Page 1

924 Sno-Thro

Service Manual

Models 924108 - 924113, 924115, 924327 - 924330, 924500, 924501

00040700 02/00

Printed in USA

Page 2

TABLE OF CONTENTS

Section 1 - Introduction . . . . . . . . . . . . . . . . . 1.3

1.1 The Manual . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.2 Service and Replacement Parts . . . . . . . 1.3

1.3 Product Registration . . . . . . . . . . . . . . . . 1.3

1.4 Unauthorized Replacement Parts . . . . . . 1.3

1.5 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.6 Technical Service Communications. . . . . 1.3

Section 2 - Safety . . . . . . . . . . . . . . . . . . . . . . 2.4

2.1 Safety Alerts . . . . . . . . . . . . . . . . . . . . . . 2.4

2.2 Signal Words . . . . . . . . . . . . . . . . . . . . . . 2.4

2.3 Notations . . . . . . . . . . . . . . . . . . . . . . . . . 2.4

2.4 Practices and Laws . . . . . . . . . . . . . . . . . 2.4

2.5 Required Operator Training . . . . . . . . . . . 2.4

2.6 Preparation . . . . . . . . . . . . . . . . . . . . . . . 2.4

2.7 Service Position. . . . . . . . . . . . . . . . . . . . 2.4

2.8 Cleaning and Storage . . . . . . . . . . . . . . . 2.4

2.9 Safety Rules. . . . . . . . . . . . . . . . . . . . . . . 2.5

Section 3 - Specifications . . . . . . . . . . . . . . . 3.7

Section 4 - General Maintenance &

Adjustments. . . . . . . . . . . . . . . . . . . . . . . .4.10

4.1 Controls and Features . . . . . . . . . . . . . . .4.10

4.2 Service Positions. . . . . . . . . . . . . . . . . . .4.11

4.3 Filling The Fuel Tank . . . . . . . . . . . . . . . .4.11

4.4 Fuel Shut-Off Valve . . . . . . . . . . . . . . . . .4.12

4.5 General Lubrication . . . . . . . . . . . . . . . . .4.12

4.6 Auger Gearcase. . . . . . . . . . . . . . . . . . . .4 .13

4.7 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . .4.13

4.8 Traction Drive Belt . . . . . . . . . . . . . . . . . .4.13

4.9 Attachment Drive Belt . . . . . . . . . . . . . . .4.14

4.10 Shear Bolts . . . . . . . . . . . . . . . . . . . . . .4.14

4.11 Tire Pressure . . . . . . . . . . . . . . . . . . . . .4.15

4.12 Adjustments . . . . . . . . . . . . . . . . . . . . . .4.15

Section 5 - HandleBars & Controls . . . . . . . .5.18

5.1 Lower Handlebar . . . . . . . . . . . . . . . . . . .5.18

5.2 Attachment Clutch Handle. . . . . . . . . . . .5.18

5.3 Wheel Drive Clutch Lever & Traction Cable5.18

5.4 Clutch Yoke and Fork. . . . . . . . . . . . . . . .5.19

Section 6 - Engine. . . . . . . . . . . . . . . . . . . . . .6.20

6.1 Engine Troubleshooting . . . . . . . . . . . . . .6.20

6.2 Removing the Engine. . . . . . . . . . . . . . . .6.21

6.3 Installing The Engine . . . . . . . . . . . . . . . .6.21

Section 7 - Reduction Drive . . . . . . . . . . . . . .7.22

7.1 Differential, Lockout, And Axle. . . . . . . . .7.22

7.2 Spur Gear and Axle . . . . . . . . . . . . . . . . .7.22

7.3 Axle Bearings. . . . . . . . . . . . . . . . . . . . . .7.22

7.4 Drive Chain . . . . . . . . . . . . . . . . . . . . . . .7.23

7.5 Drive Chain Adjustment . . . . . . . . . . . . . .7.23

Section 8 - Friction Wheel Drive . . . . . . . . . .8.24

8.1 Friction Wheel . . . . . . . . . . . . . . . . . . . . .8.24

8.2 Friction Wheel Carrier . . . . . . . . . . . . . . .8.24

8.3 Drive Plate Spindle . . . . . . . . . . . . . . . . .8.24

Section 9 - Auger/Impeller . . . . . . . . . . . . . . .9.26

9.1 Auger/Impeller Removal. . . . . . . . . . . . . .9.26

9.2 Scraper Blade . . . . . . . . . . . . . . . . . . . . .9.26

9.3 Shear Bolts . . . . . . . . . . . . . . . . . . . . . . .9.26

9.4 Discharge Chute . . . . . . . . . . . . . . . . . . .9.27

9.5 Deflector. . . . . . . . . . . . . . . . . . . . . . . . . .9.28

9.6 Runners . . . . . . . . . . . . . . . . . . . . . . . . . .9.28

Section 10 - Gear Case . . . . . . . . . . . . . . . . . 10.29

10.1 Cast Iron Gear Case (Worm Gear) . . . 10.29

10.2 Aluminum Gear Case. . . . . . . . . . . . . . 10.29

Section 11 - Electrical. . . . . . . . . . . . . . . . . . 11.32

11.1 Continuity Diagram. . . . . . . . . . . . . . . . 11.32

11.2 Wiring Diagram . . . . . . . . . . . . . . . . . . 11.33

2

Page 3

SECTION 1 - INTRODUCTION

1.1 THE MANUAL

It is the purpose of this manual to provide complete

instructions for service, maintenance, disassembly,

repair, and installation of the mechanical components

for the 924 Snow-Thro.

Dealer trained service personnel should use this

manual as a supplement to and reminder of the training

sessions conducted by the company.

Read all information for servicing a part of system

before repair work is started to avoid needless

disassembly.

Operation

Before operation of the unit, carefully and completely

read manuals supplied with the unit. The contents will

provide you with an understanding of safety

instructions and controls during normal operation and

maintenance.

Safety Messages

For your safety and the safety of others always read,

understand, and follow all DANGER, WARNING, and

CAUTION messages found in manuals and on safety

decals.

Directional Reference

All reference to left, right, front, or rear are given from

the operator in the operator position and facing the

direction of forward travel.

1.2 SERVICE AND REPLACEMENT PARTS

When ordering publications, replacement parts, or

making service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product registration form in

the unit literature package. They are printed on a serial

number label, located on the frame of your unit.

1.3 PRODUCT REGISTRATION

A warranty registration card must be filled out, signed,

and returned at the time of purchase. This card

activates the warranty. Claims meeting requirements

during limited warranty period will be honored.

1.4 UNAUTHORIZED REPLACEMENT

PARTS

Use only Ariens replacement parts. The replacement

of any part on this vehicle with anything other than a

Ariens authorized replacement part may adversely

affect the performance, durability, or safety of this unit

and may void the warranty. Ariens disclaims liability for

any claims or damages, whether warranty, property

damage, personal injury, or death arising out of the use

of unauthorized replacement parts.

1.5 DISCLAIMER

Ariens reserves the right to discontinue, make changes

to, and add improvements upon its products at any time

without public notice or obligation. The descriptions

and specifications contained in this manual were in

effect at printing. Equipment described within this

manual may be optional. Some illustrations may not be

applicable to your unit.

1.6 TECHNICAL SERVICE

COMMUNICATIONS

Ariens Technical Service communicates information to

the field using Service Letters, Service Bulletins,

Product Notices, and Campaigns. Each communication

signifies a type of information and priority . The dealer is

responsible to carry out the direc ti ve provided in the

communication. The types of communication are:

Service Letter

dealer. Technical information on how to service the

product and product improvements.

Service Bulletin

resolve certain issues or a notification of a policy

change.

Product Notices

located in a certain region. This is a limited distribution

to only those who received the product involved.

Campaigns

product must be updated and are tracked by the factory

until all units are corrected.

- General technical information for the

- Notification to update products to

- Notification of limited product

- Notification of a safety related issue. All

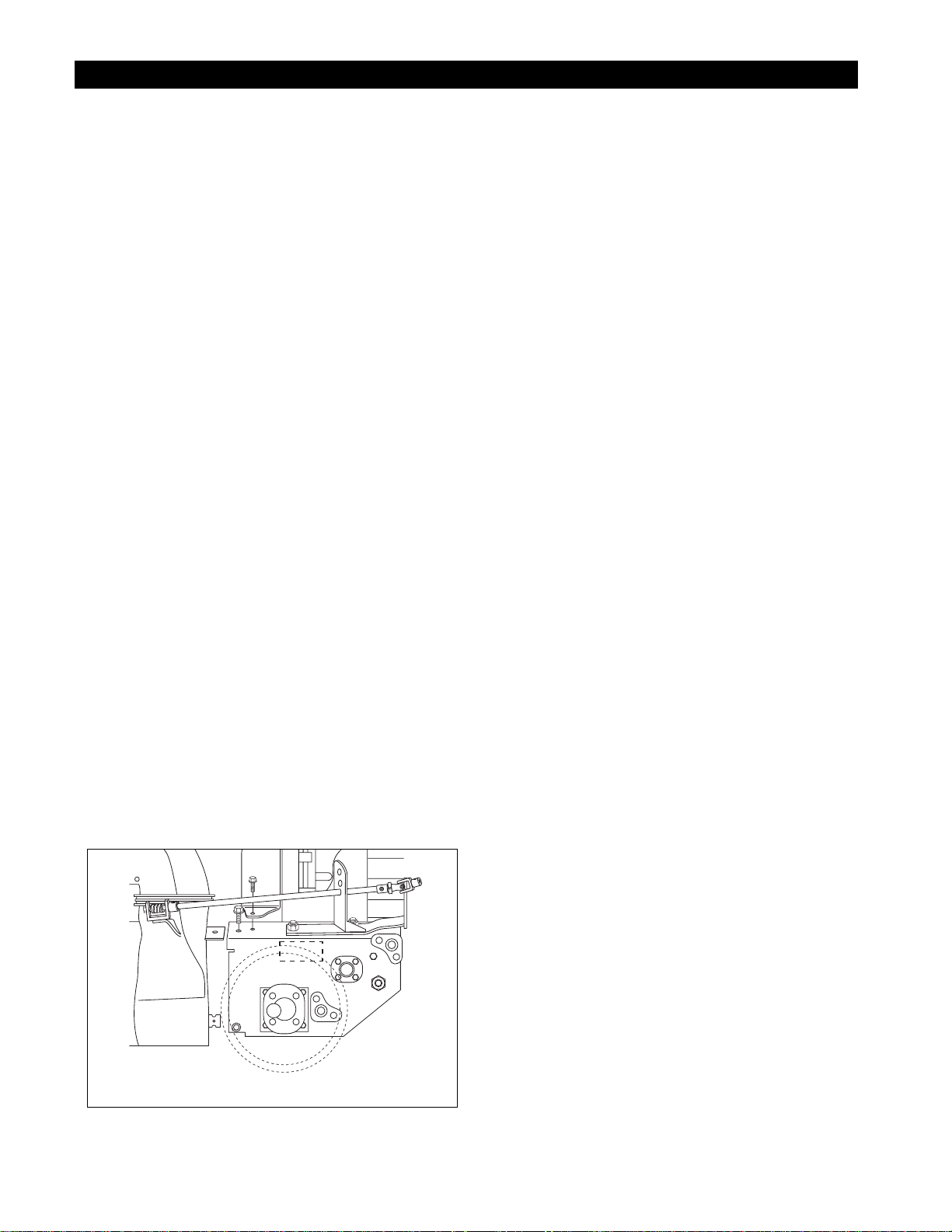

Figure 1

OS0791

1 - 3

Page 4

SECTION 2 - SAFETY

2.1 SAFETY ALERTS

Look for these symbols to point out

important safety precautions. They

mean:

Attention!

Personal Safety Is Involved!

Become Alert!

Obey The Message!

2.2 SIGNAL WORDS

The safety alert symbol is used in decals on the unit

and with proper operation procedures in this manual.

They alert you to the existence and relative degree of

hazards.

Understand the safety message. It contains important

information about personal safety on or near the unit.

DANGER:

SITUATION! If not avoided, WILL RESULT in

death or serious injury.

WARNING:

SITUATION! If not av oided, COULD RESULT

in death or serious injury.

CAUTION:

SITUATION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be used

to alert against unsafe practices.

IMMINENTLY HAZARDOUS

POTENTIALLY HAZARDOUS

POTENTIALLY HAZARDOUS

2.3 NOTATIONS

NOTE:

ation and maintenance practices.

IMPORTANT:

required to prevent damage to unit or attachment.

General reference information for proper oper-

Specific procedures or information

2.4 PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate, or serious injury or death. Learn applicable

rules and laws in your area.

2.5 REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation. If unit is to be used

by someone other than original purchaser; loaned,

rented or sold, ALWAYS provide this manual and any

needed safety training before operation.

2.6 PREPARATION

Before starting any removal of parts, proper

preparation is very important for efficient work. A clean

work area at the start of each job will allow you to

perform service repairs easily and quickly.

To reduce the incidence of misplaced tools or parts,

place removed components with all attaching hardware

in the disassembly order on a clean work surface.

Organization is a key part of proper reassembly.

Tools, instruments, and parts needed for the job should

be gathered before work is started. Interrupting a job to

locate tools or parts is a needless delay. A list of

required special tools has been included in this

manual.

2.7 SERVICE POSITION

WARNING:

that jack stands or blocks used are stable,

strong, or secure and will hold the weight of

the unit during maintenance.

To ensure the unit is positioned in the proper service

position place unit on a flat level surface. ALWAYS stop

engine. Assure unit is secure and will not tip over . Strap

and clamp onto lift if used.

For additional requirements see section on service

position.

ALWAYS block wheels and know

2.8 CLEANING AND STORAGE

WARNING:

can cut. Movement of parts can cut off fingers

or a hand. Wear gloves, and use extreme

caution when servicing.

IMPORTANT:

outdoors to help prevent sealed bearing rust or

corrosion. Water can seep into sealed bearings and

reduce component life. Bearings are sealed against dirt

and debris only.

A unit that is excessively dirty should be cleaned before

work starts. Cleaning will occasionally uncover trouble

sources. Dirt and abrasive dust reduce the efficient

work life of parts and can lead to costly replacement.

When taking unit out of extended storage:

1. Check for any damage or loose parts. Repair,

replace, or tighten hardware before operation.

2. If a preservative fluid was used in fuel tank, drain

and discard. Fill fuel tank with fresh new fuel.

AVOID SHARP EDGES which

Never spray unit with water or store unit

2 - 4

Page 5

2.9 SAFETY RULES

Walk Around Inspection

Complete a walk around inspection of unit and work

area to understand:

• Work area.

• Your unit.

• All safety decals.

Work Area

AL W AYS check overhead and side clearances carefully

before operation. ALWAYS be aware of traffic when

operating along streets or curbs.

ALWAYS keep hands and feet within the limits of the

unit.

Keep children, people, and animals away. Keep

children out of work area and under watchful care of a

responsible adult.

Keep area of operation clear of all toys, pets, and

debris. Stay alert for hidden hazards.

DO NOT run engine in an enclosed area. Always

provide good ventilation.

Unit

ALWAYS keep protective structures, guards, and

panels in good repair, in place and securely fastened.

NEVER modify or remove safety devices.

Operation

Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an Emergency

• Speed ranges

Before starting engine, disengage auxiliary power.

Always back up slowly. Always look down and behind

before and while backing.

Never leave a running unit unatt end ed. ALWAYS shut

off auxiliary power, lower throttle setting, and stop

engine before leaving unit. ALWAYS remove key to

prevent unauthorized use.

ALWAYS operate unit in good visibility and light.

Fuel is highly flammable and its vapors can explode.

Use ONLY approved RED fuel containers.

NO Smoking!

NO Sparks!

NO Flames!

Allow engine to cool before servicing.

NEVER fill fuel tank when engine is running, hot, or

unit is indoors.

Abnormal Vibrations are a warning of trouble. Striking a

foreign object can damage unit. Stop unit and engine.

Wait for all moving parts to stop. Remove wire from

spark plug. Ins pect unit and make any necessary

repairs before restart.

Hazardous Slopes

DO NOT operate on steep slopes. Avoid operating on

slopes. When you must operate on a slope, travel up

and down the slope. Never operate cross a slope.

Never operate on a slope greater than 10 degrees.

Child Safety

NEVER allow children to operate or play on or near

unit. Be alert and shut off unit if children enter area.

Personal Safety

Read and obey all warning, caution, and instructions

on the unit and in provided manuals.

• Only trained adults may operate unit.

• Training includes actual operation.

• Clearly unde rsta nd ins tructions.

• Be alert! Conditions can change.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation requires

your complete and unimpaired attention at all times.

NEVER allow anyone to operate the unit when their

alertness or coordination is impaired.

DO NOT operate unit without wearing adequate outer

garments. Wear adequate safety gear and protective

gloves. Wear proper footwear to improve footing on

slippery surfaces.

Protect eyes, face, and head from objects that may be

thrown from unit. Wear appropriate hearing protection.

Avoid Sharp Edges. Sharp edges can cut. Moving

parts can cut or amputate fingers or a hand. Wear

gloves to service unit when handling sharp edges.

ALWAYS keep hands away from any pinch points.

ALWAYS keep hands and feet away from all moving

parts during operation. Moving parts can cut off body

parts.

DO NOT touch unit parts which might be hot from

operation. Allow parts to cool before attempting to

maintain, adjust, or service.

Controls

Come to a complete stop before reversing.

Never jerk the control levers. Alw a ys use a steady ev en

action to achieve smooth control.

Always be aware of obstructions that may cause injury

to operator or damage to the unit.

Keep alert with eyes fixed in direction of travel.

Maintenance

ALWAYS maintain unit in safe operating condition.

Damaged or worn out muffler can cause fire or

explosion.

Check the conditions of the unit at the end of each day

and repair any damage or defects.

Keep nuts and bolts tight and keep equipment in safe

operating conditions.

2 - 5

Page 6

Before maintenance, adjustments, or service (except

where specifically recommended), shut off engine.

Allow hot parts to cool.

Keep unit free of dirt, stones, and other debris. Clean

up oil or fuel spills.

Storage

DO NOT store unit inside a building with fuel in the fuel

tank where any ignition sources are present. Allow unit

to cool completely.

ALWAYS clean unit before extended storage. See

Engine Manual for proper storage.

Battery

Avoid Electric Shock. DO NOT reverse battery

connections.

Explosive Gases! Poisonous battery fluid contains

sulfuric acid and its contact with skin, eyes, or clothing

can cause severe burns.

No flames. No sparks. No smoking near battery.

Always wear safety glasses and protective gear near

battery.

DO NOT TIP battery beyond a 45

direction.

ALWAYS KEEP BATTERIES OUT OF REACH of

children.

o

angle in any

Transport

Use extra care when loading or unloading unit onto

trailer or truck. Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that could be

damaged.

2 - 6

Page 7

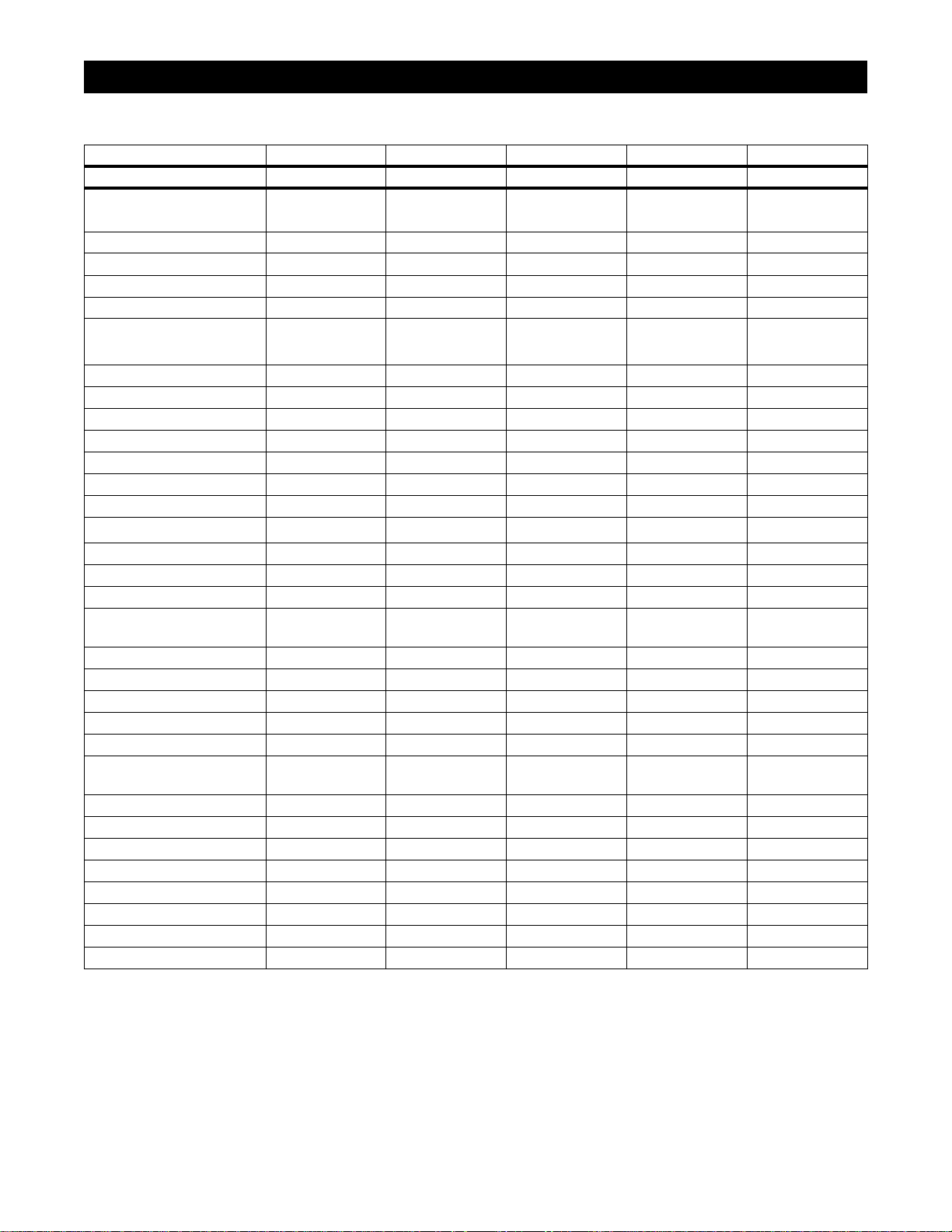

SECTION 3 - SPECIFICATIONS

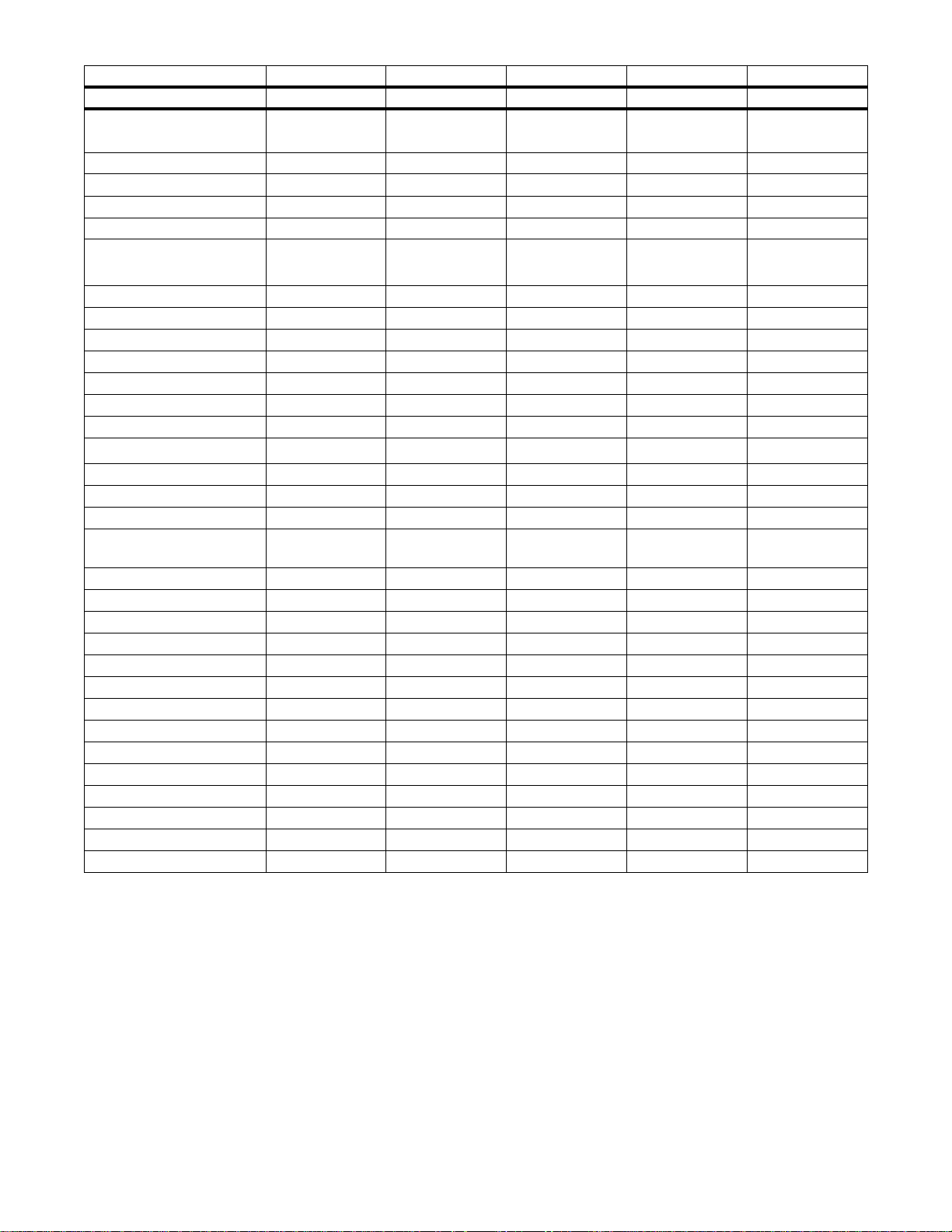

Model Number 924108 924109 924110 924111 924112

Model ST 824 SLE ST 1028 SLE ST 824 DLE SB 936 LE ST 928 LE

Engine - manufacturer Tecumseh

HMSK80

Fuel Unleaded Unleaded Unleaded Unleaded Unleaded

Fuel Tank Capacity 1 gallon 1 gallon 1 gallon 1 gallon 1 gallon

Governed RPM 3600 ± 150 3600 ± 150 3600 ± 150 3600 ± 150 3600 ± 150

Crank Case Capac ity 21 oz. 21 oz. 21 oz. 21 oz. 21 oz.

Engine Oil

5W30 below 40

30W above 40

o

Spark Plug Gap/Type .030/Champion .030/Champion .030/Champion .030/Champion .030/Champion

Drive/Differential Disc-O-Matic/No Disc-O-Matic/No Disc-O-Matic/Yes Disc-O-Matic/Yes Disc-O-Matic/Yes

Speeds-Forward 66666

-Reverse 22222

Tire Size 16/4.80-8 16/6.50-8 16/4.80-8 16/6.50-8 16/6.50-8

Tire Pressure 20 PSI 20 PSI 20 PSI 20 PSI 20 PSI

Discharge Distance (ft.) 5 - 45 5 - 45 5 - 45 N/A 5 - 50

Chute Turning Radius

220

o

Adjustable Skid Shoes Yes Yes Yes N/A Yes

Auger Size (in.) dia. 15 15 15 N/A 16

Auger RPM 110 110 110 N/A 110

Auger Clutched Belt Idler

Clutched

Impeller Size (in.) dia. 12 12 12 N/A 12

Impeller RPM 1100 1100 1100 N/A 1100

Gear Case Lube L - 2 L - 2 L - 2 N/A L - 2

Blower Housin g H ei ght (in.) 20 20 20 N/A 23.5

Blower Housing Width (in.) 24 28 24 N/A 28

Blower Housing Weight or

52407400 52407400 52407400 52407400 52407400

Snow Brush

Slicer Bars 71099700 71099700 71099700 N/A 71099700

Headlight Kit 72402500 72402500 72402500 72402500 72402500

Electric Starter Kit N/A N/A N/A N/A N/A

Rotary Broom 82401300 82401300 82401300 82401300 82401300

Tiller/Lawn Edger N/A N/A N/A N/A N/A

Remote Deflector 72405300 Standard 72405300 N/A 72405300

Service Kit 72405400 72405500 7240600 72406100

Front Weight 52407400 52407400 52407400 52407400 52407400

Tecumseh

HMSK100

o

5W30 below 40

30W above 40

Belt Idler

Clutched

220

Tecumseh

HMSK80

o

5W30 below 40

o

30W above 40

o

220

o

o

Belt Idler

Clutched

Tecumseh

OHSK90

o

5W30 below 40

30W above 40

Tecumseh

OHSK90

o

5W30 below 40

o

30W above 40

N/A

220

o

N/A Belt Idler

Clutched

o

o

3 - 7

Page 8

Model Number 924327 924328 924329 924330 924500

Model ST 1028 SLE ST 824 DLE ST 928 LE SB 1132 LE ST 1336 LE

Engine - manufacturer Tecumseh

HMSK100

Tecumseh

HMSK80

Tecumseh

OHSK90

Tecumseh

OHSK110

Tecumseh

OHSK130

Fuel Unleaded Unleaded Unleaded Unleaded Unleaded

Fuel Tank Capacity 1 gallon 1 gallon 1 gallon 1 gallon 1 gallon

Idle RPM 1800 1800 1800 1800 1800

Governed RPM 3600 ± 150 3600 ± 150 3600 ± 150 3600 ± 150 3600 ± 150

Crank Case Capacity 21 oz. 21 oz. 21 oz. 21 oz. 21 oz.

Engine Oil

5W30 below 40

30W above 40

o

5W30 below 40

o

30W above 40

o

5W30 below 40

o

30W above 40

o

5W30 below 40

o

30W above 40

o

5W30 below 40

o

30W above 40

o

o

Spark Plug Gap/Type .030/Champion .030/Champion .030/Champion .030/Champion .030/Champion

Drive/Differential Disc-O-Matic/No Disc-O-Matic/Yes Disc-O-Matic/Yes Disc-O-Matic/Yes Disc-O-Matic/Yes

Speeds-Forward 66666

-Reverse 22222

Tire Size 16/6.50-8 16/4.80-8 16/6.50-8 16/6.50-8 16/6.50-8

Tire Pressure 20 PSI 20 PSI 20 PSI 20 PSI 20 PSI

Discharge Distance (ft.) 5 - 45 5 - 45 5 - 50 5 - 50 5 - 50

Chute Turning Radius

220

o

220

o

220

o

220

o

220

o

Adjustable Skid Shoes Yes Yes Yes Yes Yes

Auger Size (in. ) dia. 15 15 16 16 16

Auger RPM 110 110 110 110 110

Auger Clutched Belt Idler

Clutched

Belt Idler

Clutched

Belt Idler

Clutched

Belt Idler

Clutched

Belt Idler

Clutched

Impeller Size (in.) dia. 12 12 12 12 14

Impeller RPM 1100 1100 1100 1100 1100

Gear Case Lube L - 2 L - 2 L - 2 L - 2 L - 2

Blower Housing Height (in.) 20 20 23.5 23.5 21.5

Blower Housing Width (in.) 28 24 28 32 36

Blower Housing Weight 52407400 52407400 52407400 52407400 52407400

Slicer Bars 71099700 71099700 71099700 71099700 71099700

Headlight Kit N/A 72402500 72402500 72402500 72402500

Electric Starter Kit N/A N/A N/A N/A STD

Rotary Broom 82401300 82401300 82401300 82401300 82401300

Tiller/Lawn Edger N/A N/A N/A N/A N/A

Remote Deflector Standard N/A 72405300 Standard Standard

Service Kit 72405600

Front Weight 52407400 52407400 52407400 52407400 52407400

3 - 8

Page 9

Model Number 924113 924115 924501

Model ST 1132 LE ST 1028 SLE ST 1336 LE

Engine - manufacturer Tecumseh

OHSK110

Tecumseh

HMSK100

Tecumseh

OHSK130

Fuel Unleaded Unleaded Unleaded

Fuel Tank Capacity 1 gallon 1 gallon 1 gallon

Governed RPM 3600 ± 150 3600 ± 150 3600 ± 150

Crank Case Capacity 21 oz. 21 oz. 21 oz.

Engine Oil

5W30 below 40

30W above 40

o

5W30 below 40

o

30W above 40

o

5W30 below 40

o

30W above 40

Spark Plug Gap/Type .030/Champion .030/Champion .030/Champion

Drive/Differential Disc-O-Matic/Yes Disc-O-Matic/No Disc-O-Matic/Yes

Speeds-Forward 6 6 6

-Reverse 2 2 2

Tire Size 16/6.50-8 16/6.50-8 16/6.50-8

Tire Pressure 20 PSI 20 PSI 20 PSI

Discharge Distance (ft.) 5 - 50 5 - 45 5 - 50

Chute Turning Radius

220

o

220

o

220

o

Adjustable Skid Shoes Yes Yes Yes

Auger Size (in.) dia. 16 15 16

Auger RPM 110 110 110

Auger Clutched Belt Idler

Clutched

Belt Idler

Clutched

Belt Idler

Clutched

Impeller Size (in.) 12 12 14

Impeller RPM 1100 1100 1100

Gear Case Lube L - 2 L - 2 L - 2

Blower Housin g H ei ght (in.) 23.5 20 21.5

Blower Housing Width (in.) 32 28 36

Blower Housing Weight 52407400 52407400 52407400

Slicer Bars 71099700 71099700 71099700

Headlight Kit 72402500 72402500 72402500

Electric Starter Kit N/A N/A Standard

Rotary Broom 82401300 82401300 82401300

Tiller/Lawn Edger N/A N/A N/A

Remote Deflector 72405300 Standard Standard

Service Kit 72406200

Front Weight 52407400 52407400 52407400

o

o

3 - 9

Page 10

SECTION 4 - GENERAL MAINTENANCE & ADJUSTMENTS

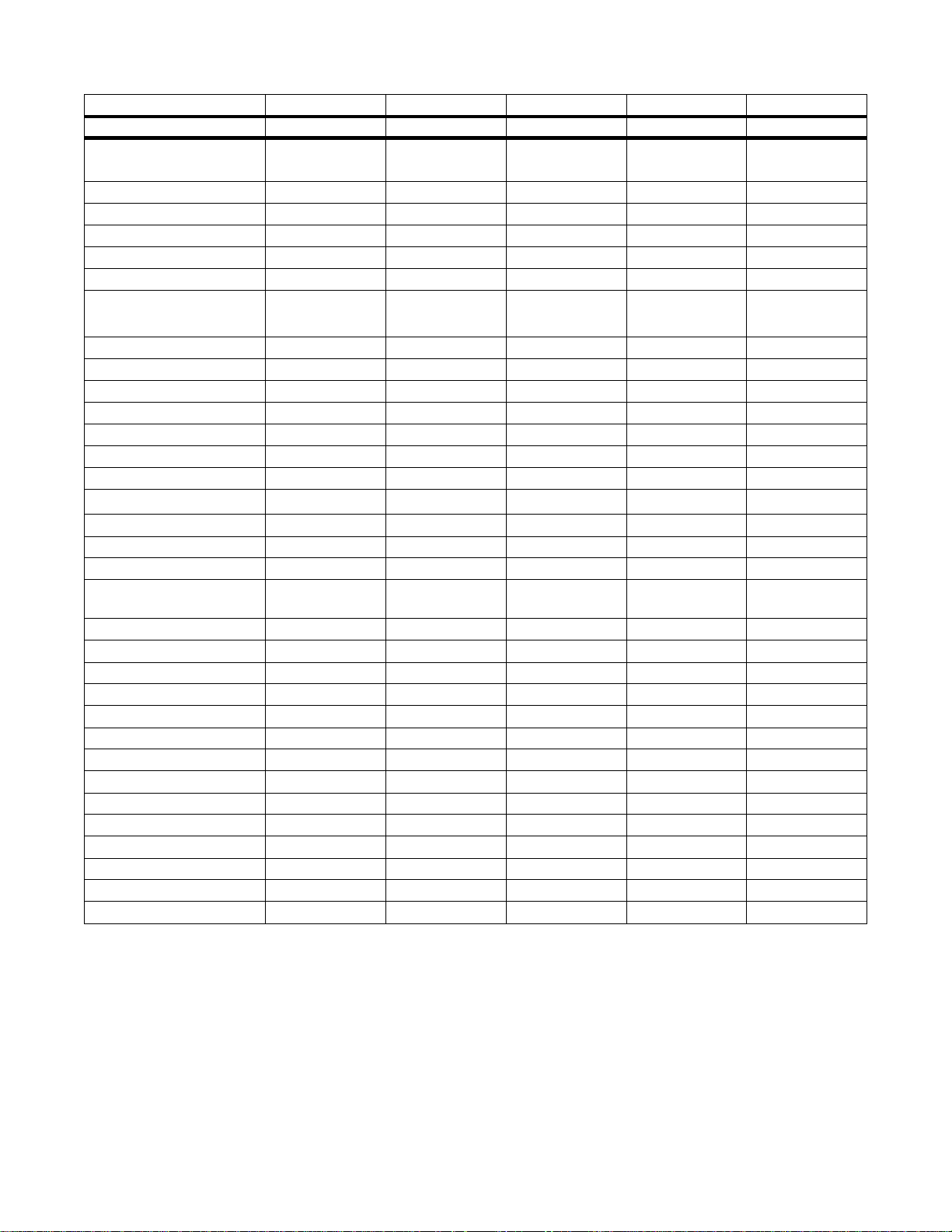

4.1 CONTROLS AND FEATURES

4

6

21

9

5

14

1

7

10

13

11

15

2

3

22

16

12

19

8

18

17

1. Attachment Clutch Le ver

2. Speed Selector

3. Chute Crank

4. Wheel Drive Clutch Lever

5. Primer Bulb

6. Throttle

7. Choke

8. Scraper Blade

9. Oil Fill and Dip Stick

10.Chute Deflector

11.Discharge Chute

12.Axle Lock Pin

Figure 1

13.Light

14.Fuel Tank and Cap

15.Fuel Shut-Off Valve

16.Belt Guard

17.Runner(s)

18.Auger

19.Impeller

20.Scraper Blade

21.Engine Ignition (Key Switch)

22.Deflector Remote Control

OS0591

OS1131

4 - 10

Page 11

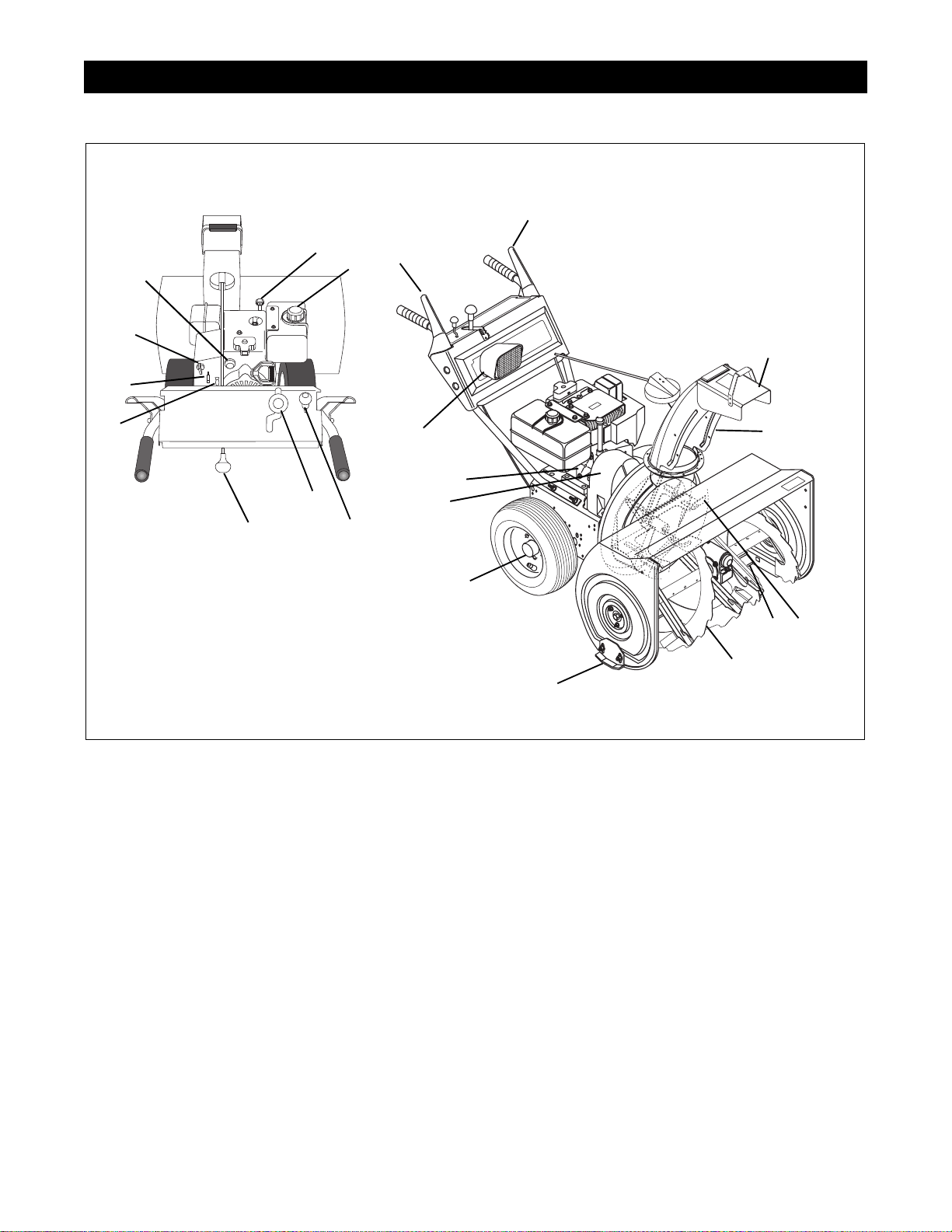

4.2 SERVICE POSITIONS

OS0792

1. Pivot Pin

2. Housing Cap Screws

3. Belt Guard Cover

4. Tapping Screw

2

3

4

1

Figure 2

Ariens Dealers will provide any service or adjustments

which may be required to keep your unit operating at

peak efficiency. Should engine service be required,

contact an Ariens dealer or an authorized engine

manufacturer’s service center.

WARNING: ACCIDENTAL ENGINE START

UP

can cause death or serious injury.

ALWAYS

moving parts to stop and remove wire from

spark plug before adjusting or servicing.

HOT SURFACES

serious injury.

hot from operation.

ALWAYS

stop engine, remove key, wait for

can result in death or

DO NOT

touch parts which are

allow parts to cool.

CAUTION: FUEL SPILLS

may result in minor

or moderate injury and/or damage to the unit.

Before unit is tipped up onto housing, remove

enough fuel so that no spillage will occur.

Belt Service Position

To place unit into Belt Service position:

1. Draw gas from gas tank to prevent spilling.

2. Remove the two screws from the belt guard and

remove the guard, Figure 2.

3. Extract the pin for the chute crank at the universal

connection nearest the chute.

4. Loosen the belt finger guards at the pulley and

pivot away from the belts.

5. Remove the attachment drive belt from the engine

pulley.

6. To avoid bending the bottom cover plate, tip the

unit up on the blower housing. Remove the plate by

unscrewing the four bolts.

7. Tip the unit back down and remove the two

capscrews securing the housing to the frame.

8. Tip the two halves apart exposing the belts and

pulleys.

Upright Service Position

To place unit into Upright Service position:

1. Drain gas from gas tank to prevent spilling.

2. Tip the unit up on the front of the blower housing.

3. Remove the bottom cover plate by unscrewing the

four bolts.

4.3 FILLING THE FUEL TANK

EXPLOSIVE VAPORS and FLAMMABLE

FUEL can result in serious injury or death.

Handle fuel with care. ALWAYS use an

approved (RED) fuel container.

No Smoking!

No Lighted Materials!

No Open Flame!

Allow engine to cool.

Use caution with fuel. Fuel is very flammable.

Keep fuel in a clean and tight container. Keep

fuel away from fire or heat. Neve r put fuel in

the fuel tank while the engine is running or

hot. Clean up any spilled fuel before starting

the engine.

Add fuel to the tank as needed. See your Engine

Manual for correct type and grade of fuel.

4 - 11

Page 12

To add fuel to the fuel tank:

Figure 3

1. Idler Chain

2. Pinion Chain

3. Shift Link

4. Hex Shaft

5. Shift Lever Arm &

Bracket

6. Axle Shaft

7. Sprocket Assembly

8. Sprocket Assembly

9. Discharge Chute Base

10.Auger and Shaft

OS0741

6

5

2

7, 8

4

1

3

9

10

OS1370

1. Refuel the unit only in a well ventilated, open area.

2. Stop the engine and allow to cool.

3. Clean the fuel cap and the area around the fuel

cap to prevent dirt from entering the fuel tank.

Remove the cap from the fuel tank.

4. Fill the fuel tank to within 1/2’ (3.1 cm) below

bottom of filler neck with unleaded gasoline. Tank

capacity is 1 gallon (3.8 liters).

5. Install the cap on the fuel tank and tighten.

6. Clean up any spilled fuel before starting the

engine.

WARNING:

POTENTIAL HAZARDOUS! Fuel

is extremely flammable and highly explosive.

Personal injury and property damage may

result if not handled properly.

• Fill the fuel tank outdoors in an open area.

Do not fill when the engine is hot. Wipe up

any fuel spills.

• Never fill the fuel tank completely full.

Empty space in tank allows fuel to

expand.

• Never smoke when handling fuel. Stay

away from open flames. Fuel fumes can

be ignited by sparks.

IMPORTANT:

DO NOT allow grease or oil to get on

friction wheel, drive disc or belts.

Apply Sten Mix Hi-Temp Grease or equivalent to the

lube fittings. Order P/N: 00036800 - three pack of 3 oz.

cartridges or P/N 00036800 - ten pack of 14 oz.

cartridges.

When using Sten Mix Hi-Temp Grease for the first time,

all components should be thoroughly cleaned prior to

lubricating.

Apply oil at all pivot points and pin connections, see

Figure 3.

Unit should be lubricated at beginning of season or

every 25 operating hours. See Maintenance Schedule.

NOTE:

To grease auger shaft, remove shear bolt nuts,

and shear bolts. Turn auger on shaft while applying

grease at zerk fittings. Replace shear bolt per instructions in Shear Bolt Replacement.

4.4 FUEL SHUT-OFF VALVE

IMPORTANT:

type of fuel system. If the Fuel Shut-Off Valve is not in

the closed "Off" position, gasoline can leak out of the

carburetor while the unit is being transported.

IMPORTANT:

two positions:

1. Closed "Off"

2. Open "On"

ALWAYS close or turn the Fuel Shut-Off Valve to the

"Off" position for servicing, transporting or storing the

unit.

The unit must have the Fuel Shut-Off Valve in the open

"On" position for proper fuel delivery to the engine

during normal operation (Figure 1).

Check the Fuel Shut-Off Valv e frequently to assure it is

in the proper position for operation or service.

The unit is equipped with a gravity feed

The unit engine Fuel Shut-Off Valve has

4.5 GENERAL LUBRICATION

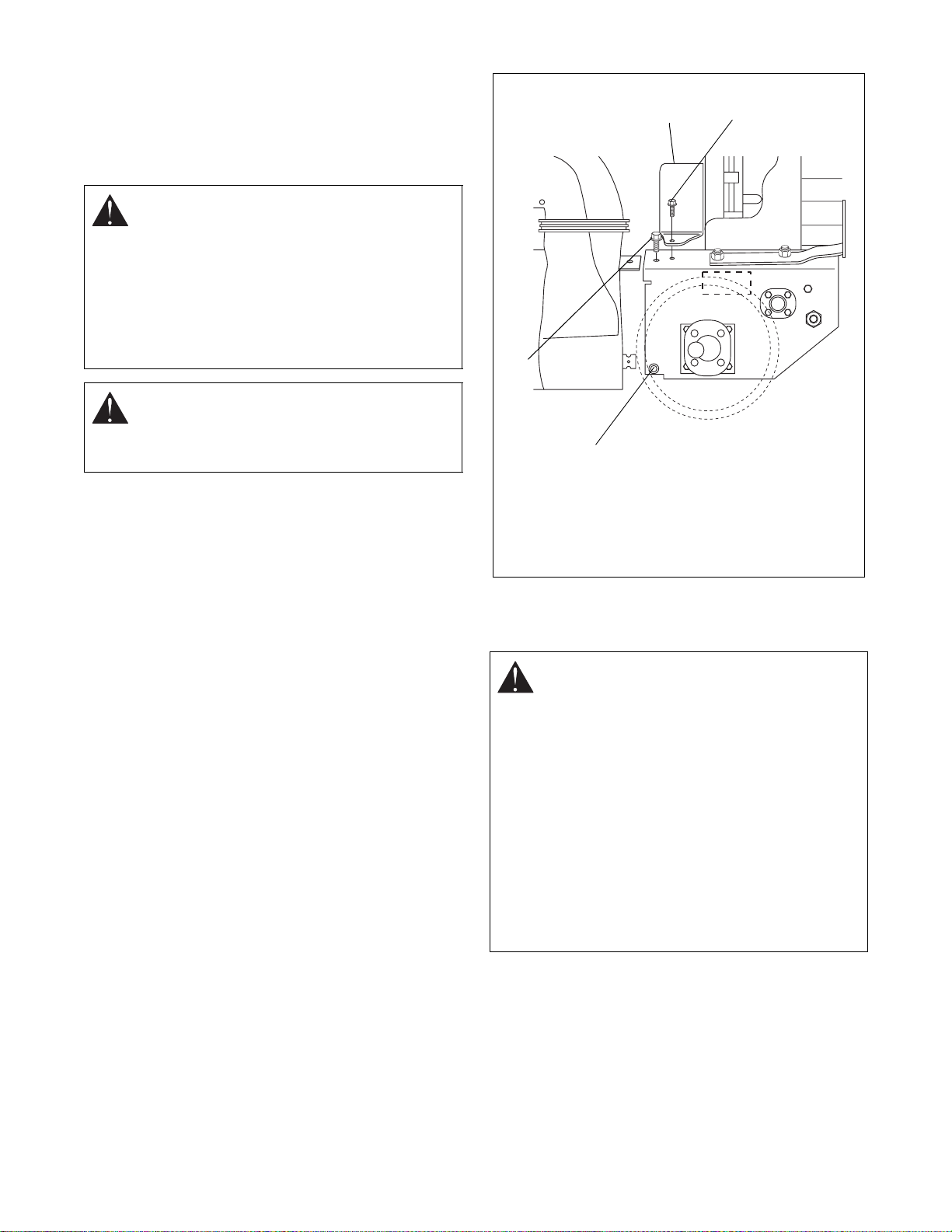

HOT SURFACES can cause death or serious

injury. DO NO T touch parts which are hot from

operation. ALWAYS allow parts to cool.

IMPORTANT:

lubrication.

Wipe each fitting clean before and after

4 - 12

Page 13

4.6 AUGER GEARCASE

IMPORTANT:

leakage. Too little lubricant will cause gear and/or

bearing damage. Proper oil level must be maintained

for operation.

Gear cases are filled to the correct level at the factory.

Unless there is evidence of leakage, no additional

lubricant should be required. Check for evidence of

leakage every 25 hours or operation.

To ensure adequate lubricant level:

1. Remove filler plug. Lubricant must be at least up to

bottom of lubricant filler hole with unit resting on a

level-surface.

2. Add lubricant, if required, allow oil to drain to level

of plug and replace plug (Figure 4).

3. Use only Ariens special gear lubricant L-2

(P/N 00008000).

Too much lubricant may cause excessive

Engine Oil Check

The engine crankcase oil should be checked daily or

every 5 hours of operation. Oil level MUST be

maintained in safe operating range on dipstick at all

times or engine damage will result (See Engine

Manual).

To check, park unit on a flat, level surface and:

1. Clean all debris away from oil cap.

2. Remove oil cap and dipstick. Wipe oil of dipstick

with a clean cloth. Replace dipst ick until cap

bottoms on tube. Remove dipstick again and

observe oil level. Oil should be at the Full (F) mark.

3. If low, add oil and bring up to the Full (F) mark.

IMPORTANT:

exceed Full (F) mark.

Engine Oil Type Ambient Temperature

DO NOT over fill. Oil level must not

1

Special

Gear

Lube-L2

3

2

4

1. Auger Gearcase-Cast Iron

2. Oil Fill and Drain Level Plug

3. Ariens Special L-2 Gear Lube

4. Auger Gearcase-Aluminum

Figure 4

2

OS0620

4.7 ENGINE

Cooling

The engine is air cooled. Air must circulate freely

around engine from Air Intake to cooling fins on

cylinder head and block, to prevent overheating.

Each year (more often if conditions require) remove

cooling shrouds and clean cooling fins. Clean external

surfaces of engine of dust, dirt, and oil deposits which

can contribute to improper cooling. See Engine

Manual.

IMPORTANT:

shrouds removed. Engine overheating and damage will

result.

DO NOT operate engine with cooling

SAE 5W30

SAE 30

Below 40

Above 40

o

F (4o C)

o

F (4o C)

4. Replace dipstick and cap. Clean up any spilled oil.

Engine Oil Change

Change oil after first 5 hours of operation, thereafter

change oil every 25 hours (more often if required).

NOTE:

Run engine just prior to changing oil. Warm oil

will flow more freely and carry away more contamination.

1. Drain crankcase by removing oil drain plug (see

Engine Manual).

2. When oil has drained replace plug and refill engine

crankcase with new oil of proper grade.

3. Recheck oil level with dipstick.

4.8 TRACTION DRIVE BELT

WARNING:

amputate body parts. Keep hands and feet

away.

Loose clothing, long hair or scarves can get

caught in rotating parts and cause death or

serious injury.

NOTE:

Unit should be in the Belt Service Position with

the attachment drive belt removed.

To Replace the Traction Drive Belt

1. Pull idler away from belt (Figure 5) and remove belt

from idler pulley, engine and drive pulley (it may be

necessary to turn engine pulley using rewind

starter).

2. Rotate belt fingers out and away from belt and

pulley by removing one cap screw and loosening

the other.

ROTATING PARTS can cut or

4 - 13

Page 14

IMPORTANT:

OS0601

1. Traction Belt Idler

2. Cap Screw

3. Belt Finger

4. Traction Drive Belt

5. Attachment Belt Idler

6. Attachment Drive Belt

7. Engine Pulleys

8. Attachment Idler

Adjustment Hardware

2

3

4

5

Figure 5

1

7

6

8

Use care when rotating the belt fingers

to prevent deformation of parts.

NOTE:

To gain clearance engage traction clutch and if

necessary pull back attachment idler arm clevis pin.

3. Replace traction drive belt and belt fingers in

reverse order making sure pulleys align. If

alignment is necessary, loosen engine pulley set

screws, reposition pulley and retighten set screws.

Check alignment of attachment driven pulley and

align if necessary.

4. Check and adjust clutch.

4.9 ATTACHMENT DRIVE BELT

WARNING:

IMPROPER ADJUSTMENT

could result in death or serious injury.

IMPELLER BRAKE MUST DISENGAGE

when clutch is engaged. Brake must be at

least 1/16" (1.6 mm) to 1/8" (3.2 mm)

minimum from belt when disengaged.

WARNING:

ROTATING PARTS can cut or

amputate body parts. Keep hands and feet

away .

Loose clothing, long hair or scarves can get

4.10 SHEAR BOLTS

caught in rotating parts and cause death or

serious injury.

WARNING:

ROTATING PARTS can cut or

amputate body parts. Keep hands and feet

To Replace the Attachment Drive Belt:

1. Place unit in the Belt Service Position.

2. Remove the belt. It may be necessary to hold the

away.

Loose clothing, long hair or scarves can get

caught in rotating parts and cause death or

serious injury.

brake open.

3. If pulley alignment is necessary, loosen pulley set

screws. Reposition pulley and retighten set screws.

4. Replace chute crank and secure with hair pin.

Replace belt guard cover and secure with screws.

5. Check and adjust clutch.

IMPORTANT:

Use only Ariens Shear Bolts for

replacement. Use of any other type of shear bolt may

result in severe damage to the unit.

Occasionally a foreign object may enter the auger/

impeller housing and jam the auger, breaking Shear

Bolts which secure the auger to the shaft (Figure 6).

This allows auger to turn freely on the shaft preventing

damage to the gear drive.

4 - 14

Page 15

(Figure 7). Allow 1/8" (3 mm) between scraper

1

2

1. Runner

2. Runner Hardware

OS0480

Figure 7

1

blade and hard smooth surface. Allow 1-1/4"

(30 mm) minimum between scraper blade and

uneven surface(s).

3

2

3. Retighten hardware.

NOTE:

Keep housing level by adjusting runners

equally. Uneven runners make unit difficult to steer and

results in uneven clearing.

4

1. Auger

2. Roll Pin

3. Shear Bolt(s)

4. Nut(s)

Figure 6

OS0401

For Replacement:

1. Slide auger outward against roll pin and align hole

in shaft with hole in auger. The holes in the shaft

for the roll pins and Shear Bolts line up.

2. Drive Shear Bolt through hole (if Shear Bolt was

broken this will drive the remaining part from shaft).

3. Secure Shear Bolt with nut.

4. The Shear Bolts should not be overtightened to

collapse the auger center tube to the auger drive

shaft.

4.11 TIRE PRESSURE

Maintain the unit tire pressure at a maximum of

20 PSI (138 kPa).

4.12 ADJUSTMENTS

WARNING:

UP can cause death or serious injury.

ALWAYS stop engine, remove key, wait for

moving parts to stop and remove wire from

spark plug before adjusting or servicing.

Discharge Chute Deflector

To adjust the drag force, loosen or tighten the two bolts

to accomplish the desired drag.

ACCIDENTAL ENGINE START

Scraper Blade

IMPORTANT:

result if blade wears down too far.

Scraper blade is adjustable to compensate for wear.

To adjust scraper blade:

1. Tip unit back onto handlebar. Support the housing

and loosen scraper blade nuts. With runners

adjusted to their full up position, reposition scraper

blade down, flush with runners. Tighten lock nuts.

Readjust runners if necessary.

Damage to auger/impeller housing will

Discharge Chute

If chute does not stay in position while operating,

tighten nut on carriage bolt at pivot point to increase

tension on spring (Figure 8).

Smooth and easy rotation of properly lubricated chute

with crank (without binding ) is obtained by adjusting

pinion and flat gear teeth so they mesh together.

Adjust, using adjustment slots in pinion bracket which

is secured to chute strap.

Runners

Runners should be adjusted as condi tio ns requir e.

Raising or lowering runners controls distance scraper

blade (auger/impeller housing) is held above surface

being cleared.

1. Position unit on a hard, flat smooth level surface.

2. Adjust runners by inserting a spacer of desired

thickness under center of scraper blade, loosen

runner hardware, slide runners to flat surface

4 - 15

Page 16

5

1

2

3

1. Drive Belt

2. Brake Shoe and Pad

3. 1/16" (1.6 mm) minimum

OS0660

Figure 9

1. Traction Clutch Cable

2. Adjustment Nut

Figure 10

1

2

OS1181

3/8"

4

10

3

1

6

7

2

8

9

11

1. Carriage Bolt

2. Spring

3. Pinion Bracket

4. Pinion

5. Chute Strap

6. Flat Gear

7. Gear Strap

8. Mounting Nut

9. Chute Ring

10.Lower Ring

11.Retainer Clip

Figure 8

Attachment Clutch/Impeller Brake

WARNING: AUGER/IMPELLER MUST

STOP within 5 seconds

Clutch/Impeller Brake lever is released or unit

damage or serious injury may result.

To adjust Attachment Clutch/Impeller Brake:

1. Remove belt cover. When clutch is disengaged

there should be a slight amount of slack in the

attachment cable to allow for brake wear.

2. Clutch cable spring should extend approximately

3/8" (9,5mm) when clutch is engaged but allow

clutch arm (at lower end) to return to its maximum

down position when clutch is disengaged. To

increase spring extension. loosen adjustment

hardware (Figure 5) and move the attachment idler

toward the belt. Approximately 1/8" (3,2 mm)

movement of the idler will increase spring

extension by 1/8" (3,2 mm).

3. To check impeller brake, tip unit forward onto

auger/impeller housing. Remove bottom cover by

removing four cap screws.

4. Measure distance between impeller brake shoe

pad and belt with attachment clutch engaged

(Figure 9). Impeller brake shoe should be 1/16"

(1.6 mm) minimum from belt. When attachment

clutch is disengaged, brake must contact belt. If

brake travel does not meet these requirements,

contact your dealer.

5. Replace bottom cover.

when Attachment

DS0112

Traction Drive Clutch

Adjust traction clutch to compensate for wear of friction

wheel when slippage occurs.

To adjust traction clutch, place speed selector in First

(1) Forward and tip unit forward onto housing.

With traction clutch disengaged turn wheels while

tightening Adjustment Nut at clutch yoke until wheels

begin to drag (Figure 10). Engage and release traction

clutch to align clutch linkage. Repeat as necessary.

When wheel drag is obtained with linkage aligned, turn

nut back three turns. Wheels will then turn freely.

4 - 16

Page 17

Speed Selector

Adjustment is required if you are unable to shift into all

gears.

1. Put unit into Upright Service Position.

2. Disconnect the speed selector rod from the

adjustment lever by removing hairpin (Figure 11).

3. Place the speed selector in the fast reverse speed

position (Figure 11).

4. Thread the rod adjustment pin along the speed

selector rod until it aligns with the mating hole on

the speed selector lever. Insert the rod adjustment

pin into hole.

5. Move the speed selector to the fastest forward

speed position.

6. Insert the hairpin into the rod adjustment pin.

3

4

5

2

1

1. Speed Selector Rod

2. Rod Adjustment Pin

3. Speed Selector Lever

4. Hairpin

Figure 11

5. Fast Reverse Speed

Selector Position

OS0021

OSs0190

Drive Chain

Chain should be taut with little or no play in it. To

compensate for looseness or excessive tightness in

drive chain:

1. Put unit into the Upright Service Position.

To maintain proper tightness, a roller is held against the

chain. To adjust the roller:

2. Loosen the nut on the hex shaft.

3. Move the shaft to achieve desired tightness.

4. Tighten the nut to lock the hex shaft in position.

5. Torque to 170-180 inch-pounds.

NOTE:

operation by checking both clutches to be sure they

operate freely without binding.

Check interlock mechanism to ensure proper

4 - 17

Page 18

SECTION 5 - HANDLEBARS & CONTROLS

2

1

11

9

3

10

8

4

Figure 12

7

1. Chute Crank Handle

6

5

2. Speed Selector Lever

3. Set Screw

4. Chute Deflector Remote

5. Attachment Clutch Arm

6. Clutch Cable Spring

7. Clutch Cable

8. Traction Clutch Arm

9. Speed Selector Rod

10.Rod Adapter

11.Traction Clutch Cable

DS0161

5.1 LOWER HANDLEBAR

Remove nut and washer attaching lower handlebar to

each side of frame and remove lower handlebar.

Check parts for wear or replacement.

Assemble, using reverse procedure.

5.2 ATTACHMENT CLUTCH HANDLE

Remove (2) push nuts, pin and (2) screws holding

Clutch Handle and pivot to upper handlebar. Remove

pivot and disconnect Clutch Handle from clutch cable.

Remove set screw, jam nut and clevis from clutch

cable.

Remove pin and remove cable.

Disconnect spring from lever.

Check parts for wear or replacement.

Assemble using reverse procedure.

5.3 WHEEL DRIVE CLUTCH LEVER &

TRACTION CABLE

Remove (2) push nuts, pin, and (2) screws holding

pivot and wheel drive clutch lever to upper handle bar.

Remove pivot and wheel drive clutch lever.

Remove set screw, nut, hair pin and clevis pin holding

the clevis to traction clutch cable.

Remove set screw in rod adapter and remove traction

clutch cable.

Check parts for wear or replacement.

Assemble using reverse procedure.

5 - 18

Page 19

5.4 CLUTCH YOKE AND FORK

Remove locknut and adapter spacer holding spring

assembly in clutch yoke (Figure 13).

Remove capscrew, nut, and rod adapter from yoke.

Remove cotter pin from end of spring assembly in

clutch fork. Remove spring assembly and extension

spring.

Punch out roll pins holding fork pivot rod in frame and

remove rod and clutch fork.

Check parts for wear or replacement.

Assemble using reverse procedure.

1. Traction Clutch Rod

2. Spacer

3. Setscrew

4. Rod Adapter

5. Extension Spring

6. Cotter Pin

7. Fork Pivot Rod

8. Cotter Pin

9. Clutch Fork

10.Spring Assembly

11.Nut

12.Clutch Yoke

13.Capscrew

14.Adapter

15.Adapter Spacer

16.Lock Nut

Figure 13

5 - 19

Page 20

SECTION 6 - ENGINE

6.1 ENGINE TROUBLESHOOTING

The following troubleshooting chart is to be used to

isolate engine problems and give possible causes and

corrective action responses.

The troubleshooting key is generic and can be used for

several types of engines. Use only those possible

causes and corrective actions that apply to the

unit.

TROUBLE POSSIBLE CAUSES

CORRECTIVE ACTION

(Refer to Key Below)

Black Exhaust 20, 22, 25, 29, 31, 32, 33 repair or replace

Blue/White Exhaust 4, 20, 25, 31, 33, 34 repair or replace

Difficult Starting 5, 7, 8, 9, 10, 20, 21, 22, 29, 31, 32, 33 repair or replace

Erratic Running 7, 8, 9, 10, 20, 21, 23, 26, 29, 33, 59, 62 repair or replace

Excessive Fuel Consumption 20, 22, 23, 25, 39, 31, 32, 33 repair or replace

High Oil Pressure 4, 41 repair or replace

Knocking 22, 26, 29, 31, 33, 36, 46, 59 repair or replace

Loss of Power or System 8, 10, 20, 21, 22, 23, 25, 26, 31, 32, 33 repair or replace

Low Cranking Power 2, 3, 4, 11 repair or replace

Low Oil Pressure 4, 36, 37, 39 repair or replace

Misfiring 10, 20, 25, 26, 28, 29, 32 repair or replace

Overheating 19, 25, repair or replace

Poor Compression 25, 28, 29, 31, 32, 33, 34,59, repair or replace

Starts and Stops 6, 10, 62 repair or replace

see electrical systems

see engine service manual

Vibration 20, 23, 25, 26, 29, 33, 45, 49 repair or replace

Will Not Crank 2, 11, 45 charge battery or replace

Will Not Start 10, 62 repair or replace

see electrical systems

see engine service manual

TROUBLESHOOTING KEY

1 Restriction in air cleaner 22 Incorrect grade of fuel 43 Faulty suction pipe

2 Bad electrical connection 23 Sticking throttle/restricted movement 44 Choked oil filter

3 Faulty starter motor 24 Exhaust pipe restriction 45 Bad solenoid switch

4 Incorrect grade of lubricating oil 25 Leaking cylinder head gasket 46 Incorrect piston height

5 Low cranking speed 26 Overheating 47 Damaged fan

6 Fuel tank empty 27 Cold running 48 Faulty engine mounting

7 Controls not in correct

operation position

8 Blocked fuel feed line 29 Sticking valves 50 Faulty thermostat

9 Faulty fuel lift pump 30 Incorrect high pressure pipes 51 Restriction in water jacket

10 Choked fuel filter 31 Worn cylinder bores 52 Loose fan belt

11 Battery capacity low 32 P itted valves and seats 53 Choked radiator

12 Air in fuel system 33 Broken, worn or sticking piston ring(s) 54 Faulty water pump

13 Faulty fuel injection pump 34 Worn valve stems and guides 55 Choked breather pipe

14 Faulty fuel injectors or incorrect

type

15 Incorrect use of cold start

equipment

16 Faulty cold start equipment 37 Insufficient oil in sump 58 Blocked sump strainer

17 Broken fuel injection pump

drive

18 Incorrect fuel pump timing 39 Oil pump worn 60 Exhaust or vacuum pipe leak

19 Incorrect valve timing 40 Pressure relief valve sticking open 61 Bad or defective water temperature

20 Poor compression 41 Pressure relief valve sticking closed 62 Bad spark plug(s)

21 Blocked fuel tank vent 42 Broken relief valve spring

28 Incorrect tappet adjustment 49 Incorrectly aligned flywheel and/or

flywheel housing

35 Restriction in air cleaner 56 Damaged valve stem oil deflector (if

fitted)

36 Worn or damaged bearings 57 Coolant level too low

38 Bad/defective oil temperature s witch 59 Broken valve spring

switch

6 - 20

Page 21

See your engine manual for information on the operation and maintenance of your engine. Follow those

instructions for oil and filter changes.

6.2 REMOVING THE ENGINE

1. Drain gasoline.

2. Place unit in the Belt Service Position.

3. Remove both belts from the engine pulleys.

Remove pulleys.

4. If the unit has a bracket at the top of the engine for

chute/deflector controls, unbolt it.

5. On electric start units, disconnect the battery.

Remove the starter.

6. Remove the four mounting bolts from the engine

base.

6.3 INSTALLING THE ENGINE

1. Position the engine in the frame.

2. Insert mounting bolts and tighten.

3. On electric start units, install the starter. Connect

battery.

4. Reattach any brackets for chute/deflector controls.

5. Install pulleys on engine shaft. Do not tighten set

screws.

6. Install belts. Adjust the engine pulleys to align with

attachment and drive pulleys. Tighten set screws.

7. Take unit out of Belt Service Position.

6 - 21

Page 22

SECTION 7 - REDUCTION DRIVE

The unit can be equipped with either of two drive axles.

The first type is a differential axle (Figure 14). To lock

into two wheel drive the left hand wheel has a lockout

hub. The second type is a spur gear drive (Figure 15).

To lock a wheel to the axle, a pin is inserted through the

wheel hub and through the axle.

7.1 DIFFERENTIAL, LOCKOUT, AND AXLE

Place unit in Upright Service Position.

1. Remove groove pin that secures lockout assembly

to left hand axle and lockout assembly from shaft

(Figure 14). (Pin is tapered and must be driven

from small end.)

2. Remove roll pin that secures knob, spring and pin

to lockout hub.

3. Remove left hand axle from unit.

4. Remove roll pin from right hand axle, then remove

differential from axle while sliding axle from unit.

(Differential is serviced as a complete assembly.)

5. Check left hand axle bushings and other parts for

wear or damage and replace as necessary.

6. Reasse mble in reverse order.

7.2 SPUR GEAR AND AXLE

Place unit in Upright Service Position.

1. Remove lockout pins and wheels (Figure 15).

2. Remove retaining rings outside of bearings.

3. Remove retaining ring next to the spur gear toward

the center.

4. Pull axle out toward the right side. The spur gear

should slide off the axle and key.

5. Check bearings and gear for wear or damage.

Replace as necessar y.

7.3 AXLE BEARINGS

To remove axle bearings, remove axles per instructions

above.

Remove cap screws and lock nut that hold bearing

retainer and bearing on the frame.

Assemble in reverse order.

7

5

10

15

6

1

2

3

13

4

1. Bearing Flange

2. Ball Bearing

3. Bearing Flange

4. Right Hand Axle

5. Left Hand Axle

6. Sleev e Bush in g

7. Sleev e Bush in g

8. Pin

9. Compression Spring

10.Lockout Hub

11.Knob

12.Groove Pin

13.Differential Assembly

14.Lock Nut

15.Cap Screw

9

8

Figure 14

14

11

12

PS0611

7 - 22

Page 23

5

1. Hex Shaft

2. Hex Shaft

3. Idler

4. Roller Chain

5. Pinion and Socket

Figure 16

2

5

3

4

1

4

1

2

3

6

1. Bearing Flange

2. Ball Bearing

3. Bearing Flange

4. Axle Shaft

5. Spur Gear

6. Pin Lock

Figure 15

7.4 DRIVE CHAIN

Place unit in Upright Service Position.

To remove link from chain and chain from sprocket:

On the continuous chain grind off end of rivet.

When replacing chain, be sure retainer clip faces

center of unit and is well seated in grooves of master

link (P/N 00004100).

7.5 DRIVE CHAIN ADJUSTMENT

Place unit in Upright Service Position.

If unit is difficult to push because of a tight drive chain,

proceed as follows:

Adjust chain tension by loosening two nuts on idler

shaft. Adjust hex shaft up or down in slot to obtain

proper tension (chain should be snug). Retighten both

nuts. Torque to 170-180 inch lbs.

NOTE:

operation as follows:

Check both clutches to be sure they operate freely

without binding

Check interlock mechanism to ensure proper

PS0612

7 - 23

Page 24

SECTION 8 - FRICTION WHEEL DRIVE

8.1 FRICTION WHEEL

1. To replace friction wheel, tip unit up into the upright

service position.

2. Remove bottom cover by removing four cap

screws.

3. Place Speed Selector in first (1) position, depress

Traction Clutch Lev er to hold friction wheel and hub

in position and remove cap screws. Release

traction clutch lever, shift to third (3) position, and

remove friction wheel (Figure 17).

4. Secure new friction wheel on hub with five cap

screws and torque cap screws to 8-10 ft. lbs.

(10,6-13,3 Nm).

5. Replace bottom cover.

6. Adjust Traction Drive Clutch (see Adjustments).

5

3

8.3 DRIVE PLATE SPINDLE

Place unit in the Belt Service Position.

Remove lock nut from pulley end of spindle and pulley

from spindle (Figure 18). To remove nut, engage

friction wheel drive to keep spindle from turning.

Remove friction wheel carrier following instructions

above. Remove drive spindle housing from frame by

removing three cap screws and lock washers from

housing. Check spindle bearings and other parts for

wear or damage and replace as necessary.

Assemble in reverse order applying Locktite Antiseize

to outside of bearing housing.

NOTE:

No. 767 Antiseize.

Mix 1 part Mobil 1 with 16 parts Locktite

4

1. Cap Screw

2. Friction Wheel

3. Friction Wheel Shift

Arm

2

1

4. Idler Hex Shaft

5. Cotter Pin

Figure 17

8.2 FRICTION WHEEL CARRIER

Remove roll pins from carrier shaft and pull shaft out of

frame far enough to free carrier (Figure 18).

Hold hex shaft on sprocket end with a wrench and

remove lock nut at outside of frame. Slide hex shaft to

center of frame until it clears sprocket and remove

carrier from frame.

Remove nylon lock nut from spindle hub and hub from

carrier.

Remove snap ring, washer, bearing and bushing from

carrier.

Check carrier bushings and other parts for wear or

damage and replace as necessary.

Assemble in reverse order.

8 - 24

Page 25

4

2

1

1. Spindle Hub

2. Friction Disk

3. Disc Hub

4. Flange Bushing

5. Sleeve Bushing

3

5

6

12

11

7

13

8

9

10

6. Ball Bearing

7. Drive Plate

8. Spindle

9. Housing Mount

10.Bearing

Figure 18

11.Bearing Spacer

12.Spindle Housing

13.Carrier

PS0451

8 - 25

Page 26

SECTION 9 - AUGER/IMPELLER

9.1 AUGER/IMPELLER REMOVAL

Place unit in the Belt Service Position.

1. Remove three nuts holding pulley to hub and

remove pulley and key.

2. Loosen set screw in hub and remove hub.

3. Remove three nuts holding bearing flange to

housing and remove bearing flange (Figure 19).

4. Remove two cap screws and lock washers on each

side of blower housing holding rake shaft in

position and remove bushing.

5. Remove three lock nuts attaching bearing support

to housing and remove bearing support.

6. Grasp auger assembly and pull gear case and

auger/impeller assembly free of housing.

7. Drive roll pin out of shaft ends, remove shear bolts

and remove auger from shaft.

8. Check all parts for wear or replacement.

9. Assemble using reverse procedure.

9.2 SCRAPER BLADE

IMPORTANT:

housing may be damaged.

Scraper blade is adjustable to compensate for wear.

To adjust scraper blade:

1. Tip unit back onto handlebar and support the

housing.

If blade wears too far auger/impeller

2. Loosen retaining blade nuts (Figure 19).

3. With runners adjusted to their full up position,

reposition scraper blade down, flush with runners.

4. Tighten lock nuts.

9.3 SHEAR BOLTS

WARNING:

moving parts to stop and remove wire from

spark plug before leaving operator’s position

and attempting to maintain or inspect auger.

IMPORTANT:

replacement. Use of any other type of shear bolt may

result in severe damage to unit.

Occasionally an object may enter auger/impeller

housing and jam auger, breaking shear bolts which

secures auger to shaft. This allows auger to turn freely

on shaft preventing damage to gear drive.

To replace shear bolt:

1. Slide auger outward against roll pin and align hole

in shaft with hole in auger (Figure 19) (holes in

shaft for roll pins and shear bolts line up).

2. Drive the new shear bolt through hole (if shear bolt

was broken this will drive remaining part from

shaft).

3. Secure with nut.

Stop engine, remove key, wait for

Use only Ariens shear bolts for

6

5

Figure 19

1

2

3

4

1. Blower Housing

2. Scraper Blade

3. Rake

4. Shear Bolt

5. Bearing Flange

6. Bearing

9 - 26

Page 27

9.4 DISCHARGE CHUTE

WARNING:

under rotating parts. Keep clear of discharge

opening at all times.

DO NOT put hands or feet near or

NOTE:

Chute must rotate freely . To adjust the gears

tighten or loosen the lower nut (Figure 20). This will

adjust the spring tension on the gears.

WARNING:

NEVER direct discharge of

material toward bystanders nor allow anyone

in front of equipment while unit is in operation.

Be familiar with area of operation.

Remove mounting clips from discharge chute, oil and

position chute on auger/impeller housing. Secure

discharge chute with mounting clips and hardware.

1

2

3

4

1. Chute Crank

2. Gear Cover

3. Pinion Gear

4. Chute Gear

5. Chute Support Bracket

5

6

7

8

6. Friction Plate

7. Compression Spring

8. Locking Center Nut

Figure 20

PS0601

9 - 27

Page 28

9.5 DEFLECTOR

To install a new deflector cable:

Remove one jam nut from deflector cable (Figure 21).

Route cable through retainer mounted on engine and

chute bracket. Replace jam nut and secure cable

threaded connector (from left side) to deflector bracket

with cotter pin. Position deflector in its lowest position

with cable control pushed full in and tighten jam nuts on

chute bracket.

NOTE:

Adjust jam nuts and/or threaded connector if necessary

to obtain full travel.

Slide handle end of deflector control cable through hole

in upper handlebar panel and secure with washer and

jam nut. Secure T-handle on end of deflector control

cable.

Check deflector movement to highest position.

9.6 RUNNERS

CAUTION:

height to clear gravel or crushed rock

surfaces.

Runners should be adjusted as conditions require

(Figure 21). Raising or lowering runners controls

distance scraper blade is held above surface being

cleared.

When operating machine on gravel surface, lower

runners so that housing will not pick up gravel. On

concrete, blacktopped or packed down snow surfaces,

raise runners so that scraper blade scrapes clean. To

reduce tendency of housing to ride up over heavy wet

or hard-packed snow, remove runners and re-install

with the narrow edge down.

Position unit on a flat level surface. Adjust runners by

inserting a spacer of desired thickness under center of

scraper blade, loosen hardware, slide runners to flat

surface and retighten hardware.

NOTE:

Above method keeps housing level by adjusting

runners equally. Uneven runners make machine difficult to steer and results in uneven clearing.

Adjust auger/impeller housing

1

3

3

4

4

2

1. Deflector Cable

2. Runner

3. Discharge Chute

4. Deflector

Figure 21

9 - 28

Page 29

SECTION 10 - GEAR CASE

10.1 CAST IRON GEAR CASE (WORM

GEAR)

Remove auger/impeller and gear case from housing

referring to Auger/Impeller Section.

Remove four bolts from bearing flange (Figure 22).

Remove flange and gasket.

NOTE:

Using bearing adjustment wrench remove adjustment

plug.

While holding input shaft in one hand and using a

mallet, strike case until bearing cone pops out of the

case.

Bronze gear can then be removed from case.

After bronze gear is removed, input shaft can then be

removed.

NOTE:

case.

T o remov e worm gear and bearings, simply remove bolt

and washer from end of shaft.

Assembly is done by inserting bronze and worm gear

at same time.

Using adjustment wrench, tighten down on adjustment

plug until input shaft is snug.

Replace side cover using a sealant on threads of two

bottom bolts.

Fill gear case with L-2 oil until level reaches bottom of

threads in filler hole.

Check oil level periodically. Oil lev el must be up to oil fill

hole. Change oil every 25 hours or once each season,

whichever comes first. Fill with Ariens Special L-2 Gear

Lubricant (P/N 000080). Use approximately 5 oz.

At this point bronze gear cannot be removed.

It is not necessary to remove the end cap from

the flat on bronze gear face will fill the hole in the side

of the gearcase.

Remove bronze bushing from front of worm shaft by

sliding it off. Replace if necessary. Notice that a flat on

the bushing flange positions the bearing inside the

gearcase.

Behind the rear bronze bushing is a seal which fits into

a groove in the gearcase. It should be replaced at time

of repair.

Rear bushing is a larger diameter than one in front, but

are identical in design. Replace if necessary.

If replacement of thrust collar is necessary, again drive

out groove pin towards direction of least resistance.

Inspect worm for burrs or black coloration. If either

show up, replace shaft.

For assembly, make sure the flats on the bushings are

in their proper place.

Apply Locktite 118 on the gear case half.

After assembly is complete you should be able to turn

input shaft freely.

Auger/impeller gearcase is lubricated with Ariens L-2

(P/N 00008000). Check lubrication by removing filler

plug on side of gear case just below left auger shaft.

Lubrication should be even with hole with unit sitting

level. Unit will not be damaged by over-lubricating.

10.2 ALUMINUM GEAR CASE

Remove auger/impeller and gear case from housing

referring to Auger/Impeller Section.

Remove six bolts that hold right and left gear case

halve s together (Figure 23).

If flange bushings need replacement, first remove seals

from outside of gearcase halves with a screwdriver.

Flange bushings can then be pressed out from outside

in with a bearing driver. Bushings are very lightly

pressed in.

When replacing bushings make sure the flat on the

flange of bushing fits in the inside notch of the case.

There are two special washers, one on either side of

bronze gear. If burred or worn they should be replaced.

Holding bronze gear on rake shaft is a groove pin.

When driving out, drive in direction of least resistance.

10 - 29

Page 30

Cast Iron Gear Case

1

2

3

7

4

6

1. Impeller

5

2. Worm Shaft

3. Adjustment Plug

4. Worm and Gear

Service Assembly

5. Rake Shaft

6. Gear Case Shaft

7. Gear Case

Figure 22

PS0472

10 - 30

Page 31

Aluminum Gear Case

1

3

4

2

5

6

1. Impeller

2. Worm Shaft and Gear Assemb ly

3. Thrush Collar

4. Case, Left Side, Large Bore

5. Case, Right Side, Small Bore

6. Rake Shaft

Figure 23

PS0281

10 - 31

Page 32

11.1 CONTINUITY DIAGRAM

The diagrams below show the various states of connection for electrical components.

The solid lines on switches show continuity.

NOTE: All switches are viewed from the rear.

Key Switch

(02739600)

SECTION 11 - ELECTRICAL

S

G

R

B

A

M

OFF START

S

G

R

B

A

M

RUN

Solenoid

(03551000)

NOT ENERGIZED ENERGIZED

S

G

R

B

A

M

11 - 32

PS0660

Page 33

11.2 WIRING DIAGRAM

HEAD LIGHT KIT

(OPTIONAL)

1

2

ENGINE

STARTER

RED

A.C. LIGHTING

YELLOW

D.C. CHARGE

RED

MAGNETO

RED

BATTERY

RED

BLACK

FUSE - 10 AMP

YELLOW

PURPLE

WHITE / BLACK

AB

RED

BLACK

M

G

A

R

B

A

S

KEY

SWITCH

STARTER

SOLENOID

BLACK

BROWN

PS0671

11 - 33

Page 34

Page 35

Page 36

Ariens Company

655 West Ryan Street

P.O. Box 157

Brillion, WI 54110-0157

920-756-2141

Fax 920-756-2407

www.ariens.com

Loading...

Loading...