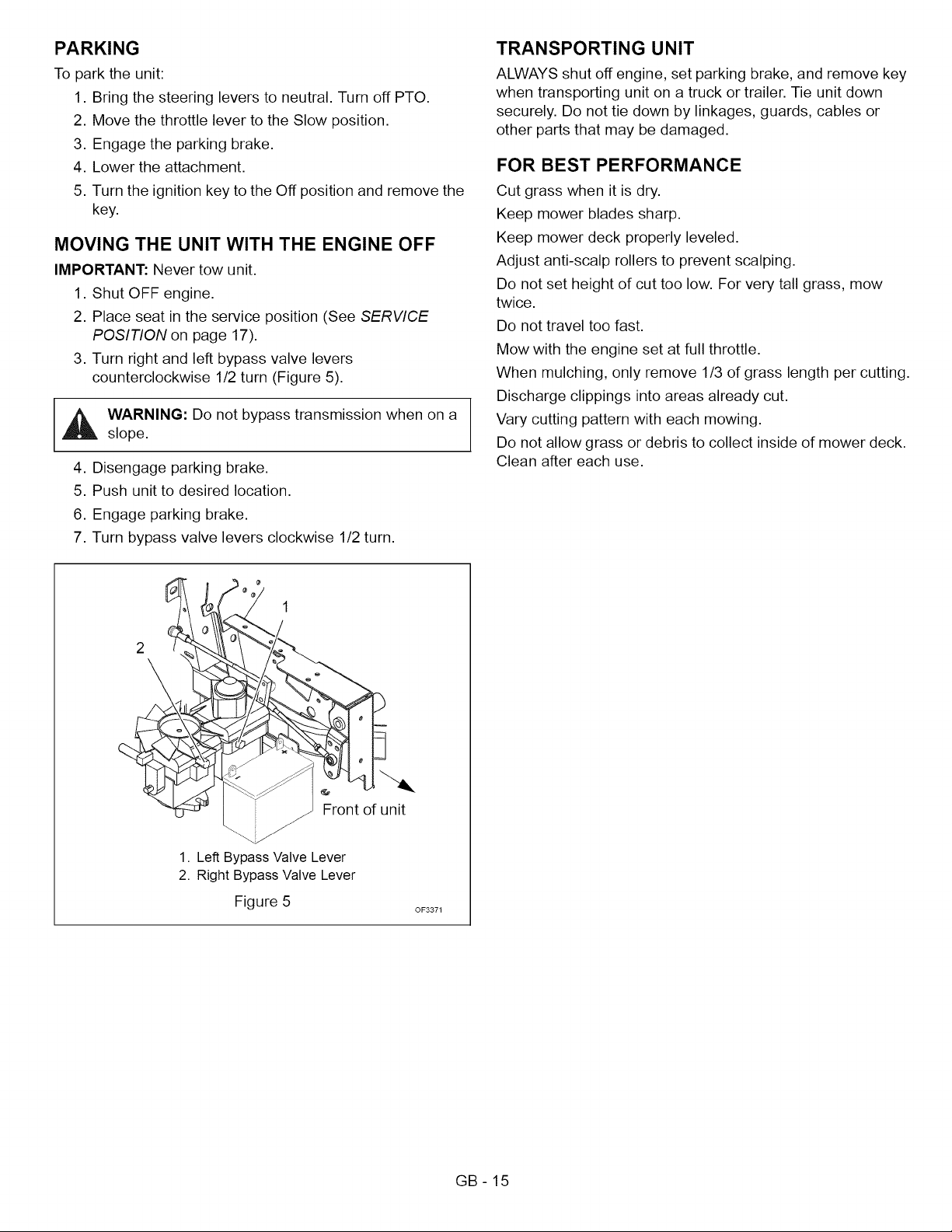

Interval Task Action

Check Safety Interlock System

_b ARNING: Safety interlock system failure and improper

Proper maintenance can prolong the life of unit. The

following charts show the recommended service schedule.

More frequent service may be required due to working

conditions (heavy loads, high ambient temperatures, dusty

conditions, or airborne debris).

See the maintenance instructions in the Engine Manual for

additional information.

operation of unit can result in death or serious injury.

Test this system each time the unit is operated. If this

system does not function as described, do not operate

until repairs are made. See Safety Interlock System on

page 12.

Check Parking Brake

Each

Use

Every 25

Hours

Every 50 Lubricate Front Axle and Pivot Points Oil all pivot points, pin connections, and apply grease to front

Hours axle grease zerk (see LUBRICATE UNITon page 20).

Every

100

Hours

Every

400

Hours

Check Hydraulic Oil Level

Check Tires

Clean Unit

Follow Engine Maintenance Schedule

Check Mower Blades

Clean Battery

Check Fasteners

Check All Belts

Grease Front Axle Castor Pivots

Engage parking brake. Push unit. If unit rolls, adjust parking

brake (see PARKING BRAKE ADJUSTMENT on page 22).

See Check Hydraufic Fluid Level on page 17.

See SPECIFICATIONS on page 28 for correct tire pressure.

Clean engine, battery, seat, mower deck, etc. of dirt and debris.

Do not use solvents, hard cleaners, or abrasives.

NOTE: Protect painted surfaces with automotive type wax.

Perform scheduled engine maintenance. Refer to Engine

Manual for detailed instructions.

Ensure mower blade hardware istightened to 115 - 125 Ibf-ft.

(156- 169 Nom). Check mower blades for wear. Sharpen or

replace mower blades as needed (see Sharpen the Mower

Blades on page 18).

Keep battery and battery terminals clean (see Clean Battery on

page 19).

Check mower blade mounting hardware and all other fasteners.

Replace missing or damaged fasteners. Tighten all nuts and

bolts to their correct torque value.

Replace worn or deteriorated belts.

• Check mower drive belt. See Replacing Mower Belts on

page 22 for belt location.

• Check PTO belt. See Replacing Mower Belts on page 22

for belt location.

Check transmission belt. See Replacing the Hydro Pump

Belt on page 23 for belt location.

Repack front axle castor pivots (see LUBRICATE UNIT on

page 20).

Every

500

Hours

Change Hydraulic Oil and Filter

See Change Hydraulic Fluid and Filter on page 17.

GB- 16

AriensDealerswillprovideanyservicewhichmayberequired

tokeepyourunitoperatingatpeakefficiency.Shouldengine

serviceberequired,itcanbeobtainedfromaAriensDealer

ortheenginemanufacturer'sauthorizedservicecenter.

_h ARNING: AVOID INJURY. Read and understand

entire Safety section before proceeding.

_ CAUTION: HOT SURFACES may result in injury.

DO NOT touch engine or drive parts which are hot

from operation. Allow parts to cool before servicing.

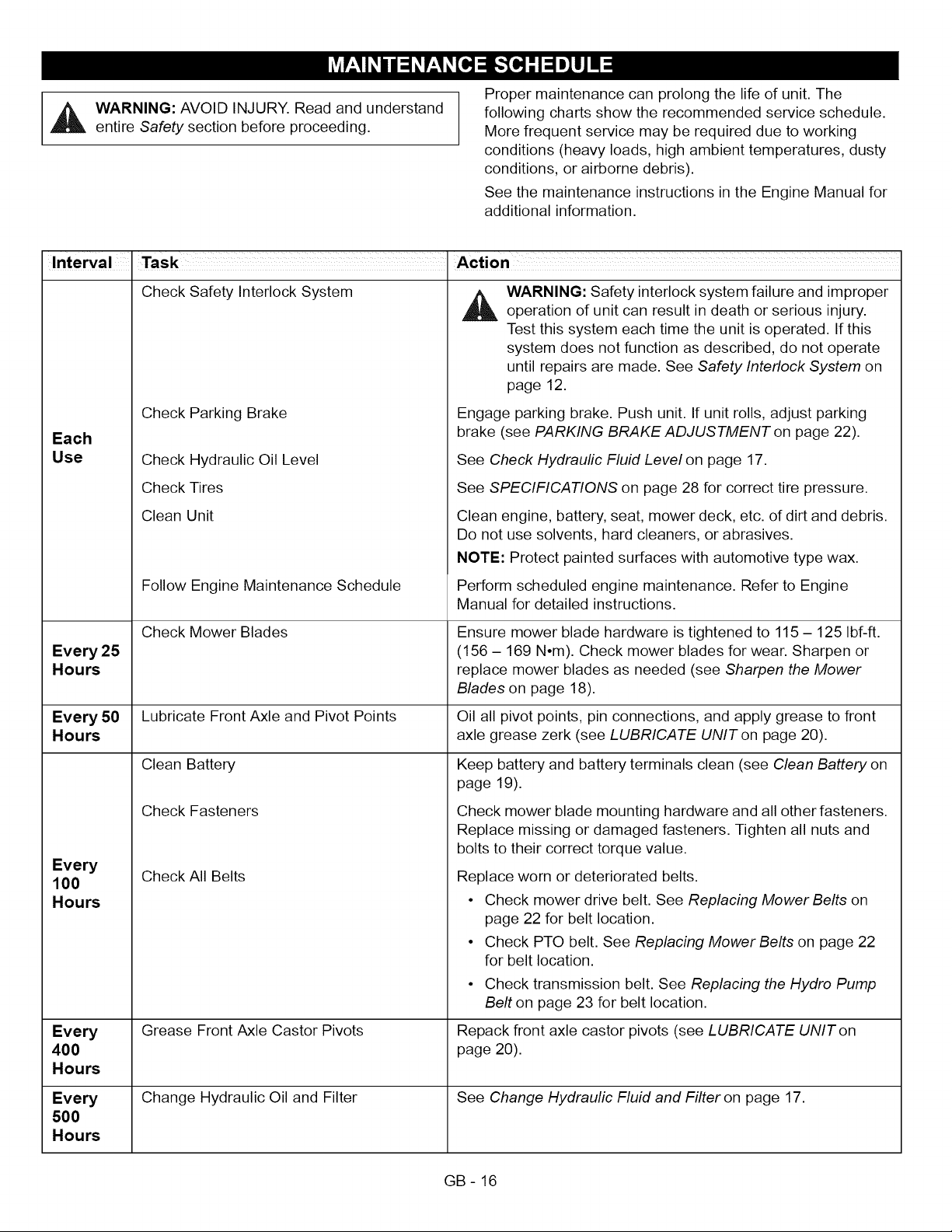

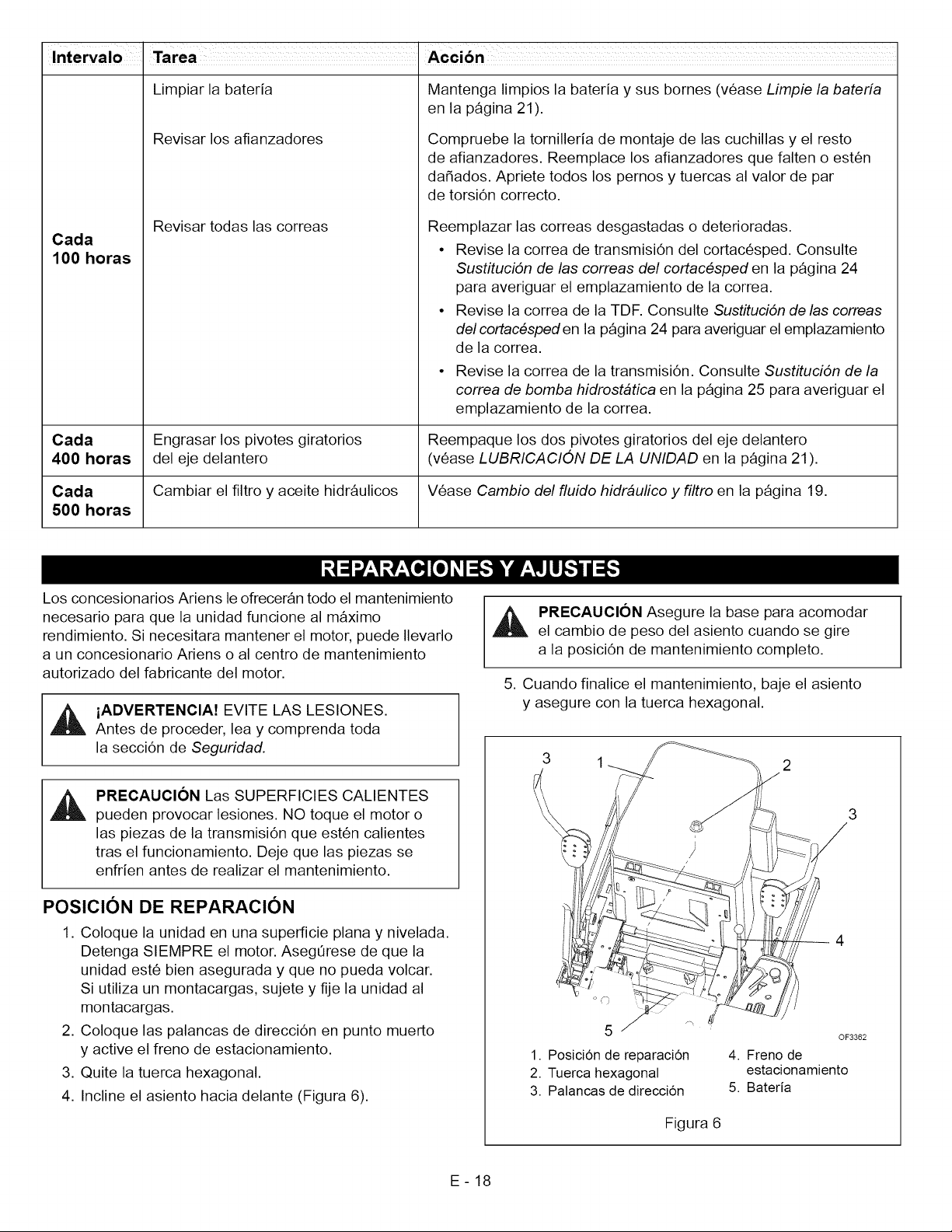

SERVICE POSITION

1. Place unit on a flat level surface. ALWAYS stop engine.

Ensure unit is secure and will not tip over. Strap and

clamp onto lift if used.

2. Place steering levers in neutral and engage parking

brake.

3. Remove hex nut.

4. Tip seat forward (Figure 6).

_i AUTION: Be sure footing is secure to

accomodate weight shift of seat when rotating it into

service position.

5. When service is complete, lower seat and secure with

hex nut.

4

5

1. Service Position 4. Parking Brake

2. Hex Nut 5. Battery

3. Steering Levers

Figure 6

OF3362

HYDRAULIC FLUID

WARNING: HYDRAULIC FLUID can result in

severe burns. Fluid in hydraulic system can

penetrate skin and result in serious injury or death.

Be sure to stop the engine before doing any work

on hydraulic parts.

Keep body and hands away from pin holes or

nozzles which expel hydraulic fluid when under

pressure. Use paper or cardboard, not hands, to

search for leaks.

Ensure all hydraulic fluid connections are tight and

all hydraulic hoses and lines are in good condition

before applying pressure to system.

FOREIGN FLUID INJECTED INTO BODY can

result in gangrene. Fluid must be surgically

removed within a few hours by a doctor familiar with

this form of injury.

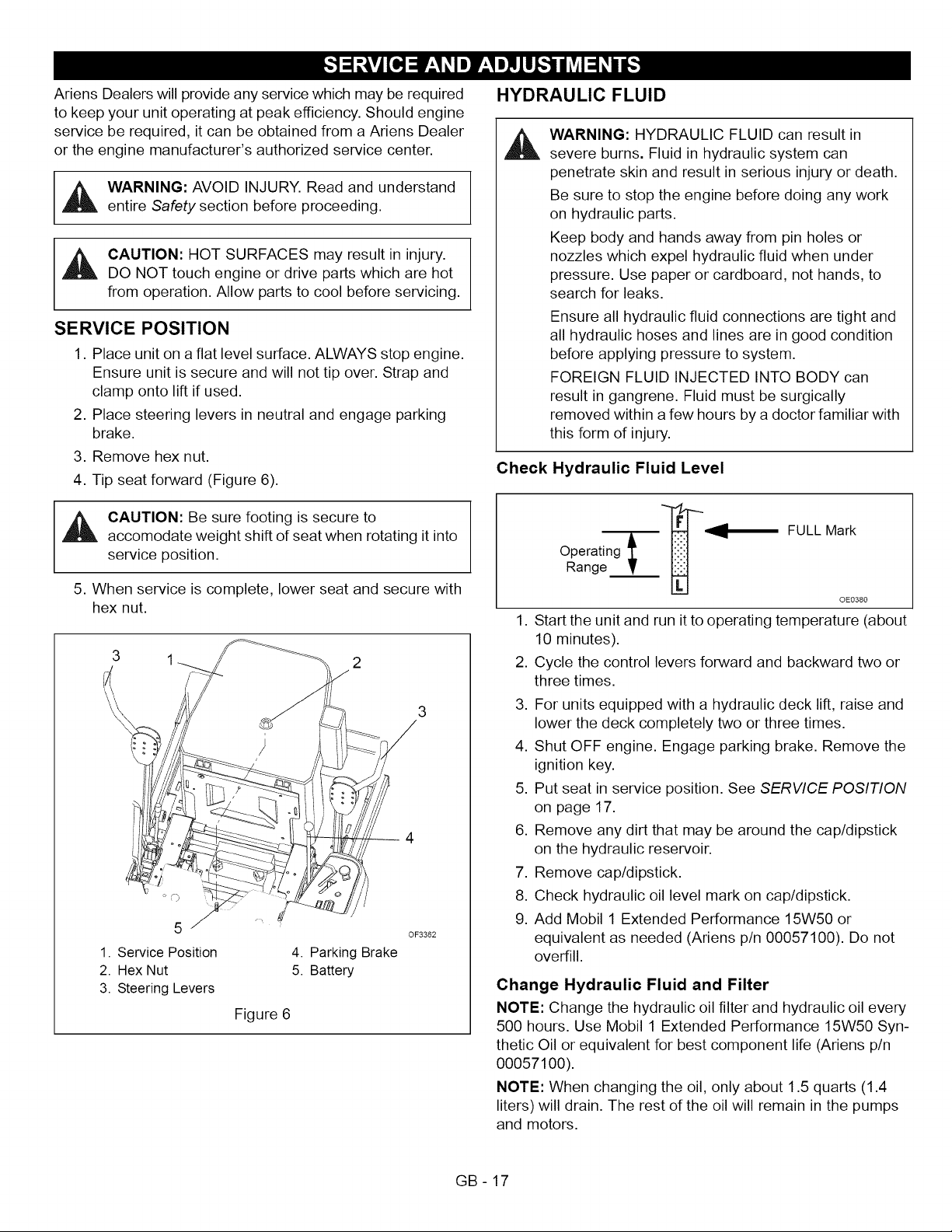

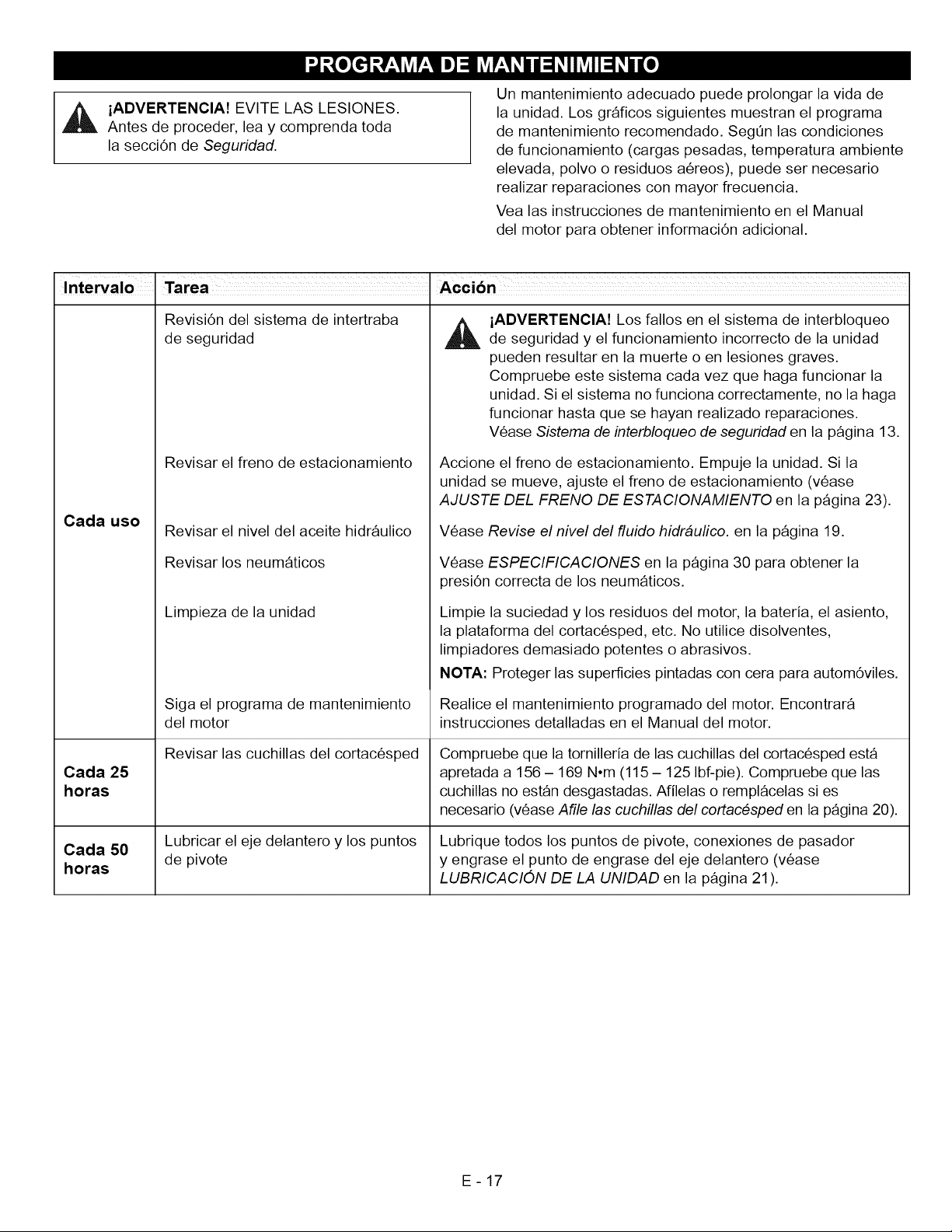

Check Hydraulic Fluid Level

Operat_Range_ --__ FULL Mark

OE0380

1. Start the unit and run it to operating temperature (about

10 minutes).

2. Cycle the control levers forward and backward two or

three times.

3. For units equipped with a hydraulic deck lift, raise and

lower the deck completely two or three times.

4. Shut OFF engine. Engage parking brake. Remove the

ignition key.

5. Put seat in service position. See SERVICE POSITION

on page 17.

6. Remove any dirt that may be around the cap/dipstick

on the hydraulic reservoir.

7. Remove cap/dipstick.

8. Check hydraulic oil level mark on cap/dipstick.

9. Add Mobil 1 Extended Performance 15W50 or

equivalent as needed (Ariens pin 00057100). Do not

overfill.

Change Hydraulic Fluid and Filter

NOTE: Change the hydraulic oil filter and hydraulic oil every

500 hours. Use Mobil 1 Extended Performance 15W50 Syn-

thetic Oil or equivalent for best component life (Ariens p/n

00057100).

NOTE: When changing the oil, only about 1.5 quarts (1.4

liters) will drain. The rest of the oil will remain in the pumps

and motors.

GB- 17

Clean around dipstick cap and dipstick. Remove

1. Sharpen the Mower Blades

dipstick.

,

Place container under oil filter to catch oil.

3.

Remove oil filter.

CAUTION: DO NOT sharpen mower blades while

on unit. An unbalanced mower blade will cause

excessive vibration and eventual damage to unit.

4.

Allow tank to drain.

5.

Lubricate rubber gasket on new oil filter with clean

hydraulic oil.

Check mower blade balance before reinstalling

blades.

NEVER weld or straighten bent blades.

6. Spin new oil filter onto filter housing until it makes

contact. Tighten oil filter another 1/2 turn.

7. Add new oil to the oil tank. It will take about 1.5 quarts

(1.4 liters). Use Mobil 1 Extended Performance 15W50

Synthetic Oil or equivalent for best component life

(Ariens pin 00057100).

8. Check hydraulic oil level mark on cap/dipstick.

9. Properly dispose of waste oil.

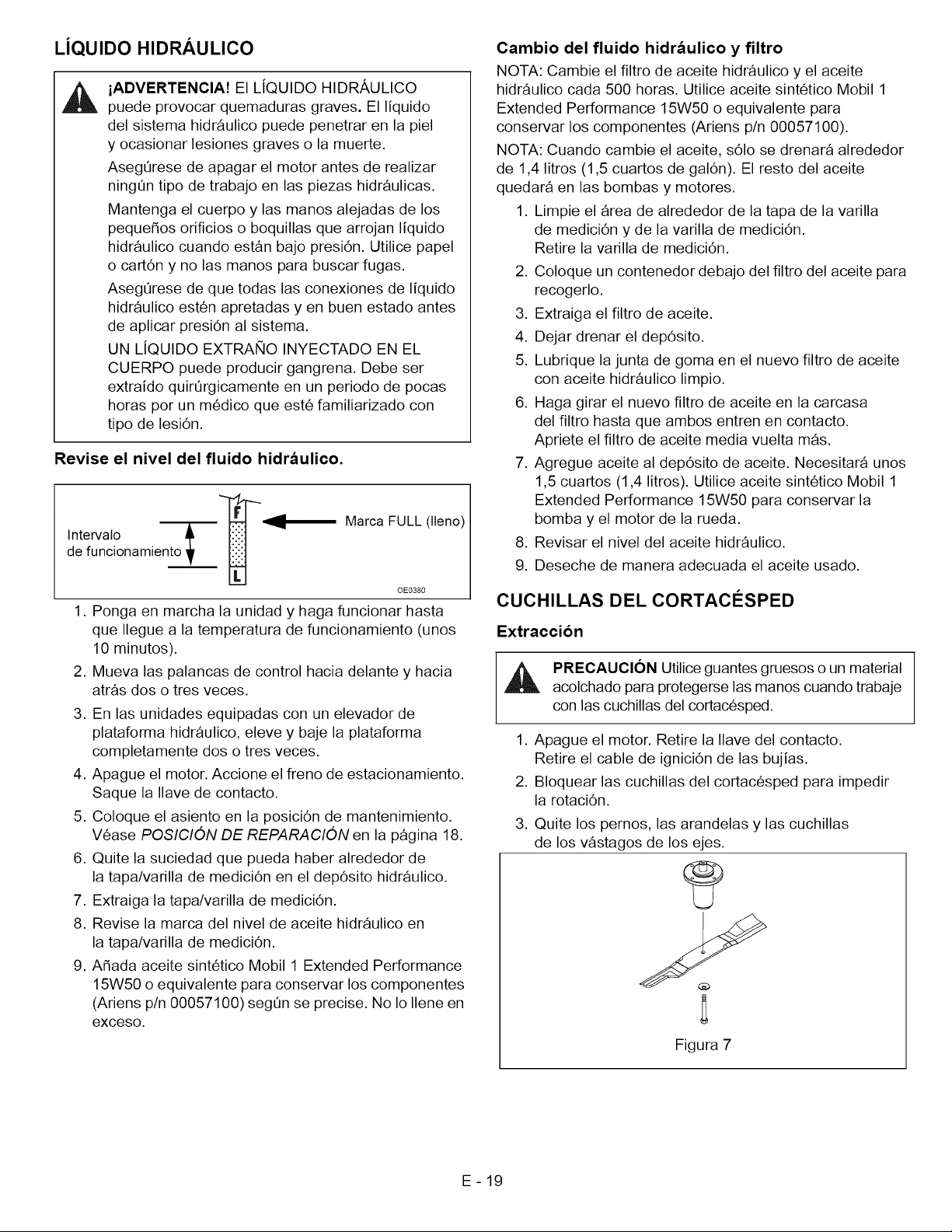

MOWER BLADES

Remove

1. Remove mower blade from unit.

Discard mower blade if:

• More than 1/2 in. (1.27 cm) of metal is removed.

• Air lifts become eroded.

• Blade is bent or broken.

2. Sharpen mower blade by removing an equal amount of

material from each end of mower blade. DO NOT

change angle of cutting edge or round the corner of the

mower blade.

3. Check mower blade balance.

Slide mower blade on an unthreaded bolt. A balanced

,_ CAUTION: Use sturdy gloves or padding to protect

hands when working with mower blades.

blade should remain in a horizontal position. If either

end of mower blade moves downward, sharpen the

heavy end until blade is balanced.

1. Turn the engine off. Remove the ignition key. Remove

the ignition wire from the spark plugs.

2. Block mower blades to prevent rotation.

4. Install mower blade(s) on unit.

5. Tighten the bolts to a torque of 115-125 Ibf-ft

(156-169 N•m).

3. Remove the bolts, washers, and blades from the

spindle shafts.

DO NOT Sharpen to This Pattern

Figure 7

Replace

1. Replace the blades, washers and bolts on the spindle

shafts.

2. Tighten the bolts to a torque of 115-125 Ibf-ft

(156-169 N-m).

3. Replace the ignition wire on the spark plugs.

GB- 18

DISCARD if More

Than 1/2 in. (1.27 cm)

Sharpen to This Pattern

1. Cutting Edge

2. Square Corner

OT0792

3. Air Lift Erosion

4. Air Lift

Figure 8

BATTERY Charging the Battery

_ ARNING: AVOID INJURY. Read and understand

entire Safety section before proceeding.

WARNING: Battery posts, terminals and related

accessories contain lead and lead compounds,

chemicals known to the State of California to cause

cancer and reproductive harm. Wash hands after

handling.

Unit comes equipped with a maintenance-free battery that

requires no regular maintenance except cleaning the

terminals.

Remove Battery

1. Place seat in the service position (See

MAINTENANCE SCHEDULE on page 16).

2. Disconnect negative (-) cable first, then positive (+)

cable (Figure 9).

3. Remove holddown and remove battery.

Replace Battery

1. Replace battery and secure with battery holddown.

2. Connect positive (+) cable first, then negative (-)

cable.

3. Coat terminals with dielectric grease or petroleum jelly.

4. Return seat to operating position.

Clean Battery

Keep battery and its terminals clean. Inspect every 100

operating hours or monthly for best performance.

WARNING: FROZEN BATTERIES CAN

EXPLODE and result in death or serious injury. DO

NOT charge a frozen battery. Let battery thaw

before charging.

Battery Electrolyte First Aid

Follow First Aid directions for contact with battery fluid.

• External Contact: Flush with water.

• Eyes: Flush with water for at least 15 minutes and get

medical attention immediately!

• Internal Contact: Drink large quantities of water. Follow

with Milk of Magnesia, beaten egg or vegetable oil. Get

medical attention immediately!

In case of internal contact, DO NOT induce vomiting!

IMPORTANT: DO NOT fast charge. Charging at a higher

rate will damage or destroy battery. ONLY use an automatic

charger designed for use with your battery.

ALWAYS follow information provided on battery by battery

manufacturer. Contact battery manufacturer for extensive

instructions to charge battery.

1. Remove battery from unit. See Remove Battery on

page 19.

2. Place battery on bench or other well-ventilated place.

3. Connect positive (+) lead of charger to positive (+)

terminal, and negative (-) lead to negative (-) terminal.

4. Charge battery according to the instructions from

battery charger manufacturer and battery

manufacturer.

5. Replace battery. See Replace Battery on page 19.

2

1. Negative terminal

2. Positive terminal

Figure 9

3. Battery

OF1671

1. Remove battery from unit. See Remove Battery on

page 19.

2. Clean terminals and battery cable ends with wire

brush.

3. Coat terminals with dielectric grease or petroleum jelly.

4. Replace battery. See Replace Battery on page 19.

Jump-Starting

Ariens does not recommend jump-starting your unit.

Jump-starting can damage engine and electrical system

components. See your engine manual for more detailed

information.

GB- 19

LUBRICATE UNIT

NOTE: Use Ariens Hi-Temp Grease or equivalent

(part number 00036700).

Apply oil at all pivot points and pin connections.

3

4

OF1793

REF LUBRICATION QTY

1 REPACK 2

OIL

Figure 10

LOCATION

CASTER PIVOT

ALL PIVOT

POINTS, PIN

CONNECTIONS

INTERVAL

400 Hrs

50 Hrs

STEERING CONTROL NEUTRAL

ADJUSTMENT

If the steering levers do not line up (match) or the unit has

excessive creeping when the steering levers are in neutral,

adjust as follows.

Adjusting the Steering Levers to Line Up (Match)

(Figure 11)

1. Shut OFF engine. Engage parking brake. Remove the

ignition key.

2. Place seat in the service position (See SERVICE

POSITION on page 17).

3. Loosen damper Iocknut on the same side as the

steering lever to be adjusted.

4. Loosen brake interlock on the same side as steering

lever to be adjusted.

5. Loosen tie rod jam nut and turn tie rod until steering

levers are aligned.

6. Tighten jam nut on tie rod, tighten brake interlock and

tighten damper Iocknut.

7

1. Damper Locknut

2. Damper

3. Tie-Rod Jam Nut

4. Tie-Rod

5. Steering Lever

6. Brake Interlock

7. Hydrostatic

Transmission

Figure 11 0F3381

Eliminating Excessive Creeping of the Unit

(Figure 11)

WARNING: This adjustment requires operating the

engine. Use extreme care to avoid contact with

moving parts and hot surfaces. Be sure rear of unit

is well-supported and secure before starting

engine.

1. If hydraulic system is cold, run unit for a minimum of

five minutes, then shut OFF engine.

2. With the unit up to and facing a wall, jack the unit up so

that both drive wheels are off the ground.

3. Start the engine and release the parking brake.

4. Move the steering levers from Forward to Reverse

several times to make sure controls are free. Then

return steering levers to neutral position.

5. Check wheel(s) for movement.

6. Shut OFF engine.

NOTE: The right and left steering levers are adjusted the

same way. To access the tie-rod, place seat in service posi-

tion. See SERVICE POSITION on page 17.

GB - 20

7.Adjusttie-rod(s):

Ifthewheelismovinginaforwarddirection:

a.Loosenthejamnutoneachendofthetie-rod.

b.Turntie-rodcounterclockwise(lengtheningthe

distancebetweenthesteeringleverandhydrostatic

transmission)severaltimes.

Ifthewheelismovinginareversedirection:

a.Loosenthejamnutoneachendofthetie-rod.

b.Turntie-rodclockwise(decreasingthedistance

betweenthesteeringleverandhydrostatic

transmission)severaltimes.

8.Returnseattooperatingposition.

9.Startengine.

10.MovesteeringleversfromForwardtoReverseseveral

times.Thenreturnsteeringleversto neutralposition.

11.ShutOFFengine.

12.Ifwheelisnotmoving,tightenjamnutsontie-rod.The

adjustmentiscomplete.

13.Ifwheelisstillmoving,repeatsteps7through12.

ADJUSTING THE UNIT TO TRACK STRAIGHT

2

1. Limiter Bolt

2. Jam Nut

3

3. Steering Lever

4. Stop Bracket

Figure 12

_ ARNING: Prior to adjusting the tracking of the

unit, shut off engine, engage parking brake, and

remove the ignition key.

Check and adjust tire pressure. Increase pressure on side

unit tracks to. DO NOT exceed maximum recommended tire

pressure (See SPECIFICATIONSon page 28).

If tire pressure adjustment does not solve tracking problem,

adjust the limiter bolts on the stop bracket (Figure 12). Front

bolts adjust forward and rear bolts adjust reverse. Lengthen

the limiter bolt (move closer to lever) on side which is too

fast.

ADJUSTING THE HEIGHT OF THE STEERING

LEVER HANDLES

The handles have three height positions (Figure 13).

Position # 1

#2

1

Position # 3

1. Eccentric Spacer

2. Handle

3. Steering Lever

Figure 13 OF357O

1. Remove the spacer, handle, and eccentric spacer from

the steering lever.

NOTE: Position the right and left handles at the same height

position.

2. Install the spacer, handle, and eccentric spacer in the

appropriate height position. Do not tighten the nut

holding the eccentric spacer.

3. Turn the eccentric spacer until the right and left

handles are the same height. Tighten nut.

GB-21

PARKING BRAKE ADJUSTMENT

The parking brake might need adjustment over time and

after new brake pads have been installed.

NOTE: After installing new brake pads in the calipers, they

must be burnished by driving for a short distance (about 100

feet) with the brake on. To do this, bring the parking brake

lever part-way up while driving in a straight line. This quickly

breaks-in the pads for maximum effectiveness

BELTS

_b WARNING: MOVING PARTS can cut or amputate

body parts. ALWAYS wait for moving parts to stop

before performing maintenance or service.

_ CAUTION: DAMAGED OR WORN BELTS may

result in injury and/or damage to unit. Check belts

for excessive wear or cracks often.

NOTE: The Ogura clutch can be adjusted if the clutch starts

to slip. Contact your Ariens dealer for this adjustment.

Belt1.Access

Properly stop and park unit (See OPERATION on

page 12).

2. Lower the mower deck.

3. Place seat in most rearward position.

4. Remove belt covers.

5. Place foot board in open position (Figure 15).

6. Secure raised footboard with latch.

1. Parking Brake Lever 4. Trunnion

2. Brake Rod 5. Spring

3. Return Nuts 6. Jam Nuts

Figure 14

OF3303

Check Adjustment

NOTE: Be sure to check the parking brake on both sides of

the unit (Figure 14).

With the parking brake engaged, the spring length should

measure 1 1/2 in. (3.81 cm) between the jam nuts and the

trunnion and the clearance between the return nuts and

trunnion should measure 1/16 to 1/8 in. (1.59 to 3.18 mm). If

either of these measurements is off, adjust the parking brake

appropriately.

Adjust the Parking Brake

1. Engage the parking brake.

2. Turn the jam nuts clockwise to compress the spring or

counterclockwise to extend the spring until there is

1-1/2 in. (3.81 cm) clearance between the jam nuts

and trunnion.

,

Tighten jam nuts together.

4.

Turn the return nuts clockwise to decrease the

distance or counterclockwise to increase the distance

until there is 1/16 to 1/8 in. (1.59 to 3.18 mm) between

the return nuts and trunnion.

5. Tighten return nuts together.

1. Footboard in

open position

2. Frame

3. Latch

Figure 15 OF3_80

Replacing Mower Belts

NOTE: Long PTO mower belt must be removed from blade

spindle pulleys prior to removing short mower drive belt.

_hk AUTION: Use care when releasing idler spring

tension. Keep body parts well away from idlers

when performing this operation.

,

Slowly release the tension on the PTO mower belt idler

until all the tension is removed from the springs.

2.

Remove PTO mower belt from left blade spindle and

remove from deck.

3.

Slowly release the tension on the mower drive belt

idler until all the tension is removed from the springs.

4.

Remove mower drive belt from right blade spindle and

from deck. Idler pivot bolt must be loosened slightly to

gain clearance to remove belt from under idler pulley

(Figure 16).

GB - 22

5.Arrangenewmowerbelt(s)ondeck(mowerdrivebelt

first).Retightenshortmowerbeltidlerpivotbolt.Install

beltsonsheaves.Putbeltsontocentersheavelast.

IMPORTANT: Prior to starting the unit, ensure that there are

no twists in the mower drive belt as any twist in the PTO

mower belt will drastically reduce the belt life.

6. Replace belt covers and return foot board to closed

position.

6

2

4 7

1

6

1. PTO Mower Belt

2. Mower Drive Belt

3. Springs

4. Mower Drive Belt Idler

5. PTO Belt Idler

6. PTO Clutch Sheave

7. Center Sheave

Figure 16

Replacing the Hydro Pump Belt

1. Properly stop and park unit (See OPERATION on

page 12).

2. Remove the PTO mower belt from the PTO clutch

sheave (See Replacing Mower Belts on page 22).

_i AUTION: Use care when releasing idler spring

tension. Keep body parts well away from idlers

when performing this operation.

1. Hydro Belt

2. Spring

3. Idler

4. Engine Sheave

Figure 17

5. Left Hand Hydrostat

6. Right Hand Hydrostat

7. Clutch

8. Clutch Anchor

OF163I

MOWER DECKS

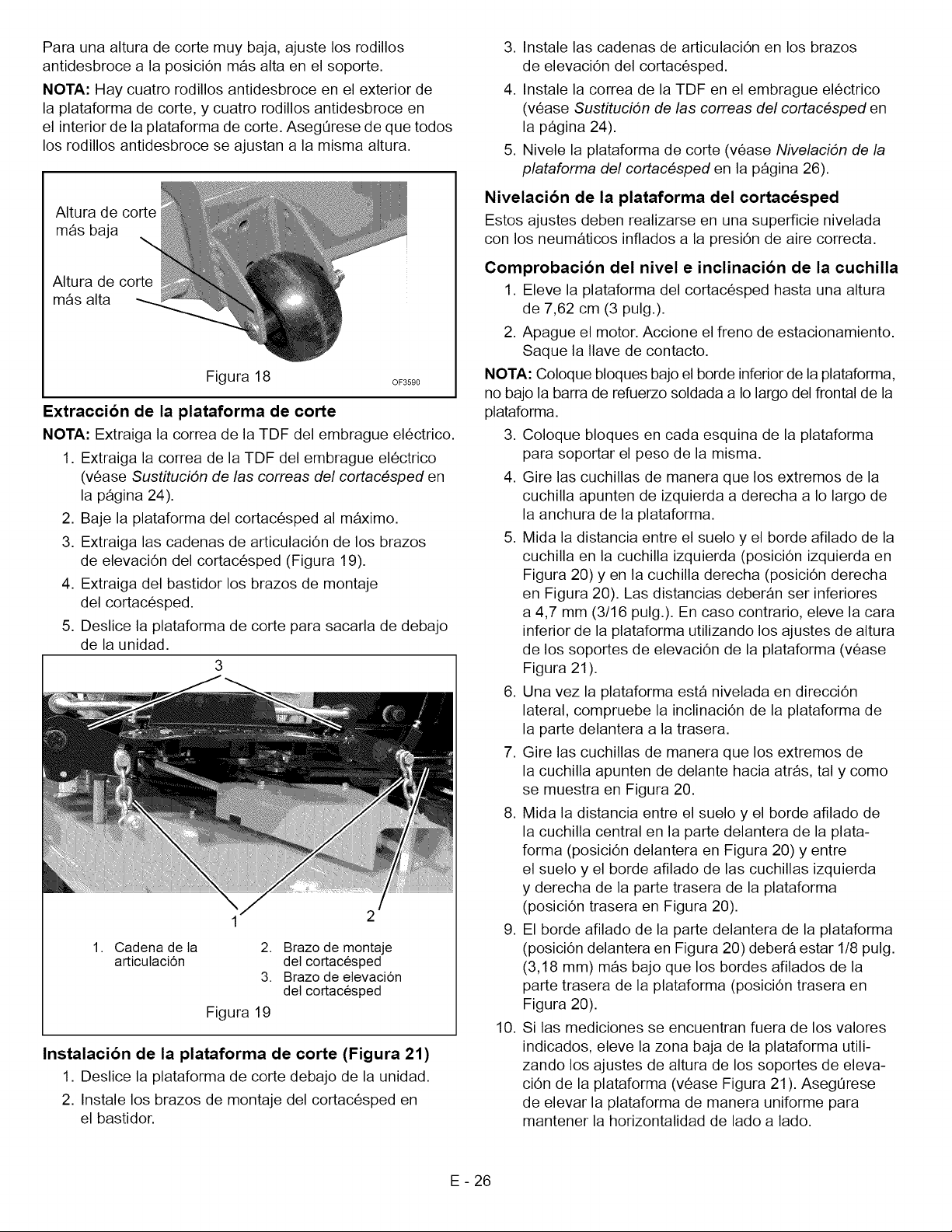

Anti-scalp Roller Adjustment

The anti-scalp rollers are set at the factory for typical

mowing height, but can be adjusted for high or low cutting

conditions (Figure 18).

Anti-Scalp rollers are intended to prevent lawn scalping, not

to control cutting height.

For a very high cutting height, set the anti-scalp rollers in the

lowest position on the bracket.

For a very low cutting height, set the anti-scalp rollers in the

highest position on the bracket.

NOTE: There are four anti-scalp rollers on the outside of the

mower deck and four anti-scalp rollers on the inside of the

mower deck. Make sure all anti-scalp rollers are set at the

same height.

Remove clutch anchor.,

4. Slowly release the tension on the hydro pump belt idler

until all the tension is removed from the springs.

5. Remove old hydro pump belt from right hand hydrostat

sheave first (Figure 17).

6. Install new hydro pump belt by positioning belt on

sheaves. Put belt onto right hand hydrostat sheave

last.

7. Replace clutch anchor.

8. Replace PTO mower belt on PTO clutch sheave. See

Replacing Mower Belts on page 22.

GB - 23

Lowest

Cutting

Height

Highest

Cutting

Height

Figure 18

OF3590

Removing the Mower Deck

NOTE: Only remove PTO belt from electric clutch.

1. Remove PTO belt from electric clutch (see Replacing

Mower Belts on page 22).

2. Lower mower deck all the way down.

3. Remove link chains from mower lift arms (Figure 19).

4. Remove mower mounting arms from frame.

5. Slide mower deck out from under unit.

1

1. Link Chain 3.

Mower lift Arm

2

2. Mower Mounting Arm

Figure 19

Installing the Mower Deck 0

1. Slide mower deck under unit.

2.

Install mower mounting arms on frame.

3.

Install link chains on the mower lift arms.

4.

Install PTO belt on electric clutch (see Replacing

Mower Belts on page 22).

,

Level mower deck (see Leveling the Mower Deck on

page 24).

Leveling the Mower Deck

These adjustments should be made on a level surface with

the tires inflated to the correct air pressure.

Check Blade Level and Pitch

1. Raise mower deck to a 3 in. (7.62 cm) cutting height.

2. Shut off engine. Engage parking brake. Remove the

ignition key.

NOTE: Place blocks under the bottom edge of the deck, not

under the reinforcement bar welded along deck face.

3. Place blocks at each corner of the deck to support the

weight of the deck.

4. Turn the blades so the blade ends point left to right

across the width of the deck.

5. Measure the distance between the ground and cutting

edge of the blade on the left blade (Left position in

Figure 20) and on the right blade (Right position in

Figure 20). Distances should be within 3/16 in.

(4.7 mm). If they are not, raise the low side of the deck

using the height adjusters on the deck lift brackets (see

Figure 21).

6. After deck is level side to side, check the deck front to

back pitch.

7. Turn the blades so the blade ends point front to back

as shown in Figure 20.

8. Measure the distance between the ground and the

cutting edge of the middle blade at the front of the deck

(Front position in Figure 20) and between the ground

the cutting edge of the left and right blades at the rear

of the deck (Rear position in Figure 20).

9. The cutting edge at the front of the deck (Front position

in Figure 20) should be 1/8 in. (3.18 mm) lower than

the cutting edges at the rear of the deck (Rear position

in Figure 20).

10. If measurements are out of range, raise the low side of

the deck using the height adjusters on the deck lift

brackets (see Figure 21). Be sure to raise the deck

evenly to keep the deck level side to side.

NOTE: Pitching the front of the blades lower than the rear

provides a balance between cut quality and the power

needed to cut grass. Certain cutting conditions require the

deck to be pitched with the rear of the blades lower than the

front. Heeling the deck this way requires more engine power

but can provide better cut quality.

11. Remove the blocks from under the deck.

GB - 24

Left

Blade Side-to-Side Level

Blade Front-to-Back Pitch

_ ARNING: AVOID INJURY. Read and understand

entire Safety section before proceeding.

SHORT TERM

NEVER spray unit with high pressure water or store unit

outdoors.

Inspect unit for visible signs of wear, breakage or damage.

Keep all nuts, bolts and screws properly tightened and know

unit is in safe working condition.

Store unit in a cool, dry protected area.

Front

Rear Rear

Figure 20

Adjust Blade Height

Level and pitch the mower with the height adjusters on each

deck lift bracket (Figure 21).

Loosen the jam nut on the deck lift bracket bolt about

1/4 turn to reduce clamp load on the height adjusters.

Loosen the jam nut on the deck adjuster bolt and then

turn the bolt clockwise to raise the deck or

counterclockwise to lower the deck. Tighten both jam

nuts.

LONG TERM

Clean unit thoroughly with mild soap and low pressure water

and lubricate (See LUBRICATE UNITon page 20 in

Maintenance). Touch up all scratched painted surfaces.

Remove weight from wheels by putting blocks under frame

or axle.

When storing unit for extended periods of time, remove all

fuel from tank and carburetor (run dry). Refer to Engine

Manual.

Clean and charge the battery. Charge battery every three to

four weeks when storing unit.

To Take the Unit Out of Storage

1. Refer to the engine service manual to prepare the

engine for service.

2. Put fresh, clean fuel in the fuel tank.

3. Begin the maintenance schedule.

4. Charge and install the battery.

Height Adjusters

DO NOT place blocks under reinforcement bar.

Figure 21

1

GB - 25

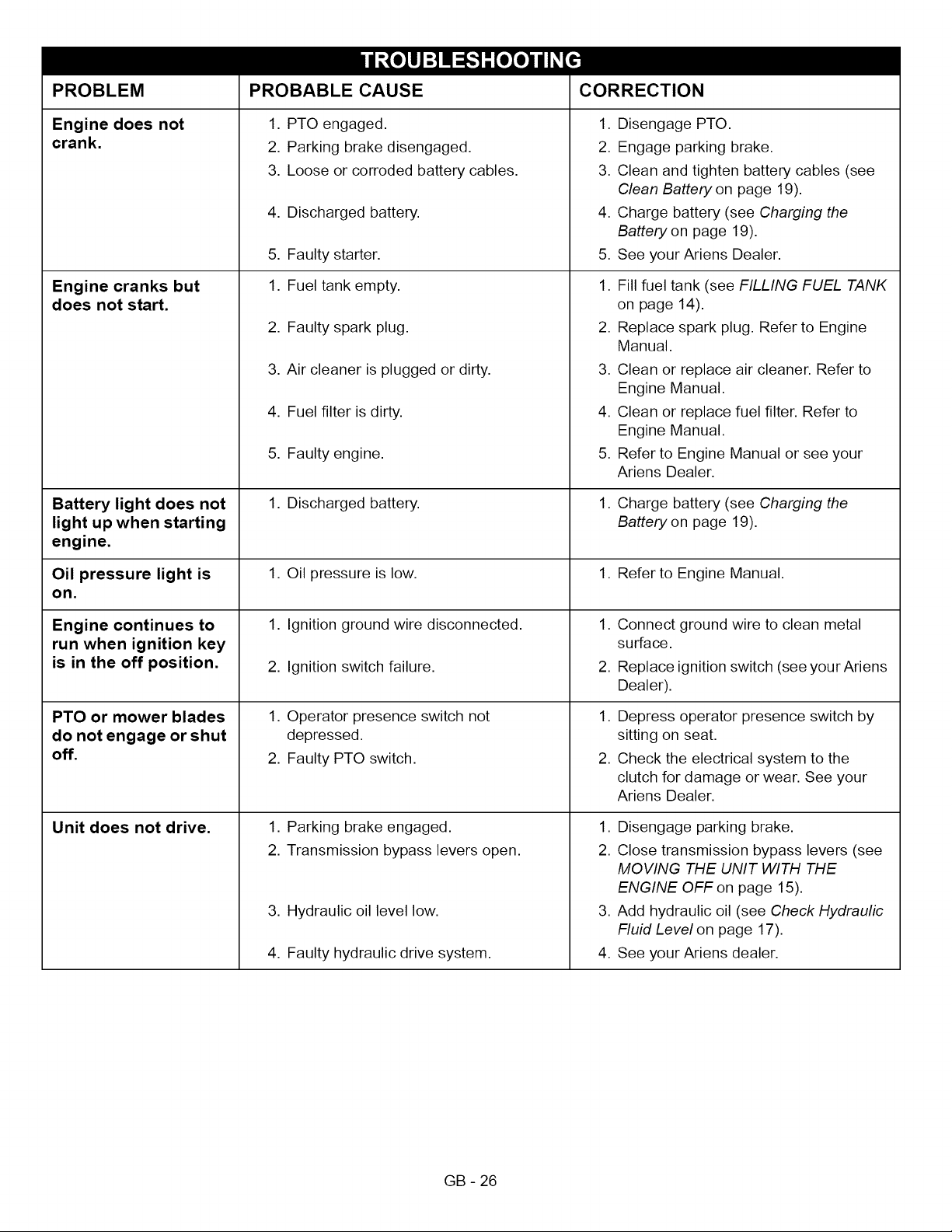

PROBLEM

PROBABLE CAUSE

CORRECTION

Engine does not

crank.

1. PTO engaged. 1.

2. Parking brake disengaged. 2.

3. Loose or corroded battery cables. 3.

Disengage PTO.

Engage parking brake.

Clean and tighten battery cables (see

Clean Battery on page 19).

4. Discharged battery. 4.

Charge battery (see Charging the

Battery on page 19).

See your Ariens Dealer.

Fill fuel tank (see FILLING FUEL TANK

on page 14).

Replace spark plug. Refer to Engine

Engine cranks but

does not start.

5. Faulty starter. 5.

1. Fuel tank empty. 1.

2. Faulty spark plug. 2.

Manual.

3. Air cleaner is plugged or dirty. 3.

Clean or replace air cleaner. Refer to

Engine Manual.

4. Fuel filter is dirty. 4.

Clean or replace fuel filter. Refer to

Engine Manual.

5. Faulty engine. 5.

Refer to Engine Manual or see your

Ariens Dealer.

Battery light does not

light up when starting

1. Discharged battery. 1.

Charge battery (see Charging the

Battery on page 19).

engine.

Oil pressure light is Refer to Engine Manual.

on.

1. Oil pressure is low. 1.

Engine continues to

run when ignition key

is in the off position.

PTO or mower blades

do not engage or shut

off.

Unit does not drive.

1. Ignition ground wire disconnected. 1.

2. Ignition switch failure. 2.

1. Operator presence switch not 1.

depressed.

2. Faulty PTO switch. 2.

1. Parking brake engaged. 1.

2. Transmission bypass levers open. 2.

3. Hydraulic oil level low.

4. Faulty hydraulic drive system.

Connect ground wire to clean metal

surface.

Replace ignition switch (see your Ariens

Dealer).

Depress operator presence switch by

sitting on seat.

Check the electrical system to the

clutch for damage or wear. See your

Ariens Dealer.

Disengage parking brake.

Close transmission bypass levers (see

MOVING THE UNIT WITH THE

ENGINE OFF on page 15).

,

Add hydraulic oil (see Check Hydraulic

Fluid Level on page 17).

4.

See your Ariens dealer.

GB - 26

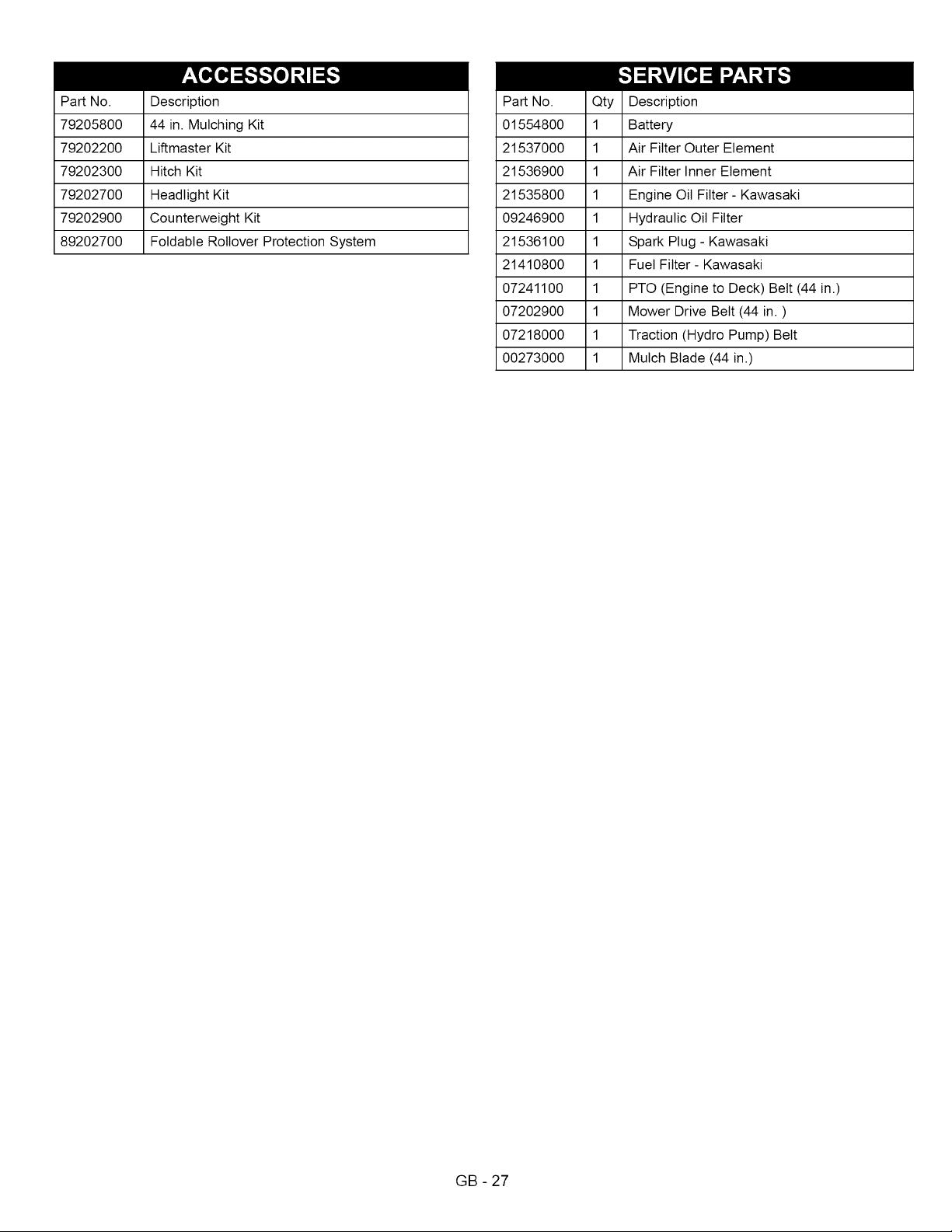

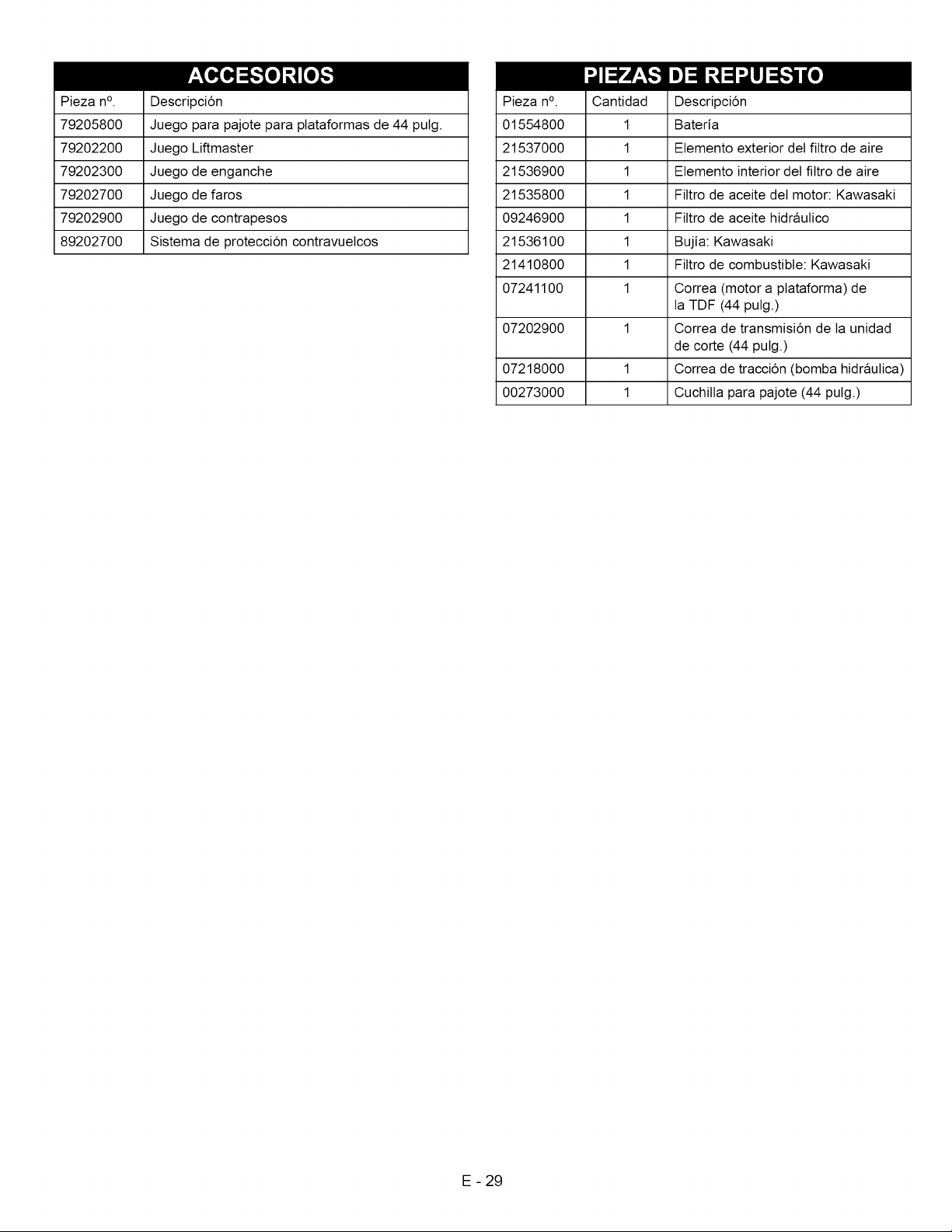

Pa_ No.

79205800

79202200

79202300

79202700

79202900

89202700

Description

44 in. Mulching Kit

Liftmaster Kit

Hitch Kit

Headlight Kit

Counterweight Kit

Foldable Rollover Protection System

Pa_ No.

01554800

21537000

21536900

21535800

09246900

21536100

21410800

07241100

07202900

07218000

00273000

Description

1

Battery

1

Air Filter Outer Element

1

Air Filter Inner Element

1

Engine Oil Filter- Kawasaki

1

Hydraulic Oil Filter

1

Spark Plug - Kawasaki

1

Fuel Filter- Kawasaki

1

PTO (Engine to Deck) Belt (44 in.)

1

Mower Drive Belt (44 in. )

1

Traction (Hydro Pump) Belt

1

Mulch Blade (44 in.)

GB - 27

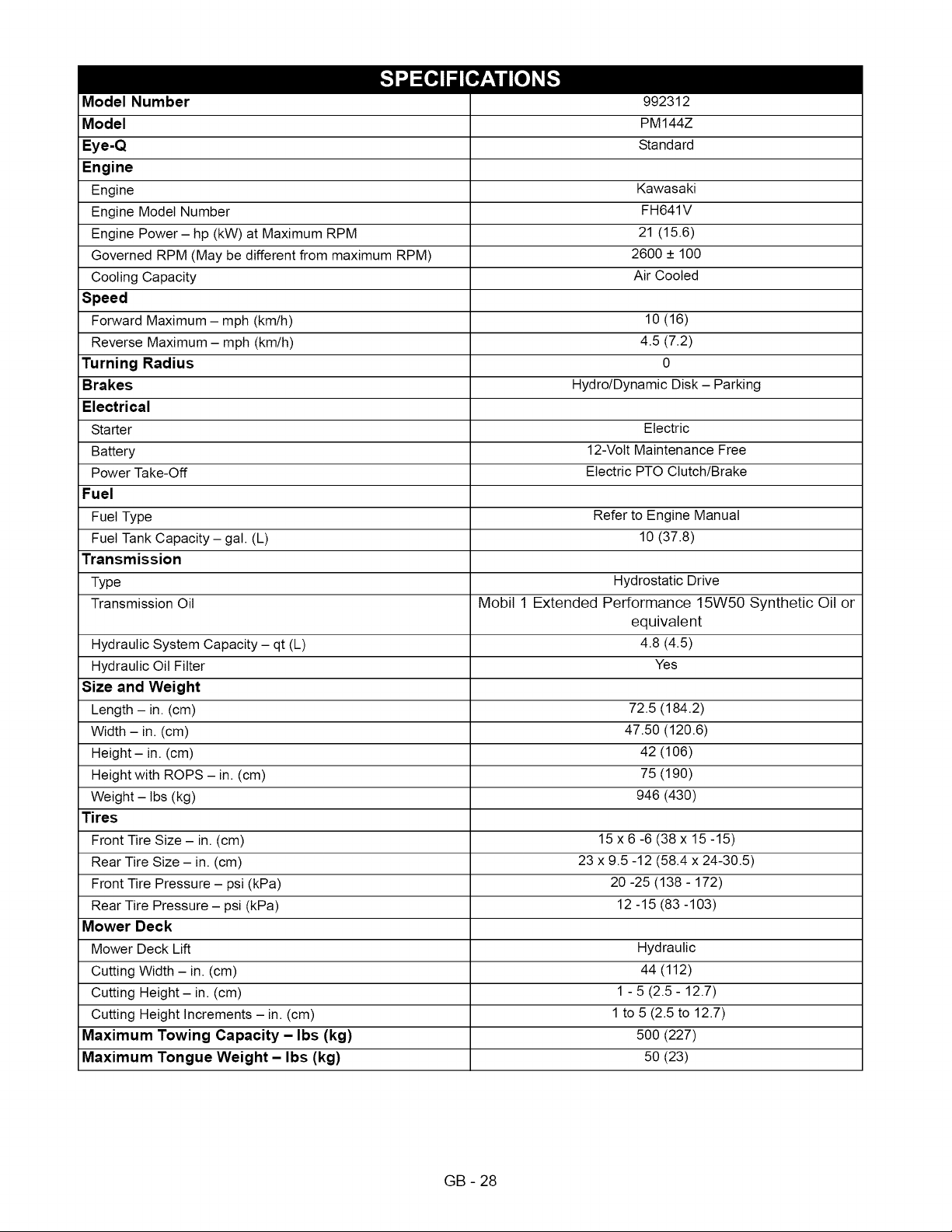

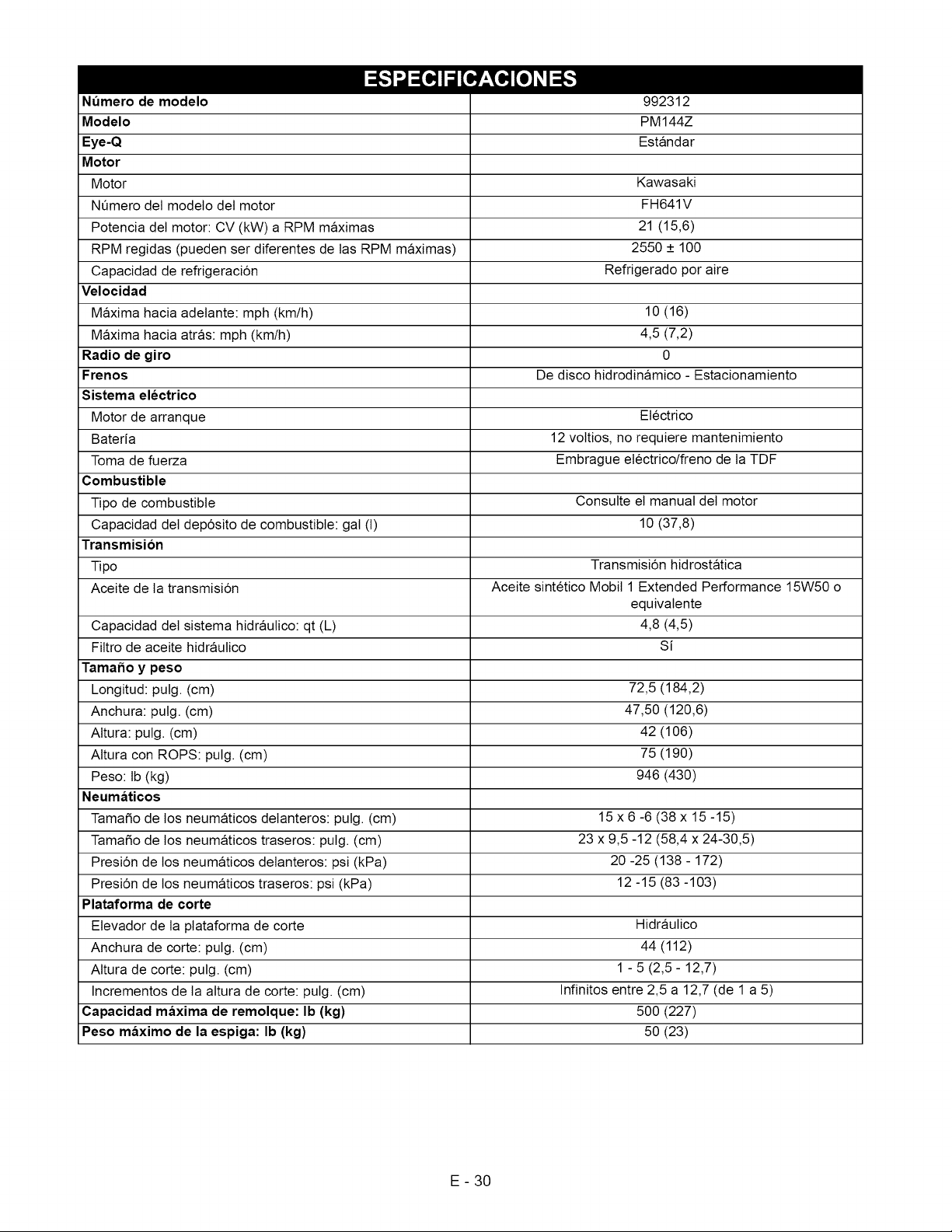

Model Number

Model

Eye-Q

Engine

Engine

Engine Model Number

Engine Power- hp (kW) at Maximum RPM

Governed RPM (May be different from maximum RPM)

Cooling Capacity

Speed

Forward Maximum - mph (km/h)

Reverse Maximum - mph (km/h)

Turning Radius

Brakes

Electrical

Starter

Battery

Power Take-Off

Fuel

Fuel Type

Fuel Tank Capacity - gal. (L)

Transmission

Type

Transmission Oil

Hydraulic System Capacity - qt (L) 4.8 (4.5)

Hydraulic Oil Filter Yes

Size and Weight

Length - in. (cm) 72.5 (184.2)

Width -in. (cm) 47.50 (120.6)

Height- in. (cm) 42 (106)

Height with ROPS - in. (cm) 75 (190)

Weight - lbs (kg) 946 (430)

Tires

Front Tire Size - in. (cm) 15 x 6 -6 (38 x 15 -15)

Rear Tire Size - in. (cm) 23 x 9.5 -12 (58.4 x 24-30.5)

Front Tire Pressure - psi (kPa) 20 -25 (138 - 172)

Rear Tire Pressure - psi (kPa) 12 -15 (83 -103)

Mower Deck

Mower Deck Lift Hydraulic

Cutting Width -in. (cm) 44 (112)

Cutting Height -in. (cm) 1 - 5 (2.5 - 12.7)

Cutting Height Increments -in. (cm) 1 to 5 (2.5 to 12.7)

Maximum Towing Capacity - Ibs (kg) 500 (227)

Maximum Tongue Weight - Ibs (kg) 50 (23)

Mobil 1 Extended Performance 15W50 Synthetic Oil or

Hydro/Dynamic Disk - Parking

12-Volt Maintenance Free

Electric PTO Clutch/Brake

Refer to Engine Manual

992312

PM144Z

Standard

Kawasaki

FH641V

21 (15.6)

2600 + 100

Air Cooled

10(16)

4.5 (7.2)

0

Electric

10 (37.8)

Hydrostatic Drive

equivalent

GB - 28

Ariens Company

655 West Ryan Street

RO. Box 157

Brittion, Wl 54110-0157

920-756-2141

Fax 920-756-2407

www.ariens.com

,_, WARNING ,_

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

Promaster 144Z

Owner/Operator Manual-- Manuel du proprietaire/utilisateur- Betriebsanlei-

tung -- Eigenaars/gebruikshandleiding -Instruktionsbog -- Manuale d'uso/

del proprietario -- Manual del propietario/operador- Brukerh&ndboken -

Instruktionsboken -- Omistajan/kuljettajan k_ytt6ohjekirja -- Instrukcj¢

obsfugi/operatora -- PyKOBOACTBO BJqaAeJqbL_a/noJqb3OBaTeJq£ -- Navod k

obsluze/pro obsluhu -- Manual do Operador / Proprietario

992312 21 HP 144Z

ENGLISH

(_ FRAN(_AIS

@ DEUTSCH

(_ NEDERLANDS

DANSK

ITALIANO

(_ ESPANOL

NORSK

(_ SVENSKA

SUOMI

(_ POLSKI

(_ PYCCKVIH R3BIK

(_ CESKY

_) PORTUGUESE

00678500 10/06

Printed in USA

AriensCompany

655WestRyanStreet

RO.Box157