Page 1

™

Imperial

Rear-Engine Riders

Owner/Operator Manual

Models

927046 - RM1028

927055 - RM1332

927056 - RM1330

ENGLISH

FRANÇAIS

ESPAÑOL

02758400B 4/02

Supercedes 02758400,A

Printed in USA

Page 2

12

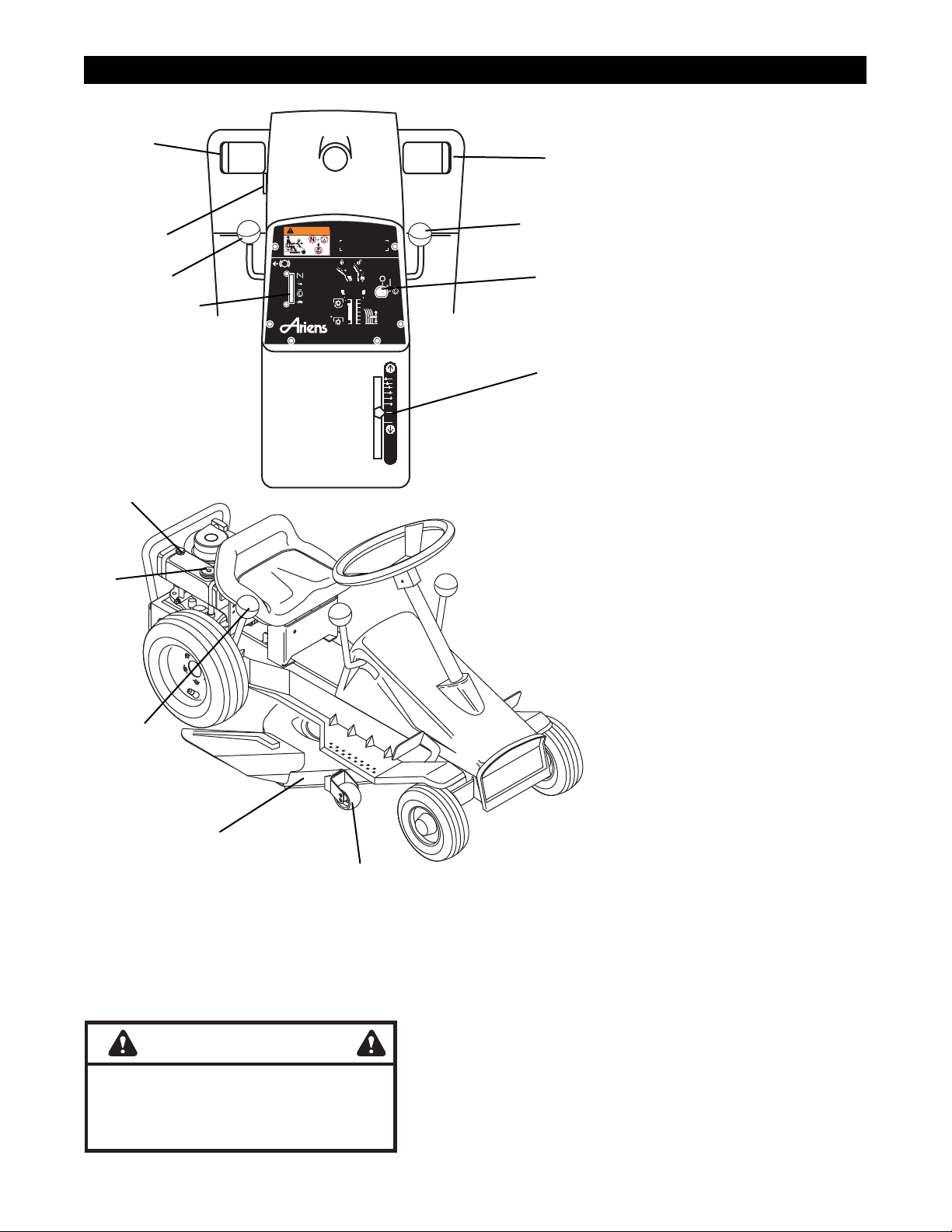

CONTROLS AND FEATURES

ENGLISH

1. Throttle/Choke Control

2. Mower Clutch Lever

3. Parking Brake

4. Clutch Pedal

5. Brake Pedal

6. Mower Height Lever

7. Ignition Key Switch

8. Speed Indicator

9. Roller

10. Mower Pan

11. Speed Selector

12. Fuel Tank Fill

13. Engine Oil Fill

FRANÇAIS

1. Manette des gaz/Starter

2. Embrayage de l'unité de

coupe

3. Fein de stationnement

4. Pédale d'embrayage

5. Pédale de frein

6. Levier de hauteur de

coupe

7. Contacteur d'allumage

8. Indicateur de vitesse

9. Roulette

10. Carter de l'unité de

coupe

11. Sélecteur de vitesse

12. Bouchon du réservoir

d'essence

13. Bouchon d'huile moteur

13

4

5

3

WARNING

Depress clutch pedal

P

and push latch to set.

2

6

7

1

6

5

4

3

2

1

N

R

Speed

Selector

Located on

right hand

side of

driver's seat

OA0012

8

11

10

WARNING

ESPAÑOL

1. Control del acelerador/

estrangulador

2. Palanca del embrague

del cortacésped

3. Freno de mano

4. Pedal del embrague

5. Pedal del freno

6. Palanca de la altura del

cortacésped

7. Interruptor de la llave de

la ignición

8. Indicador de la velocidad

9. Rodillo

PA0012

9

10. Recolector del

cortacésped

11. Selector de la velocidad

12. Llenado del tanque de

combustible

13. Llenado de aceite del

motor

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

3

Page 3

TABLE OF CONTENTS

Controls and Features. . . . . . . . . . . . . . . . . . . . . 3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Service and Adjustments . . . . . . . . . . . . . . . . . 12

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . 22

INTRODUCTION

THE MANUAL

Before operation of unit, carefully and completely read

your manuals. The contents will provide you with an

understanding of safety instructions and controls

during normal operation and maintenance.

All reference to left, right, front, or rear are given from

operator sitting in operation position and facing the

direction of forward travel.

MODEL AND SERIAL NUMBERS

When ordering replacement parts

Transfer

model & serial

number label

from product

registration

here.

or making service inquiries, know

the Model and Serial numbers of

your unit and engine.

Numbers are located on the product

registration form in the unit literature

package. They are printed on a

serial number label, located on the

frame of your unit.

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

PRODUCT REGISTRATION

A warranty registration card must be filled out, signed,

and returned at time of purchase. This card activates

the warranty. Claims meeting requirements during

limited warranty period will be honored.

UNAUTHORIZED REPLACEMENT PARTS

Use only Ariens replacement parts. The replacement of

any part on this vehicle with anything other than an

Ariens authorized replacement part may adversely

affect the performance, durability, or safety of this unit

and may void the warranty. Ariens disclaims liability for

any claims or damages, whether warranty, property

damage, personal injury or death arising out of the use

of unauthorized replacement parts.

For a brief list of replacement parts see Service Parts

in this manual. To obtain a complete parts manual, find

your model and serial number. Then go to

www.ariens.com or call 1-800-678-5443.

Serial

Number

Label

Figure 2

• Record Unit Model and Serial numbers here.

• Record Engine Model and Serial numbers here.

OA0041

DISCLAIMER

Ariens reserves the right to discontinue, make changes

to, and add improvements upon its products at any time

without public notice or obligation. The descriptions

and specifications contained in this manual were in

effect at printing. Equipment described within this

manual may be optional. Some illustrations may not be

applicable to your unit.

DELIVERY

Customer Note: If you have purchased this product

without complete assembly and instruction by your

retailer, it is your responsibility to:

1. Read and understand all assembly instructions in

this manual. If you do not understand or have

difficulty following the instructions, contact your

nearest Ariens Dealer for assistance.

all assembly has been properly completed.

NOTE: To locate your nearest Ariens Dealer, call

1-800-678-5443 or go to www.ariens.com on the internet.

Make sure

GB - 4

Page 4

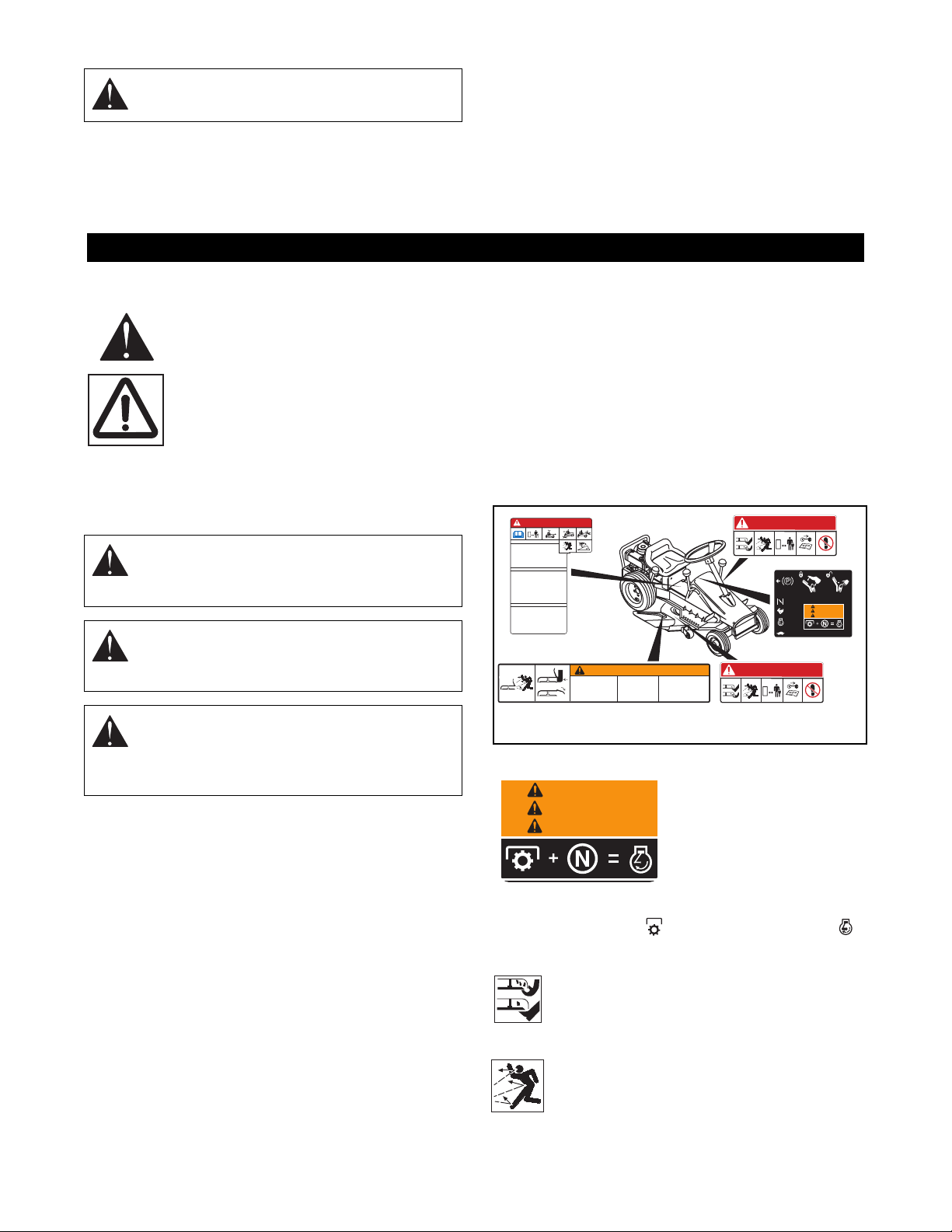

OA0032

WARNING/AVERTISSEMENT/ADVERTENCIA

Do not operate mower

unless guards are in

operating position or

bagger is attached.

Ne jamais utiliser

la tondeuse sans

protecteur sur le

canal d'ejection ou

sans le bac monte.

No operar segadora a

menos que las defensas

esten en posicion de

operacion o el

recogedor este fijo.

07742300B

DANGER/PELIGRO

07731400D

DANGER/PELIGRO

07731400D

DANGER / PELIGRO

TO AVOID SERIOUS INJURY OR DEATH

POUR EVITER LES BLESSURES GRAVES OU LA MORT

PARA EVITAR DAÑOS SERIOS O LA MUERTE

• Leer el manual del operador.

• Mantenga la unidad alejada de los niños u otras personas cuando esté en

funcionamiento.

• Antes y durante retroceso mirar hacia abajo y detras.

• Nunca monten niños.

• Remueva objetos que puedan ser lanzados por la cuchilla.

• Suba y baje pendientes, no transversalmente.

• Si la maquina se detiene subiendo cuesta, desactive la cuchilla y baje

lentamente.

• Evite viradas subitas.

• Mantenga artefactos de seguridad (defensas, protectores, interruptores,

etc.) en su lugar y trabajando.

• Verifique en el manual el sistema de engranar antes de usar.

• Tenga conocimiento de funciones y localizaciones de todos los controles.

• Lire le manuel d'utilisation.

• Éloigner les enfants et toute autre personne pendant le fonctionnement de la

machine.

• Regardez derriere et sur les cotes lorsque vous reculez.

• Ne transportez jamais dénfant.

• Ne jamais décharger directement en direction de quelqu’un. Des particules

projetées peuvent provoquer des blessures.

• Tondez toujours de haut en bas et inversement jamais le long des pentes.

• Si la machine sárrete en montee. Debrayez la lame et redescendez

doucement.

• Evitez les virages brusques.

• Maintenez toujours en place tous les elements de securite (protecteurs,

interupteurs, etc.).

• Controlez le bon fonctionnement des interrupteurs de securité avant

utilisation tel q'uindiqué dans le manuel d'utilisation.

• Comprenez bien la fonction et la situation de chacun des leviers et boutons de

commande.

MAX

1

• Read the operator's manual.

• Keep children and others away from unit while operating.

• Look down and behind before and while backing.

• Never carry children.

• Never direct discharge toward other people. Thrown objects

can cause injury.

• Go up and down slopes, not across.

• If machine stops going uphill, stop blade and back down slowly.

• Avoid sudden turns.

• Keep safety devices (guards, shields,switches, etc.) in place and working.

• Check interlock system per manual before use.

• Understand location and function of all controls.

07739000B

WARNING

AVERTISSEMENT

ADVERTENCIA

08093500

Figure 3

1

2

4

3

2

WARNING: Improper assembly or

adjustments can cause serious injury.

2. Understand all Safety Precautions provided in the

manuals.

3. Review control functions and operation of the

unit. Do not operate unit unless all controls

function as described in this manual.

SAFETY

4. Review recommended lubrication, maintenance

and adjustments.

5. Review Limited Warranty Policy.

6. Fill out Original Purchaser Registration Card and

return the card to Ariens Company.

SAFETY ALERTS

Look for these symbols to point out

important safety precautions. They mean:

Attention!

Personal Safety Is Involved!

Become Alert!

Obey The Message!

The safety alert symbols above and signal words below

are used on decals and in this manual.

Read and understand all safety messages.

DANGER: IMMINENTLY HAZARDOUS

SITUATION! If not avoided, WILL RESULT in

death or serious injury.

WARNING: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, COULD RESULT

in death or serious injury.

CAUTION: POTENTIALLY HAZARDOUS

SITUATION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTATIONS

NOTE: General reference information for proper opera-

tion and maintenance practices.

IMPORTANT: Specific procedures or information

required to prevent damage to unit or attachment.

REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation by the seller. If unit

is to be used by someone other than original

purchaser; loaned, rented or sold, ALWAYS provide

this manual and any needed safety training before

operation.

SAFETY DECALS AND LOCATIONS

ALWAYS replace missing or damaged Safety Decals.

Refer to figure below for Safety Decal locations.

1. WARNING

WARNING

AVERTISSEMENT

ADVERTENCIA

Be sure speed selector is in Neutral (N) and Mower

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate, or serious injury or death. Learn applicable

rules and laws in your area. Always follow the practices

set forth in this manual.

Clutch is disengaged ( ) before starting engine ( ).

2. DANGER!

Always keep feet and hands away from

rotating parts.

OL3030

Always stand clear of the discharge area

when operating this unit.

OL0910

GB - 5

Page 5

3.

Keep children and others away from unit while

operating.

OL4140

Stop engine and remove ignition key before

servicing or leaving operator’s position for

any reason.

OL4010

NO STEP! Always keep feet away from

rotating parts.

OL4420

DANGER! To avoid serious injury or death

Read the operator’s manual.

Allow operation only by properly trained adult,

never children.

OL1801

DO NOT mow when children or others are

around.

Keep children out of work area and under

OL4140

watchful care of a responsible adult.

Look down and behind before and while

backing.

DO NOT operate in reverse unless

OL4100

absolutely necessary. Always back up slowly.

Turn machine off when children are in the

area. Use extra care when approaching

blind corners, shrubs, trees or other objects

OL4110

that may obscure vision.

Never carry children.

Never carry riders.

OL4120

Remove objects that could be thrown by the

blade.

OL0910

Go up and down slopes, not across.

If machine stops going uphill, stop blade and

10°MAX

back down slowly.

OL4770

DO NOT operate on slopes over 10°.

Avoid sudden turns.

Keep safety devices (guards, shields, switches, etc.) in

place and working.

Check interlock system per manual before use.

Understand location and function of all controls.

4. WARNING!

Always stand clear of the discharge area

when operating this unit.

OL4430

Do not operate mower unless guards are in

operating position or bagger is attached.

OL3320

ASSEMBLY SAFETY RULES

Read, understand, and follow all safety practices in

Owner/Operator Manual before beginning assembly.

Failure to follow instructions could result in personal

injury and/or damage to unit.

ALWAYS remove key from ignition and wire from spark

plug before assembly. Unintentional engine start up

can cause death or serious injury.

OPERATIONAL SAFETY RULES

Walk Around Inspection

Complete a walk around inspection of unit and work

area to understand:

• Work area • Your unit • All safety decals

Work Area

ALWAYS check overhead and side clearances carefully

before operation. ALWAYS be aware of traffic when

operating along streets or curbs.

Keep children and people away. Keep children out of

work area and under watchful care of a responsible

adult.

NEVER allow children to operate or play on or near

unit. Be alert and shut off unit if children enter area.

Keep area of operation clear of all toys, pets, and

debris. Thrown objects can cause injury.

Check for weak spots on docks, ramps or floors. Avoid

uneven work areas and rough terrain. Stay alert for

hidden hazards.

Avoid uneven and rough terrain. DO NOT operate near

drop offs, ditches, or embankments. Unit can suddenly

turn over if a wheel is over the edge of a cliff or ditch, or

if an edge caves in.

Dust, fog, etc. can reduce vision and cause an

accident. Operate unit only when there is good visibility

and light.

Personal Safety

Data indicates that operators, age 60 and above, are

involved in a larger percentage of riding mower related

injuries. These operators should evaluate their ability to

operate the riding mower safely enough to protect

themselves and others from serious injury.

Only trained adults may operate unit. Training includes

being familiar with controls and actual operation.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation requires

your complete and unimpaired attention at all times.

NEVER allow anyone to operate this unit when their

alertness or coordination is impaired.

GB - 6

Page 6

Wear adequate safety gear and protective gloves.

Wear proper footwear to improve footing on slippery

surfaces.

DO NOT wear loose clothing or jewelry and tie back

hair that may get caught in rotating parts.

Protect eyes, face and head from objects that may be

thrown from unit. Wear appropriate hearing protection.

Always wear safety goggles or safety glasses with side

shields when operating mower.

Avoid sharp edges. Sharp edges can cut. Moving parts

can cut off fingers or a hand.

ALWAYS keep hands and feet away from all rotating

parts during operation. Rotating parts can cut off body

parts.

ALWAYS keep hands away from all pinch points.

DO NOT touch unit parts which might be hot from

operation. Allow parts to cool before attempting to

maintain, adjust or service.

NEVER place your hands or any part of your body or

clothing inside or near any moving part while unit is

running.

NEVER direct discharge towards persons or property

that may be injured or damaged by thrown objects. Use

extreme caution on gravel surfaces. Stay alert for

hidden hazards or traffic.

ALWAYS stand clear of the discharge area.

Fumes from engine exhaust can cause injury or death.

DO NOT run engine in an enclosed area. Always

provide good ventilation.

ALWAYS disengage attachment, stop unit and engine,

remove key and allow moving parts to stop before

leaving operator’s position.

Operation

Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an Emergency

• Braking and steering characteristics

• Turning radius and clearances

Disengage PTO when attachment is not in use.

DO NOT operate unit if safety interlock system is

damaged or disabled. Check safety interlock before

each use (see Operation ).

ALWAYS disengage PTO, stop unit and engine,

remove key, engage parking brake and allow moving

parts to stop before leaving operator’s position.

ALWAYS remove key to prevent unauthorized use.

Only allow responsible adults who are trained and

familiar with the instructions to operate the machine.

Training includes actual operation.

DO NOT operate at too fast a rate. DO NOT change

engine governor settings or over-speed engine. Slow

down before turning.

DO NOT mow near dropoffs, ditches or embankments.

The mower could suddenly turn over if a wheel is over

the edge of a cliff or ditch, or if an edge caves in.

Stop engine before removing grass catcher or

unclogging chute.

DO NOT mow on wet grass. Reduced traction could

cause sliding.

DO NOT try to stabilize the machine by putting your

foot on the ground.

Know the weight of loads. Limit loads to those you can

safely control and the unit can safely handle.

ALWAYS keep protective structures, guards and panels

in good repair, in place and securely fastened.

Do not operate without either entire grass catcher or

the discharge guard in place.

DO NOT operate in reverse unless absolutely

necessary. ALWAYS look down and behind before and

while backing.

Watch for holes, ruts, or bumps. Uneven terrain could

overturn the machine.

Be aware of the mower discharge direction and DO

NOT point it at anyone.

Follow the manufacturer’s recommendations for wheel

weights or counterweights to improve stability when

using attachments.

NEVER carry passengers.

Follow the manufacturer’s recommendation for wheel

weights or counterweights.

Use extra care when approaching blind corners or

objects that may obscure vision.

Hazardous Slopes

If you cannot back up a slope or you feel uneasy on it,

do not mow it.

Mow up and down slopes, not across them.

Use slow speed on any slope. Choose a low gear so

that you will not have to stop or shift while on the slope.

Tires may lose traction on slopes even though the

brakes are functioning properly.

Keep all movements on the slope slow and gradual.

DO NOT make sudden changes in speed or direction.

Avoid starting or stopping on a slope. If tires lose

traction, disengage the blades and proceed slowly

straight down the slope.

DO NOT operate on slopes over 10˚.

DO NOT park on slopes unless necessary. When

parking on slope always chock or block wheels. Always

set parking brake.

DO NOT shift to neutral and coast downhill.

GB - 7

Page 7

TOWING

Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the

hitch point.

Follow the manufacturer’s recommendations for weight

limits for towed equipment and towing on slopes.

NEVER allow children or others in or on towed

equipment.

On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

Travel slowly and allow extra distance to stop.

Transport

Use extra care when loading or unloading unit onto

trailer or truck.

Secure unit chassis to transport vehicle. NEVER

secure from rods or linkages that could be damaged.

DO NOT transport machine while engine is running.

Cleaning

Keep unit free of debris. Clean up oil or fuel spills.

Keep muffler area free of grass clippings, leaves and

other debris.

Spark Arrester

This product is equipped with an internal combustion

type engine. DO NOT use unit on or near any

unimproved, forest-covered or brush covered land

unless exhaust system is equipped with a spark

arrester meeting applicable local, state or federal laws.

A spark arrester, if it is used, must be maintained in

effective working order by operator.

FUEL SAFETY RULES

Fuel is highly flammable and its vapors are explosive.

Handle with care. Use an approved fuel container.

NO smoking, NO sparks, NO flames. ALWAYS allow

engine to cool before servicing.

NEVER fill fuel tank when engine is running or hot from

operation.

NEVER fill or drain fuel tank indoors.

Replace fuel cap securely and clean up spilled fuel.

NEVER fill containers inside a vehicle or on a truck or

trailer bed with a plastic liner. Always place containers

on the ground away from your vehicle before filling.

When practical, remove gas-powered equipment from

the truck or trailer and refuel it on the ground. If this is

not possible, then refuel such equipment on a trailer

with a portable container, rather than from a gasoline

dispenser nozzle.

Keep the nozzle in contact with the rim of the fuel tank

or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

If fuel is spilled on clothing, change clothing

immediately.

BATTERY SAFETY RULES

Avoid Electric Shock. Objects contacting both battery

terminals at the same time may result in injury and unit

damage. DO NOT reverse battery connections.

Explosive Gases from battery can cause death or

serious injury. Poisonous battery fluid contains sulfuric

acid and its contact with skin, eyes or clothing can

cause severe chemical burns.

NO flames, NO sparks, NO smoking near battery.

ALWAYS wear safety glasses and protective gear near

battery.

DO NOT TIP battery beyond a 45˚ angle in any

direction.

ALWAYS keep batteries out of reach of children.

Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals known to

the State of California to cause cancer and

reproductive harm. Wash hands after handling.

Reverse connections may result in sparks which can

cause serious injury. Always connect positive (+) lead

of charger to positive (+) terminal, and negative (-) lead

to negative (-) terminal.

ALWAYS connect positive (+) cable FIRST, and

negative (-) cable SECOND.

A frozen battery can explode and result in death or

serious injury. DO NOT charge or jump start a battery

containing frozen fluid. Thaw the battery before putting

on a charger or jump starting.

Battery Electrolyte First Aid

Follow First Aid directions for contact with battery fluid.

• External Contact: Flush with water.

• Eyes: Flush with water for at least 15 minutes and

get medical attention immediately!

• Internal Contact: Drink large quantities of water.

Follow with Milk of Magnesia, beaten egg or

vegetable oil. Get medical attention immediately!

In case of internal contact, DO NOT induce vomiting!

MAINTENANCE AND SERVICE SAFETY

RULES

ALWAYS keep protective structures, guards, and

panels in good repair, in place and securely fastened.

NEVER modify or remove safety devices.

DO NOT change engine governor settings or

over-speed engine.

Fumes from engine exhaust can cause injury or death.

DO NOT run engine in an enclosed area. Always

provide good ventilation.

ALWAYS maintain unit in safe operating condition.

Damaged or worn out muffler can cause fire or

explosion.

GB - 8

Page 8

Stop and inspect equipment if you strike an object.

Repair, if necessary, before restarting. Never make

adjustments or repairs with the engine running.

Mower blades are sharp and can cut you. Wrap the

blade(s) or wear gloves, and use extra caution when

servicing them.

Check brake operation frequently. Adjust and service

as required.

Keep all hardware properly tightened.

Stored energy in springs can cause injury.

Maintain or replace safety and instruction labels, as

necessary.

OPERATION

STANDARD CONTROLS

See Figure 1 for all Controls and Features locations.

Throttle/Choke

Throttle/Choke lever controls engine speed

(to increase, push up – to decrease, pull

down) and activates choke (push lever up

and to right past offset).

To start a cold engine move lever to

“CHOKE” position and after engine has

started, gradually pull lever down to open

choke and allow engine to warm up at 1/2

throttle setting. (It should not be necessary

to choke a warm engine).

OT0690

STORAGE SAFETY RULES

Never store the machine or fuel container inside a

building where there is an open flame, such as a water

heater.

Allow engine to cool completely before storing in

closed area or covering unit.

For extended storage, clean unit thoroughly. See

Engine Manual for proper storage.

ACCESSORY AND ATTACHMENT SAFETY

RULES

Use only attachments or accessories designed for your

unit.

Check attachment components frequently. If worn or

damaged, replace with manufacturer’s recommended

parts.

Brake Pedal

When Brake Pedal is depressed (with clutch pedal

depressed), brake band on friction wheel hub stops

riding lawn mower.

CAUTION: Brake will not stop riding mower

without depressing Clutch Pedal. To stop unit

in an emergency, fully depress clutch pedal,

then depress brake pedal.

If unit rolls backward down a slope, with

Speed Selector in forward speed, fully

depress clutch pedal then depress brake to

stop. DO NOT release clutch pedal until unit

has stopped rolling and Speed Selector has

been moved to first or second speed.

CAUTION: DO NOT change engine governor

setting or over speed engine.

1

Ignition

2

The Ignition Switch is operated by a

removable Key. It has three positions:

3

1.Stop

2.Run

OT0681

3.Start

Electric Start (Optional)

The Electric Starter will start a properly choked and

cranked engine when the key is turned to the “Start”

position.

Recoil Starter Handle

Pull handle to start engine (see Manual Start).

Clutch Pedal

When Clutch Pedal is depressed, transmission is

disengaged from engine, permitting shifting from

neutral (N) to desired direction of travel. With Speed

Selector in 1st or 2nd speed, release Clutch Pedal

slowly for smooth acceleration and remove foot from

pedal.

IMPORTANT: Do not leave foot on pedal during

operation as belt slippage may occur.

When unit is in motion, use of Clutch Pedal is not

required when shifting between forward travel speeds.

Depressing Clutch Pedal beyond clutching point will

activate brake.

GB - 9

Page 9

Travel Speed Selector

The Speed Selector controls the unit travel in a forward

or reverse direction when positioned in notch of speed.

Speed Selector lever is used to select

neutral (N) or travel speeds that provide six

forward speeds with one reverse speed.

6

These speeds are shown at indicator on

5

side of frame. First (1) speed is slowest,

4

3

(6) indicates fastest speed, (R) indicates

2

reverse and (N) indicates neutral position.

1

To start engine, Speed Selector must be in

N

neutral (N).

R

Ariens recommends starting forward travel

in first (1) or second (2) speed, then

Speed

Selector

Located on

right hand

side of

driver's seat

shifting “on the go” to desired travel speed.

078552

Attachment Clutch

1.Move Mower Clutch Lever to left, then

forward to (ON) position to start mower

blade rotation and cutting (move to right to

latch).

2.Pull lever to left, then to rear (OUT)

position to apply blade brake and stop

blade rotation.

Attachment Lift

Move Attachment Control to right then to

rear position for maximum cutting height

(4" [10 cm]). Move lever to right, then to

forward position for lowest cutting height

(1.5" [3.8 cm]). Intermediate positions allow selection

of cutting heights between these values.

Parking Brake

P

Brake and Latch engaged will damage brake band and

friction wheel.

Parking Brake is provided to prevent

tractor from rolling when parked or left

unattended.

To engage Parking Brake, fully depress

Clutch Pedal and engage Parking Brake

Latch, then remove pressure from Clutch

Pedal.

To disengage Parking Brake, depress

Clutch Pedal fully and disengage Parking

Brake Latch.

IMPORTANT: Operating unit with Parking

PRE-STARTING

Crankcase Oil

Check that the engine crankcase oil is at proper level

by setting dipstick into tube. Fill or change per

instructions in Service and Adjustments Section.

CAUTION: Make sure all hardware is tight, all

safety devices are in place and all

adjustments are made correctly.

Air Cleaner

Check air filter for dirt. Clean as required. See Service

and Adjustments Section.

Engine Fuel

Refer to Service and Adjustments Section.

Check fuel supply. Wipe dust, dirt and debris from

around cap before removing to prevent foreign particles

from entering tank.

NOTE: For cold weather starts, use a winter grade gasoline which has a higher volatility to improve starting.

DO NOT use gasoline left over from summer.

Seat Adjustment

Be sure all controls can be reached safely from

operator’s position. To move seat, loosen four bolts

under seat, move seat to desired position, and tighten

bolts.

Safety Interlock System

With operator on seat, engine must not start if PTO is

engaged.

Engine MUST STOP if operator leaves seat when:

• speed selector lever is not in neutral or

• parking brake is disengaged or

• PTO is engaged

Engine MUST NOT start unless:

• parking brake is set/brake pedal is depressed and

• speed selector lever is in neutral and

• PTO is disengaged.

WARNING: Safety interlock system failure

and improper operation of unit can result in

death or serious injury. Check system before

each use to make sure it is functioning

properly.

GB - 10

Page 10

STARTING AND SHUT OFF

PARKING

CAUTION: DO NOT attempt to start unit at

this time. Read and understand entire manual

before starting unit.

Electric Start

See Figure 1 for all Controls and Features locations.

1. Place mower unit on level ground.

2. Place Speed Selector in neutral (N).

3. Place Mower Clutch Lever in disengaged (OUT)

position.

4. Depress both Brake and Clutch Pedals to prevent

rolling.

5. Insert key into ignition switch.

6. Set throttle to “Choke” position.

7. Turn key to “Start” position to crank engine and

release when engine starts.

IMPORTANT: DO NOT operate starter motor more

than 15 seconds per minute, as overheating and

damage can occur.

8. Set throttle to Part Throttle or Slow position for

adaptation to ambient temperature or transport.

Once achieved, set throttle to Fast position for

normal operation.

9. Select Speed Control range.

Manual Start

1. Follow the previous starting steps 1-3.

2. Engage Parking Brake.

3. Turn key to Run position.

4. Set throttle to “Choke” position.

5. Grasp starter handle and pull rope out slowly until

it pulls harder, this is compression stroke, let rope

rewind slowly.

6. Pull rope with a rapid continuous full arm stroke.

Let rope rewind slowly.

IMPORTANT: DO NOT let Starter Handle snap against

Starter.

7. Repeat until engine starts. (If engine does not

start, refer to Engine Manual).

8. Follow the previous starting steps 8-9.

STOPPING

1. Depress clutch/brake pedal, disengage

Implement Power (lever OUT), lower attachment,

fully depress clutch pedal and engage parking

brake latch and then remove pressure from

pedal.

2. Turn Ignition Key counterclockwise to stop

engine.

3. Remove key.

CAUTION: MACHINE ROLL AWAY can

cause injury or death. ALWAYS engage

parking brake when leaving unit unattended.

Stop engine, and remove key before cleaning

or servicing unit.

To park, stop the unit on level ground and engage the

Parking Brake. Always take all possible precautions

when leaving equipment unattended.

MOWING TIPS

The following tips will help you to mow safely, achieve

maximum performance from your unit and maintain the

desired appearance of the lawn.

WARNING: MOVING PARTS can cut or

amputate body parts.

NEVER attempt to clear rotary mower pan or

discharge while engine is running.

ALWAYS stop engine, remove key, and wait

for moving parts to stop before clearing rotary

mower.

CAUTION: Stay alert for holes, rocks, roots

and hidden hazards in area of operation.

Exercise extreme caution when operating on

or crossing gravel surfaces. Stay alert for

traffic.

NOTE: Clean mower pan after each use. DO NOT

allow grass clumps or a coating of grass and debris to

collect inside of mower pan. Avoid operation over bare

ground intermittent with grass cutting as this causes

dirt and grass to collect and cake under pan surface.

Grass should be cut when it is dry, not when it is wet

from dew, rain or from watering. Wet grass tends to

pack inside mower pan and will not discharge, mulch or

bag properly, especially if height of cut is set low.

Keep mower blades sharp. Dull blades will tear grass

and a white cast will result over a freshly cut lawn. The

tips of the grass blades will then turn brown. A new

lawn has soft blades of grass and a high moisture

content.

Proper leveling and pitch of the rotary mower pan is

needed for a smooth even lawn. If the pitch of the

mower pan is in reverse or inadequate, grass will be cut

twice, resulting in frayed grass ends. Too much pitch

causes an uneven cut.

Upon first use of mower, cut the grass at a longer

length. This will prevent scalping due to the

irregularities in lawn.

To insure most complete and even cut, overlap each

swath.

GB - 11

Page 11

Plan your cutting so that you always trim with the left

side of the mower pan.

Following the same pattern each time you mow the

lawn can develop ridges. Change direction in mowing

pattern (when possible) to prevent ridges.

Generally, grass should be cut at about 1-1/2" (3.8 cm)

long in the spring, and not less than 2" (5.1 cm) long in

the hot summer weather.

Lower speed at turns to prevent scuffing.

If grass is high, or if it contains a high degree of

moisture, cut it first with the mower pan set high. Cut

the grass a second time, with the mower pan set lower,

for a better distribution of clippings and a cleaner cut.

For thick, lush or heavy growth lawns do not set the

cutting height too low. Grass cut too short may die.

When the blade is set too low, the mower pan will drag

on the grass and restrict air flow, causing a reduction in

the discharge of grass clippings.

SERVICE AND ADJUSTMENTS

Discharge grass clippings away from borderline objects

(sidewalks, driveways, fences) when cutting grass.

Discharge grass clippings over cut grass when not

cutting borderlines. This will prevent a buildup of grass

clippings on uncut grass area.

Adjust anti-scalp wheels properly for smooth

appearance in cut.

Mow with engine set at full throttle to maintain proper

blade speed and air flow for discharge of clippings.

CAUTION: Grass catcher components are

subject to wear, damage, and deterioration

which could expose moving parts or allow

objects to be thrown. Frequently check

components and replace with manufacturer’s

recommended parts when necessary.

Ariens Dealers will provide any service or adjustments

which may be required to keep your unit operating at

peak efficiency. Should engine service be required,

contact an Ariens dealer or an authorized engine

manufacturer's service center.

WARNING: ACCIDENTAL ENGINE START

UP can cause death or serious injury.

ALWAYS stop engine, remove key, wait for

moving parts to stop and remove wire from

spark plug before adjusting or servicing.

HOT SURFACES can cause death or serious

injury. DO NOT TOUCH parts which are hot

from operation. ALWAYS allow parts to cool.

ROTATING PARTS can cut off body parts.

Keep hands and feet away. Loose clothing,

long hair or scarves can get caught in rotating

parts and cause death or serious injury.

SERVICE POSITION

Place unit on a flat level surface. ALWAYS stop engine

and disengage clutches. Tip up on the service bar for

ease of access during some procedures. Assure unit is

secure and will not tip over. Strap and clamp onto lift if

used.

CAUTION: Remove enough fuel so that no

spillage will occur. Remove battery to prevent

spillage of electrolyte.

FILLING FUEL TANK

WARNING: FLAMMABLE FUEL and its

EXPLOSIVE VAPORS can result in death or

serious injury.

Handle fuel with care. ALWAYS use an

approved fuel container.

No Smoking! No Lighted Materials!

No Open Flame!

Allow engine to cool before any service.

To add fuel to Fuel Tank (figure 4):

1. ALWAYS place unit in open or well ventilated

area.

2. Stop engine and allow to cool for 2 minutes.

3. Clean Fuel Cap and surrounding area to prevent

dirt from entering Fuel Tank.

4. Remove Cap.

IMPORTANT: DO NOT use gasohol or gasoline

containing alcohol. Alcohol will cause internal parts to

deteriorate. See Engine Manual for correct type and

grade of fuel.

5. Fill fuel tank to within 1/2" (1.3 cm) below bottom

of filler neck with unleaded gasoline.

6. Replace Fuel Cap and tighten.

7. ALWAYS clean up any spilled fuel.

IMPORTANT: When unit is tipped up onto its service

bar, undrained gasoline drawn into cylinder may wash

cylinder wall and shorten engine life.

GB - 12

Page 12

ENGINE

See Figure 4. For further information on the engines,

refer to the enclosed Engine Manual.

1

6

5

4

1. Oil Fill Cap and

Dipstick

2. Air Cleaner Cover

3. Spark Plug

4. Oil Drain Plug

5. Fuel Tank

6. Fuel Cap

Figure 4

Cooling

Engine is air cooled. Air must circulate freely around

engine from Air Intake to cooling fins on cylinder head

and block, to prevent overheating.

Every 100 hours of operation or yearly (more often if

conditions require) remove cooling shrouds and clean

cooling fins. Clean external surfaces of engine of dust,

dirt and oil deposits which can contribute to improper

cooling.

IMPORTANT: DO NOT operate engine with blower

housing removed or engine overheating damage will

result.

2

3

4. If low, add oil and bring up to the Full (F) mark.

DO NOT over fill. Oil level must not exceed Full

(F) mark.

5. Replace dipstick and cap.

6. Clean up any spilled oil.

IMPORTANT: DO NOT overfill. Be sure engine is level

when adding oil.

Changing Oil

IMPORTANT: Change engine crankcase oil after first

two (2) hours of operation. Thereafter, change oil every

twenty five hours of operation (more often in dusty dirty

conditions).

NOTE: Run engine just prior to changing oil. Oil will

flow more freely and carry away more contamination

when warm.

1. Drain engine crankcase by removing oil drain

plug. After oil has drained, replace plug.

2. Remove oil fill cap and dipstick.

3. Pouring slowly, fill crankcase with oil. (See

specifications).

4. Check oil level with dipstick. Replace dipstick and

retighten cap.

Air Cleaner

IMPORTANT: Never run engine without complete air

cleaner installed on engine.

1

CAUTION: Periodically clean muffler and

manifold areas to remove all grass, dirt and

combustible debris. If engine muffler is

equipped with spark arrester screen

assembly, remove every 50 hours for cleaning

and inspection. Replace if damaged.

Engine Oil

See engine manufacturer’s instructions for proper type,

viscosity and amount required.

Engine Oil Check

The engine crankcase oil should be checked daily or

every five (5) hours of operation. Oil level MUST be

maintained in safe operating range on dipstick at all

times or engine damage will result.

To Check:

1. Clean all debris away from around oil cap.

2. Remove oil cap and dipstick. Wipe oil off dipstick

with a clean cloth.

3. Replace dipstick until cap bottoms on tube.

Remove dipstick again and observe oil level. Oil

should be at the Full (F) mark.

2

3

1. Cover

2. Filter Element

3. Paper Element

4

4. Body

Figure 5

Inspect filter every twenty-five (25) operating hours

(more often if unit is used under extremely dirty or

dusty conditions).

Foam Filter

Clean and reoil every three (3) months or every

25 operating hours. Clean and reoil daily if used in

extremely dusty conditions.

1. Wash in water and detergent solution and

squeeze (don’t twist) until all dirt is removed.

2. Rinse thoroughly in clear water.

3. Wrap in a clean cloth and squeeze (do not twist)

until completely dry.

GB - 13

Page 13

4. Saturate with engine oil and squeeze (do not

1. Mower Belt

2. Rear Belt Finger

3. Engine Pulley

4. Drive Belt

5. Idler Arm

6. Friction Wheel

7. Drive Disc

Figure 6

1

2

3

7

6

5

4

twist) to distribute oil and remove excess oil.

Paper Filter

Do not attempt to clean or oil filter. Replace once a

year or every 100 operating hours, more often if used in

extremely dusty conditions.

Clean inside of cover and body of filter holder. Replace

filter and cover and secure.

Spark Plug

Spark plug should be cleaned or replaced (if

necessary) and gap reset to .030" every 100 hours of

operation or yearly whichever comes first.

To clean:

1. Remove debris from area around spark plug

base.

2. Remove spark plug from engine.

3. Scrape and wash spark plug with a commercial

solvent. DO NOT blast clean.

4. Replace spark plug.

NOTE: Sparking can occur if wire terminal does not fit

firmly on spark plug. Replace terminal if damaged.

Mower Drive Belt Replacement

See Figures 6-7.

1. Remove rear belt finger from back cover and

mower belt from engine pulley.

2. Remove five cap screws with lock washers that

secure friction wheel and guard to hub (this

provides clearance for removal of belt).

3. Place Speed Selector in neutral (N), release drive

belt from idler and remove it from drive disk and

engine pulley.

4. Install new belt around engine pulley, drive disk

and idler with belt properly seated in grooves.

5. Secure friction wheel and guard on hub with five

cap screws and lock washers.

6. Install mower belt on engine pulley and secure

rear belt finger to back cover.

Muffler

Worn out mufflers should be replaced immediately.

Continued use could result in fire or explosion.

Rotary Mower Belt Replacement

See Figures 6-7.

1. Disengage (OUT) Mower Clutch lever.

2. Loosen three nuts securing rear belt finger to

back cover and rotate belt finger

counterclockwise to remove from unit.

3. On 32" mowers, remove mower pulley belt finger,

loosen cap screw on clutching idler and fixed idler

to provide clearance for belt between belt fingers

and idlers.

4. Remove old belt and place new belt in position on

mower and engine pulley.

5. Position rear belt finger with 1/16" clearance

between belt and finger, secure rear belt finger to

rear cover by tightening top two nuts first, then

bottom nut (see Figure 6).

6. On 32" mowers tighten cap screws on clutching

idler (with 1/8" clearance between belt and finger)

and fixed idler (with tab on mount engaged in hole

of belt finger).

7. Install belt finger at mower pulley with 1/16"

clearance between belt and finger (bend finger as

required).

4

3

5 1/4" to 5 3/8"

6

2

1

5

1. Mower Pulley

2. Mower Belt

3. Fixed Idler

4. Clutching Idler

5. Belt Finger

6. Adjustable Clutch Rod

Figure 7

GB - 14

Page 14

MOWER BLADE

1. Hairpin

2. Front Hanger Pin

3. Rear Links

4. Swivel Bracket

5. Rear Hanger Pin &

Hair Pin

6. Coupling Nut

7. Jam Nut

8. Upper Jam Nut

9. Lower Jam Nut

10. Lift Rod

Figure 9

OM0180

B. Rear Hanger

A. Front Hanger

1

2

3

4

5

7

6

9

8

10

CAUTION: Replace bent, worn or damaged

blades.

See figure 8.

Regularly check mower blades for wear and that lock

washer is fully compressed by hardware.

28" and 32" decks: torque cap screw to 25-30 lbf-ft

(34-47 N•m).

30" decks: torque nut to 50-60 lbf-ft (68-81 N•m).

When blade needs sharpening:

1. Block blade to prevent rotation.

2. Remove hardware and blade from shaft.

3. Sharpen the beveled edges of the blades in a

straight line. Do not change the angle of the

beveled edge.When blade becomes less than

2.00" wide, discard the blade. Make sure the

sharpened blades are balanced. Balance must

be held within 1.3 inch ounces.

4. Install blade, lock washer, and tighten hardware

to torque listed above.

IMPORTANT: If mower is used under sandy soil

conditions, replace blades when air lifts become

eroded.

4. Remove cotter pin from clutch rod and rod from

clutch link.

5. Remove hair pin and front hanger pin to

disconnect front linkage.

6. On 32" mower, remove hair pins and positioning

arms from front mounting bracket.

7. Remove mower pan from rider.

8. Install mower pan on rider in reverse order.

2

3

IMPORTANT: On 28" & 32", when replacing blade,

blade should be 3/8" (9 mm) above flange. To position,

turn cap screws on each end of blade tray until both

tips of blade clear flange by 3/8" (9 mm) all the way

around pan.

Mower Pan Removal

See Figure 9.

1. Remove rear belt finger from back cover and

mower belt from engine pulley (See Mower Belt

section).

2. Position mower on flat level surface. Lower

mower pan with Height Control lever. (Lowering

mower pan down on blocks will relieve weight on

linkage and make removal of pins easier).

3. Remove hair pin and rear hanger pin from swivel

bracket to disconnect rear link.

1

4

1. Cutting Edge

2. Square Corner

3. Air Lift Erosion

4. Air Lift

5. Cap Screw

6. Tip of Blade

Figure 8

5

6

BATTERY

When Charging battery remove it from the unit first.

WARNING: ELECTRIC SHOCK may result in

injury and/or damage to unit.

DO NOT allow objects to come into contact

GB - 15

with both terminals at the same time.

REVERSE CONNECTIONS may result in

sparks which can cause death or serious

injury. ALWAYS connect positive (+) lead of

charger to positive (+) terminal, and negative

(–) lead to negative (–) terminal.

ALWAYS connect positive (+) cable FIRST,

and negative (–) cable SECOND.

Page 15

WARNING: EXPLOSIVE GASES from

battery can cause death or serious injury.

ALWAYS keep open flames, sparks, or

smoking materials away from batteries.

POISONOUS BATTERY FLUID contains

sulfuric acid and its contact with skin, eyes or

clothing can cause severe chemical burns.

ALWAYS wear safety glasses and protective

gear near battery.

DO NOT TIP any battery beyond 45° angle in

any direction.

ALWAYS KEEP BATTERIES OUT OF REACH

of children.

Battery Electrolyte First Aid

Follow First Aid directions for contact with battery fluid.

• External Contact: Flush with water.

• Eyes: Flush with water for at least 15 minutes and get

medical attention immediately!

• Internal Contact: Drink large quantities of water.

Follow with Milk of Magnesia, beaten egg or

vegetable oil. Get medical attention immediately!

IMPORTANT: In case of internal contact, DO NOT

induce vomiting!

Cleaning Terminals

Place unit on a level surface, shut off engine and open

battery compartment to gain access to battery.

1. Disconnect negative (–) cable first, then positive

(+) cable.

2. Loosen strap and remove battery.

3. Place Battery on bench or other well ventilated

place where electrolyte spill will not create

damage.

4. Remove caps and fill each cell to level indicated

with electrolyte at 1.265±.05 specific gravity and

80°F (27°C).

5. Let battery stand for one half hour.

6. Check electrolyte level and add more if necessary.

7. Connect positive (+) lead of charger to positive (+)

terminal, and negative (–) lead to negative (–)

terminal.

8. Charge the battery at two and a half amps for ten

hours or until all cells are gassing freely and the

specific gravity is constant over three 30 minute

intervals.

9. Immediately after charging, check electrolyte level.

If low, add distilled water to bring cell up to required

level.

10. Replace caps finger tight, wash off and dry battery.

11. Reinstall battery into unit and connect positive (+)

cable first, then negative (–) cable.

WARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and reproductive

harm. Wash hands after handling.

Keep battery and its terminals clean. Inspect monthly

to maintain best performance.

Remove corrosion from battery terminals and cable

connections with a wire brush, then wash with a weak

baking soda solution.

After cleaning, apply a thin coat of grease or petroleum

jelly to terminals and cable ends to retard corrosion.

Electrolyte Level

Every 25 hours or each week check electrolyte level of

each cell by removing caps one at a time. The

electrolyte level should be at level indicator. Use

distilled water to fill each cell if needed.

IMPORTANT: When distilled water is added to battery

during freezing weather, it must be charged to mix

water with electrolyte or water will remain at top and

freeze.

Charging

ALWAYS follow information provided on battery by

battery manufacturer. Contact battery manufacturer for

extensive instructions to charge battery.

Battery Charger

Under normal conditions the engine alternator will have

no problem keeping battery charged. When unit has

set for an extended period of time without operation

and the battery has been completely discharged, a

battery charger will be required for recharging.

Before using a charger, an attempt can be made to

recharge the battery using the engine alternator by

jump starting the unit and allowing the to engine run.

JUMP STARTING

Jump starting, battery charging or replacement is

required when the starter motor will not crank the

engine.

CAUTION: FROZEN BATTERIES CAN

EXPLODE and result in death or serious

injury.

DO NOT charge a frozen battery. Let the

battery thaw out before putting on a charger.

To jump start battery:

1. Ensure battery is not frozen. If the fluid is frozen,

remove battery from unit and allow it to thaw

before charging.

2. The unit used for jump starting should have a 12

volt battery with at least 500 cold cranking

amperes, and a negatively grounded system.

GB - 16

Page 16

WARNING: UNIT MOVEMENT can result in

death or serious injury. NEVER jump start unit

directly to the starter or starter solenoid. Unit

can move forward or backward and injure the

person jump starting unit.

TIRES

NOTE: Keep tires properly inflated at all times. For

proper tire inflation when working under various conditions, refer to chart below. Use a low pressure tire

gauge for accurate pressure readings.

3. Connect the positive (+) jumper cable to the

positive terminal of the discharged battery.

4. Connect the other end of the same jumper cable

to the positive (+) terminal of the booster battery.

5. Connect one end of the second jumper cable to

the negative (–) terminal of the booster battery.

6. Make the final jumper cable connection to the

engine block or the furthest ground point away

from the discharged battery.

7. Follow steps in “Starting and Shut OFF”.

8. Remove jumper cables in the reverse order of

their connection: Remove cable from ground

point, the negative (–) terminal of the booster

battery, the positive (+) terminal of the booster

battery, and then the positive (+) terminal of the

discharged battery.

CAUTION: REVERSE CONNECTIONS may

result in sparks which may result in injury.

ALWAYS connect/disconnect cables in proper

order.

5

3

4

Front

Back

14 psi

14 psi

Check tire pressure at least once a month. Over

inflation may cause operator discomfort and excessive

tire tracks on lawns or soft surfaces, while under

inflation causes short tire life.

NOTE: After checking and/or inflating, replace and

tighten valve caps to prevent air loss.

SEAT

Clean seat regularly, using a vinyl cleaner (not solvent).

Extreme temperatures can damage seat when left

unprotected against weather. If seat should tear, apply

vinyl repair tape to protect damaged area.

GENERAL LUBRICATION

IMPORTANT: Wipe each grease zerk fitting clean

before and after lubrication. Keep grease and oil off

belts to avoid slippage and deterioration.

Apply Sten Mix Hi-Temp Grease or equivalent to the

lube fittings. Order P/N: 00036800 - three pack of 3 oz.

cartridges or 00036700 - ten pack of 14 oz. cartridges.

Apply oil at lubrication points.

The steering system, front wheels, left rear wheel and

linkage pivot points (figure 11) should be lubricated

every 25 hours of operation, or twice each season,

whichever occurs first.

6

1

2

1. Battery

2. Battery Cover

3. Battery Strap

4. Positive Terminal (+)

5. Negative Terminal (–)

6. Filler Caps

Figure 10

IMPORTANT: DO NOT fast charge. Charging at higher

rate will damage or destroy battery.

GB - 17

Page 17

MAINTENANCE SCHEDULE

Before

Service Performed

Each

Use

25 50 100

Figure 11

MAINTENANCE SCHEDULE

The chart below shows the recommended

maintenance schedule that should be performed on a

regular basis. More frequent service may be required

due to working conditions (heavy loads, high ambient

temperatures, dusty conditions, or airborne debris).

See Engine Manuals for further maintenance and

trouble shooting information.

MAINTENANCE SCHEDULE

Before

Service Performed

Fasteners

Safety Interlock

System

Air Cleaner

Engine Oil

Engine Oil

Foam Air Filter

Each

Use

•

•

•

•

*

25 50 100

•

•

Tire Pressure

Battery

Battery Fluid

Brake

Adjustment

Mower Blades

Mower and Drive

Belts

General Lubrication

Steering System,

Front Axle and

Mower Spindles

Engine Oil Filter

Spark Plugs

Fuel Filter

Engine

Paper Air Filter

Clean Cooling Fins

After first 2 Hours of operation

•

•

•

•

•

•

**

•

•

•

•

•

•

•

•

*

After first 25 Hours of operation

**

ADJUSTMENTS

Ariens Company recommends that you have

adjustments made by your Ariens dealer. They have

the knowledge and tools to properly perform

adjustments which may be required to keep your

equipment operating at peak efficiency. Should you

decide to make the following adjustments on your unit

yourself, Ariens Company recommends that you call

your dealer for answers to any questions that might

arise.

Clutch and Brake

• Clutch and brake adjustments are dependent upon

each other. If depressing Clutch and Brake Pedal

fully does not stop riding mower and/or hold it on hill,

brake must be adjusted.

• With Speed Selector in neutral (N), depress Clutch

Pedal fully and engage Parking Brake.

GB - 18

Page 18

• Adjust double nuts on clutch rod until carrier yoke

1. Steering Gear

2. Adjustment Cap Screw

3. Height Control

4. Height Lever

5. View Quadrant Through

Slot

6. Spring Clip

Figure 13

1

2

3

4

5

6

clears neutral stop by 1/8 to 1/4 inch (3–6 mm).

• Release Parking Brake and turn both rear wheels by

hand. They should rotate freely in neutral (N) but not

rotate with Speed Selector in any other position.

• Using two 1/2" wrenches (to avoid twisting or

distorting brake band), hold inner adjusting nut with

one wrench and loosen outer lock nut with the other.

• Turn rear wheel by hand while tightening inner

adjustment nut until brake band just binds on hub.

Back off adjusting nut by 1-1/2 turns and secure with

locknut.

• Test by fully depressing Clutch Pedal and trying to

turn wheels by hand. They should not turn.

2. Belt engagement should occur when front edge

of Mower Clutch is positioned in line with rear

edge of forward notch of quadrant (as viewed

through slot in left side of cowl).

3. Full locked-in engagement should occur when

lever is positioned completely into front notch of

quadrant. (Some resistance should be felt when

moving lever into notch.)

1. Neutral Stop

2. Brake Rod

3. Clutch Rod

4. Clutch Adjustment

Nuts

Mower Belt

Adjust mower belt after first five (5) hours of operation.

To adjust 28" and 30" mowers:

1. Place height control lever in midnotch position,

depress spring clip and tighten yoke on front of

unit with a 3/4" socket wrench (Figure 13).

2. When tightening cap screw, hold Mower Clutch

lever so that front edge of lever is positioned in

line with rear edge of forward notch of quadrant.

3. Tighten belt just enough to prevent slippage

under load. Mower Clutch lever (when tightening

cap screw) will move slightly to rear of this point

when tension is correct.

To adjust the 32" mower:

1. The 32" mower belt clutch rod should be adjusted

so the compressed spring length is from 5-1/4" to

5-3/8" (13.3–13.7 cm) when belt is engaged

(See Figure 7 on page 14).

2

5

1

5. Brake adjustment

Nuts

6. Brake Band

Figure 12

3

4

6

Mower Level (Side to Side)

2

1

3

1. Adjustment Cap Screw

2. Adjustment Lever

3. Mower Pan

Figure 14

GB - 19

Page 19

1

2

3

4

1

6

1. Cutting Tip

2. Mower Pan

3. Blade

5

Figure 15

4. Ground Level

5. Cutting Height

6. Discharge Chute

OT0860

CAUTION: Rotate mower blade with Mower

Clutch disengaged (OUT) and take

measurements with Mower Clutch engaged

(ON).

NOTE: A wood block (about 1" square by 5" long) may

be used under pan for blade measurement. Wrap block

with masking tape, mark tape with cutting edge of

blade and measure distance from end of block to

mark(s). This method avoids errors by having to read

any measurements under pan.

NOTE: These adjustments should be made on a level

surface with the tires inflated to the correct air pressure.

Cutting height range is 1.5" to 4.25" (3.8 –10.8 cm).

Place Tractor on a smooth, flat, level surface. Do the

following:

1. With blade(s) positioned side to side, measure

distance of blade(s) tips to floor at right and left

side of mower pan.

2. Rotate blade(s) 180° and check again. The

measurement should be equal within 1/8" side to

side.

To correct for difference in height of blade tips from side

to side,

1. Loosen nuts on adjustment levers (Figure 14).

2. Turn adjustment cap screw clockwise on low side

of mower pan to raise low side one half the

difference in height.

3. Turn adjustment cap screw counterclockwise on

high side to lower high side the other one half of

the height difference.

4. Tighten nuts on adjustment levers.

2

4

1. Blade Cutting Edges

2. Ground Level

3. Front Blade Height

4. Rear Blade Height

Figure 16

3

Front of Unit

OT0130

Mower Pitch and Height

Proper blade pitch is when the blade tip, measured

from the bottom surface (Figure 16), is 1/4" to 3/8"

(6–9 mm) lower at front of mower pan than when same

tip is at rear of mower pan.

Adjusting front lift link raises or lowers front of mower

pan and changes both cutting height and pitch

(Figure 9).

To adjust:

1. Loosen jam nut on front link to allow for

movement of coupling nut.

2. Turn coupling nut clockwise to raise and

counterclockwise to lower front of mower pan.

3. Secure coupling in position by tightening jam nut.

Adjusting rear lift links raises or lowers rear of mower

pan and changes both cutting height and pitch

(Figure 9).

To adjust:

1. Loosen both lower jam nuts to allow for

movement of upper jam nuts on lift rods.

2. Turn both upper jam nuts on each lift rod equally

to raise or lower rear of pan.

3. Secure lift rods in position by tightening lower jam

nuts.

If proper pitch cannot be obtained with front and rear lift

links:

1. Loosen nut on carriage bolt and remove cap

screw holding lift strap and adjustment strap

together (Figure 17).

2. Slide lift strap and adjustment strap together to

raise, or apart to lower rear of pan.

3. Select tapped hole in lift strap that provides

proper adjustment, install cap screw in tapped

hole and tighten nut on carriage bolt to secure.

GB - 20

Page 20

1

2

3

1. Lift Strap

2. Cap Screw - Remove to Adjust

3. Carriage Bolt

4. Adjustment Strap

Figure 17

Anti-Scalp Rollers

See figure 1 for Controls and Features.

Secure rollers in middle position for average lawn

4

mowing.

1. Use lowest roller position when mowing in higher

2. Use highest roller position when cutting at lowest

For smoothest appearing cut when using frame

suspended models with anti-scalp rollers, keep

anti-scalp rollers adjusted to the minimum 1/2" (13 mm)

above flat hard smooth surface after setting height of

cut.

NOTE: The rollers are intended for anti-scalping, not

for controlling cutting height.

STORAGE

cutting heights and rough terrain to guard against

most scalping.

cutting height.

IMPORTANT: DO NOT clean with a high pressure

wash or store unit outdoors to aid in prevention of rust

or corrosion. Water can seep into sealed bearings,

which are sealed against dirt and debris only, causing

reduced component life.

Keep all nuts, bolts and screws tight and know unit is in

safe working condition. Check all hardware at regular

intervals.

Inspection

Inspect unit for visible signs of wear, breakage or

damage. Order any parts required and make

necessary repairs to avoid delays when beginning use

again.

Grass Bag

Remove Grass Bag and clean out all debris prior to

storage. Grass Bag may be stored in position on

mower. Keep Grass Bag dry during storage.

Battery

Fully charge battery and store in a cool dry location.

Engine

When storing mower for an extended period, refer to

engine instruction for proper engine storage

procedures.

Cleaning

Use a mild soap on a damp cloth to thoroughly clean

unit of soil buildup. Touch up all areas to prevent rust.

Matching touch up paint is available from your Ariens

Dealer. Store mower in a cool, dry protected location.

GB - 21

Page 21

TROUBLE SHOOTING

Problem Probable Cause

Starter will not

operate when the

ignition key is

turned to the "S"

position

Solenoid switch

clicks but starter

will not operate

when the ignition

is turned to the “S”

position.

Engine starter

operates but

engine will not

start when the

ignition switch is

turned to the “S”

position.

Engine starts but

runs roughly.

Engine stops when

PTO or Fwd-Rev is

engaged.

Shift lever in gear (no spark).

PTO engaged.

Defective solenoid switch.

Blown Fuse.

Discharged battery.

Loose battery cables.

Defective starter.

Faulty interlock switch.

Discharged battery.

Defective starter.

Loose battery cable.

Fuel tank empty.

Fuel shut-off valve at the fuel tank turned off.

Engine failure - See Engine Manual.

Shift lever in gear (no spark).

PTO engaged (no spark).

Engine choke in “ON” position.

Restricted air cleaner element.

Restricted fuel cap vent.

Engine carburetor malfunction - See Engine

Manual.

Engine electrical system trouble - See

Engine Manual.

Operator presence seat switch not pressed.

Faulty seat switch.

Wiring to PTO switch incorrect.

SERVICE PARTS

Part No. Qty. Description

02749400 1 Battery

07216900 1 PTO Belt (Engine to 28”, 30”

Decks)

07215500 1 PTO Belt (Engine to 32” Deck)

07211200 1 Transmission Belt

00300300 1 Friction Disk

02749300 1 Blade 28”

02728700 1 Blade 30”

02747000 1 Blade 32”

ATTACHMENTS

82702000 2 Bucket Bagger 26"/30" Mowers

82702600 2 Bucket Bagger 28"/32" Mowers

ACCESSORIES

See your authorized dealer to add the additional

accessories available for your unit.

70398500 Tire Chains

72701300 Dethatcher

72701600 Front Weight

72703400 Leaf Mulcher 30"

72703500 28" Mulching Kit

72703600 32"Mulching Kit

The tractor will not

move when the

direction control

lever or pedal is

moved to

“FORWARD” or

“REVERSE”

position.

Attachment will not

operate.

Gear shift lever in “NEUTRAL” position.

Fwd-Rev clutch needs adjustment.

Transmission disconnect is in the

disengaged position.

PTO belt is off.

GB - 22

Page 22

SPECIFICATIONS

Model Number 927046 927055 927056

Description RM1028 RM1332 RM1330

Length - cm (in) 159 (62.5)

Height - cm (in) 99 (39)

Width - cm (in)

Actual Weight - kg(lbs) 168 (370) 170 (375) 168 (370)

Battery 180 CCA

Brakes Drum

Steering Gear & Pinion

Turning Radius - cm (in.) 66 (26)

Max. Angle of Slope Operation Not to exceed 10°

Tire Size Front - cm (in.)

Rear - cm (in)

Engine Briggs & Stratton

HP 10 HP 13 HP

Starting System Electric

Fuel Tank Cap. (2.84L) 3 Qt.

Fuel Unleaded

Idle RPM 1800

Governed RPM 3250

Crank Case Cap. (1.66L) 56 Oz.

Air Cleaner Paper Element/Foam Precleaner

Engine Oil Type SAE 30

Spark Plug - mm (in.) 0,76 (0.30)

Transmission Sealed Case

Speed - Forward Max. MPH (km/hr)

Reverse Max. MPH (km/hr)

Transmission Lube 150 Grease

Drive Clutch Disc-O-Matic

Tire Pressure - Front

Rear

Lift System Manual

Power Take-off Manual

Mower Deck - Flex & Float Standard

High Performance Standard

Cutting Width - cm (in.)

Cutting Height - cm (in.) 3.8-10.8 (1.5-4.25)

Cut Increments - cm (in.) 1.27 (0.5)

89 (35) 99 (39) 104 (41)

4.10-3.50x4.00

16x6.5x8.00

1.6-5.5 (2.6-8.8)

2.7 (4.3)

14

14

71.1 (28)

81.3 (32)

76.2 (30)

GB - 23

Page 23

2 Year Limited Warranty

Ariens Company warrants to the original purchaser that consumer products manufactured

by Ariens Company will be free from defects in material and workmanship for a period

of two (2) years after the date of purchase, and will repair any defect in material or

Ariens Company

655 West Ryan Street

P.O. Box 157

Brillion, WI 54110-0157

920-756-2141

Fax 920-756-2407

www.ariens.com

This warranty is subject to the following conditions, limitations, and exclusions:

This warranty is valid only if the following conditions are

met:

• The warranty registration card must be completed and

returned to Ariens Company.

• The purchaser must perform maintenance and minor

adjustments explained in the owner’s manual.

• The purchaser must promptly notify Ariens Company or an

authorized Ariens service representative of the need for

warranty service.

This warranty is subject to the following limitations:

• The purchaser must transport the product to and from the

place of warranty service.

• Warranty service must be performed by an authorized Ariens

service representative. (To find an authorized Ariens service

representative, contact Ariens Company at the number or

address above.)

• Batteries are warranted only for a period of twelve (12)

months after date of purchase, on a prorated basis. For the

first ninety (90) days of the warranty period, a defective

battery will be replaced free of charge. If the applicable

warranty period is more than 90 days, Ariens Company will

cover the prorated cost of any defective battery, for up to

twelve(12) months after the date of purchase.

workmanship, and repair or replace any defective part, subject to the conditions, limitations

and exclusions set forth herein.

The two year duration of this warranty applies only if the product is put to ordinary,

reasonable, and usual personal, family, or household uses. If the product is put to any

business, commercial, or industrial use such as, but not limited to, commercial landscaping,

mowing or snow removal services, or golf course or park maintenance, or agricultural

or farmstead use, then the duration of this warranty is ninety (90) days after the date

of purchase, or one (1) year after the date of purchase if the product is labeled as a

Professional/Commercial Product. If any product is rented or leased, then the duration

of this warranty is ninety (90) days after the date of purchase.

Genuine Ariens service parts and accessories not purchased with the product covered

by this warranty, but which are later purchased and used with that product, are warranted

to be free from defects in material and workmanship for a period of ninety (90) days

after date of purchase, and Ariens Company will repair or replace any such part or

accessory free of charge, except for labor, during that period.

The following items are not covered by this warranty:

• Engines and engine accessories are covered only by the

warranty made by the engine manufacturer, and are not

covered by this warranty.

• If the product is equipped with a Peerless gearbox and/or

transmission, the gearbox and/or transmission are covered

only by the warranty made by Peerless, and are not covered

by this warranty.

• If the product is equipped with a Hydro-Gear transmission

and/or Hydro-Gear drive components, the Hydro-Gear

transmission and/or drive components are covered only by

the warranty made by Hydro-Gear, and are not covered by

this warranty.

• Parts that are not genuine Ariens service parts are not

covered by this warranty.

• Shoes, runners, scraper blades, shear bolts, string trimmer

height guide, mower blades, mower vanes, trimmer line,

headlights, light bulbs, are not covered by this warranty.

• Any defect which is the result of misuse, alteration, improper

assembly, improper adjustment, neglect, or accident, is not

covered by this warranty.

• Products which were not purchased in the United States,

Puerto Rico, or Canada are not covered by this warranty. In

all other countries, contact place of purchase.

LIMITATION OF REMEDY AND DAMAGES

Ariens Company’s liability under this warranty, and under any

implied warranty that may exist, is limited to repair of any

defect in workmanship, and repair or replacement of any

defective part. Ariens Company shall not be liable for incidental,

special, or consequential damages (including lost profits).

Some states do not allow the exclusion of incidental or

consequential damages, so the above limitation or exclusion

may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

DISCLAIMER OF FURTHER WARRANTY

Ariens Company makes no warranty, express

or implied, other than what is expressly made

in this warranty. If the law of your state provides

that an implied warranty of merchantability, or

an implied warranty of fitness for particular

purpose, or any other implied warranty, applies

to Ariens Company, then any such implied

warranty is limited to the duration of this

warranty. Some states do not allow limitations