Page 1

CT^iens

Series

A SAFETY MESSAGE A

The product for which you have requested

information or repiacement parts is not a

current product. The repiacement models

incorporate product designs, safety features,

safety instructions or warnings which repre

sent the latest "State Of The Art” develop

ments. For your safety and those around you

please contact your nearest Ariens/Gravely

Dealer for a demonstration of the current

product safety provisions and features.

Owner's

Sno-Thro

Manual

Page 2

A Message to Ariens Customers...

Welcome to the world of Ariens equipment. We are

pleased that you have purchased the best equipment

available. The care you give your Ariens equipment

will determine the satisfaction and service life you will

obtain from it. Use this manual, and the engine

manual supplied, as your guide. By observing the

instructions and suggestions in these manuals, your

Ariens equipment will serve you well for many years.

Your Ariens dealer will be happy to supply any

service or advice which may be required to keep your

Ariens equipment operating at peak efficiency. He

stocks genuine Ariens parts and lubricants

manufactured with the same precision and skill as the

original equipment. His factory trained staff is kept

well informed on the best methods of servicing Ariens

equipment and is ready and able to serve you. If

engine repair or service is required, they can be

Safety Alert Symbol And Notations

obtained from an Ariens dealer or from an authorized

engine manufacturer's service center. If service is

required, be prepared to supply the sen/ice person

with the Model and Serial Number of the equipment

and the engine, as well as a full description of the

problem encountered.

NOTE: The descriptions and specifications

contained in this manual were in effect at the time the

manual was approved for printing. Ariens Company

reserves the right to discontinue models without

notice and without incurring obligation. The

equipment described within this manual may not be

identified as either standard or optional and the

various illustrations may not all be applicable to your

particular unit. If you have questions, always check

with your Ariens dealer.

The following safety notations are used throughout

this manual to call attention to special information or

operating procedures. Understand the message in

each notation and be alert to unsafe conditions and

the possibility of personal injury.

NOTE: A NOTE points out general reference

inforrriation regarding proper operation and

maintenance practices.

IMPORTANT: An IMPORTANT statement indicates

specific procedures or information that is required to

prevent damage to the machine or its attachments.

This safety alert symbol is used to

attract your attention! PERSONAL

A

SAFETY IS INVOLVED! When you see

this symbol - BECOME ALERT - HEED

ITS MESSAGE.

A

A

A

CAUTION: A CAUTION identifies safe

operating practices or indicates unsafe

conditions that could result in personal

injury.

________________________________

WARNING: A WARNING describes a

condition where failure to follow the

instructions couid result in severe

personal injury.

DANGER: A DANGER designates a

condition where failure to follow

instructions or heed warning will most

likely result in serious personal injury

or death.

Page 3

Contents

Model

IT Accessory..............................................................12

Adjustments........................................................10

Controls and Features........................................ 5

Decals....................................................................3

Lubrication and Maintenance

Operation

Preparation for Operation

Safety Alert Symbol and Notations

Safety Precautions

Specifications.....................................................12

Storage...............................................................

Warranty

Specific Model and Serial Numbers are on a label

located on the frame of your Rotary Brush and on a

label located on the product registration.form.

Record those numbers below and transfer the label

from the product registration to place indicated below.

Use these numbers whenever parts or service is

required.

.............................................................

..............................................

.............................................................

......

.......................

...................................

.....................

12

14

r

TRANSFER

I

Model Number

Serial Number.

I

I

.1

I

MODEL SERIAL

LABEL FROM

PRODUCT

REGISTRATION

6

Model 937004 Ariens Recoil Start

3 H.P. 21" Two Stage Sno-Thro

Serial No. 000101 and up.

9

4

i

1

NOTE: All references to “Left”, “Righf, “Front” and

“Rear'’ are given from operator’s position.

Safety Precautions

Training

Read and understand this Owner's Manual and

engine instructions before operating unit. Be

thoroughly familiar with controls and proper use of

equipment. Know how to stop unit and disengage

control quickly in an emergency.

Use only accessories designed for your unit. See

your Ariens Dealer for a complete list of accessories.

Understand and follow each Danger, Warning,

Caution and instruction decal installed on equipment.

NEVER allow children to operate equipment. DO

NOT allow adults to operate unit without proper

instructions.

Keep the area of operation clear of all persons,

particularly children and pets.

©Ariens 1994

Safe operation of this equipment requires your

complete and unimpaired attention at all times. DO

NOT operate unit after or during the consumption of

medication, drugs or alcohol.

Preparation

Before first snowfall of the season clearly mark

location of all obstacles (such as driveway markers,

water or gas shut off and etc.) so that they can be

avoided when throwing snow.

Thoroughly inspect and clear work area of objects

which might be picked up and thrown. Remove all

doormats, sleds, boards, wires, bones and other

foreign objects.

Wear adequate winter outer garments, gloves and

rubber footwear which will improve footing on slippery

surfaces.

Part Number 037097A

Printed in U.S.A.7/94

Page 4

Safety Precautions (Continued)

Wear eye protection such as safety goggles to

protect eyes from objects that may be thrown from

machine.

DO NOT wear loose clothing or scarves that may get

caught in rotating parts of unit.

Gasoline is highly flammable and its vapors are

explosive. Handle with care. Use an approved

(RED) fuel container.

NEVER allow smoking materials, sparks or flame

(match, pilot light, etc.) near equipment or fuel

container.

Check fuel supply before starting engine. Fill fuel

tank outdoors with extreme care; DO NOT fill fuel

tank indoors, when engine is running or while engine

is still hot from operation. Replace fuel cap securely

and wipe spilled fuel before starting engine.

DO NOT use unit on loose gravel that may be picked

up and thrown out discharge chute causing damage

or injury.

NEVER attempt to make any adjustments to unit

while engine is running (except where specifically

recommended).

Operation

DO NOT put hands or feet near rotating parts,

clear of discharge opening at all times.

Check function of all controls before starting engine.

Keep all safety devices and guards in position and

operating properly or personal injury may result.

Open doors if engine is run in garage, exhaust fumes

are dangerous. DO NOT run engine in an enclosed

area.

Operate equipment only when there is good visibility

and tight.

Always be sure of your footing (walk never run).

Exercise caution to avoid slipping or falling.

Disengage power to auger/impeller when unit is

being transported or is not in use.

Keep

DO NOT overload machine capacity by attempting to

clear snow at too fast a rate.

NEVER direct discharge of material toward

bystanders nor allow anyone in front of equipment

while unit is in operation. Be familiar with area of

operation.

Stay alert for holes, rocks, roots and hidden hazards

in area of operation.

Exercise extreme caution when operating on or

crossing gravel drives, walks or roads. Stay alert for

hazards and traffic. DO NOT operate unit near glass

enclosures, automobiles, window wells, drop-offs,

etc., without proper adjustment of discharge direction

and angle.

DO NOT clear snow across face of slopes. Exercise

extreme caution when changing direction on slopes.

DO NOT attempt to clear steep slopes.

Stop engine, remove key and wait for moving parts to

stop before leaving operator's position for any reason

such as; unclogging auger/impeller housing or

discharge chute, when making any repairs,

adjustments, inspections or cleaning unit.

DO NOT touch equipment parts which might be hot

from operation. Before attempting to maintain, adjust

or service allow such parts to cool.

If equipment vibrates abnormally, disengage

attachment, stop engine at once, and remove key.

Abnormal vibration is a warning of trouble. Repair

any damage before restarting unit.

After striking a foreign object, stop engine, remove

key and wait for moving parts to stop before leaving

operator's position. Thoroughly inspect unit for any

damage and repair damage before restarting and

operating unit.

Run unit a few minutes after throwing snow to

prevent freeze up of auger/impeller in housing.

Take all possible precautions when leaving unit

unattended, such as disengaging power to

attachment, stopping engine and removing key to

prevent unauthorized use.

Page 5

Safety Precautions (Continued)

Maintenance and Storage

DO NOT change engine governor setting or

overspeed engine.

Keep aii nuts, bolts and screws tight and be sure

equipment is in safe working condition. Check all

hardware at regular intervals.

Refer to Owner's Manual for important instructions if

Sno-Thro is to be stored for extended periods.

Never store equipment with fuel in tank inside a

building where fumes mdy resbh an open flame or

spark. Allow engine ff.. eool before storing in any

enclosure.

Maintain or replace safety and instruction decals as

necessary.

Page 6

SAFETY INSTRUCTIONS

TO AVOID POSSIBLE INJURY READ

OWNERS MANUEL AND UNDERSTAND

PURPOSE OF ALL SAFETY ALERTS

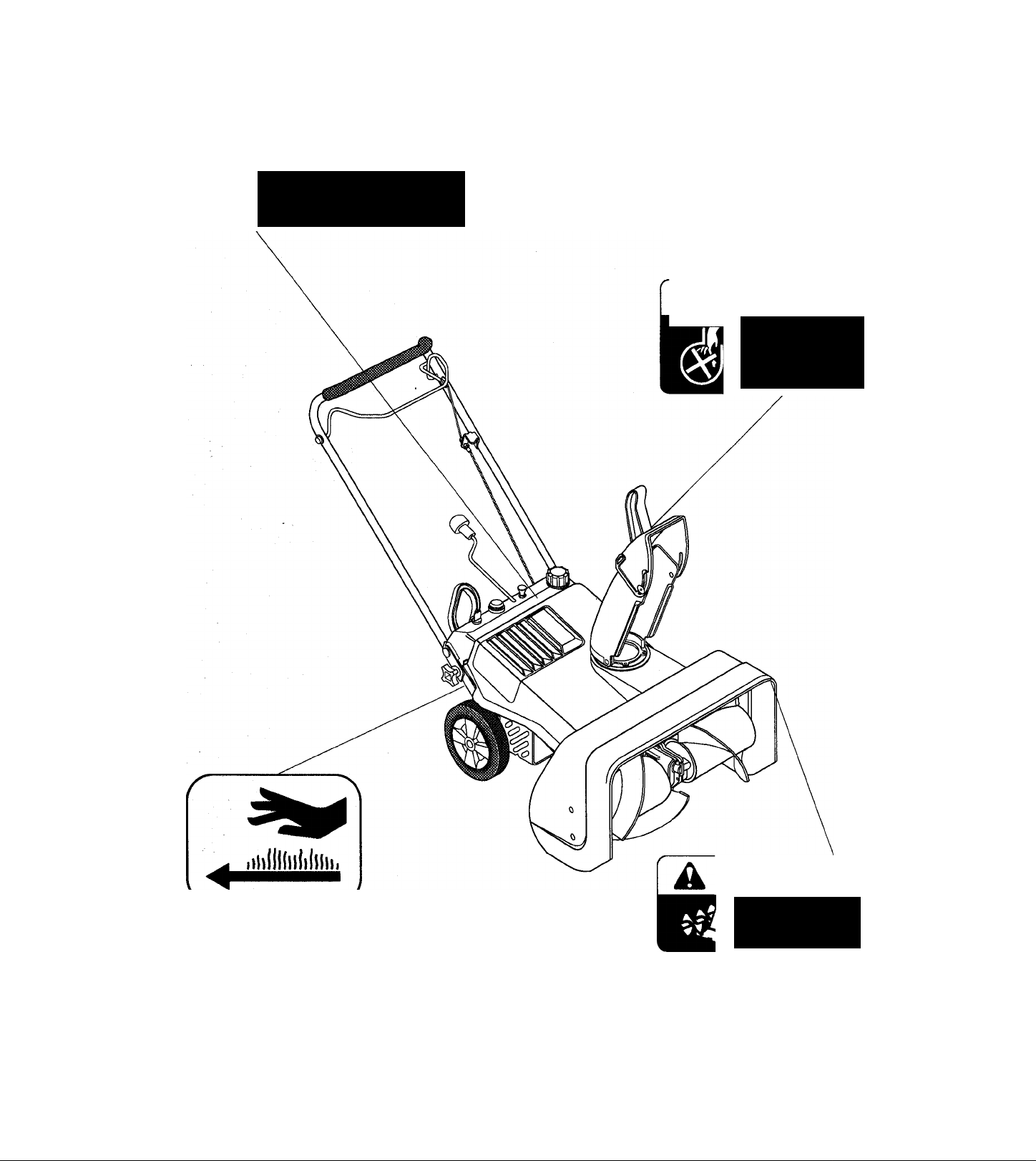

Safety Decals

A DANGER

ROTATING

PARTS

Stop engine &

remove ignition

key before clearing

Figure 1: Decal Locations

4

DANGER]

Keep clear of

auger while

engine is running.

Page 7

Dealer Preparation For Operation

Customer Note: Your Ariens Dealer is expected to

complete these preparation steps and review

important information, including this manual, with you

before or upon delivery of machine or attachment.

The preparation information is included here so that

you and your dealer may review it together.

WARNING: Failure to follow all

instructions could result in personal

A

IMPORTANT: 2 cycle engines require that oil be

mixed with fuel. Refer to Fuel in Operation Section of

this manual for recommended mixture.

Discharge Chute

Remove rear cap screws and nuts from rear of

discharge chute, tip discharge chute up and install

hardware just removed. Tighten hardware at rear of

discharge chute first then at sides.

injury and/or damage to sno-thro.

Remove wire from spark plug before

attempting any adjustment or assembly

procedure.

Engine Fuel

WARNING: Gasoline is highly

A

A

Fill fuel tank with unleaded gasoline and oil mixture.

Tank capacity is 1 quart.

Registration

Complete Sno-Thro Prewarranty Registration Form

and mail original copy to Ariens Company.

Warranty is registered under model and serial

number found on a label on unit.

Delivery

flammable and its vapors are explosive.

Handle with care. Use an approved

(RED) gasoline container.

CAUTION: Check function of all

controls before starting engine. All

safety devices and guards must be in

position and operating properly or

personal injury may result.

Discharge Chute Crank

With discharge chute facing forward, remove engine

cover. With knob down, place Discharge Chute

Crank rod through hole in dash panel and into pinion

on discharge chute. Secure with hair pin. Replace

enginecover.

Handlebar

Attach upper handlebar to lower using washers,

washers, lock bars and knobs.

Refer to Adjustments Section and check Attachment

Brake and Clutch for proper function.

Auger Gear Case

Check grease level in auger gear case (refer to

Lubrication and Maintenance Section of this manual).

lock

Using the Owner's Manual instruct the customer on

controls and operation of unit. Emphasize safety and

discuss the Safety Precautions.

Explain recommended lubrication and maintenance

of unit.

Advise customer on adjustments.

Explain Ariens Company, Limited Warranty Policy, fill

out Original Purchaser Registration Card, Parts and

Repair Manuals order Form and return to Ariens

Company. Place Model and Serial Number on page

(1) of this manual.

Give customer his Owner's Manual and advise him to

thoroughly read and understand Sno-Thro Owner's

Manuals.

Page 8

Controls and Features

O

1. Chute Bail

2. Fuel Tank and Cap 10.

3. Chute Deflector

Discharge Chute

4.

Auger/Impeller Housing 13. Primer Bulb

5.

Auger 14. Chute Crank

6.

Scraper Blade 15. Choke

7.

Impeller

8.

Figure 2: Control and Feature Locations

6

9. Handlebar Knob

Lock Bar

11. Recoil Starter

12.

Key Switch

Page 9

A

Operation

WARNING: Wear adequate winter outer

garments and footwear which will

improve footing on slippery surfaces.

Wear eye protection such as safety

goggles to protect eyes from objects

that may be thrown from machine. DO

NOT wear loose clothing or scarves

that may get caught in rotating parts of

unit.

Ariens 2 cycle oil has been formulated to insure

maximum engine performance and increased engine

life. Premix Ariens oil (1-50 ratio) per instructions on

container. If Ariens oil is not available, select a

quality 2 cycle oil BIATC (Boating Industry

Association Two Cycle) approved oil and use

unleaded gasoline.

If oil manufacturer does not recommend mixing ratio,

mix at the 1 to 50 ratio.

CAUTION: Make sure all hardware is

tight, all safety devices in place and all

A

IMPORTANT: Check impeller to be sure it is not

frozen. With key in its off position move clutch bail to

engaged position, and pull recoil starter. If impeller is

frozen, (can not pull recoil starter) move Sno-Thro to

a heated area and thaw to prevent possible damage

to unit.

NOTE: This product is equipped with an internal

combustion engine. DO NOT use unit on or near any

unimproved, forest-covered or brush-covered land

unless exhaust system is equipped with a spark

arrester meeting applicable local, state or federal

laws. A spark arrester, if it is used, must be

maintained in effective working order by operator.

Fuel

IMPORTANT: Failure to mix oil with gasoline will

result in seizure and severe damage to engine. DO

NOT use gasohol or gasoline containing alcohol

because alcohol will attack and cause internal parts

to deteriorate.

NOTE: To prevent foreign particles from entering

tank while filling: wipe snow, dust, dirt and debris

from around cap before removing.

A

adjustments correct.

WARNING: Gasoline is highly

flammable and must be handled with

care. Allow engine to cool several

minutes before removing fuel tank cap.

Never fill tank when engine is running

or hot from operation. DO NOT allow

open flame, matches, or smoking in

area. DO NOT overfill. Wipe up any

spills and allow vapors to dissipate.

Use approved (RED) gasoline

container.

NOTE: After fuel mixture has been left standing for a

prolonged time it will begin to separate, therefore

thoroughly shake mixture before using.

Chute Deflector

Position Deflector at desired height. DO NOT throw

snow any higher than necessary.

NOTE: Tighten locking hardware on chute deflector

if it does not stay in set position.

Discharge Chute Crank

DANGER: DO NOT put hands or feet

near or under rotating parts. Keep clear

A

A

IMPORTANT: DO NOT operate Sno-Thro near glass

enclosures, automobiles, window wells, drop off etc.,

without proper adjustment of discharge direction and

angle.

Direct snow away from area to be cleared and with

direction of wind whenever possible. Crank rotates

chute 210 degrees.

Snow is best removed as soon as possible after a

snow fall.

of discharge opening at all times.

WARNING: NEVER direct discharge of

material toward bystanders nor allow

anyone in front of equipment while unit

is in operation. Be familiar with area of

operation.

Page 10

Operation (Continued)

starting

CAUTION: DO NOT attempt to start

A

NOTE: Try out each control without running engine

to see how they work and what they do.

your engine at this time. Thoroughly

read this entire Owner's Manual and

engine manufacturers operating

instructions first.

Figure 3: Engine Ignition

Primer Bulb

Push primer bulb two or three times when engine is

cold. When temperatures are below -15 degrees

Fahrenheit, additional priming may be needed.

Recoil Starter

WARNING: To prevent discharge

A

Stand to right of unit. Grasp starter handle and pull

rope out slowly until it pulls harder, this is

compression stroke, let rope rewind slowly.

Then pull rope with a rapid continuous full arm stroke.

Let rope rewind slowly.

IMPORTANT: DO NOT let starter handle snap

against bracket.

Repeat above instructions until engine starts. (Refer

to engine manufacturers instructions).

toward operators' starting position,

always turn discharge chute straight

ahead for starting unit.

Engine Ignition

WARNING: If equipment vibrates

abnormally disengage attachment, stop

A

A

To start engine, place Key in Switch and turn it

clockwise to "RUN" position.

Choke

Pull choke control to “Choke" position. When engine

has started, open choke gradually.

NOTE: A warm engine requires less choking than a

cold engine.

engine at once, and remove key.

Abnormal vibration is a warning of

trouble. Repair any damage before

restarting unit.

CAUTION: Turn Key "OFF" and remove

it before attempting any maintenance,

adjustment or leaving unit unattended.

Electric Starter (Optional Accessory)

Connect power cord to switch box first then plug

other end into 120 volt AC receptacle.

Push Starter Button to crank engine.

IMPORTANT: This electric starter is not equipped

with a thermal cut-out switch. DO NOT crank engine

for more than a total of 20 seconds without allowing

electric starter to cool down for 10 minutes. Failure

to do this can severely damage electric starter.

When engine starts, release starter button and

disconnect power cord from receptacle first, then

from switch box.

CAUTION: DO NOT overload machine

A

capacity by attempting to clear snow at

too fast a rate.

Page 11

CAUTION: Operate equipment only with

A

A

Clutch Bail

good visibility and light.

CAUTION: Stay alert for holes, rocks,

roots and hidden hazards in area of

operation. Exercise extreme caution

when operating on or crossing gravel

drives, walks or roads. Slay alert for

hidden hazards or traffic.

Operation (Continued)

During snow removal, auger propels unit forward

while collecting snow. The forward speed will vary

according to snow depth and moisture content, and

scraper blade adjustment.

Efficient unit operation depends on proper scraper

blade adjustment. Refer to Scraper Blade in

Adjustment Section.

NOTE: When transporting, unit should be shut off.

To transport unit to or from an area to be cleared,

press down on handlebar enough to raise front of

Sno-Thro slightly off surface and push or pull unit.

%

CAUTION: Stop engine and remove

wire from spark plug after striking a

A

Snow is best removed as soon as possible after a

snow fall. Squeezing Clutch Bail against handlebar

engages auger and impeller so machine will move

forward and throw snow. Releasing Bail disengages

auger and impeller and brake stops rotation.

IMPORTANT: Check impeller to be sure it is not

frozen. If belt squeals when Clutch Bail is engaged,

impeller is frozen, release Clutch Bail and move unit

to a heated area to thaw.

A

foreign object. Thoroughly inspect snothro for any damage and repair damage

before restarting and operating unit.

CAUTION: Check clutch disengagement

before each use. If auger/impeller does

not stop quickly, when clutch bail is

released, adjust or repair per

Adjustment Section of this manual

before operating unit.

To clear an area, run Sno-Thro in an overlapping

series of paths. For large areas start in middle and

throw snow to each side so you do not have to move

it more than once.

Stopping

WARNING: Take all possible

precautions when leaving unit

A

IMPORTANT: Run attachment a few minutes after

throwing snow to prevent freeze-up of auger/impeller.

Release Clutch Bail and turn engine Ignition Key to

"OFF".

unattended. Such as disengaging

power to attachment, stopping engine

and removing key to prevent

unauthorized use.

Page 12

Lubrication and Maintenance

Ariens Dealers will provide any service which may be

required to keep your Sno-Thro operating at peak

efficiency. Should engine service be required, it can

be obtained from an Ariens dealer or an authorized

engine manufacturer's service center.

WARNING: Stop engine, remove key

and wait for moving parts to stop before

A

A

Engine Cooling

Engine is air cooled. Air must circulate freely around

engine from air intake screen, over cooling fins on

cylinder head and block, to prevent overheating.

attempting any lubrication or

maintenance procedures.

CAUTION: DO NOT touch engine or

Sno-Thro drive parts which are hot from

operation. Allow such parts to cool

before servicing unit.

Every 100 operating hours or yearly (more often if

conditions require) remove cooling shrouds and clean

cooling fins. Also clean external surfaces of engine

of dust, dirt and oil deposits which can contribute to

improper cooling.

IMPORTANT: DO NOT operate engine with cooling

shrouds removed, this will cause overheating and

engine damage.

Drive Belts

WARNING: Gasoline is highly

flammable and its vapors are explosive.

A

A

Handle with care. Never allow smoking

materials, sparks or flame (match, pilot

light, etc.) near equipment or fuel

container.

CAUTION: When unit is tipped up onto

housing, remove enough fuel so that no

spillage will occur.

1. Auger/Impeller Drive

Belt

2. Engine Drive Belt

3. Idler

4. Idler Pin

5. Extension Spring

6. Compression Spring

Washer

7.

8.

Lock Nut

9.

Pivot Bracket

Hair Pin

10.

Bracket Pin

11.

Pin Plate

12.

13. Cap Screws

10

Figure 4: Drive Belts

Page 13

Lubrication and Maintenance (Continued)

When replacing belts, replace both belts at same

time. To replace drive belts, disconnect extension

spring and relieve compression of compression

spring on pivot bracket.

Remove idler pin from idler and bracket then idler

from machine.

Remove two hair pins from bracket pin. Cap screw

from pin plate and pin and plate from unit.

Remove pivot bracket and belts from unit.

Install new belts in reverse order.

NOTE: Make sure pulleys align. If-alignment is

necessary, loosen pin plate cap screw, align belts

and tighten cap screw.

Auger Gear Case

IMPORTANT: Too much lubricant may cause

excessive leakage. Too little lubricant will cause gear

and/or bearing darhage.

Gear cases are filled to the correct level at the

factory. Unless there is evidence of leakage, no

additional lubricant should be required. Check for

evidence of leakage every 25 hours of operation.

To insure adequate oil level, (2 oz. mininum), the

following checking procedure is recommended,

especially if there is evidence of leakage. Find a flat

level surface adjacent to a vertical surface (floor next

to wall or post etc). Make a mark on the vertical

surface with marker or tape 10.0 inches up from the

flat level surface. (One inch wide masking or

wrapping tape works especially well).

Remove the gear case oil fill plug. Wipe the inside

end clean with a soft cloth and replace finger tight.

Move the front of the sno thro near the vertical

surface and slowly raise the handlebars until the

mark is seen at the top of the auger/impeller housing.

Count to 100 while holding at the position to insure

that the lubricant has had time to seek a stable level.

Return the sno thro to its level operating position and

remove the gear case oil fill plug to determine if the

end previously wiped clean has been “wetted” by the

lubricant. If so, lubricant level is adequate. Replace

the fill plug.

'A

1. Auger Gear Case

2. Gear Lube Fill

3. Ariens Special L-2 Gear Lube

Figures: Auger Gear Case

When adding lubricant, add only Ariens special gear

lube L-2 (Part Number 000080). After adding

lubricant, you may want to check to insure the level is

not too high. To do this, repeat the above procedure

with the mark on the vertical surface one inch higher.

Allow plenty of time to drain at this position with the

fill plug removed. 5 inch high blocks inserted under

the wheels of all models serve well to hold them in a

“drain-to-maximum-level” position.

11

Page 14

Adjustments

Ariens Company recommends that you have

adjustments made by your Ariens dealer. He has

tools and the know-how to properly perform

adjustments which may be required to keep your

Sno-Thro operating at peak efficiency. Should you

decide to make the following adjustments on your

Sno-Thro yourself, Ariens Company recommends

that you call your dealer for answers to any questions

that might arise.

WARNING: Gasoline is highly

flammable and Its vapors are explosive.

A

A

Scraper Blade

A

Handie with care. Never aiiow smoking

materials, sparks or flame (match, pilot

light, etc.) near equipment or fuel

container.

CAUTION: When unit is tipped up onto

housing, remove enough fuel so that no

spillage will occur.

CAUTION: DO NOT use this machine on

loose gravel. Gravel may be picked up

and thrown from discharge chute

resulting in damage to nearby property

and/or injury to bystanders.

To adjust scraper blade, tip unit back and rest unit on

handlebar. Loosen nuts on carriage bolts along

scraper support. If unit does not scrape cleanly,

move scraper blade forward. If unit does not drive

forward and scraper blade drags, move scraper blade

to the rear.

NOTE: Tighten hardware and test unit. Repeat

adjustment as required until proper operation is

obtained.

Engine Belt

CAUTION: For proper braking and

engine belt engagement, with Clutch

A

To adjust, turn nuts on upper cable end until there is

the proper spring extension and lock in position by

locking nuts against bracket.

Bail disengaged, there must be slack in

cable. There should be 3/16" to 1/4"

extension of cable spring when Clutch

Bail Is held against handlebar.

1. Scraper Blade

Figures-. Scraper Blade

Scraper Blade is adjustable to compensate for wear

and to control auger traction (auger propels unit).

Adjust scraper blade equally its full length if machine

does not scrape cleanly or if machine does not drive

forward properly.

2. Carriage Bolts

and Nuts

12

Page 15

Adjustments (Continued)

Belt Alignment

When replacing belts, replace both belts at the same

time. To align belts, loosen pin plate cap screw, align

pulleys and secure with cap screw.

Auger/Impeller Belt

For proper tension of auger/impeller belt, tip unit up

on auger/impeller housing. Check that idler pin is in

position with flat of pin toward center of unit.

Loosen lock nut far enough so that compression

spring and washer are free to rotate. Then tighten

nut until spring no longer turns freely. From this

position, tighten lock nut exactly eight (8) turns to

provide proper tension on auger/impeller belt.

WARNING: With improper use injury

may result if clutch bail is released and

A

brake DOES NOT STOP auger/impeller

within 5 seconds.

1. Lock Nut

2. Compression Spring

3. Idler Pin

Figure 8: Auger/impeller Belt Adjustment

m

13

Page 16

PRODUCTS

GUARANTEE

LEVIITED

WARRANTY

PROTECTION PLAN

• The Company will provide for the replacement of any

part found upon examination by the Company to be

defective. Such repair or replacement will be free of

charge to the purchaser (labor and parts) for two years

(24 months) from the date of purchase. Ariens

manufactured parts (but not labor) will be free of charge

for an additional thme years (36 months) thereafter

This warranty Is subject to the following exceptions and limitations:

PURCHASER RESPONSIBILITIES -

• Maintenance & minor adjustments per owners manual

• Notification of need for warranty senrice

• Transportation to/from place of warranty repair

PRODUCT REGISTRATION -

• Return of registration card required to validate

warranty

PURCHASED COMPONENTS AND NORMAL WEAR -

• TWO year labor and parts on purchased components

i.e., (tractor drive train components manufactured by

'PURCHASED!

W»R

Dana, Eaton, Foote, Sundstrand and any plastic and

electrical components, wire harnesses, bags, boots

tubes, etc.).

• Two year labor and parts on normal wear items i.e.,

(belts and rubber components, bearings, cables,

controls, clutches, tines, etc,).

BATTERY WARRANTY PRORATED -

• One to six months • free replacement

• Seven to twelve months - 50 % credit

• Thirteen to twenty-four months - 25% credit

WARRANTY - COMMERCIAL PRODUCTS -

• One year parts and labor

• Product labeled commercial / professional

• Household use - 5 year limited warranty applies

RENTAL USE - ALL PRODUCTS

• NINETY DAYS LABOR & PARTS

CONSUMER PRODUCT - PUT TO

COMMERCIAL, INDUSTRIAL, INSTITUTIONAL USE

• NINETY DAYS LABOR & PARTS

SERVICE PARTS AND ACCESSORIES -

• NINETY DAYS LABOR & PARTS

Ariens Company hereby wanarrts to the original consumer purchaser that

products manutaetured by Ariens Company will be free from defects In material

and worionwishlp FOR A PERIOD OF FIVE (SI YEARS FROM THE DATE OF

PURCHASE EXCEPT AS NOTED BELOW.

SERVICE -

• For warranty service, contact any Ariens Distributor or

[c4lem

Ariens Company reserves the right to Incorporate any changes in design

Into its products without obligation to make such changes on products

previously manufactured.

DISCLAIMER OF FURTHER WARRANTY

There Is no other express warranty. Implied warranties. Including any

warranty of merchantability or fitness for a particular purpose, are limited

to the duration of this written warranty, and are excluded to the extent

permitted by law. There are no warranties which extend beyond the

description of the product contained herein. In no event shall the company

be liable for Indirect, special or conaequentlal damages (such as loss of

anticipated profits) In connection with the consumer's use of the product.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state. Some states do not allow the

exiuslon of Incidental or consequential damages, or limitations on how

tong an Implied warranty lasts, so the above limitation and exclusions may

not apply to you.

Dealer. For the name and location of the Ariens

Distributor or Dealers In your area, and for further

warranty information, write or call the Ariens

Company,

ENGINES, ENGINE ACCESSORIES, AND

PEERLESS PRODUCTS -

• Covered only by manufacturer's warranty.

EXCLUSIONS -

• No warranty Is extended to blades, mower vanes, skid

shoes, runners, scraper blades, shear bolts, light

bulbs, headlights and any equipment which has been

altered, misused, misassembled. Improperly

adjusted,neglected, or damaged by accident.

• No warranty Is extended for service completed by

someone other than an authorized distributor or

dealer.

• No warranty Is extended on any parts that are not

genuine Ariens service pans.

Iffk CnIM

onrkns

14

Page 17

Ask your dealer for information about these other fine Ariens Products:

Front and Rear Tine Tillers

21" Walk-Behind Lawn Mowers

Walk-Behind Sno-Thros

Rear Engine Riding Mowers

Yard and Garden Tractors

Commercial Walk-Behind and Riding Mowers

cHrlens

® P.O. Box 157

Ariens Company

655 W. Ryan Street

Brillion,WI 54110-1098

Loading...

Loading...