Page 1

Professional Walk

Owner/Operat or Ma nu al

Manuel Du Propriétaire/Utilisateur

Models

988811 – APWKA1636S

988812 – APWKA1648S

ENGLISH

FRANÇAIS

04318700 1/11

Printed in USA

Page 2

TABLE OF CONTENTS

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . 12

Controls and Features. . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance Schedul e . . . . . . . . . . . . 21

Service and Adjustments . . . . . . . . . . 22

INTRODUCTION

Storage . . . . . . . . . . . . . . . . . . . . . . . . . 29

Accessories . . . . . . . . . . . . . . . . . . . . . 29

Service Parts . . . . . . . . . . . . . . . . . . . . 29

Trouble s hooting. . . . . . . . . . . . . . . . . . 30

Specifications . . . . . . . . . . . . . . . . . . . 31

Warranty . . . . . . . . . . . . . . . . . . . . . . . 32

NON-ENGLISH MANUALS

Manuals in languages other than

English may be obtained from

your Dealer. Visit your dealer or

www.ariens.com for a list of

languages available for your

equipment.

Manuals printed in languages

other than English are also available as a free

download on our website:

http://www.ariens.com

MANUALES EN IDIOMAS

DIFERENTES DEL INGLES

Puede obtener manuales en

idiomas diferentes del inglés en su

distribuidor. Visite a su distribuidor

o vaya a www.ariens.com para

obtener una lista de idiomas

disponibles para su equipo.

T ambién puede imprimir manuales

en idiomas diferentes del inglés

descargándolos gratuitamente de nuestra

página Web:

http://www.ariens.com

MANUELS NON ANGLAIS

Des manuels dans différentes

langues sont disponibles chez

votre revendeur. Rendez-vous

chez votre revendeur ou allez sur

le site www.ariens.com pour

consulter la liste des langues

disponibles pour votre

équipement.

Les manuels imprimés dans des langues

différentes de l’anglais sont également

disponibles en téléchargement gratuit sur

notre site Web :

http://www.ariens.com

THE MANUAL

Before operation of unit, carefully and

completely read your manuals. The contents

will provide you with an understanding of

safety instructions and controls during normal

operation and maintenance.

All reference to left, right, front, or rear are

given from operator standing in operation

position and facing the direction of forward

travel.

ENGINE MANUAL

The engine on this unit is covered by a

separate manual specific to the engine. This

manual is included in the literature package

that shipped with the unit. Refer to this

manual for engine service recommendations.

If the engine manual is not available, contact

the engine manufacturer for a replacement

manual.

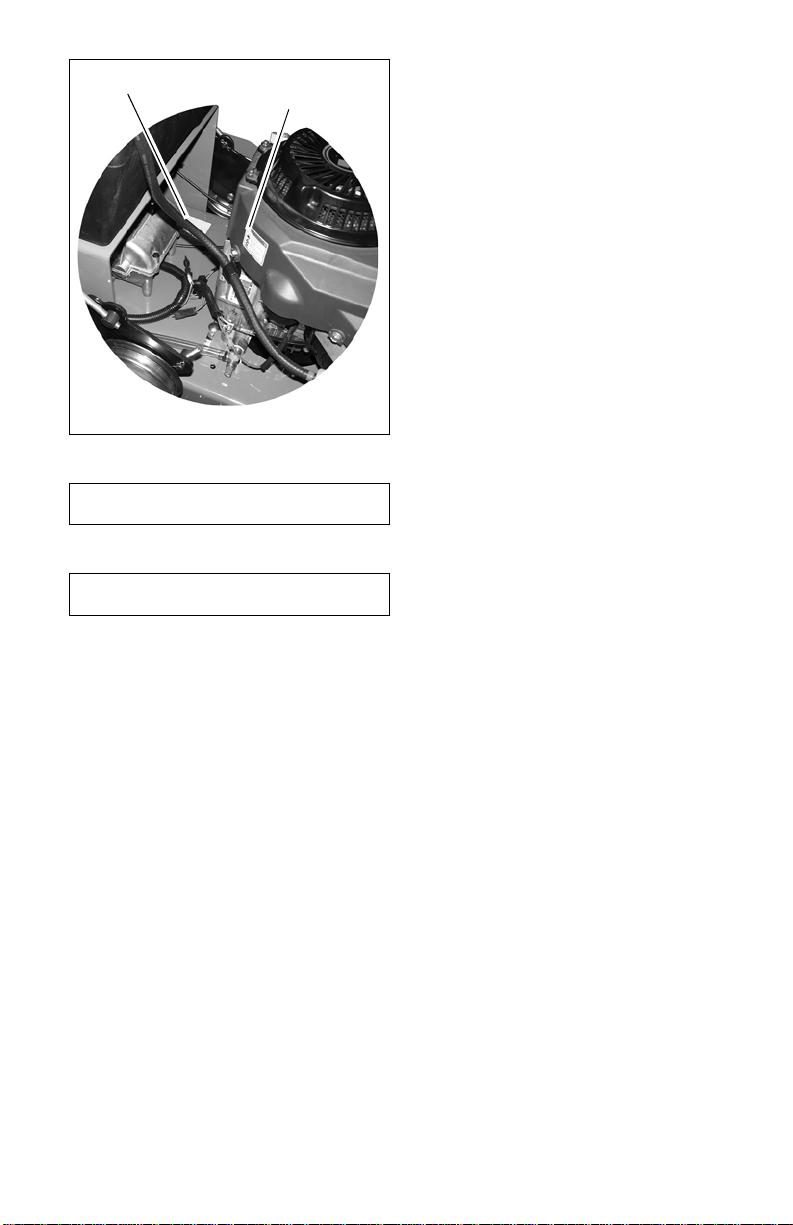

MODEL AND SERIAL NUMBERS

When ordering replacement parts or making

service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product

registration form in the unit literature

package. They are printed on a serial number

label, located on the frame of your unit.

GB - 2

Page 3

• Record Unit Model and Serial

Unit Serial Number

Label

Figure 1

Engine Serial

Number Label

numbers here.

• Record Engine Model and Serial

numbers here.

PRODUCT REGISTRATION

The Ariensdealer must register the product at

the time of purchase. Registering the product

will help the company process warranty

claims or contact you with the latest service

information. All claims meeting requirements

during the limited warranty period will be

honored, whether or not the product

registration card is returned. Keep a proof of

purchase if you do not register your unit.

Customer Note: If the Dealer does not

register your product, please fill out, sign and

return the product registration card to Ariens.

UNAUTHORIZED REPLACEMENT

PARTS

Use only Ariens replacement parts. The

replacement of any part on this vehicle with

anything other than a Ariens authorized

replacement part may adversely affect the

performance, durability, or safety of this unit

and may void the warranty. Ariens disclaims

liability for any claims or damages, whether

warranty, property damage, personal injury or

death arising out of the use of unauthorized

replacement parts. To locate your nearest

Ariens Dealer, go to www.ariens.com on the

Internet.

DISCLAIMER

Ariens reserves the right to discontinue,

make changes to, and add improvements

upon its products at any time without public

notice or obligation.The descriptions and

specifications contained in this manual were

in effect at printing. Equipment described

within this manual may be optional. Some

illustrations may not be applicable to your

unit.

DEALER DELIVERY

Dealer should:

1. Check all controls for proper function.

2. Check the safety interlock system to

make sure that it is functioning properly.

See Check Safety Interlock System on

(

page 14.)

3. F ill out Original Purchaser Registration

Card and return the card to

AriensExplain Limited Warranty Policy.

4. Explain recommended lubrication and

maintenance. Advise customer on

adjustments.

5. Instruct customer on controls and

operation of unit. Discuss and

emphasize the Safety Precautions. Give

customer Owner/Operator, Parts, and

Engine Manuals. Advise customer to

thoroughly read and understand them.

GB - 3

Page 4

SAFETY

WARNING: This cutting machine

is capable of amputating hands

and feet and throwing objects.

Failure to observe the safety

instructions in the manuals and on

decals could result in serious

injury or death.

Slopes are a major factor related

to loss-of-control and tip-over

accidents. Operation on all slopes

requires extra caution.

Tragic accidents can occur if the

operator is not alert to the

presence of children. Never

assume that children will remain

where you last saw them.

Gasoline is extremely flammable

and the vapors are explosive,

handle with care.

Disengage attachment, stop unit

and engine, remove key, engage

parking brake, and allow moving

parts to stop before leaving

operator’s position.

SAFETY ALERTS

Look for these symbols to point

out important safety precautions.

They mean:

Attention!

Personal Safety Is

Involved!

Become Alert!

Obey The Message!

The safety alert symbols above and signal

words below are used on decals and in this

manual.

Read and understand all safety messages.

CAUTION: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, MAY RESULT in minor or

moderate injury. It may also be used

to alert against unsafe practices.

NOTATIONS

NOTE: General reference information for

proper operation and maintenance practices.

IMPORTANT: Specific procedures or

information required to prevent damage to

unit or attachment.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and

others. Understand and follow all safety

messages. Be alert to unsafe conditions and

the possibility of minor, moderate, or serious

injury or death. Learn applicable rules and

laws in your area, including those that may

restrict the age of the operator.

REQUIRED OPERATOR

TRAINING

Original purchaser of this unit was instructed

by the seller on safe and proper operation. If

unit is to be used by someone other than

original purchaser; loaned, rented or sold,

ALWAYS provide this manual and any

needed safety training before operation.

DANGER: IMMINENTLY

HAZARDOUS SITUATION! If not

avoided, WILL RESULT in death or

seriou s injury.

WARNING: POTENTIALLY

HAZARDOUS SITUATION! If not

avoided, COULD RESULT in death

or serious injury.

GB - 4

Page 5

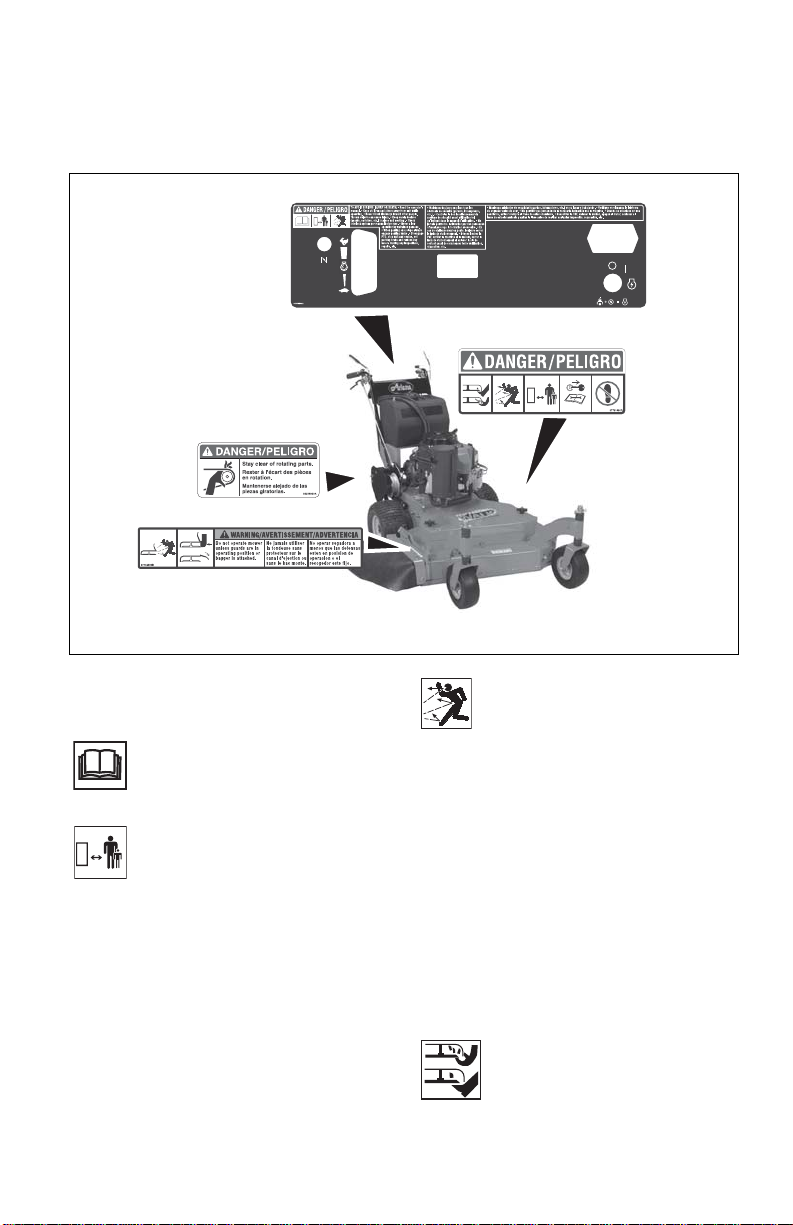

SAFETY DECALS AND

Figure 2

4

3

1

OG1491

2

OL1801

OL4370

OL3030

LOCATIONS

ALW AYS replace missing or damaged Safety

Decals. Refer to figure below for Safety Decal

locations.

1. Danger! To avoid serious injury or

death

Read the operator’s manual.

Keep children and others away

from unit while operating.

Never direct discharge toward

other people. Thrown objects can

cause injury.

• Keep safety devices (guards, shields,

switches, etc.) in place and working.

• Check interlock system per manual

before use.

• Never allow operation by untrained

persons.

• When parking on a slope always

chock or block the wheels.

• Disengage PTO, stop unit and

engine, set parking brake and

remove key before making any

inspections, repairs, etc.

2. Danger! Rotating Blades

ROTATING BLADE! Keep

hands and feet away.

GB - 5

Page 6

Always stand clear of

OL0910

OL4370

OL4010

OL4420

OL0910

OL3320

OL5100

discharge area. DO NOT direct

discharge toward other people.

Remove objects that could be

thrown by the blade. DO NOT

operate mower over gravel and

hard surfaces.

Keep people and pets away

when operating unit. Keep

children out of the work area

and under the watchful care of

a responsible adult.

Shut off engine, remove key,

read manual before you

unplug, adjust or repair unit.

NO STEP! Always keep feet

away from rotating parts.

3. Warning!

(

4. Danger!

Stay clear of rotating parts.

Always stand clear of discharge.

DO NOT operate mower unless

guards are in operating position

or bagger is attached.

EMISSION CONTROL SYSTEM

This equipment and/or its engine may include

exhaust and evaporative emissions control

system components required to meet U.S.

Environmental Protection Agency (EPA)

and/or California Air Resources Board

(CARB) regulations. Tampering with

emission controls and components by

unauthorized personnel may result in severe

fines or penalties. Emission controls and

components can only be adjusted by an

Ariens Company dealer or an authorized

engine manufacturer's service center.

Contact your Ariens Company Equipment

Retailer concerning emission controls and

component questions.

SAFETY RULES

Operator T r ain ing Re quire d

• Read the operator’s manual and other

training material. If the operator or

mechanic cannot read English, it is the

owner’s responsibility to explain this

material to them. This publication is

available in other languages.

• Become familiar with the safe

operation of the equipment, operator

controls, and safety signs.

• All operators and mechanics should

be trained. The owner of the machine

is responsible for training the users.

• Never let children or untrained people

operate or service the equipment.

Local regulations may restrict the age

of the operator.

• The owner/user can prevent and is

responsible for accidents or injuries

occurring to themselves, other people,

or property.

• Operate the machine in an open,

unobstructed area under the direction

of an experienced operator.

Preparation

• Evaluate the terrain to determine what

accessories and attachments are

needed to properly and safely perform

the job. Only use accessories and

attachments approved by the

manufacturer.

• Wear appropriate clothing including

hard hat, safety glasses and hearing

protection. Long hair, loose clothing or

jewelry may get tangled in moving

parts.

• Inspect the area where the equipment

is to be used and remove all objects

such as rocks, toys and wire which

can be thrown by the machine.

GB - 6

Page 7

• Use extra care when handling

gasoline and other fuels. They are

flammable and vapors are explosive.

a. Use only an approved container.

b. Never remove gas cap or add

fuel when engine is running. Do

not smoke.

c. Never refuel or drain the

• Check that the operator’s presence

machine indoors.

controls, safety switches and shields

are attached and functioning properly.

Do not operate unless they are

functioning properly.

Operating Safely

• Never run an engine in an enclosed

area where dangerous carbon

monoxide fumes can collect.

• Only operate in good light, keeping

away from holes and hidden hazards.

• Be sure all drives are in neutral and

parking brake is engaged before

starting engine. Only start engine from

the operator’s position.

• Be sure of your footing while using

pedestrian-controlled equipment,

especially when backing up. Walk,

don’t run. Never operate on wet grass.

Reduced footing could cause slipping.

• Slow down and use extra care on

hillsides. Be sure to travel in the

recommended direction on hillsides.

For this machine, drive across

hillsides, not up and down. Turf

conditions can affect the machine’s

stability. Use caution while operating

near drop-offs.

• Slow down and use caution when

making turns and when changing

directions on slopes.

• Never raise deck with the blades

running.

• Never operate with guards not

securely in place. Be sure all

interlocks are attached, adjusted

properly, and functioning properly.

• Never operate with the discharge

deflector raised, removed or altered,

unless using a grasscatcher. Do not

operate mower without discharge

chute or entire grasscatcher in place.

• Do not change the engine governor

setting or overspeed the engine.

Operating the engine at excessive

speed can increase the hazard of

personal injury.

• Stop on level ground, lower

implements, disengage drives, engage

parking brake, and shut off engine

before leaving the operator’s position

for any reason including emptying the

grasscatchers or unclogging the

chute.

• Stop equipment and inspect blades

after striking objects or if an abnormal

vibration occurs. Make necessary

repairs before resuming operations.

• Keep hands and feet away from the

cutting units.

• Look behind and down before backing

up to be sure of a clear path.

• Never carry passengers and keep pets

and bystanders away.

• Slow down and use caution when

making turns and crossing roads and

sidewalks. Stop blades if not mowing.

Watch for traffic when operating near

or crossing roadways.

• Be aware of the mower discharge

direction and do not point it at anyone.

• Do not operate the machine while

under the influence of alcohol or

drugs.

• Use care when loading or unloading

the machine into or off of a trailer or

truck.

• Use care when approaching blind

corners, shrubs, trees, or other objects

that may obscure vision.

• Inspect machine before you operate.

Be sure hardware is tight. Repair or

replace damaged, badly worn, or

missing parts. Be sure guards and

shields are in good condition and

fastened in place. Make any

necessary adjustments before you

operate.

• Before using, always visually inspect

to see that the blades, blade bolts and

the mower assembly are not worn and

damaged. Replace worn and

damaged blades and bolts in sets to

preserve balance.

• Keep safety labels visible when

installing accessories and

attachments.

• Do not wear radio or music

headphones. Safe service and

operation require your full attention.

• When machine is left unattended,

stored, or parked, lower the mower

deck unless a positive mechanical lock

is used.

• Be sure all drives are in neutral and

parking brake is locked before starting

engine. Stand as far away from the

discharge chute as possible with feet

well away from the underside of the

deck to start machine.

• Do not hang or secure any item to the

control console. The operator’s station

should always remain unobstructed.

• Do not pull mower backwards while

the blades are rotating. Use the

reverse gear to move the machine in

reverse.

GB - 7

Page 8

Using a Spark Arrestor

The engine in this machine is not equipped

with a spark arrestor muffler. It is a violation of

California Public Resource Code Section

4442 to use or operate this engine on or near

any forest-covered, brush-covered or grasscovered land unless the exhaust system is

equipped with a spark arrestor meeting any

applicable local or state laws. Other states or

federal areas may have similar laws.

A spark arrestor for your machine may be

available from your authorized dealer. An

installed spark arrestor must be maintained in

good working order by the operator.

Checking Mowing Area

• Clear mowing area of

objects that might be

thrown. Keep people and

pets out of mowing area.

• Low-hanging branches

and similar obstacles can injure the

operator or interfere with mowing

operation. Before mowing, identify

potential obstacles such as lowhanging branches, and trim or remove

those obstacles.

• Study mowing area. Set up a safe

mowing pattern. Do not mow where

traction or stability is doubtful.

Parking Safely

1. Stop machine on a level surface, not on

a slope.

2. Disengage mower blades.

3. Lock the park brake.

4. Stop the engine.

5. Remove the key.

6. Wait for engine and all moving parts to

stop before you leave the operator’s

station.

7. Close fuel shut-off valve, if your machine

is equipped.

8. Remove the spark plug wire (for

gasoline engines) before servicing the

machine.

Operating Safely on Slopes

• Slopes are a major factor related to

slip and fall accidents which can result

in severe injury. Operation on all

slopes requires extra caution. If you

feel uneasy on a slope, do not mow it.

• Mow across the face of slope, never

up and down. Use extreme caution

when changing direction on slopes.

• Keep all movement on slopes slow

and gradual. Do not make sudden

changes in speed or direction.

• Watch for holes, ruts, bumps, rocks or

other hidden objects. Uneven terrain

could cause a slip and fall accident.

Tall grass can hide obstacles.

• Do not mow on wet grass or

excessively steep slopes. Poor footing

could cause a slip and fall accident.

• Do not mow near drop-offs, ditches,

embankments, as well as ponds and

other bodies of water. The operator

could lose footing or balance. The

machine could suddenly turn over if a

wheel is over the edge of a cliff or

ditch, or if an edge caves in.

• Follow the manufacturer’s

recommendations for counterweights

for added stability when operating on

slopes. Remove weights when not

required.

• Use extra care with grasscatchers.

These can change the stability of the

machine. Do not use grasscatcher on

steep slopes.

Rotating Blades are Dangerous

HELP PREVENT

SERIOUS OR

FATAL

ACCIDENTS:

•Rotating blades can

cut off arms and legs,

and throw objects.

safety instructions could result in

serious injury or death.

• Keep hands, feet and clothing away

from mower deck when engine is

running.

• Be alert at all times, drive forward

carefully. People, especially children

can move quickly into the mowing

area before you know it.

• Before backing up, stop mower blades

or attachments and look down and

behind the machine carefully,

especially for children.

• Do not mow in reverse.

• Shut off blades when you are not

mowing.

• Park machine safely before leaving

the operator’s station for any reason

including emptying the catchers or

unplugging the chute.

Failure to observe

GB - 8

Page 9

Rotating Blades

are Dangerous Protect Children

and Prevent

Accidents

Protect Children:

• Tragic accidents can occur if the

operator is not alert to the presence of

children. Children are often attracted

to lawn-mowing machines and

mowing activity. Stay alert to the

presence of children. Never assume

that children will remain where you last

saw them.

• Keep children indoors, out of the

mowing area, and in the watchful eye

of a responsible adult, other than the

operator, when a mower is being

operated.

• Be alert and turn mower off if a child

enters the work area. They don’t

understand the dangers of rotating

blades or the fact that the operator is

unaware of their presence.

• Never allow a child or an untrained

person to operate the machine.

• Use extra care when approaching

blind corners, shrubs, trees, or other

objects that may block your view of a

child.

Checking Wheel Hardware

• A serious accident could occur

causing serious injury if wheel

hardware is not tight.

• Check wheel hardware tightness often

during the first 100 hours of operation.

• Wheel hardware must be tightened to

specified torque using the proper

procedure anytime it is loosened.

Wear

Appropriate

Clothing

•Always wear

safety goggles,

or safety

glasses with

side shields,

when operating the machine.

• Wear close fitting clothing and safety

equipment appropriate for the job.

• While mowing, always wear

substantial footwear and long

trousers. Do not operate the

equipment when barefoot or wearing

open sandals.

• Wear a suitable protective device such

as earplugs. Loud noise can cause

impairment or loss of hearing.

and a hard hat

Maintenance and

Storage

•Never operate

machine in a closed

area where

dangerous carbon

monoxide fumes can

collect.

lower implement, lock parking brake,

stop engine and remove key or

disconnect spark plug (for gas

engines). Wait for all movement to

stop before adjusting, cleaning or

repairing.

• Clean grass and debris from cutting

units, drives, mufflers, and engine to

help prevent fires. Clean up oil or fuel

spillage.

• Let engine cool before storing and do

not store near flame.

• Shut off fuel while storing or

transporting. Do not store fuel near

flames or drain indoors.

• Park machine on level ground. Never

allow untrained personnel to service

machine. Understand service

procedure before doing work.

• Use jack stands or lock service latches

to support components when required.

Securely support any machine

elements that must be raised for

service work.

• Before servicing machine or

attachment, carefully release pressure

from any components with stored

energy, such as hydraulic components

or springs.

• Release hydraulic pressure by

lowering attachment or cutting units to

the ground or to a mechanical stop

and move hydraulic control levers

back and forth.

• Disconnect battery or remove spark

plug (for gas engines) before making

any repairs. Disconnect the negative

terminal first and the positive last.

Reconnect positive first and negative

last.

• Use care when checking blades. Wrap

the blades or wear gloves, and use

caution when servicing them. Only

replace blades. Never straighten or

weld them.

• Keep hands, feet, clothing, jewelry and

long hair away from moving parts. If

possible, do not make adjustments

with the engine running.

•Disengage drives,

GB - 9

Page 10

• Charge batteries in an open well

ventilated area, away from spark and

flames. Unplug charger before

connecting or disconnecting from

battery. Wear protective clothing and

use insulated tools.

• Keep all parts in good working

condition and all hardware tightened.

Replace all worn or damaged decals.

• Check grasscatcher components and

the discharge guard frequently and

replace with manufacturer’s

recommended parts, when necessary.

Grasscatcher components are subject

to wear, damage, and deterioration

which could expose moving parts or

allow objects to be thrown.

• Keep all nuts and bolts t ight, especially

blade attachment bolts, to be sure the

equipment is in safe working condition.

• Check brake operation frequently.

Adjust and service as required.

• On multi-bladed machines, take care

as rotating one blade can cause other

blades to rotate.

Avoid High Pressure Fluids

• Hydraulic hoses and lines can fail due

to physical damage, kinks, age, and

exposure. Check hoses and lines

regularly. Replace damaged hoses

and lines.

• Hydraulic fluid connections can loosen

due to physical damage and vibration.

Check connections regularly. Tighten

loose connections.

• Escaping fluid under pressure can

penetrate the skin causing serious

injury. Avoid the hazard by relieving

pressure before disconnecting

hydraulic or other lines. Tighten all

connections before applying pressure.

• Search for leaks with a piece of

cardboard. Protect hands and body

from high pressure fluids.

• If an accident occurs, see a doctor

immediately. Any fluid injected into the

skin must be surgically removed within

a few hours or gangrene may result.

Doctors unfamiliar with this type of

injury should reference a

knowledgeable medical source.

Prevent Fires

• Machine fires and structure fires can

occur if a machine is stored before

allowing it to cool, or if debris is not

removed from around the engine and

muffler, or if stored near combustible

materials.

• Remove grass and debris from engine

compartment and muffler area, before

and after operating machine,

especially after mowing or mulching in

dry conditions.

GB - 10

• Empty the grasscatcher completely

before storing. Always shut off fuel

when storing or transporting machine,

if the machine has a fuel shutoff.

• Do not store machine near an open

flame or source of ignition, such as a

water heater or furnace.

• Check fuel lines, tank, cap, and fittings

frequently for cracks or leaks. Replace

if necessary.

Tire Safety

Explosive separation of

a tire and rim parts can

cause serious injury or

death:

•Do not attempt to

mount a tire without the

experience to perform the job.

• Always maintain the correct tire

pressure. Do not inflate the tires above

the recommended pressure. Never

weld or heat a wheel and tire

assembly. The heat can cause an

increase in air pressure resulting in a

tire explosion. Welding can structurally

weaken or deform the wheel.

• When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to one

side and NOT in front of or over the

tire assembly.

• Check tires for low pressure, cuts,

bubbles, damaged rims or missing lug

bolts and nuts.

proper equipment and

Handling Fuel

Safely

T o avoid personal injury

or property damage,

use extreme care in

handling fuel. Fuel is

extremely flammable

and fuel vapors are

explosive:

•Extinguish all

cigarettes, cigars,

pipes, and other

• Use only an approved fuel container.

Use only non-metal, portable fuel

containers approved by the

Underwriter’s Laboratory (U.L.) or the

American Society for Testing &

Materials (ASTM). If using a funnel,

make sure it is plastic and has no

screen or filter.

• Never remove the fuel tank cap or add

fuel with the engine running. Allow

engine to cool before refueling.

sources of ignition.

Page 11

• Never add fuel to or drain fuel from the

machine indoors. Move machine

outdoors and provide adequate

ventilation.

• Clean up spilled fuel immediately. If

fuel is spilled on clothing, change

clothing immediately. If fuel is spilled

near machine, do not attempt to start

the engine but move the machine

away from the area of spillage. Avoid

creating any source of ignition until

fuel vapors have dissipated.

• Never store the machine or fuel

container where there is an open

flame, spark, or pilot light such as on a

water heater or other appliance.

• Prevent fire and explosion caused by

static electric discharge. Static electric

discharge can ignite fuel vapors in an

ungrounded fuel container.

• Never fill containers inside a vehicle or

on a truck or trailer bed with a plastic

liner. Always place containers on the

ground away from your vehicle before

fueling.

• Remove fuel-powered equipment from

the truck or trailer and refuel it on the

ground. If this is not possible, then

refuel such equipment with a portable

container, rather than from a fuel

dispenser nozzle.

• Keep the nozzle in contact with the rim

of the fuel tank or container opening at

all times until the fueling is complete.

Do not use a nozzle lock-open device.

• Never overfill fuel tank. Replace fuel

tank cap and tighten securely.

• Replace all fuel container caps

securely after use.

• Fuel is highly flammable and its

vapors are explosive. Handle with

care. Use only an approved gasoline

container with an appropriately sized

dispensing spout.

• For gasoline engines, do not use gas

with methanol. Methanol is harmful to

your health and to the environment.

Handling Waste

Product and

Chemicals

• A Material Safety Data Sheet (MSDS)

provides specific details on chemical

products: physical and health hazards,

safety procedures, and emergency

response techniques. The seller of the

chemical products used with your

machine is responsible for providing

the MSDS for that product.

Waste products, such

as, used oil, fuel,

coolant, brake fluid,

harm the environment and people:

• Do not use beverage containers for

waste fluids - someone may drink from

them.

• See your local Recycling Center or

authorized dealer to learn how to

recycle or get rid of waste products.

and batteries, can

GB - 11

Page 12

ASSEMBLY

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

1. Remove the unit from shipping

container.

2. Adjust tire pressure to 8 to 16 psi (55 to

kPa).

110

CAUTION: Avoid injury! Explosive

separation of tire and rim parts is

possible when they are serviced

incorrectly:

• Do not attempt to mount a tire

without the proper equipment

and experience to perform the

job.

• Do not inflate the tires above

the recommended pressure.

• Do not weld or heat a wheel

and tire assembly. Heat can

cause an increase in air

pressure resulting in an

explosion. Welding can

structurally weaken or deform

the wheel.

• Do not stand in front or over

the tire assembly when

inflating. Use a clip-on chuck

and extension hose long

enough to allow you to stand

to one side.

3. Check the adjustments outlined in

Service & Adjustments.

4. Check engine oil level. See engine

manual.

5. F ill fuel tank. DO NOT OVERFILL! See

FILLING FUEL TANK on page 15

6. Check for loose hardware.

7. Be sure that safety interlock system

operates correctly.

Interlock System on page 14.

8. Be sure that unit tracks straight.

Unit must not pull sharply to the left or

right when the steering levers are

released.

ADJUSTMENT on page 22.

See TRACKING

See Check Safety

GB - 12

Page 13

CONTROLS AND FEATURES

Figure 3

1

2

2

3

3

7

7

4

6

5

11

8

9

10

1. Shift Lever

2. Steering Lever Latches

3. Steering Levers

4. Throttle Lever

5. Ignition Switch

6. PTO Switch

7. Operator Presence Controls

8. Fuel Cap

9. Recoil Starter Handle

10. Traction Belt Guard

11. Choke Control

GB - 13

Page 14

OPERATION

OF1212

OG1180

1

2

WARNING: AVOID INJURY. Read

and understand the entire Safety

section before proceeding.

CONTROLS AND FEATURES

See Figure 3 for controls and features

locations.

SAFETY INTERLOCK SYSTEM

DANGER: SAFETY INTERLOCK

SYSTEM FAILURE and improper

operation of unit can result in death or

serious injury. ALWAYS know the

safety interlock system is operating

properly.

System on page 14 for testing

instructions.

Check Safety Interlock System

Test the safety interlock system at each

operation. If the system does not function

properly, do not operate the unit until repairs

are made.

The engine will only start with the PTO

disengaged. The shift lever must be in neutral

for engine to start.

Engine must not start unless PTO is

disengaged and the shift lever is in neutral.

To test:

1. With engine off, engage PTO.

2. Turn ignition switch to On. Pull recoil

start handle. Engine must not start.

3. Disengage PTO.

The engine MUST stop whenever the

operator removes both hands from controls

while the PTO or transmission is engaged. To

test:

1. Start engine and engage PTO.

2. Release operator presence control

lever(s). Engine must stop.

3. Disengage PTO.

4. Restart engine.

5. Place shift lever in Forward.

6. Release operator presence control lever.

Engine must stop.

Operator Presence Control

The operator presence control lever must be

pressed to operate the PTO or traction drive.

When the shift lever or PTO is engaged,

releasing the operator presence control lever

stops the engine.

See Check Safety Interlock

CAUTION: AVOID INJURY. Operate

only when operator presence control

is functioning correctly.

Safety Inte r l o ck System on page 14

for testing instructions.

See Check

Steering Levers

WARNING: AVOID INJURY. When

the engine is running and the shift

lever is engaged, releasing only one

steering latch causes the unit to

circle around one drive wheel.

ALWAYS hold both steering levers

against the handlebar when

releasing the steering lever latches.

ALWAYS release levers slowly.

The steering levers are used to steer, operate

in forward and reverse, and stop the unit.

When held against the handlebar, the brakes

are engaged.

Steering Lever Latches

The steering lever latches hold the steering

levers in the neutral position and keep the

brakes applied.

Ignition Switch

Operate the ignition switch

with the removable key. The

switch uses two positions: Off

(1) and On (2). To start the

engine, turn the key to On (2)

and pull the recoil handle. To

stop the engine, turn the key

to Off (1).

Throttle Lever

The throttle lever changes the

speed of the engine. Move the

throttle lever to Fast (1) to

increase engine speed. Move

the lever to Slow (2) to

decrease engine speed.

GB - 14

Page 15

Choke Control

OG1190

Figure 4

OE0260

1

2

Use the choke control to start a

cold engine. Pull the control out

to choke the engine. Push the

control in when the engine gets

warm.

Shift Lever

The shift lever sets the direction and speed of

the unit.

R = reverse

N = neutral

1 = the slowest forward speed

5 = the fastest forward speed.

PTO Clutch

Pull the PTO (power take

off) switch On (1) to

engage the mower blades.

Push the PTO switch Off

(2) to disengage the

mower blades.

Recoil Starter Handle

Pull the recoil starter handle to start the

engine.

FILLING FUEL TANK

To add fuel to the fuel tank:

1. Clean fuel cap and surrounding area to

prevent dust, dirt, and debris from

entering fuel tanks.

2. Remove fuel cap.

IMPORTANT: Refer to Engine Manual for

correct type and grade of fuel.

3. Fill fuel tank to the bottom of filler neck.

SPECIFICATIONS on page 31 for

See

fuel tank capacity.

IMPORTANT: DO NOT OVERFILL! This

equipment and/or its engine may include

evaporative emissions control system

components, required to meet EPA and/or

CARB regulations, that will only function

properly when the fuel tank has been filled to

the recommended level. Overfilling may

cause permanent damage to evaporative

emissions control system components. Filling

to the recommended level ensures a vapor

gap required to allow for fuel expansion. Pay

close attention while filling the fuel tank to

ensure that the recommended fuel level

inside the tank is not exceeded. Use a

portable gasoline container with an

appropriately sized dispensing spout when

filling the tank. Do not use a funnel or other

device that obstructs the view of the tank

filling process.

4. Replace fue l cap and tighten.

5. ALWAYS clean up spilled fuel.

GASOLINE

IMPORTANT: ALWAYS use gasoline that

meets the following guidelines:

• Clean, fresh gasoline.

• A minimum of 87 octane/87 AKI (91

RON). High altitude use may require a

different octane. Consult your engine

manual.

• Gasoline with up to 10% ethanol

(gasohol) or up to 10% MTBE (methyl

tertiary butyl ether) is acceptable.

• Use of any gasoline other than those

approved above will void the engine

warranty. If the pumps are not marked

for the content of alcohol or ethers,

check ethanol and MTBE levels with

the fuel supplier.

• Do not modify the fuel system to use

different fuels.

• Never mix oil and gasoline.

NOTE: All gasoline is not the same. If the

engine experiences starting or performance

problems after using a new gasoline, switch

to a different fuel provider or fuel brand.

IMPORTANT: Excessively oxygenated or

reformulated fuels (fuels blended with

alcohols or ethers) can damage the fuel

system or cause performance problems. If

any undesirable operating problems occur,

use a gasoline with a lower percentage of

alcohol or ether.

GB - 15

Page 16

Fuel Stabilizer

OG1410

Gasoline left in the fuel system for extended

periods without a stabilizer will deteriorate,

resulting in gum deposits in the system.

These deposits can damage the carburetor

and the fuel hoses, filter and tank. Prevent

deposits from forming in the fuel system

during storage by adding a quality fuel

stabilizer to the fuel. Follow the

recommended mix ratio found on the fuel

stabilizer container.

TO STOP IN AN EMERGENCY

1. Release operator presence control(s).

2. Turn the ignition key Off.

3. Allow engine to stop completely.

4. Lock steering levers in neutral.

STARTING AND SHUT OFF

Before Each Use

Check each item in Each Use in the

Maintenance Schedule.

NOTE: The engine will not start unless the

shift lever is in neutral, and the Power Take

Off (PTO) is Off.

Recoil Start

1. Lock the steering lever latches in

neutral.

2. Put the shift lever in neutral.

3. Move PTO switch to Off.

4. Set throttle to the proper starting

position. If the engine is cold, choke the

engine.

5. Turn ignition swi tch to On.

6. Grasp recoil starter handle and pull rope

out slowly until it pulls harder. This is the

compression stroke.

7. Let the rope rewind slowly.

8. Pull rope with rapid continuous full arm

stroke to start engine. Allow rope to

rewind slowly.

IMPORTANT: DO NOT let starter handle

snap against engine.

9. Repeat until engine starts. (If engine

does not start, refer to Engine Manual.)

10. After engine starts, adjust choke as

needed. Allow engine to warm and run

smoothly before operating unit.

Shut Off

1. Lock steering levers in neutral.

2. Shut off the PTO.

3. Move the throttle lever to Slow.

4. Put the shift lever in neutral.

5. Turn the ignition key Off.

6. Allow engine to stop completely.

TO OPERATE UNIT

Operate the unit only in the operator’s

position directly behind the handlebars.

WARNING: AVOID INJURY. When

the engine is running and the speed

control lever is engaged, holding only

one steering lever in neutral causes

the unit to circle sharply around one

drive wheel.

To shift unit:

1. Stop unit movement by pulling both

steering levers all the way up.

2. You can move the shift lever one of two

ways:

• Continue to hold up both steering

levers and use your knee to move the

shift lever to the desired position.

• Lock both steering levers. Move the

shift lever to the desired position. Hold

the steering levers up as you unlock

them.

3. Release bot h steering levers slowly.

To operate:

1. Start the engine (See STARTI NG AND

SHUT OFF on page 16).

2. Move the throttle lever to the Fast

position.

3. Engage the operator presence control

and move shift lever to desired direction

and speed.

4. Hold steering levers against the

handlebar and release steering latch

levers.

WARNING: AVOID INJURY. When

the engine is running and the shift

lever is engaged, releasing only one

steering latch causes the unit to

circle around one drive wheel.

ALWAYS hold both steering levers

against the handlebar when

releasing the steering lever latches.

ALWAYS release levers slowly.

• To move straight forward; slowly

release both steering levers to the full

outward position.

GB - 16

Page 17

• To stop unit in neutral, hold levers in

OG1420

OG1430

OG1440

OG1450

the neutral position.

• To lock unit in neutral, engage both

steering latches.

• To turn to the left, pull the left hand

lever up.

• To turn to the right, pull the right hand

lever up.

To move in reverse:

1. Hold the steering levers against the

handlebar.

2. Engage steering lever latches.

3. Engage the operator presence control

and move shift lever to Reverse.

4. Release steering levers slowly.

WARNING: Uncontrolled reverse

travel can result in serious injury.

Do not put shift lever into the reverse

position unless you are prepared to

operate in reverse.

To mow :

1. Lock steering levers in neutral.

2. Put the shift lever in neutral.

3. Move the throttle lever to the fast

position.

4. Engage the operator presence control

lever.

NOTE: Operator presence control must

remain engaged.

5. Move the PTO switch to On to engage

mower.

IMPORTANT: NEVER engage the PTO if the

mower is plugged with grass or other

material. This will damage the PTO belt.

6. Move the shift lever to set a slow ground

speed.

7. Hold steering levers against the

handlebar and release the lock latches.

8. Release st eering levers slowly.

When you know how to operate the unit,

select a speed appropriate to your mowing

conditions.

To stop mowing:

1. Lock the steering levers in neutral.

2. Keep one hand on the operator

presence control and move the shift

lever to the neutral position.

3. Move the throttle lever to 1/2 speed.

4. Turn off PTO switch.

CUTTING HEIGHT ADJUSTMENT

WARNING: ALWAYS block wheels,

engage parking brake and know all

jack stands are strong, secure and

will hold weight of unit during

maintenance.

NOTE: Adjust the cutting height using a

combination of the deck mounting location on

the deck carrier frame, spacers on the front

casters, and spacers between the mower

blades and the deck spindles. The desired

cutting height may be set by adjusting only

the blade spacers and caster spacers.

Refer to the cutting height charts below to

determine which combination of deck

mounting location, blade spacers and caster

spacers will set the desired cutting height.

1. Shut off the unit. See Shut Off on

page 16 and "To stop mowing."

2. Support the rear of the machine and the

back edge of the mower deck.

3. Remove the six deck mounting bolts

(three per side).

4. Align the mounting holes in the deck

frame with the unit frame and re-install

the mounting bolts in the appropriate

holes and tighten to 35 –40

N•m).

lbf-ft (47– 54

GB - 17

Page 18

5. Using a suitable lifting device, lift the

Top Mounting Holes

Bottom Mounting Holes

Figure 5

1. Lynch Pin

2. Spacer

Bushing

3. Spacers

4. Washer

5. Caster Yoke

1

2

3

4

5

Figure 6

Figure 7

Store unused 1/4" blade

spacers here when not in use.

front of the machine.

6. Remove lynch pin and spacer bushing.

IMPORTANT: Do not allow washer (item 4 in

Figure 6) to sit on caster yoke (item 5 in

Figure 6). It must be on top of height-of-cut

spacer bushings (item 3 in Figure 6).

NOTE: Adjust caster wheel spacers to keep

mower deck tilted slightly down at the front.

7. Adjust caster wheel spacers to set the

front cutting height accordingly.

WARNING: Sharp edges can cut.

Moving parts can cut off fingers or a

hand. Wrap blade(s), wear sturdy

gloves and use extreme caution

when servicing. On multi-blade

mowers, rotation of one blade will

cause all blades to rotate.

8. Remove the mower blade from the

spindle and place the appropriate

number of 1/4" spacers between the

spindle and the blade.

IMPORTANT: DO NOT allow the blade to be

less than 1/8 in. (3.2mm) above the lip of the

mower deck.

IMPORTANT: If two or three spacers are

removed, shorter blade bolts must be used.

The shorter blade bolts for this application are

mounted under the belt cover.

9. Replace mower blade and tighten

mounting bolt to 120 lbf-ft (163

N•m).

10. Remove supports from deck and mower

frame.

NOTE: Store the unused 1/4" blade spacers

on hex bolts mounted to the deck:

GB - 18

Page 19

Cutting Height Chart – Deck Bolted to Frame with Top Holes

Approximate

Cutting Height

Inches (cm) Stored Between

1.25 (3.2) 0 3 0 6

1.5 (3.8) 1 2 0 6

1.75 (4.4) 2 1 0 6

2.0 (5.1) 3 0 0 6

1.5 (3.8) 0 3 1 5

1.75 (4.4) 1 2 1 5

2.0 (5.1) 2 1 1 5

2.25 (5.7) 3 0 1 5

1.75 (4.4) 0 3 2 4

2.0 (5.1) 1 2 2 4

2.25 (5.7) 2 1 2 4

2.5 (6.35) 3 0 2 4

2.0 (5.1) 0 3 3 3

2.25 (5.7) 1 2 3 3

2.5 (6.35) 2 1 3 3

2.75 (7.0) 3 0 3 3

1/4" Blade Spacers 1/2" Caster Spacers

Spindle and

Blade

Below

Weldment

Above

Weldment

Cutting Height Chart – Deck Bolted to Frame with Bottom Holes

Approximate

Cutting Height

Inches (cm) Stored Between

2.75 (7.0) 0 3 3 3

3.0 (7.62) 1 2 3 3

3.25 (8.3) 2 1 3 3

3.5 (8.9) 3 0 3 3

3.0 (7.62) 0 3 4 2

3.25 (8.3) 1 2 4 2

3.5 (8.9) 2 1 4 2

3.75 (9.5) 3 0 4 2

3.25 8.3) 0 3 5 1

3.5 (8.9) 1 2 5 1

3.75 (9.5) 2 1 5 1

4.0 (10.2) 3 0 5 1

3.5 (8.9) 0 3 6 0

3.75 (9.5) 1 2 6 0

4.0 (10.2) 2 1 6 0

4.25 (10.8) 3 0 6 0

1/4" Blade Spacers 1/2" Caster Spacers

Spindle and

Blade

Below

Weldment

Above

Weldment

Recommended

Range for Best

Cut Quality

Cut Quality

Range for Best

Recommended

GB - 19

Page 20

PARKING

1. Shut off the unit. See Shut Off on

page 16 and "To stop mowing."

2. Remove the key.

3. Lock both steering lever latches in

neutral to engage the brakes.

4. Chock or block the wheels if parked on a

slope.

TO PUSH UNIT BY HAND

To move the unit without the engine running:

1. Put the shift lever in neutral.

2. Disengage the lock latches. Release

steering levers. The brake is disengaged

when the steering levers are released.

3. Push unit to desired location.

IMPORTANT: Towing the unit will damage

transmission.

TO TRANSPORT UNIT

Transporting Machine on a Trailer

Use a heavy-duty trailer to transport your

machine. Trailer

must have signs and lights required by law.

CAUTION: Avoid injury! Use extra

care when loading or unloading the

machine into a trailer or truck.

Close fuel shut-off valve, if your

machine is equipped.

IMPORTANT: Avoid damage! Transporting a

machine on a trailer or on a truck bed at high

speeds can result in hood or engine cover

raising and possibly coming off machine if not

secured.

• Position machine on trailer so hood or

engine cover opens from rear of trailer

to prevent wind from blowing hood or

cover open.

• Secure hood or engine cover with

existing machine locks or latches.

• Secure hood or engine cover with tie

down straps if no locks or latches

exist.

1. Drive machine onto a trailer.

2. Engage brake lever locks.

3. Place transmission in NEUTRAL.

4. Shut engine off.

5. Remove key.

6. Turn fuel shutoff valve to off position.

7. Fasten machine to trailer with heavyduty straps, chains or cables. Both front

and rear straps must be directed down

and outward from machine.

GB - 20

Page 21

MAINTENANCE SCHEDULE

Period Service Task

Check Safety Interlock

System

described, do not operate until repairs are made.

Check Safety Interlock System on page 14.

Each

Use

Every 25

Hours

Every 50

Hours

Every

100

Hours

Check Air Cleaner Check the air cleaner element before each use. See

Check Engine Oil Check the engine oil level before each use. Never operate

Check Engine Cooling Check the engine air cooling system before each use. See

Check Fasteners Check all nuts, bolts, and other fasteners before each use.

Check Tire Pressure Check tires for proper inflation, excessive wear or damage

Follow Engine Manual

Maintenance Schedule

Check All Belts Check all belts for wear or damage. If belts slip, check for

Mower Blades Check mower blades for wear. Sharpen or replace as

Clean Air Cleaner

Foam Element

General Lubrication Oil all pivot points and pin connections. Grease lube

Change Engine Oil*

Check Fuel Filter See engine manual for detailed instructions.

Check Spark Plug See engine manual for detailed instructions.

Check Muffler Check muffler for damage or wear. Replace if necessary.

Clean Air Cleaner

Paper Element

engine manual for detailed instructions.

the engine when the oil level is low . See engine manual f or

detailed instructions.

engine manual for detailed instructions.

Replace missing or damaged fasteners.

before each use. The correct air pressure is 8 – 16 psi (55

– 110

Perform scheduled engine maintenance. See engine

manual for detailed instructions.

damaged belt tensioner.

needed.

See engine manual for detailed instructions.

fittings.

Open the petcock to drain oil through oil drain hose on the

right side of engine. See engine manual for additional

instructions.

See engine manual for detailed instructions.

WARNING: Safety interlock system failure and

improper operation of unit can result in death or

serious injury. Test this system each time the unit

is operated. If this system does not function as

See

kPa).

See MOWER BLADES on page 26.

See GENERAL LUBRICATION on page 22.

* Change oil after first 8 hours of operation and every 100 hours thereafter.

GB - 21

Page 22

SERVICE AND ADJUSTMENTS

Figure 8

1. Half Shafts

2. Wheel Bearings

3. Spindle Bearings

4. Caster Pivots

OG1485

2

3

1

2

4

NOTE: 32-Inch Deck Shown.

WARNING: AVO ID INJURY. Read

and understand the entire Safety

section before proceeding.

GENERAL LUBRICATION

Apply a small amount of oil to the pivot points

as required for smooth operation (

Apply high quality lithium based grease to all

lube fittings every 50 hours of operation

(spindle bearings every 160 hours).

Figure 8).

If unit turns to the left:

1. Reduce the air pressure in the right tire.

2. Increase the air pressure in the left tire.

3. Check for brake binding on left wheel

and adjust as needed.

ADJUST STEERING LEVERS

For each lever:

1. Turn off the engine, remove the key and

allow unit to cool.

2. Release steering or control levers

Figure 9).

(

3. Shift transmission into neutral. Operate

steering or control lever several times.

Do not move unit.

4. Remove the hair pin and disconnect the

trunnion from the wheel clutch

weldment.

5. Adjust the trunnion on the steering

control rod until the gap between the

ends of the steering lever and handlebar

grip is 3 – 3 1/4 in. (7.62

6. Connec t trunnion to wheel clutch

weldment and secure with hair pin.

7. Repeat for other steering lever.

– 8.26 cm).

TRACKING ADJUSTMENT

Check Forward Tracking

1. Start engine and run unit at full throttle.

2. Shift into a forward gear and slowly

release both steering levers to the full

outward position.

3. Note to which direction, if any, the unit

pulls.

4. Stop unit and engine.

5. Adjust tracking if needed.

Try each of the following steps until the unit

tracks straight. It may not be necessary to

perform all the steps.

If unit turns to the right:

1. Reduce the air pressure in the left tire.

2. Increase the air pressure in the right tire.

3. Check for brake binding on right wheel

and adjust as needed.

GB - 22

Page 23

Figure 9

1. Steering

Lever

2. Whee l Clut ch

Weldment

3. Trunnion

4. Steering

Control Rod

5. Hair Pin

1

2

5

4

3

3 – 3 1/4 in.

(7.62 – 8.26 cm)

Figure 10

1. Trunnion

2. Wheel Clutch Weldment

3. Brake Rod

1

3

2

4. Start engine and test in low gear for

proper brake engagement.

REPLACE TRACTION BELTS

1. Turn off the engine, remove the key and

allow unit to cool.

2. Release the steering levers.

3. Raise the rear of the unit so that the

drive wheels are off the ground.

4. Disconnect clutch idler pulley spring

Figure 11).

(

5. Remove traction belt guard.

ADJUST BRAKES

NOTE: The traction belt must disengage as

the brake starts to engage.

1. Turn off the engine, remove the key and

allow unit to cool.

2. If brakes do not disengage fully when

traction belt is engaged, the brakes are

too tight. Disconnect trunnion from the

clutch weldment and turn the trunnion up

the brake rod to reduce braking.

Reconnect the trunnion to the clutch

weldment (

3. If brakes do not engage fully when

traction belt is disengaged, the brakes

are too loose. Disconnect trunnion from

the clutch weldment and turn the

trunnion down the brake rod to increase

braking. Reconnect the trunnion to the

clutch weldment (

Figure 10).

Figure 10).

WARNING: AVOID INJURY. An

extension spring, when extended,

stores energy and can be

dangerous. Always use tools

specifically designed for installing

or removing an extension spring.

GB - 23

Always compress or extend

springs slowly.

6. Remove hair pin and trunnion holding

steering control rod to wheel clutch

weldment.

7. While slowly turning the drive wheel,

work the traction belt off the

transmission shaft pulley and drive

wheel.

8. Install new traction belt.

9. Connect steering control rod to wheel

clutch arm weldment with trunnion and

hair pin.

10. Replace traction belt guard.

11.Replace clutch idler pulley spring.

Page 24

12. Lower the unit.

OG0751

1. Clutch Idler

Pulley Spring

2. Traction Belt

Guard

3. Hair Pin

4. Trunnion

5. Steering

Control Rod

6. Wheel

Clutch

Weldment

7. Traction Belt

8. Transmission

Shaft Pulley

9. Drive Wheel

Figure 11

5

9

1

8

4

3

6

7

2

Figure 12

NOTE: Move spring anchor location to

hole to gain more traction on hilly terrain.

Traction Clutch Spring

Anchor

1. Shift Lever

2. 5/16-18

Bolts

3. Transmission

Figure 13

1

2

3

13. Check steering lever adjustment. See

ADJUST STEERIN G LEVERS on

page 22.

ADJUST SHIFT LEVER LINKAGE

IMPORTANT: If the shift lever and the

transmission detent are improperly aligned,

the transmission may fail prematurely. Align

the shift lever and detent as carefully as

possible. The .030 (.8mm) clearance helps

prevent premature wear of the detent plate

and shift lever.

The transmission shift lever is attached to the

transmission shift arm with two 5/16-18 bolts

Figure 13).

(

To adjust:

1. Stop the engine. Remove ignition key.

Put PTO lever in the "OFF" position. Put

the shift lever in neutral.

2. Loosen two 5/16-18 bolts on shift lever.

3. Align the shift lever so it is centered in

gear position 2 on the detent plate and is

.030 in. (.8mm) from the V (

NOTE: If the shift lever cannot be adjusted to

tolerance with the shift lever hardware alone,

loosen the hardware holding the detent plate

to the frame and adjust the detent plate to

tolerance.

Figure 14).

4. Tighten bolts securely.

NOTE: Before starting unit, test the shift lever

to make sure it engages all gear positions.

GB - 24

Page 25

REPLACE TRANSMISSION BELT

Figure 14

.8mm (.030 in.)

Loosen hardware and adjust detent plate,

if necessary.

Figure 15

1. Transmission

Belt

2. Transmission

Sheave

3. Transmission

Belt Idler

4. Transmission

Belt Idler

Mounting

Hardware

5. Mower

Clutch

Sheave

6. Clutch

Bracket

Mounting

Hardware

7. Clutch

Bracket

1

2

3

4

5

7

6

Figure 16

1. Belt

2. Idler Spring

3. Deck Sheave

4. Mower

Clutch

Sheave

5. Deck Idler

6. Idler Arm

4

5

3

3

6

2

1

1. Stop the engine. Remove ignition key.

Put PTO switch in the "OFF" position.

Put the shift lever in neutral.

2. Remove mower drive belt from mower

clutch sheave. See

REPLACEMENT on page 25 or 48"

BELT REPLACEMENT on page 26.

3. Loosen idler pulley mounting bolt and

slide idler pulley away from the belt

Figure 15).

(

4. Loosen one and remove one engine

mounting bolt and turn the clutch stop

away from the clutch. Save the

hardware.

5. Remove old transmission belt from

mower clutch sheave and transmission

sheave.

6. Install new transmission belt in the top

groove of the clutch hub and on the

transmission sheave.

7. Slide idler pulley to the belt to tension it,

and then tighten the mounting bolt to

hold the position. (

8. Reposition clutch stop, replace engine

bolt, and torque both engine bolts to 17

N•m).

lbf-ft (23

9. Reinstall mower drive belt on mower

clutch sheave.

36" BELT

Figure 15).

36" BELT REPLACEMENT

1. Stop engine, remove key and wait for all

hot parts to cool.

GB - 25

Page 26

2. Remove deck cover.

Figure 17

1. Mower

Clutch

Sheave

2. Mower Drive

Belt Idler

3. Deck Sheave

4. Mower Drive

Belt Idler

Spring

5. Mower Drive

Belt

6. Deck Belt

7. Deck Belt

Idler Spring

8. Deck Belt

Idler

3

1

2

3

5

3

6

7

8

4

1. Cutting Edge 2. Air Lift

Erosion

1

2

OT0792

Figure 18

DO NOT sharpen to this pattern

Sharpen to this pattern

DISCARD if more than

1/2 in. (1.27 cm)

3. Turn the idler spring adjusting nut to

relieve tension from the idler spring.

4. Remove belt from deck sheaves and

mower clutch sheave.

5. Install new belt.

6. Tighten the adjusting nut to tension the

belt. Tighten the nut until the idler spring

compresses to 2 in. ± 1/8 in. (5.1cm ±

.32 cm). See

7. Replace deck cover and secure.

Figure 16.

48" BELT REPLACEMENT

Deck Belt

1. Stop engine, remove key and wait for all

hot parts to cool.

2. Remove deck cover.

3. Turn the deck belt idler spring adjusting

nut to relieve tension from the idler

spring.

4. Remove deck belt from deck sheaves.

5. Install new deck belt.

6. Tighten the adjusting nut to tension the

belt. Tighten the nut until the idler spring

compresses to 2 in. ± 1/8 in. (5.1cm ±

.32 cm). See

7. Replace deck cover.

Mower Drive Belt

NOTE: Deck belt must be removed before

removing the mower drive belt.

1. Stop engine, remove key and wait for all

hot parts to cool.

2. Remove deck cover.

3. Remove deck belt.

4. Turn the mower drive belt idler spring

adjusting nut to relieve tension from the

idler spring (

5. Remove mower drive belt from deck

sheaves and mower clutch sheave.

6. Install new mower drive belt on deck

sheaves and mower clutch sheave.

7. Tighten the adjusting nut to tension the

belt. Tighten the nut until the idler spring

compresses to 2 in. ± 1/8 in. (5.1cm ±

.32 cm). See

8. Replace deck belt.

9. Replace deck cover and secure.

NOTE: Make sure wing knobs do not

interfere with cutting height adjustments.

Figure 17.

Figure 17).

Figure 17.

MOWER BLADES

NOTE: If mower is used under sandy soil

conditions, replace blades when air lifts

become eroded through at ends (

Figure 18).

GB - 26

Page 27

Remove Mower Blades

Figure 19

1. Spacers (Number will vary based on

cutting height.)

2. Blade

3. Blade Bolt

3

1

2

WARNING: Sharp edges can cut.

Moving parts can cut off fingers or a

hand. Wrap blade(s), wear sturdy

gloves and use extreme caution

when servicing. On multi-blade

mowers, rotation of one blade will

cause all blades to rotate.

1. Turn the engine off. Remove the ignition

key. Remove the ignition wire from the

spark plugs.

2. Block the blades with a wooden block to

prevent blade rotation.

3. Remove the bolts, blades and spacers

from the spindle shafts.

Replace Mower Blades

1. Install the spacers, blades, and bolts on

the spindle shafts.

2. Block blades with a wooden block to

prevent blade rotation.

3. Tighten each blade bolt to a torque of

120

lbf-ft (163 N•m).

4. Replace ignition wire on spark plugs.

Sharpen the Mower Blades

Figure 18.

CAUTION: DO NOT sharpen

mower blades while on unit. An

unbalanced mower blade will

cause excessive vibration and

eventual damage to unit. Check

mower blade balance before

reinstalling blades.

NEVER weld or straighten bent

blades.

1. Remove mower blade from unit.

Discard mower blade if:

• More than 1/2 in. (1.27 cm) of metal is

removed.

• Air lifts become eroded.

• Blade is bent or broken.

2. Sharpen mower blade by removing an

equal amount of material from each end

of mower blade. DO NOT change angle

of cutting edge or round the corner of the

mower blade.

3. Check mower blade balance.

Slide mower blade on an unthreaded

bolt. A balanced blade should remain in

a horizontal position. If either end of

mower blade moves downward, sharpen

the heavy end until blade is balanced.

4. I nstall mower blade(s) on unit (See

Replace Mower Blades on page 27).

Replacing Mower Spindle Bearings

1. Turn the engine off. Remove the ignition

key. Remove the ignition wire from the

spark plugs.

2. Remove mower blade.

3. Remove nut, flat washer, spacer and

pulley.

4. Remove spindle shaft, lower bearing

and spacer from spindle housing.

Discard bearing.

5. Remove and discard upper bearing.

6. Clean entire assem bly.

7. Install a new lower bearing and spacer

on the spindle shaft.

IMPORTANT: Avoid damage! The clearance

between the lower bearing and the housing is

only .002 in (.05

into housing.

8. I nstall the spindle shaft, lower bearing

and spacer into the spindle housing.

9. I nstall the upper bearing.

10. Install spacer.

11.Install pulley and nut. Tighten nut to 85

lbf-ft (115 N•m).

mm). Do not force bearing

GB - 27

Page 28

12. Grease the spindle. See GENERAL

1

1. Grease Fitting

2. Nut

3. Flat Washer

4. Spacer

5. Pulley

6. Retaining Ring

7. Upper Bearing

8. Spindle Housing

9. Spindle Spacer

10. Lower Bearing

11. Spindle Shaft

2

5

4

6

7

8

9

10

11

3

Figure 20

1. Lynch Pin

2. Cutting

Height

Spacers

3. Bushing

4. Washer

5. Caster Yoke

6. Wheel Nut

7. Bolt

8. Wheel

Spacer

9. Roller

Bearing

10. Bearing

Retainer

11. Wheel

Assembly

NOTE: Do not

remove the caster

yoke from the deck

to replace the

bearings and

bushings.

1

2

3

4

2

6

7

8

9, 10

5

11

Figure 20

LUBRICATION on page 22.

13. Install mower blade, blade washers and

blade bolt assembly. Tighten bolt to 120

lbf-ft (163 N•m).

6. Install caster yoke and wheel assembly,

washer, spacer bushings and lynch pin.

7. Apply grease to lubrication fitting.

Replacing Caster Pivot Bearing

Bushings

1. Turn the engine off. Remove the ignition

key. Remove the ignition wire from the

spark plugs.

2. Raise and securely support the front of

the mower deck.

3. Remove lynch pin, spacer bushings,

washer and caster yoke and wheel

assembly.

4. Remove and discard upper and lower

bushings.

5. Install new bushings.

IMPORTANT: Do not allow washer to sit on

caster yoke. It must be on top of height-of-cut

spacer bushings.

SERVICE ELECTRICAL

Replace Fuse

IMPORTANT: Avoid damage! When

replacing fuses use only 25-amp fuses or you

may damage the circuit.

The machine is equipped with one 25-amp

fuse to protect the charging circuit. This fuse

is located on the main harness, near the

engine ground.

1. Remove defective fuse from socket.

GB - 28

Page 29

2. Check metal clip in fuse window and

Fuse holder. Replace with an

automotive type 25-amp fuse.

Figure 21

discard fuse if clip is broken.

3. Install new fuse into socket.

STORAGE

Fuel System

Gasoline left in the fuel system for extended

periods without a stabilizer will deteriorate,

resulting in gum deposits in the system.

These deposits can damage the carburetor

and the fuel hoses, filter and tank. Prevent

deposits from forming in the fuel system

during storage by adding a quality fuel

stabilizer to the fuel. Follow the

recommended mix ratio found on the fuel

stabilizer container.

To treat the fuel system for storage:

1. Add fuel stabilizer according to

manufacturers’s instructions.

2. Run engine for at least 10 minutes after

adding stabilizer to allow it to reach the

carburetor.

NEVER store the engine with fuel in the fuel

tank inside of a building with potential

sources of ignition.

ACCESSORIES

Part No. Description

79260500 36-in. Mulch Kit (988811)

79260000 48-in. Mulch Kit (988812)

WARNING: AVO ID INJURY. Read

and understand the entire Safety

section before proceeding.

Storage – Two Months or More

Check each item in the MAINTENANCE

SCHEDULE on page 21, but do not add

gasoline.

Clean the unit. T ouch up all scratched painted

surfaces.

IMPORTANT: Never spray unit with high-

pressure water or store unit outdoors. Store

unit in a cool, dry, protected location.

NOTE: Clean unit thoroughly with mild soap

and low pressure water and lubricate (

GENERAL LUBRICATION on page 22).

Touch up all scratched painted surfaces. Do

not allow gasoline or oil to remain on any

decals.

Engine

Refer to the engine manual to prepare the

engine for storage.

See

SERVICE PARTS

Always use genuine Ariens parts to keep

your mower running like new.

00201010 1 Mower Deck Belt (36-in.

Deck)

D38019 1 Mower Deck Belt (48-in.

Deck)

07200533 1 Deck Drive Belt (48-in.

Deck)

07243600 2 Traction Drive Belt

07225500 1 Transmission Belt

GDU10231 2 Blade (36-in. Decks)

GDU10230 3 Blade (48-in. Decks)

21538000 1 Air Filter Paper Element

21538100 1 Air Filter Foam

Precleaner

21535800 1 Engine Oil Filter

21538400 1 Engine Fuel Filter

21533600 1 Spark Plug

GB - 29

Page 30

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE CORRECTION

Engine will not

start

Unit wi ll not

move or mow

when the

engine is

running

Changes in the

sound or

vibrations of

the unit

Unit does not

straighten

immediately

when the

steering levers

are released

Unit lo s es

power

1. Safety Interlock System is

preventing start.

2. Fuel tank is empty or fuel

is contaminated.

3. Air cleaner is clogged or

damaged.

4. Safety Interlock System

out of adjustment or

defective.

5. Dirty or damaged spark

plug.

1. Transmission belt or

mower belt is broken,

worn, or off the pulleys.

1. Loose or missing

fasteners.

2. Mower blade problem.

3. Worn or damaged clutch.

1. Rust on the clutch sliding

pin.

2. Steering levers out of

adjustment.

1. Binding in the steering or

brake linkage.

2. Steering levers out of

adjustment.

1. The engine will not start unless the shift

lever is in neutral, the key is in the On

position, and the Power Ta ke Off (PTO)

is Off.

2. Add fuel. If necessary, replace the fuel

with clean, fresh fuel. See

FUEL TANK on page 15.

3. Clean or replace the filter element. See

engine manual.

4. See your Dealer for repairs.

5. See Engine Manual.

1. Check belts for wear, damage and

correct position on pulleys. Replace

belts if worn or damaged.

REPLACE TRANSMISSION BELT on

page 25.

1. Check all the fasteners. Replace if

necessary.

2. Check blades for wear or damage. See

MOWER BLADES on page 26.

3. See your Dealer for repairs.

1. Clean heavy rust deposits from the pin.

See Service and Adjustments.

2. See ADJUST ST EERING LEVERS on

page 22.

1. Check linkage for debris or damage.

Repair if necessary. See ADJUST

BRAKES on page 23 or your Dealer for

repairs.

2. See ADJUST STEERING LEVERS on

page 22.

FILLING

See

3. Worn or damaged traction

belts.

4. Traction belt slipping.

5. Transmission shaft pulley

worn.

GB - 30

3. Check belts for wear or damage.

Replace if necessary. See REPLACE

TRACTION BELTS on page 23.

4. Move the traction belt idler spring

anchor to the rearmost position.

REPLACE TRACT ION BEL TS on

page 23

5. If pulley shows excessive wear, replace

it. See your Dealer for repairs.

See

Page 31

SPECIFICATIONS

Model Number 988811 988812

Model APWKA1636S APWKA1648S

Engine

Engine Kawasaki

Engine Model Number FS481V

Governed RPM (May be different from

maximum RPM)

Cooling Capacity Air Cooled

Speed

Forward Maximum – mph (km/h) 5.4 (8.7)

Reverse Maximum – mph (km/h) Reverse Assist

Turning Radius 0

Brakes 6-Inch Band

Electrical

Starter Recoil

Power Take-Off Electric PTO Clutch

Fuel

Fuel Type Refer to Engine Manual

Fuel Tank Capacity – gal. (L) 5.8 (22)

Transmission

Type Peerless 5-Speed + Reverse

Size and Weight

Length – in. (cm) 75.6 (192.0) 70.9 (180.0)

Width – in. (cm) 48.4 (122.9) 60.8 (154.4)

Height – in. (cm) 41.9 (106.4) 41.9 (106.4)

Weight – lbs (kg) 464 (210.5) 530 (240.4)

Tires