Page 1

MAX ZOOM

™

Owner/Operator Manual

Models

991056 – Max Zoom 2560

991065 – Max Zoom 2552

ENGLISH

FRANÇAIS

03790900B 9/09

Printed in USA

Page 2

TABLE OF CONTENTS

Figure 1

Serial Number Label

OF4300

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . 10

Controls and Features. . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance Schedule . . . . . . . . . . . . 16

Service and Adjustments . . . . . . . . . . 18

INTRODUCTION

Storage . . . . . . . . . . . . . . . . . . . . . . . . . 30

Accessories . . . . . . . . . . . . . . . . . . . . . 30

Service Parts . . . . . . . . . . . . . . . . . . . . 30

Specifications . . . . . . . . . . . . . . . . . . . 31

Warranty . . . . . . . . . . . . . . . . . . . . . . . . 34

NON-ENGLISH MANUALS

Manuals in languages other than

English may be obtained from your

Dealer. Visit your dealer or

www.ariens.com for a list of

languages available for your

equipment.

Manuals printed in languages other

than English are also available as a

free download on our website:

http://www.ariens.com

MANUALES EN IDIOMAS

DIFERENTES DEL INGLES

Puede obtener manuales en

idiomas diferentes del inglés en su

distribuidor. Visite a su distribuidor

o vaya a www.ariens.com para

obtener una lista de idiomas

disponibles para su equipo.

También puede imprimir manuales

en idiomas diferentes del inglés

descargándolos gratuitamente de

nuestra página Web:

http://www.ariens.com

MANUELS NON ANGLAIS

Des manuels dans différentes

langues sont disponibles chez

votre revendeur. Rendez-vous

chez votre revendeur ou allez sur

le site www.ariens.com pour

consulter la liste des langues

disponibles pour votre équipement.

Les manuels imprimés dans des

langues différentes de l’anglais

sont également disponibles en

téléchargement gratuit sur notre

site Web :

http://www.ariens.com

THE MANUAL

Before operation of unit, carefully and

completely read your manuals. The contents

will provide you with an understanding of

safety instructions and controls during normal

operation and maintenance.

All reference to left, right, front, or rear are

given from operator sitting in the operation

position and facing the direction of forward

travel.

SERVICE AND REPLACEMENT

PARTS

When ordering publications, replacement

parts, or making service inquiries, know the

Model and Serial numbers of your unit and

engine.

Numbers are located on the product

registration form in the literature package.

They are printed on a serial number label,

located on the frame of your unit (Figure 1).

GB - 2

Page 3

• Record Unit Model and Serial numbers

here.

• Record Engine Model and Serial numbers

here.

PRODUCT REGISTRATION

The Ariens dealer must register the product

at the time of purchase. Registering the

product will help the company process

warranty claims or contact you with the latest

service information. All claims meeting

requirements during the limited warranty

period will be honored, whether or not the

product registration card is returned. Keep a

proof of purchase if you do not register your

unit.

Customer Note: If the Dealer does not

register your product, please fill out, sign and

return the product registration card to Ariens

or go to www.ariens.com on the internet.

UNAUTHORIZED REPLACEMENT

PARTS

Use only Ariens replacement parts. The

replacement of any part on this equipment

with anything other than an Ariens authorized

replacement part may adversely affect the

performance, durability, and safety of this unit

and may void the warranty. Ariens disclaims

liability for any claims or damages, whether

regarding warranty, property damage,

personal injury or death arising out of the use

of unauthorized replacement parts.

NOTE: To locate your nearest Ariens Dealer,

go to www.ariens.com.

DISCLAIMER

Ariens reserves the right to discontinue,

change, and improve its products at any time

without public notice or obligation to the

purchaser. The descriptions and

specifications contained in this manual were

in effect at printing. Equipment described

within this manual may be optional. Some

illustrations may not be applicable to your

unit.

DEALER DELIVERY

Dealer should:

1. Test brakes after unit is assembled to be

sure adjustment has not been disturbed

in shipment (See Parking Brake

Interlock System on page 12). Wheel

brakes are properly adjusted at factory.

2. Check the safety interlock system to

make sure that it is functioning properly.

With operator on seat, unit must not start

unless steering levers are in neutral (N)

and Power Takeoff (PTO) is disengaged

(Off). Engine must stop if operator

leaves seat when steering levers are in

any drive position or PTO is engaged

(On). See Safety Interlock System on

page 12.

3. Fill out Original Purchaser Registration

Card and return the card to Ariens.

4. Explain Limited Warranty Policy.

5. Explain recommended lubrication and

maintenance. Advise customer on

adjustments. Instruct customer on

controls and operation of unit. Discuss

and emphasize the Safety Precautions.

Give customer Owner/Operator, Parts,

and Engine Manuals. Advise customer

to thoroughly read and understand them.

Customer Note: Your Dealer has been

provided complete set-up and preparation

instructions which must be completed prior to

you taking delivery of this unit. The dealer is

required to review important information in

this manual with you before or upon delivery

of the unit or attachment.

GB - 3

Page 4

SAFETY

OL1253

OL3900

WARNING: This cutting machine

is capable of amputating hands

and feet and throwing objects.

Failure to observe the safety

instructions in the manuals and

on decals could result in serious

injury or death.

Slopes are a major factor related

to loss-of-control and tip-over

accidents. Operation on all slopes

requires extra caution.

Tragic accidents can occur if the

operator is not alert to the

presence of children. Never

assume that children will remain

where you last saw them.

Gasoline is extremely flammable

and the vapors are explosive,

handle with care.

Disengage attachment, stop unit

and engine, remove key, engage

parking brake, and allow moving

parts to stop before leaving

operator’s position.

SAFETY ALERT

SYMBOL

These are safety alert

symbols. They mean:

•ATTENTION!

•YOUR SAFETY IS

INVOLVED!

When you see this symbol:

•BECOME ALERT!

•OBEY THE MESSAGE!

SIGNAL WORDS

The safety alert symbols above and signal

words below are used on decals and in this

manual.

Read and understand all safety messages.

WARNING: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, COULD RESULT in

death or serious injury.

CAUTION: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, MAY RESUL T in minor or

moderate injury. It may also be

used to alert against unsafe

practices.

NOTATIONS

NOTE: General reference information for

proper operation and maintenance practices.

IMPORTANT: Specific procedures or

information required to prevent damage to

unit or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and

others. Understand and follow all safety

messages. Be alert to unsafe conditions and

the possibility of minor, moderate, or serious

injury or death. Learn applicable rules and

laws in your area, including those that may

restrict the age of the operator.

REQUIRED OPERATOR

TRAINING

Original purchaser of this unit was instructed

by the seller on safe and proper operation. If

unit is to be used by someone other than

original purchaser (loaned, rented or sold),

ALWAYS provide this manual and any

needed safety training before operation.

SAFETY DECALS AND

LOCATIONS

ALW AYS replace missing or damaged Safety

Decals. Refer to Figure2 for Safety Decal

locations.

DANGER: IMMINENTLY

HAZARDOUS SITUATI ON! If not

avoided, WILL RESULT in death

or serious injury.

GB - 4

Page 5

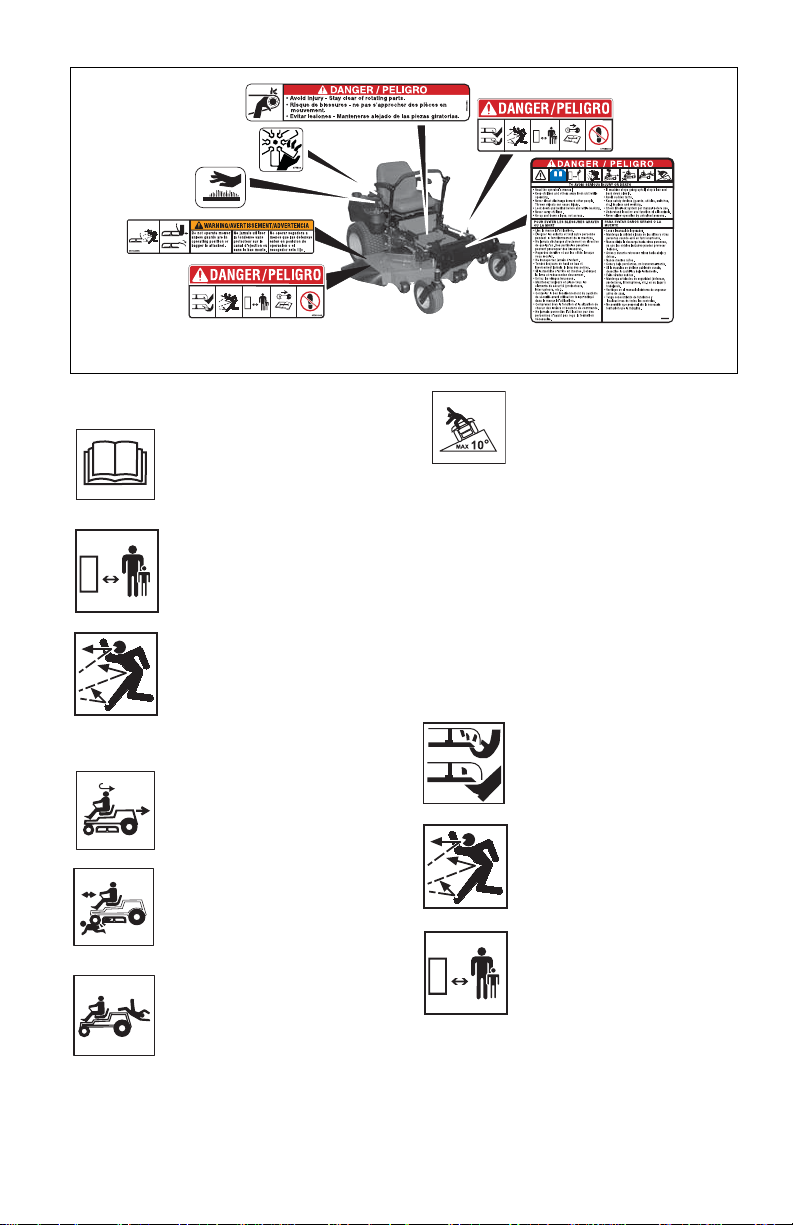

1. DANGER! TO AVOID SERIOUS

Figure 2

OF1625

1

2

6

5

4

3

2

OL1801

OL4370

OL0910

OL4460

OL4470

OL4480

OL4450

OL3030

OL0910

OL3292

INJURY OR DEATH

Read Owner/Operator Manual.

Keep children and others away

from unit while operating.

Never direct discharge toward

other people. Thrown objects

can cause injury. Remove

objects that could be thrown by

the blade.

Look down and behind before

and while backing.

Keep children out of work area

and under watchful care of a

responsible adult.

NEVER CARRY CHILDREN.

Go up and down slopes, not

across.

DO NOT operate on slopes

over 10°.

• If machine stops going uphill, stop

blade and back down slowly.

• Avoid sudden turns.

• Keep safety devices (guards, shields,

switches, etc.) in place and working.

• Check interlock system per manual

before use.

• Understand location and function of all

controls.

• Never allow operation by untrained

persons.

2. DANGER! ROTATING PARTS

Always keep feet and hands

away from rotating parts.

Always stand clear of discharge

area. Do not direct discharge

toward other people.

Keep people away from unit

while operating.

GB - 5

Page 6

Shut off engine, remove key,

OL4010

OL4420

OL4430

OL3320

OS0731

OF3450

OL4730

read manual before you adjust

or repair unit.

NO STEP! Always keep feet

away from rotating parts.

3. WARNING!

Do not operate mower unless guards are in

operating position or bagger is attached.

Always stand clear of discharge

area.

Do not operate mower unless

bagger is attached or guards

are in operating position.

4. HOT SURFACES!

DO NOT touch parts which

are hot from operation.

ALWAYS allow parts to cool.

5. ROTATING PARTS

AVOID INJURY. Stay clear of

rotating parts.

6. DANGER!

AVOID INJURY. Stay clear of

rotating parts.

SAFETY RULES

Read, understand, and follow all safety

practices in Owner/Operator Manual before

beginning assembly. Failure to follow

instructions could result in personal injury

and/or damage to unit.

ALWAYS remove key and/or wire from spark

plug before assembly. Unintentional engine

start up can cause death or serious injury.

Complete a walk around inspection of unit

and work area to understand:

• Work area • Your unit • All safety decals

Determine which attachments are needed

and can be used safely.

Inspect unit before each use for: missing or

damaged decals and shields, correctly

operating safety interlock system, and

deterioration of grass catchers. Replace or

repair as needed.

ALWAYS check overhead and side

clearances carefully before operation.

ALWAYS be aware of traffic when operating

along streets or curbs.

Keep children and people away.

Keep children out of work area and under

watchful care of a responsible adult.

Keep area of operation clear of all toys, pets,

and debris. Thrown objects can cause injury.

Check for weak spots on docks, ramps or

floors. Avoid uneven work areas and rough

terrain. Stay alert for hidden hazards or traffic.

DO NOT operate near drop-offs, ditches, or

embankments. Unit can suddenly turn over if

a wheel is over the edge of a cliff or ditch, or if

an edge caves in.

Data indicates that operators, age 60 and

above, are involved in a larger percentage of

riding mower related injuries. These

operators should evaluate their ability to

operate the riding mower safely enough to

protect themselves and others from serious

injury.

Read the entire Owner/Operator manual and

other training material. If the operator or the

mechanic cannot read the manual, it is the

owner’s responsibility to explain it to them.

Only the user can prevent and is responsible

for accidents or injuries occurring to

themselves, other people or property.

Only trained adults may operate or service

unit. Training includes actual operation.

Local regulations may restrict the age of the

operator.

NEVER allow children to operate or play on

or near unit. Be alert and shut off unit if

children enter area.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation

requires your complete and unimpaired

attention at all times.

GB - 6

Page 7

DO NOT wear loose clothing or jewelry and

tie back hair that may get caught in rotating

parts.

Wear adequate outer garments.

NEVER wear open sandals or canvas shoes

during operation. Wear adequate safety gear,

protective gloves and footwear.

Wear proper footwear to improve footing on

slippery surfaces.

Always wear safety goggles or safety glasses

with side shields when operating mower.

Moving parts can cut or amputate fingers or a

hand. Wrap blade(s) or wear gloves to

service. On multiblade mowers, rotation of

one blade will cause all blades to rotate.

NEVER place your hands or any part of your

body or clothing inside or near any moving

part while unit is running.

ALWAYS keep hands and feet away from all

rotating parts during operation. Rotating parts

can cut off body parts.

ALWAYS keep body and hands away from

pin holes or nozzles which eject hydraulic

fluid under pressure.

DO NOT touch parts which are hot. Allow

parts to cool.

ALWAYS keep hands and feet away from all

pinch points.

Fumes from the engine exhaust can cause

death or serious injury. DO NOT run engine in

an enclosed area. Always provide good

ventilation.

Read, understand, and follow all instructions

in the manual and on the machine before

starting. Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an Emergency

• Braking and steering characteristics

• Turning radius and clearances

Keep safety devices or guards in place and

functioning properly. NEVER modify or

remove safety devices.

Do not operate without either entire grass

catcher or the discharge guard in place.

Stop engine before removing grass catcher or

unclogging chute.

Ensure Safety Interlock System is functioning

properly. DO NOT operate unit if safety

interlock is damaged or disabled.

Start and operate unit only when seated in

operator’s position. Steering control levers

must be in neutral, PTO disengaged and

parking brake set when starting engine.

Use care when approaching blind corners,

shrubs, trees or other objects that may

obscure vision.

Dust, smoke, fog, etc. can reduce vision and

cause an accident. Mow only in daylight or

good artificial light.

Avoid slippery surfaces. Always be sure of

your footing.

DO NOT mow on wet grass. Reduced

traction could cause sliding and effect the

machine’s stability.

Watch for traffic when operating near or

crossing roadways.

Never carry passengers.

DO NOT try to stabilize the machine by

putting your foot on the ground.

Never direct discharge towards persons or

property that may be injured or damaged by

thrown objects. Use extreme caution on

gravel surfaces.

Always stand clear of the discharge area.

ALWAYS disengage PTO, stop unit and

engine, remove key, engage parking brake

and allow moving parts to stop before leaving

operator’s position.

Never engage PTO while raising attachment

or when attachment is in raised position.

DO NOT operate at too fast a rate. DO NOT

change engine governor settings or overspeed engine. Slow down before turning.

DO NOT operate in reverse unless absolutely

necessary. ALWAYS look down and behind

before and while backing.

Stop and inspect equipment if you strike an

object or if there is an unusual vibration.

Repair, if necessary, before restarting. Never

make adjustments or repairs with the engine

running.

Mower blades are sharp and can cut you.

Wrap the blade(s) or wear gloves, and use

extra caution when servicing them. NEVER

weld or straighten mower blades.

Rotation of one blade may cause rotation of

the other blades.

Take all possible precautions when leaving

unit unattended. Shut off engine. Remove

wire from spark plug and secure it away from

spark plug.

ALW A YS remove key to prevent unauthorized

use.

Know the weight of loads. Limit loads to those

you can safely control and the unit can safely

handle.

GB - 7

Page 8

Disengage PTO when attachment is not in

use. ALWAYS turn off power to attachment

when travelling, crossing driveways, etc.

Mow up and down slopes, not across them.

Do not operate on slopes over 10° maximum.

Use of a Rollover Protection System (ROPS)

is recommended for slope operation. See

Attachments and Accessories.

Always wear a seat belt when operating unit

using a Rollover Protection System (ROPS).

Keep all movements on the slope slow and

gradual. Do not make sudden changes in

speed or direction.

Avoid starting or stopping on the slope. If tires

lose traction, disengage the blades and

proceed slowly straight down the slope.

If you cannot back up a slope or you feel

uneasy on it, do not mow it.

DO NOT park on slopes unless necessary.

When parking on slope always chock or block

wheels. Always set parking brake.

Use a slow speed. Tires may lose traction on

slopes even though the brakes are

functioning properly.

Do not bypass transmission when on a slope.

Tow only with a machine that has a hitch

designed for towing. Do not attach towed

equipment except at the hitch point.

Follow the manufacturer’s recommendations

for weight limits for towed equipment and

towing on slopes.

NEVER allow children or others in or on

towed equipment.

On slopes, the weight of the towed equipment

may cause loss of control.

Travel slowly and allow extra distance to stop.

Use extra care when loading or unloading

unit onto trailer or truck.

Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that

could be damaged.

DO NOT transport machine while engine is

running.

ALWA YS turn off power to attachment and

shut off fuel when transporting unit.

Keep unit free of debris. Clean up oil or fuel

spills.

This product is equipped with an internal

combustion type engine. DO NOT use unit on

or near any unimproved, forest-covered or

brush covered land unless exhaust system is

equipped with a spark arrester meeting

applicable local, state or federal laws. A spark

arrester, if it is used, must be maintained in

effective working order by operator.

Fuel is highly flammable and its vapors are

explosive. Handle with care. Use an

approved fuel container.

NO smoking, NO sparks, NO flames.

ALWAYS allow engine to cool before

servicing.

NEVER fill fuel tank when engine is running

or hot from operation.

NEVER fill or drain fuel tank indoors.

Replace fuel cap securely and clean up

spilled fuel.

Never fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always

place containers on the ground away from

your vehicle before filling.

When practical, remove gas-powered

equipment from the truck or trailer and refuel

it on the ground. If this is not possible, then

refuel such equipment on a trailer with a

portable container, rather than from a

gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until

fueling is complete. Do not use a nozzle lockopen device.

If fuel is spilled on clothing, change clothing

immediately.

Avoid Electric Shock. Objects contacting both

battery terminals at the same time may result

in injury and unit damage. DO NOT reverse

battery connections.

Reverse connections may result in sparks

which can cause serious injury. Always

connect positive (+) lead of charger to

positive (+) terminal, and negative (-) lead to

negative (-) terminal.

ALW A YS disconnect negative (-) cable FIRST

and positive (+) cable SECOND. ALWAYS

connect positive (+) cable FIRST, and

negative (-) cable SECOND.

Explosive Gases from battery can cause

death or serious injury. Poisonous battery

fluid contains sulfuric acid and its contact with

skin, eyes or clothing can cause severe

chemical burns.

No flames, No sparks, No smoking near

battery.

ALWAYS wear safety glasses and protective

gear near battery. Use insulated tools.

DO NOT TIP battery beyond a 45° angle in

any direction.

ALWAYS keep batteries out of reach of

children.

GB - 8

Page 9

Battery posts, terminals and related

accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and reproductive

harm. Wash hands after handling.

ALWAYS block wheels and know all jack

stands are strong and secure and will hold

weight of unit during maintenance.

Release pressure slowly from components

with stored energy.

NEVER attempt to make any adjustments to

unit while engine is running (except where

specifically recommended). Stop engine,

remove key or spark plug wire and wait for all

moving parts to stop before servicing or

cleaning.

Check parking brake operation frequently.

Adjust and service as required.

ALWAYS maintain unit in safe operating

condition. Damaged or worn out muffler can

cause fire or explosion.

Maintain or replace safety and instruction

labels, as necessary.

NEVER store unit with fuel in fuel tank, inside

a building where any ignition sources are

present.

Shut off fuel and allow engine to cool

completely before storing in closed area or

covering unit.

Clean grass and debris from unit, especially

from around muffler and engine, to help

prevent fires.

For extended storage, shut off fuel and clean

unit thoroughly. See engine manual for proper

storage.

Lower cutting deck unless a positive

mechanical lock is used.

Use only attachments or accessories

designed for your unit.

Check all hardware at regular intervals,

especially blade attachment bolts. Keep all

hardware properly tightened.

Check attachment components frequently. If

worn or damaged, replace with

manufacturer’s recommended parts.

GB - 9

Page 10

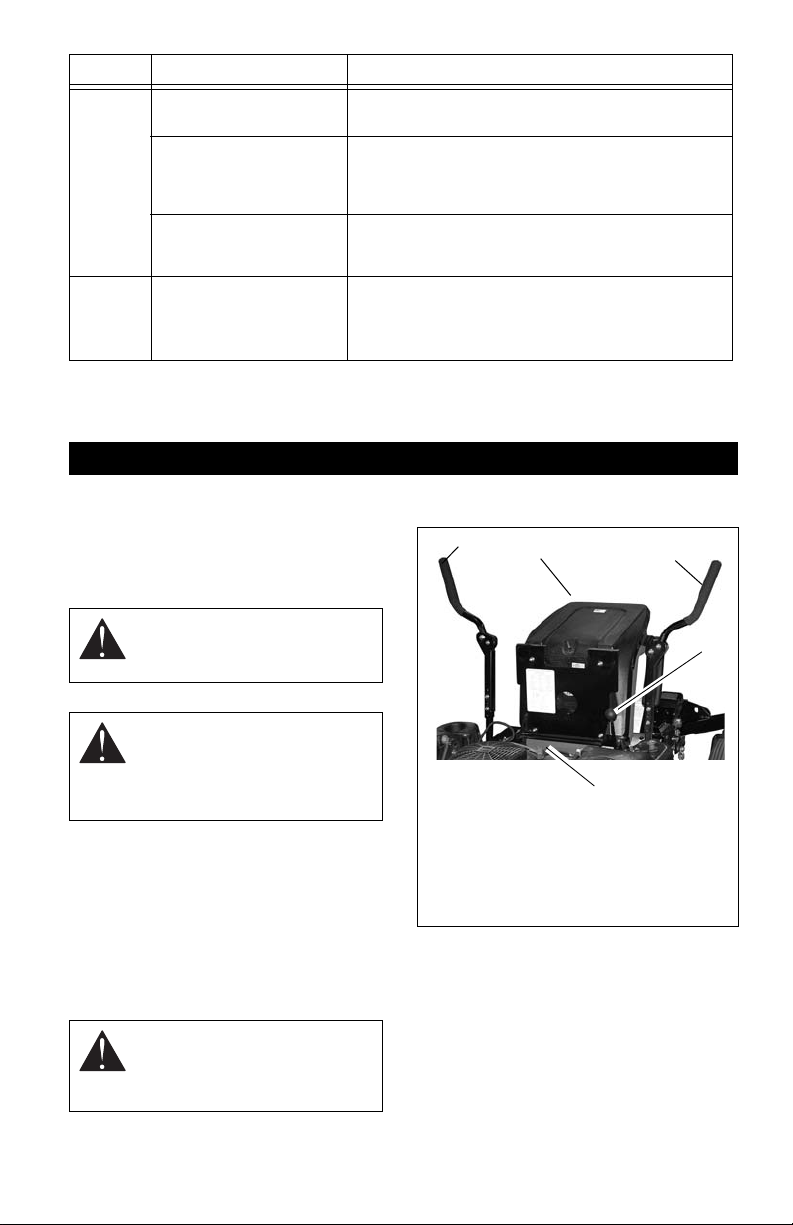

WARNING: AVOID INJURY.

1. Steering

Levers

2. Seat

3. Mounting

Hardware

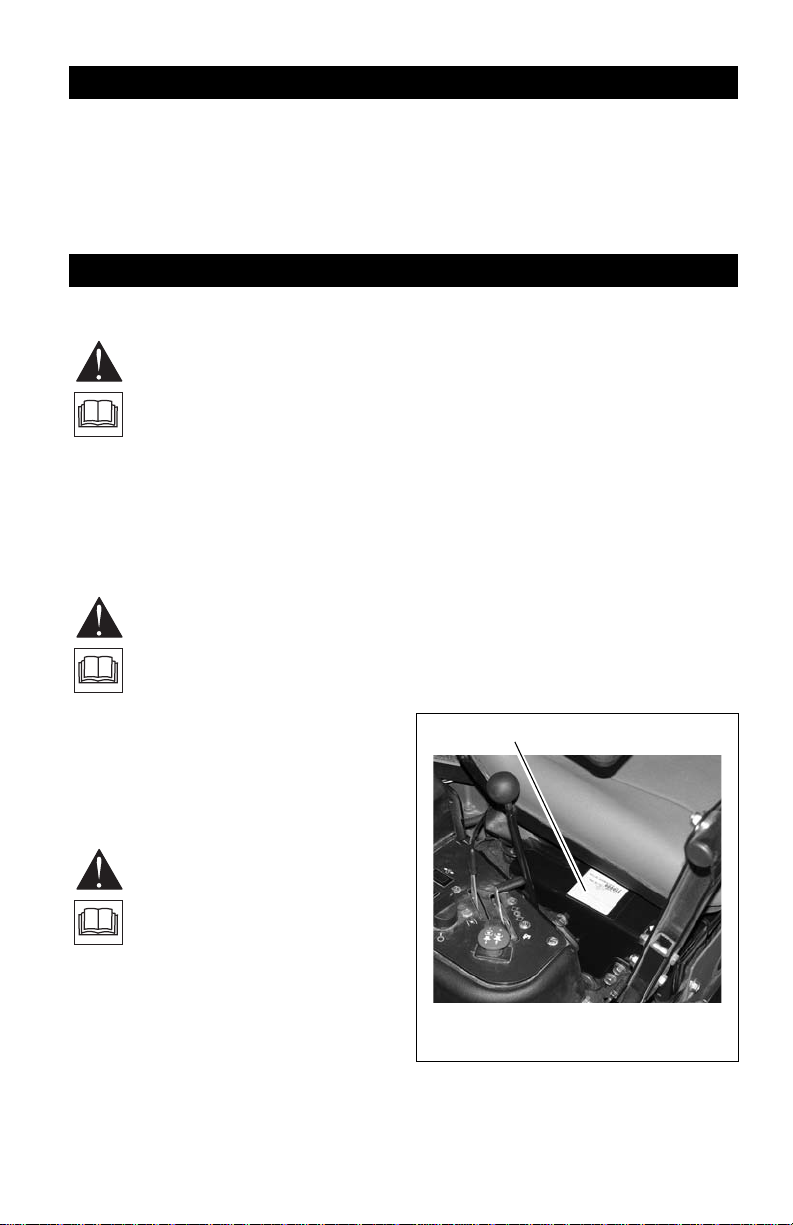

OF3141

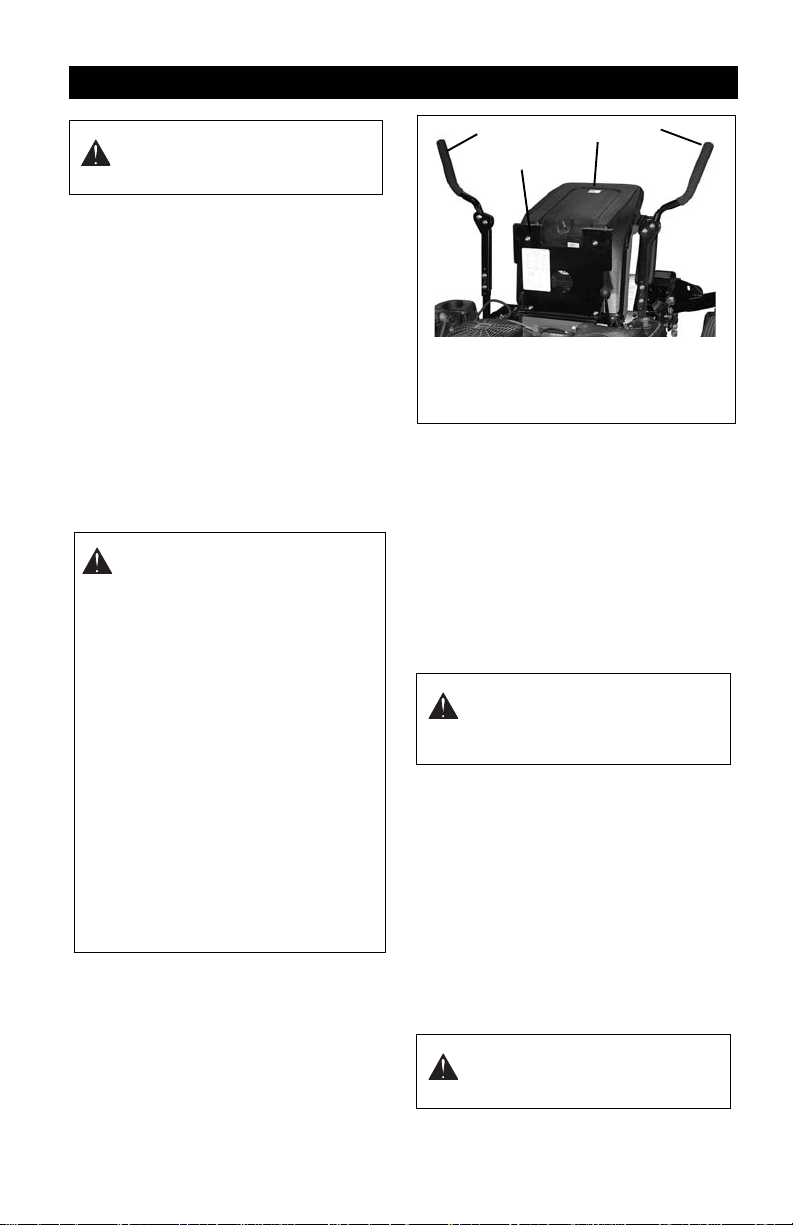

Figure 3

1

3

2

1

Read and understand entire

Safety section before proceeding.

UNIT ASSEMBLY

Package Contents:

Unit, Mower Deck and Literature Pack

Preparation Checklist

Refer to the Owner/Operator manual as

required.

1. Unpack Unit - Remove shrink wrap and

packaging materials.

2. Remove Unit From Container - Open

Bypass Valves (dump valves) (See

Moving the Unit with the Engine Off on

page 15).

Push unit from container onto a level

surface. Close the bypass valves.

3. Tires - See Specifications on page 31.

CAUTION: Avoid injury! Explosive

separation of tire and rim parts is

possible when they are serviced

incorrectly:

• Do not attempt to mount a

tire without the proper

equipment and experience

to perform the job.

• Do not inflate the tires

above the recommended

pressure.

• Do not weld or heat a wheel

and tire assembly. Heat can

cause an increase in air

pressure resulting in an

explosion. Welding can

structurally weaken or

deform the wheel.

• Do not stand in front or over

the tire assembly when

inflating. Use a clip-on

chuck and extension hose

long enough to allow you to

4. Seat - See Seat Adjustments on

page 13 and Service Position on

page 18.

5. Position Steering Levers - Remove

eccentric spacers and rotate steering

levers to the operating position. Reinstall

spacers. Tighten hardware securely.

See Aligning the Steering Levers

(Figure 14) on page 24.

stand to one side.

ASSEMBLY

6. Battery - Remove battery from unit and

charge (See Battery on page2 2).

7. Check Engine Crankcase - Check and

add oil if needed. See Engine Manual for

specifications.

8. Fill Engine Fuel Tank - Add clean fuel to

the fuel tank.

NOTE: See engine manual for fuel type.

9. Hardware - Check for loose hardware.

10. Check Safety Interlock System - Check

to see that the interlock system operates

correctly (See Safety Interlock System

on page 12).

11.Lubrication - Lubricate all fittings per

maintenance label under seat and check

hydrostat oil level (See Lubricate Unit on

page 23).

12. On 60-inch Decks: Remove the

discharge chute from the transport

position and place the discharge chute

in the operating position.

13. Level Deck - Check unit to ensure deck

level set at factory has been maintained

(See Leveling the Mower Deck on

page 28).

14. Check Function of all Controls - Ensure

unit runs and performs properly.

WARNING: FAILURE OF

INTERLOCK together with

improper operation can result in

severe personal injury.

WARNING: FAILURE OF

CONTROLS could result in death

or serious injury.

GB - 10

Page 11

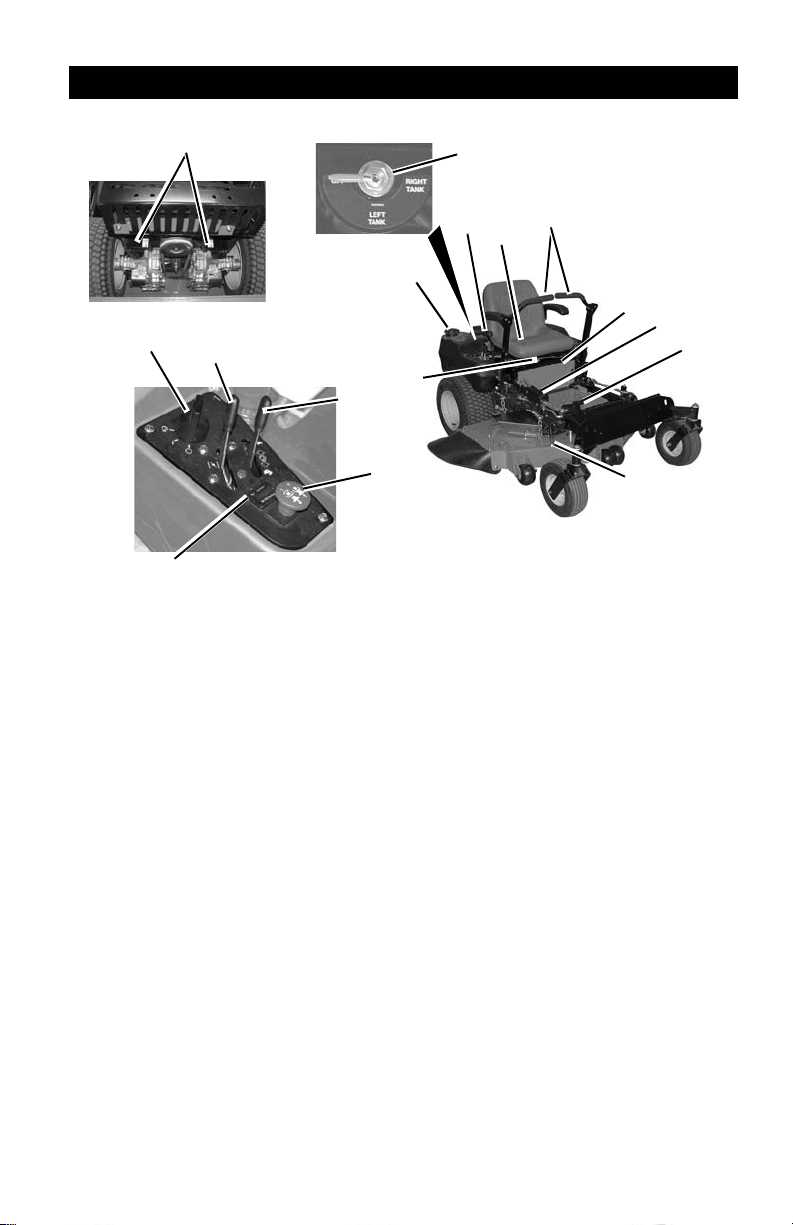

CONTROLS AND FEATURES

16

Figure 4

1

2

4

5

7

8

3

9

10

11

12

13

14

15

6

OF4035

OF4095

OM4090

OM4085

1. Fuel Tanks and Caps

2. Steering Levers

3. Hydraulic Oil Reservoir

4. Ignition Switch

5. Hour Meter

Throttle Lever

6.

7. Choke Control

8. Power Take Off (PTO) Switch

9. Battery

10. Fuel Shut Off Valve

11.Mower Lift Pedal

12. Mower Deck

13. Mower Lift Lock

14. Seat Adjustment Lever

15. Parking Brake

16. Bypass Valve Lever

GB - 11

Page 12

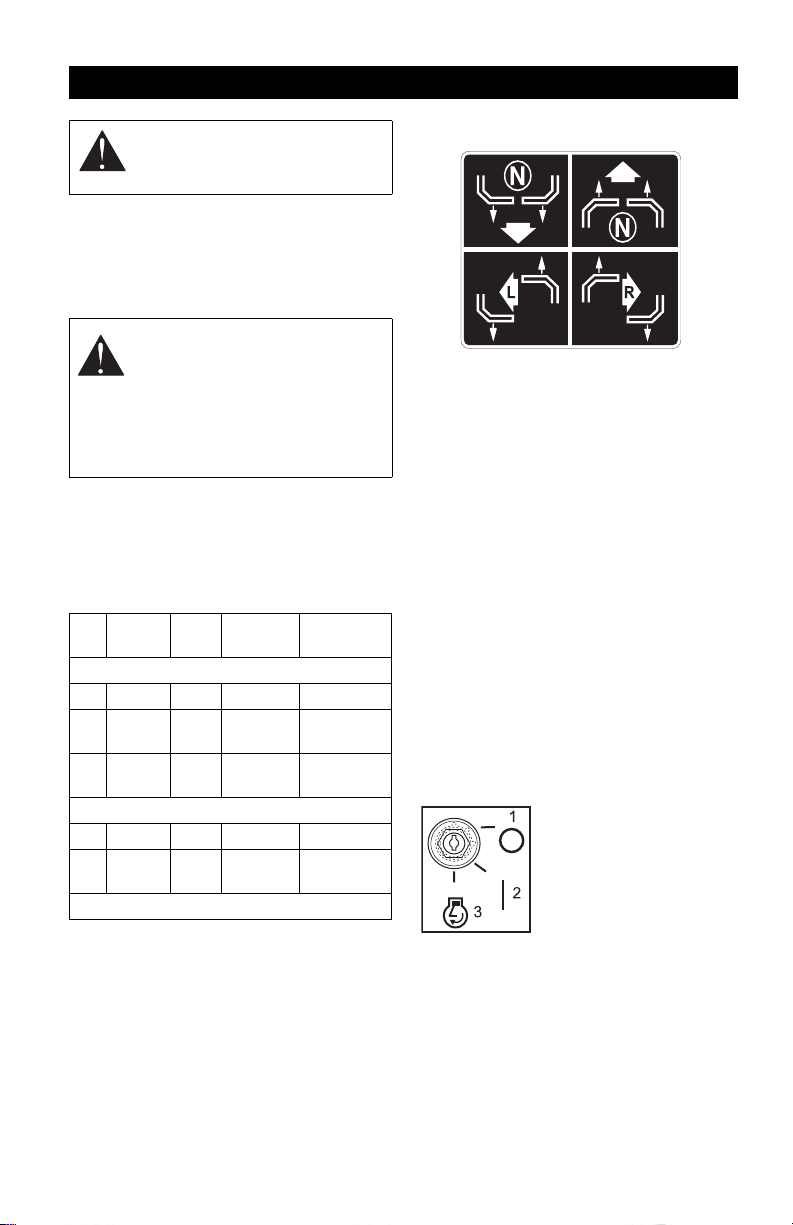

WARNING: AV OID INJURY.

07757600B

A

B

C

D

OF1750

Read and understand entire

Safety section before proceeding.

CONTROLS AND FEATURES

See Figure 4 for Controls and Features

locations.

Safety Interlock System

WARNING: Safety interlo c k

system failure and improper

operation of unit can result in

death or serious injury. Test this

system each time the unit is

operated. If this system does not

function as described, do not

operate until repairs are made.

Perform the following tests to ensure the

safety interlock system is working properly. If

the unit does not perform as stated, contact

your Ariens dealer for repairs.

NOTE: When the parking brake is engaged,

the steering levers are locked in neutral.

Test Steering

Levers

STARTING INTERLOCK

1 Neutral Off Engaged Starts

2 Neutral On Engaged Doesn’t

3 Neutral Off Dis-

OPERATING INTERLOCK (ENGINE ON)

4* Neutral On Engaged Shuts Off

5* Neutral Off Dis-

* Operator lifts off seat.

Parking Brake Interlock System

With the parking brake engaged, the steering

levers must be locked in neutral.

With the parking brake disengaged, the

engine must not start and the engine must

shut off if the operator leaves the seat.

PTO Parking

Brake

engaged

engaged

OPERATION

Engine

Start

Doesn’t

Start

Shuts Off

Steering Levers

The steering levers control speed and

direction. In addition, they will stop the unit.

A. For reverse travel, pull both steering

control levers backward.

B. For straight forward travel, push both

steering control levers forward.

C. To turn left, pull the left back or push

the right steering control lever forward

or a combination of both.

D. To turn right, pull the right back or

push the left steering control lever

forward or a combination of both.

T o stop, return both steering levers to neutral.

NOTE: The steering controls are

mechanically locked in neutral whenever the

parking brake is engaged.

NOTE: Aggressive turning can scuff or

damage lawns. ALWAYS keep both wheels

rotating when making sharp turns. DO NOT

make turns with inside wheel completely

stopped. To obtain minimum turning radius,

slowly reverse inside wheel while moving

outside wheel slowly forward.

Ignition Switch

Operate the ignition switch

with the removable key.

The switch has three

positions: Off (1), On (2)

and Start (3). To start the

engine, turn the key to

Start, then release to On.

To stop the engine, turn

the key to Off.

GB - 12

Page 13

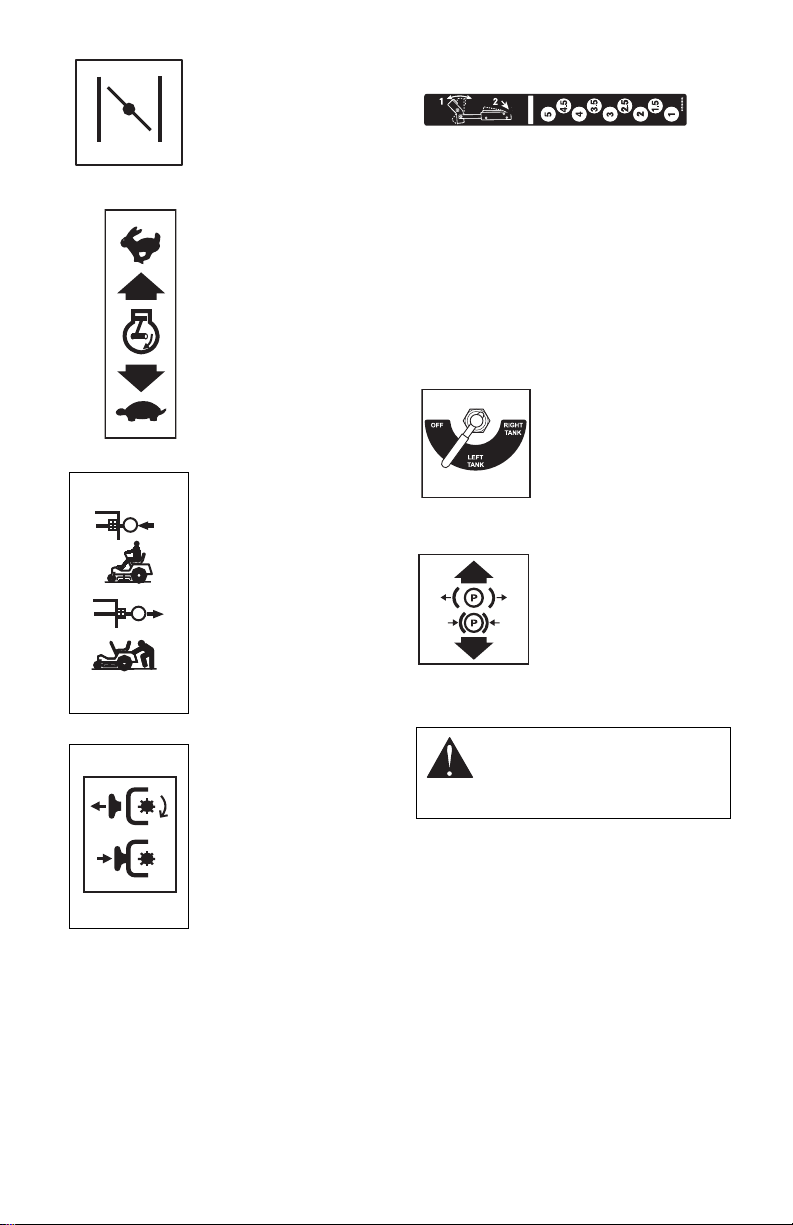

Choke Control

OF1680

OF1700

2

1

Drive

Neutral

OE0261

OFF

ON

OF1700

OF1740

Push the choke lever

forward to start a cold

engine. Pull the choke

lever to the rear when the

engine gets warm.

Throttle Lever

The throttle lever changes

the engine speed. Move

the throttle lever to Fast (1)

to increase engine speed.

Move the lever to Slow (2)

to decrease engine speed.

Bypass Valve Lever

Pull the lever back to set

the pump in neutral and

move the unit with the

engine off.

Push the lever in to set the

pump in the drive position

and operate the unit.

Mower Lift Pedal

Mower lift pedal raises and lowers mower

deck for mowing or transport.

Transport:

Push mower lift pedal all the way forward until

lift lock engages.

Cutting Height:

Put cutting height adjustment pin in desired

hole. Push mower lift pedal forward and hold

it while pushing down on the lift lock. Slowly

lower mower lift pedal until deck lift contacts

cutting height adjustment pin.

Fuel Shut-Off Valve

Use this valve to control

fuel flow from left or right

fuel tank.

Open the valve to operate

the engine. Turn the valve

to "Off" when storing or

transporting the unit.

Parking Brake Lever

1. Pull lever up to engage

parking brake.

2. Push lever down to

disengage parking brake.

Power Take Off (PTO)

Switch

Power take off (PTO)

switch engages and

disengages the mower

blades.

Pull the power take off

(PTO) switch to "On"

position to engage mower

blades.

(PTO) switch to "Off" position to disengage

mower blades.

NOTE: The engine will not start unless the

steering control levers are in the neutral

position, the PTO switch is in the “Off”

position and parking brake is set.

Push the power take off

Seat Adjustments

WARNING: Make all seat

adjustments with unit stationary,

parking brake on and engine shut

off.

To adjust seat forward or backward :

1. While seated, pull seat adjustment lever

outward and slide seat into desired

position.

2. Release lever and slide seat forward or

back to lock seat into position.

GB - 13

Page 14

Hour Meter

Records total number of

hours the engine has

been run.

IMPORTANT: Keep a

record of Hour Meter

readings for

recommended Lubrication

and Maintenance

intervals.

NOTE: For accurate readings be sure Ignition

Switch is OFF when unit is not in operation.

FILLING FUEL TANK

WARNING: AV OI D INJURY.

Read and understand entire

Safety section before proceeding.

Add fuel to Fuel Tank as needed. See your

Engine Manual for correct type and grade of

fuel.

To add fuel to the fuel tank:

1. Place unit in an open or well-ventilated

open area.

2. Stop the engine and allow it to cool.

3. Clean the fuel cap and the area around

the fuel cap to prevent dirt from entering

the fuel tank. Remove the cap from the

fuel tank.

4. Fill the fuel tank to within 1 in. (25 mm)

below bottom of filler neck.

5. Replace fuel cap and tighten.

6. Clean up any spilled fuel.

GASOLINE

IMPORTANT: ALWAYS use gasoline that

meets the following guidelines:

• Clean, fresh gasoline.

• A minimum of 87 octane/87 AKI (91

RON). High altitude use may require a

different octane. Consult your engine

manual.

• Gasoline with up to 10% ethanol

(gasohol) or up to 15% MTBE (methyl

tertiary butyl ether) is acceptable.

• Use of any gasoline other than those

approved above may void the engine

warranty. If the pumps are not marked

for the content of alcohol or ethers,

check ethanol and MTBE levels with

the fuel supplier.

• Do not modify the fuel system to use

different fuels.

• Never mix oil and gasoline.

NOTE: All gasoline is not the same. If the

engine experiences starting or performance

problems after using a new gasoline, switch

to a different fuel provider or fuel brand.

IMPORTANT: Excessively oxygenated or

reformulated fuels (fuels blended with

alcohols or ethers) can damage the fuel

system or cause performance problems. If

any undesirable operating problems occur,

use a gasoline with a lower percentage of

alcohol or ether.

Fuel Stabilizer

Gasoline left in the fuel system for extended

periods without a stabilizer will deteriorate,

resulting in gum deposits in the system.

These deposits can damage the carburetor

and the fuel hoses, filter and tank. Prevent

deposits from forming in the fuel system

during storage by adding a quality fuel

stabilizer to the fuel. Follow the

recommended mix ratio found on the fuel

stabilizer container.

PRE-START

CAUTION: Make sure all

hardware is tight, all safety

devices are in place and all

adjustments are made correctly.

1. Check Safety Interlock System

If this system does not function as described

do not operate until repairs are made.

2. Check Air Cleaner

Check air filter for dirt. Clean as required.

Follow Engine Manual Maintenance

Schedule.

3. Check Engine Fuel and Crankcase

Oil

Check and add fuel if required. Check that

engine crankcase oil is full. Follow Engine

Manual Maintenance Schedule.

4. Check Tire Pressure

See Specifications on page 31 for correct tire

pressure.

5. Check Hydraulic Fluid Level

See Check Hydraulic Fluid Level on page 19.

6. Adjust Seat

Be sure all controls can be reached safely

from operator’s position.

7. Set Cutting Height

Make sure the deck is set to the correct

cutting height.

GB - 14

Page 15

STOPPING IN AN EMERGENCY

The unit can be stopped immediately at any

time by turning the ignition key to the "Off"

position.

STARTING AND SHUT OFF

CAUTION: Read entire

Owner/Operator Manual, Clutch

Manual, and Engine Manual first.

DO NOT attempt to start engine

at this tim e .

To start the engine:

1. Make sure the steering levers are in

neutral.

2. Put the PTO switch in the “Off” position.

3. Engage parking brake.

4. If the engine is cold, move the choke

control to the “On” position. If the engine

is warm or hot, do not use choke.

5. Move the throttle to 3/4 “Fast” position.

See Engine Manual for detailed

instructions.

6. Put the ignition key in the switch and

turn it to the “Start” position.

7. As soon as the engine starts, release the

key.

8. Move the choke control to the “Off”

position from the “Choke” position. Wait

until the engine is running smoothly

before operation.

To stop the engine:

1. Bring the steering levers to neutral.

Disengage the PTO and engage the

parking brake.

2. Move the throttle lever to the “Slow”

position.

3. Turn the ignition key to the “Off” position.

TO MOW WITH UNIT

Operate the unit only when seated in the

operator’s position.

1. Start the engine. Let the engine warm

until it is running smoothly.

2. Release parking brake.

5. Turn ON the PTO switch to engage the

mower.

IMPORTANT: Never engage the PTO if the

mower is plugged with grass or other

material. This may cause damage to the

electric clutch.

6. Move throttle control to fa s t.

7. Move the steering levers forward to

obtain a slow ground speed.

8. To disengage the mower, move the PTO

switch to the “Off” position.

9. When you know how to operate the unit,

select a speed appropriate to your

mowing conditions.

PARKING

To park the unit:

1. Bring the steering levers to neutral. Turn

off PTO.

2. Move the throttle lever to the “Slow”

position.

3. Engage the parking brake.

4. Lower the attachment.

5. Turn the ignition key to the “Off” position

and remove the key.

MOVING THE UNIT WITH THE

ENGINE OFF

IMPORTANT: Never tow unit.

1. Shut OFF engine.

2. Place seat in the service position (See

Service Position on page 18).

3. Pull the right and left bypass levers to

the neutral position.

WARNING: Do not bypass

transmission when on a slope.

4. Disengage parking brake.

5. Push unit to desired location.

6. Engage parking brake.

7. Push the right and left bypass levers to

the drive position.

WARNING: Move the steering

control levers slowly and keep the

throttle control lever at slow

speed until you learn how to

operate the unit.

3. Bring the steering levers to neutral.

4. Slow the engine down to about 3/4

speed.

GB - 15

Page 16

FOR BEST PERFORMANCE

OF4105

OF4110

Pull Lever Out to the Neutral Position

Figure 5

Push Lever In to Drive Position

Cut grass when it is dry.

Keep mower blades sharp.

Keep mower deck properly levelled.

Adjust anti-scalp rollers to prevent scalping.

Do not set height of cut too low. For very tall

grass, mow twice.

Do not travel too fast.

Mow with the engine set at full throttle.

When mulching, only remove 1/3 of grass

length per cutting. Do not cut more than 1

inch (2.54 cm) at any one time.

Discharge clippings into areas already cut.

Vary cutting pattern with each mowing.

Do not allow grass or debris to collect inside

of mower deck. Clean after each use.

MAINTENANCE SCHEDULE

WARNING: AV OI D INJURY.

Read and understand entire

Safety section before proceeding.

Proper maintenance can prolong the life of

unit. The following charts show the

recommended service schedule. More

frequent service may be required due to

working conditions (heavy loads, high

ambient temperatures, dusty conditions, or

airborne debris).

See the maintenance instructions in the

Engine Manual for additional information.

GB - 16

Page 17

Period Service Task

Check Safety Interlock WARNING: Safety interlock system

Check Parking Brake

Interlock System

Check Hydraulic Fluid Check hydraulic oil level mark on cap/dipstick. Add

Check Tires See Specifications on page 31for correct tire

See Parking Brake Interlock System on page 12.

20W50 engine oil as needed. Do not overfill. See

Check Hydraulic Fluid Level on page 19.

pressure.

• Do not attempt to mount a tire without the

Each

Use

Every

25

Clean Unit Clean engine, battery, seat, mower deck, etc. of dirt

Follow Engine Manual

Maintenance Schedule

Check Mower Blades Check mower blades for wear. Sharpen or replace

• Do not inflate the tires above the

• Do not weld or heat a wheel and tire

• Do not stand in front or over the tire

and debris. Do not use solvents, hard cleaners, or

abrasives.

Do not spray the unit with water, especially when

the unit is warm from operation. Water can seep

into bearings and damage them.

NOTE: P rotect painted surfaces with automotive

type wax.

Perform scheduled engine maintenance. Refer to

engine manual for detailed instructions.

as needed.

Hours

failure and improper operation of unit can

result in death or serious injury. Test this

system each time the unit is operated. If

this system does not function as

described, do not operate until repairs are

made. See Safety Interlock System on

page 12.

CAUTION: Avoid injury! Explosive

separation of tire and rim parts is possible

when they are serviced incorrectly:

proper equipment and experience to

perform the job.

recommended pressure.

assembly. Heat can cause an increase in air

pressure resulting in an explosion. Welding

can structurally weaken or deform the

wheel.

assembly when inflating. Use a clip-on

chuck and extension hose long enough to

allow you to stand to one side.

See Mower Blades on page 20.

Every

50

Hours

Check Air FIlter Check air filter for dirt. Clean as required. Follow

Engine Manual for maintenance schedule.

Lubricate Unit Oil all pivot points and pin connections. Grease

lube fittings. See Lubricate Unit on page 23.

Check Brake Gap Adjust gap if necessary. See Adjusting the Parking

Brake on page 25.

GB - 17

Page 18

Period Service Task

1. Service

Position

2. Steering

Levers

3. Parking Brake

4. Battery

Figure 6

2

3

4

OF4310

1

2

Every

100

Hours

Every

400

Clean Battery Keep battery and its terminals clean. See Clean

Check Fasteners Check mower blade mounting hardware and all

Check Belts Replace worn or deteriorated belts. See Replacing

Change Hydraulic Fluid

and Filter

*

Battery on page 22

other fasteners. Replace missing or damaged

fasteners. Tighten all nuts and bolts to their correct

torque value.

Mower Belts on page 26 and Replacing the Hydro

Pump Belt on page26.

Drain hydraulic fluid tank, replace hydraulic oil filter,

refill system. See Hydraulic Fluid on page 19.

Hours

*Change hydraulic fluid and filter after the first 75 hours of operation and then

every 400 hours.

SERVICE AND ADJUSTMENTS

Ariens Dealers will provide an y servic e whi ch

may b e required t o keep your unit operating at

peak efficiency. Should engine service be

required, it can be obtained from a Ariens

Dealer or the engine manufacturer’s

authorized service center.

WARNING: AV OI D INJURY.

Read and understand entire

Safety section before proceeding.

.

5. When service is complete, lower seat

and secure with wing knob or hex nut.

SERVICE POSITION

1. Place unit on a flat level surface.

ALWAYS stop engine. Ensure unit is

secure and will not tip over. Strap and

clamp onto lift if used.

2. Place steering levers in neutral and

engage parking brake.

3. Remove wing knob.

4. Tip seat forward (Figure 6).

CAUTION: HOT SURFACES

may result in injury. DO NOT

touch engine or drive parts which

are hot from operation. Allow

parts to cool before servicing.

CAUTION: Be sure footing is

secure to accomodate weight

shift of seat when rotating it into

service position.

GB - 18

Page 19

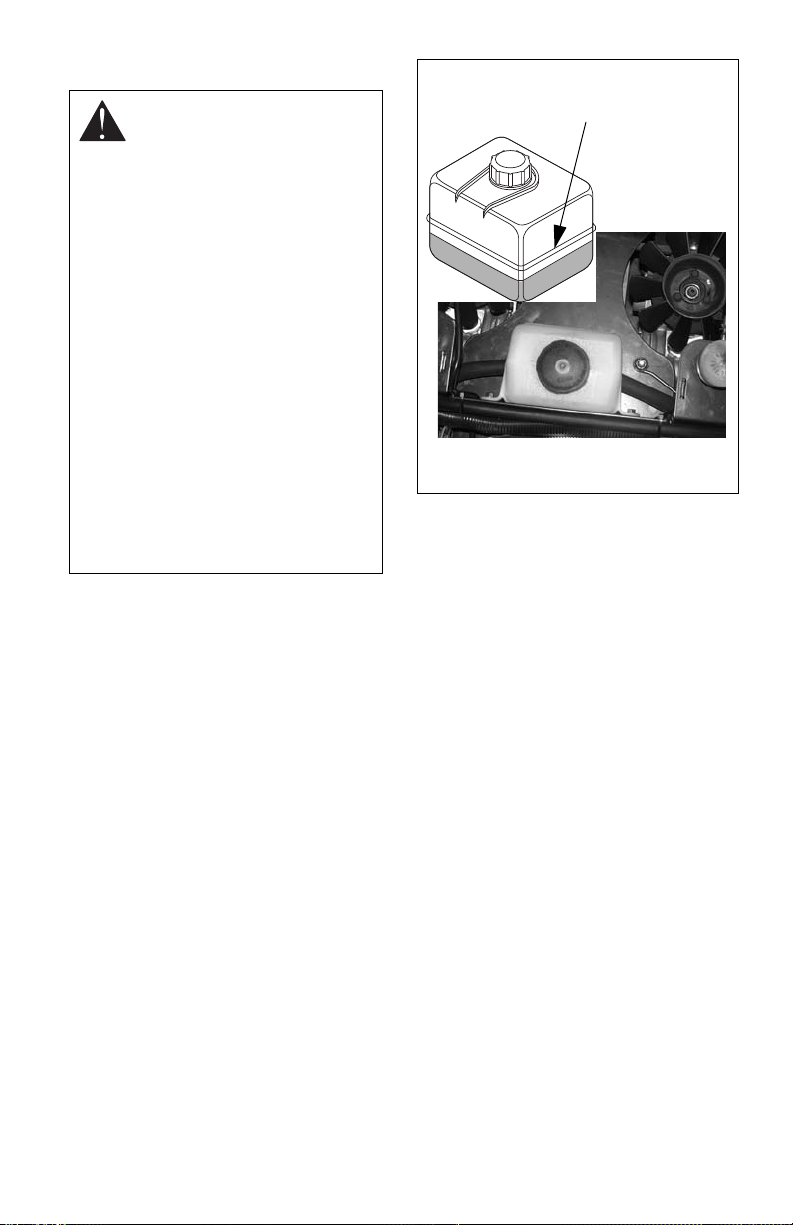

HYDRAULIC FLUID

Figure 7

The hydraulic fluid should be at the cold

fill line of the expansion tank.

WARNING: HYDRAULIC FLUID

can result in severe burns. Fluid

in hydraulic system can penetrate

skin and result in serious injury or

death.

Be sure to stop the engine before

doing any work on hydraulic

parts.

Keep body and hands away from

pin holes or nozzles which expel

hydraulic fluid when under

pressure. Use paper or

cardboard, not hands, to search

for leaks.

Ensure all hydraulic fluid

connections are tight and all

hydraulic hoses and lines are in

good condition before applying

pressure to system.

FOREIGN FLUID INJECTED

INTO BODY can result in

gangrene. Fluid must be

surgically removed within a few

hours by a doctor familiar with

this form of injury.

Check Hydraulic Fluid Level

Check the system with the unit cold and

parked on a flat, level surface.

Then run the unit for about one minute and

recheck the levels.

To Add Hydraulic Fluid:

1. Remove the cap from the expansion

tank.

2. Fill the expansion tank with 20W-50

engine oil with an SL API classification

until oil level reaches the cold fill line on

the tank.

3. Install the expansion tank cap and then

purge the system. See Purging the

Hydraulic System on page 20.

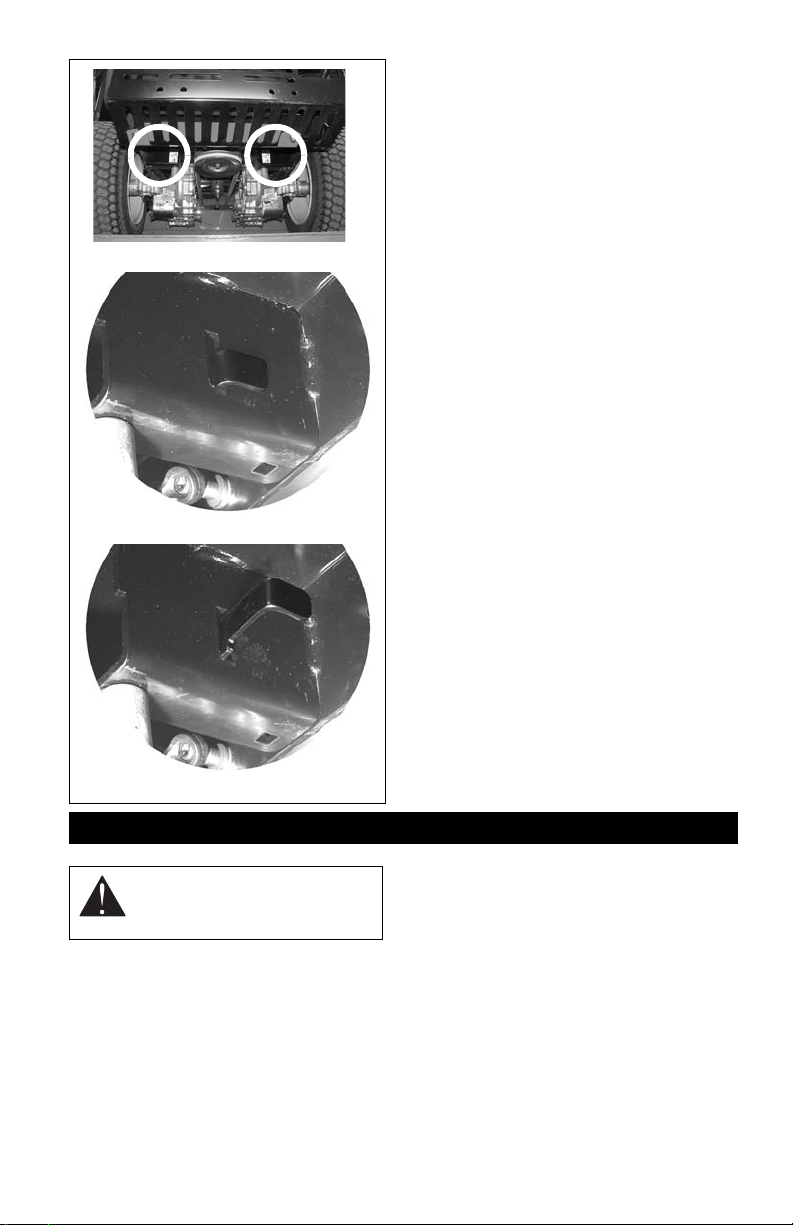

Change Hydraulic Fluid and Filter

NOTE: Change hydraulic fluid and filter after

the first 75 hours of operation and then every

400 hours. Use 20W-50 engine oil with an SL

API classification.

1. Place container under oil filter to catch

oil.

2. Remove the filter guard and oil filter from

the transaxle.

3. Remove the oil drain plug or fitting from

the inlet port and allow the transaxle to

drain completely.

4. Clean the filter mounting surface and

then lubricate rubber gasket on new oil

filter with clean hydraulic oil.

5. Spin new oil filter onto filter housing until

it makes contact. Tighten oil filter

another 3/4 turn.

6. Install the filter guards removed in

step 2. Tighten the mounting screws to

65 lbf-in (7.3 N•m).

7. Fill with 20W-50 engine oil with an SL

API classification until oil appears at the

bottom of the drain plug (about 2 quarts

per transaxle). Install the drain plug and

tighten it to 180 lbf-in (20.3 N•m).

8. Repeat steps 1–7 for the other

transaxle.

9. Follow the instructions in To Add

Hydraulic Fluid: on page 19.

GB - 19

Page 20

Purging the Hydraulic System

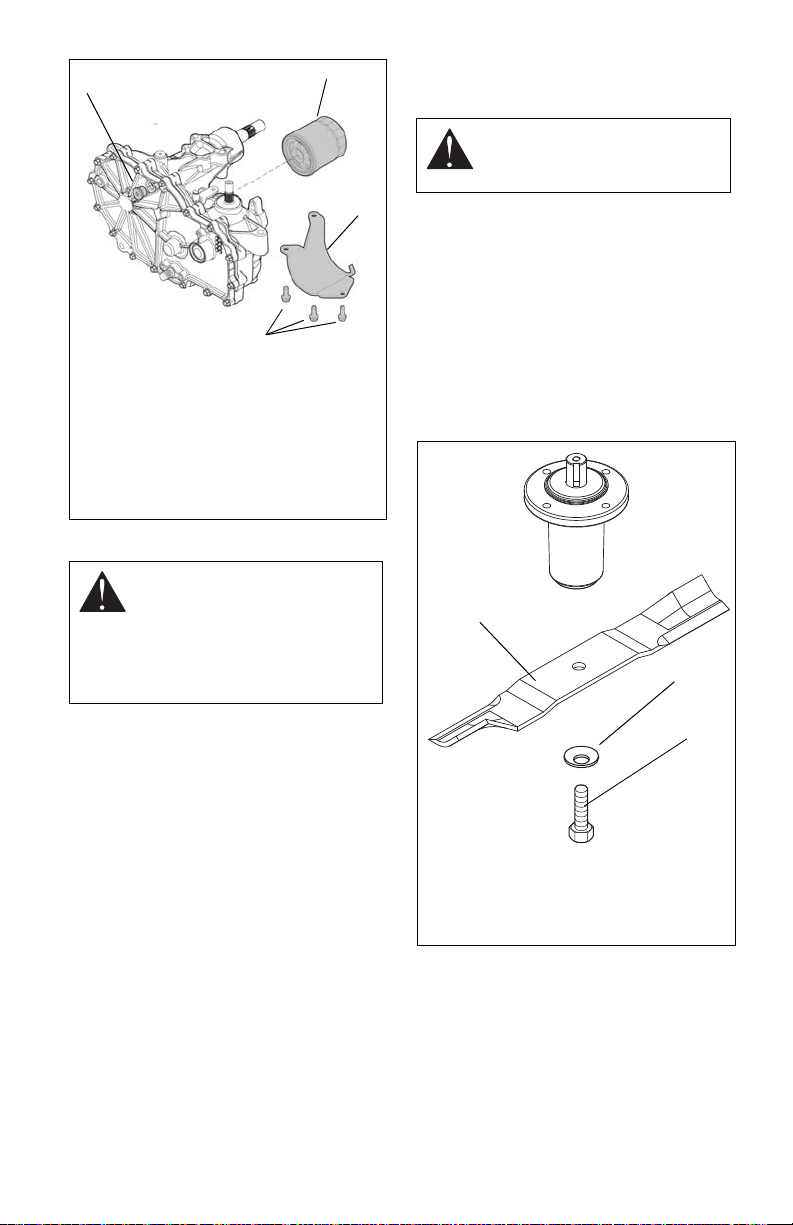

Figure 8

1. Drain Plug

2. Oil Filter

3. Filter Guard

4. Mounting Hardware

1

4

3

2

Figure 9

1. Blade

2. Cup Washer

3. Bolt

1

3

2

WARNING: This adjustment

requires operating the engine.

Use extreme care to avoid

contact with moving parts and hot

surfaces. Be sure rear of unit is

well supported and secure before

starting engine.

MOWER BLADES

Remove

CAUTION: Use sturdy gloves or

padding to protect hands when

working with mower blades.

1. Turn the engine off. Remove the ignition

key. Remove the ignition wire from the

spark plugs.

2. Remove the bolts, cup washer, and

blades from the spindle shafts.

Replace

1. Put the blades, cup washers, and the

bolts back on the spindle shafts.

2. Tighten the bolts to a torque of

115-160 lbf-ft (156-217 N•m).

3. Replace the ignition wire on the spark

plugs.

1. With the unit up to and facing a wall, jack

up the unit so that both drive wheels are

off the ground.

2. Disengage the parking brake and put the

transaxle bypass levers in the neutral

position. See Moving the Unit with the

Engine Off on page 15.

3. Start the engine and slowly move the

steering levers in forward and reverse

five or six times.

4. Stop the engine and put the transaxle

bypass levers in the drive position. See

Moving the Unit with the Engine Off on

page 15.

5. Start the engine and slowly move the

steering levers in forward and reverse

five or six times.

6. Stop the engine, check the oil level and

add oil as needed.

7. Repeat steps 2–6 until the transaxles

operate smoothly in forward and reverse

at normal speeds without excessive

noise.

GB - 20

Page 21

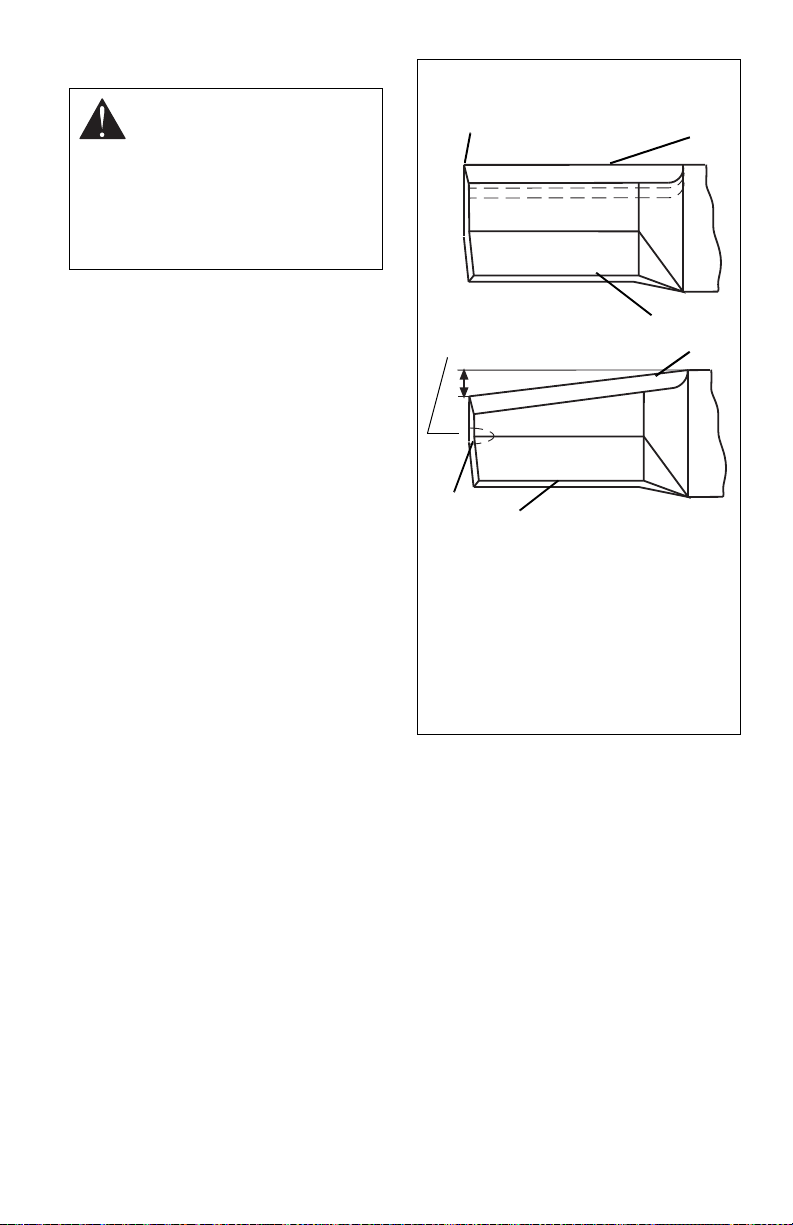

Sharpen the Mower Blades

1. Cutting Edge

2. Square

Corner

3. Air Lift

Erosion

4. Air Lift

OT0792

Figure 10

DO NOT Sharpen to This Pattern

Sharpen to This Pattern

DISCARD if More Than

1/2 in. (1.27 cm)

1

1

4

2

4

3

CAUTION: DO NOT sharpen

mower blades while on unit. An

unbalanced mower blade will

cause excessive vibration and

eventual damage to unit. Check

mower blade balance before

reinstalling blades.

NEVER weld or straighten bent

blades.

1. Remove mower blade from unit.

Discard mower blade if:

• More than 1/2 in. (1.27 cm) of metal is

removed.

• Air lifts become eroded.

• Blade is bent or broken.

2. Sharpen mower blade by removing an

equal amount of material from each end

of mower blade. DO NOT change angle

of cutting edge or round the corner of the

mower blade.

3. Check mower blade balance.

Slide mower blade on an unthreaded

bolt. A balanced blade should remain in

a horizontal position. If either end of

mower blade moves downward, sharpen

the heavy end until blade is balanced.

4. Install mower blade(s) on unit.

5. Tighten the bolts to a torque of

115-160 lbf-ft (156-217 N•m).

GB - 21

Page 22

BATTERY

1. Negative

terminal

2. Positive

terminal

3. Battery

OF1671

Figure 11

1

2

3

WARNING: AV OI D INJURY.

Read and understand entire

Safety section before proceeding.

WARNING: Battery posts,

terminals and related accessories

contain lead and lead

compounds, chemicals known to

the State of California to cause

cancer and reproductive harm.

Wash hands after handling.

Unit comes equipped with a maintenancefree battery that requires no regular

maintenance except cleaning the terminals.

Remove Battery

1. Shut OFF engine. Engage parking

brake. Remove the ignition key.

2. Place seat in the service position (See

Maintenance Schedule on page 16).

3. Disconnect cables from battery

(negative, then positive) (Figure 11).

4. Remove hold down and remove battery.

Replace Battery

1. Replace battery and secure with battery

hold down.

2. Reconnect cables to battery (positive,

then negative). Position boot over

positive terminal.

3. Return seat to operating position.

Clean Battery

Keep battery and its terminals clean. Inspect

every 100 operating hours or monthly for best

performance.

1. Remove battery from unit. See Remove

Battery on page 22.

2. Clean terminals and battery cable ends

with wire brush.

3. Coat terminals with dielectric grease or

petroleum jelly.

4. Replace battery . See Replace Battery on

page 22.

Charging the Battery

Battery Electrolyte First Aid

Follow First Aid directions for contact with

battery fluid.

• External Contact: Flush with water.

• Eyes: Flush with water for at least 15

minutes and get medical attention

immediately!

• Internal Contact: Drink large quantities

of water. Follow with Milk of Magnesia,

beaten egg or vegetable oil. Get

medical attention immediately!

In case of internal contact, DO NOT induce

vomiting!

IMPORTANT: DO NOT fast charge. Charging

at a higher rate will damage or destroy

battery. ONLY use an automatic charger

designed for use with your battery.

ALWAYS follow information provided on

battery by battery manufacturer. Contact

battery manufacturer for extensive

instructions to charge battery.

1. Remove battery from unit. See Remove

Battery on page 22.

2. Place battery on bench or other wellventilated place.

GB - 22

Page 23

3. Connect positive (+) lead of charger to

R

E

F

LUBRICA-

TION

QTY LOCATION INTER-

VAL

1 REPACK 2 CASTER

PIVOT

400 Hrs

OIL ALL PIVOT

POINTS, PIN

CONNEC-

TIONS

50 Hrs

OF1794

1

Figure 12

Figure 13

Axle Direction

Return to Neutral

Adjusting Screw

Speed and

Direction

Control Arm

positive (+) terminal, and negative (–)

lead to negative (–) terminal.

4. Charge battery according to charger and

battery manufacturers’ instructions.

5. Replace battery. See Replace Battery on

page 22.

Jump-Starting

Ariens does not recommend jump-starting

your unit. Jump-starting can damage engine

and electrical system components. See your

engine manual for more detailed information.

LUBRICATE UNIT

Apply oil at all pivot points and pin

connections.

3. Remove the drive wheels from the unit.

4. Start the engine, run engine at full

throttle, and release the parking brake.

5. Move the steering levers from Forward

to Reverse several times to make sure

controls are free. Then return steering

levers to neutral position.

6. Check wheel(s) for movement.

NOTE: The right and left hydraulic pumps are

adjusted the same way.

7. If a wheel moves, adjust the return to

neutral mechanism on the hydraulic

pump:

a. Loosen the return to neutral screw

on the pump.

b. Slowly move the speed and

direction control bracket clockwise

or counterclockwise until the

wheel stops moving.

c. Hold the stop bracket in position

and tighten the return to neutral

screw on the pump.

8. Move steering levers from Forward to

Reverse several times and return

steering levers to neutral position.

Check wheel(s) for movement.

9. If wheel is still moving, repeat steps 7

and 8.

10. Shut OFF engine.

11.Replace drive wheels.

STEERING CONTROL NEUTRAL

ADJUSTMENT

Eliminating Excessive Creeping of

the Unit (Figure 13)

WARNING: This adjustment

requires operating the engine.

Use extreme care to avoid

contact with moving parts and hot

surfaces. Be sure rear of unit is

well supported and secure before

starting engine.

1. If hydraulic system is cold, run unit for a

minimum of five minutes, then shut OFF

engine.

2. With the unit up to and facing a wall, jack

up the unit so that both drive wheels are

off the ground.

GB - 23

Page 24

Aligning the Steering Levers

1. Tie-Rod Jam

Nut

2. Tie-Rod

3. Steering

Lever

4. Brake

Interlock

5. Hydrostatic

Transmission

Figure 14

OF3381

1

2

3

4

5

1

Figure 15

1. Limiter Bolt

2. Jam Nut

3. Steering

Lever

4. Stop

Bracket

1

2

3

1

4

2

(Figure 14)

1. Shut OFF engine. Engage parking

brake. Remove the ignition key.

2. Place seat in the service position (See

Service Position on page 18).

3. Loosen brake interlock on the same side

as steering lever to be adjusted.

4. Loosen tie rod jam nuts and turn tie rod

until steering levers are aligned.

5. Tighten jam nut on tie rod, tighten brake

interlock.

ADJUSTING THE UNIT TO TRACK

STRAIGHT

WARNING: Prior to adjusting the

tracking of the unit, shut OFF

engine, engage parking brake,

and remove the ignition key.

Check and adjust tire pressure. Increase

pressure on side unit tracks to. DO NOT

exceed maximum recommended tire

pressure (See Specifications on page 31).

If tire pressure adjustment does not solve

tracking problem, adjust the limiter bolts on

the stop bracket (Figure 15). Front bolts

adjust forward and rear bolts adjust reverse.

Lengthen the limiter bolt (move closer to

lever) on side which is too fast.

GB - 24

Page 25

ADJUSTING THE HEIGHT OF THE

Figure 16

OF4315

1. Handle

2. Eccentric

Spacer

3. Steering Lever

4. Mounting

Hardware

1

3

2

4

Figure 17

1. Parking Brake Cable

2. Adjuster

3. Nuts

1

2

3

STEERING LEVER HANDLES

NOTE: Align handlebars by adjusting

eccentric spacer until the height of

handlebars are the same.

1. Remove mounting hardware and move

handlebar up or down until the steering

levers are at the appropriate height.

2. Install mounting hardware.

Adjust the Parking Brake

1. Disengage the parking brake.

2. Loosen the nuts on the parking brake

cable adjuster and then turn the adjuster

until the cable is taut, not tight.

3. Engage the parking brake and check the

adjustment. Repeat as needed.

4. Tighten the nuts.

NOTE: Set both bypass valves to the drive

position when finished adjusting the brake.

ADJUSTING THE PARKING

BRAKE

The parking brake should not need

adjustment, however if the parking brake

does not hold the unit properly, the brake may

need adjustment.

Check Adjustment

NOTE: Be sure to check the parking brake on

both sides of the unit (Figure 17).

1. Engage parking brake and set both

transmission bypass valves to the

neutral position. See Moving the Unit

with the Engine Off on page 15.

2. Push the unit forward.

If the unit easily rolls forward the

transmission brakes are not fully

engaging. Tighten the brake cable to

fully engage the brake lever on the

transmission.

PTO BELT

WARNING: MOVING P ARTS can

cut or amputate body parts.

ALWAYS wait for moving parts to

stop before performing

maintenance or service.

CAUTION: DAMAGED OR

WORN BELTS may result in

injury and/or damage to unit.

Check belts for excessive wear or

cracks often.

PTO Belt Access

1. Properly stop and park unit (See

Operation on page 12).

2. Lower the mower.

3. Place seat in most rearward position.

4. Remove belt covers.

5. Place foot board in open position

(Figure 18).

GB - 25

Page 26

Replacing Mower Belts

3

1. Footboard in

open position

2. Support Frame

3. Pivot

Figure 18

1

2

Figure 19

1. PTO Mower Belt

2. Mower Drive Belt

3. Springs

4. Mower Drive Belt Idler

5. PTO Mower Belt Idler

6. Mower Clutch Sheave

7. Center Sheave

1

2

4

7

6

5

3

NOTE: Long mower belt must be removed to

remove short mower belt.

CAUTION: Use care when

releasing idler spring tension.

Keep body parts well away from

idlers when performing this

operation.

1. Slowly release the tension on the long

mower belt idler until all the tension is

removed from the springs.

2. Remove long mower belt from left blade

spindle and remove from deck.

3. Slowly release the tension on the short

belt idler until all the tension is removed

from the springs.

4. Remove short mower belt from right

blade spindle and from deck. Idler pivot

bolt must be loosened slightly to gain

clearance to remove belt from under

idler pulley (Figure 19).

5. Arrange new mower belt(s) on deck

(short belt first). Retighten short mower

belt idler pivot bolt. Install belts on

sheaves. Put belts onto center sheave

last.

6. Replace belt covers and return foot

board to closed position.

Replacing the Hydro Pump Belt

1. Properly stop and park unit (See

Operation on page 12).

2. Remove the PTO belt from the mower

clutch sheave (See Replacing Mower

Belts on page 26).

CAUTION: Use care when

releasing idler spring tension.

Keep body parts well away from

idlers when performing this

operation.

3. Slowly release the tension on the hydro

pump belt idler until all the tension is

removed from the springs.

4. Remove old hydro pump belt from right

hand hydrostat sheave first (Figure 20).

5. Install new hydro pump belt by

positioning belt on sheaves. Put belt

onto right hand hydrostat sheave last.

6. Replace long mower belt on mower

clutch sheave. See Replacing Mower

Belts on page 26.

GB - 26

Page 27

OF1631

1. Hydro Belt

2. Spring

3. Idler

4. Engine

Sheave

5. Right Hand

Hydrostat

6. Left Hand

Hydrostat

7. Clutch

8. Clutch

Anchor

Figure 20

6

1

5

2

7

8

4

3

Highest

Cutting

Height

OF3590

Figure 21

Lowest Cutting

Height

MOWER DECKS

Anti-scalp Roller Adjustment

The anti-scalp rollers are set at the factory for

typical mowing height, but can be adjusted for

high or low cutting conditions (Figure 21).

Anti-Scalp rollers are intended to prevent

lawn scalping, not to control cutting height.

For a very high cutting height, set the antiscalp rollers in the lowest position on the

bracket.

For a very low cutting height, set the antiscalp rollers in the highest position on the

bracket.

NOTE: There are four anti-scalp rollers on

the outside of the mower deck and four antiscalp rollers on the inside of the mower deck.

Make sure all anti-scalp rollers are set at the

same height.

Removing the Mower Deck

1. Remove PTO belt (See Replacing

Mower Belts on page 26).

WARNING: AVOID INJURY.

Mower lift arms and mower lift

pedal could cause severe injury if

they are not locked before

removing the mower de ck.

ALWAYS lock mower deck lift

before removing the deck.

2. Lock the mower deck in the service

position.

Push the mower lift pedal forward

between cutting height number 4 and

number 5 to align the holes in the deck

lift shaft and the deck lift cover. Insert the

cutting height pin in the holes on the side

of the deck lift cover so it passes all the

way through the deck lift cover and

shaft.

IMPORTANT: The mower lift arms are not

locked unless the cutting height adjustment

pin passes all the way through both the deck

lift cover and shaft.

NOTE: Support the mower deck on blocks or

jack stands before disconnecting link chains

from mower lift arms to prevent the deck from

falling.

3. Remove link chains from mower lift

arms. Note hole location on mower lift

arms for replacement.

4. Remove the mower mounting pins

connecting the mower mounting arms to

the deck.

5. Slide mower deck out from under unit.

GB - 27

Page 28

Figure 22

1. Mower Lift

Arm

2. Link Chain

3. Mower

Mounting

Arm

4. Mower

Mounting

Pin

5. Mower Lift

Arms

Locked

3

OF3765

4

2

2

1

1

5

Installing the Mower Deck (Figure 22)

1. Slide mower deck under unit.

2. Connect mower mounting arms to deck

with mower mounting pins.

3. Install link chains on the mower lift arms

in the same holes they were removed

from.

4. Install PTO mower belt (See Replacing

Mower Belts on page 26).

5. Level mower deck (See Leveling the

Mower Deck on page 28).

Leveling the Mower Deck

These adjustments should be made on a

level surface with the tires inflated to the

correct air pressure.

Check Blade Level and Pitch

1. Raise mower deck to a 3 in. (7.62 cm)

cutting height.

2. Shut off engine. Engage parking brake.

Remove the ignition key.

NOTE: Place blocks under the bottom edge

of the deck, not under the reinforcement bar

welded along deck face.

3. Place blocks at each corner of the deck

to support the weight of the deck.

4. Turn the blades so the blade ends point

left to right across the width of the deck.

5. Measure the distance between the

ground and cutting edge of the blade on

the left blade (Left position in Figure 23)

and on the right blade (Right position in

Figure 23). Distances should be within

3/16 in. (4.7 mm). If they are not, raise

the low side of the deck using the height

adjusters on the deck lift brackets (see

Figure 24).

6. After deck is level side to side, check the

deck front to back pitch.

7. Turn the blades so the blade ends point

front to back as shown in Figure 23.

8. Measure the distance between the

ground and the cutting edge of the

middle blade at the front of the deck

(Front position in Figure 23) and

between the ground the cutting edge of

the left and right blades at the rear of the

deck (Rear position in Figure 23).

9. The cutting edge at the front of the deck

(Front position in Figure 23) should be

1/8 in. (3.18 mm) lower than the cutting

edges at the rear of the deck (Rear

position in Figure 23).

10. If measurements are out of range, raise

the low side of the deck using the height

adjusters on the deck lift brackets (see

Figure 24). Be sure to raise the deck

evenly to keep the deck level side to

side.

NOTE: Pitching the front of the blades lower

than the rear provides a balance between cut

quality and the power needed to cut grass.

Certain cutting conditions require the deck to

be pitched with the rear of the blades lower

than the front. Heeling the deck this way

requires more engine power but can provide

better cut quality.

11.Remove the blocks from under the deck.

GB - 28

Page 29

Adjust Blade Height

Figure 23

Blade Side-to-Side Level

Blade Front-to-Back Pitch

Front

Left

Rear

Rear

Right

Figure 24

DO NOT place blocks under

reinforcement bar.

Height

Adjusters

Figure 25

OG1500

1. Armature

2. Rotor

3. Inspection

Slot

4. Gap

Adjustment

Nut

1

2

3

4

4

Level and pitch the mower with the height

adjusters on each deck lift bracket

(Figure 24).

Loosen the jam nut on the deck lift

bracket bolt about 1/4 turn to reduce

clamp load on the height adjusters.

Loosen the jam nut on the deck adjuster

bolt and then turn the bolt clockwise to

raise the deck or counterclockwise to

lower the deck. Tighten both jam nuts.

CLUTCH ADJUSTMENT

If clutch fails to engage or disengage properly

or begins to make abnormal noise, check the

air gap adjustment at the three inspection

slots.

To check:

1. Stop engine, remove key and wait for all

hot parts to cool.

2. Measure the air gap between the

armature and the rotor.

Minimum: A .016" feeler gauge should

slide between armature and rotor with

slight contact.

Maximum: A .020" feeler gauge should

slide between armature and rotor with

slight contact.

3. Repeat for each inspection slot.

To adjust:

1. If necessary, loosen gap adjustment

nuts until a .016" feeler gauge fits

between armature and rotor.

2. Slide a .020" feeler gauge between

armature and rotor.

3. Tighten gap adjustment nut until there is

slight contact on feeler gauge.

4. Repeat steps 1 – 3 at each inspection

slot.

NOTE: Adjust air gap as evenly as possible.

5. Start unit, engage and disengage PTO.

6. Shut off unit.

7. Recheck air gap and adjust if needed.

GB - 29

Page 30

STORAGE

WARNING: AV OI D INJURY.

Read and understand entire

Safety section before proceeding.

SHORT TERM

NEVER spray unit with high-pressure water

or store unit outdoors.

Inspect unit for visible signs of wear,

breakage or damage.

Keep all nuts, bolts and screws properly

tightened and know unit is in safe working

condition.

Store unit in a cool, dry protected area.

LONG TERM

Clean unit thoroughly with mild soap and low

pressure water and lubricate (See Lubricate

Unit on page 23 in Maintenance). Touch up

all scratched painted surfaces.

Remove weight from wheels by putting

blocks under frame or axle.

When storing unit for extended periods of

time, remove all fuel from tank and carburetor

(run dry). Refer to Engine Manual.

Clean and charge the battery. Charge battery

every three to four weeks when storing unit.

Fuel System

Gasoline left in the fuel system for extended

periods without a stabilizer will deteriorate,

resulting in gum deposits in the system.

These deposits can damage the carburetor

and the fuel hoses, filter and tank. Prevent

deposits from forming in the fuel system

during storage by adding a quality fuel

stabilizer to the fuel. Follow the

recommended mix ratio found on the fuel

stabilizer container.

To treat the fuel system for storage:

1. Add fuel stabilizer according to

manufacturers’ instructions.

2. Run engine for at least 10 minutes after

adding stabilizer to allow it to reach the

carburetor.

NEVER store the engine with fuel in the fuel

tank inside of a building with potential

sources of ignition.

To Take the Unit Out of Storage

1. Refer to the engine service manual to

prepare the engine for service.

2. Put fresh, clean fuel in the fuel tank.

3. Begin the maintenance schedule.

4. Charge and install the battery.

ACCESSORIES

Part No. Description

79206400 Mulching Kit 52" Decks

79206500 Mulching Kit 60" Decks

79100500 Striper Kit

79100800 Discharge Cover Kit

79206800 Discharge Cover Kit

79202700 Headlight Kit

79102500 Bagger Adapter Kit - 60"

79102600 Bagger Adapter Kit - 52"

89100200 CZ-HD 2-Bag Bagger

89100300 HD Series Bagger

(991065)

(991056)

(991065)

(991056)

Decks

Decks

SERVICE PARTS

Part No. Qty Description

21542700 1 Air Filter - Kohler

21541400 1 Engine Oil Filter -

21545100 2 Hydraulic Oil Filter

21541700 2 Spark Plug - Kohler

21541500 1 Fuel Filter - Kohler

07200026 1 PTO Belt - 52” Decks

07200028 1 PTO Belt - 60” Decks

07211500 1 Traction (Hydro Pump)

03253800 1 Blade - 52” Decks

03253900 1 Blade - 60” Decks

Courage

Kohler Courage

Courage

Courage

Belt

GB - 30

Page 31

\

SPECIFICATIONS

Model Number 991056 991065

Model Max Zoom 2560 Max Zoom 2552

Engine Kohler Kohler

Engine Model Number Courage Courage

Engine Displacement - in3 (cc) 44.2 (725.0) 44.2 (725.0)

Governed RPM (May be different from

maximum RPM)

Liquid or Air Cooled Air

Speed

Forward Maximum – mph (km/h) 8.0 (12.9)

Reverse Maximum – mph (km/h) 4.0 (6.4)

Turning Radius Zero

Brakes Hydro - Parking

Electrical

Starter Electric

Battery 12-Volt Maintenance Free U1-250

Power Take-Off Electric PTO Clutch/Brake

Fuel

Fuel Type Refer to Engine Manual

Fuel Tank Capacity – gal. (L) 7 (26.5)

Transmission

Typ e Hydrostatic Drive

Transmission Oil

Hydraulic Oil Filter Yes

Size and Weight

Length – in. (cm) 71.5 (181.6)

Width (With Chute Up) – in. (cm) 63.0 (160) 55.5 (140.9)

Height – in. (cm) 42 (106)

Weight – lbs (kg) 820 (372.7) 800 (362.9)

Tires

Front Tire Size – in. 13 x 5-6

Rear Tire Size – in. 20 x 10-10

Front Tire Pressure – psi (kPa) 20 - 25 (138 -172)

Rear Tire Pressure – psi (kPa) 15 -18 (103 -124)

Mower Deck

Mower Deck Lift Mechanical

Cutting Width – in. (cm) 60 (152) 52 (132)

Cutting Height – in. (cm) 1 - 5 (2.5 - 12.7)

Cutting Height Increments – in. (cm) 0.5 (1.25)

Use 20W-50 engine oil with an SL API

3600 ± 75

classification

GB - 31

Page 32

Two-Year Limited Lawn and

Garden Consumer Ride-On

Warranty

Ariens Company (Ariens) warrants to the original purchaser that Ariens and Gravely brand consumer

products manufactured and sold by Ariens after December 31, 2007 will be free from defects in material and

workmanship for a period of two years after the date of purchase. An authorized Ariens dealer (Ariens brand

products) or Gravely dealer (Gravely brand products) will repair any defect in material or workmanship, and

repair or replace any defective part, subject to the conditions, limitations and exclusions set forth herein.

Such repair or replacement will be free of charge (labor and parts) to the original purchaser except as noted

below.

Five-Year Limited Warranty on Mower Deck Shell

The deck shell on zero-turn riding mowers is warranted to the original purchaser for five years from

the date of purchase. Any defect in material or workmanship of the deck shell will be repaired free of

charge (p ar t s and l abo r) to th e o rig i n al pu r c ha s er fo r tw o year s after the date of purchase . Fo r th e t hir d