Page 1

OWNBS MANUAL

SERIAL NUMBER

cAnimi

lOHHP

MODEL NO. 931014 S-10G

MANUAL LIFT W/FRONT AND

REAR ROCKSHAFT

SERIAL NO. 000101 AND UP

MODEL NO. 931013 S-14G

HYDRAULIC LIFT W/FRONT AND

REAR ROCKSHAFT

SERIAL NO. 000101 AND UP

PART NO. 31974

fianInllwMR

ARIENS COMPANY

BRILLION, WIS. 54110

Page 2

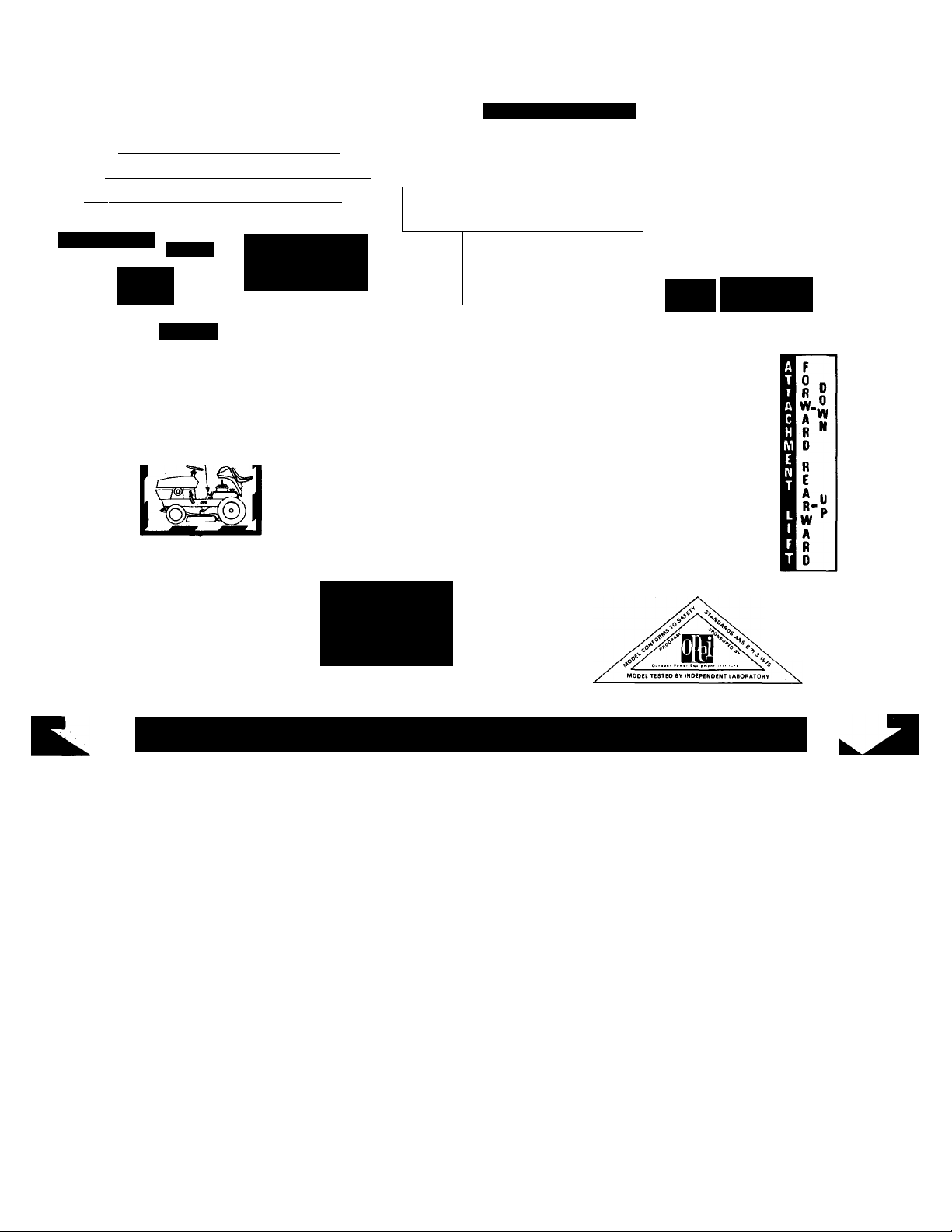

DECALS FOR MODELS 931013 & 931014 GEAR TRACTOR

WARNING

•BRAKES Will NOT STOP TRACTOlf >

<;UNLESS CLUTCH PEDAL IS DEPRESSED”

^3r"sHIFT selector is in NEUTRAL.Xji^

LIFT SELEQOR

REAR LIFT

‘FRONT AND

CENTER LIFT

78392

©CAUTION

KTOW [MSCOMNtC‘tl^l6

HVOWtK P«OK F«0"* TMOTO«,

ItekCMK FLOAT

PARKING BRAKE

UEPRL'SS BRAKE PEDAL

!HEN ENGAGE PARKING/'N^

BRAKt lOCK />G j

S-l-TE/y

S-14G R.H. 78374 /

S-14G L.H. 78375 /

S-10G R.H. 78363 /

S-10G L.H. 78364 i

@c^

L.H. 78362

R.H. 78361

LIFT

SELECTOR

78278

78373

DEPRESS BRAKE PEDAL

THEN ENGAGE PARKING

BRAKE LOCK.

A

READ ALL DECALS AND FOLLOW

DIRECTIONS CAREFULLY.

ENGAGED

► DISENGAGED

78311

INSTRUCTIONS FOR SAFE OPERATION

1. Know the controls and how to stop quickly. READ THE

OWNER'S MANUAL.

2. Do not allow children to operate the vehicle. Do not allow

adults to operate it without proper instruction.

3. Do not carry passengers. Keep children and pets a safe dis

tance away.

4. Clear the work area of objects which might be picked up

and thrown.

5. Disengage all attachment clutches and shift into park

before attempting to start the engine.

78340

S-10G ONLY

78226

9. Take all possible precautions when leaving the vehicle un

attended, such as disengaging the power take-off, lowering

the attachment, shifting into park, setting the parking brake,

stopping the engine, and removing the key.

10. Do not stop or start suddenly when going uphill or down

hill. Mow up and down the face of steep slopes: never across

the face.

11. Reduce speed on slopes and in sharp turns to prevent

tipping or loss of control. Exercise extreme caution when

changing direction on slopes.

12. Stay alert for holes in the terrain and other hidden hazards.

6. Disengage power to attachment, stop the engine and place

shift lever to"Park-Start"position before leaving the operator's

position.

7. Disengage power to attachment and stop the engine before

making any repairs or adjustments.

8. Disengage power to attachment when transporting or not in

use.

13. Use care when pulling loads or using heavy equipment.

a. Use only approved drawbar hitch points.

b. Limit loads to those you can safely control.

c. Do not turn sharply. Use care when backing.

d. Use counterweightls) or wheel weights when suggested,

in the owner's manual.

14. Watch out for traffic when crossing or near roadways.

2-

Page 3

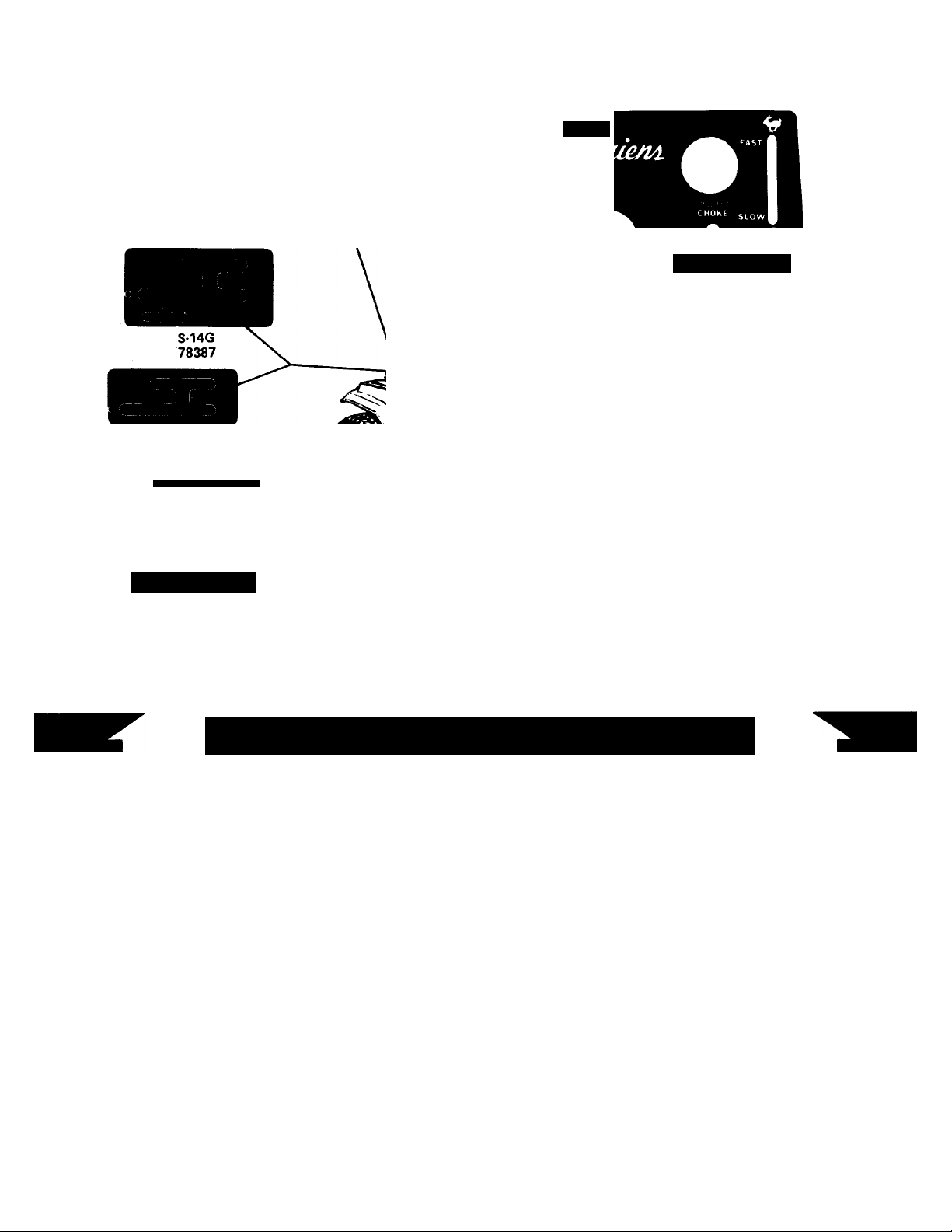

DECALS FOR MODELS 931013 & 931014 GEAR TRACTOR

Awarning]

I Grasp handle, not chain.

78282

S-10 G ONLY

S-10G

78388

P , I ii FR T-(,T R

LIGHTS IMPL POWER

DASH PANEL - 78341

%RTiMG PROCEDURE

+ CAUTION

CERTFIE CONFORME AU REGLEMENT CANADIEN SUR LE BROUILLACE RADIOELECTRIQUE

78367

BE AWARE OF SAFETY DECALS

15. When using any attachments, never direct discharge of

material toward bystanders nor allow anyone near the vehicle

while in operation.

16. Handle gasoline with care—it is highly inflammable.

a. Use approved gasoline container.

b. Never remove the cap of the fuel or add gasoline to a

running or hot engine, or fill the fuel tank indoors. Wipe

up spilled gasoline.

c. Open doors if the engine is run in the garage—exhaust

fumes are dangerous. Do not run the engine indoors.

17. Keep the vehicle and attachments in good operating con

dition, and keep safety devices in place.

18. Keep all nuts, bolts, and screws tight to be sure the equip

ment is in safe working condition.

^ 19. Never store the equipment with gasoline in the tank inside a

building where fumes may reach an open flame or spark. Al

low the engine to cool before storing in any enclosure.

^CAUTION

RELEASE LIFT ASSIST SPRING

BEFORE DISCONNECTING

I ATTACHMENT FROM TRACTOR

78281

S-10 G ONLY

COMPLIANCE WITH CANADIAN RADIO INTERFERENCE REGULATIONS CERTIFIED

REPLACE SPARK PLUG WITH RESISTOR SPARK PLUG ONLY !

REMPLACER LA ROUGIE PAR UNE ROUGIE A RESISTANCE SEULEMENT I

78400

(UNDER HOOD, NEXT TO SPARK PLUG)

20. To reduce fire hazard, keep the engine free of grass, leaves,

or excessive grease.

21. The vehicle and attachments should be stopped and in

spected for damage after striking a foreign object, and the

damage should be repaired before restarting and operating

the equipment, see numbers 6 & 7 opposite page.

22. Do not change the engine governor settings or overspeed the

engine.

23. When using the vehicle with mower, proceed as follows:

a. Mow only in daylight or in good artificial light.

b. Never make a cutting height adjustment while the engine

is running if the operator must dismount to do so.

c. Shut the engine off when removing the grass catcher or

unclogging chute.

d. Check the blade mounting bolts for proper tightness at

frequent invervals.

24. Check the grass catcher bags frequently for wear or. de

terioration. Replace with new bags for safety protection.

I

Page 4

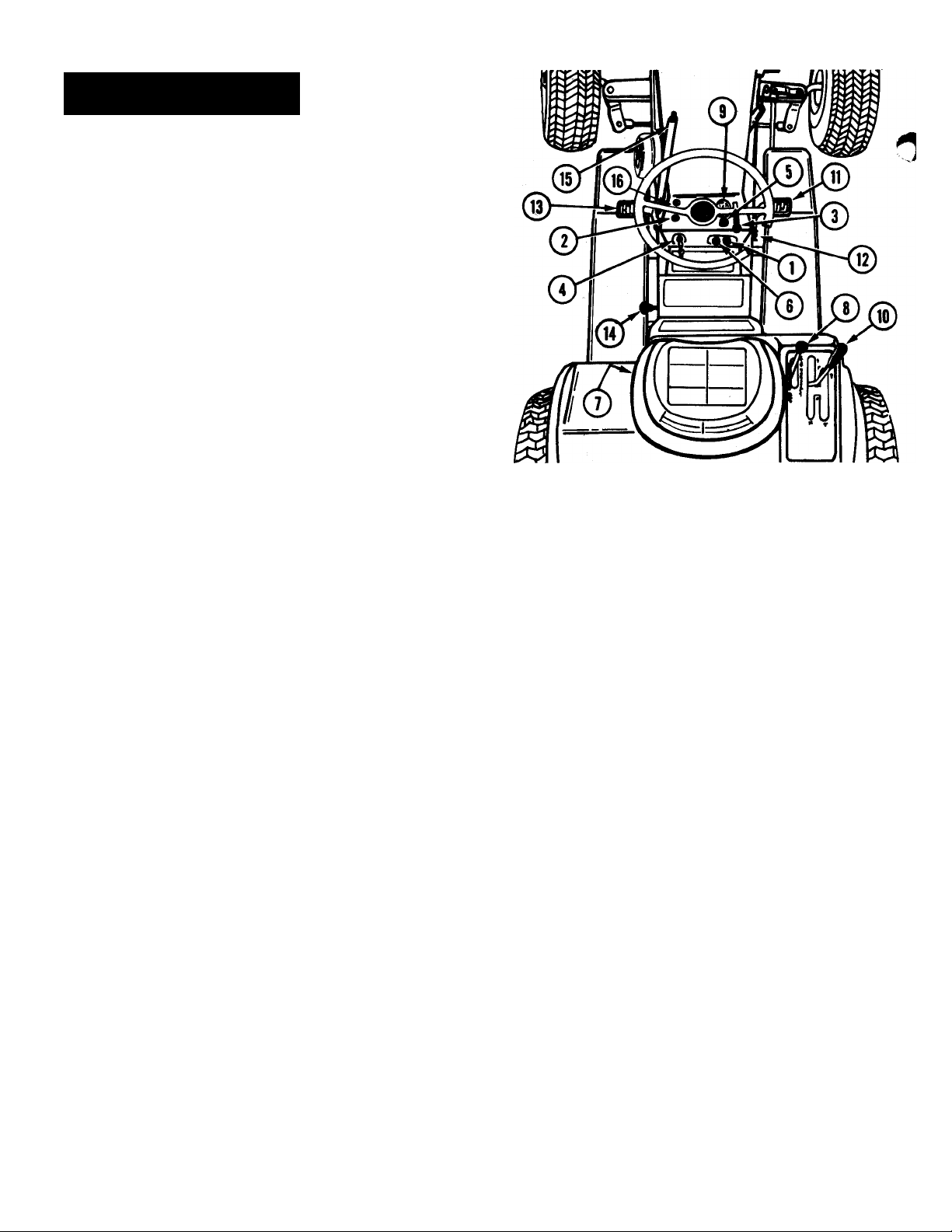

CONTROLS

Implement Power Control Switch (Figure 1).

Pull the switch out (ON) to engage the electro

magnetic clutch to drive the mower and front mount

ed attachments.

NOTE: This switchQ must be pushed in (OFF) to

disengage the drive before the engine will start or to

allow engine to keep running if the operator gets

off the seat.

©

Implement Power Indicator Light (Figure 1). This

light glows red when the implement power control

«witch (T) is pulled out to indicate that the mower

or front mounted attachment is engaged.

©

©

©

©

©

©

©

Throttle Lever (Figure 1). Raise the lever to in

crease engine speed. Lower the lever to decrease

engine speed.

Ignition Switch (Figure 1). Turn the key fully

clockwise to start the engine and release when the

engine starts. Turn the key counterclockwise to stop

the engine.

Choke Control (Figure 1). Pull choke control out

when attempting to start a cold engine or when

starting during cold weather. When engine starts,

gradually push choke in. Normally, it is not necessary

to use the choke when starting a warm engine.

Light Switch (Figure 1). Pull the switch out to

turn on the front and rear lights. The ignition key

must be turned on before the lights work.

Seat Safety Interlock Switch (Figure 1) This

switch, located in the seat, is closed by the operators

weight. If the operator leaves the seat for any

reason while the PTO is "ON" or the shift lever

is not in "NEUTRAL" the PTO clutch and engine

ignition are both shut off. When the PTO is "OFF"

and the shift lever is in "NEUTRAL" leaving the seat

will not cause the engine to stop.

Hydraulic Lift (Figure 1) Model S-14G only).

This lever controls the hydraulic system used to

raise and lower attachments. The lever has four

positions - UP, HOLD, DOWN and FLOAT. The

normal out-of-use position is the "HOLD" position,

whereby the attachment will not raise or lower. When

it is desired to raise the implement, move the lever

to the "UP" position, to lower the attachment move

the lever to the "DOWN" position. Place the lever

in the "FLOAT" position to allow the attachments

to follow the ground contours.

Ammeter (Figure)). The ammeter indicates the

rate of battery charge or discharge. The indicator

should register on the (-)-) side of the dial when the

engine is running at any speed above a slow idle.

When the engine is idling or with a fully charged

battery, the ammeter may not show charge. Should

the ammeter register on the (—) side of the dial for

an extended period of time with the engine running,

it indicates the alternator is not charging the battery.

Check the battery connections or contact your dealer.

©

®

®

®

®

FIGURE 1

Gear Shift Lever (Figure 1) This lever selects any

of four forward speeds or reverse.

NOTE: This lever must be placed in the NEUTRAL

position before engine will start

Brake Pedal (Figure 1) When this pedal is depressed

the friction brakes will be applied to stop the tractor,

DEPRESS THE CLUTCH PEDAL ® BEFORE AT

TEMPTING TO STOP THE TRACTOR WITH THE

WHEEL BRAKES.

Parking Brake (Figure 1) The parking brake is a

latch that locks the brake pedal. To apply the park

ing brake, depress the brake pedal, flip up the parking

brake latch.® To disengage the parking brake,

depress the brake pedal and push down the latch.

Clutch Pedal (Figure 1) Depressing this pedal re

moves the idler pulley from the drive belt and dis

connects the engine from the drive train. Depress the

clutch to shift gears or before attempting to stop.

Lift Selector - Connects the attachment lift to

front/center or rear rock shaft. See page 12 and

Figure 23 for operation.

Manual Lift Lever (Figure 1) (Model S-10G only).

To raise attachment, press the thumb release, pull lever

rearward and lock in the raised position. To lower

attachment, press the thumb release and move lever

forward. This lever is spring loaded to the rear position

when the manual lift assist springs are engaged.

Implement Reset Button - Press to restart PTO in

the event the operator leaves the seat momentarily.

Under these conditions the PTO and engine ignition

will be shut off. If the operator sits down before the

engine stops revolving, the engine will restart, but

the PTO will not start until the reset button ® is

pushed. If the engine stops, the normal starting

procedure (Implement switch ®OFF; Shift lever

® in NEUTRAL) must be followed.

-4

Page 5

OPERATION

PRE-STARTING INSPECTION

Prior to starting the engine for each day's operation, the

following checks and services should be performed;

a. Check oil in engine crankcase. Add oil as required to

maintain proper level.

b. Check fuel supply. Use regular gasoline only.

c. Check air filter for excessive dirt. Clean as required.

d. Make visual check with regards to safety precautions,

obstructions, lubrication, and maintenance.

STARTING THE ENGINE

Use the following procedure to start the engine:

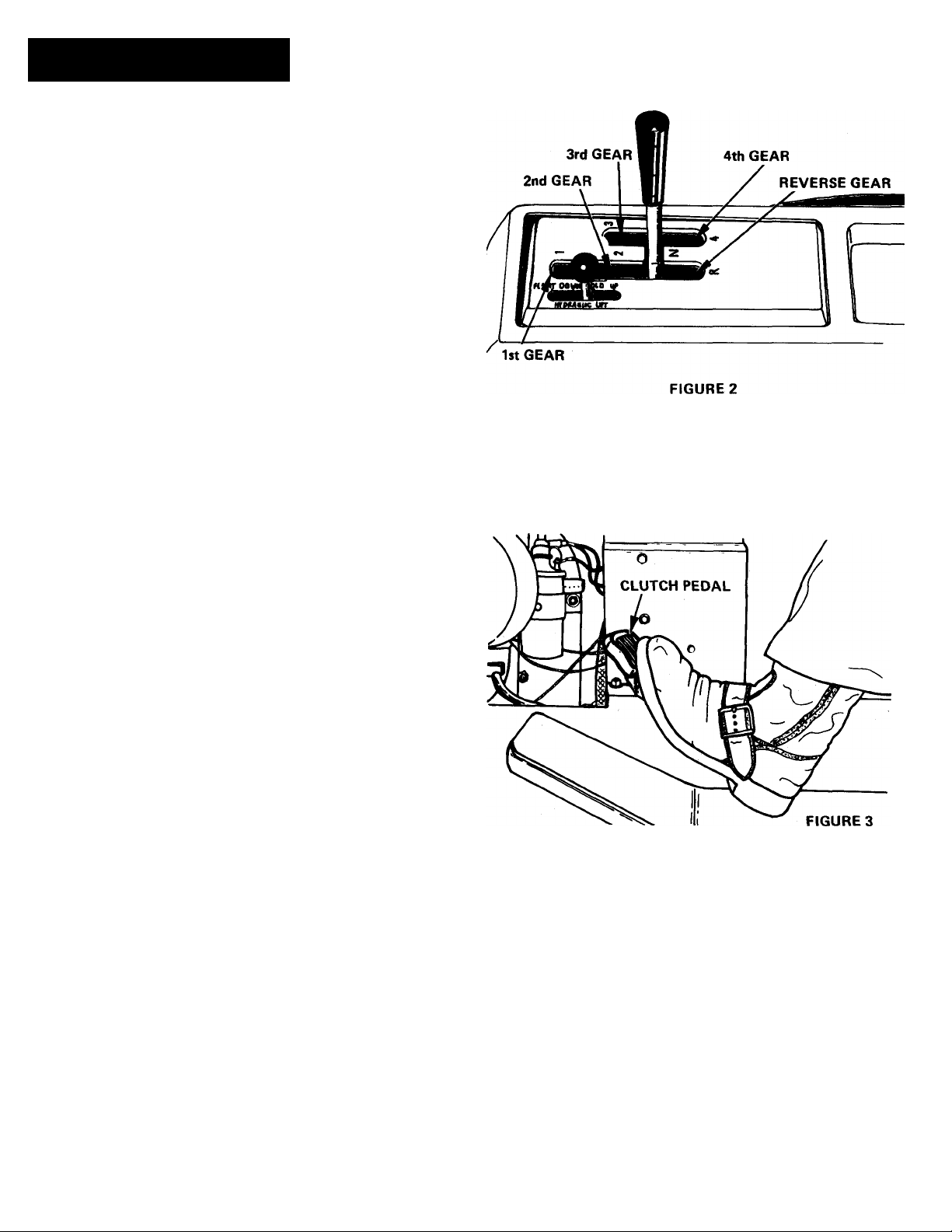

1. Place the gear shift lever in the "Neutral" position, shown

in Figure 2.

To run the tractor in REVERSE, shift to reverse gear.

NOTE: This is a safety feature. The engine wili not start

unless the shift lever is in neutral.

2. Be sure the Implement Power Control SwitchMJFigure

1„is pushed in (OFF). ^

NOTE: This is a safety feature. The engine will not start un

less the switch is off (pushed in).

3. Raise throttle lever^^Figure 1, to approximately 1/3

fast position.

4. Pull choke control^^Figure 1, all the way out if engine

is Cold. If engine iswarm, little or no choke may be

required.

5. Turn ignition key(|^Figure 1, clockwise all the way.

Release key as soon as the engine starts and push choke

button in. In cold weather it may be necessary to push choke

in gradually until engine warms up. If engine fails to start

bn the first attempt, turn key to off, wait a few minutes and

try again. Do not operate the starting motor continuously

for more than 30 seconds at a time.

Always allow engine to warm up before applying load.

In below freezing weather, allow engine to run at a fast idle

for a period of at least 5 minutes before using the tractor.

Serious internal damage to the engine could result if this

procedure is not followed.

OPERATING THE TRACTOR - GEAR SHIFT LEVER

When the gear shift lever is placed in the neutral position

the interlock switch is closed and the engine can be started:

the rear wheels are not in gear and the tractor may be pushed

around by hand as required after releasing the parking brake.

In general, best results will be secured by running the

tractor engine at full throttle while selecting the gear that

gives the desired ground speed. This insures that the attach

ment operates at maximum efficiency.

THROTTLE LEVER SETTING

When operating power driven attachments such as the

mower, snow thrower or the rotary tiller, run the engine at

full throttle unless the attachment operator's manual specifies

otherwise. Use the shift control lever, not the throttle lever

to select a safe travel speed when using power driven

attachments.

To run the tractor FORWARD, shift to one of the four

forward speeds. Speed for each gear (with engine at full

throttle) is shown below:

1st Gear .7 mph

2nd Gear 2.1 mph

3rd Gear 3.7 mph

4th Gear 5.4 mph

Reverse Gear 2.9 mph

Safe or proper travel speed depends on the attachment

used as well as the type of terrain or lawn, field and garden

conditions in which the tractor is operated.

-5-

Page 6

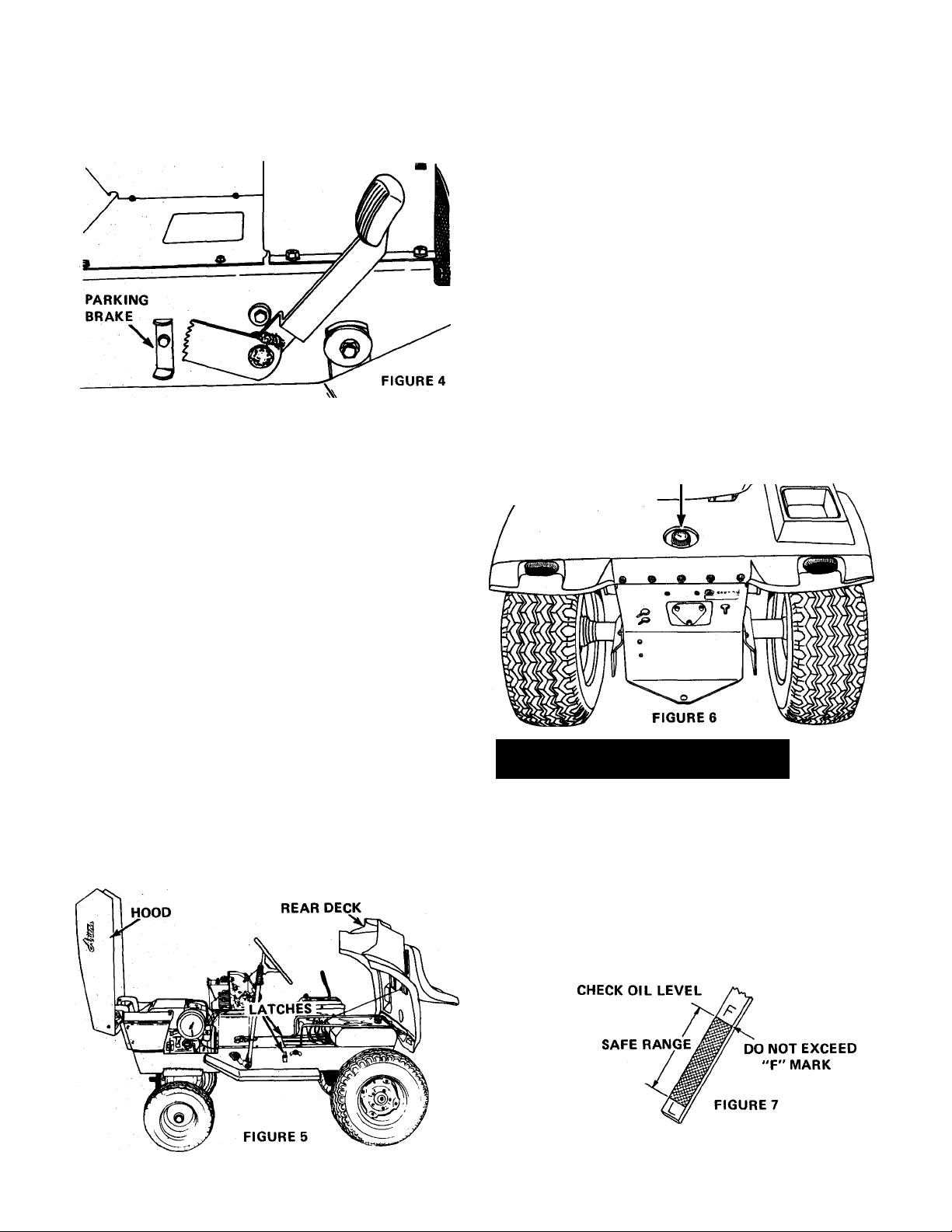

STOPPING THE TRACTOR

To stop the tractor, depress the clutch pedal @ and

depress the brake pedal (ñ) . Then place the shift lever in the

"Neutral" position and set the parking brake. Figure 4.

STOPPING THE ENGINE

Always use the following procedure to stop the engine:

1. Move the gear shift lever (j^ Figure 1, in "Neutral"

position, depress the brake pedal and set the parking brake

(Figure 4).

2. Disenga^ Implement Power Control Switch(^Figure 1,

and rear driven attachments.

CAUTION: Always shut off engine before raising the

rear deck. Be sure to lock the rear deck down with

A

A

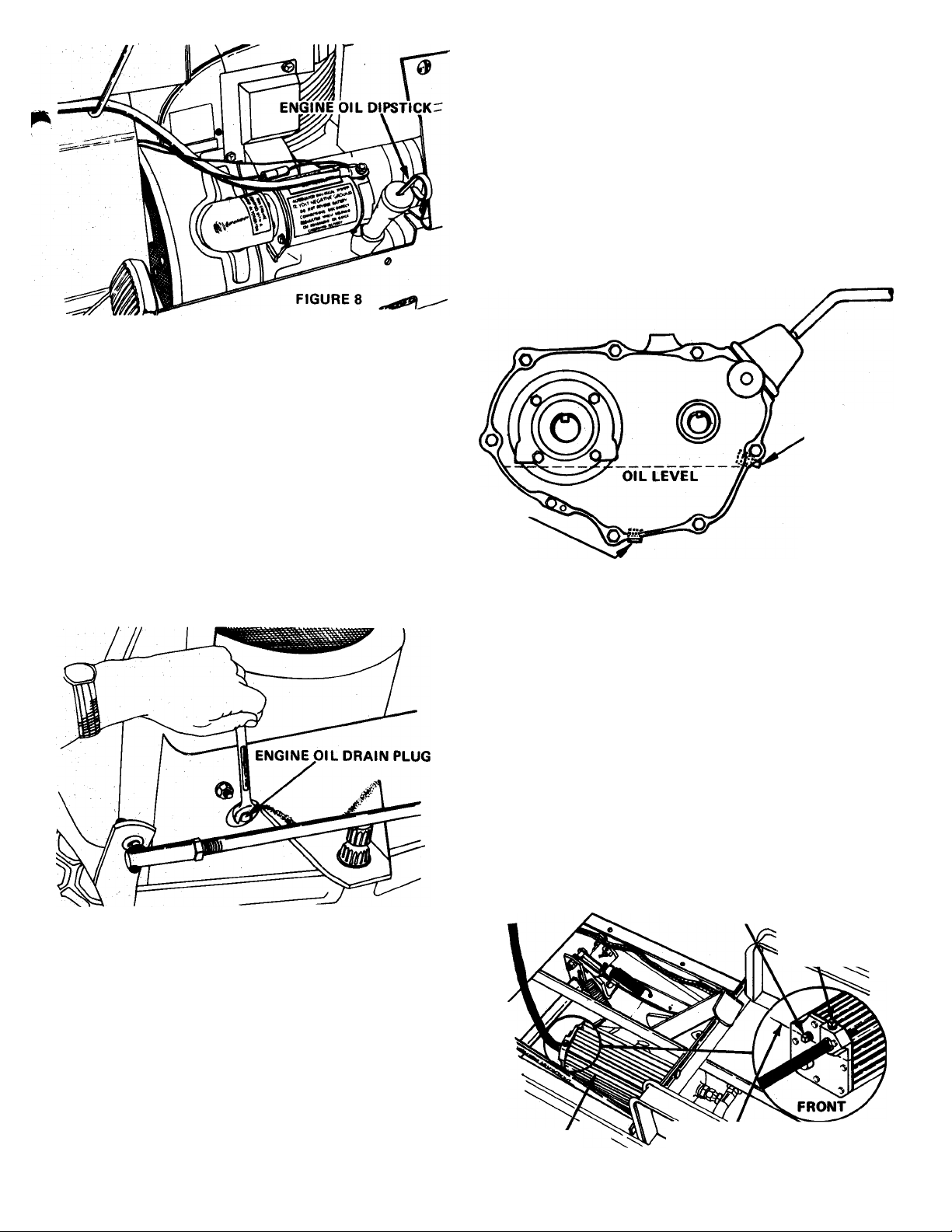

FILLING THE TANK

Figure 6. Wipe the dust and dirt from around the cap before

removing it to prevent dirt from falling into the tank while

filling. Use an approved gasoline container and keep it clean.

fresh. Do not use premium gasoline. Do not mix oil with

gasoline. FILLER CAP

the latches provided before operating the tractor.

RAISING THE HOOD

The engine, battery and electrical components are readily

accessible by raising the hood, see Figure 5. To raise the hood

grasp each side and raise it ud and forward to its stop.

CAUTION: ALWA YSSHUT ENGINE OFF BEFORE

RAISING HOOD. NEVER TOUCH MUFFLER, EX

HAUST PIPE OR ENGINE UNTIL THEY HAVE

HAD TIME TO COOL AFTER OPERATING THE

ENGINE.

The fuel tank filler cap is located behind the seat, see

The fuel tank capacity is 4.5 gallons.

Use regular grade gasoline. Be sure the gasoline is clean and

ia!_p-

3. Lower attachment so that it is resting on the floor or

ground.

4. Lower the throttle lever Figure 1, and allow engine to

idle for a short period before turning it off.

5. Turn the ignition key^MFigure 1,

stop engine.

IMPORTANT — Remove ignition key before dis

mounting from tractor. This will prevent children

A

and inexperienced operators from starting the tractor.

RAISING THE REAR DECK

The transaxle and control linkage are readily accessible

by raising the rear deck, shown in Figure 5. To raise the

rear deck, place the shift control lever in the "Neutral"

position, release the two latches and raise the rear deck to

its stop.

counterclockwise to

LUBRICATION

ENGINE

Check the engine crankcase oil level daily or every 5

hours operation. It is essential that the oil level be maintained

in the "safe" operating range as shown in Figure? at all

times or serious engine damage could result.

To check the oil, stop engine and wipe all dirt and dust

from around the dip stick. Figures. Pull dip stick out, wipe

off the oil, re-insert dip stick and push it down tight. Pull

the dip stick out and observe the oil level. Add sufficient oil

of the proper viscosity to bring the oil up to the "fill"

(F) mark, see Figure 7. Be sure tractor is level when checking

oil.

DO NOT OVERFILL — Oil level must never exceed full mark.

Oil capacity of the engine crankcase is 4 U.S. pints.

-6

Page 7

Use AriensGard-N-Yardoil (SAE 10W-30 SE classification)

when using lawn and garden attachments. Use Ariens SnoThro oil (SAE 5W-20 SE classification) when using snow

removal attachments.

1. Drive tractor onto level ground.

2. Stop engine.

3. Wipe dirt from around the oil level filler plugs. See

Figure 10.

4. Remove filler plug. Oil level should level with the filler

plug hole, see Figure 10.

5. If necessary, use a small funnel to add sufficient MP-90

oil to bring the oil up to the proper level. Replace plug.

Be very careful to prevent dirt and foreign materials from

entering the transaxle when checking or adding oil.

CHANGE ENGINE OIL

When the tractor is new, the oil should be changed after

the first 5 hours of operation.

Under normal operating conditions, the oil should be

changed every 25 hours of operation. If extremely dusty or

dirty conditions prevail, change oil more frequently, use a

filter precleaner, consult Engine Manual.

Drain the crankcase by removing the drain plug, shown in

Figure 9 , and allow the oil to drain into a container. If

■k possible, run engine just prior to changing oil, as the oil will

^ flow more freely and carry away more contamination when

hot.

PIL FILLER

DRAIN

HDLE

FIGURE 10

HYDRAULIC LIFT DIL LEVEL (Model 931013only)

The hydraulic lift system should seldom require additional

hydraulic fluid unless a leak should develop. The hydraulic

fluid is stored in a reservoir/cooler located under the floor

panel in front of the seat. To check oil level, drive the tractor

on to level ground; move the hydraulic lift lever to the

"DOWN" position until the lift cylinder is fully retracted.

Remove the panel. The hydraulic reservoir is now exposed.

Clean away all dirt and remove the pipe plug at the front of

the reservoir. The oil level should be to the bottom of the

edge as shown in Figure 11. Rock the machine while looking

down the fill hole to be sure of the oil level position. If

additional oil is required, fill to the proper level with SAE

10W-30 Gard-N-Yard oil or equivalent by removing the top

plug, adding oil, and removing the front plug, again, to set the

oil level. Replace all pipe plugs, clean excessive dirt from

the cooler fins and replace floor panel.

NOTE: Bottom of engine shown. FIGURE 9

Replace drain plug. Remove dip stick and refill crankcase

with 4 U.S. pints of oil. Check oil on the dip stick to see that

the oil level is at the full (F) mark. Do not overfill.

TRANSAXLE OIL GRADE AND VISCOSITY

Ariens MP-90 Gear Lube or an equivalent oil meeting the

requirements of the American Petroleum Institute (A.P.I.)

should be used. Oil viscosity (weight) should be SAE 90 and is

I recommendedfor year-round use.

TRANSAXLE OIL LEVEL

The oil level in the transaxle should be checked every 25

hours of operation or monthly.

Use the following procedure to check the transaxle oil

level:

7-

RESERVDIR

DIL CHECK PLUG

DIL LEVEL

'EVEN WITH

BDTTDM DF

PIPE PLUG

'DIL FILL PLUG

FIGURE 11

Page 8

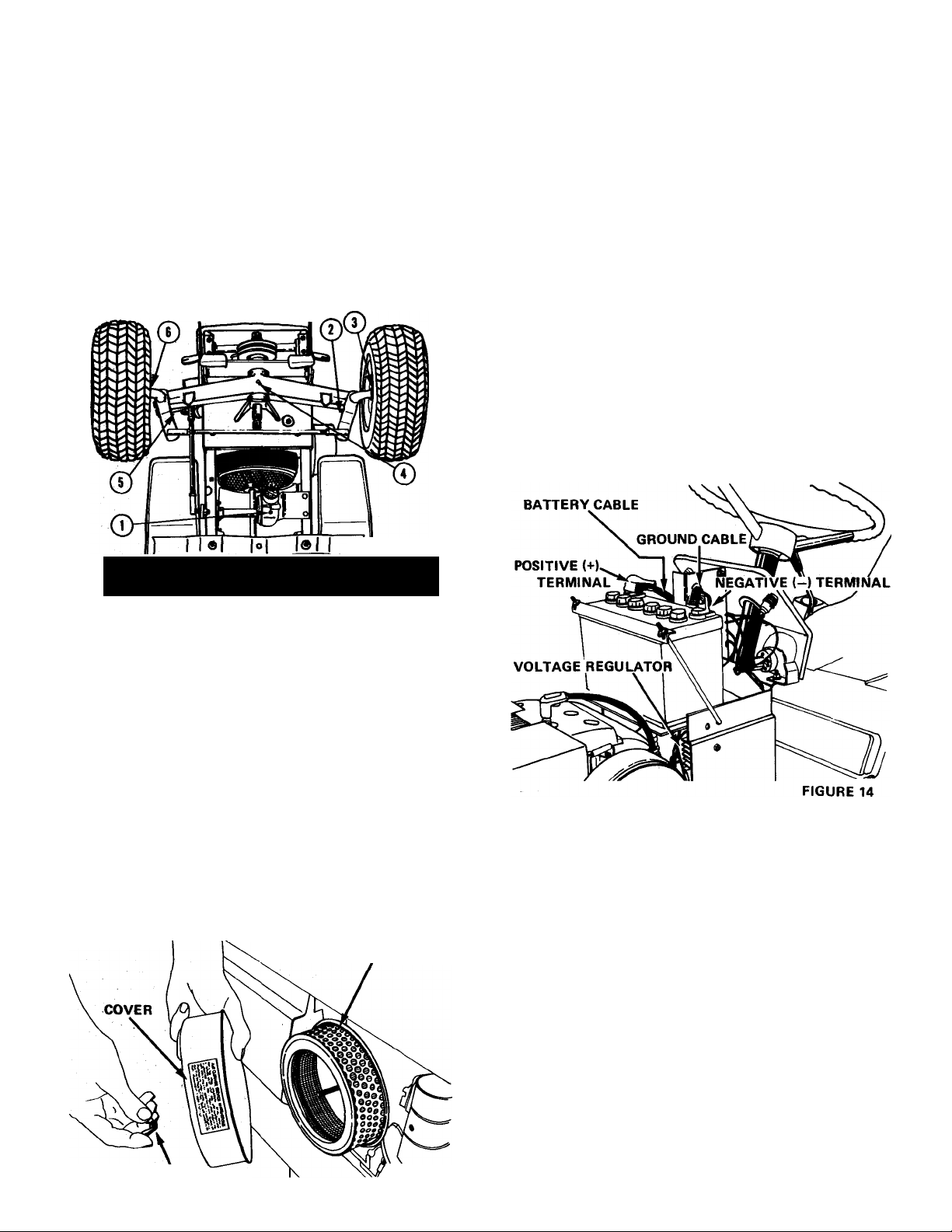

GREASE STEERING SYSTEM

Under normal conditions the steering system should be

lubricated every J50 hours of operation or quarterly whichever

occurs first. The following list of grease fittings are identified

in Figure 12. Wipe each fitting clean before and after

lubrication! Use a good grade of general purpose grease such

as Ariens Multi-Purpose grease.

Rotate steering wheel clockwise until the spindle arm con

tacts the axle stop and fill gearbox until grease is forced out

around the cam follower adjusting screw.

O Steering gearbox.

® Left king pin.

©Front L.H. Wheel

©Axle pivot

© Right king pin.

© Front R.H. Wheel

To clean the cartridge, remove the wing nut and the cover,

shown in Figure 13. and then remove the cartridge. Gently

tap the cartridge on a flat surface. Do not use any liquid

cleaner to wash cartridge. Do not use compressed air to re

move dirt as this may rupture the cartridge.

Examine cartridge carefully and replace it with a new one

if it is bent, crushed or if there is a noticeable loss of power.

Re-assemble cartridge and cover making sure it seats around

the back plate. Install wing nut and tighten finger tight.

A

IMPORTANT:

removed.

BATTERY SERVICE

Check the battery electrolyte level once each month. Add

distilled water to bring the level to the bottom of the split

ring in the filter tube of each cell.

Each spring and fall remove corrosion from the terminals

and apply a light coat of grease, to the terminals. Keep

battery cables securely tightened to terminals and be sure

battery is properly fastened down in battery holder at all

times. Keeping battery clean will prolong battery life.

Do not run engine with air fitter

FIGURE 12

MAINTENANCE

/VOTE THAT ALL ENGINE SERIAL NUMBERS

HIGHER THAN THOSE LISTED BELOW HAVE A

A

10 H.P. MODEL NO. K241S SERIAL NO. 7541007

14H.P. MODEL NO. K321S SERIAL NO. 8117916

HOUR METER

Ariens Garden Tractors models.

right side, just ahead of the dash panel. The hour meter will

record the actual time the engine operates. Keep a record of

hour meter readings in order to perform Maintenance and

Lubrication services at the recommended hourly intervals.

AIR FILTER SERVICE

When operating in extremely dusty conditions, check the air

filter daily. A precleaner is available. Consult the Engine

Manual.

GOVERNOR SETTING OF 3250 RPM, NO LOAD

(+ 75 RPM}. IDLE SET AT 1600 RPM, NO LOAD.

The hour meter is available as an optional accessory for all

The hour meter is located under the engine hood, on the

Check the air filter daily or every 5 hours of operation.

AIR FILTER CARTRIDGE

CAUTION: Storage batteries give off highly in

flammable hydrogen gas. Do not allow sparks or

flame near battery. Do not lay tools across battery

A

during winter months to prevent freezing. When water is

added during freezing weather, run the engine at least one hour

to thoroughly mix the water and electrolyte.

cable is connected to the negative (—) terminal on the battery,

see Figure 14. Be sure the battery cable is connected to the

positive (+) terminal.

terminals which may cause a spark resuiting in an

expiosion.

Maintain the battery at full charge during storage and

When installing the battery, make certain that the ground

WING NUT

FIGURE 13

A

WARNING: Reversed battery cables or reversed

cables from a battery charger or booster battery can

cause damage to the regulator rectifier (Figure 16).

Always disconnect plug from the regulator rectifier

before using a charger, booster battery or when

electric welding is done on the tractor.

Page 9

LUBRICATION AND PERIODIC SERVICE SCHEDULE

Hours of Operation/

T- , ^ , Service Required

Time Interval

Every 5 Hours or Daily Check Engine Crankcase Oil

Service Engine Air Filter

Every 25 Hours or Monthly

Service Battery

Check Tire Pressures

Check Transaxle Oil Level

Change Engine Oil

Clean Park Lock Assembly

Grease Steering System

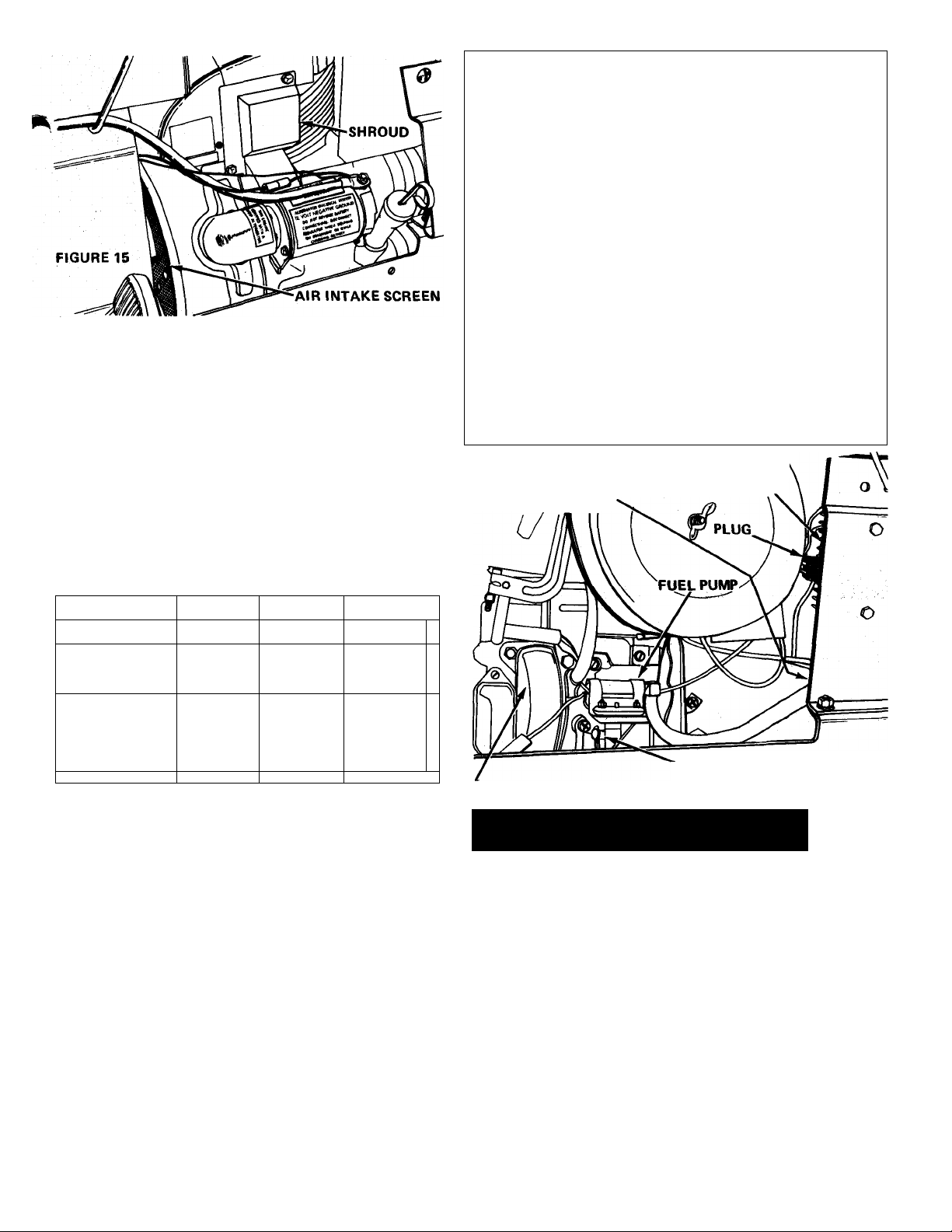

The engine is air cooled. Air must circulate freely around

the engine from the air intake screen shown in Figure 15 and

over the cooling fins in the cylinder head and block to prevent

overheating.

Every 50 hours of operation or quarterly check the air

intake screen. Wipe away any dirt or debris which has col

lected on the screen. Remove the shroud. Figure 15 and in

spect the cooling fins. Remove any dirt, or chaff accumulations

from the cooling fins with compressed air. Replace shroud.

TIRE PRESSURES

Check tire pressure at least once each month. Inflate

tires to pressures shown in the chart below. Use a low pressure

tire gauge for accurate readings.

TIRE SIZE

Front

16x6.50x8

Rear

23 X 8.50 X 12

23 X 10.50 X 12

Light Medium

(Lawn Work)

8 p.s.i.

(Lawn Work)

6 p.s.i.

LOADING

(Sno-Thro)

12 p.s.i.

(Rotary-Tiller)

8 p.s.i.

Heavy

16p.s.i.

10 p.s.i.

Every 50 Hours or Quarterly

Every 250 Hours or Yearly

NOTE: When tractor is new, change the engine oil after the

first five hours of operation.

FUEL FILTER IS

LOCATED UNDER

FLOOR PLATE

Clean Reservoir/Cooler Fins

Check Spark Plug

Clean Fuel Filter

REGULATOR

RECTIFIER

Keep tires properly inflated at all times. Over-inflation

will cause operator discomfort. Under-inflation will cause

short tire life. Always see that the tire valve caps are in place

and securely tightened to prevent air loss.

FUEL PUMP AND FILTER

The engine may fail to start due to lack of fuel at the

carburetor if the fuel pump shown in Figure 16 loses its

prime. This can occur when the fuel tank is run dry or may be

due to evaporation of fuel from the system after a storage

period. In either case, make certain there is fresh fuel in the

tank and operate the priming lever on the fuel pump several

times to start fuel flow.

If a faulty fuel pump is suspected, see your Ariens dealer.

When dirt or other foreign material is allowed to enter the

fuel tank it will collect in the fuel filter shown in Figure 16.

This will eventually cause fuel stoppage. The filter can be dis

assembled and cleaned.

PRIMING LEVER

IGNITION BREAKER POINT COVER FIGURE 16

ADJUSTMENTS

CAUTION: ARIENS RECOMMENDS THE CUS

TOMER CONSULT HIS LOCAL ARIENS DEALER

A

SEAT ADJUSTMENT

positions. To adjust seat position, grasp seat back and raise

seat. Slide the seat forward or backward as required to the

most comfortable position.

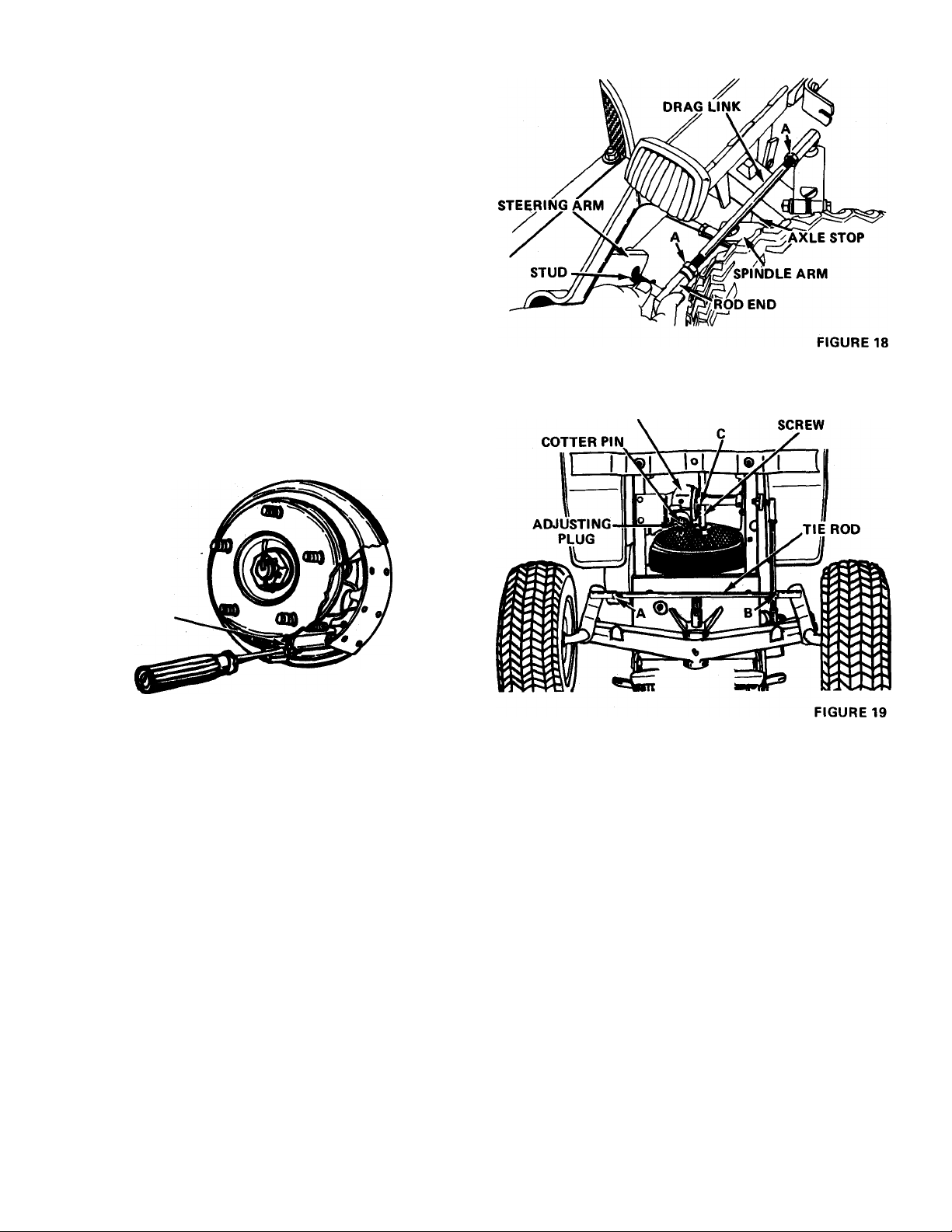

FRONT WHEEL TOE-IN ADJUSTMENT

proper steering and to reduce tire wear. The proper amount

of toe-in is when the front of the wheels are 1/16" to 1/8"

closer together than the rear of the wheels, measured at the

horizontal centerline of the rim flange.

-9

FOR PROPER ADJUSTMENTS. THE USE OF

IMPROPER TOOLS OR INCORRECT ADJUST

MENT COULD RESULT IN DAMAGE TO THE

TRACTOR OR INJURY TO OPERATOR.

The seat is adjustable forward and backward to seven

Proper toe-in of the front wheels is necessary to assure

Page 10

If the steering develops a wandering characteristic or if

excessive tire wear develops, the toe-in of the front wheels

should be checked. If the toe-in is incorrect, adjust as follows;

1. Loosen jam nuts A and B, Figure IB.

2. Rotate tie-rod until toe-in is correct. Shorten tie-rod to

decrease toe-in. Lengthen it to increase toe-in.

3. Tighten jam nuts A and B after correct toe-in is obtained.

BRAKE ADJUSTMENT

The tractor brakes will require adjustment when the brake

pedal depresses over two inches. To adjust the brakes proceed

as follows:

1. Block up the rear of the tractor with the wheels off the

ground.

2. Remove the wheel lug nuts and remove the wheel.

3. Insert a screw driver in the slot in the brake drum (See

Figure 17)' and tighten the star washer until the brakes are

snug and the drum does not turn. Back off the star washer

one full turn.

4. Replace the wheel and secure with the wheel lug nuts.

Repeat adjustment on the opposite wheel.

STEERING GEAR

CAM FOLLOWER

ADJUSTING

STAR WASHER

FIGURE 17

STEERING GEAR ADJUSTMENT

If loose play is noticed in the steering system after con

tinued use, the steering gear may require adjusting to remove

excessive backlash between the gears. Adjust steering gear

using the followirig procedure:

1. Raise front of tractor so that the tires clear the ground.

2. Remove cotter pin identified in Figure 19.

3. Loosen jam nut C, Figure 19 and turn adjusting screw out

(counter-clockwise) IVi turns.

4. Tighten adjusting plug. Figure 19, to 10-14 ft. lbs. of

torque.

5. Rotate adjusting plug out slightly to align nearest slot in

the plug with the cotter pin hole and reinstall the cotter pin.

6. Hold jam nut and turn adjusting screw. Figure 19,

clockwise (in) until backlash is removed from steering wheel.

DO NOT FORCE ADJUSTING SCREW. Torque jam nuts

35-45 ft. lbs. while holding adjusting screw in position.

7. Turn Steering wheel from lock to lock and check for

binding or dragging inside gearbox. If any binding or

dragging exists, it will be necessary to loosen the adjusting

screw and/or the adjusting plug slightly until steering wheel

turns freely with no loose play.

STEERING STOP ADJUSTMENT

When making a full right hand turn, the spindle arm

should contact the axle stop as shown in Figure 18. When

making a full left hand turn, the left spindle arm should

contact the left axle stop. Proceed as follows to adjust the

steering stops.

1. Rotate front wheels to the right until right spindle arm

contacts the axle stop. Figure 18.

2. Remove drag link rod end from steering arm. Figure 18,

and loosen jam nuts A.

2a. Rotate steering wheel clockwise until steering gear

bottoms. Back off 1/8-1/4 turn counter clockwise.

3. Rotate drag link as required while preventing the loose rod

end from turning until the stud is approximately V: hole to

the rear of hole in steering arm, Figure 18. Be sure axle stop

contacts steering arm.

4. Reinstall rod end stud in steering arm and tighten jam

nuts A.

5. Rotate wheels completely to the left. The left spindle

arm should contact left axle stop. If it does not, repeat step j|

2 and shorten drag links slightly until both spindle arms contact their respective axle stops when making full turns In '

either direction.

10-

Page 11

REAR WHEEL TREAD ADJUSTMENT

The rear wheels are normally assembled in the narrow

tread position, shown in Figure 20. The wheels can be turned

on the hubs for a wider tread. The wide tread provides greater

stability on hillsides and on rough terrain.

Remove the wheel lug nuts, turn the wheels around with

the valve stems inward and re-assemble on the hub.

NARROW WHEEL TREAD SETTING

10.50 X 12 TIRES SHOWN)

• *er

I A Al c

NARROW

23 X 10.50 X 12 = 32%

0 WIDE

23 X 10.50 X 12 = 35'/4

FIGURE 20

If Chevron tread tires are used, remove the wheel lug

nuts and re-assemble the wheels on opposite sides of the

tractor with the valve stems turned inward. Interchanging

the wheels is necessary to maintain proper direction of

rotation for traction tires.

The center rock shaft pan flotation spring, shown in Figure

24 provides mower flotation. The tension on the spring can be

increased or decreased by presetting the latch bar to a dif

ferent notch when the pan is fully raised. The bottom notch

provides the greatest flotation.

The front/center or rear rock shaft is selected for operation

by the manual lift lever by the lift selector knob. Figure 23.

To change selection, locate selector knob to proper end and

rotate the mechanical lift lever past the last notch to the

overtravel area. This allows the selector latch to change po

sition. This allows a rear attachment to be used without re

moving the front/center attachment, or vise versa.

HYDRAULIC LIFT OPERATION

The hydraulic lift system is standard equipment on the

S-14G.

The hydraulic control lever is located on the control

console, shown in Figure 2. It is a four position lever to per

form four functions, UP, HOLD, DOWN and FLOAT. The

normal out-of-use position is the "HOLD" position whereby

the attachment will not lower or raise. When it is desired to

raise the attachment, the lever is pulled to the "UP" position

and the cylinder is actuated to lift the attachment. When the

lever is moved to the "DOWN" position, the oil pressure in

the cylinder is reversed and the cylinder forces the attachment

down.

When an attachment is being used which is designed to fol

low ground contours, the lever should be placed in the

"FLOAT" position. The cylinder is then free to move as the

attachment position requires.

Figure 25 shows the components of the hydraulic lift

system. The hydraulic pump supplies the oil flow from the

oil reservoir/cooler. Oil flow to and from the cylinder is con

trolled by the valve.

MANUAL LIFT OPERATION

Manual Lift Lever {Figure 21) (Model S-10G only). To

raise attachment, depress thumb release and pull lever to the

rear until the locking pin engages in the proper quadrant

notch to obtain desired attachment height. To lower attach

ment, depress thumb release and push lever forward. After the

attachment touches the ground the force from the lift assist

springs will resist the forward motion of the lift lever. The

amount of resistance is relative to the spring adjustment.

The two springs shown in Figure 24 are used to provide

lift assist. The tension on these springs should be adjusted

using the chains shown in Figure 22, so the front mounted

attachments can be raised or lowered with the lift lever by

the operator.

CAUTION: WHEN ADJUSTING CHAIN TENSION

ALWA YS GRASP CHAIN HANDLE FIRML Y (NOT

A

and lower the rotary mower. This rock shaft is connected to

the manual lift lever through the link. The connection at the

rock shaft is made through the slotted hole which allows

the rock shaft to move up and down when in the lowered

position, allowing the mower to float without causing the lift

lever to move.

THE CHAIN) AS CONSIDERABLE TENSION IS ON

THE CHAIN AND INJURY TO THE HANDS

COULD RESULT.

The' center rock shaft shown in Figure 24 is used to raise

When the cylinder is extended or retracted, the bell crank

pivots and raises or lowers both the front and center rock

shafts at the same time through the front and center rock

shaft linkages shown in Figure 25. The connection to the

center rock shaft is made through the slotted hole which allows

the center rock shaft to move up and down, allowing the

mower to float independent of the flotation provision in

the hydraulic system.

MANUAL LIFT LEVER

ATTACHMENT HEIGHT CONTROL QUADRANT

o

FIGURE 21

The center rock shaft pan flotation spring shown in Figure

25 provides mower flotation. The torsion on the spring can be

increased or decreased by presetting the latch bar to a different

notch when the pan is fully raised. The bottom notch pro

vides the greatest flotation.

-11 -

Page 12

ADJUSTING CHAINS

FOR S10G MANUAL

LIFT, ASSIST SPRINGS

CAUTION - WHEN ADJUSTING CHAIN TENSION ALWAYS GRASP

CHAIN HANDLE FIRMLY (NOT THE CHAIN) AS CONSIDERABLE TENSION

A

IS ON THE CHAIN AND INJURY TO THE HANDS COULD RESULT.

HYDRAULIC LIFT REAR ROCK SHAFT

The rear rock shaft comes with a lift selector device so

that the front and center rock shafts can be operated indepefidentty of the rear rock shaft while utilizing only one

hydraulic cylinder. The alternately latched, split lift linkage

systeih holds the front and center rock shafts in their raised

positions while the rear rock shaft is operated by the cylinder

.or vice versa. This allows a rear mounted attachment to be

used without removing the front or center mounted attach

ments and vice versa.

FIGURE 22

To make the rear rock shaft operational, move the hy

draulic control lever to the "UP" position and hold it there

until the cylinder is fully extended. Place the selector knob in

the front notch (Figure 23).

To make the front and center rock shafts operational,

move the hydraulic control lever to the "UP" position and

hold it there until the cylinder is fully extendi. Place the

selector knob in the rear notch as shown in Figure23.

IN REAR NOTCH - FRONT AND CENTER ROCKSHAFTS

c

<

Page 13

STORAGE

FIGURE 25

PREPARATION FOR STORAGE

1. Remove all oil, grease and dirt from engine and trans

mission.

2. Clean the tractor exterior and tires thoroughly, removing

all mud, dirt and grease.

3. Touch up all unpainted and exposed areas with paint to

prevent rust.

4. Change engine oil.

5. Disconnect fuel line at fuel filter and drain fuel tank. Run

the engine until the fuel is exhausted from the system.

Drain the carburetor by loosening the nut on the bottom of

the carburetor bowl. Clean the fuel filter.

6. Remove and clean the battery. Check electrolyte level and

have battery fully charged. Store battery in a cool, dry place

where it will not freeze.

•

7. Remove the spark plug and pour one tablespoon of SAE

30 oil into the cylinder. Turn engine over manually at least

two revolutions.

8. Re-gap spark plug. Replace if required.

9. Grease the steering system.

10. Store tractor in a cool, dry place to reduce tire de

terioration. Block up tractor to take the weight off the tires.

11. Inspect tractor for visible signs of wear, breakage or

damage. Order any parts required and make necessary re

pairs to avoid delays when starting next season.

NOTE: Your authorized Ariens dealer is trained and equipped

to service your tractor. A periodic check-up by your dealer

will help to reduce your maintenance costs.

PREPARATION FOR USE AFTER STORAGE

1. Replace battery and check electrolyte level.

2. Fill fuel tank with fresh, clean regular gasoline.

3. Check transmission oil level.

4. Check tire inflation.

5. Check oil level in hydraulic reservoir - Model 931013 only.

-13-

Page 14

FRAME, STEERING, FRONT WHEEL

GEAR MODELS 931013 & 931014

SEE PAGE 15 FOR

INTERNAL PARTS

I

- 14-

Page 15

FRAME. STEERING, FRONT WHEEL

GEAR MODELS 931013 & 931014

REF

PART

NO.

N0.

031084 STEERING WHEEL 1

1

059004 CAPSCREW, HH,3/8 - 16x 1

2

631131

3

4

031173

5 031038

031049 PAD

6

7

531065 FRAME (for Model931014)

531066

064063 WASHER

8

10 054101 BALLBEARING

11 065098 LOCKNUT, 3/8" 2

031020

12

031262

13

14

064126

15 031130

065105 NUT, Hex Jam 1/2"-20 UNF (L.H.)

16

17 031929

065044 NUT, Hex Jam 1/2 -20 UNF (R.H.)

18

031129

19

031175 STEERING ARM 1

20

21

531011

22 055091 BUSHING

031140

23

075067 WASHER, 1-1/32 ID x 1-3/4 OD. x .060 Thick 2

24

031552 SPINDLE, L.H.

25

26 031169

27 031551

28 064029

29 054121

631084

30

31

32 071103 TIRE 1

33 067024 PIN, cotter 1/8 X 3/4

DESCRIPTION

STEERING GEAR ASS'Y 1

BRACKET, Mounting 1 37

CLAMP

FRAME (for Model 931013)

BEARING FLANGE

STEERING ARM

WASHER, 2" OD. x 9/16" ID x .135 Thick

BALL JOINT, L.H.

DRAG LINK, 11-1/8" Long 1

BALL JOINT, R.H.

FRONT AXLE W/BUSHING, ZERKS

SPINOLE COLLER,L.H. 1

ROD, 18-1/2" Long

SPINDLE, R.H.

WASHER 2

RAOIAL'BEARING

FRONT WHEEL ASS'Y - Consists of

071110 RIM 1

NO

REQ'D

2 35

1 38

1

1

1

AR

1

2

1

1

2

2

6

2

1

4

1

1

1

4 63 010353 ZERK FITTING

2

2

REF

Part

NO.

NO.

34

031568

059154

36 063006

029013

029024 WASHER, Spring

029014 LATCH R.H.

39

40 029015

41

065117 NUT, Hex Jam, 5/8"

42

059145

43 063021

44

064008 WASHER, Flat, 3/8"

45

065018

064002 WASHER, Flat, 5/16"

46

47

063003

48 065015

50 059022

51 062015

52 059146

53

065121

54

065042

55 059152

56 064131

57

022093 ZERK FITTING

58 031121

058037

59

058004 ROLL PIN

60

61 064043

62 031083

069094

64

65

031031 COVER

031734

66

67

063030

DESCRIPTION

WASHER, SPECIAL

CAPSCREW, 3/8 X 6 X 3/4 Grade 5

LOCKWASHER, 1/2"

LOCK STOP

LATCH L.H.

CAPSCREW, HH, 3/8x1" GR.5

LOCKWASHER, 3/8"

NUT, Hex, 3/8"

LOCKWASHER, 5/16"

NUT, Hex, 5/16"

CAPSCREW, HH, 5/16x 3/4

BOLT, Carriage, 5/16 x 1"

CAPSCREW, HH, 1/2 x 1-1/4" GR. 5

LOCKNUT

LOCKNUT

CAPSCREW, HH, 3/8 X 2-1/2

WASHER, Flat, 3/8"

ZERK FITtlNG,90°

ROLL PIN, 1/4 X 1-3/4

WASHER

CAP

CLAMP

BRACE

LOCKWASHER EXT.

NO

REQ'D

2

2

1

2

4

1

1

1

7

8

4

5

2

8

5

3

7

1

5

2

1

2

2

1

1

2

2

1

2

1

1

1

2

STEERING GEAR ASSEMBLY

*Not Available.

Order Complete

Steering Gear

Assembly No. 631131

REF.

NO.

1

2

3

4

5

6

7

8

9

10 031699 SEAL 1

11

12

13

14

15 064158

PART

NO.

031694

055099

075078 DUST COVER

067018 COTTER PIN, 1/8" X 1/2" 1

031695

064159

531042

065016

031696

031698 RETAINER, Seal 1

031697

031263

065119

DESCRIPTION

HOUSING 8i TUBE ASSEMBLY 1

BUSHING 1

PLUG, Adjusting

WASHER, Special

BEARING KIT 2

NUT, Hex Jam, 3/4" 2

LUBE FITTING, 1/4" Straight

STUD, Lever

LEVER & SHAFT

NUT, Hex Jam, 9/16"

WASHER, Special

15

NO.

REQ'D

1

1

1

1

1

1

1

1

Page 16

REAR DECK. SEAT. DASH SUPPORT. RUNNING BOARD

GEAR MODELS 931013 & 931014

Page 17

REAR DECK. SEAT. DASH SUPPORT. RUNNING BOARD

GEAR MODELS 931013 & 931014

REF

PART

N0.

N0.

1

031713 REAR DECK

2

031132

3

031133

4

031197 SEAT SUPPORT

5 031134

6 069102

7

031798

8 031135

9

031131

DESCRIPTION

SEAT BRACKET, right hand 1

SEAT BRACKET, left hand

SUPPORT

CABLE, 24"

BOTTOM COVER

ROD, 12-5/16” Long 2

CHANNEL 2

NO

REQ'D

12 031711 CHANNEL 2

13 031710

14

031094

SEAT

CLAMP

15 031517 CHANNEL 2

16 031055 SUPPORT 1

17

531070

531071

18

062034 BOLT, Carriage, 5/16 -18 x 3/4

19

531073

531072

20

031569

21 031019

22

075066 GROMMET

23

031028

24

531068 OASH SUPPORT - Model 931014

CONSOLE DECK-Model 931014 1

CONSOLE DECK-Model 931013

FLOOR PLATE-Model 931013

FLOOR PLATE-Model 931014

RUNNING BOARD

SPACER

HINGE

531069 DASH SUPPORT - Model 931013

25

065032

26

074044

27

031086

28

070015

29

059069

30

065042

31

062011

32

069094

33

031784

34

031089

NUT, Hex, 1/4"

SCREW, Self-Tapping, No. 10 x 3/8"

BATTERY TIE OOWN 1

FLANGE WHI2L0CK SCREW, 5/16-18

X 1/2 4

CAPSCREW, HH, 5/16x1-1/4

LOCKNUT, Hex, 5/16"

BOLT, Carriage, 5/16 X 3/4

"J" CLAMP

SUPPORT BRACE

ROD, Battery Tie Down

1 35

1 37

1

1

1

38 059150

39

40 064123

1 41

42

43

44

1

2

45 067003

49 059023

50 063021

51 061012

52 063026

1

2

1

1

1

4

4

\

1

1

3

4

S3

54

55 031556

56

57

58 063002 LOCKWASHER, 1/4"

59

60

61 070015 FLANGE, Whitlock Screw

62 031709

63

65 065099

69

4

4

4

4

1

2

REF

PART

NO.

NO.

065070

031701 BATTERY TRAY

36

DESCRIPTION

NUT, Crown

075065 GROMMET

CAPSCREW.HH, 1/4x1 1/2

061042

SCREW, Machine, Truss H, 5/16 x3/4- -

WASHER, Flat, 5/16

063003

065015

074043

064127

L0CKWASHER,5/16

NUT, Hex, 5/16

SCREW. Self-Tapping, HH, No. 10 x 1/2"

WASHER, Flat, 1/4"

PIN, Cotter, 1/16 X 1/2"

CAP SCREW, HH, 3/8" X 3/4"

LOCKWASHER,3/8"

SCREW, Machine R.H. No. 10-32 x 1/2"

LOCKWASHER, No. 10

065026

074017

NUT, Hex, No. 10-32 4

SCREW, Self-Tapping, HH, 5/16 x 3/4

X WASHER

064002 WASHER, Flat, 5/16

061039

SCREW, Machine, Truss H, 1/4 x 3/4

065089 SPEED NUT

064123 WASHER

HOSE

075044

64 062015

GROMMET

CARRIAGE BOLT - Model 931013 only)

NUT

065040

70

010289

•

LOCKNUT

EYE BOLT

NO

REQ'D

2

1

1

1

4

4

10

10

6

6

4

4

4

5

4

5

1

17

1

2

4

2

4

1

1

1

1

2

1

17

Page 18

HOOD, GRILL, HEADLIGHTS AND HEAT SHIELD

GEAR MODELS 931013 & 931014

^

-------

REF

PART

NO.

NO.

1

531056

531055

4

031046

5

031139

031138

6

7 031185 HINGE, Right Hand

8 031186

9 031145

075064 GROMMET 2

10

11 031986 MUFFLER SHIELD, S-10G .S-14G

12

075066

069094 "J” CLAMP

13

14

031093

15 061039 SCREW, Machine, Truss H, 1/4 X 3/4 5

064127

16

17

063002 LOCKWASHER, 1/4" 5

18

065032 NUT, Hex, 1/4"

^

DESCRIPTION

HO0D,S-10G

H00D,S-14G

GRILL

SIDE, Right Hand

SIDE, Left Hand

HINGE, Left Hand 1

SPACER, 3/4"

GROMMET 1

LATCH

WASHER, Flat, 1/4" 5

----

(j?)

NO.

RED'D.

M)

REF

NO.

1

1

1

1

1 24

1

2

1

2

1

5

20

21

22

23

(22

PART

NO.

064008

062032

062013

063021

065018

061042

25

064123

26

29

075058 HOOD STOP

30 063018

DESCRIPTION

WASHER, Flat, 3/8"

BOLT, Carriage 3/8" x 2

BOLT, Carriage, 3/8" x 1 ■

LOCKWASHER, 3/8"

NUT, Hex, 3/8"

SCREW, Machine, Truss H, 5/16 x 3/4

WASHER, Flat, 5/16"

STAR LOCKWASHER

NO.

REO'D.

6

2

6

8

8

2

2

2

2

18-

Page 19

MUFFLER, FUEL LINES & TANK

GEAR MODELS 931013 & 931014

I

I

PART

REF

NO.

NO.

031155 MUFFLER

1

2 031266

031082

3

. 4

5 070039

031180

6

030020

8

029108 FILTER, Fuel

9

069094

10

DESCRIPTION

CLAMP

BRACKET, Muffler

ENGINE, S-10, Kohler No. 46725D

ENGINE, S-14 Kohler No. 321-S 60238

LOCKNUT, Special

PIPE, Nipple

HUSt bb'^

"J"CLAMP

*0rder Replacement Engine and Replacement Engine Parts From Your

Nearest Kohler Service Central

to

••

0

1

1 1 13

1 1

1 1

1

1 1

1

1 1

1 1

1

REF.

N0.

i

J4

15

1

1

20

22

1

-19-

PART

NO.

031818

031904 FOAM 6" Long

031819

16

031190

17

063021

18 065018 NUT, Hex, 3/8 4 4

059151

19

029172

069053

DESCRIPTION

TANK, Fuel

GAS GAUGE 8> CAP

ELBOW, Street, 45°, 1-1/4

L0CKWASHER,3/8 4

CAPSCREW, HH, 3/8 x 1-1/2 GR.5

HOSE CLAMP

TIE 1 1

o

CO

9>

1

AR

1

444

iO

o

<o

o>

AR

1

1

1

4

4

Page 20

HYDRAULIC LIFT AND FRONT ROCK SHAFT

GEAR MODEL 931013 ONLY

-20-

Page 21

HYDRAULIC LIFT AND FROISIT ROCK SHAFT

GEAR MODEL 931013 ONLY

REF

PART

N0,

NO.

1

531067

• 2

031170

031779

3

031692

4

031778

5

031058

6

7

031780

8

059050

064127

9

10 031051

DESCRIPTION

CYLINDER ASS'Y (includes adapters) 1

VALVE

HOSE, 20" Long, Pump to Valve

HOSE, 2714" Long, Valve to Cylinder

HOSE, 19" Long, Valve to Reservoir

HOSE, 2414" Long, Valve to Cylinder

ADAPTER, 1/4 to 9/16,45°

CAPSCREW, HH, 1/4 x M/2

WASHER, Flat, 1/4" 2

PIN, Clevis

NO

REQ'D.

11 031063 BELL CRANK 1

068061 PIN

12

031500

13

14

067029

16 063002

LINK 1

HAIRPIN COTTER 1

LOCKWASHER, 1/4"

16 031189 CONTROL ROO

17

075052

531005

18

KNOB

FRONT ROCKSHAFT

19 031015 CONNECTOR LINK

20

029011

21 065032

067004

22

067006

23

24 067026

031014 BRACE

25

031076

26

064115

27

28 064009

058053

29

062005

30

065039 LOCKNUT, Hex, 3/8

31

32 063003

059134

33

34

059022 CAPSCREW, HH, 5/16x3/4

35 064002

065015

36

069094

37

38 031495

031634 ADAPTOR

39

40 031785

BEARING BLOCK

NUT, Hex, 1/4"

PIN, Cotter, 1/8 X 1 2

PIN, Cotter, 3/16 X M/4

PIN, Cotter, 3/16 X 1" 2

BRACKET

SHIM, .005Thick

WASHER, Flat, 3/4

GROOVE PIN, 1/4 X 3/4

BOLT, Carriage, 3/8 x 2-1/4

LOCKWASHER, 5/16"

CAPSCREW, HH, 5/16 X 1-1/4 gR.5 1

WASHER, Flat, 5/16

NUT, Hex, 5/16

J-CLAMP

ADAPTOR, 9/16

OIL RESERVOIR

REF

NO.

1

1

1

»* ^

1

PART

NO.

41

031787

42 030009

43

031789

031727

031794

45

1 46 031781

47

1

031783

2 48 031782

49 062011

059004

2

50

51 064078

1

3

1

1

1

1

4

6

1

1

1

4

1

1

4

4

6

52 063021

53

065018 NUT, 3/8-16

54

074027

55

074059

56 062012

57 064007 WASHER

58

001138 PIPE PLUG

59 066032

60

060008

61 031795 SHEAVE

031797

62

63 031788

64

072088

004226

65

66

030013

67

030011

68 030012

69 030014

70

065075

71

063019

72

030008

73 030010 CONNECTOR

3

7

2

1

1

1

1

DESCRIPTION

CIRCULATION COVER

FILLER COVER

GASKET RESERVOIR

PUMP HYDRAULIC

PUMP MOUNTING BRACKET

HOSE, 14" Pump to Reservoir

BRACKET

BRACKET, Mounting

BOLT, Carriage 5/16-18x3/4"

CAP SCREW, 3/8-16 X 1

WASHER

LOCKWASHER

TAPTITE 12

TAPTITE 2

BOLT, Carriage 1/4-20 x 3/4"

KEY 1

SETSCREW

ADAPTOR 1

ADAPTOR 3/8 to 9/16

BELT

PIPE PLUG

COVER

FITTING

OIL EXPANSION CUP

FIBER WASHER

NUT

LOCKWASHER

HOSE, 16" Long

*531041 Section Repair Kit Available

*531057 Spool Repair Kit Available

**531075 Pump Repair Kit Available for most

maintenance repairs.

NO

REQ'D.

1

1

2

1

1

1

1

1

2

4

4

4

4

1

1

1

2

1

1

1

1

1

1

1

1

2

1

1

1

21 -

Page 22

REAR BRAKE & CLUTCH ASSEMBLY

GEAR MODELS 931011&931012

Page 23

REAR BRAKE & CLUTCH ASSEMBLY PARTS

GEAR MODELS 931013 & 931014

REF

PART

N0.

N0

1

031679

2 031678 DUST SHIELD 2

3 531039

4

031680 PIVOT NUT

5

031682

6

083162

7

083161

8

083160

9 031763 CLUTCH ARM 1

10

031681

11

067032

12

031675

13 031677

14

064156 WAVE WASHER

15 031702

067001

16

031507 BRAKE LATCH

17

18 059001

064127

19

011091 SPACER, Bushing 1

20

21 065040

031935

22

031939

23

24 031940 ARM

25 031938

26 031808

27

064048

28 058040

031941

29

30

031509

31 059003 CAPSCREW, HH 5/16"

063004

32

DESCRIPTION

TORQUE, Spider 2

BRAKE SHOE (sold in sets of two only) 2

SOCKET, Adjusting Screw 2

SPRING, Adjusting Shoe

SPRING', Shoe Return, L.H. 2

SPRING,Shoe Return, R.H.

ADJUSTING SCREW, (star wheel) 2

HAIR PIN RETAINER 4

STRUTS. LEVER ASSEMBLY

PIN

RETAINER CLIP

PIN,Cotter3/32"x3/4"

CAPSCREW, HH, 1/4" X 3/4" 1

WASHER, Special

LOCKNUT, Hex, 1/4"

ROD

ARM

BRAKE ARM

BRAKE ROD

WASHER, Flat 3/8" 1

PIN, Drive 1/4" X 1-1/4"

BRAKE SHAFT 1 1

PLATE

LOCKWASHER,3/8"

NO

REQ'D

931014 931013

2

2

2

2

2

2

2

7

1

2

1

1

2

1

2

2

1

4

REF

NO.

2

2

2

2

2

2

2

2

1

2

4

2

2

2

2

7

1

1

1

1

1

2

1

1

2

1

1

2

2

2

4

33 062013

34

35

36 069113

37

38

39

40

41 063021

42

43

44 031505

45

46 059135

47

48 055095

49

50

51

52 025135

53 031936

54

55

56 064057

58

59

60 064062

61

62 031937

PART

NO

067006

031791

031762

031674

083122

013303

065018

075051

059030

058003 ROLL PIN

075055

064002

031504

065042

074046

031676

064043 WASHER

055095 BUSHING

055096 BUSHING

631107

631108 L.H.BRAKE ASSEMBLY 1 1

DESCRIPTION

BOLT, Carriage 3/8" x 1" 4

PIN, Cotter 3/16" X 1-1/4"

L.H. PEDAL

L.H. PEDAL

CLUTCH CABLE

BRAKE DRUM

SPRING

CLEVIS PIN

NUT, Hex 3/8"

LOCKWASHER,3/8"

PEDAL PAD

CAP SCREW, HH 3/8" X 2-1/4"

ARM, Brake

CAP SCREW, 5/16-18x3/4

GROMMET

BUSHING

WASHER, 5/16"

R.H. PEDAL

LDCKNUT, Hex 5/16"

SPACER

BAL. LINK 1

FLANGE WHIZLDCKSCREW 8

PARK BRAKE LEVER

WASHER, 5/16"

WASHER

R.H. BRAKE ASSEMBLY

CLIP

NO

REQ'D

931014 931013

1

1

1 1

2 2

2 2

2

5 5

1

2 2

1

1

1

1

2

1

1

1

3

1

2

2

7

1

AR

AR

1

1

4

1

1

2

1

1

1

1

1

2

1

2

1

4

2

1

8

2

2

7

2

1

1

23

Page 24

MAIN DRIVE

GEAR MODELS 931013 & 931014

•24

Page 25

MAIN DRIVE

GEAR MODELS 931013 & 931014

REF

FART

NO.

NO.

1

2

031771 BRACKET

3

4

031821 STRAP

5 031766 SUPPORT -L.H. Axle

031685

6

7

031728

8 062028 BOLT, Carriage 3/8-16 x 1 Gr. 5

9

064043

10 060032

11

083168

12 031956

13

031958

14 031743

031755 BELT FINGER 3

15

031735

16

031957

17

18 031773

19 031793

20 031772

21 031742

031744 IDLER PIN 1

22

23 631002

071105 TIRE, 23x 10.50x 12

071106

631097

23

071114 TIRE, 23x8.50x 12

071115

059135

26

27

072090

073055 IDLER

28

O6504O

29

059022

30

31

031953

33

064002 Washer, Flat 5/16" 8

34

031952

531093

35

37

031978

38

062010 BOLT, Carriage 3/8-16 x 34

39 065053

40

059001

DESCRIPTION

* TRANSAXLE

* T-DRIVE HEAD ASSEMBLY

SUPPORT - R.H. Axle

WHEEL HUB

WASHER

SETSCREW 2

SPRING EXT.

BRACKET

ROD

IDLER ARM

BRACKET

BELL CRANK

BELL CRANK

ROD

SHEAVE

SHEAVE

TIRE 8i WHEEL ASSEMBLY S-14G 2 65

WHEEL RIM W/Valve

TIRE & WHEEL ASSEMBLY S-10G only 2

WHEEL RIM

CAPSCREW, 5/16-18x3/4 1

V-BELT, Matched Set 1

LOCKNUT

CAP SCREW, HH. 5/16-18x3/4

COUPLING, Input

SPACER.COUPLING

DRIVE SHAFT ASSEMBLY, W/Roll Pin

DRIVE COUPLING

LOCKNUT, 3/4" 3

CAP SCREW 2

NO

REQ'D

1 41

1

1

1

1

1

2

1

1

2

1

1 54 070044

1 55

1

1 59

1

1

1

2

2

2

2

1

2

8

1

2

1

1

3

REF

NO.

42

43 083120 COMPRESSION SPRING 2

44

45 057012 SNAPPING EXTENSION 1

46

47 069094 J- Clamp

48 063003

49 066030

51 066003

52

53

56 064003

57

58 059028

60 031949

62

63

64

66

67

68

70

71

72 067004

73

74

75

76

77

78 003086

79

80 064164

81

82

PART

NO.

059099

065115 LOCKNUT

059068 CAP SCREW, 3/18-16x2 1

065120

059151

065039

070031

058009

064007

064002

067024

062047

065127

062015

065042

062016 BOLT, Carriage

065039

066014

064008 WASHER 3/8

065114

067016 COTTER PIN

031755

065061 JAM NUT

063021

065122

067021

DESCRIPTION

CAP SCREW, HH, 3/8-16 x 5/8 Grade 5

NUT, Hex Jam 2

LOCKWASHER,5/16 3

KEY,Woodruff 1/4" X 1-1/8" 2

KEY, Woodruff No. 9

CAP SCREW, 3/8-16 X 1-1/2" GR 5

LOCKNUT

LUG BOLT 10

SCREW, Whiziock

WASHER

ROLL PIN, 1/8x1

CARRIAGE BOLT 5/16x3/4

WASHER, 1/4 Standard

BELT FINGER MOUNT 1

WASHER

COTTER PIN, 1/8 X 3/4

BOLT, Carriage 1/2-13 x 1-1/4 GR5

LOCKNUT, 1/2-13 GRC

BOLT, Carriage 5/16-18 x 1

LOCKNUT

LOCKNUT, 3/16

KEY, Woodruff No. 61

PIN COTTER, 5/32x1

LUG NUT

BELT FINGER

BALL JOINT

LOCKWASHER 3/8"

WASHER, .805/.842x2x 16 Ga.

LOCKNUT, 3/8-16 GRC

COTTER PIN, 1/8 X 1-1/2

NO

REQ'D

4

2

1

2

4

1

3

5

2

1

2

2

4

4 '

4

1

7

2

3 1

1

1

1

10 1

1

1

3

2

4

1

4

1

*See Y6ur Nearest Tecumseh Service Central For Repairs

Tec. Model No. 2335 Transaxle

Tec. Model No. 3179-P91 T-Drive Head Assy.

I

-25-

Page 26

MODEL 931014 MANUAL LIFT & LINKAGE ASSEMBLY PARTS

REAR

LEFT BRAKE

PEDAL

Page 27

REF

NO

MODEL 931014 MANUAL LIFT & LINKAGE ASSEMBLY PARTS LIST

PART

NO

DESCRIPTION

NO

REQ'D

REF

PART

NO

NO DESCRIPTION

NO

REQ'D

1

031759

LIFT HANDLE 1 26

2 031760 PLUNGER 1

3 058034 PIN, Roll 1/8" X 3/4" 1

4

064096

083104

5

WASHER, Special 1

SPRING

6 055057 BUSHING SLEEVE 2

7

031775

064127

8

9 067003

031761

10

11

062050

12

065039 LOCKNUT

13

066022

14

031745

15

064160

PIN 1

WASHER 2

COTTER PIN 1

LATCH

CARRIAGE BOLT, 3/8-16 x 2-3/4

KEY, Straight 1

ARM 1

WASHER, Special 1

16 031757 ARM 1

17

031758

18

031746

19 031729

ARM 1

CENTER LIFT LINK

REAR LIFT LINK 1

20 067026 COTTER PIN

031017 CHAIN 2

21

083107 SPRING 2

22

23

031753 SPRING CLIP

24

031813

STRAP

25 031051 CLEVIS PIN

1

1 35

1

1

1

2

1

1

1

067004

27

062005

031764

28

COTTER PIN 1

CARRIAGE BOLT 3/8 x 2-1/4 4

QUADRANT

29 062010 BOLT, Carriage 3/8-16x3/4

30

063021 LOCKWASHER 2

31 065018

32 031748

33

065001 NUT, Jam 1

34

075052

031747

083105

36

37 064043

067024

38

NUT 2

LATCH ROD-Model 931011

KNOB

LATCH

COMPRESSION SPRING

WASHER

COTTER PIN 2

39 031015 FRONT ROCK SHAFT, Connector Link 1

064009

40

41

067029 PIN, Hair Cotter 1

42 067006

43 065042

44

059022 CAPSCREW, 5/16-18x3/4

45

067026 COTTER PIN

46

531005

47

029011

48

031014

49

059134

50

063003 LOCKWASHER 1

064115 SHIM, .005 Thick

51

WASHER

COTTER PIN

LOCKNUT, 5/16-18

FRONT ROCK SHAFT

BLOCK

BRACE

CAP SCREW, 5/16-18 X 1-1/4 Gr. 5

52 055021 FLANGED BUSHING

1

2

1

1

1

4

4

1

1

1

1

2

1

4

4

1

AR

1

27-

Page 28

GEAR SHIFT LINKAGE & CONSOLE PARTS

GEAR MODELS 931013 & 931014

GEAR SHIFT LINKAGE & CONSOLE PARTS LIST

GEAR MODELS 931013 & 931014

PART

REF

NO.

1

NO.

031736

1

055101

2

031955

3

075049

4

631121

5

031737

6

064008 WASHER

7

059004

8

064002 WASHER, 5/16

9

063003 LOCKWASHER

10

065015 NUT

11

062017

12

064007

13

14 063002 LOCKWASHER 1/4 4

065032

15

16 022093

17

031S67 ADJUSTING BLOCK

065046 LOCKNUT

DESCRIPTION

CONTROL BOX

BUSHING FLANGE

SHIFT HANDLE

HANDLE

SHIFT LEVER

SHIFT SUPPORT

CAPSCREW, 3/8-16 X 1"

BOLT, Carriage 1/4-20 x 5/8

WASHER 1/4 Standard 4

NUT 1/4-20

ZERK FITTING

NO

REQ'D

1

2

1

1

1

1

4

1

3

3

3

4

4

1

1

1

REF

PART

NO.

NO.

031960

19

064121

20

067004

21

031024 BRACE

22

059023

23

24 062013

064008

25

063021

26

065018 NUT

27

031765

28

062011

29

30 055100

31

059185

065019

32

33 067001 COTTER PIN

34 064037 WASHER

075044 GROMMET 2

35

28-

DESCRIPTION

SHAFT PIN 1

WASHER

COTTER PIN

CAPSCREW, 3/8-16x3/4

BOLT, Carriage, 3/8-16 x 1

WASHER, 3/8

LOCKWASHER

SWITCH BRACKET

BOLT, Carriage, 5/16-18x3/4

SLEEVE BUSHING

CAPSCREW

LOCKNUT

NO

REQ'D

2

1

1

1

3

1

5

5

1

2

2

1

1

1

2

I

i

Page 29

REAR ROCK SHAFT

REF

PART

NO.

N0.

1

031534

2 031497

3 055085

4

031693

5

031498

6 083105 SPRING

7

031499

8 075052

9 067022 HAIRPIN COTTER

10 031012

11

031008

031007

12

13 068055 RIVET, Drilled

067029

14

18 067025 PIN, Cotter, 3/16x2

16 067012 PIN, Cotter, 3/16 X M/2

17

067024

18 064043 WASHER, Flat, 3/8 2

19 065001 NUT, Hex, Jam, 3/8

20 067004

21 059023

22

063021 L0CKWASHER,3/8 2

064004

23

DESCRIPTION

ARM

SHAFT

BEARING, Rockshaft

WASHER, 1-1/32 Hex

LATCH

LATCH ROD

KNOB

PIN

PIN, Clevis

BRACKET

HAIRPIN COTTER

PIN, Cotter, 1/8 X 3/4

PIN, Cotter, 1/8 X 1

CAP SCREW, HH, 3/8 X 3/4 2

WASHER. Flat, 3/8

29-

NO.

REQ'D.

2

1

4

1

1

2

1

1

4

2

1

1

2

1

2

1

2

1

2

2

Page 30

CENTER ROCK SHAFT

PART

REF

NO.

NO.

1

031790 CENTER ROCK SHAFT 1

2 029011 BEARING BLOCK 4

064115

3

4

031811

5

058063 PIN GROOVE, 1/4x2 1

083167

6

7

031809 SPRING HANDLE 1

8 011120

062005 BOLT, Carriage, 3/8 x 2-1/4 4

9

063021

10

11 065018 NUT, Hex, 3/8 4

12 064003

065039

13

DESCRIPTION

SHIM, .005 Thick 4

R.H. ROCKSHAFT LEVER

SPRING, Torsion

BOLT, Shoulder 1

LOCKWASHER,3/8

WASHER

LOCKNUT

NO.

REQ'D.

«

1

1

4

1

1

■30-

Page 31

FRONT PTO AND ELECTRICAL CLUTCH

GEAR MODELS 931013 & 931014

PART

REF

N0.

N0.

1

531013

2 031183 SHAFT

3 054102

4

054052 BEARING

5 057062

6 057024 SNAP RING

7 031979

8 073055

9 031148

10

031157

11

083176

12

072076

13 031544

14

059142 CAPSCREW, HH, 7/16 X 1

15

075060

16

083148

DESCRIPTION

PTO HOUSING W/Needle Bearing

NEEDLE BEARING 1

EXTERNAL SNAP RING

SHEAVE 1

IDLER PULLEY 1

IDLER ARM 1

SPACER 1

SPRING 1

"V" BELT ■ Matched Set of Two 1 28

STUD

COVER, PTO Shaft 2

SPRING

NO

REQ'D

1

1

1

2

1

4

1

4

REF

NO.

PART

NO.

17 066027 KEY, Square, 1/4 x 5/8"

18 059023

063021

19

20 059068

059042

21

031158 SHIM SPACER

22

064045

23

24 065018

065097

25

26 065116

27

063005

531023

29 031358

031265 TERMINAL

30

31 060012 SET SCREW

32 031545

DESCRIPTION

CAPSCREW, HH, 3/8 X 3/4

LOCKWASHER,3/8"

CAPSCREW, HH, 3/8" X 2

CAPSCREW, HH, 1/2" X 1-1/4 1

WASHER, Special 2

NUT, Hex, 3/8"

NUT, Hex, 1/2"

LOCKNUT, 5/16"

LOCKWASHER,7/16"

CLUTCH

SLEEVE

PLATE

-31 -

NO

REQ'D

1

2

3

1

1

1

1

4

5

1

1

1

2

1

Page 32

DASH, CONTROLS AND ELECTRICAL

ALL MODELS

REF

PART

NO.

NO.

1

531058 DASH W/Decal

2 031150

3 031151

4 065104

5 075068

6 031152

7 013157 KEY SET 1

8

065106

9 031179 PTO Indicater 8t Wire Ass'y

10

074043

11

059001

12

069103

069104 THROTTLE CONTROL 1

13

14

075019

15 031085 BATTERY, 12 Voit

16

031111

17

031720

18 031117 AMMETER 1

19 029131 SWITCH, Safety

20 075057

21 065096 NUT, Special, 5/8"

22 031102 CIRCUIT BREAKER, 20 Amp 1

23

031108

24

031110

25 031103

26

031109

27

063002

064127

28

061012

29

DESCRIPTION

SWITCH, Clutch

SWITCH, Lights 1

NUT, Jam, 1/2"

KNOB, Switch 2

SWITCH, Ignition 1

NUT, Speciai,9/16"

SCREW, Self-Tapping, No. 10 x 1/2 4

CAP SCREW, HH, 1/4 X 3/4 8

CHOKE CONTROL ASS'Y

KNOB, Throttie Controi

CABLE ASS'Y, Soienoid to Starter

SOLENOlO STARTER SWITCH 1

INSULATOR

CIRCUIT BREAKER, 6 Amp

CABLE ASS'Y, Battery to Solenoid 1

CABLE ASS'Y, Battery to Ground 1

REGULATOR RECTIFIER 1

L0CKWASHER,1/4"

WASHER, Flat 1/4"

MACHINE SCREW, No. 10-24 x 1/2

NO.

REQ'D

1

1

2

1

1

1

1

1

1

1

1

1

1

8

4

2

REF

NO.

-32-

PART

NO.

30

025172

31 065032

32

063029

33

075061

34

063011

35

065055

36 031070

37

064141

38

065026

39 063011

531074

40

41

031716

42

031833

43 031839

44

075045

45

023478

46 023595

47

031106

48

029170 CONNECTOR HOUSING, 2 Wire

49

031105

50 031149

51

031159

52

061040

53

064001

631006

54

031375 LENS - Red for item 54 (not ill.)

55

031962

DESCRIPTION

SWITCH 1

NUT, Hex, 1/4" 8

LOCKWASHER, Internal Tooth, 9/16" j 1

GROMMET

LOCKWASHER, External Tooth, No. 10 14

NUT, Hex, No. 10-24

CLIP

WASHER 4

NUT

LOCKWASHERS 4

RELAY - Diode 1

SEAT SWITCH 1

BRACKET-Switch i

RELAY - Clutch Control j 1

RUBBER BOOT 1

CONNECTOR HOUSING, 5 Wire 1

CONNECTOR HOUSING, 4 Wire

CONNECTOR HOUSING, 3 Wire

CONNECTOR

HEAD LIGHT 2

RETAINER RING 2

SCREW, Machine, Truss H. No. 10-1/2"

WASHER 8

TAIL LIGHT

BULB - for item 54 GE 1895 (not ill.)

HOUR METER 1

NO.

REQ'O

1

14

2

4

1

1

1

1

8

2

2

2

Page 33

ELECTRICAL WIRING DIAGRAM

ALL MODELS EQUIPPED WITH INTERLOCK MODULE 531074

PART

REF

N0.

N0.

1

031150

2 031151 SWITCH, Lights 1

3

031152

4

031179 PTO Indicator 8i Wire Ass'y

5

031085 BATTERY, 12 Volt

031111

6

7

031720

8 031117

031107

9

10

631006

11

031102 CIRCUIT BREAKER, 20 Amp

12

031108

13 031110

14

031103

15

16 025172

17 531099

18 031716 SEAT SWITCH

023478

20

21 023595

031106

22

031895 CONNECTOR HOUSING, 2 Wire

23

24

031105 CONNECTOR

DESCRIPTION

SWITCH, Clutch 1 25 031149

SWITCH, Ignition

CABLE ASS'Y, Solenoid to Starter 1

SOLENOID STARTER SWITCH

AMMETER

SWITCH, Safety

TAIL LIGHt

CIRCUIT BREAKER, 6 Amp

CABLE ASS'Y, Battery to Solenoid

CABLE ASS'Y, Battery to Ground

REGULATOR RECTIFIER

KOHLER 237335

SWITCH, Reset

INTERLOCK MODULE

CONNECTOR HOUSING, 5 Wire

CONNECTOR HOUSING, 4 Wire

CONNECTOR HOUSING, 3 Wire

NO.

REQ'D

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

PART

REF

NO.

NO.

26 031722 WIRE HARNESS, 2 Wire

27

031147

031114

28

29

031113

30 031104

31

031101

32

031168 WIRE ASS'Y, 44%" Long

33

031119 WIRE, Ignition to Rectifier (blue)

34

031721

35

031712

031715 WIRE, (blue) Switch to Solenoid 1

39

031823 WIRE, (red) 1

40

41 031824 WIRE, (black) Ammeter to Switch

43

031895

031192

DESCRIPTION REQ'D

HEAD LIGHT 2

WIRE HARNESS, 35" Long (white)

Ground for Tail Lites 1

WIRE HARNESS, SVz" Long (blue)

Brake to Lite Switch

WIRE HARNESS, m" Long (black) 20 Amp

Circuit Breaker to Ign. Switch. 6 Amp

Circuit Breaker to Clutch Switch

WIRE HARNESS, (white) Ground for Head Lite 1

WIRE CONNECTOR

WIRE, Wire to Ground (purple)

WIRE , Seat Switch to Ground 1

CONNECTOR

BULB (For Item No. 4, PTO Light) 1

-33

NO.

1

1

2

7

1

1

1

1

1

Page 34

ELECTRICAL WIRING DIAGRAM

GEAR MODELS

EQUIPPED WITH INTERLOCK MODULE 31976 OR 531099

REF

PART

NO.

NO.

1

031150 SWITCH, Clutch

031151 SWITCH, Lights

2

3 031152 SWITCH, Ignition

031085

5

031111

6

031720

7

031117 AMMETER

8

031107

9

631006

10

031102

11

031108

12

031110

13

031103

14

15

025172

16

031976

17

031716

18

023478

20

023595

21

031106

22

029170

23

031105

24

DESCRIPTION

BATTERY, 12 Volt

CABLE ASS'Y, Solenoid to Starter

SOLENOID STARTER SWITCH

SWITCH, Safety

TAIL LIGHT

CIRCUIT BREAKER, 20 Amp

CIRCUIT BREAKER, 6 Amp

CABLE, Battery to Solenoid