Page 1

®

Sno-Thro

Owner/Operator Manual

Models

938015 - 322

938016 - 522

ENGLISH

FRANÇAIS

ESPAÑOL

03810900B 5/00

Supersedes 03810900,A

Printed in USA

Page 2

ENGLISH

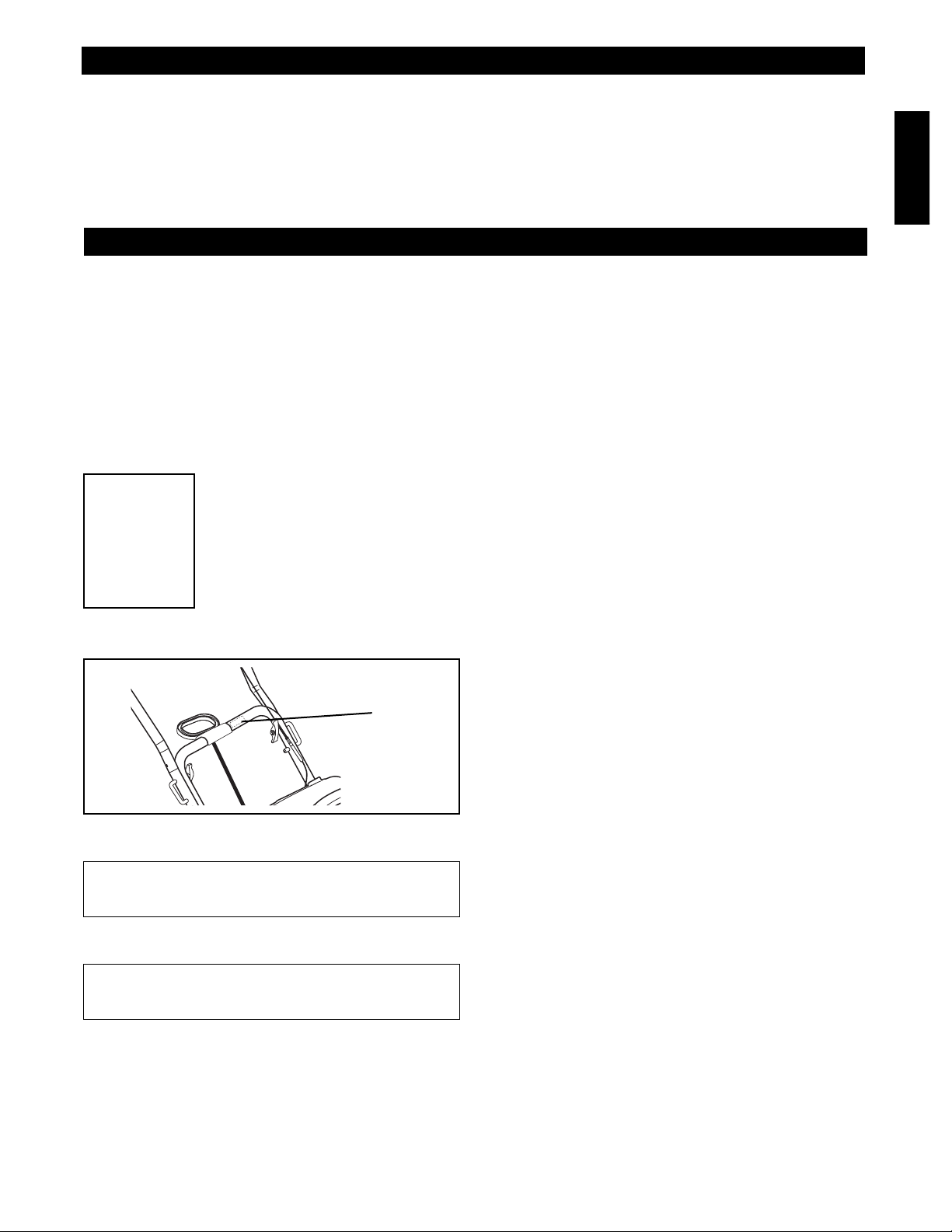

1. Auger Clutch Bail

2. Recoil Starter Handle

3. Handlebar Knob

4. Chute Deflector Handle

5. Exhaust

6. Discharge Chute

Deflector

7. Discharge Chute

8. Auger Housing

9. Auger

10. Scraper Blade

11. Discharge Chute

Rotation Handle

12. Fuel Tank and Cap

13. Cowl

14. Auger Control Cable

15. Upper Handlebar

16. Lower Handlebar

17. J - Bolt

18. Primer Bulb

19. Ignition Switch

20. Fuel Level Indicator

21. Starter Button (optional)

22. Power Cord (optional)

23. Choke Control Knob

FRANÇAIS

1. Commande d'embrayage

de la turbine

2. Poignée du démarreur à

cordon

3. Bouton du guidon

4. Poignée du déflecteur de

la goulotte

5. Échappement

6. Déflecteur de la goulotte

de décharge

7. Goulotte d'évacuation

8. Carter de la turbine

9. Rotor

10. Lame racleuse

11. Poignée de rotation de la

goulotte d'évacuation

12. Réservoir de carburant et

bouchon

13. Garant

14. Câble de commande du

rotor

15. Guidon supérieur

16. Guidon inférieur

17. Vis en J

18. Poire d'amorçage

19. Commande d'allumage

20. Indicateur de niveau de

carburant

21. Bouton du démarreur (en

option)

22. Cordon d'alimentation

(en option)

23. Bouton du starter

ESPAÑOL

1. Asa del embrague del

sinfín

2. Manilla de retroceso del

arranque

3. Perilla del manillar

4. Asa del deflector de la tolva

5. Escape

6. Deflector de la tolva de

descarga

CONTROLS AND FEATURES

1

15

2

17

12

11

13

10

7. Tolva de descarga

8. Alojamiento del sinfín

9. Sinfín

10. Cuchilla raspadora

11. Asa de rotación de la

tolva de descarga

12. Depósito del combustible

y tapón

13. Cubierta

14. Cable de control del sinfín

15. Manillar superior

16. Manillar inferior

17. Perno en J

18. Botón del cebador

19. Interruptor de encendido

20. Indicador del nivel de

combustible

21. Botón del motor de

arranque (opcional)

2

18

19

22

23

21

20

16

3

14

4

5

6

7

9

22. Cable de alimentación

(opcional)

23. Perilla de control del

estrangulador

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

OS0241

8

OS1500

Page 3

TABLE OF CONTENTS

Controls and Features . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

INTRODUCTION

Service and Adjustments . . . . . . . . . . . . . . . . 14

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 16

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Accessories and Service Parts. . . . . . . . . . . . 17

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ENGLISH

THE MANUAL

Before operation of unit, carefully and completely read

your manuals. The contents will provide you with an

understanding of safety instructions and controls

during normal operation and maintenance.

All reference to left, right, front, or rear are given from

operator standing in operation position and facing the

direction of forward travel.

MODEL AND SERIAL NUMBERS

When ordering replacement parts

Transfer

model & serial

number label

from product

registration

here.

or making service inquiries, know

the Model and Serial numbers of

your unit and engine.

Numbers are located on the product

registration form in the unit literature

package. They are printed on a

serial number label, located on the

frame of your unit.

Serial

Number

Label

PRODUCT REGISTRATION

A warranty registration card must be filled out, signed,

and returned at time of purchase. This card activates

the warranty. Claims meeting requirements during

limited warranty period will be honored.

UNAUTHORIZED REPLACEMENT PARTS

Use only Ariens replacement parts. The replacement of

any part on this vehicle with anything other than an

Ariens authorized replacement part may adversely

affect the performance, durability, or safety of this unit

and may void the warranty. Ariens disclaims liability for

any claims or damages, whether warranty, property

damage, personal injury or death arising out of the use

of unauthorized replacement parts.

DISCLAIMER

Ariens reserves the right to discontinue, make changes

to, and add improvements upon its products at any time

without public notice or obligation.The descriptions and

specifications contained in this manual were in effect at

printing. Equipment described within this manual may

be optional. Some illustrations may not be applicable to

your unit.

• Record Unit Model and Serial numbers here.

• Record Engine Model and Serial numbers here.

OS0192

GB - 3

Page 4

DELIVERY

Customer Note: If you have purchased this product

without complete assembly and instruction by your

retailer, it is your responsibility to:

• Read and understand all assembly instructions in

this manual

If you do not understand or have difficulty following the

instructions, contact your nearest Ariens Dealer for

assistance. To locate your nearest Ariens Dealer, call

1-800-678-5443 or visit our web site at

http://www.ariens.com.

.

WARNING: Improper assembly or

adjustments can cause serious injury.

SAFETY

SAFETY ALERTS

Look for these symbols to point out

important safety precautions. They mean:

Attention! Personal Safety Is

Involved!

Become Alert! Obey The Message!

• Do not operate the Sno-Thro unless all controls

function as described in this manual.

Before attempting to operate your Sno-Thro:

1. Make sure all assembly has been properly

completed.

2. Understand all Safety Precautions provided in the

manuals.

3. Review control functions and operation of the unit.

4. Review recommended lubrication, maintenance

and adjustments.

5. Review Limited Warranty Policy.

6. Fill out Original Purchaser Registration Card and

return the card to Ariens Company.

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate, or serious injury or death. Learn applicable

rules and laws in your area.

The safety alert symbol is used in decals on the unit

and with proper operation procedures in this manual.

Understand the safety message. It contains important

information about personal safety on or near the unit.

DANGER: IMMINENTLY HAZARDOUS

SITUATION! If not avoided, WILL RESULT in

death or serious injury.

WARNING: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, COULD RESULT

in death or serious injury.

CAUTION: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTATIONS

NOTE: General reference information for proper opera-

tion and maintenance practices.

IMPORTANT: Specific procedures or information

required to prevent damage to unit or attachment.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation. If unit is to be used

by someone other than original purchaser; loaned,

rented or sold, ALWAYS provide this manual and any

needed safety training before operation.

GB - 4

Page 5

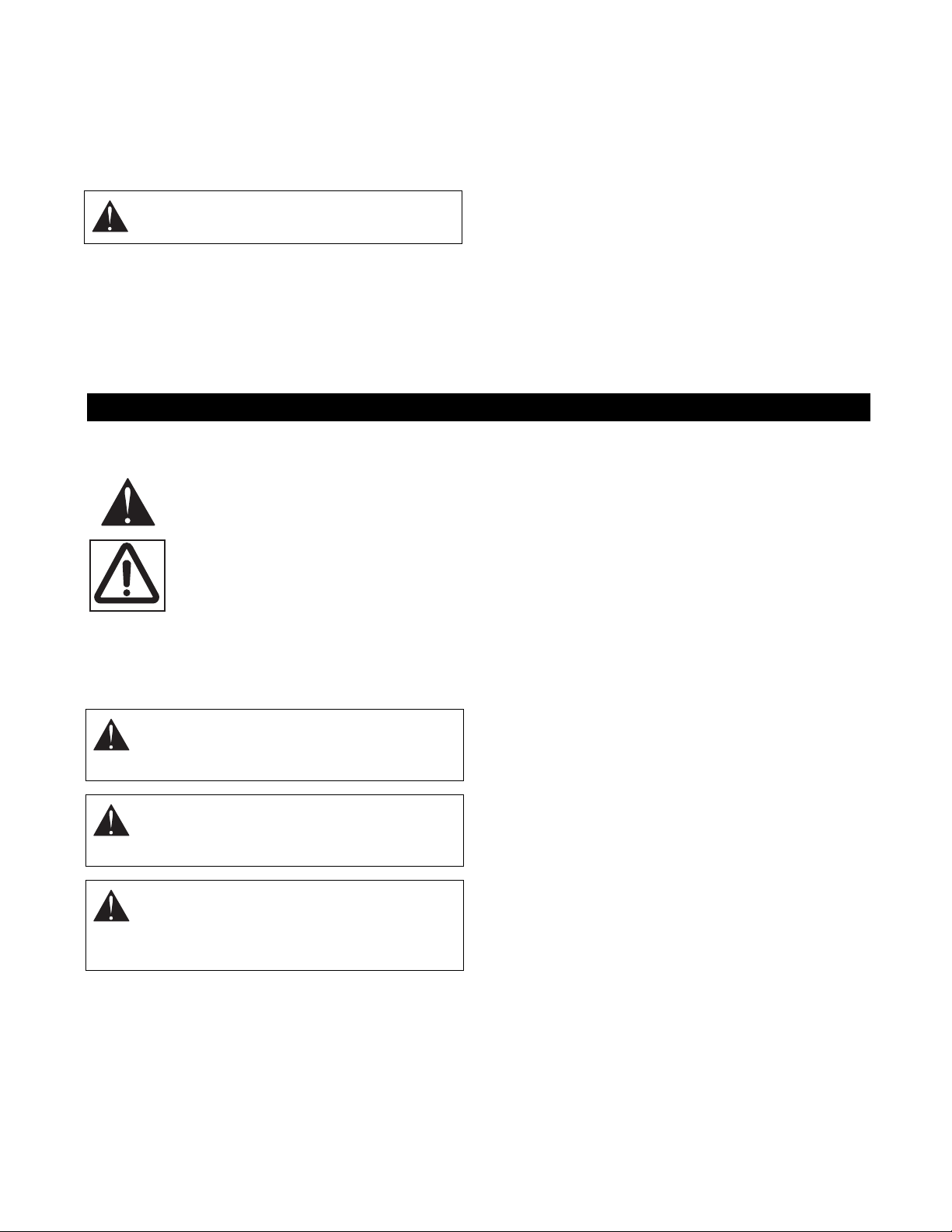

OL0900

3.

SAFETY DECALS AND LOCATIONS

ALWAYS replace missing or damaged Safety Decals.

Refer to figure below for Safety Decal locations.

2

3

1

4

1 & 2. DANGER

Keep clear of auger while engine is

running.

OL1070

SAFETY

Read operator’s manual.

OL1801

• Allow operation only by properly trained adult,

never children.

Stop engine and remove ignition key

prior to leaving operator’s position for

any reason.

OL4010

OS1681

• Keep all controls, guards and safety devices

properly serviced and functional.

• Never direct discharge towards persons or

property that may be injured or damaged by

thrown objects.

DANGER! ROTATING PARTS! Stop

engine and remove ignition key before

clearing.

4. IMPORTANT ENGINE INFORMATION

CAUTION: For personal protection refer to

owner’s manual for important safety and

maintenance information.

GB - 5

Page 6

SAFETY RULES

Walk Around Inspection

Complete a walk around inspection of unit and work

area to understand:

• Work area.

• Your unit.

• All safety decals.

Work Area

ALWAYS check overhead and side clearances carefully

before operation. ALWAYS be aware of traffic when

operating along streets or curbs.

Keep children and people away. Keep children out of

work area and under watchful care of a responsible

adult.

DO NOT allow adults to operate unit without proper

training.

Keep area of operation clear of all toys, pets, and

debris. Thrown objects can cause injury.

Check for weak spots on dock, ramps or floors. Avoid

uneven work areas and rough terrain. Stay alert for

hidden hazards.

Always be sure of your footing, especially when

operating in reverse. Walk, never run during operation.

Falling snow, fog, etc. can reduce vision and cause an

accident. Operate unit only when there is good visibility

and light.

Unit

ALWAYS keep protective structures, guards, and

panels in good repair, in place and securely fastened.

NEVER modify or remove safety devices.

Check clutch and brake operation frequently. Adjust

and service as required. Auger must stop quickly when

control bail is released.

Use only approved extension cords and receptacles

when starting units equipped with Electric starter. DO

NOT connect electric starter cord to any wiring system

that is not a three wire grounded system.

Operation

Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an Emergency

Before starting engine, disengage control(s).DO NOT

operate at too fast a rate.

DO NOT change engine governor settings or

over-speed engine.

Slow down and turn corners slowly.

Disengage attachment drive when traveling from one

work area to another.

ALWAYS allow unit and engine to adjust to outdoor

temperatures before clearing snow.

ALWAYS disengage attachment drive, stop unit and

engine, remove key, allow moving parts to stop before

leaving operator’s position for any reason.

Run unit a few minutes after clearing snow to prevent

freeze-up of attachment.

Disengage attachment when not in use.

Do not operate in reverse unless absolutely necessary.

ALWAYS back up slowly. Always look down and

behind before and while backing.

Never leave a running unit unattended. ALWAYS shut

off engine before leaving unit. ALWAYS remove key to

prevent unauthorized use.

Never carry passengers.

Avoid uneven and rough terrain. DO NOT operate near

drop offs, ditches, or embankments. Unit can suddenly

turn over if a wheel is over the edge of a cliff or ditch, or

if an edge caves in.

Abnormal Vibrations are a warning of trouble. Striking a

foreign object can damage unit. Immediately stop unit

and engine. Remove key and wait for all moving parts

to stop. Remove wire from spark plug. Inspect unit and

make any necessary repairs before restart.

Hazardous Slopes

DO NOT operate on steep slopes. DO NOT clear snow

across the face of slopes. Keep all movement on

slopes slow and gradual. DO NOT make sudden

changes in speed or direction.

DO NOT park unit on a slope unless absolutely

necessary. When parking on a slope always block the

wheels.

Child Safety

NEVER allow children to operate or play on or near

unit. Be alert and shut off unit if children enter area.

Personal Safety

Only trained adults may operate unit.

Training includes actual operation.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation requires

your complete and unimpaired attention at all times.

NEVER allow anyone to operate this unit when their

alertness or coordination is impaired.

DO NOT operate unit without wearing adequate winter

outer garments. Wear adequate safety gear and

protective gloves. Wear proper footwear to improve

footing on slippery surfaces.

Protect eyes, face and head from objects that may be

thrown from unit. Wear appropriate hearing protection.

Avoid sharp edges. Sharp edges can cut. Moving parts

can cut off fingers or a hand.

GB - 6

Page 7

ALWAYS keep hands and feet away from all rotating

parts during operation. Rotating parts can cut off body

parts.

ALWAYS keep hands away from all pinch points.

DO NOT touch unit parts which might be hot from

operation. Allow parts to cool before attempting to

maintain, adjust or service.

NEVER place your hands or any part of your body or

clothing inside or near any moving part while unit is

running.

DO NOT wear loose clothing or jewelry and tie back

hair that may get caught in rotating parts.

Keep children and people away from unit during

operation.

Never direct discharge towards persons or property

that may be injured or damaged by thrown objects. Use

extreme caution on gravel surfaces. Stay alert for

hidden hazards or traffic.

Deflected materials can cause injury and property

damage.

Always stand clear of the discharge area when

operating this unit.

Fumes from engine exhaust can cause injury or death.

DO NOT run engine in an enclosed area. Always

provide good ventilation.

Storage

For unit storage or extended storage:

• NEVER store with fuel in fuel tank, inside a

building where any ignition sources are present.

• Allow engine to cool completely.

• For extended storage, clean unit thoroughly. See

Engine Manual for proper storage.

Transport

Use extra care when loading or unloading unit onto

trailer or truck.

Secure unit chassis to transport vehicle. NEVER

secure from rods or linkages that could be damaged.

DO NOT transport machine while engine is running.

Spark Arrester

This product is equipped with an internal combustion

type engine. DO NOT use unit on or near any

unimproved, forest-covered or brush covered land

unless exhaust system is equipped with a spark

arrester meeting applicable local, state or federal laws.

A spark arrester, if it is used, must be maintained in

effective working order by operator.

Service

Before cleaning, removing clogs or making any

inspections, repairs, etc.: disengage clutch(es), stop

unit and engine, remove key, allow moving parts to

stop. Allow hot parts to cool.

Before tipping unit up onto housing, remove enough

fuel so no spills will occur. Ensure unit is secure and

will not tip over during maintenance.

Fuel is highly flammable and its vapors are explosive.

Handle with care. Use an approved fuel container.

NO smoking, NO sparks, NO flames. ALWAYS allow

engine to cool before servicing.

NEVER fill fuel tank when engine is running or hot from

operation.

NEVER fill or drain fuel tank indoors.

Replace fuel cap securely and clean up spilled fuel.

ALWAYS maintain unit in safe operating condition.

Damaged or worn out muffler can cause fire or

explosion.

Keep all hardware properly tightened.

Cleaning

Keep unit free of ice or other debris. Clean up oil or fuel

spills.

GB - 7

Page 8

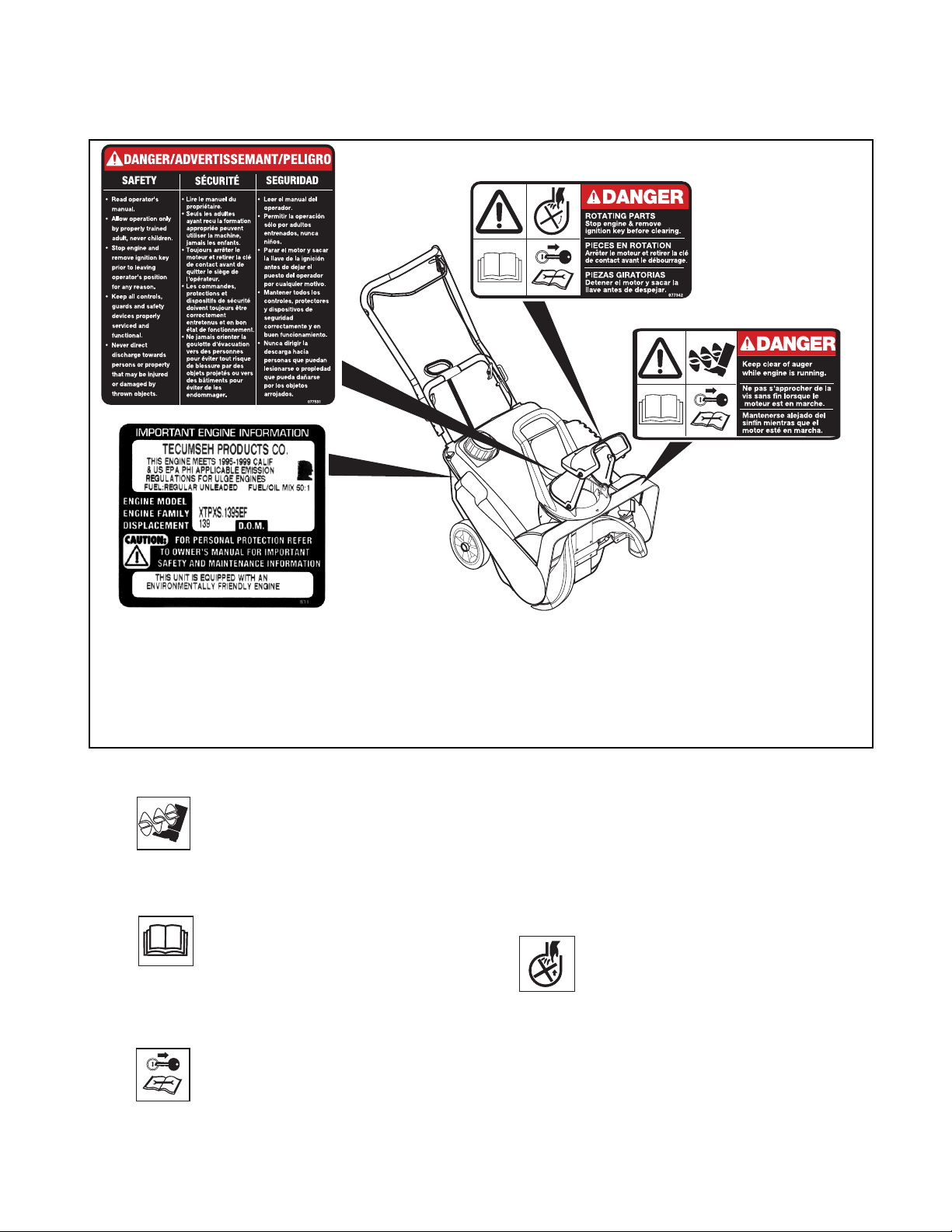

1. Lower Handle Bar

2. Upper Handle Bar

3. J-Bolt

4. Knob

5. J-Bolt Holes

6. Auger Clutch Bail

7. Retaining Nuts

OS1530

4

3

1

6

2

5

7

1. Discharge Chute

2. Rear Screw and

Nut

3. Side Hardware

4. Chute Handle

OS1520

1

2

4

3

ASSEMBLY

TOOLS REQUIRED

• 7/16" Open-end wrench

TO REMOVE UNIT FROM CARTON

1. Cut off top of carton.

2. Remove front and rear inserts and literature pack.

3. Cut out back of carton and roll unit out.

4. Remove protective packaging materials.

ASSEMBLY

Handlebar Assembly

Hardware/

Literature

Pack

Discharge Chute Assembly

1. Remove retaining nuts and handlebar knobs and

release J-bolts from lower handlebar.

2. Unfold upper handlebar.

NOTE:

operator. Refer to Handlebars in Operation.

3. Put J-bolts through the upper handlebar and lower

4. Replace retaining nuts and tighten handlebar

Adjust handlebar to a height comfortable for the

handlebar holes.

knobs to secure upper handlebar.

OS1510

1. Remove screw and nut from rear of discharge

chute.

2. Tip discharge chute up and install hardware just

removed. Tighten hardware at rear of discharge

chute first, then sides.

CHECKLIST

Please complete the following checklist before

proceeding:

All assembly instructions have been completed.

❑

❑

No remaining loose parts in carton.

❑

Handlebar is adjusted comfortably and tightened

securely.

While learning how to use your unit, pay extra

attention to the following important items:

❑

Fill fuel tank with proper gasoline/oil mix.

Become familiar with all controls – their location

❑

and function.

❑

Be certain that all hardware is properly tightened.

GB - 8

Page 9

OS1620

OS1570

OPERATION

CONTROLS AND FEATURES

Refer to Figure 1 on the inside front cover for controls

and features locations.

Ignition Switch

The ignition switch is operated with a removable key

that has two positions.

WARNING: ACCIDENTAL ENGINE START

UP or UNAUTHORIZED USE could result in

death or serious injury. ALWAYS shut off unit

and remove key before servicing or leaving

unit unattended.

STOP

OS1680

To start the engine, the key must be in the "RUN"

position.

To stop the engine, turn the key to the "STOP" position.

"STOP" Position: Ignition system is shut

down.

"RUN" Position: All controls are

RUN

operable.

Auger Clutch Bail

Squeeze the auger clutch bail

against the handlebar to engage

auger.

Engaged

Release bail to disengage and

Disengaged

IMPORTANT:

OS1560

Check auger to be sure it is not frozen. If

brake auger.

belt squeals when clutch bail is engaged, auger is

frozen. Immediately release the clutch bail and move

the unit to a heated area to thaw.

IMPORTANT:

Check clutch/brake function before each

use. If auger clutch bail moves freely with no resistance

before contacting handlebar, adjust or repair unit

before operating.

Primer Bulb

Push in the primer Bulb to add fuel for

easier engine start. See Starting and

Shut Off .

Auger

WARNING: THROWN OBJECTS could cause

personal injury and/or property damage.

ALWAYS discharge in a safe direction.

Disengage auger when unit is traveling to

work area or is not in use. Use extreme

caution when operating on or crossing gravel

surfaces.

CAUTION: STRIKING FOREIGN OBJECTS

may damage unit and result in minor or

moderate injury. Shut off unit and engine.

Check for any damage or loose parts and

repair before restart.

When handlebar is lifted so auger contacts the ground,

auger propels unit forward while collecting snow.

Forward speed will vary according to depth and

moisture content.

WARNING: IMPROPER ADJUSTMENT

could result in death or serious injury. AUGER

BRAKE MUST DISENGAGE when clutch is

engaged. BRAKE MUST STOP AUGER

WITHIN 5 SECONDS of releasing auger

clutch bail.

Choke Control Knob

When pulled out (away from auger

housing) the choke control knob chokes

off air to the engine for easier start.

When pushed in, control knob allows for

normal operation.

IMPORTANT:

When engine has started, open choke

slowly by gradually pushing choke control in.

Recoil Starter Handle

When pulled, handle will crank engine.

IMPORTANT:

DO NOT let handle snap back against

unit.

Discharge Chute

The discharge chute directs the flow of snow away from

the area being cleared. The discharge chute rotates

220°. Rotate chute with the discharge chute handle.

DANGER: ROTATING PARTS will cause

serious injury or death. NEVER reach into

discharge chute or housing while engine is

running.

GB - 9

Page 10

WARNING: THROWN OBJECTS can result in

personal injury and/or property damage.

ALWAYS position discharge chute and

deflector in safe direction and angle before

starting engine. DO NOT allow anyone in front

of unit during operation. Be familiar with area

of operation.

IMPORTANT: DO NOT force frozen chute controls.

Start engine and run for 3-5 minutes. If still frozen, take

unit to a warm place to thaw.

Discharge Chute Deflector

The discharge chute deflector controls how high snow

is thrown.

CAUTION: THROWN OBJECTS can cause

personal injury and/or property damage. DO

NOT throw snow any higher than necessary

If chute deflector does not stay in set position,

adjust as directed in Service and

Adjustments, or repair before operation.

Use handle at rear of deflector to position deflector at

desired height.

Push down handle to increase height of discharge.

Pull up on handle to decrease height of discharge.

Handlebars

Adjust upper handlebar by selecting alternate holes for

"J" Bolts.

Tighten handlebar knobs to secure upper handlebar.

The upper handlebar can be folded for storage.

Scraper Blade

The scraper blade allows the back of the housing to

keep better contact with the surface being cleared. It

also prevents damage to the housing from normal

wear.

IMPORTANT: DO NOT allow scraper blade to wear

down too far or auger housing will become damaged.

Fuel Level Indicator

The fuel level indicator is an extension of the fuel tank

that allows you to see the level of fuel in the tank

without removing the fuel cap.

STOPPING IN AN EMERGENCY

Immediately release auger clutch bail to stop unit

movement.

Stop Engine, remove Key and wait for all rotating parts

to stop before leaving operators position.

BEFORE STARTING ENGINE

WARNING: IMPROPER CLOTHING AND

SAFETY GEAR could result in death or

serious injury. Wear adequate winter gear,

protective gloves and footwear which will

improve footing on slippery surfaces. DO NOT

wear loose clothing or jewelry and tie back

hair that may get caught in rotating parts.

THROWN OBJECTS could result in death or

serious injury. Wear safety goggles to protect

eyes.

CAUTION: THROWN OBJECTS can result in

personal injury and/or property damage. DO

NOT throw snow any higher than necessary.

1. Check for Frozen Auger

• With key in "Stop" position, squeeze auger clutch

bail to Engaged position and pull recoil starter

handle.

• If you cannot pull starter handle, auger is frozen.

Move unit to a heated area to thaw to prevent

possible damage.

2. Check Function of Clutches

WARNING: FAILURE OF CLUTCHES OR

BRAKES may result in death or serious injury.

Check clutch and brake function before each

use. Repair or adjust before operation.

With key in "Stop" position, squeeze auger clutch bail

to Engaged position and pull recoil starter handle.

Auger should rotate with the turning of the engine.

Release the auger clutch bail.

If the auger clutch bail moves freely with no resistance

before contacting handlebar, adjust or repair before

operation.

3. Check Engine Fuel Level

WARNING: FLAMMABLE FUEL and its

EXPLOSIVE VAPORS can cause death or

serious injury. handle fuel with extreme care.

ALWAYS use an approved fuel container. NO

Smoking! NO Lighted Materials! NO Open

Flames! Allow engine to cool before any

service.

Add fuel if required. Refer to Filling the Fuel Tank.

GB - 10

Page 11

STARTING AND SHUTOFF

WARNING: FAILURE TO FOLLOW

INSTRUCTIONS could result in personal

injury and/or damage to unit. DO NOT attempt

to start your unit at this time. Read entire

Owner/Operator Manual and the Engine

Manual first.

IMPORTANT: At start up, allow unit and engine to

adjust to the outdoor temperatures before clearing

snow. Before shut off, run auger a few minutes to

prevent freeze-up of auger.

NOTE: Try out each control without the engine running

to see how they work and what they do.

WARNING: THROWN OBJECTS could cause

death or serious injury. ALWAYS position

discharge chute straight ahead (away from

operator) for starting.

Manual Start

1. Turn discharge chute straight ahead.

2. Push primer Bulb 1 to 3 times for cold engine.

NOTE: When temperature is below -15° F (-26° C)

additional priming may be needed.

3. Pull choke control knob out.

NOTE: A warm engine requires less choking than a

cold engine.

4. Insert key into ignition switch.

5. Turn key to "Run" position.

6. Stand to right of unit. Grasp starter handle and pull

rope out slowly until it pulls harder, this is

compression stroke, let rope rewind slowly.

7. Pull rope with a rapid continuous full arm stroke.

Let rope rewind slowly.

IMPORTANT: DO NOT let starter handle snap against

unit.

8. Repeat until engine starts. (If engine does not

start, refer to Troubleshooting.)

9. When engine has started, open choke slowly by

gradually pushing choke control knob in.

5. Turn key to "Run" position.

6. Connect Female End of power cord to switch Box.

7. Plug Male End of power cord into 120 Volt AC

receptacle.

8. Push starter button to crank engine.

9. When engine starts, release starter button

10. Open choke slowly by gradually pushing choke

control knob in.

11. Disconnect power cord from receptacle first, then

from switch box.

Shutoff

1. Engage and run auger a few minutes after use to

prevent freeze-up of auger.

2. Release auger clutch bail and allow auger to stop.

3. Turn ignition switch to "Stop" position.

4. Remove key.

Electric Start (optional)

IMPORTANT: DO NOT crank engine for more that 20

seconds. ALWAYS allow starter to cool down for 10

minutes between each try or starter will be damaged.

1. Turn discharge chute straight ahead.

2. Push primer Bulb 1 to 3 times for cold engine.

NOTE: When temperature is below -15° F (-26° C)

additional priming may be needed.

3. Pull choke control knob out.

NOTE: A warm engine requires less choking than a

cold engine.

4. Insert key into ignition switch.

GB - 11

Page 12

TO THROW SNOW

CAUTION: HIDDEN HAZARDS may result in

minor or moderate injury and/or damage to

unit. Stay alert for holes, rocks, roots, traffic,

and other hazards.

To propel unit and throw snow:

1. Start engine.

2. Squeeze auger clutch bail against handlebar to

engage auger.

3. Lift handlebar so auger contacts surface to be

cleared. Lift the handlebar only high enough to

propel unit forward.

NOTE: Do not lift so high to allow snow to kick back

from under unit.

Tips for Operation

Snow is best removed as soon as possible after a snow

fall.

To clear an area, run unit in an overlapping series of

paths. For large areas; start in the middle and throw

snow to each side, so snow is not cleared more than

once.

ALWAYS direct snow away from area to be cleared and

with direction of the wind.

IMPORTANT: DO NOT overload unit capacity by

attempting to clear snow at too fast a rate.

TO TRAVEL TO ANOTHER WORK AREA

1. Release auger clutch bail to disengage auger.

2. Press down on handlebar enough to raise front of

unit slightly off the ground and push or pull unit.

TO TRANSPORT UNIT

Use extra care when loading or unloading unit onto

trailer or truck.

Secure unit chassis to transport vehicle. NEVER

secure by rods or linkages that could be damaged.

Always shutoff engine for transport.

FILLING THE FUEL TANK

Check fuel level by looking at fuel level indicator on rear

of unit. Add fuel as required.

WARNING: FLAMMABLE FUEL and its

EXPLOSIVE VAPORS can result in death or

serious injury.

Handle fuel with extreme care.

ALWAYS use an approved fuel container.

No Smoking! No Lighted Materials! No Open

Flames!

Allow engine to cool before any service.

ALWAYS clean up any spilled fuel.

To add fuel to fuel tank:

IMPORTANT: Two cycle engines require that oil be

mixed with fuel. Failure to mix oil with fuel will result in

seizure and severe damage to engine. DO NOT use

gasohol or gasoline containing alcohol because

alcohol will cause internal parts to deteriorate. See

Engine Manual for correct type and grade of fuel.

1. ALWAYS place unit in open or well ventilated area.

2. Stop engine and allow to cool.

3. See engine manual for proper fuel/oil mixture.

4. Clean fuel cap and surrounding area to prevent dirt

from entering fuel tank.

5. Remove cap.

6. Fill fuel tank with mixture. Tank capacity is 1.2

quarts (1.1 liters).

NOTE: Fuel mixture left standing for prolonged periods

will begin to separate; thoroughly shake mixture before

use.

7. Replace fuel cap and tighten.

GB - 12

Page 13

MAINTENANCE

GENERAL RECOMMENDATIONS

WARNING: ACCIDENTAL ENGINE START

UP can cause death or serious injury.

ALWAYS stop engine, remove key, and wait

for moving parts to stop, before performing

maintenance or service.

HOT SURFACES can cause death or serious

injury. DO NOT touch parts which are hot from

operation. ALWAYS allow parts to cool.

Some adjustments must be made periodically to

properly maintain your unit. All adjustments in the

SERVICE AND ADJUSTMENTS section of this manual

should be checked at least once each season.

MAINTENANCE SCHEDULE

The chart below shows the recommended

maintenance schedule that should be performed on a

regular basis. More frequent service may be required

due to heavy loads or use.

See Engine Manual for further maintenance and

troubleshooting information.

CHECK CLUTCH FUNCTION

WARNING: FAILURE OF CLUTCHES OR

BRAKES may result in death or serious injury.

Check clutch and brake function before each

use. Repair or adjust before operation.

With key in "STOP" position, squeeze auger clutch bail

to Engaged position and pull recoil starter handle.

Auger should rotate with the turning of the engine.

Release the auger clutch bail.

If the auger clutch bail moves freely with no resistance

before contacting handlebar, adjust or repair.

NOTE: The unit will require control cable and/or idler

adjustment after 20 hours of operation on a new unit or

new drive belt. See Service and Adjustments for

instructions.

WARNING: IMPROPER ADJUSTMENT

could result in death or serious injury. AUGER

BRAKE MUST DISENGAGE when clutch is

engaged. BRAKE MUST STOP AUGER

WITHIN 5 SECONDS of releasing auger

clutch bail.

MAINTENANCE

SCHEDULE

Check Clutch Function

Check Fasteners

Clean Engine Cooling

System

Clean Unit

After Each Use

Before Each Use

•

•

Every Season

Every 10 Hours

•

•

CHECK FASTENERS

Keep all nuts, bolts, and screws properly tightened.

CLEAN ENGINE COOLING SYSTEM

Engine is air cooled. Air must circulate freely around

engine to prevent overheating.

Every year (more often if conditions require) remove

cooling shrouds and clean cooling fins. Clean external

surfaces of engine of dust, dirt and oil deposits which

can contribute to improper cooling. Refer to Engine

Manual.

IMPORTANT: DO NOT operate engine with cooling

shrouds removed. Engine overheating and damage will

result.

CLEAN UNIT

After each use, brush snow and debris off with a soft

bristled brush. Occasionally apply a light coat of spray

lubricant to exposed metal joints and surfaces. Wipe off

excess with soft cloth. Do not use abrasives or harsh

cleaners.

IMPORTANT: Take steps to prevent rust and corrosion.

Never spray unit with water or store unit outdoors.

Water can seep into sealed bearings, which are sealed

against dirt and debris only, causing reduced

component life.

GB - 13

Page 14

1. Extension Spring

2. Idler Arm/Brake

3. Idler

4. Slot

5. Belt Fingers

6. Auger Clutch

Control Cable

7. Drive Belt

8. Auger Drive Pulley

9. Cap Screw, Washer, Auger Shaft

OS0053

2

1

3

4

6

5

7

8

9

1/32"-1/16"

(1-1.6 cm)

5 (3HP)

SERVICE AND ADJUSTMENTS

WARNING: ACCIDENTAL ENGINE START

UP can cause death or serious injury.

ALWAYS stop engine, remove key, and wait

for moving parts to stop before performing

maintenance or service.

HOT SURFACES can cause death or serious

injury. DO NOT touch parts which are hot from

operation. ALWAYS allow parts to cool.

CAUTION: FUEL SPILLS may result in minor

or moderate injury and/or damage to unit. If

unit must be tipped, remove enough fuel so

that no spills will occur.

SERVICE POSITION

Place unit on a flat level surface.

TO ADJUST DISCHARGE CHUTE

DEFLECTOR

If discharge chute deflector does not stay in set

position during operation, adjust chute by tightening

fasteners evenly until deflector stays in position.

NOTE: Use a T30 Torx Drive or a 3/16” (.19 cm) wide

Straight Screwdriver to tighten.

TO REPLACE THE DRIVE BELT

1. Remove fuel cap.

2. Remove cowl and replace fuel cap.

3. Disconnect extension spring on idler arm/brake.

4. Remove cap screw and washer from end of auger

shaft and pull off auger drive pulley.

5. Remove old belt.

6. Install new belt onto pulleys

7. Reinstall auger drive pulley and secure with

washer and cap screw

8. Reconnect extension spring to idler arm/brake.

9. Ensure belt finger(s) and auger clutch control cable

are properly adjusted. See To Adjust Belt Finger

and To Adjust Auger Control Cable.

10. Remove fuel cap and replace cowl.

11. Replace fuel cap.

Fasteners

OS0181

GB - 14

TO ADJUST BELT FINGER

3HP units have two belt fingers.

5HP units have one belt finger.

With the auger clutch engaged, there should be 1/32 to

1/16" (1-1.6 cm) clearance between the belt finger and

drive belt.

To adjust:

1. Loosen bolt holding the belt finger.

2. Rotate the belt finger around the bolt to the correct

position.

3. Tighten bolt.

Page 15

TO ADJUST AUGER CONTROL CABLE

1. Idler Arm/Brake

2. Idler

3. Slot

4. Auger Clutch

Control Cable

5. Belt Fingers

OS0053

1

2

3

4

5

1/32"-1/16"

(1-1.6 cm)

5 (3HP)

WARNING: IMPROPER ADJUSTMENT

could result in death or serious injury. AUGER

BRAKE MUST DISENGAGE when clutch is

engaged. BRAKE MUST STOP AUGER

WITHIN 5 SECONDS of releasing auger

clutch bail.

There must ALWAYS be some slight noticeable slack in

the auger control cable when the auger is disengaged.

This allows Extension Spring to pull idler Arm/Brake,

which applies the brake to the Belt.

The auger clutch bail should travel 6-3/4 to 7-1/4”

(17.1-18.4 cm) before contacting handlebar.

A properly adjusted clutch must extend control cable

Spring approximately 1/4 to 3/8” (6-10 mm) before

clutch bail contacts handlebar.

1. Shut off engine.

2. Loosen locknut on threaded section of control

cable adjusting feature.

3. Turn solid section to provide some slight,

noticeable slack in cable.

4. Hold the solid section with a pliers and gently, with

a small wrench, tighten the locknut.

IMPORTANT: If there is still no resistance, the idler

position must be adjusted. See To Adjust Idler Position.

1/4 to 3/8”

1/4 - 3/8"

(6-10 mm)

TO ADJUST IDLER POSITION

The idler must be as close as possible to the drive belt

when the auger clutch is disengaged, but not so close

that it causes auger rotation.

WARNING: ROTATING PARTS can cut off

body parts. Keep hands and feet away. Loose

clothing, long hair or scarves can get caught

in rotating parts and cause death or serious

injury.

To adjust the idler position:

IMPORTANT: If adjustment cannot be achieved, the

Drive Belt must be replaced.

1. Shut off engine, allow to cool, and remove cowl.

2. Ensure control cable has some slight, noticeable

slack when auger clutch is disengaged (bail in

lowered position).

3. Ensure belt fingers are properly adjusted. See To

Adjust Belt Finger.

4. Loosen idler hardware, reposition idler along slot in

idler arm, and tighten hardware.

5. Check for proper extension of control cable spring.

See To Adjust Auger Control Cable.

6. Start engine and ensure auger does not rotate

when auger clutch is disengaged.

7. Shut off engine.

8. Repeat the above steps until proper adjustment is

achieved.

9. Replace cowl.

1. Control Cable

Spring

2. Adjusting Feature

1

2

4

3

5

3. Locknut

4. Threaded Section

5. Solid Section

OS1220

GB - 15

Page 16

STORAGE

UNIT

WARNING: FLAMMABLE FUEL and its

EXPLOSIVE VAPORS can cause death or

serious injury. DO NOT store unit inside a

building with fuel in the fuel tank where any

ignition sources are present. Drain fuel

outdoors away from any ignition source. Allow

engine to cool before storing in any enclosure.

Only use approved fuel containers.

Run with auger clutch engaged a few minutes after

each use to free unit of any loose or melting snow.

Inspect unit for visible signs of wear, breakage or

damage. Order any parts required and make

necessary repairs to avoid delays when beginning use

again.

Keep all nuts, bolts and screws properly tightened and

know unit is in safe working condition.

ENGINE

When storing unit for extended periods of time, remove

all fuel from tank and carburetor (run dry). Refer to

Engine Manual.

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE CORRECTION

Engine will

not crank

Engine will

not start

Engine stops

Discharge

chute will not

turn

Auger will not

turn or throw

snow

1. Ignition switch not in "RUN" position.

2. Bad starter or wire connection.

3. Electrical problem

1. Ignition switch not in "RUN" position.

2. Bad starter or wire connection.

3. Engine ignition problem.

4. Fuel tank is empty.

1. Improperly mixed or contaminated

fuel.

2. No spark.

1. Chute gears are frozen. 1. Move unit to a warm area to thaw.

1. Auger is frozen in place.

2. Ice or debris is obstructing auger.

3. Auger control cable out of

adjustment

4. Drive belt slipping; idler out of

adjustment.

1. Turn key to "RUN" position.

2. Check connections. See your Dealer.

3. Check wiring for wear, damage or poor

connections. See your Dealer.

1. Turn key to "RUN" position.

2. Check connections. See your Dealer.

3. See Engine Manual.

4. Fill tank with properly mixed fuel. Prime

engine, set choke for easier start.

1. Use only clean, properly mixed fuel. If

necessary, drain tank and refill with new fuel

mixture.

2. Check spark plug and connecting wire.

1. Move unit to a warm area to thaw.

2. With engine off, and auger disengaged,

check for obstructions and remove.

3. Adjust cable. See Service and Adjustments.

4. Adjust idler. See Service and Adjustments.

GB - 16

Page 17

SPECIFICATIONS

Model Number 938015 938016

Description 322 522

Engine Power - HP (KW) 2 Cycle

Engine Operating Fast Idle

Speed - RPM

Engine Displacement - cu.

in. (cc)

3 (2.24) 5 (3.73)

4300 3600

6.0 (98) 8.46 (139)

ACCESSORIES

See your authorized Ariens Dealer to add these

optional accessories.

73700100 Electric Starter (3 HP)

73700200 Electric Starter (3 HP) - Canada

73800300 Discharge Chute Crank Kit

73800400 Service Kit (5 HP)

73800500 Service Kit (3 HP)

Fuel See Engine Manual for type

and grade

Fuel to Oil Mix See engine manual.

Fuel Tank Capacity - qt

(Liters)

Fuel Filter Neck Inside Dia.

- in (cm)

120V Electric Start Optional Installed

Snow Clearing Width - in

(cm)

Snow Throwing Distance ft (meters)

Chute Rotation Angle 220°

Chute Inside Dia - in (cm) 6.0 (15.2)

Handlebars Max. Extended

Height - in (cm)

Minimum Folded Height - in

(cm)

Length - in (cm) 43.2 (110)

1.2 (1.1)

2.8 (7.1)

22 (56)

3-30 (0.9-9.1)

40.8 (104)

25.8 (65.5)

SERVICE PARTS

Be sure to always use genuine Ariens parts to keep

your unit running like new.

Part no. Qty Description

07236400 1 Drive Belt (3HP)

07236300 1 Drive Belt (5HP)

Minimum Folded Length in (cm)

Width - in (cm) 22 (56)

Weight - lbs (Kg) 58 (26.4) 75 (38.5)

Auger Dia - in (cm) 9.0 (23)

Auger Speed - RPM 1220 1200

Drive Belt 3L Section, Single “V”

Construction, Raw Edge

Kevlar Cord

Wheel Size - in (cm) 7.0 x 1.5 (18 x 3.8)

34.5 (87.6)

GB - 17

Page 18

2 Year Limited Warranty

Ariens Company warrants to the original purchaser that consumer products manufactured

by Ariens Company will be free from defects in material and workmanship for a period

of two (2) years after the date of purchase, and will repair any defect in material or

Ariens Company

655 West Ryan Street

P.O. Box 157

Brillion, WI 54110-0157

920-756-2141

Fax 920-756-2407

www.ariens.com

This warranty is subject to the following conditions, limitations, and exclusions:

This warranty is valid only if the following conditions are

met:

• The warranty registration card must be completed and

returned to Ariens Company.

• The purchaser must perform maintenance and minor

adjustments explained in the owner’s manual.

• The purchaser must promptly notify Ariens Company or an

authorized Ariens service representative of the need for

warranty service.

This warranty is subject to the following limitations:

• The purchaser must transport the product to and from the

place of warranty service.

• Warranty service must be performed by an authorized Ariens

service representative. (To find an authorized Ariens service

representative, contact Ariens Company at the number or

address above.)

• Batteries are warranted only for a period of twelve (12)

months after date of purchase, on a prorated basis. For the

first ninety (90) days of the warranty period, a defective

battery will be replaced free of charge. If the applicable

warranty period is more than 90 days, Ariens Company will

cover the prorated cost of any defective battery, for up to

twelve(12) months after the date of purchase.

workmanship, and repair or replace any defective part, subject to the conditions, limitations

and exclusions set forth herein.

The two year duration of this warranty applies only if the product is put to ordinary,

reasonable, and usual personal, family, or household uses. If the product is put to any

business, commercial, or industrial use such as, but not limited to, commercial landscaping,

mowing or snow removal services, or golf course or park maintenance, or agricultural

or farmstead use, then the duration of this warranty is ninety (90) days after the date

of purchase, or one (1) year after the date of purchase if the product is labeled as a

Professional/Commercial Product. If any product is rented or leased, then the duration

of this warranty is ninety (90) days after the date of purchase.

Genuine Ariens service parts and accessories not purchased with the product covered

by this warranty, but which are later purchased and used with that product, are warranted

to be free from defects in material and workmanship for a period of ninety (90) days

after date of purchase, and Ariens Company will repair or replace any such part or

accessory free of charge, except for labor, during that period.

The following items are not covered by this warranty:

• Engines and engine accessories are covered only by the

warranty made by the engine manufacturer, and are not

covered by this warranty.

• If the product is equipped with a Peerless gearbox and/or

transmission, the gearbox and/or transmission are covered

only by the warranty made by Peerless, and are not covered

by this warranty.

• Parts that are not genuine Ariens service parts are not

covered by this warranty.

• Shoes, runners, scraper blades, shear bolts, mower blades,

mower vanes, trimmer line, headlights, light bulbs, are not

covered by this warranty.

• Any defect which is the result of misuse, alteration, improper

assembly, improper adjustment, neglect, or accident, is not

covered by this warranty.

• Products which were not purchased in the United States,

Puerto Rico, or Canada are not covered by this warranty.

LIMITATION OF REMEDY AND DAMAGES

Ariens Company’s liability under this warranty, and under any

implied warranty that may exist, is limited to repair of any

defect in workmanship, and repair or replacement of any

defective part. Ariens Company shall not be liable for incidental,

special, or consequential damages (including lost profits).

Some states do not allow the exclusion of incidental or

consequential damages, so the above limitation or exclusion

may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

DISCLAIMER OF FURTHER WARRANTY

Ariens Company makes no warranty, express

or implied, other than what is expressly made

in this warranty. If the law of your state provides

that an implied warranty of merchantability, or

an implied warranty of fitness for particular

purpose, or any other implied warranty, applies

to Ariens Company, then any such implied

warranty is limited to the duration of this

warranty. Some states do not allow limitations

on how long an implied warranty lasts, so the

above limitation may not apply to you.

Form: ALW2-031500

GB - 18

Page 19

DURA-CLEAN™ Auger

s

t

y

e

b

e

Limited Lifetime Warranty

Ariens Company

655 West Ryan Street

P.O. Box 157

Brillion, WI 54110-0157

920-756-2141

Fax 920-756-2407

This warranty is subject to the following exceptions, conditions, and limitations:

Usage Requirement

The lifetime limited warranty shall apply if the product is put

to ordinary, reasonable, and usual personal household use.

If the product is put to any business, commercial, industrial,

rental, or leased use, the warranty shall be against defects

in material and workmanship for ninety (90) days following

the date of purchase.

Ariens Company may from time to time change the design of its products. Nothing contained in this warranty shall b

construed as obligating Ariens Company to incorporate such design changes into previously manufactured products

shall such changes be construed as an admission that previous designs were defective.

Ariens Company hereby warrants to the original purchaser that the rubber component

of the DURA-CLEAN™ Auger manufactured by Ariens Company will be free from

defects in material and workmanship and will not wear out for the life of the snothro, except as noted below.

Protection Plan

Ariens Company will provide for the replacement of any of the rubber components

of the DURA-CLEAN™ Auger found upon examination by the Ariens Company to

be defective or worn out. Replacements will be supplied free of charge. Labor is no

included after two (2) years from the date of purchase of the sno-thro.

Exclusions (No Warranty)

There will be no warranty coverage if the product has

altered, misused, mis-assembled, improperly adjusted

neglected, damaged by accident, or if service is compl

by someone other than an authorized Ariens dealer.

This warranty applies only to products purchased in th

United States (including Puerto Rico) and Canada. In

other countries, contact place of purchase.

LIMITATION OF REMEDY AND DAMAGES

Ariens Company’s liability under this express warranty, and

under any implied warranty that may exist, is limited to repair

or replacement of any defective part. In no event shall Ariens

Company be liable for incidental, special, or consequential

damages (including lost profits). This warranty gives you

specific legal rights. You may also have other rights which

vary from state to state. Some states do not allow the

exclusion of incidental or consequential damages, or

limitations on how long an implied warranty lasts, so the

above limitations and exclusions may not apply to you.

DISCLAIMER OF FURTHER WARRANTY

Ariens Company makes no warranty other tha

what is expressly made in this warranty. If the

of your state provides that an implied warrant

merchantability, or an implied warranty of fitn

for a particular purpose, applies to Ariens Comp

any such implied warranty is limited to the dura

of this express warranty.

GB - 19

Page 20

Ariens Company

655 West Ryan Street

P.O. Box 157

Brillion, WI 54110-0157

920-756-2141

Fax 920-756-2407

www.ariens.com

Loading...

Loading...