Page 1

c Hr i en s O W NE R S M AN U AL

924000 SERIES

SNO-THROS

MODEL 924046 5 H.P. 24"

SMALL WHEEL

SERIAL NUMBER 000101 AND UP

MODEL 924048 7 H.P. 24"

SMALL WHEEL W/DIFFERENTIAL

SERIAL NUMBER 000101 AND UP

MODEL 9240S0 8 H.P. 24"

LARGE WHEEL W/DIFFERENTIAL

SERIAL NUMBER 000101 AND UP

MODEL 924052 10 H.P. 32"

LARGE WHEEL W/DIFFERENTIAL

SERIAL NUMBER 000101 AND UP

MODEL 924049

7 H.P. TRAC-TEAM TRACTOR

SMALL WHEEL W/DIFFERENTIAL

SERIAL NUMBER 000101 AND UP

MODEL 924081

8 H.P. TRAC-TEAM TRACTOR

LARGE WHEEL W/DIFFERENTIAL

SERIAL NUMBER 000101 AND UP

A mSA6i TO THE ARIENS CUSTOMER...

Welcome to the world of Ariens equipment. We are pleased

that you have selected Ariens and sincerely believe you have

purchased the best equipment available. The care you give

your new Ariens equipment will greatly determine the satis

faction and service life you will obtain from it. Use this manual

and the engine manual supplied, as your guide. By observing

the instructions and suggestions in these manuals, your Ariens

equipment will serve you well for many years.

Your Ariens dealer will be happy to supply any service or

advice which may be required to keep your Ariens equipment

operating at peak efficiency. He stocks genuine Ariens parts

and lubricants; manufactured with the same precision and

skill as the original equipment. His factory trained staff is

kept well informed on the best methods of servicing Ariens

ATTACHMENTS:

MODEL 824006 24" SNO-THRO

ATTACHMENT FOR SMALL WHEEL TRACTOR

SERIAL NUMBER 000101 AND UP

MODEL 824005 24" SNO-THRO

ATTACHMENT FOR LARGE WHEEL TRACTORS

SERIAL NUMBER 000101 AND UP

MODEL 824008 32" SNO-THRO

ATTACHMENT FOR LARGE WHEEL TRACTORS

SERIAL NUMBER 000101 AND UP

A SAFETY MESSAGE A

The product for which you have requested

information or repiacement parts is not a

current product. The replacement modeis

incorporate product designs, safety features,

safety instructions or warnings which repre

sent the latest “State Of The Art” develop

ments. For your safety and those around you

please contact your nearest Ariens/Gravely

Dealer for a demonstration of the current

product safety provisions and features.

equipment and is ready and able to serve you. If engine repairs

or services are required, they can be obtained from an Ariens

dealer or from an authorized engine manufacturer's service

station.

Should service be required on equipment, be prepared to

supply the serviceman with the Model Number and Serial

Number of the equipment and the engine, as well as a full

description of the trouble encountered.

Finally, your local Ariens dealer is in the best position to

answer your questions and service equipment. If for some

reason he is unable to satisfy your requirements, assistance is

aiways available from the Consumer Services, Ariens Company,

Brillion, Wisconsin 54110. Telephone: (414) 756-2141.

CT^riens

PART NUMBER 024449B

COMPANY BRILLION, WISCONSIN 54110

'A CUT ABOVE THE REST!

PRINTED IN U.S.A.

Page 2

SAFETY

INSTRUCTIONS

/VOID POTENTIAL HAZARDS

1. Read owners manual (or operating

and safely InstructionB

2. Observe alMabeisand Inatrucllont

3. Stop engine and wbH tor all movement

to atop before unclogglng or

servicing machine

4. Never allow children to operate the

equipment Never allow adults to

operate the equipment without proper

Inatruchon

5. Keep the area of operation clear of

all persons, especially children

6. Never direct discharge at bystanders

or allow anyone in front of unit

1 Keep machine properly maintained

and serviced with all shields, guards

and protective devices in place

78638

78617

78616

cT^riens

5 HP. 78640

7 HP. 78641

8 HP. 78642

10 HP. 78643

INSTRUCTIONS FOR SAFE OPERATION

A IMPORTANT

Safe Operation Practices for Snow Throwers

Training

1. Read the owner's manual carefully. Be thoroughly familiar

with the controls and the proper use of the equipment.

Know how to stop the unit and disengage the controls

quickly.

2. Never allow children to operate the equipment. Never allow

adults to operate the equipment without proper instruction.

3. Keep the area of operation clear of all persons, particularly

small children, and pets.

4. Exercise caution to avoid slipping or falling, especially

when operating in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is to be

used and remove all doormats, sleds, boards, wires, and

other foreign objects.

2. Disengage all clutches and shift into neutral before starting

the engine (motor).

3. Do not operate the equipment without wearing adequate

winter outer garments. Wear footwear which will improve

footing on slippery surfaces.

ORDER ALL DECALS BY ARIENS PART NUMBER SHOWN

4. Handle fuel with care; it is highly flammable.

a. Use an approved fuel container.

b. Never add fuel to a running engine or hot engine.

c. Fill fuel tank outdoors with extreme care. Never fill fuel

tank indoors.

d. Replace gasoline cap securely and wipe up spilled fuel.

5. Use a grounded three-wire plug-in for all units with electric

drive motors or electric starting motors.

6. Adjust the collector housing height to clear gravel or

crushed rock surface.

7. Never attempt to make any adjustments while the engine

is running (except where specifically recommended by

manufacturer).

8. Let engine and machine adjust to outdoor temperatures

before starting to clear snow.

Operation

1. Do not put hands or feet near or under rotating parts. Keep

clear of the discharge opening at all times.

2. Exercise extreme caution when operating on or crossing

gravel drives, walks, or roads. Stay alert for hidden hazards

or traffic. Do not carry passengers.

3. After striking a foreign object, stop the engine, remove the

wire from the spark plug, thoroughly inspect the snow

thrower for any damage, and repair the damage before re

2 -

starting and operating the snow thrower.

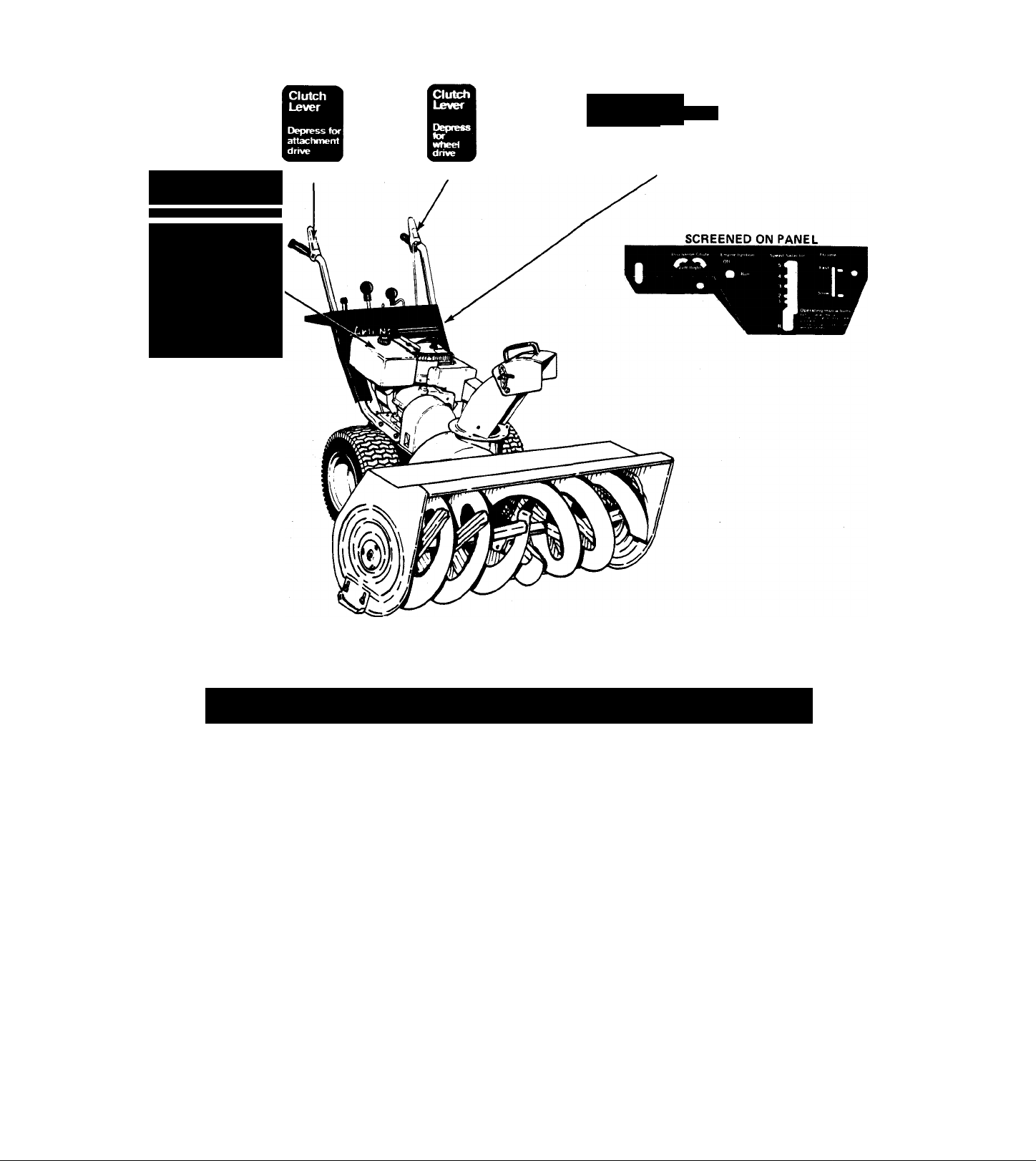

Page 3

AWARNINGir^:;;;^^^

ROTATING PARTS

Stop engine and remove

spark plug ignition wire before

removing obstructions.

78618

(8,10 HP.[ 7 H.P. ENGINE DECAL 78637

5 H.P. ENGINE DECAL 78611

8 H.P. ENGINE DECAL 78636

10 H.P. ENGINE DECAL 78635

78645

WUfmllll

ROTATING PARTS

Keep clear of collector

rakes while engine

is running

78644 (ON LEFT

78345

WHEEL HUB OF

MODELS 924048,

924050 & 924052)

BE AWARE OF SAFETY DECALS

4. If the unit should start to vibrate abnormally, stop the

engine and check immediately for the cause. Vibration

is generally a warning of trouble.

5. Stop the engine whenever you leave the operating position,

before unclogging the collector/impeller housing or dis

charge guide, and when making any repairs, adjustments, or

inspections.

6. When clearing, repairing, or inspecting, make certain the

collector/impeller and all moving parts have stopped. Dis

connect the spark plug wire.

7. Do not run the engine indoors, except when starting the

engine and for transporting the snow thrower in or out of

the building. Open the outside doors: exhaust fumes are

dangerous.

8. Do not clear snow across the face of slopes. Exercise ex

treme caution when changing direction on slopes. Do not

attempt to clear steep slopes.

9. Never operate the snow thrower without proper guards,

plates, or other safety protective devices in place.

10. Never operate the snow thrower near glass enclosures, auto

mobiles, vyindow wells, drop-offs, etc, without proper ad

justment of the snow discharge angle. Keep children and

pets away.

11. Do not overload the machine capacity by attempting to

clear snow at too fast a rate.

This engine

has provisions

for electric

starter kit.

78607

®|iTecumseh Engine

instructions

CAUTION

i^or your personal protecfinn.

““read all safety notes in engine

own«T s manual

OPERATION

F-or detailed lubru alion start

inq A operating instriu.('ons,

see (‘ngme owner s manual 4

equipment mtr s insfrut ttons

LUBRICATION

Summer SAE 10 Oil

78608

Winter SAt SW 30 0.1

Te< umseh Prectiu Is ( ompany

son Ni'rt.i

r-aften wi S,l0/'4 USA

78609

ORDER ALL DECALS BY ARIENS PART NUMBERS SHOWN

12. Never operate the machine at high transport speeds on

slippery surfaces. Use care when backing.

13. Never direct discharge at bystanders or allow anyone in

front of the unit.

14. Disengage power to the collector/impeller when snow

thrower is transported or not in use.

15. Use only attachments and accessories approved by the

manufacturer of snow thrower (such as wheel weights,

counterweights, cabs, etc).

16. Never operate the snow thrower without good visibility or

light. Always be sure of your footing, and keep a firm hold

on the handles. Walk; never run.

Maintenance and Storage

1. Check shear bolts, engine mounting bolts, etc, at frequent

intervals for proper tightness to be sure the equipment is in

safe working condition.

2. Never store the machine with fuel in the fuel tank inside a

building where open flame or sparks are present. Allow the

engine to cool before storing in any enclosure.

3. Always refer to owner's manual instructions for important

details if the snow thrower is to be stored for an ex

tended period.

4. Run the machine a few minutes after throwing snow to

• 3 -

prevent freeze-up of the collector/impeller.

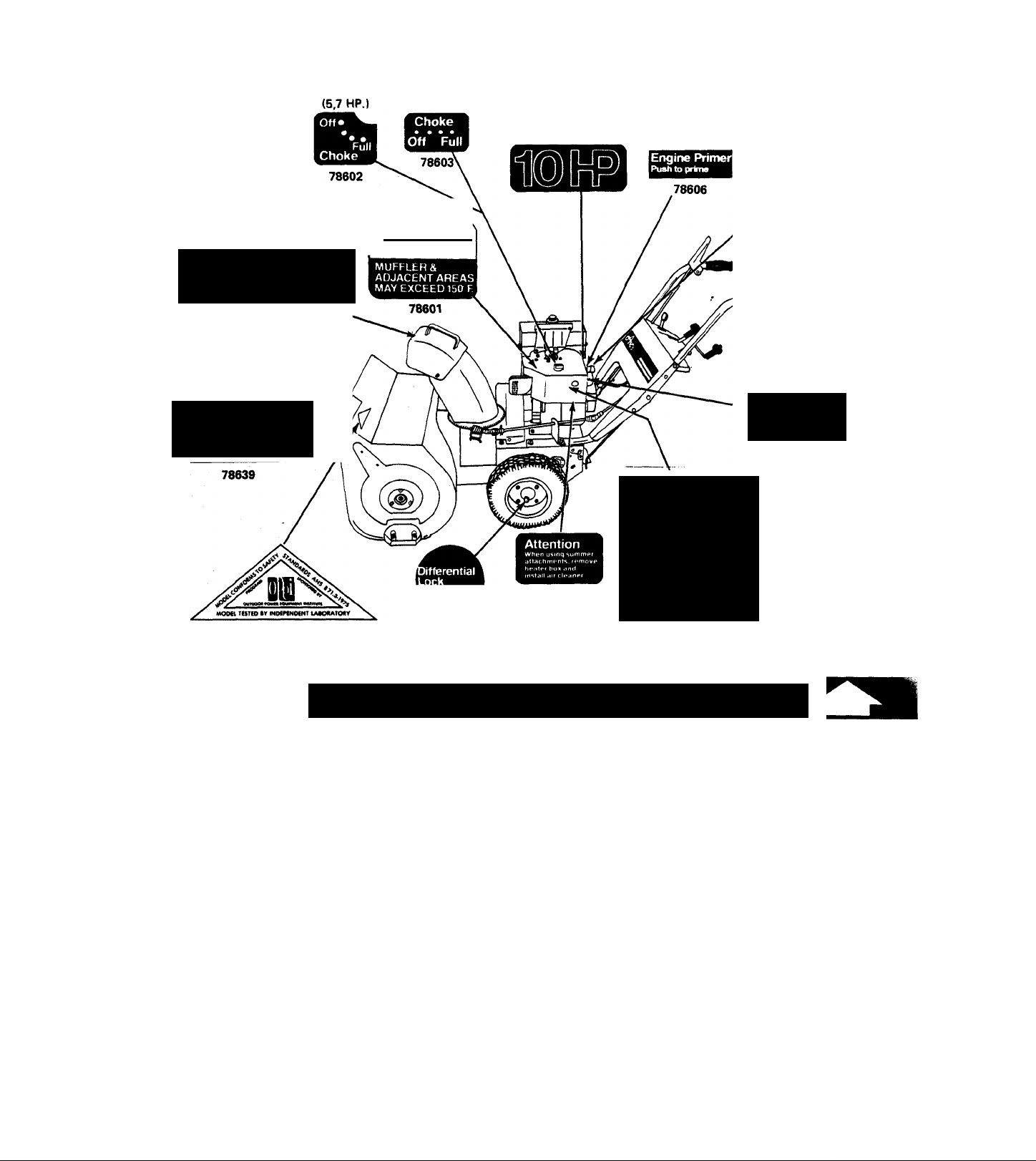

Page 4

CONTROLS

SPEED SELECTOR: Sets speed of tractor. Change

©

speed or shift to reverse.

THROTTLE: Controls engine speed. On 5 and 7 HP

Models move throttle control to "FAST" position

after engine has stopped to minimize throttle damage

due to freezing. On 8 and 10 HP Models move

©

throttle to "SLOW" position after engine has stopped

to minimize throttle damage due to freezing.

WHEEL DRIVE CLUTCH LEVER: Activates tractor

drive. Depress to move tractor, release to disengage

©

drive and stop machine.

ATTACHMENT DRIVE CLUTCH LEVER: Activates

auger and impeller. Depress to run auger and im

©

peller. Depress to run auger and impeller, release both

attachment and tractor clutch to stop attachment.

HAND CRANK: Turns discharge chute 230° so snow

©

can be thrown away from area being cleared.

CHOKE: Move choke to choke position to start

©

engine. Models 924046 and 924048 have choke on

top of heater box. Models 924050 and 924052 have

choke at rear of heater box.

PRIMER BUTTON: Injects gas directly into car

©

buretor. (A) Move choke lever to full. (B) Push

primer bulbtwo times. (C) Pull start rope three times.

If engine fails to start, repeat procedure from step

(B).

KEY SWITCH: Prevents unauthorized use. Turn on

to run, turn off to stop.

©

STARTER BUTTON: The starter button (i^ is found

oh all units equipped with electric starters. Plug the

©

120 volt cord into the starter block; plug the op

posite end into a convenient 120 volt outlet. Push

the starter button to start the engine.

OPERATION

BEFORE STARTING:

Fill engine crankcase with Ariens Sno-Thro oil 5W-20

when using Sno-Thro.

Fill fuel tank with fresh, clean, regular gasoline.

Do not mix oil with gasoline.

Make visual check with regards to safety precautions, ob

structions, lubrication and maintenance.

DIFFERENTIAL LOCK: Models 924048, 924050 & 924052.

The differential lock is located in the left wheel hub.

When preparing to blow snow, turn the differential lock till it

snaps IN. In this position the differential is locked and both

wheels turn together. Power is applied equally to both. To use

the differential, pull back on the knob and turn it to the

OUT position. This unlocks the differential for easy turning

with mower, vacuum or broom attachments.

If tractor is to be used with lawn attachments, be sure

heater box is removed and air cleaner installed. Follow de

tailed instructions packed with attachment.

NOTE:

Check for frozen throttle control and for frozen impeller fan

before starting engine. These problems arise in wet, slushy

snow. If the impeller is frozen, it is best freed by thawing

in a heated garage or other building. A frozen throttle control

may be freed by starting the engine and letting it run long

enough to heat up the carburetor and loosen the cable. The

best solution for both problems is preventing freezing. Allow

the engine to run for a short time before shutting down to

throw the remaining slush and water out of the blower

housing and thus prevent freezing of the impeller fan. On

5 and 7 HP Models move throttle control to "FAST" position

after engine has stopped to minimize throttle damage due to

freezing. On 8 and 10 HP Models move throttle to "SLOW"

position after engine has stopped to minimize throttle damage

due to freezing.

TO ST ART: Controls are identified in Figure 6.

Turn key to "run" position.

Move choke lever to CHOKE position:

Move throttle to FAST position.

Push primer bulb (l) 2 times.

Pull recoil starter nn to start engine. If the machine is

equipped with an electric starter attach the starter cable to the

starter switch, plug the cable into any convenient 120 volt

electrical outlet ■ and depress the starter button to crank and

start the engine. Follow the starter manufacturers instructions

supplied with the starter.

Move choke ^6^ to no choke gradually as engine warms up.

- 4 -

Page 5

TO TRANSPORT:

Move speed selector to desired speed.

Press down on handle bars to raise front of Sno-Thro

slightly off the ground.

Depress wheel drive clutch lever to transport unit.

TO OPERATE:

Move deflector to desirwJ height.

Turn hand crank direct discharge chute.

Depress attachment clutch (£) to engaged position.

Move speed selector to desired speed.

Move throttle (T) to desired speed.

Depress the wheel drive clutch lever to move tractor.

Speed of the machine is controlled by the throttle and

speed selector.

TOSTOP:

Release wheel drive clutch lever Qj Depress attachment

clutch lever ^ to allow the Sno-Thro to run for a short

time to throw out slush and water and prevent freezing the

impeller fan.

Turn key(^ to "off" position to stop.

5 and 7 HP Models: Move throttle to "FAST" position after

engine has stopped.

8 and 10 HP Models: Move throttle to "SLOW" position

after engine has stopped.

NOTE: This Sno-Thro is equipped with a mechanics/ interiock between wheel drive dutch and attachment dutch levers.

When both dutch levers are engaged the mechanical interlock

mil engage and the attachment dutch will remain angled as

long as the wheel drive dutch lever is not released. This frees

the right hand to operate other controls. Once the mechanics/

interlock is engaged, both the wheel drive and attachment

clutch levers must be released to disengage the attachment

drive.

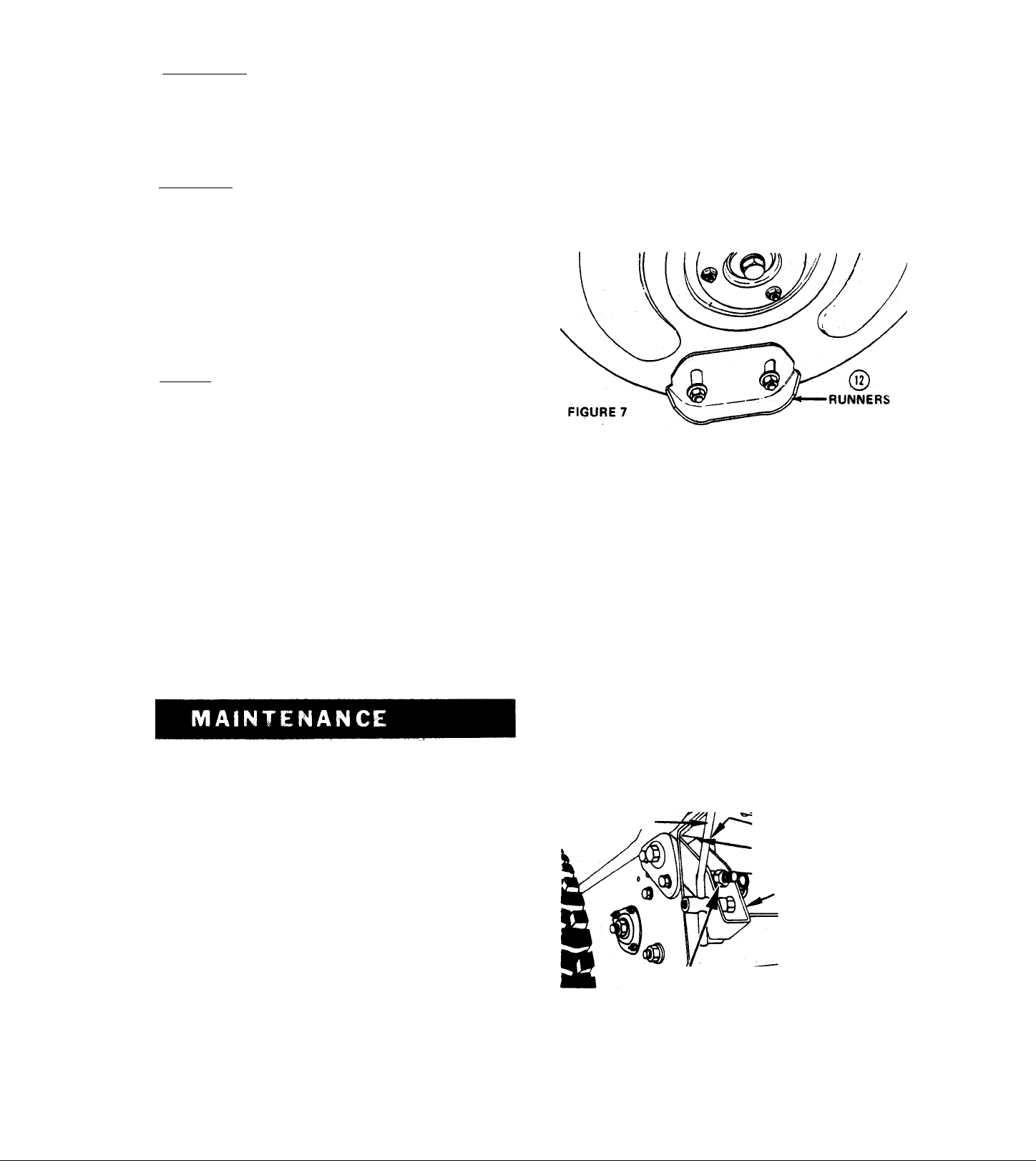

RUNNERS AND SCRAPER BLADE

The runners on each side of the blower housing, and the

scraper blade, along the back of the blower housing, are all ad

justable to suit conditions. Raising or lowering the runners

controls the distance the scraper blade is held above the sur

face being cleared. Runners are adjusted by loosening the two

nuts securing each runner. Move the runner to the desired

position and retighten the nuts. Be sure to adjust both runners

to the same height to keep blower housing level. Uneven

runners make the machine difficult to steer and will result in

an uneven clearing job.

Adjustment of the runners is critical to good cleaning. If the

machine is to be used on a gravel surface lower the runners

so the. blower will not pick up gravel then after the remaining

snow is packed down, the runners may be raised for close

scraping. On smooth concrete or blacktopped surfaces, the

runners may be raised so the scraper blade rests on the sur

face and scrapes clean.

The scraper is adjustable so it may be lowered to compensate

for wear. If the blade is allowed to wear down too far the

blower housing may be damaged.

ATTACHMENT CLUTCH ADJUSTMENT

The Attachment Clutch is adjusted by connecting the chain

to the spring just below the clutch handle. Connect the spnnii

to a chain link so the chain is snug but so the idler drops away

from the belt with the handle all ^e way up.

Ariens Company recommencte that you have adjustments

made by your local Ariens dealer. He has the tools and know

how to properly perform these maintenance adjustments

which may be required to Heap the Sno-Thro operating at

peak efficiency. The Sno-Thro is equipped with the finest

quality engine obtainable. However, should servicing be

required, it can be obtained from an Ariens dealer or an

authorized engine manufacturer's service station. Should you

decide to make adjustments on your Sno-Thro yourself,

Ariens recommends that you call your dealer for the answers

to any questions that might arise in performing this work.

SHEAR BOLT REPLACEMENT —_

Occasionally a small object may enter the collector and jam

the rakes. When this occurs, the shear bolts securing the rakes

to the shaft will break and allow the rake to turn freely on the

shaft preventing damage to the gear drive. When this happens,

turn off the engine, remove wire from spark plug, remove the

broken shear bolt and replace with a new ARIENS shear bolt.

Use of any other type of shear bolt may result in severe

damage to the machine. USE ONLY ARIENS SHEAR BOLTS

FOR REPLACEMENT.

WHEEL DRIVE CLUTCH ADJUSTMENT

A drive disc adjustment is provided to compensate for wear

on the friction wheel. If slippage occurs when the wheel

drive clutch it engaged, tighten the drive disc adjustment. This

adjustment is accessibie without removing the bottom cover.

See Figure 8.

CLUTCH ROD

ADJUSTMENT NUT

Adjust as follows: Place speed selector between first and

reverse. Tip machine forward on blower housing. Tighten

the adjustment nut while turning the wheels until the wheels

begin to bind. Back off 3 turns. Wheels should then turn

easily.

TOP OF SLOT

1/16" CLEARANCE

CLUTCH LEVER

FIGURE 8

Page 6

CHUTE CRANK ADJUSTMENT

In the event the chute crank fails to rotate freely, loosen the

nut securing the worm clevis to the bracket. This hole in the

bracket is slotted to permit adjustment. Position the worm

so there is a little clearance between worm and the gear

teeth on the blower. Tighten the nut. Rotate the discharge

chute through its full travel to see that it turns easily. Re

adjust if required. Uubricate as described under LUBRICATION

for smooth operation.

BELT REPLACEMENT

CAUTION

Since replacing the belts will involve turning the engine over

with the starter, and the engine might accidentaily start, re

sulting in injury, the spark plug wire MUST be disconnected

during this procedure.

The drive belt and the attachment drive belt are both accessible

by removing the blower housing as follows;

1. Remove the hair pin cotter in the chute crarik assembly.

Separate the chute crank.

2. Remove the two flanged whizlock screws securing the belt

guard to the tractor. Remove the belt guard.

NOTE: Tipping the tractor back on the handlebars when

separating the units may result in bending the bottom cover.

To avoid diis situation, either tip the unit up on the blower

housing and remove the bottom cover before separating the

units; or support the handlebars so the tractor does not tip all

the way over; then lift off the blower housing.

3. Remove the cap screws on each side that secures the blower

housing to the frame. As the blower housing and tractor

are tipped apart, roll the belt off the engine sheave between

the sheave and belt finger. This can be easily done by

pulling the recoii starter rope to rotate the engine sheave.

With the beit disconnected, the biower housing may then

be lifted from the frame.

A

REPLACEMENT OF TRACTOR DRIVE BELT (See Figure 10.)

The drive belt is held in place on the sheaves by an idler

pulley. To free the belt, the idler can be pulled from the

belt and the belt removed from the sheave. Activate clutch to

gain clearance. It may be necessary to pull back blower idler

arm clevis pin for additional clearance.

To replace the belts, position on the engine sheave first,

then on the drive sheave. .Position the idler carefully on the

belt.

With the belt in position and the idler in place, check the

belt alignment. The engine sheave and the tractor sheave must

align with one another WITH THE TRACTOR CLUTCH

ENGAGED. If the sheaves are not properly aligned, loosen the

setscrews on the engine sheave and align the sheaves. Re-tighten

the setscrews. Recheck the belt alignment WITH THE CLUTCH

ENGAGED.

ENGINE

REPLACEMENT OF THE ATTACHMENT DRIVE BELT

The sno-thro attachment drive belt is on the sheave on the

blower housing. To replace this belt, hold the impeller brake

away from the belt and slip the belt from the sheave. See

Figure 9.

Replace the belt by slipping it into position on the sheave;

positioning the brake shoe on the belt.

REPLACEMENT OF BLOWER HOUSING (See Figure 11.)

Position the blower housing on the rod in the tractor frame

and secure as follows:

1. Tip the blower and tractor together. Hold the attachment

drive belt up as the units are tipped together. Secure with

two cap screws into the frame. As the cap screws are

tightened, hold up on the handlebars to be sure the two

units are secured together.

- 6

Page 7

2. Roll the attachment belt on to the engine sheave. Pull the

recoil starter rope to turn the engine sheave and roll the belt

into place under the belt finger.

3. Check the belt finger spacing. There should be 1/8 inch

clearance all around the belt finger and belt with the

attachment clutch engaged. Readjust the belt finger if

required.

4. Check the sheave alignment with the attachment belt in

place. Readjust the position of the blower sheave as re

quired to align the sheaves. Be sure the brake pad aligns

with the blower sheave.

5. The idler on the attachment belt is adjustable. If the belt

slips, adjust the idler in the slot in the idler arm to apply

more tension to the belt. Belt should declutch when

attachment clutch is disengaged.

6. Replace the belt guard and chute crank assemblies.. Re

adjust the chute crank as described in the paragraph above.

Replace the spark plug wire.

DRIVE CHAIN ADJUSTMENT

MODELS 924050 and 924052

If sno-thro is difficult to push because of tight or inter

fering drive chains, proceed as follows:

1. Stand unit up on blower housing and remove bottom cover.

2. Chain tension is adjusted by loosening the two nuts on

the 24364 Reduction Shaft. Adjust reduction sprocket

up or down in slot to obtain proper tension (chain should

be snug). Retighten both nuts. Torque to 170-180 inch

lbs.

3. Chain interference with the 3085 Bearing Flange on 24045

Hex Shaft occurs if these is no 64058 Washer between the

10276 Sprocket and 54079 Bearing. Install washer.

LUBRICATION

FIGURE 12

REPLACEMENT OF FRICTION WHEEL

1. Tip the machine up on the blower housing and brace

securely. Remove two cap screws and loosen the other two,

securing the bottom cover and remove the cover.

2. Place the speed selector in FIRST position. Depress the

wheel drive clutch lever to hold the friction wheel while

the five bolts securing the friction wheel to the hub are

loosened. Remove the five bolts, shift to THIRD position

and disconnect the shift link. See Figure 12.

3. Position a new friction wheel on the hub and replace the

five bolts. Tighten these bolts to 8-10 foot pounds with

a torque wrench. Replace the shift links.

4. Replace the bottom cover. Readjust the drive disc as

described in the WHEEL DRIVE CLUTCH ADJUSTMENT

on page 5.

Fill crankcase with Ariens Sno-Thro oil 5W-20 when

using Sno-Thro at temperatures below 40 degrees F.

Use Ariens Gard-N-Yard oil MS classification SAE-30 when

using lawn attachments at temperatures above 40 degrees F.

Fill fuel tank with fresh, clean, regular gasoline.

NOTE:

For detailed instructions on engine refer to manufacturer's

booklet packed with the machine.

-7 -

Page 8

TRACTOR DRIVE

MÓDEL 924052 GEARCASE

At start of season, grease gears, pinion sprocket, hex and axle

shaft as indicated in Figure 13. Use Ariens Moly Lithium grease.

Put two or three drops of light oil on speed selector and other

linkage points. CAUTION: Do not allow grease or oil to

come in contact with friction wheel, drive disc or belts.

SNO-THRO UNIT

ZERK FITTINGS

SHEAR BOLTS

OIL FILL

Check oil level periodically. Oil level must be up to oil fill hole.

Change oil every 25 hours or once each season which ever

comes first. Fill with Ariens Special L-2 Gear Lubricant.

Approximately 5 oz.

FIGURE 15

FIGURE 14

NOTE:

When replacing a worn or broken shear bolt, use

shear bolts only.

Grease rake shaft periodically or each time a shear bolt is re

placed. At the end of the'season, remove shear bolts, use a

grease gun on zerk fittings to grease rake shaft, turn rakes on

shaft several times and replace shear bolts. See Figure 14. Use

Ariens Moly Lithium grease.

ARIENS

MODELS 924046,924048 8i 924050 GEARCASE

The blower gear case is lubricated with Ariens Liquid

Grease (Part No. 000070). This grease will not flow at lower

temperatures. It is therefore difficult to Check the lubricant

level. Best method for checking is to place the unit in a warm

location overnight. This allows the grease to flow to level.

Check the lubrication by removing the filler plug on the side

of the gear case just above the left auger shaft. Lubrication

should be even with the hole with the machine sitting level. It

may be necessary to insert a wire into the hole to check level.

The unit will not be damaged by over lubricating.

STORAGE

ENGINE: Follow detail instructions in the engine manual.

SNO-THRO: Lubricate, clean and repaint as necessary.

Cover and store in dry place.

- 8-

Page 9

24" & 32" SNOW-THRO FOR

MODELS 924046, 48,

50&52

SNO-THRO DE ET 32"

MODELES 924046, @H

48, 50 ET 52

USE ARIENS L-2

GEAR LUBRICANT

APPROX. 5 OZ.

Page 10

24" & 32" SNOW-THRO FOR MODELS 924046, 48, 50 & 52 SNO-THRO DE 24" ET 32" MODELES 924046, 48, 50 ET 52

NoDE

NO DE CODE '

REF.

PIECE D'INV

„ „ DESCRIPTION

REF.

N0.

11 024383

PART STOCK

NO. CODE

1

0243790GEARCASE, L.H. Half

2

0243800QEARCASE, R.H. Half

3 055122S

4

056081

5

024382

6

058045

7

032103STHRUST COLLAR

8

055111

9

055112

056047

10

FLANGE BUSHING

M SEAL

WORM SHAFT & GEAR

S

M GROOVE PIN

FLANGED BUSHING

s

FLANGED BUSHING

s

M

"0" RING

0 RAKE SHAFT

024065

0 RAKE SHAFT

12 058069MGROOVEPIN

13

14

058030

064166M

M ROLLPIN, 3/16x1)4"

WASHER

15 032038M GASKET

16 082054MCARRIAGE BOLT

17

18

19

062013M

070010M FLGOWHIZLOCKSCREV)/

024237

CARRIAGE BOLT

FAN

0

0243760 FAN

20

058037MROLLPIN, 1/4 X 1-3/4"

21 072108FVEE BELT

072086FVEEBELT

22

23

062010M

060012M SETSCREW

24 024434

CARRIAGE BOLT, 3/8-16x6

0 CHUTE CRANK BRACKET 1

25 0243490DISCHARGE CHUTE

26 059023M

024403

27

074054

28 010193M

29

30

510012sDEFLECTOR CHUTE

065039M LOCKNUT

31 0244050

32 024389

33

34

35

36

37

073070

066001M

0243460

059001MCAP SCREW, 1/4-20 x 3/4

056070M

38 024013

39

40

41

42

43

44

45

002008M GASKET

055059M flanged bushing

5240CfiM WORM AND WORM GEAR

001138MPIPE PLUG

024002

057075M

065040M

46 010142

0 DISCHARGE CHUTE

CAPSCREW, 3/8-16x3/4

M TAPTITE

WING NUT

BRAKE ARM EXTENSION

S PULLEY HUB

s

SHEAVE

KEY,Woodruff, 3/16x7/8

ROD

SEAL

0 GEARCASECOVER

s

GEAR CASE

•SNAP RING

LOCKNUT

s

BEARING FLANGE

031859sBEARING FLANGE

47

48 075083

49

50 054044

51 624065M

52 024461

53

54

55 058034

56

57

58

59

010198

s

s KNOB

624035M

s

022123

024427

s

M

s WORM GEAR, L.H.

M ROLLPIN, 1/2 X 3/4

063023M

065042

M

010438M

524036

524037

524038

0

0

0

CAP

BRAKE ARM ASSEMBLY

BEARING CUP

UNIVERSAL JOINT

CHUTE CRANK

WORM CLEVIS

LOCKWASHER

LOCKNUT

CHUTE CLAMP

BLOWER HOUSING

BLOWER HOUSING

BLOWER HOUSING

QUANTITE'

NO. REd'O

CO o

CO

^ S lO

o o e

s

^ wr ^

CN

03 os S)

a>

1

1

1

1 1

2

2 2

2

2 2

1

1 1

1

1 1

1

1 1

1

1

1

1 1 -

1

1

1

1 1

-

-

1

1 1

2

2 2 2

2

2 2

1

1 1

2

2 2

- -

1 1 1

1

1 1

-

-

2

1

-

2

-

2 2

- 1

1

w

1

6

6

2

2 2

1

1

1 1 -

-

-

“

2

6

1

1

6

«

1

1

1

1 1 1

-

-

-

-

- -

-

- -

-

- - -

3

1

-

1

1

1 1 1 1

-

2

1

1

1

3

1

2

2

6 8

6

1

1

1 1

1

6 6

6

-

1

1 1 1

1 1 1

1

1 1

-

-

-

-

- -

- -

-

-

-

- -

3

1 1

- -

1 1 1 106

1 1 1

-

-

2

2

1 1 1

1

1

1 1

1

3 3 3

1

1

5 5 5 6

3 3 3 4

1

1

-

-

-

1

- -

1

1 1

-

1 1

3

Node No OE CODE

REF, PIECE D'INV,

REF. PART STOCK

DESCRIPTION

NO. NO. CODE

_

60054063

-

-

- 031860

-

-

-

054052SBALLBEARING--

61003017

064002M

62

63010164

024373

64054045

-

-

1

-

029225

070058M

66

67024374

68065056M FLANGED WHIZLOCK NUT10

010165MRUNNER

65

69 064047M

-

70063006

-

71059024M

72022093

73 510015

2

-

74

524039

524013

_

-

4

1

2

524014

76

524035

77

524030

010494D

79

065015M NUT

80

010260

81

067019M

82

002005

83

084046M WASHER, 1.505 x 1.0052

84

524040

75

1

85

1

86062011

87058015

88

-

89

90

91 070060

92

1

93024345MCLEVIS PIN

4 94

2 95

1 96

97

1

98

2

99

1

100

1

101

1

102

1

103

3

_

104059022

105

1

107 064082

108

2

108

2

109 070026M

110

1

111074027

112

113 024381

1

114

115

116

-

-

S RADIAL BEARING

S BEARING FLANGE

S BEARING FLANGE

WASHER,5/16x7/8x.083

M

SCRAPER BLADE

M

SCRAPER BLADE

BEARING CONE

s

M RUNNER

RIBBED NECK BOLT6

BEARING SUPPORT

s

WASHER, .516x1.441x1/8 22 2

M

LOCKWASHER2

CAP SCREW, 1/2-13x1

M SPIN DRIVE ZERK FITTING 4

F

SHEAR BOLTW/NUT

s

RIGHT RAKE

s

RIGHT RAKE

s

LEFT RAKE 1

s

LEFT RAKE

s

GEARCASE ASSEMBLY, 32'

s

GEARCASE ASSEMBLY, 24'

WORM SHAFT11 1 1

M WAVE WASHER

HAIR PIN 1 1 1 1

M BEARING SPACER

083164

063032M

M

SPRING 1

CARRIAGE BOLT, 5/16-18 X 1

M

ROLLPIN, 5/16x1-3/4

M

LOCKWASHER1 1

070031M FLGO'WHIZLOCK SCREW!! 2

0243750

0240150

WORM SHAFT

RIBBED NECK BOLT

M

ADJUSTMENT PLUG

065078MFLANGED WHIZLOCK NUT 3

056061FSEAL

063017MLOCKWASHER

055035

064087M

FLANGE BUSHING

s

WASHER, 1.626 X 2.5 X.012

022178M BRAKE LINING11 1 1

068062M RIVET

067010

024064

004037

M HAIRPIN COTTER

GEARCASESHAFT

0

DUST CAP

s

CAP SCREW, 5/16-18x3/4

M

063003M LOCKWASHER

066008M

067010

067004

KEY,Woodruff No.6-

M

WASHER

M

HAIRPIN

M

COTTER PIN

NUT RETAINER

062001M

062026

066013

059028

065056M

CARRIAGE BOLT2

M

TAPTITE 2

M

CARRIAGE BOLT

M

WORM GEAR1

M

KEY, STRAIGHT

M

CAP SCREW

WHIZLOCK NUT

1

OUANTITE'

NO. REQ'D

CO

00 O <N

^ LO Un

s

eoo

^ ^ ^

CN

<N CN CN

03 03 03

03

1

1

1

1

-

9

1

-

-

2

-

2

-

1

1

-

-

9

9

1

-

-

10

1

- 1

- 2

2 2

-

-

6

6

2 2 2

1010 6

2

2

2 2

2 2

4 4

2

1

- -

- «

- -

1

1

1

2 2

2

1 1

-

1

1

-

1 1

1 1

1

1 1 1

- -

2 2

2

1 1 1

-

-

1 1

1

-

1

2 2

-

-

3 3 3 3

-

1

- - -

- ■ -

2

_

2

-

-

1 1

3

2

-

2

3

-

2

-

2 2

1 1 1 1

- - -

-

- -

- - -

_

-

- _

-

- -

1

2

—

1

2 2

1

- —

2

2 2 2

2

2

5

5

5

1

— _

-

-

1

—

1

_

1

-

_

2

6

4

-

I

-

1

2

2

-

1

-

1

1

-

2

2

2

1

1

3

4

2

2

1

1

2

_

2

6

1

_

1

1

1

1

1

1

1

SUGGESTED PARTS STOCKING CODE

F -FAST S -SLOW

M -MEDIUM O -CUSTOMER ORDER ONLY

F — FAST (rapidel S - SLOW (lent)

M - MEDIUM (moyen) 0 - Commande du client seulement

■ 11

CODE SUGGÉRÉ D'INVENTAIRE DES PIÈCES

Page 11

TRACTOR PARTS FOR MODELS ) 924046, 924Û48,

PIECES DU TRACTEUR DES MODÈLES f 924050 & 924052

REO ROUGE

CAUTION

I ORDER PARTS BY PART NUMBER

NOT BY REFERENCE NUMBER OR

DESCRIPTION. ANY PART

I ORDERED BY REFERENCE

NUMBER WILL BE DISREQARDED.

-12-

ATTENTION

COMMANDEZ LES PIECES PAR

numero, non par

numero DE RÉFÉRENCE NI PAR

DESCRIPTION. TOUTE COMMANDE

PAR NUMÉRO DE RÉFÉRENCE

SERA ICNORÉE.

Page 12

TRACTOR PARTS FOR MODELS

924046, 924048, 924050 & 924052

PIECES DU TRACTEUR DES MODELES

Node N0 DE CODE

REF. piece D'INV

»re CT«»., DESCRIPTION

REF. PART STOCK

NO. NO. CODE

FLANGE WHIZL0CK SCREW

1 070009

2 060012

3 063003

4 024074

5 024073 M

6 065040 M

7 059028 M

8 024236

9 010142 s

9 024363

10 054136

10 054093

11 065056

12 070058

13 070015

14 024077

15 070011

16012023SBEARING SUPPORT

17 055039

18 003017

19 024338

19 024045 0 HEX SHAFT 20 066015

21 010276 s

22 025089

23 064058

24 003085 S BEARING FLANGE

25 054080 S BEARING, RADIAL

26 065054MLOCKNUT

27 065094

28 024366

28 024339

- 29 022063 M

30 065018

31 063014 M

32 064093

33 055040MBUSHING

34 024364

35 024367

36 064036 M WASHER .В5/.в35х.005х.062 5 5 5 5

37 058009 F

38 055026 M

39 058029FROLL PIN 3 3

40 063025

41 610938 0

41 624074

41 624083

42 055029 M SLEEVE BUSHING

43 010374sPIN 1 1 1

44 083007

45 058042MGROOVE PIN 1

46 010372 F

47 058032

48 010375 S KNOB 1

49 067001

50 024233

51 024232 S LEVER SHIFT ARM

52 012151 S CLEVIS PIN 2 2 2 2

53 059039

54 059136

55 024231 0

56 024115

57 065042

M

SETSCREW 1

M

M LOCKWASHER

M PINION CHAIN

IDLERCHAIN

M IDLER CHAIN

012078

LOCKNUT

CAP SCREW y.-20x)4 2 2

M BELT FINGER

BEARING FLANGE

BEARING RETAINER ■

s

M BEARING BALL

M BEARING,RADIAL

LOCKNUT

M

F RIBBED NECK BOLT

FLANGE WHIZLOCK SCREW

F

SHAFTSUPPORT

M

F RIBBED NECK BOLT 6

M FLANGED BUSHING 2

M BEARING FLANGE 2

6 HEX SHAFT

M KEY, WOOD RUFF 1/8x5/8

9 TOOTH SPROCKET 1 1

s ROLLER

M WASHER .500/.505x1x.062 2 2

F LOCKNUT

SHAFTSUPPORT 1

S

S CLUTCH STOP

SPIN-DRIVE ZERK FITTING

F

NUT

LOCKWASHER

F

WASHER .380/.385x3/16x.062

S REDUCTION SHAFT •

S

PINION SHAFT

ROLL PIN

FLANGED BUSHING

F

LOCKWASHER

AXLE ASSEMBLY L.H.

0 AXLE LH. -

AXLE ASSEMBLY L.H. 1

0

s SPRING

LOCKNUT, HOB 1

F

ROLL PIN 3/32x1

F

COTTER PIN

S SHIFT LINK

M CAPSCREW 5/16-18x14

M CAPSCREW 5/16-18x3

BRACKET SHIFT LEVER 1 1

SPACER

s

F

LOCKNUT

SUGGESTED PARTS STOCKING CODE

F - FAST S -SLOW

M - MEDIUM 0 - CUSTOMER ORDER ONLY

QUANTITÉ

Ш eoo»

1 I I

(N СМеМ

OB 99 Ç

8

5 5

1 1 •

2

1 1

6 6 6

■ - - ■ 8

9 9

4 4

2

1 1

1 1

1 1

1 1

1 1

4 4

1 1

1 1

4 4

3

2 2

1 1

4 4

1 1 1 1

1

3 3 3 3

NO. RÉQ'D

0999 99

8 8

8

1 1

1

5 5

1 1

•

1

2

-

2 •

2 2

2 2

•

2

9

4 4

• 6

•

• -

•

1 1

1 1

1 1

•

2 2

1 1

1 1

1

1

4 4

1

1 1

2

2

2 2

2

2 2

2 2

4

3

1

1

2

1

1

3

4 4

1 1 1

Sa a

OO O

- -

1 1

1 1

1

1

1

1

1

1 1

1

1 1

3

2 2

1

1 1

Node No DE CODE

REF. PIECE D'INV.

REF. PART STOCK DESCRIPTION

NO. NO. CODE

58 067002

59 024069 0

60 024272 0

1

2

2

1

8

9

1

1

2

2

1

4

3

1

1

1

1

1

1

3

1

61 083094

62 624027 s

63 010542 s

64 065062

65 054039

66 022002 s SPINDLE HOUSING

67 024155 s BEARING SPACER

68 022003

69 003034 M

70 024076 s SPINDLE

71 010546 M DRIVE PLATE

72 024071

73 064123 F

74 059003

75 063018 M

78 065015

77 010485 S STREET ELBOW

78 012222

79 025208 M CAP

80 075040

81 075050

82 022161

83 624022 0 CARRIER 1 1 1

84 65086

85 054093

86 064071

87 057021

88 024454 s

89 003003

90 065077

91 024455

92 059022

93 024228 0

94 024086 s

95 024227

96 022135 s

97 524002 0

97 524032 0

98 624072 0

99 024081

100 066006 M

101 055057 M

101 055029

102 024141

103 055126

104 013136

105 073049

F - FAST (rapide) S - SLOW (lent)

M — MEDIUM (moyen) O — Commande du client seulement

-13-

F

COTTER PIN 3/32x1 2 2

FORK PIVOT ROD 1

CLUTCH FORK 1 1

SPRING

S

SPRING ASSEMBLY 1

ADAPTER SPACER .

M

LOCKNUT, NYLON

M

BEARING, BALL

s DRIVE SPINDLE HOUSING

ROLLER

M

DRIVE DISC SPACER

WASHER, 5/16x11/16x.065

M CAPSCREW 5/16-18x1

LOCKWASHER

F

NUT

M

NIPPLE

0 BUTTON PLUG 1 1 1

SNAP BUSHING

M

0 SHORTING WIRE 1 1 1

M LOCKNUT

M BEARING, RADIAL 1

M

WASHER 1

M SNAP RING' INTERNAL

DISC HOB 1 1 1

F FRICTION DISC

M

LOCKNUT 1

SPINDLE HUB 1 1 1

s

M

CAP SCREW, 5/16-18x3/4

CLUTCH ENGAGEMENT YOKE

SPACER

s ADAPTER

ROD ADAPTER

PINION 8i SPROCKET

PINION & SPROCKET

SPROCKET ASSEMBLY

s

CARRIER SHAFT

WOODRUFF KEY

BUSHING

M

BUSHING

M

BEARING FLANGE

M SPACER

M

ZERK FITTING

M

PULLY

CODE SUGGÈRE D'INVENTAIRE DES PIÈCES

QUANTITÉ NO, REQ'D

CO 00 09 о ^

H « s 'A £ ^

о о о о о о

^ ^ ^ ЧГ

«N ГМ <М «N esj

09 09 09 09 09 09

2 2

1

1 1

1

1 1 1

1

2 2 2

1

1

1 1 1

1 1

1

1

1

1

1

3 3

4

1 1 1

1

1

1

1

1 1

1 1 1 1

1

1 1 1

1

_

1

1 1

1 1

1 1

1 1

1 1

1

1 1

1 1

4

1 1 1

1

1 1

1 1

1 1

1

1 1

1 1

1

_

1 1

1

1

_

2

1 1 1

1 1 1 1

1

1

1

1 1 1

1

1 1

1

1

1 1

3

4

1

1

1 1

1 1

1

1 1

1

1

1 1

1

1

1

1

1

1 1

2 1

1 1

1 1

1

1

1

1

1

1

3

4

1

1

1

1

Г

1

1

1

1

1

1

1

1

1

1

1

_

1

1

1

1

1

Page 13

TRACTOR PARTS FOR MODELS \

PIECES DU TRACTEUR DES MODELES )

924046, 924048,

924050 & 924052

• 14-

Page 14

TRACTOR PARTS FOR MODELS

924046, 924048, 924050 & 924052

PIECES DU TRACTEUR DES MODELES

924046, 924048, 924050 & 924052

Node no de code QUANTITE

REF. PIECE D'INV « -,

REF. PART STOCK “ASCRIPTION | |3

NO. NO. CODE 8 8S

1 070008

2 024406

3 072088

3 872066FVBELT

4

5 058053

6 063032

7

1 084002

9

9 024357 s ENGINE SHEAVE

to 066818

t1

12

13

14

14

IS 075006

18 810860

IS 603002sWHEEL ASSEMBLY

16

17

18 068105

18

18

18 024433MCLUTCH ROD, Trector

20

21 532008MCLUTCH HANDLE, Attechment 1 1 1

22

23

24

25 064033MWASHER, .7501,760 x 1.375 x .1251

26 063004

27

28

28

30 064007

31

32

33

34

35 032010 s LEVER

36

37

38 058003

38

40

41

42

43 024322

44

44

44

4S

46

47

47

48

48

50

51

52

53

53

54

55

M FLANGE WHIZL0CK SCREW 4 4

F

BELT COVER

F

VBELT 1

M SETSCREW

080012

M CAP SCREW, 5/16-24x3/4"

M

LOCKW ASHER 2 2

M

024253

024021

024435 0 HANOLEBAR PANEL

024447 M

024U8

024432

024431MUPPER HANDLEBAR

603848

075018

068124

0244U M CLUTCH ROO.Tttctor

532007

065051MKEPS NUT

074038

022128 s HANDLE PIVOT

065018

024442

024441

065042

0244280ACTIVATING SHAFT 1 1

024456sCLUTCH ROD ATTACHMENT 1 1 1

058026FROLL PIN

024428 s LEVER

055037 M

024354

067001

066011MKEY, Feether 3/16 X 3/16 X 1-1/4

065031MNUT

010370MAXLE, R.H.

024371MAXLE, R.H.

024408MAXLE ASSEMBLY. R.H.

0630180LOCKW ASHER

024430

024437

024436 0

066012

058003

058068 M

010358

070015

064036

064170

003377

010366 s

BELT FINGER

M

WASHER. 5/16 X 7/8 x .083 4

s ENGINE SHEAVE 1

M KEY.Stniiht 1/4 X 1/4 X 1-3/4 1

LOWER HANOLEBAR. R.H. 1

M

LOWER HANOLEBAR, L.H.

M

UPPER HANDLEBAR 1

M

GRIP 2 2

s TIRE & WHEEL ASSEMBLY

Consists Of

M 071048 TIRE

M

071050 TUBE 2

s 071052 RIM 2 2

M

071062 TIRE

071037 TUBE, Aveileble

M

s 071076 RIM

s TERRA TIRE & WHEEL ASSEMBLY

M

071021 TURV SAVER TIRE

M 071067 TUBE AVAILABLE

071077 RIM

s

M

KNOB 1 1 1

F

THROTTLE CONTROL 1

F

THROTTLE CONTROL

M CLUTCH HANOLE.Trector 1

s TAPPING SCREW

F

LOCKW ASHER 4 4

F

NUT

s SHIFT ROD UPPER

s SHIFT ROD LOWER

F

WASHER, 1/4 X 47/64 X.065 1 1

F

LOCKNUT

FLANGED BUSHING 2

M CAP SCREW. 5/16-18x1

F

CLEVIS PIN

F

COTTER PIN 2 2 2

M

AXLE SHAFT

0

BOTTOM COVER

0

FRAME

FRAME

M

KEY,WoodruH1/4x3/4 -

M

ROLL PIN, 3/16x1-1/4

CAP SCREW, 5/16-18 x1-1/4

s

SPACER

F

FLANGE WHIZLOCK SCREW

F

WASHER, .87S/.885 x 1.385 x .062

F

WASHER, .87S/.885X 1.385 x .062

0

HUB CAP

PUSHNUT

NOTE: FOR OECALS SEE PAGES 2 & 3

NOTE: OECALQUES (voir p. 2 & 3)

NO. REQ'D

liii

1 gs я

i •» •» m

1 1 1

- 2

2 2 2 2

1 1

- -

1

1 1 1

_ _

2 2

2 2

- -

- -

-

- -

-

- - -

- -

-

- 1 1

- -

4

- 1

2

2

2

4 4 4

- 1 1 63 024222 s IDLER ARM 1 1

1

1

1

1 1 66

-

2

- -

•

- -

- _

2

2

2

-

2

2

-

-

-

-

-

- -

1

-

1

2 2 2

2

4 4

2 2

4 4

1 1 1

1

3 3

1 1 1

1

1 1 1

1

1 1 1

2

1 1 1

1

-

- -

-

1 \ 1

1 1

- 1 1

1

2

1

1

5

-

_ _

2 1

-

4

2

- -

4

4

1 1

3

1

2 2

2

1

- -

- - -

- -

1

—

-

1

_

_ _ _

_ _ _

1

1 1

S s

_ _

1

2

1 1

Node

No OE CODE

REF.

PIECE D'INV.

REF.

PART STOCK

NO.

NO. CODE

4

56 003376 8

57

070032 S

058003 M

56

1

58 056030

2

2 60

1

1

_

1

2

-

-

-

-

2

2 81 065042 M

2

2

1

1

1

4

2 94

4

4 87 002270 M

1

3 101

1

1

1

2

-

1

-

1

1

087014

58

612888 s

60

624073

010211 s

60

61 024348 s

012132 s IDLER

62

64 064052 M

65 010280 s

067004 F

67 083187 s SPRING

012131

BS

024347

68

024353 M RETURN CLIP

70

71 074054 F

72 024323MWHEEL HUB

624087

73

013157

74

75 065075MNUT 1 1

011031

76

77 024458

024460 0 BELL CRANK 1 1

78

79 064080 M

024457

80

82 055132 s SLEEVE BUSHING

83 065040 M

064037 M

84

055131

85

86 060036MSETSCREW

87

065088

024458 M

88

067018 M

88

80 067018

061057 M

81

83 063148 M

024443

083184 M

85

083183 M

86

88 062061 M

88 062062 M

too 058005 M

083084

102 062060

103 065058 M

064084

104

105

058150

106 058131 M

107

024448 M

075086 M

108

108 057086 M

110 075085 M

111

024466

111 024467

065078 M

113

114

058050 M

058132 M

115

067024

116

117

068012

118.

075060

SPINDLE CUP

WHEEL BOLT

ROLL PIN, 3/16x1-1/4

M

ROLL PIN. 3/16 X 1-1/2

M

COTTER PIN

DIFFERENTIAL ASSEMBLY

s DIFFERENTIAL ASSEMBLY

SPUR GEAR

IDLER ARM 1 1 1

WASHER, .380/.385 x 13/16 x 24 1 1

WAVE WASHER

COTTER PIN

BEARING SPACER 1

s

0

BRACKET

TAPTITE

M

KEY SWITCH

s IGNITION KEY

s SPACER 1 1

0 SLIDER 1 1

WASHER

s

CLEVIS

LOCKNUT

LOCKNUT

WASHER

s SLEEVE BUSHING

M

NUT

CLEVIS PIN

HAIRPIN 1 1

M

COTTER PIN

MACHINE SCREW. 10-24 x 1/2

SPRING 1 1

s PIVOT 1

SPRING 1

CLUTCH SPRING 1 1

CLUTCH CHAIN 1 1

CARRIAGE BOLT, 5/18-18x5/8 2 2 2

CARRIAGE BOLT, 5/18-18 XI»

ROLL PIN, 3/18x7/8 1 1

M

SPRING 1

M

CARRIAGE BOLT, 1/4-20 x 1» 4

FLANGEWHIZLOCK NUT

M

WASHER

M

CAP SCREW, 1/4-20 x IK Grede 5

CAPSCREW

ROD

KNOB

SNAP RING

SNAP BUSHING

M

STIFFENER. R.H.

M

STIFFENER, L.H.

FLANGEWHIZLOCK NUT

CAP SCREW, 1/4-20x1»

CAP SCREW, 1/4-20x1"

M

COTTER PIN 1 1 1 1

M

CLAMP 1 1 1 1

SNAP BUSHING

M

DESCRIPTION 1

1

5

2

1

QUANTITÉ

II ill

As Am s

mm mm m

•1

2

6 6 8

_

2

_

_

2

2

2

2

2

2 2 2 2

2 2 2

6

3

2

2

2

2

5

1

1

1

1 1 1 1

1 1 1 1

1

t 1 Î 1

1 1 1

1

4 4

2 2 2

1 1 1 1

NO. REQ'D

1

1

_

_ _ _

_

1

-

1 1

-

-

2

2 2

Î 1

2 2

1 1 1

1 1

1

1 1

1 1 1

2 2

-

-

1

1

1

t 1

1

2

2 2

6 6

3

3

1

1 1

2

2 2

2

2 2

1

1

2

2

1 1

1 1

2

2 2

1 1

4

4

5

5 5

1

1 1

1

1

1

1 1

1

1 1

1

1 1

4

t 1 1

1

8

1

_

_

t

1

1

2

2

1

1

1

1

1

1

2

6

3

1

1

2

1

1

1

2

1

4

1

1

4

2

SUGGESTED PARTS STOCKING CODE

F - FAST S -SLOW

M - MEDIUM 0 - CUSTOMER ORDER ONLY

CODE SUGGERE D'INVENTAIRE DES PIECES

F - FAST (r«pid«l S -SLOW(l«nt)

■IS' M - MEDIUM (mov»n) 0 - Comminde du client seulement

Page 15

DEALER

1. GENERAL

All hardware and parts required for assembly are shipped in

the parts bag pr are located, in place, on the machine. The

upper handlebars and panel are assembled at the factory with

the two clutch rods and interlock system in place and adjusted.

The lower handlebars must be installed. The snow head and

tractor are shipped assembled with lower shift rod in place.

Attachment clutch rod is in place on handle panel assembly.

Model 924052 (the 32" snow head) is shipped with the runners

and discharge chute detached and they will have to be

installed.

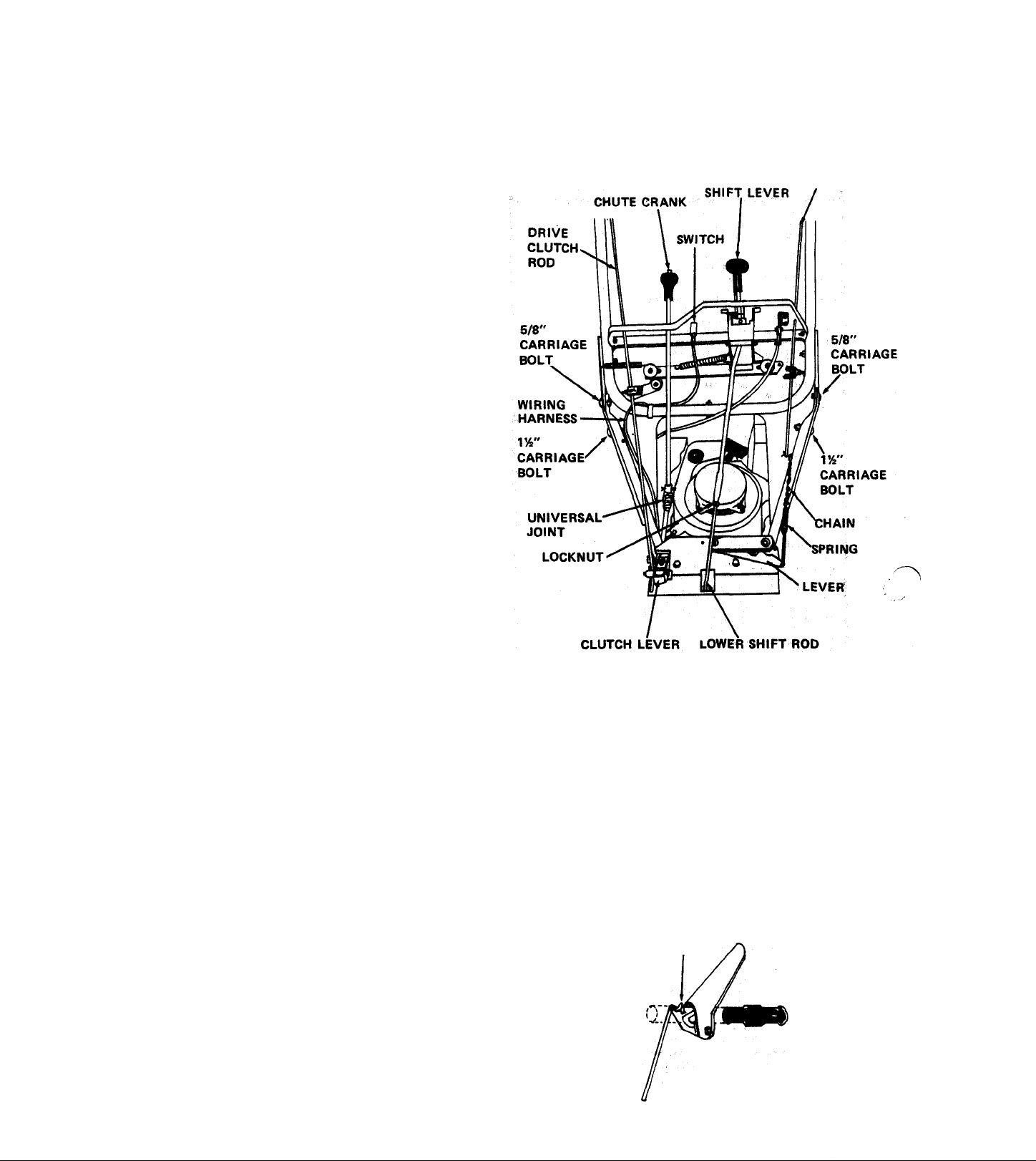

2. HANDLEBAR

Install the lower handlebars on the frame using the studs and

hardware in place on the frame. (Leave the hardware loose on

the studs until the upper handlebars are installed). Be sure to

install the chute crank bracket on the left rear stud on top of

the handlebar.

Install the upper handlebar and panel on the lower handlebars.

Use a flat washer on the outside of each cap screw. Use a 5/8"

carriage bolt and locknut in each of the top holes, and an

VA" carriage bolt and locknut in each of the lower holes. With

everything in place, tighten all handlebar hardware.

UP AND PRE-SERVICE

ATTACHMENT

CLUTCH ROD

3. THROTTLE CONTROL

Route throttle control under handlebar and insert into

position in handlebar panel. See Figure 16. Secure with

two machine screws #(10-24xVa) and two keps nuts

from parts bag. Install knob on throttle lever.

4. SHI FT CONTROL ROD

Remove the upper shift rod from the shift lever and place the

shift lever in REVERSE position. Pull up on the lower shift

rod which is already installed in the frame. Hold the lower

shift rod up while screwing the upper rod in place. Turn the

upper rod into the lower until the end of the upper rod

lines up with the hole in the shift handle. Install the upper rod

in the shift handle and tighten the locknut joining the upper

and lower shift rods.

S. ATTACHMENT CLUTCH ROD

The attachment clutch rod is installed in the upper handlebars

but the chain must be hooked to the spring already in place on

the clutch bell crank. Connect the spring to a link in the chain

that will keep the chain snug without pulling up on the bell

crank. The clutch idler pulley must tighten up on the belt

when the handle is down and must fall away from the belt

when the handle is upright. Adjust chain as required.

6. DRIVE WHEEL CLUTCH ADJUSTMENT

FIGURE 16

c. Position the clutch handle so that it is all the way up.

See Figure 17.Tighten the tractor clutch rod in the rod

adapter with the setscrew. With handle down, clutch

lever should come within 1/16" of top of slot in frame.

Adjust as required. See Figure 8 of owners section.

7. KEY SWITCH CONNECTION

The key switch is factory installed in the handlebar

panel and the wiring is connected to the engine. Route

the wiring harness up the inside of the panel, alongside

the lower handlebar. Connect wire harness to switch.

See Figure 16.

TIP HANDLE FORWARD

AS FAR AS POSSIBLE

a. The clutch handle is already positioned on the handle

bar and the tractor clutch rod is in place in the handle.

Check to be sure the clutch handle is free to fall down

on the grip.

b. Insert the lower end of the tractor clutch rod into the

rod adapter.

FIGURE 17

-16

Page 16

8. DISCHARGE CHUTE (MODEL 9240S2 ONLY)

The discharge chute is shipped with the four mounting clips

attached to the chute. Remove the clips and hardware. Po

sition the discharge chute on the blower housing. Secure with

the clips and hardware. Be sure the chute rotates freely.

13. BLOWER GEAR CASE

On 32" Models 924052, and 824008. Check the oil level in the

auger gear case. Oil level must be even with the oil filler hole.

Fill with Ariens Special L-2 Gear Lubricant. Replace the filler

plug.

9. DEFLECTOR

The deflector is installed on the discharge chute but must be

raised into operating position. Remove the carriage bolt and

wing nut. Rotate delfector up into operating position. Reinstall

the carriage bolt and wing nut.

10. CHUTE CRANK

The chute crank is packed separately in the carton. The inter

mediate shaft, universal joints and chute crank bracket are in

place on the machine. The chute crank bracket should be in

stalled on the rear, left hand stud at the time the handlebars

are installed. Insert the chute crank down into the hole in the

handlebar panel and connect to the universal joint on the

intermediate shaft with the hairpin cotter provided. On all

models, after completing the chute crank connection, check

the alignment of worm and chute by rotating the discahrge

chute through its full travel. Chute should rotate easily, if

not, reposition worm as required.

11. RUNNERS- ON MODEL 924052 ONLY

Install runners on each side of the blower housing. Use

longer carriage bolts (62013) in the rear holes, shorten

carriage bolts (6201.0) in the front holes. Use a washer

(64002) and locknut (65039) on each bolt outside thé

housing. Adjust the runners to equal height on each side. See

paragraph on page 5 for proper adjustment.

12. ENGINE

Before starting the engine, fill the crankcase with Ariens Sno-

Thro oil 5W-20 for snow blower operation below 40 degrees

F. Use Ariens Gard-N-Yard oil 10W-30 for operation at

temperatures above 40 degrees F.

On 24" Models 924046, 924048, 924050, 824006 and 824007.

The blower gear case if factory lubricated and should require

no lubrication by the dealer. Full instructions for checking are

given in the LUBRICATION section of the manual.

14.TIRE PRESSURE

Tires have been over inflated for shipping purposes. For

operation, reduce tire pressure to 12 to 20 PSI. If tire chains

are used, a pressure of 20 PSI is recommended for proper

operation.

15.MECHANICAL INTERLOCK

Check for proper operation of mechanical interlock. Adjust

slider hardware if necessary to assure free operation. See page

5 for proper operation of mechanical interlock.

16. BELT ADJUSTMENT

Check the position of the belt fingers on the engine sheave

and the alignment of the sheaves. Adjust as shown in Figure

10 and as described in REPLACEMENT OF TRACTOR

DRIVE BELT on page 6.

17. DRIVE CHAIN ADJUSTMENT

If Models 924050 or 924052 Sno-Thro are difficult to push

because of tight or interferring drive chains, re-adjust as des

cribed in DRIVE CHAIN ADJUSTMENT on Page 7.

ATTACHMENT CLUTCH

SHORT BOLT

LONG BOLT

RUNNER

•(■CHUTE CRANK BRACKET

^ yi I

FIGURE 18

TRACTOR CLUTCH

CHUTE CONTROL CRANK

DEALER MUST MAKE SURE ALL SAFETY DEVICES

AND GUARDS ARE IN POSITION AND OPERATING

PROPERLY. DEALER MUST INSTRUCT THE CUSTOMER

ON SAFETY PRECAUTIONS, OPERATION, CARE AND

MAINTENANCE. FILL OUT WARRANTY REGISTRA

TION AND MAIL TO ARIENS COMPANY.

-17-

Loading...

Loading...