Page 1

Obriens

▲ SAFETY MESSAGE A

The product for which you have requested

information or repiacement parts is not a

current product. The repiacement models

incorporate product designs, safety features,

safety instructions or warnings which repre

sent the latest “State Of The Art” develop

ments. For your safety and those around you

please contact your nearest Ariens/Gravely

Dealer for a demonstration of the current

product safety provisions and features.

Series

Sno-Thro®

Service

Manual

Ariens

Page 2

A Message To Ariens Repair Manuai User

Your Ariens Dealer will be happy to supply any

service or advice which may be required to keep

your Ariens equipment operating at peak efficiency.

He stocks genuine Ariens parts and lubricants;

manufactured with the same precision and skill as

the original equipment. His factory trained staff is

kept well informed on the best methods of servicing

Ariens equipment and is ready and able to serve

you. If engine repair or service are required, they

can be obtained from an Ariens dealer or from an

authorized engine manufacturer's service center. If

service is required, be prepared to supply the service

person with the Model and Serial Numbers of the

equipment and engine, as well as a full description

of the problem encountered.

The information contained herein is intended for

use by Ariens Dealers' trained servicemen and serves

Introduction

How To Use Your Service Manual

This Ariens Service manual is arranged for quick,

easy reference and is divided into numbered sec

tions. Each section is then divided into sub-sections.

To use this manual proceed as follows:

Refer to the Index to determine section within

which desired information will be contained and

proceed to front of that section for its Table of

Contents.

as a supplement to and reminder of training sessions

conducted by Ariens Company. Before you attempt

any repair, adjustment or maintenance project be

certain that you have read and fully understand the

instructions in your Owner's Manual. Understand

and follow each Danger, Warning, Caution and all

instructions exactly as given. Also be sure that you

have Parts Manuals, all tools, replacement parts and

other materials required to complete the project.

IMPORTANT: All fittings, measurements, torque

recommendations and instructions are significant

and approximations or substitutions must be

avoided, improper repair, maintenance and/or

adjustments or service attempted by anyone other

than an authorized Ariens Service Dealer could void

future warranty claims, and damage unit and/or

result in injury to operator and/or bystanders.

Service Bulletins

In addition to the information contained in this

Ariens Service Manual, Ariens Service Bulletins

are issued to Ariens Dealers from time to time,

which cover interim engineering changes and supple

mentary information. Service Bulletins should be

consulted to complete information on models

covered by this manual.

Replacement Parts

Locate subject desired. Page number is listed across

from subject and consists of section number and

page number.

NOTE: Read all information for servicing a part or

system before repair work is started to avoid need

less disassembly.

Preparation For Service

Proper preparation is very important for efficient

service work. A clean work area at the start of each

job will allow you to perform the repair as easily

and quickly as possible, and reduce incidences of

misplaced tools and parts. A unit that is excessively

dirty should be cleaned before work starts. Cleaning

will occasionally uncover trouble sources. Tools,

instruments and parts needed for the job should be

gathered before work is started. Interrupting a job

to locate tools or parts is a needless delay. Special

tools required for a job are listed at the end of this

Introduction.

When replacement parts are required, use only

genuine Ariens parts. Failure to do so may result

in product malfunction and possible injury to opera

tor and/or bystander.

NOTE: All references to "Left", "Right", "Front"

and "Back" are given from operators position.

NOTE: The descriptions and specifications con

tained in this manual were in effect at the time the

manual was approved for printing. Ariens company

reserves the right to discontinue models without

notice and without incurring obligation. The equip

ment identified as either standard or optional and

the various illustrations may not all be applicable

to your unit. If you have questions, always check

with your Ariens dealer.

Page 3

Safety Alert Symbol And Notations

The following safety notations are used throughout

this manual to call attention to special information

or operating procedures. Understand the message in

each notation and be alert to unsafe conditions and

the possibility of personal injury.

NOTE: A NOTE points out general reference infor

mation regarding proper operation and maintenance

practices.

IMPORTANT: An IMPORTANT statement indi

cates specific procedures or information that is

required to prevent damage to the machine or its

attachments.

This safety alert symbol is used to attract

your attention! PERSONAL SAFETY IS

A

INVOLVED! When you see this symbol -

BECOME ALERT - HEED ITS MESSAGE.

A

A

A

CAUTION: A CAUTION identifies safe

operating practices or indicates unsafe con

ditions that could result in personal injury.

WARNING: A WARNING describes a con

dition where failure to follow the instruc

tions could result in severe personal injury.

DANGER: A DANGER designates a con

dition where failure to follow instructions

or heed warning will most likely result in

serious injury or death.

Safety Precautions

Before test operating or making repairs of adjust

ments to the unit, read and understand the oper

ating and safety instructions in the Owner's Manual.

Disengage power to attachment, stop engine, remove

key and wait for moving parts to stop before

performing any repair or maintenance adjustment

procedures. DO NOT make any adjustment or

perform any maintenance or repair procedures

while engine is running unless specifically instructed

to do so in this manual.

DO NOT touch tractor or attachment parts which

might be hot from operation. Before attempting

to maintain, adjust or service, allow such parts to

cool.

Open doors if engine is run in garage, exhaust fumes

are dangerous. DO NOT run engine in an enclosed

area.

Do repair work in a well-lighted, ventilated area.

When unit is tipped to preform service procedures

in this manual, remove enough fuel so that no spil

lage will occur and block securely.

Gasoline is highly flammable and its vapors are

explosive. Handle with care. Use an approved fuel

container. DO NOT smoke or allow open flame

(match, pilot light, etc.) or sparks near equipment

or fuel container when refueling or servicing fuel

system.

Use non-flammable solvent to clean parts - DO NOT

use gasoline.

Use only Ariens original replacement parts when

making repairs.

After all repair procedures are performed, make sure

that unit is in good operating condition and all

safety devices and shields are in place and in good

working condition. Be sure all fasteners are tight,

all adjustments are correct and all tools are removed.

To prevent accidental starting, disconnect wire to

spark plug(s) and position wire away from plug.

Always wear safety goggles when cleaning or making

repairs to parts or machine.

DO NOT change engine governor setting or over

speed engine.

Never store equipment with fuel in tank inside a

building where fuel fumes may reach an open flame

or spark. Allow engine to cool before storing in any

enclosure.

Ill

Page 4

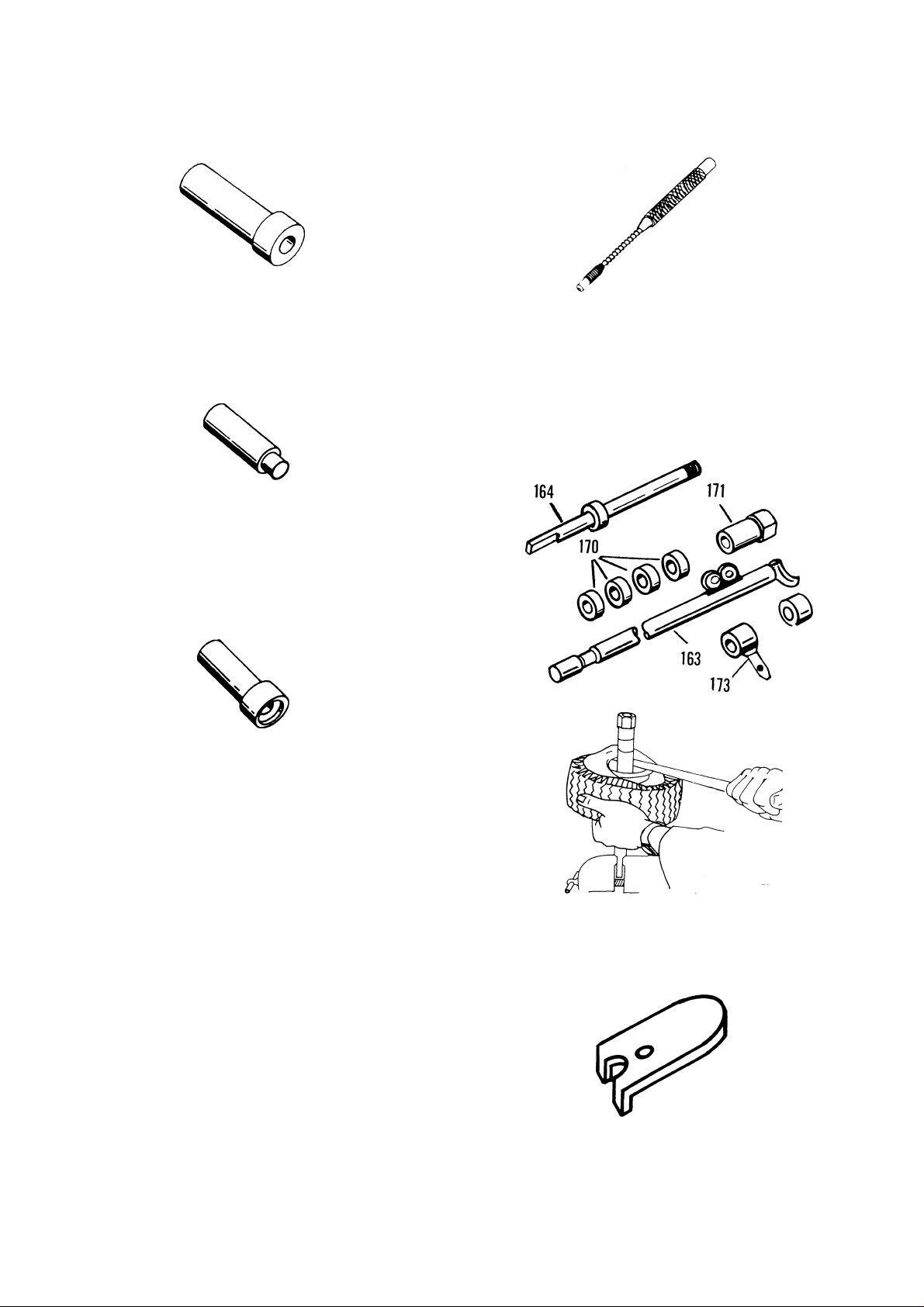

Special Tools

000078 - Bearing Driver for SnoThro axle shaft and Sno-Thro gear

case.

000097 - Bearing Driver for SnoThro gear case flange and blower

bearing supports.

Roll Pin Driver for installation of

roll pins on all Ariens equipment.

000096 - 1/8

000162-3/16

000099-5/16

000098 - 1-1/4

000131 - Bearing Cup Driver for

Sno-Thro gear case. Slide Driver.

(£

000246 - Spring Tool. For most

Ariens Springs.

5)

000200 - Tire Removal and Re

placement Tool for small pneuma

tic tires.

000090 - Bearing Adjusting Wrench

for Sno-Thro gear case adjustment

plug.

IV

Page 5

Index

Section

Specifications.

Handlebars and Controls.

Speed Selector and Wheels

Belt Drive

Reduction Drive

Friction Wheel Drive.

Auger/Impeller.

Gear Case.

Engine and Headlight

Attachments..............

© Ariens 1987

RM-924

Part No. 000123A

Printed in U.S.A. 8/87

Page 6

Notes

Page 7

Specifications

Length.................................................................... 60-63 inches

Height....................................................................40"

Cleaning Width

Shipping Weight................................................... 245 lbs to 345 lbs.

Wheel Size.............................................................(4.80/4.00 x 8) (16/6.50 x 8) (4.10/3.50 x 6)

Engine, Horsepower

Fuel........................................................................Unleaded - 1 Gallon Tanks

Governed R.P.M

Impeller R.P.M

Discharge Distance..............................................3' - 30'

Air Cleaner

Engine Oil

Spark Plug and Gap.................................................030 Champion RJ-17LM

Friction Wheel Drive

Differential.............................................................Standard or Available

.....................................................

............................................

...................................................

......................................................

............................................................

.............................................................

............................................

24"-36"

7-11 H.P.

• 3600

1080

Required with Summer Attachment

10W30, 5W30

Yes

Forward Speed

Reverse Speed

Electric Start Available

Headlight Available..............................................Yes

.....................................................

.....................................................

........................................

5 Forward .80 to 2.8 MPH

1 Reverse - 1 MPH

Yes - Available On All Models

1-1

Page 8

Handlebars and Controls

Table of Contents

Page

2.1 Upper Handlebar Panel and Key Switch...............................................................................................2-4

2.2 Lower Handlebar.......................................................................................................................................2-4

2.3 Clutch Handle.............................................................................................................................................2-5

2.4 Attachment Clutch Adjustment............................................................................................................ 2-5

2.5 Wheel Drive Clutch Lever and Traction Rod........................................................................................2-5

2.6 Clutch Yoke and Fork...............................................................................................................................2-6

2.7 Traction Drive Clutch Adjustment..........................................................................................................2-6

2.8 Mechanical interlock Adjustment...........................................................................................................2-7

2.9 Bellcrank and Slider..................................................................................................................................2-7

2.10 Chute Crank.............................................................................................................................................2-8

2.11 Electrical Interlock Adjustment..........................................................................................................2-10

List of Illustrations

Page

2-1: Handlebars and Controls..........................................................................................................................2-1

2-2: Handlebars and Controls Exploded View..............................................................................................2-2

2-3: Handlebar Assembly..................................................................................................................................2-4

2-4: Attachment Clutch and Traction Rod..................................................................................................... 2-5

2-5: Clutch Yoke and Fork Assembly............................................................................................................. 2-6

2-6: Traction Drive Clutch.................................................................................................................................2-6

2-7: Interlock........................................................................................................................................................2-7

2-8: Bellcrank and Slider...................................................................................................................................2-7

2-9: Chute Crank............................................................................................................................................... 2-8

2-10: Electrical Interlock....................................................................................................................................2-9

2-11: Electrical Interlock Adjustment............................................................................................................2-10

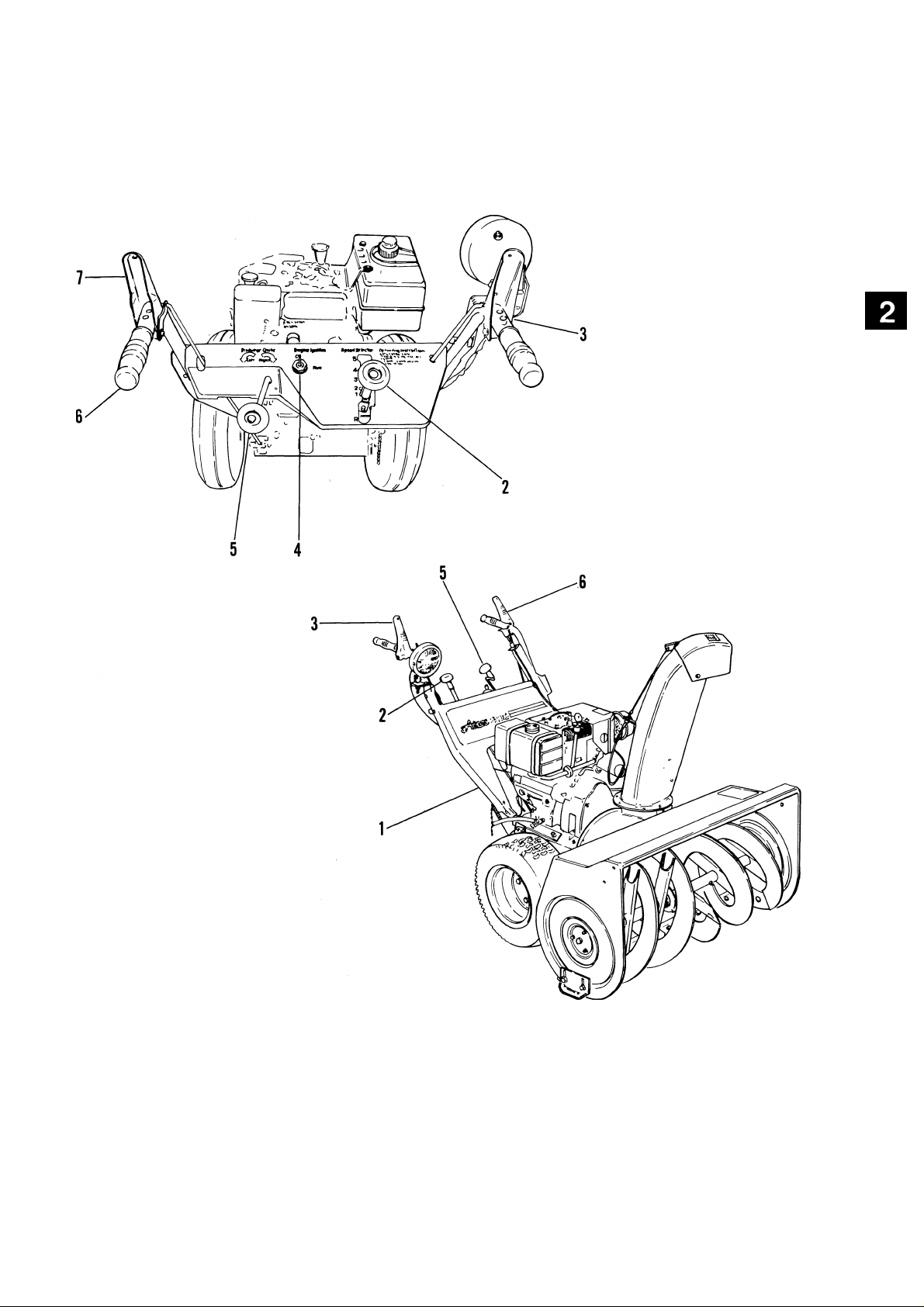

Page 9

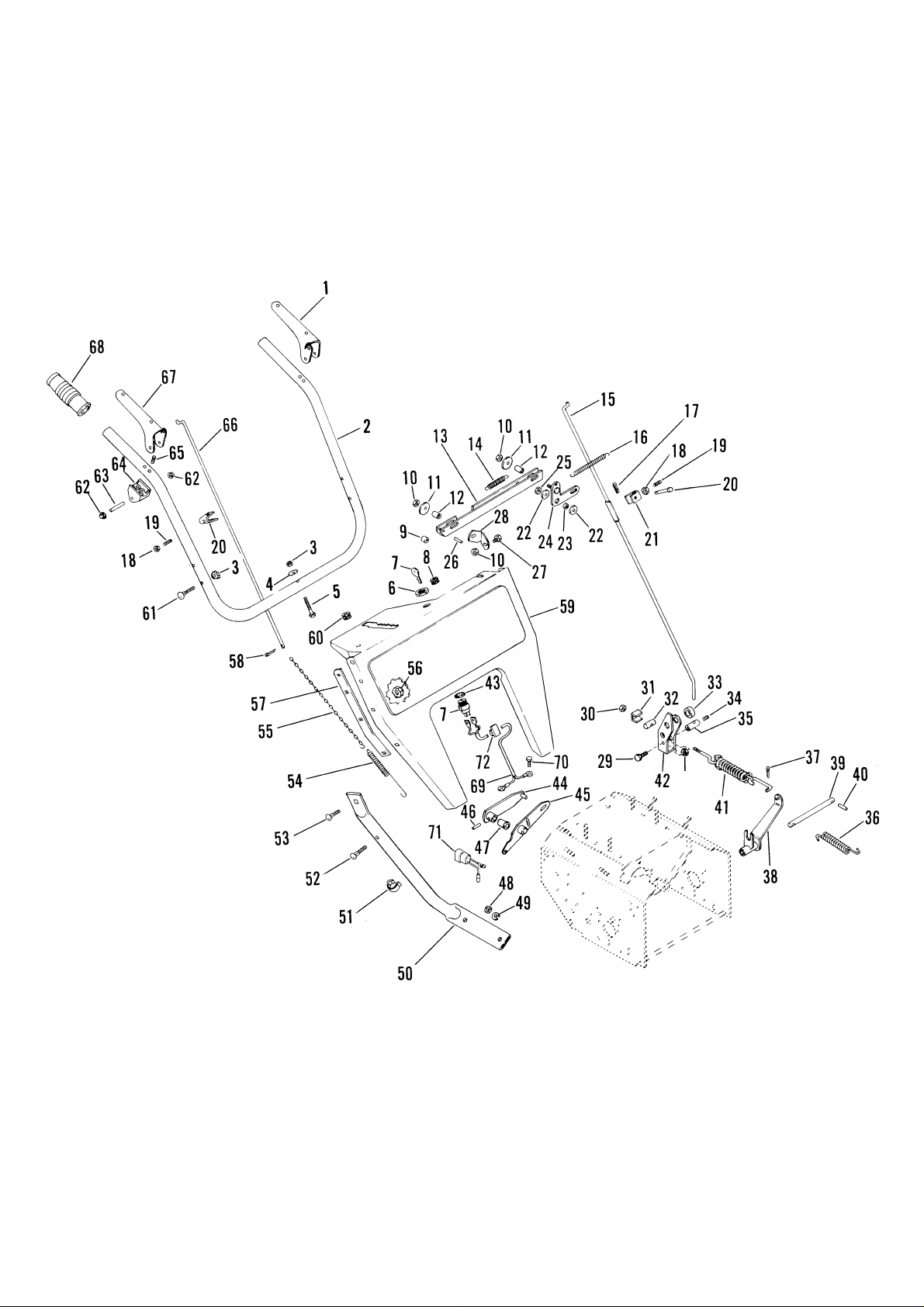

Handlebars and Controls

1. Lower Handlebar

2. Speed Control Lever

3. Attachment Clutch Handle

4. Key Switch

5. Chute Crank

6. Upper Handlebar

7. Wheel Drive Clutch Handle

Figure 2-1: Handlebars and Controls

2-1

Page 10

Handlebars And Controls

MECHANICAL INTERLOCK

Figure 2-2: Handlebars and Controls

2-2

Page 11

Handlebars And Controls

ITEM

NO.

1

2

3

4

5 Cap Screw 1/4-20 x 1-1/2

6 Key Switch Nut 5/8-32

7

8 Snap Bushing

9

10

11

12

13 Slider

14 Extension Spring

15 Traction Clutch Rod

16 Extension Spring

17

18

19

20

21

22

23 Spacer Bushing

24 Bellcrank

25

26 Roll Pin 3/16x7/8

27

28

29

30

31

32

33

34

35

36

DESCRIPTION

Wheel Drive Clutch Lever

Upper Handle Bar

Lock Nut 1/4-20

Washer 1/4

Key Switch Assembly

Bushing

Lock Nut 1/4-20

Washer 9/32

Bushing

Hair Pin Int. 1/16 X 49/64

Jam Nut 1/4-20

Set Screw 1/4-20 x 3/4

Clevis Pin

Clevis

Washer 5/16

Lock Nut 5/16-18

Cap Screw 1/4-20 x 1/2

Stud Brace

Cap Screw 5/16-18 x 3/4

Lock Nut 5/16-18

Adapter Spacer

Adapter

Spacer

Set Screw 5/16-18 x 3/8

Rod Adapter

Extension Spring

ITEM

NO.

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

DESCRIPTION

Cotter Pin 3/32 X 3/4

Clutch Fork

Fork Pivot Rod

Cotter Pin 3/32 X 1"

Spring Assembly

Clutch Engagement Yoke

Lock Washer Int. 5/8

Lever

Lever

Roll Pin 5/32 X 7/8

Bushing

Nut 3/8-16

Lock Washer 3/8

R.H. Lower Handlebar

Clamp

Carriage Bolt 5/16-18 x 1-1/2

Carriage Bolt 5/16-18 x 3/4

Extension Spring

Clutch Chain

Lock Nut 5/16-18

L.H. Stiffener

Cotter Pin 1/8 X 1/2

Upper Handle Bar Panel

Snap Bushing

Carriage Bolt 1/4-20 x 1-1/2

Push Nut

Pin

Handle Pivot

Tapping Screw No. 12-14 x 1-1/2

Attachment Clutch Rod

Attachment Clutch Handle

Grip

Shorting Wire

Taptite 1/4-20 x 3/8

Jumper (924071)

Wire Clip

2-3

Page 12

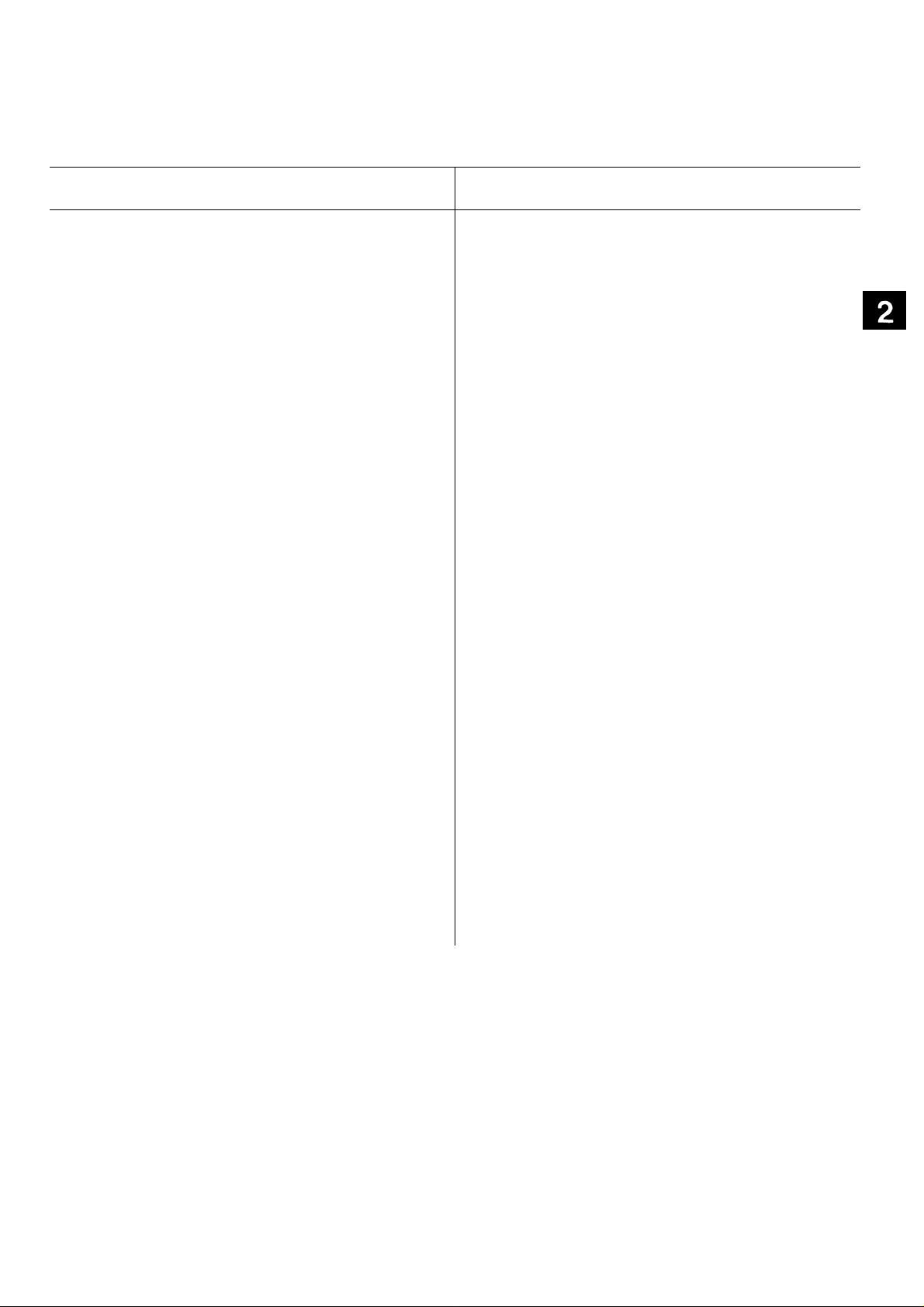

1. Key

2. Stiffener

3. Wire

4. Nut

5. Washer

6. Lower Handlebar

7. Carriage Bolt 5/16-18 x 1-1/2

8. Key Switch

9. Key Switch Nut

10. Cap Screw

11. Carriage Bolt 1/4-20 x 1-1/2

12. Lock Nut

Handlebars and Controls

Figure 2-3: Handlebar Assembly

2.1 Upper Handlebar Panel and Key Switch

Disconnect wires to key switch.

Remove key switch nut and remove key switch from

upper handlebar panel.

Remove (4) nuts and bolts on each side of handlebar

panel plus the bolt, nut and washer in center of

cross piece of upper handle bar and remove panel

stiffeners and upper handlebar.

Check parts for wear or replacement.

Assemble, using reverse procedure.

2.2 Lower Handlebar

Remove nut and washer attaching lower handlebar

to each side of frame and remove lower handlebar.

Check parts for wear or replacement.

Assemble, using reverse procedure.

2-4

Page 13

Handlebars and Controls

1. Push Nut

2. Pin

3. Attachment Clutch Rod

4. Setscrew

5. Clevis

6. Cotter Pin

7. Chain

8. Spring

9. Rod Adapter

10. Traction Clutch Rod

11. Setscrew

12. Clevis

13. Push Nut

14. Pin

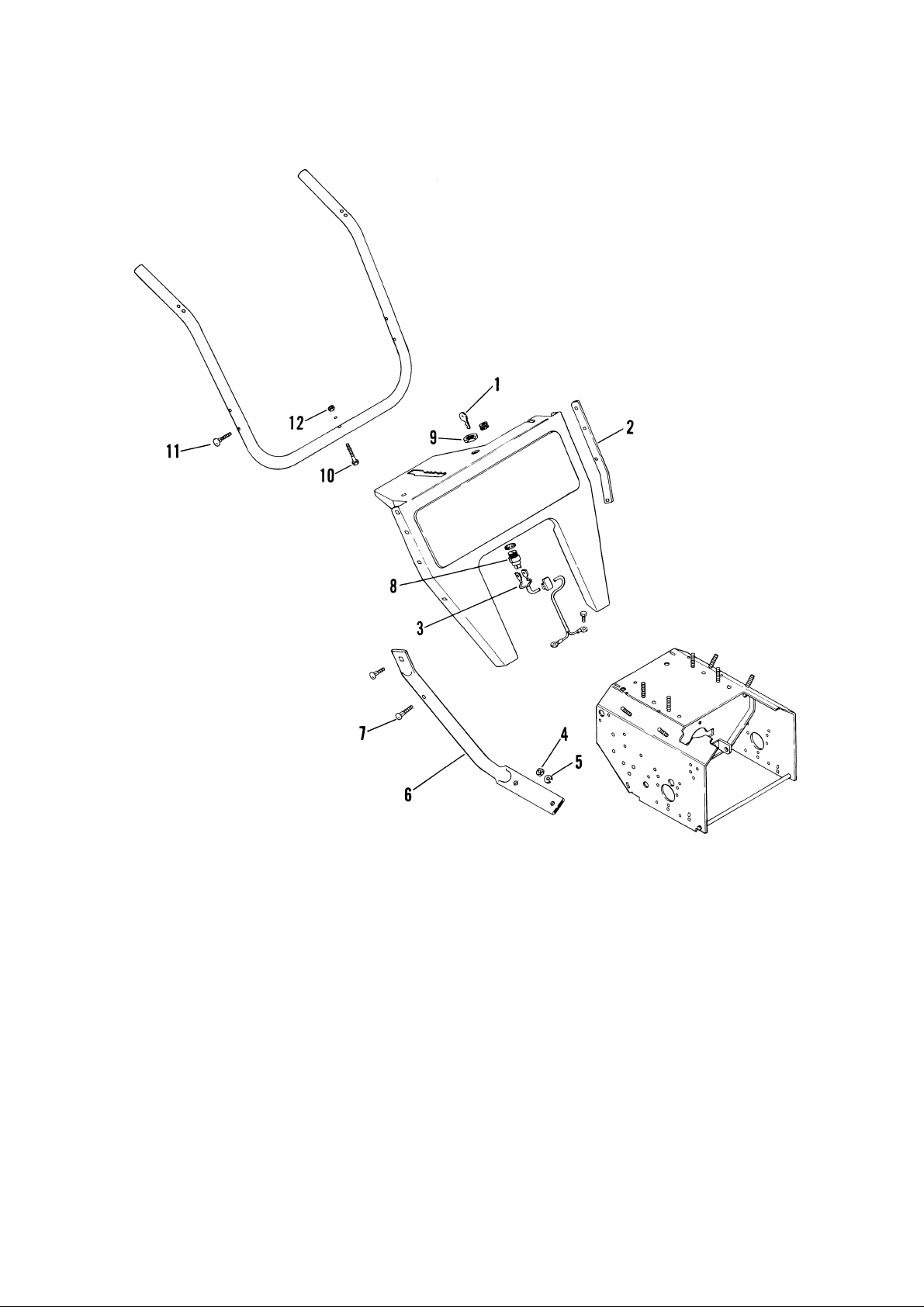

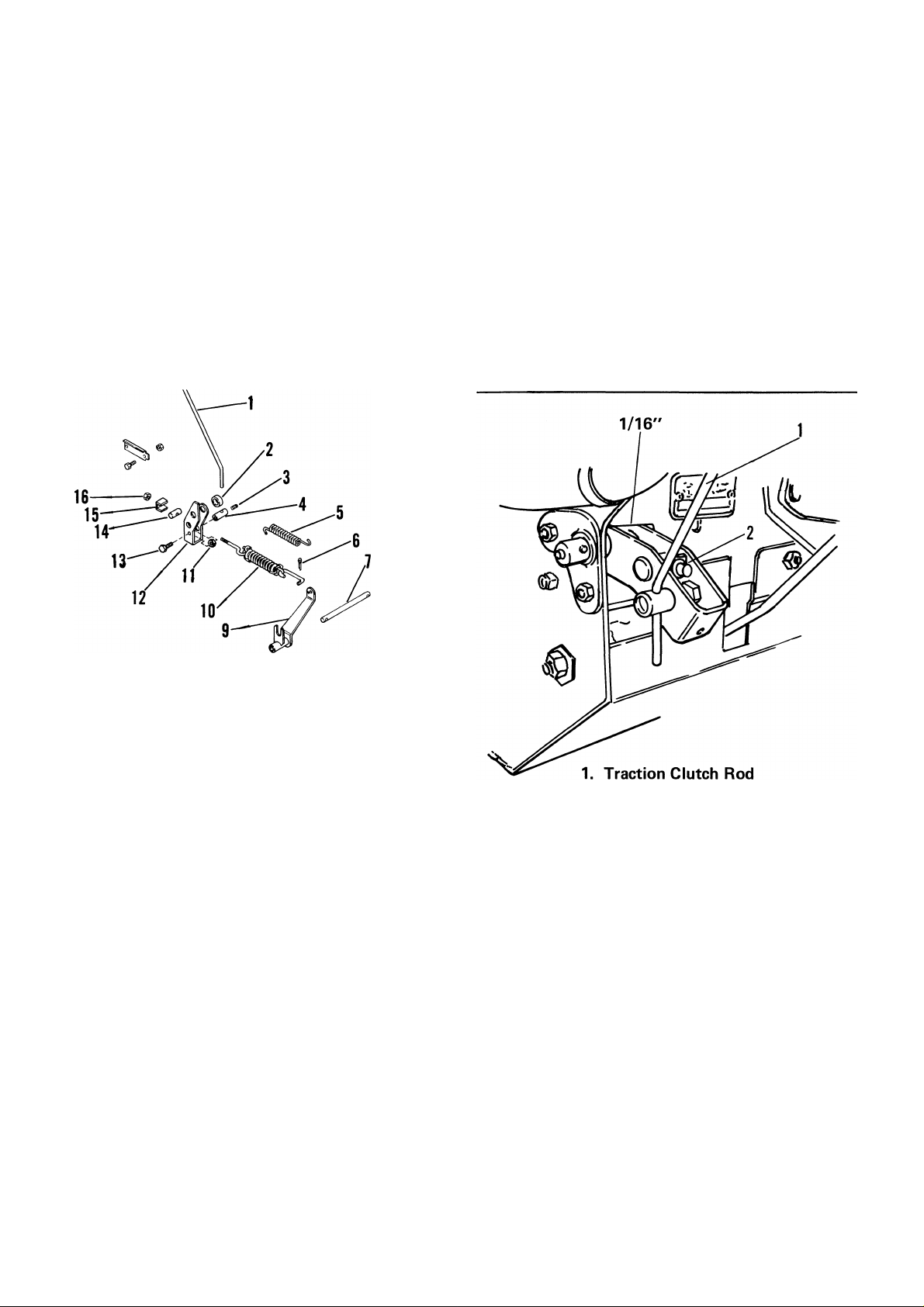

Figure 2-4: Attachment Clutch and Traction Rod

2.3 Clutch Handle

Remove (2) push nuts, pin and (2) screws holding

Clutch Handle and pivot to upper handle bar and

remove pivot and disconnect Clutch Handle from

clutch rod.

Remove set screw, jam nut and clevis from clutch

rod.

Remove cotter pin connecting rod to chain and

remove rod.

Disconnect chain and clutch spring from lever.

Check parts for wear or replacement.

Assemble, using reverse procedure.

2.4 Attachment Clutch Adjustment

Attachment Clutch is adjusted by connecting chain

to spring just below attachment clutch rod. Connect

spring to a chain link so chain is snug but so attach

ment idler drops away from belt with lever all the

way up.

2.5 Wheel Drive Clutch Lever and Traction Rod

Remove (2) push nuts, pin and (2) screws holding

pivot and Wheel Drive Clutch Lever to upper handle

bar and remove pivot and Wheel Drive Clutch Lever.

Remove set screw, nut, hair pin and clevis pin

holding clevis to Traction Clutch Rod.

Remove set screw in rod adapter and remove Trac

tion Clutch Rod.

Check parts for wear or replacement.

Assemble, using reverse procedure.

2-5

Page 14

Handelbars and Controls

2.6 Clutch Yoke and Fork

Remove locknut and adapter spacer holding spring

assembly in clutch yoke.

Remove capscrew, nut and rod adapter from yoke.

Remove cotter pin from end of spring assembly

in clutch fork and remove spring assembly and

extension spring.

2.7 Traction Drive Clutch Adjustment

WARNING: Gasoline is highly flammable

A

A

and its vapors are explosive. Handle with

care. Never allow smoking materials, sparks

or flame (match, pilot light, etc.) near

equipment or fuel container.

CAUTION: When unit is tipped up onto

housing remove enough fuel so that no

spillage will occur.

Traction Clutch Rod

1.

2. Spacer

3. Setscrew

Rod Adapter

4.

Extension Spring

5.

Cotter Pin

6.

Fork Pivot Rod

7.

Cotter Pin

8.

Figure 2-5: Clutch Yoke and Fork Assembly

Punch out roll pins holding fork pivot rod in frame

and remove rod and clutch fork.

Check parts for wear or replacement.

Assemble, using reverse procedure.

9. Clutch Fork

10. Spring Assembly

11. Nut

12. Clutch Yoke

13. Capscrew

14. Adapter

15. Adapter Spacer

16. Lock Nut

2. Adjustment Nut

Figure 2-6: Traction Drive Clutch

Adjust traction clutch to compensate for wear of

friction wheel when slippage occurs.

To adjust traction clutch, place speed selector in

First (1) and tip machine forward onto housing.

With traction clutch disengaged turn wheels while

tightening adjustment nut, at clutch yoke, until

wheels begin to drag. Engage and release traction

clutch to align clutch linkage. Repeat procedure as

necessary. When wheel drag is obtained with linkage

aligned, turn nut back three turns. Wheels will then

turn freely.

2-6

Page 15

Handelbars and Controls

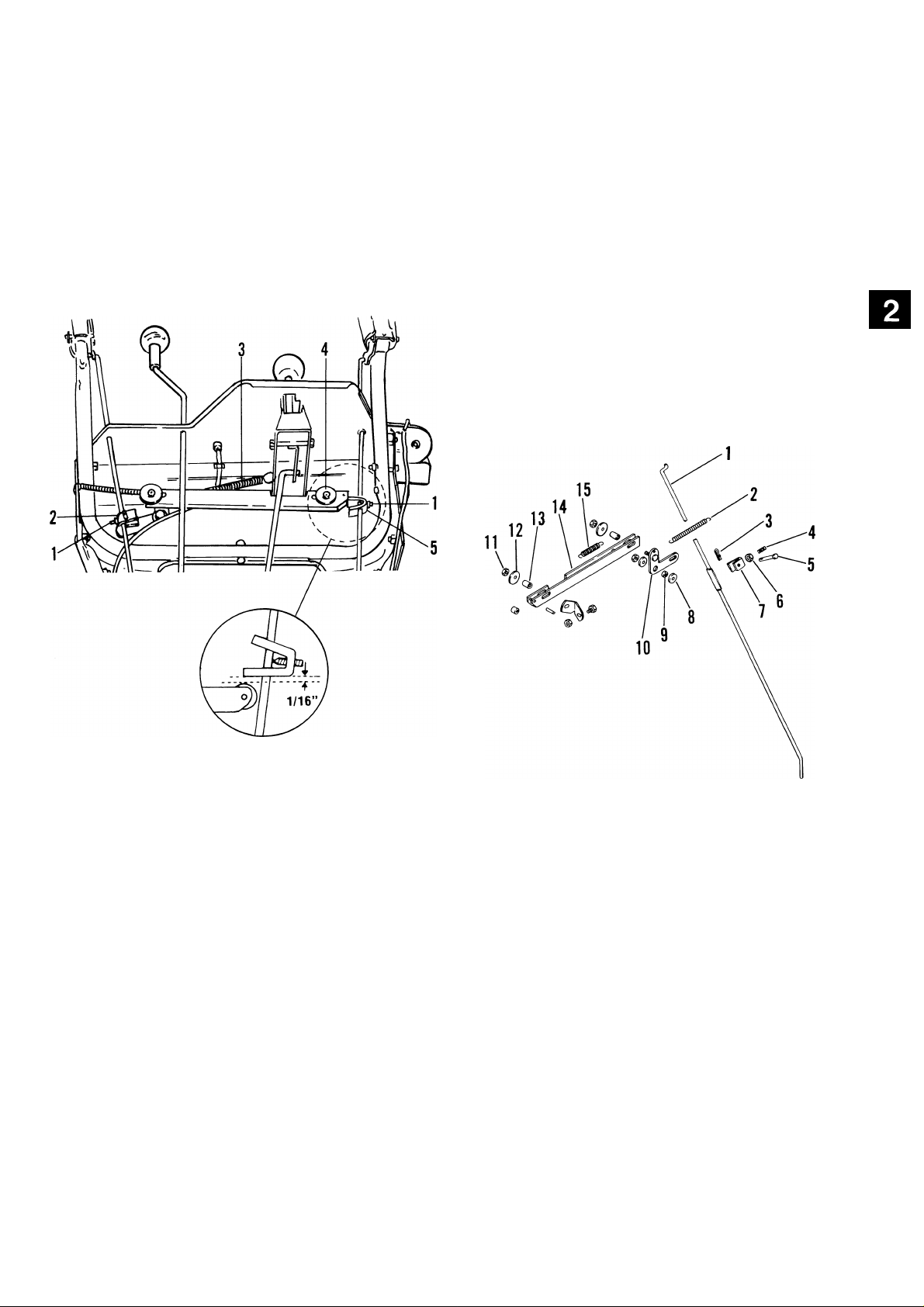

2.8 Mechanical Interlock Adjustment

WARNING: With improper usage of unit,

failure of interlock if unnoticed, could

A

result in severe personal injury.

Check interlock by pressing down on clutch levers

(engaging both clutches). Remove hand from

attachment clutch lever, attachment clutch should

remain engaged until traction clutch lever is re

leased then both clutches must disengage.

2.9 Bellcrank and Slider

Remove nut and washer holding bellcrank to upper

handlebar panel.

Remove nut and washer holding slider to upper

handlebar panel and disconnect spring from upper

panel.

1.

Setscrew

Traction Clutch Clevis

2.

Slider

3.

4. Roller

5. Attachment Clutch Clevis

Figure 2-7: Interlock

With traction clutch lever "UP" (disengaged) loosen

clevis set screw on traction clutch rod, pull clevis

down until slider is at end of slot and tighten set

screw.

Engage both clutch levers "DOWN", loosen clevis

set screw on attachment clutch rod and slide clevis

to clear roller on slider by 1/16 inch. Tighten set

screw with leg of clevis parallel to slider.

1. Attachment Clutch Rod 9.

2. Extension Spring

3. Hair Pin

4. Setscrew

5. Clevis Pin

6. Jam Nut 14.

7. Clevis

8. Washer

Figure 2-8:

Bellcrank and Slider

Spacer Bushing

10.

Bellcrank

Lock Nut

11.

12.

Washer

13.

Bushing

Slider

15.

Extension Spring

Remove slider assembly and check all parts for

replacement or repair.

NOTE: Be sure to check bushings and spacers for

wear.

Assemble, using reverse procedure.

2-7

Page 16

2.10 Chute Crank

Handelbars and Controls

Smooth and easy rotation of properly lubricated

chute with crank (without binding) is obtained by

adjusting clearance between worm and discharge

chute gear teeth. To adjust, loosen nut on bracket

supporting worm, position worm to fully engage

(without binding), gear teeth on discharge chute

and tighten nut.

On ST 1136 to prevent discharge chute from rotat

ing by itself when unit is being operated, tighten jam

nuts on end of crank rod to put increased tension on

worm gear.

1. Bracket

2. Worm Gear

3. Adjustment Nuts

Figure 2-9: Chute Crank

2-8

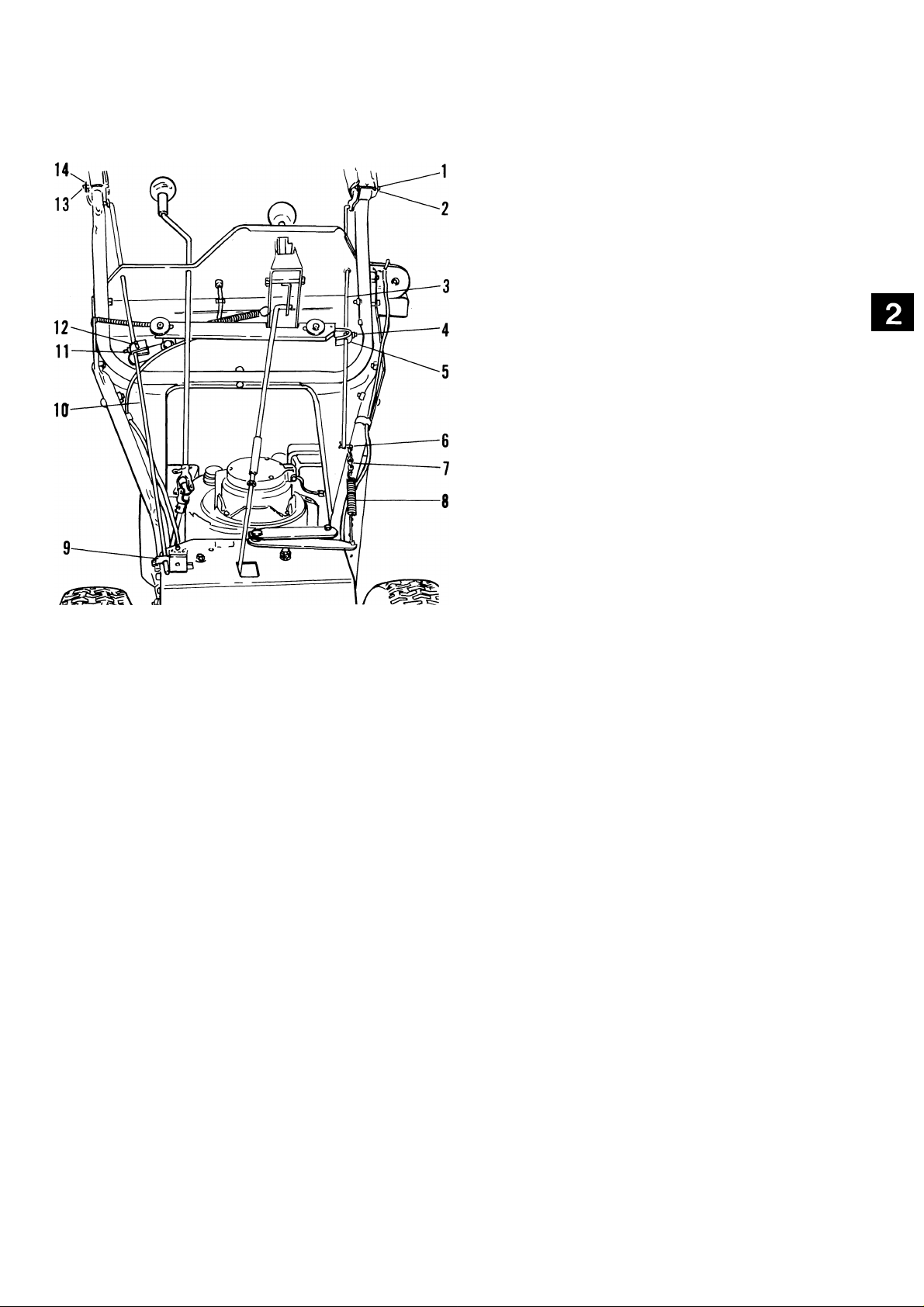

Page 17

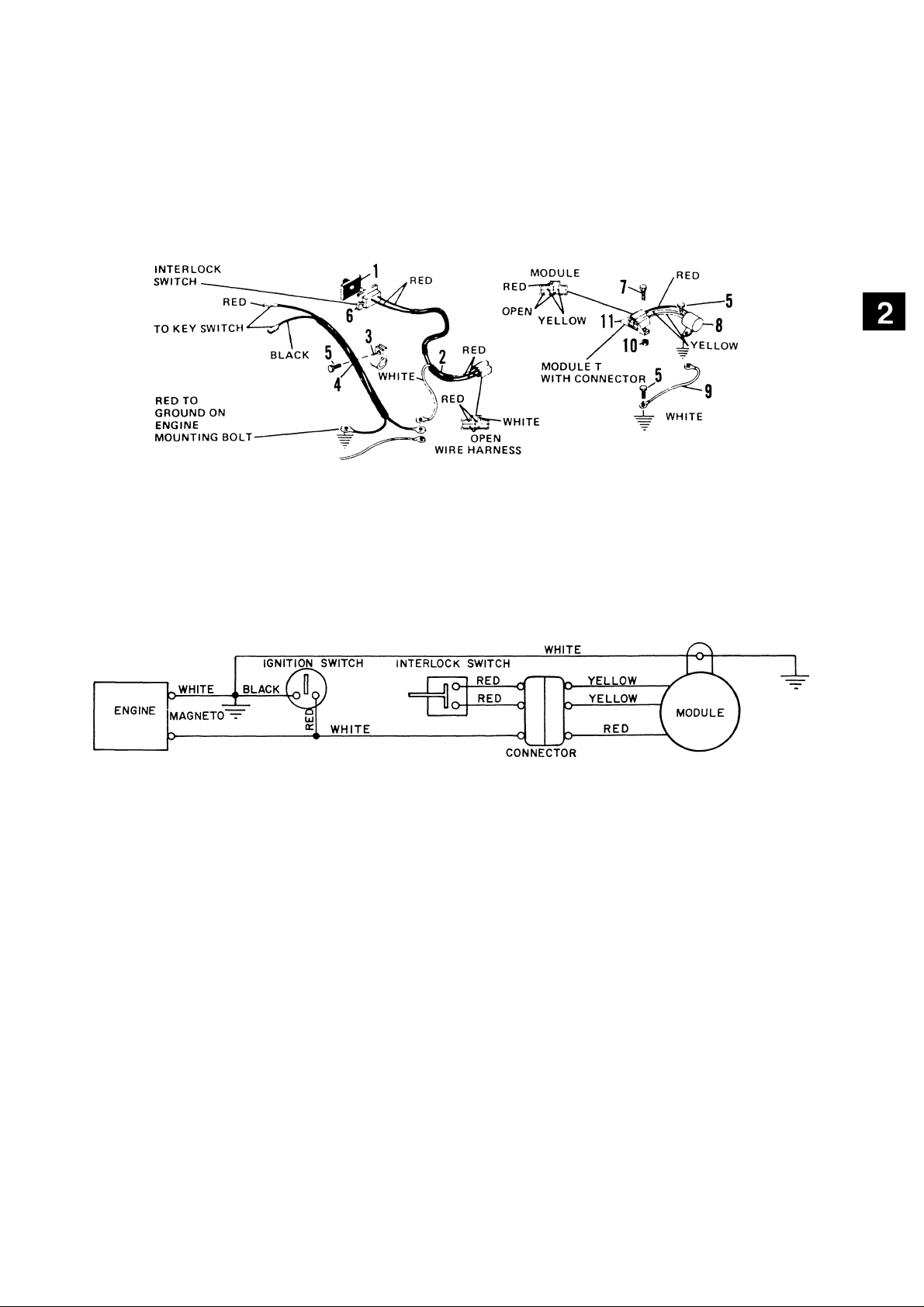

WHITE

TO ENGINE ■

MAGNETO

Handlebars and Controls

ELECTRICAL INTERLOCK

1. Switch Boot

2. Wiring Harness

3. Clip

4. Shorting Wire

5. Flange Whiziock Screw

6. Switch

7. Cap Screw 10-24 x 3/8

8. Modulet

9. Wire Ground

10. Keps Nut

11. Connector

Figure 2-10: Electrical Interlock

2-9

Page 18

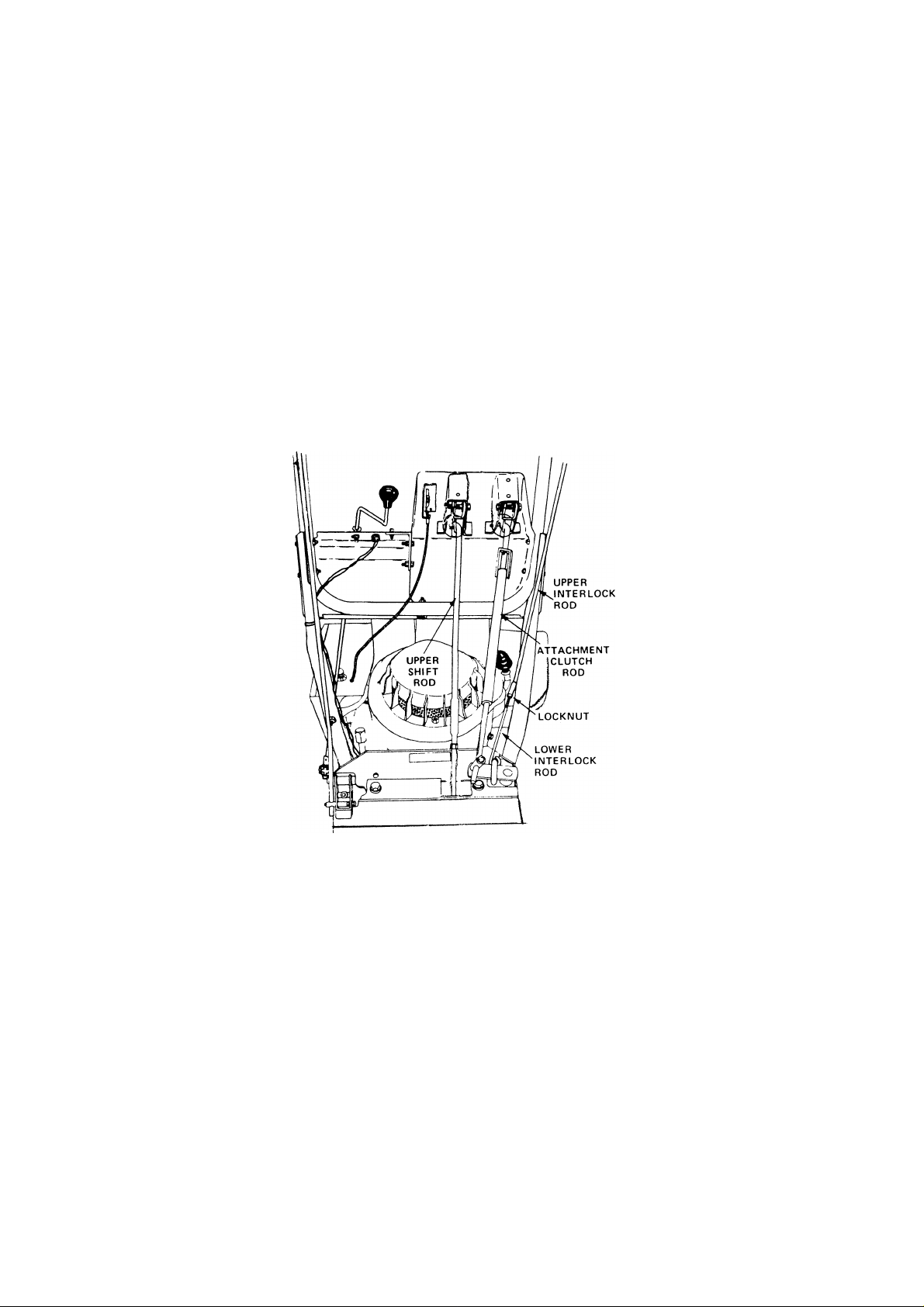

Handlebars and Controls

2.11 Electrical Interlock Adjustment

Engine runs with interlock and/or traction clutch

engaged. Engine must stop if both are disengaged

with attachment clutch engaged.

Shorten interlock rod if engine will not run with

interlock, attachment clutch and/or traction clutch

engaged. Lengthen interlock rod if engine stays

running when both interlock and traction handle are

released with attachment clutch disengaged.

Check switch bracket alignment with switch and

align if necessary.

To adjust length of rod, remove cotter pin from

upper interlock rod at handle, loosen lock nut and

turn rod to lengthen or shorten.

Figure 2-11: Electrical Interlock

2-10

Page 19

Notes

Page 20

Speed Selector and Wheels

Table of Contents

Page

3.1 Speed Selector...........................................................................................................................................3-4

3.2 Speed Selector Adjustment.....................................................................................................................3-4

3.3 Shift Arm Lever and Links.......................................................................................................................3-4

3.4 Wheel Assembly.........................................................................................................................................3-4

List of Illustrations

Page

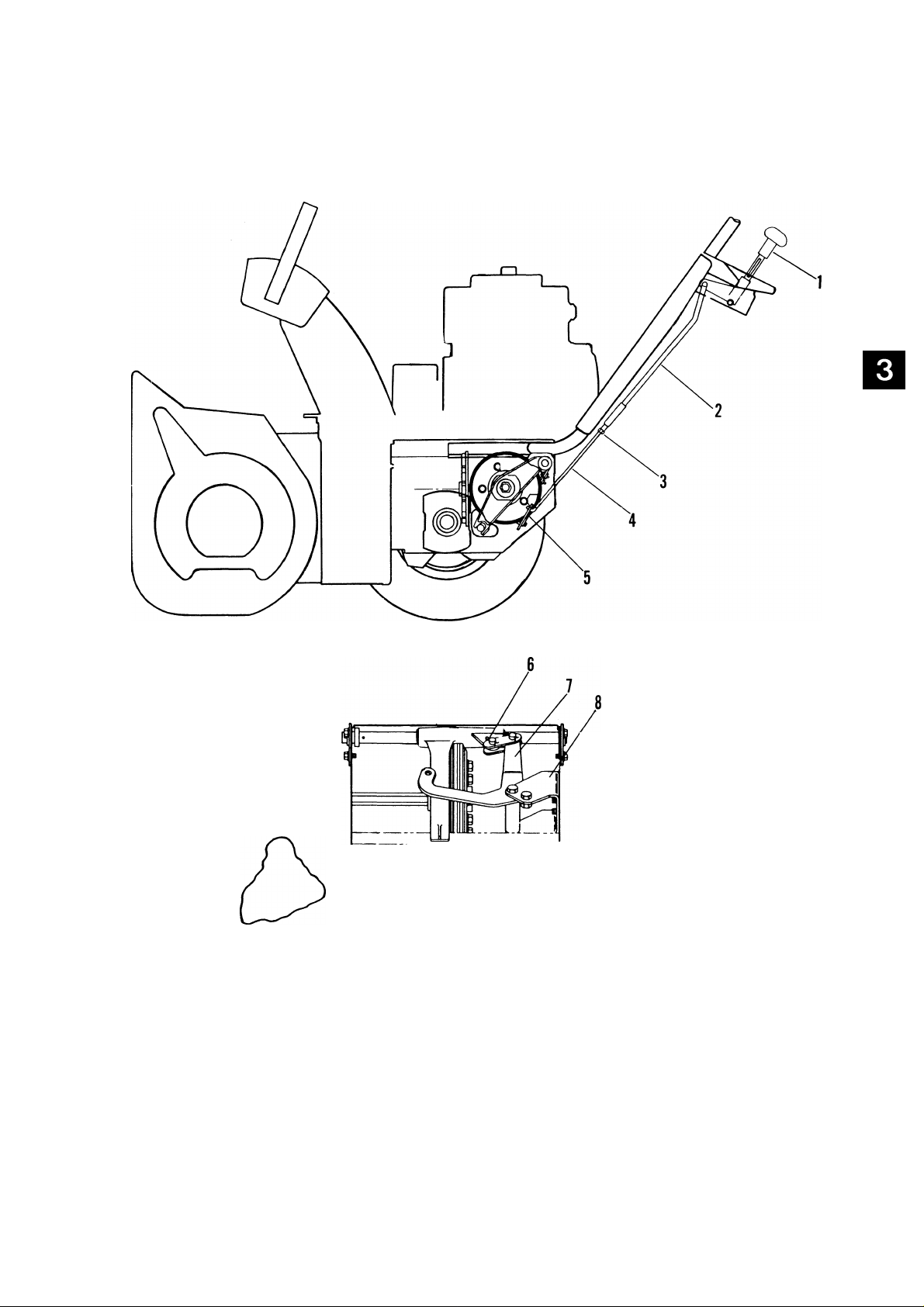

3-1: Speed Selector and Wheels......................................................................................................................3-1

3-2: Speed Selector and Wheels Exploded View..........................................................................................3-2

3-3: Speed Selector............................................................................................................................................3-4

Page 21

Speed Selector and Wheels

f—

V—a__rt__a--'

1. Speed Selector

2. Upper Shift Rod

3. Nut

4. Lower Shift Rod

j—If—\J—

i

5. Shift Links

6. Shift Links

7. Shift Arm Lever

8. Shift Lever Bracket

Figure 3-1: Speed Selector and Wheels

3-1

Page 22

Speed Selector And Wheels

©-

3-2

Page 23

Speed Selector And Wheels

ITE M

NO .

1

2

3

4

5

6

7

8

9

10

11 Upper Shift Rod

12 Nut 5/16-24

13 Cotter Pin 3/32 X 3/4

14 Shift Link

15

DE SC R IP TI ON

Snap Ring Ext. 1/2

Knob

Rod 18

Extension Spring

Pivot

Lock Nut 5/16-18

Lock Nut 1/4-20

Cap Screw 1/4-20 X 1"

Cap Screw 5/16-18 x 2-1/2

Cotter Pin 1/8 X 3/4

Clevis Pin

ITE M

NO .

16

17

19

20

21

22

23

24

25

26

27 Taptite 5/16-18 X 1/2

28

29

DE SC R IP TI ON

Lower Shift Rod

Shift Arm Lever

Frame

Bottom Cover

Spindle Cup

Push Nut or Cotter Pin

Wheel Assembly

Hub Cap

Taptite 1/2-20 x 5/8

Cap Screw 5/16-18 x 1/2

Shift Lever Bracket

Cap Screw 5/16-18 x 3"

Spacer

3-3

Page 24

Speed Selector and Wheels

3.1 Speed Selector

Remove cotter pin in upper rod and disconnect

rod from pivot.

Remove cotter in lower rod and disconnect from

shift arm lever.

Remove upper cap screw and nut in pivot and

remove shift rod and knob.

Remove lower cap screw and nut in pivot and

remove pivot from upper handle bar panel.

Check parts for wear or replacement.

Assemble, using reverse procedure.

3.2 Speed Selector Adjustment

Place Speed Selector in Reverse (R) position. While

pulling lower rod up to its maximum up position,

turn upper shift rod into lower rod until end of

upper rod lines up with hole in shift handle. Insert

upper rod into shift handle, install cotter pin and

tighten lock nut on shift rod.

3.3 Shift Arm Lever and Links

Remove cotter pin and clevis pin holding shift links

to shift arm lever.

Remove (3) capscrews, on outside of frame, holding

shift lever bracket to frame and remove bracket.

Remove capscrews, nut and spacer from shift arm

lever and disconnect lever from shift lever bracket.

Check parts for wear or replacement.

Assemble, using reverse procedure.

ggsl

isssi

- j

1. Lock Nut

2. Cotter Pin

3. Upper Shift Rod

4. Lower Shift Rod

5. Capscrew

6. Speed Selector Knob and Rod

Figure 3-3: Speed Selector

3.4 Wheel Assembly

Remove hub cap, push nut and spindle cap.

Remove (3) bolts holding wheel to wheel hub and

remove wheel.

Check parts for wear or replacement.

Assemble, using reverse procedure.

3-4

Page 25

Notes

Page 26

Belt Drive

Table of Contents

Page

4.1 Introduction.............................................................................................................................................. 4-4

4.2 Attachment Drive Belt...............................................................................................................................4-4

4.3 Traction Drive Belt.....................................................................................................................................4-4

List of Illustrations

Page

4-1: Belt Drive Assembly...................................................................................................................................4-1

4-2: Belt Drive Exploded View..........................................................................................................................4-2

4-3: Drive Belts....................................................................................................................................................4-4

4-4: Impeller Brake..............................................................................................................................................4-4

Page 27

Belt Drive

1. Pulley

2. Attachment Pulley

3. Idler

4. Belt

5. Engine Pulley

6. Belt

Figure 4-1: Belt Drive Assembly

4-1

Page 28

Belt Drive

4-2

Page 29

Belt Drive

ITE M

NO .

9

10

11

12

13

14

15

16 Set Screw 5/16-18 x 3/8 38

17

18

19 Pulley

20

21 V-Belt

22 Rib Neck Bolt 5/16-18x7/8

23 Pulley

24

25

26 Lock Nut 1/4-20

27 V-Belt

28 Hub

29

30

DE SC R IP TI ON

Taptite 1/4-20 x 1/2

Washer 17/64

Belt Cover 33

Belt Finger

Washer 3/8

Lock Washer Ext. 5/16

Cap Screw 5/16-24 x 3/4

Pulley

Straight Key 1/4 x 1-3/4 x 1/4

Lock Nut 5/8-18

Belt Retainer

Cap Screw 1/4-20 x 1/2

Lock Nut 5/16-18

Lock Nut 5/16-18

ITE M

NO .

31

32

34

35

36

37 Bracket

39

40

41 Taptite No. 10-24 x 3/8

42

43

44

45

46

47

48

49

50

51

52

DE SC R IP TI ON

Washer 5/16

Idler

Bearing Spacer

Cap Screw 5/16-18 x 1-1/4

Idler Arm

Clevis Pin

Taptite 1/4-20 x 3/8

Cotter Pin 3/32 X 3/4

Return Clip

Activating Shaft

Extension Spring 3-3/8

Bushing

Spacer

Idler Arm

Extension Spring

Cotter Pin 1/8 x 1"

Washer 3/8

Wave Washer

R.H. Support

L.H. Support

4-3

Page 30

Belt Drive

4.1 Introduction

WARNING: Remove wire from spark plug

before attempting any repair or adjustment

A

When unit is tipped to preform the service proce

dures in this section, remove enough fuel so that no

spillage will occur, block securely and remove bot

tom cover.

A

Separate auger/impeller housing per instructions in

Auger/Impeller Section.

4.2 Attachment Drive Belt

procedures.

WARNING: Gasoline is highly flammable

and its vapors are explosive. Handle with

care.

Remove attachment drive belt from pulley (hold

brake away from belt).

Replace attachment drive belt in reverse order

making sure pulleys align. If alignment is necessary,

loosen attachment pulley set screws, reposition

pulley and retighten set screws.

WARNING: When clutch is engaged, impel

ler brake disengages. If brake is not 1/16 to

A

1/8" from belt when disengaged

1. Traction Drive Belt

2. Engine Pulley

3. Attachment Drive Belt

4. Attachment Belt Idler

5. Traction Belt Idler

Figure 4-3: Drive Belts

1. Brake Shoe

2. Drive Belt

Figure 4-4: Impeller Brake

4.3 Traction Drive Belt

Pull idler away from belt and remove belt from idler

pulley, engine and driven pulley (it may be neces

sary to turn engine engine pulley using rewind

starter).

NOTE: To gain clearance engage traction clutch and

if necessary pull back attachment idler arm clevis

pin.

Replace traction drive belt in reverse order making

sure pulleys align. If alignment is necessary, loosen

engine pulley set screws, reposition pulley and re

tighten set screws. Check alignment of attachment

driven pulley and align if necessary.

4-4

i

Page 31

Notes

Page 32

Reduction Drive

Table of Contents

Page

5.1 Introduction................................................................................................................................................5-4

5.2 Differential, Lockout and Axle................................................................................................................5-4

5.3 Axle Bearings.............................................................................................................................................5-4

5.4 Pinion, Shaft and Sprocket......................................................................................................................5-4

5.5 Reduction Shaft.........................................................................................................................................5-4

5.6 Hex Shaft.....................................................................................................................................................5-4

5.7 Drive Chains...............................................................................................................................................5-5

5.8 Drive Chain Adjustment...........................................................................................................................5-5

List of Illustrations

Page

5-1: Reduction Drive Assembly.......................................................................................................................5-1

5-2: Reduction Drive Exploded View...............................................................................................................5-2

5-3: Drive Chains.................................................................................................................................................5-5

Page 33

Reduction Drive

Figure 5-1: Reduction Drive Assembly

1. Idler Chain

2. Hex Shaft

3. Pinion Shaft

4. Drive Spindle Housing

5. Spindle

6. Differential

7. Differential Lockout

8. Axle

9. Pinion and Sprocket

10. Sprocket

11. Pinion Chain

5-1

Page 34

Reduction Drive

5-2

Figure 5-2: Reduction Drive

Page 35

Reduction Drive

ITE M

NO .

1

2

3

4

5

6

7

8

9

10 9 Tooth Sprocket

11

12

13

14

15

16

17

18

19

20

21 Reduction Shaft

22

23

24

25

26

27

28

29 Roll Pin 1/8 X 1"

30

DE SC R IP TI ON

Taptite 1/4-20 x 3/8

Shaft Support

Bearing Retainer

Ball Bearing 1-1/8 I.D.

Washer 7/8

Rib Neck Bolt 1/4-20 x 1/2

Lock Nut 1/4-20

Hex Shaft

Woodruff Key 1/8 x 5/8 x 1/4

Idler Chain

Washer 17/32

Bearing Flange

Ball Bearing 1/2 I.D.

Bearing Flange

Lock Nut No. 10-24

Lock Nut 1/2-20

Nut 3/8-16

Lock Washer 3/8

Washer 3/8

Bushing

Reduction Sprocket (Double or Single)

Shaft Support

Taptite 1/4-20 x 1/2

Washer 5/8

Pinion Shaft

Roll Pin 5/32x1"

Pinion Chain

ITE M

NO .

31

32

33

34

35

36

37 Lock Washer Ext. 1/4

38

39 Bushing

40

41

42 Roll Pin 3/32 X 1"

43

44

45 Compression Spring

46

47

48

49

50

51

52

53

54

55

DE SC R IP TI ON

Pinion and Sprocket

Bushing

Zerk Fitting

Differential or Spur Gear

L.H. Axle

Bushing

Zerk Fitting

Groove Pin 1/4 X 1-3/4

Lockout Hub Assembly

Knob

Lockout Hub

Pin

Wheel Hub

Washer 3/4

Roll Pin 3/16 X 1-1/4

Cotter Pin 1/8 X 1-1/4

Feather Key 3/16 x 1-1/4 x 3/16

Axle Shaft

Woodruff Key 1/4x3/4x5/16

Roll Pin 3/16 X 1-1/2

R.H. Axle

5-3

Page 36

Reduction Drive

5.1 Introduction

WARNING: Gasoline is highly flammable

and its vapors are explosive. Handle with

A

When unit is tipped to preform the service proce

dures in this section, remove enough fuel so that

no spillage will occur, block securely and remove

bottom cover.

A

5.2 Differential, Lockout and Axle

Remove groove pin that secures lockout assembly

to left hand axle and lockout assembly from shaft.

(Pin is tapered and must be driven from small

end.)

care.

WARNING: Remove wire from spark plug

before attempting any repair or adjust

ment procedures.

Remove cap screws and lock nuts that retain

bearing retainer and bearing on frame.

Assemble in reverse order.

5.4 Pinion, Shaft and Sprocket

Remove L.H. rear wheel per instructions in Speed

Selector and Wheels Section.

Remove the roll pins from pinion shaft. Note

position of washers and remove shaft from frame.

Check pinion and sprocket bushings as well as

other parts for wear or damage and replace as

necessary.

Assemble in reverse order.

5.5 Reduction Shaft

Remove nuts and lock washers from ends of reduc

tion shaft.

Remove shaft and reduction sprocket from unit.

Remove roll pin that secures knob, spring and pin

to lockout hub.

Remove L.H. axle from unit.

Remove roll pin from R.H. axle, then remove

differential from axle while sliding axle from unit.

(Differential is serviced as a complete assembly.)

Check L.H. axle bushings and other parts for wear

or damage and replace as necessary.

Assemble in reverse order.

On units with spur gear, to remove axle, remove

cotter pins that secure wheel hubs to axle, roll pins

from axle and parts from unit.

Check components for wear or damage and replace

as needed.

Assemble in reverse order.

5.3 Axle Bearings

Check reduction sprocket bushings and other parts

for wear or damage and replace as necessary.

Assemble in reverse order and adjust chain per

instructions in Drive Chain Adjustment.

5.6 Hex Shaft

Hold hex shaft on sprocket end with a wrench and

remove lock nut at outside of frame. Slide hex

shaft to center of frame until it clears sprocket and

remove 9 tooth sprocket.

To service hex shaft ball bearing, remove four lock

nuts from bearing flanges then flanges and bearing

from unit.

Check parts for wear or damage and replace as

necessary.

Assemble in reverse order being sure that washers

are in position at outside of bearing flanges.

To replace axle bearings, remove axles per above

instructions.

5-4

Page 37

Reduction Drive

5.7 Drive Chains

Remove link from chain and chain from sprocket.

On continuous chain grind off end of rivet.

When replacing chain, be sure retainer clip faces

center of unit and is well seated in grooves of master

link, No. 000041.

5.8 Drive Chain Adjustment

If Sno-Thro is difficult to push because of tight or

interfering drive chains, proceed as follows:

Stand unit up on auger/impeller housing and re

move bottom cover.

Chain tension is adjusted by loosening two nuts on

Reduction Shaft. Adjust reduction sprocket up or

down in slot to obtain proper tension (chain

should be snug). Retighten both nuts. Torque to

170-180 inch lbs.

Chain interference with the Bearing Flange on Hex

Shaft can occur if there is no Washer between

Sprocket and Bearing. Make sure washer is installed.

NOTE: Check interlock mechanism to ensure pro

per operation as follows:

Check both clutches to be sure they operate freely

without binding.

Figure 5-3: Drive Chains

5-5

Page 38

Friction Wheel Drive

Table of Contents

Page

6.1 Introduction........................................................................................................................6-3

6.2 Friction Wheel....................................................................................................................6-3

6.3 Friction Wheel Carrier.......................................................................................................6-3

6.4 Drive Plate Spindle.............................................................................................................6-3

List of Illustrations

Page

6-1: Friction Wheel Assembly.................................................................................................. 6-1

6-2: Friction Wheel Exploded View..........................................................................................6-2

6-3: Friction Wheel.....................................................................................................................6-3

Page 39

Friction Wheei Drive

1. Hex Shaft

2. Friction Disc

3. Drive Plate

4. Drive Spindle Housing

Figure 6-1: Friction Wheel Assembly

6-1

Page 40

Friction Wheel Drive

iTEM

NO.

1

2 Drive Disc Spacer

3

4

5

6

7

8

9

10

11

12

13

14

15

DESCRIPTION

Drive Plate

Spindle 18

Woodruff Key 1/8 x 1/2 x 13/64

Drive Spindle Housing

Bearing 5/8 I.D.

Bearing Spacer

Bearing Housing

Roller 24

Washer 11/32

Lock Washer 5/16

Cap Screw 5/16-18 X 1"

Shaft Support 28

Taptite 1/4-20 x 3/8

Carrier Shaft

6-2

ITEM

NO.

16

17

19

20

21

22

23

25

26

27 Spindle Hub

29

30

31

DESCRIPTION

Roll Pin 5/32 X 1"

Bushing

Nylon Lock Nut 7/8-14

Bushing

Carrier

Radial Bearing 7/8

Washer 7/8

Snap Ring Int. 1-3/4

Hub

Friction Wheel

Taptite 5/16-18 X 1/2

Cap Screw 5/16-18 x 1/2

Lock Washer 5/16

Pulley

Lock Nut

Page 41

Friction Wheel Drive

6.1 Introduction

WARNING: Remove wire from spark plug

before attempting any repair or adjustment

A

When unit is tipped to preform the service proce

dures in this section, remove enough fuel so that

no spillage will occur, block securely and remove

bottom cover.

A

6.2 Friction Wheel

Remove bottom cover by removing four cap screws.

Place Speed Selector in first "1" position, depress

Traction Clutch Lever to hold friction wheel and

loosen five cap screws securing friction wheel to

hub. Release traction clutch lever, remove cap

screws, shift to third "3" position, disconnect

shift link and remove friction wheel.

procedures.

WARNING: Gasoline is highly flammable

and its vapors are explosive. Handle with

care.

6.3 Friction Wheel Carrier

Remove roll pins from carrier shaft and pull shaft

out of frame far enough to free carrier.

Hold hex shaft on sprocket end with a wrench and

remove lock nut at outside of frame. Slide hex

shaft to center of frame until it clears sprocket and

remove carrier from frame.

Remove nylon lock nut from spindle hub and hub

from carrier.

Remove snap ring, washer, bearing and bushing from

carrier.

Check carrier bushings and other parts for wear or

damage and replace as necessary.

Assemble in reverse order.

6.4 Drive Plate Spindle

Separate auger/impeller housing per instructions in

Auger/Impeller Section.

Remove lock nut from pulley end of spindle and

pulley from spindle. (To remove nut, engage friction

wheel drive to keep spindle from turning.)

Secure new friction wheel on hub with five cap

screws and torque cap screws to 8-10 foot pounds.

Install shift link.

1. Cap Screw

2. Friction Wheel

Remove friction wheel carrier per previous instruc

tions.

Remove drive spindle housing from frame by re

moving three cap screws and lock washers from

housing.

Check spindle bearings and other parts for wear or

damage and replace as necessary.

Assemble in reverse order applying Locktite Anti

seize to outside of bearing housing.

NOTE: Mix 1 part Mobil 1 with 16 parts Locktite

No. 767 Antiseize.

Figure 6-3: Friction Wheel

6-3

Page 42

Auger/Impeller

Table of Contents

Page

7.1 Introduction....................................................................................................................... 7-4

7.2 Auger/Impeller Housing....................................................................................................7-4

7.3 Auger/Impeller Removal...................................................................................................7-4

7.4 Attachment Clutch/Impeller Brake

7.5 Discharge Chute................................................................................................................7-5

7.6 Deflector.............................................................................................................................7-5

7.7 Scraper Blade.................................................................................................................. 7-6

7.8 Shear Bolt Replacement...................................................................................................7-6

7.9 Runners..............................................................................................................................7-6

..................................................................................

7-4

List of Illustrations

Page

7-1: Auger/Impeller Assembly..........................................................................................7-1

7-2: Auger/Impeller Exploded View..................................................................................7-2

7-3: Impeller Brake.............................................................................................................7-4

7-4: Discharge Chute....................................................................................................... 7-5

7-5: Deflector......................................................................................................................7-5

7-6: Scraper Blade..............................................................................................................7-6

7-7: Runners.......................................................................................................................7-6

Page 43

Auger/Impeller

1. Chute Crank

2. Universal Joint

3. Impeller

4. Gear Case

5. Scraper Blade

Figure 7-1: Auger/Impeller Assembly

6. Runner

7. Auger Housing

8. Auger

9. Discharge Chute

10. Worm Gear

7-1

Page 44

Auger/Impeller

¿^>,3

7-2

Figure 7-2: Auger/Impeller

Page 45

Auger/Impeller

ITEM

NO.

1 Deflector 36

2

3

4

5

6 Universal Joint

7

8 Rod

9

10

11

12

13

14

15

16

17

18

19

20 Runner 55

21

22 Lock Nut 3/8-16

23

24

25 Radial Bearing 3/4 or Ball Bearing

26 Bearing Flange

27

28

29

30 Lock Nut 5/16-18 65

31 Zerk Fitting

32 Auger

33

34

35 Bearing Support

36

DESCRIPTION

Cap

Knob 38

Chute Control Crank

Hair Pin or Cotter Pin

Roll Pin 1/8 X 3/4

Chute Crank Bracket

Worm Shaft

Wave Washer

L.H. Worm Gear 47

Washer 25/64 - Plastic

Carriage Bolt 5/16-18 x 3/4 49

Worm Clevis

Lock Washer 3/8

Lock Washer 5/16

Nut 5/16-18

Auger/Impeller Housing

Washer 3/8

Carriage Bolt 3/8-16 x 1"

Carraige Bolt 3/8-16 x 3/4

V

Rib Neck Bolt 1/4-20 x 1/2

Scraper Blade

Carriage Bolt 5/16-18 x 5/8

Shear Boltw/Nut

Washer 1"

ITEM

NO.

37

39

40

41

42

43

44

45

46

48

50

51

52

53

54

56

57

58

59

60

61

62

63

64

66

67

68

69

70

DESCRIPTION

Lock Nut 1/4-20

Bushing

Washer 1/2

Lock Washer 1/2

Cap Screw 1/2-13 x 1"

Extension Spring

Lock Nut 1/4-20

Arm Extension

Arm w/Lining

Clevis Pin

Cotter Pin 1/16 X 3/4

Brake Lining

Oval Rivet 3/16 x 7/16

Cap Screw 1/4-20 x 5/8

Nut Retainer 3/8-16

Flanged Screw 3/8-16 x 3/4

Bearing Flange

Taptite No. 10-24 x 3/8

Chute Clamp

Cotter Pin 3/32 X 3/4

Control Cable

Machine Screw No. 10-32 x 1/2

Tee Handle

Deflector Control Bracket

Discharge Chute

Lock Nut 3/8-16

Washer 13/32

Plastic Washer

Cap Screw 3/8-16 x 3/4

Rib Neck Bolt 5/16x7/16

Pulley

Hub

Set Screw 5/16-18 x 3/8

Nut 5/16-18

Impeller and Gear Case

7-3

Page 46

Auger/Impeller

7.1 Introduction

WARNING: Remove wire from spark plug

before attempting any repair or adjustment

A

When unit is tipped to preform the service proce

dures in this section, remove enough fuel so that no

spillage will occur, block securely and remove bot

tom cover.

A

7.2 Auger/Impeller Housing

To separate housing from unit, remove two screws

securing belt guard to unit and remove belt guard.

Remove hairpin from chute crank assembly at "U"

joint and separate.

Remove attachment drive belt from engine pulley

(it may be necessary to turn engine pulley using

rewind starter).

procedures.

WARNING: Gasoline is highly flammable

and its vapors are explosive. Handle with

care.

Grasp auger assembly and pull gear case and auger/

impeller assembly free of housing.

Drive roll pin out of shaft ends, remove shear bolts

and remove auger from shaft.

Check all parts for wear or replacement.

Assemble using reverse procedure.

7.4 Attachment Clutch/Impeller Brake

WARNING: With improper use injury may

A

To check and/or adjust impeller brake, tip unit

forward onto auger/impeller housing. Remove bot

tom cover by removing four cap screws. Measure

distance between impeller brake shoe and belt with

attachment clutch engaged. When attachment clutch

is disengaged, brake must contact belt.

result if attachment clutch lever is released

and brake DOES NOT STOP auger/impeller

within 5 seconds.

IMPORTANT: To avoid bending bottom cover,

when tipping unit apart, support handlebars firmly

or tip unit up on housing and remove bottom cover

by removing four cap screws before separating

unit.

Remove cap screws securing housing to frame (one

on each side). Tip housing and frame apart on pivot

pin.

7.3 Auger/Impeller Removal

Remove (3) three nuts holding pulley to hub and re

move pulley and key.

Loosen set screw in hub and remove hub.

Remove (3) three nuts holding bearing flange to

housing and remove bearing flange.

Remove (2) two cap screws and lockwashers on each

side of blower housing holding rake shaft in position

and remove bushing.

Remove (3) three lock nuts attaching bearing

support to housing and remove bearing support.

1. Brake Shoe

2. Drive Belt

3. 1/16" -1/8" Between Shoe and Belt

4. Spring Extension - 3/8"

Figure 7-3: Impeller Brake

7-4

Page 47

Auger/Impeller

If impeller brake shoe is not 1/16 to 1/8 inch from

belt, disengage clutch, loosen attachment idler nut,

reposition idler to compensate for belt length,

tighten nut and adjust attachment clutch per in

structions below.

Adjust attachment clutch with both clutch lever and

clutch arm in disengaged position, pull clutch chain

taut and connect chain link to spring. Spring should

extend approximately 3/8" when clutch is engaged

but allow clutch arm (at lower end) to return to it's

maximum down position when clutch is disengaged.

7.5 Discharge Chute

DANGER: DO NOT put hands or feet near

A

A

or under rotating parts. Keep clear of dis

charge opening at all times.

WARNING: NEVER direct discharge of

material toward bystanders nor allow any

one in front of equipment while unit is in

operation. Be familiar with area of opera

tion.

7.6 Deflector

On ST 1136 remove one jam nut from deflector

cable, route cable through retainer mounted on

engine and chute bracket. Replace jam nut and

secure cable threaded connector (from left side) to

deflector bracket with cotter pin. Position deflector

in its lowest position with calDle control pushed full

in and tighten jam nuts on chute bracket.

NOTE: Check deflector movement to highest posi

tion. Adjust jam nuts and/or threaded connector if

necessary to obtain full travel.

Slide handle end of Deflector Control Cable through

hole in upper handlebar panel and secure with

washer and jam nut. Secure T-Handle on end of

Deflector Control Cable.

1. Discharge Chute

2. Mounting Clip

Figure 7-4: Discharge Chute

Remove mounting clips from discharge chute, oil

and position chute on auger/impeller housing.

Secure discharge chute with mounting clips and

hardware.

NOTE: Chute must rotate freely.

1. Discharge Chute

2. Deflector

3. Cotter Pin

7-5

4. Cable Control

5. Deflector Bracket

6. Mounting Clip

Figure 7-5: Deflector

Page 48

Gear Case

Table of Contents

Page

8.1 Introduction.........................................................................................................................8-6

8.2 Cast Iron Gear Case (Worm Gear)....................................................................................8-6

8.3 Aluminum Gear Case (Worm Gear)..................................................................................8-6

8.4 Cast Iron Gear Case (Helicon Gear)..................................................................................8-7

List of Illustrations

Page

8-1; Gear Case Assemblies.......................................................................................................8-1

8-2: Cast Iron Gear Case (Worm Gear) Exploded View

8-3: Aluminum Gear Case (Worm Gear) Exploded View........................................................8-4

8-4: Cast Iron Gear Case (Helicon Gear) Exploded View.......................................................8-5

......................... ...............................

8-2

Page 49

Gear Case

1. Cast Iron Gear Case (Worm)

2. Cast Iron Gear Case (Helicon)

3. Aluminum Gear Case (Worm)

Figure 8-1: Gear Case Assemblies

8-1

Page 50

Gear Case

Cast Iron

Page 51

Gear Case

Cast Iron

ITEM

NO.

1

2

3

4 Worm Shaft

5

6

7 Seal

8

9

10

11

12

13

14

15

16

17

DESCRIPTION

Roll Pin 5/16 X 1-3/4

Fan

Woodruff Key 3/16x7/8x3/8

Straight Key 3/16 x 1" x 3/16

Adjusting Plug

Bearing Cup 1-25/32 O.D.

Bearing Cone 3/4 I.D.

Bearing Spacer

Worm & Gear

Snap Ring Int. 1-25/32

Seal 1-5/8

Pipe Plug

Washer 21/64

Lock Washer 5/16

Cap Screw 5/16-18 x 3/4

ITEM

NO. DESCRIPTION

18

19

20

21

22

23

24

25

26

27

28

29

30

31

Dust Cap

Roll Pin 3/16 X 1-1/2

Gear Case

Bushing

Washer 1-5/8

Woodruff Key 1/4 X 7/8 X 3/8

Gear Case Shaft

Gasket

Gear Case Cover

Lock Washer Int. 1/4

Cap Screw 1/4-20 x 3/4

Rake Shaft

Gear Case Assembly

Requires 5 oz. L-2 Special Gear

Lube Part No. 000080

L-2 Special Gear Lube

16 oz. Bottle

8-3

Page 52

Gear Case

Aluminum

ITEM

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

ITEM

DESCRIPTION

Roll Pin 1/4 X 1-3/4 15

Impeller

0-Ring

Bushing

Thrust Collar

Groove Pin 3/16 X 1-1/4

Woodruff Key 3/16 x 7/8 x 3/8

Worm Gear & Shaft

L.H. Gear Case Half

Carriage Bolt 1/4-20 x 1-1/4

Seal

Taptite No. 10-24 x 3/4

Carriage Bolt 1/4-20 x 7/8

Roll Pin 3/16 X 1-1/2

NO.

8-4

20

21

22

23

24

25

16

17

18

19

DESCRIPTION

Bushing

Bushing

Washer 1"

Groove Pin 5/16 x 1-7/16

Gasket

R.H. Gear Case Half

Lock Nut 1/4-20

Taptite 3/8-16 x 1/2

Rake Shaft

Gear Case Assembly

Requires 2 oz. Liquid Grease

Part No. 000072

Liquid Grease 8 oz. Tube

Page 53

Figure 8-4: Cast Iron Gear Case (Helicon Gear)

Gear Case

Cast Iron

ITEM

NO.

1

2

3

4

5

6

7

8

9

10

11

19 ' I

DESCRIPTION

Roll Pin 1/4 X 1-1/4

Fan

Seal

Adjustment Plug 15

Bearing Cup 16

Bearing Cone

Helicon Pinion Shaft

Bearing Spacer 19

Snap Ring

Roll Pin 5/16x1-3/8

Washer

ITEM

NO.

12 Seal

13 Gear Case

14

17

18

20

21

DESCRIPTION

Gasket

Flange Whiziock Screw

Pipe Plug

Bushing

Helicon Gear

Front Gear Shaft

Roll Pin 3/16 X 1-1/2 1

Gear Case Flange

8-5

Page 54

Gear Case

8.1 Introduction

WARNING: Remove wire from spark plug

A

When unit is tipped to preform the service proce

dures in this section, remove enough fuel so that no

spillage will occur, block securely and remove bot

tom cover.

A

Remove Auger/Impeller and gear case from housing

per instructions in Auger/Impeller Section to pre

form the following service procedures.

8.2 Cast Iron Gear Case (Worm Gear)

before attempting any repair or adjustment

procedures.

WARNING: Gasoline is highly flammable

and its vapors are explosive. Handle with

care.

Using adjustment wrench, tighten down on adjust

ment plug until input shaft is snug.

Replace side cover using a sealant on threads of two

bottom bolts.

Fill gear case with L-2 oil until level reaches bottom

of threads in filler hole.

Check oil level periodically. Oil level must be up to

oil fill hole. Change oil every 25 hours or once each

season whichever comes first. Fill with Ariens

Special L-2 Gear Lubricant (Part No. 000080). Use

approximately 5 oz.

8.3 Aluminum Gear Case (Worm Gear)

Remove (6) six bolts that hold right and left gear-

case halves together.

If flange bushings need replacement, first remove

seals from outside of gearcase halves with a screw

driver. Flange bushings can then be pressed out from

outside in with a bearing driver. Bushings are very

lightly pressed in.

Remove four bolts from bearing flange.

Remove flange and gasket.

NOTE: At this point bronze gear cannot be re

moved.

Using bearing adjustment wrench remove adjust

ment plug.

While holding input shaft in one hand and using a

mallet, strike case until bearing cone pops out of

the case.

Bronze gear can then be removed from case.

After bronze gear is removed, input shaft can then

be removed.

NOTE: it is not necessary to remove the end cap

from case.

To remove worm gear and bearings, simply remove

bolt and washer from end of shaft.

When replacing bushings make sure flat on the

flange of bushing fits in the inside notch of case.

There are (2) special washers, one on either side of

bronze gear. If burred or worn they should be

replaced.

Holding bronze gear on rake shaft is a groove pin.

When driving out, drive in direction of least resis

tance. Flat on bronze gear face's fill hole side of

gearcase.

Remove bronze bushing from front of worm shaft

by sliding it off. If replacement is necessary, replace.

Notice a flat on the bushing flange when installed

sets against flat in gearcase.

Behind rear bronze bushing is an "0-Ring" which

fits into a groove in gearcase. It should be replaced

at time of repair.

Rear bushing is a larger diameter than one in front,

but are identical in design. Replace if necessary.

Assembly is done by inserting bronze and worm gear

at same time.

If replacement of thrust collar is necessary, again

drive out groove pin towards direction of least

resistance.

8-6

Page 55

Gear Case

Inspect worm for burrs or black coloration. If either

show up, replace shaft.

To assemble make sure you replace the case gasket

and make sure flats on bushings are in their proper

place.

This case requires No. 70 Liquid Grease and should

be half full.

After assembly is completed you should be able

to turn input shaft freely.

Auger/impeller gear case is lubricated with Ariens

Liquid Grease (Part No. 000070). This grease will

not flow at lower temperatures. It is therefore

difficult to check lubricant level. Best method for

checking is to place unit in a warm location over

night. This allows grease to flow to level. Check

lubrication by removing filler plug on side of gear

case just above left auger shaft. Lubrication should

be even with hole with machine sitting level. It may

be necessary to insert a wire into hole to check

level. Unit will not be damaged by over lubricating.

8.4 Cast Iron Gear Case (Helicon Gear)

To remove Gear Case from Auger/impeller Housing

refer to Auger/impeller Section.

Tools Required:

Open End Wrench - 7/16"

Ratchet Wrench with 7/16" socket

Hammer

Punch-5/16", 3/8"

Screwdriver (two required)

AriensToolsNo. 37, No. 90, No. 130 & No. 131

Unscrew adjustment plug. (Use No. 90 Bearing

Adjustment Wrench.)

Insert punch through the oil filler hole and drive

pinion shaft assembly out of gearcase.

Remove bearing cup and snap ring from inner por

tion of gearcase only if necessary.

To assemble proceed as follows:

Pin helicon gear on front gear shaft.

Insert front gear shaft assembly into gear case.

Install in helicon pinion shaft assembly and drive in

bearing cup. Use No. 131 Bearing Driver.

Install new seal against shoulder in adjustment plug.

On adjustment nuts, insert the seal so that top of

seal is flush with bottom of the spanner slot or

about 1/32 of an inch below the bottom of the nut.

Use No. 130 Seal Driver.

Seal the adjusting nut in position by putting a

small bed of gasolia sealer in the gear case threads.

The nut will drag the sealer around threads. Tighten

adjustment nut until a slight drag is felt while

turning the pinion shaft.

Use No. 90 Bearing Adjustment Wrench.

Check the oil level in the snow rotar gear case. Tip

machine back on handlebars. Remove filler and

drain plugs. Fill with Ariens Gear Oil (SAE MP90)

until it runs out the drain. Replace drain and filler

plugs.

Remove pipe plug and drain oil. Use 7/16" Open

End Wrench.

Remove cap screws holding flange and remove

flange and gasket.

Insert punch through oil filler hole and drive roll

pin out of helicon gear just far enough to clear

shaft.

Pull out front gear shaft.

After shaft is removed, it is possible to remove

helicon gear by tipping to clear pinion shaft.

8-7

Page 56

Engine and Headlight

Table of Contents

Page

9.1 Engine Oil...........................................................................................................................9-2

9.2 Engine Cooling.................................................................................................................. 9-2

9.3 Engine Oil Recommendations..........................................................................................9-2

9.4 Headlight.............................................................................................................................9-2

9.5 Engine Air Cleaner.............................................................................................................9-2

9.6 Headlight Assembly...........................................................................................................9-3

9.7 Add-On Alternator..............................................................................................................9-4

List of Illustrations

Page

9-1: Engine Components..........................................................................................................9-1

9-2: Headlight Assembly and Location....................................................................................9-3

9-3: Add-On Alternator..............................................................................................................9-4

Page 57

Engine and Headlight

1. Engine

2. Hex Cap

3. Nipple

4. Street Elbow

5. Tube

6. Hose Clamp

7. Drain Lock

8. Adapter

9. Nut 5/16-18

10. Lock Washer 5/16

11. Plate

12. Choke

13. Throttle

14. Primer Bulb

15. Spark Plug and Wire

16. Oil Fill and Dipstick

17. Carburator

18. Fuel Tank and Cap

Figure 9-1: Engine Components

9-1

Page 58

Engine and Headlight

Ariens Dealers will provide any service which may

be required to keep your Sno-Thro operating at

peak efficiency. Should engine service be required,

it can be obtained from an Ariens dealer or an

authorized engine manufacturer's service center.

WARNING: Stop engine, remove key, wait

A

A

9.1 Engine Oil Checking

The engine crankcase oil should be checked daily or

every 5 hours of operation. Oil level MUST be

maintained in safe operating range on dipstick at

all times or engine damage will result.

for moving parts to stop and remove wire

from spark plug (keep wire away from

spark plug to prevent accidental starting)

before any lubrication or maintenance

procedures.

CAUTION: DO NOT touch engine or Sno-

Thro drive parts which are hot from opera

tion. Allow such parts to cool before ser

vicing unit.

crankcase with new oil of proper grade (per engine

manufacturer's instructions). Recheck oil level with

dipstick.

9.2 Engine Cooling

The engine is air cooled. Air must circulate freely

around engine from air intake screen, over cooling

fins on cylinder head and block to prevent over

heating.

Every 100 operating hours or yearly (more often if

conditions require) remove cooling shrouds and

clean cooling fins. Also clean external surfaces of

your engine of dust, dirt and oil deposits which can

contribute to improper cooling.

IMPORTANT: DO NOT operate engine with cooling

shrouds removed - this will cause overheating and

engine damage.

Fill crankcase with oil as recommended below.

Refer also to Engine Manufacturer's Instructions

supplied with the product. Check oil level before

each use and change oil regularly according to

Engine Manufacturer's Instructions.

9.3 Engine Oil Recommendations

To check oil, park Sno-Thro on a flat level surface.

Wipe all debris from around dipstick, remove it and

wipe oil off. Screw dipstick assembly firmly but

slowly until cap bottoms on tube. Remove dipstick

and observe oil level. If low add clean fresh oil, of

same type and viscosity as is in engine, to bring oil

level to Full (F) mark (per engine manufacturer's

instructions).

IMPORTANT: DO NOT overfill. Level must not

exceed full (F) mark.

Changing

IMPORTANT: Change oil after first 5 hours of oper

ation, thereafter change oil every 25 hours of opera

tion (more often in dusty, dirty conditions). See

Engine Manufacturer's Instructions for proper type,

viscosity and amount required.

NOTE: Run engine just prior to changing oil. Oil

will flow more freely and carry away more conta

mination when warm.

Drain crankcase by removing oil drain plug (open

petcock on ST 1136). When oil has drained replace

plug (close petcock on AT 1136) and refill engine

Summer:

(Above 32° F)

Winter SAE 5W20, 5W30 or Substitute:

(Below 32° F) SAE 10W

9.4 Headlight

To replace lamp remove metal ring or remove lamp

from rubber housing.

CAUTION: When handling glass lamp

A

Disconnect electrical plug and assemble new lamp in

reverse order.

NOTE: Be sure headlight assembly is grounded at

headlight bracket for single wire models and at

terminal on two wire models.

9.5 Engine Air Cleaner

IMPORTANT: When using tractor with summer

attachments, install air cleaner and clean element

every 25 hours of operation (more often under

dusty-dirty conditions).

breakage may occur.

SAE 30W or Substitutes:

10W30

9-2

Page 59

d.6 Headlight

Engine and Headlight

Install headlight bracket (level with floor) on right

handlebar with hardware provided (Figure 10-1).

NOTE; Two washers go between bracket and

handlebar at top hole.

Assemble headlight, bracket and U-bracket with

hardware provided and install onto headlight

bracket.

Position headlight wire harness behind name plate

along handlebar and plug into alternator connector.

Secure harness to handlebar with clips.

9-3

Page 60

Engine and Headlight

9.7 Add-On Alternator

Remove rewind starter keps nuts and starter from

engine. (Note location of rewind starter handle).

Remove pushout plug from top center of rewind

starter.

On die cast recoils, remove center hole cast material

with 1/4 inch drill.

Rotate pulley to expose 3 punch-outs (Figure 1),

place starter on back-up surface and remove punchouts with 1/8" punch.

NOTE: Remove quadrant mounting hardware (on

Models 932001, 4, 6 and 7) for additional clearance

when mounting alternator. Secure quadrant when

assembled.

For Use On Sno-Thro Models

Model

924050

924051

924074

924075

Install alternator shaft over crank shaft nut (tap hex

with pipe or light drift until it contacts flywheel

washer) and place centering tube onto alternator

shaft.

NOTE: 3" alternator shaft and short centering tube

are for 932000 Series and ST 524. 4" alternator

shaft and long centering tube are for ST 824. Alter

nator shaft must extend approximately 5/8" beyond

top of starter, if not, incorrect shaft has been in

stalled.

Center rewind starter (using centering tube) and

secure with keps nuts removed earlier.

Remove centering tube and position alternator on

to alternator shaft with lighting connector receptical

to right (as viewed from operator's position).

Serial No.

050501 & Up

000501 & Up

000101 & Up

000101 & Up

Secure alternator to rewind starter with 3 self

tapping screws.

IMPORTANT: DO NOT exceed 15 inch pounds

seating torque (after threads are formed) to prevent

screws from contacting pulley or distorting alter

nator.

9-4

Page 61

Notes

Page 62

Attachments

Table of Contents

Page

10.1 Caster Wheels

10.2 Rotary Mower Lubrication.

.....................

List of Illustrations

10-3

10-7

Page

10-1: Rotary Brush ..................................................................................................................10-2

10-2: Rotary Mower Drive....................................................................................................... 10-4

10-3: Rotary Mower Pan..........................................................................................................10-6

Page 63

Notes

10-1

Page 64

Attachments

Figure 10-1: Rotary Brush

10-2

81 1 0 /V

82^m 1

\

J

0p%

s'a

Page 65

Attachments

ITEM

N0.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

DESCRIPTION

Nut 5/16-18

Lock Washer 5/16

Set Screw 1/4-20

Bearing 47

Carriage Bolt 5/16-18 x 3/4