Page 1

Date: September 29, 2011 No. B-2079

Service Bulletin

Ariens Company

655 W. Ryan St.

Brillion, WI 54110

www.ariens.com

Product Family: 920 Series Sno-Tek™ Snow Throwers

Subject: LCT Engine Oil Drain Tube Seepage

Dealer Action: Inspect and Correct as Necessa ry

Ariens Company has been notified by LCT Engines (Liquid Combustion Technology) that there is a poten-

™

tial for oil seepage from the oil drain tube on some engines used on Ariens Sno-Tek

LCT has released the following Technical Service Bulletin which identifies the issue and explains steps to

take if a machine displays this defect. Please read the attached bulletin and inspect and repair all Sno-Tek

models in your inventory per the instructions in the bulletin.

snow throwers.

If you need to contact LCT USA customer service please have the Ariens model and serial numbers and

LCT engine model and serial numbers available. Dealers can contact LCT USA customer service at

800-552-8094 for information on any warranty claims.

Page 1 of 1

Page 2

Liquid Combustion

100 Roe Road

Travelers Rest, SC 29690

Technology

Oil Drain Tube Oil Seepage 9/28/2011

PROBLEM DEFINITION:

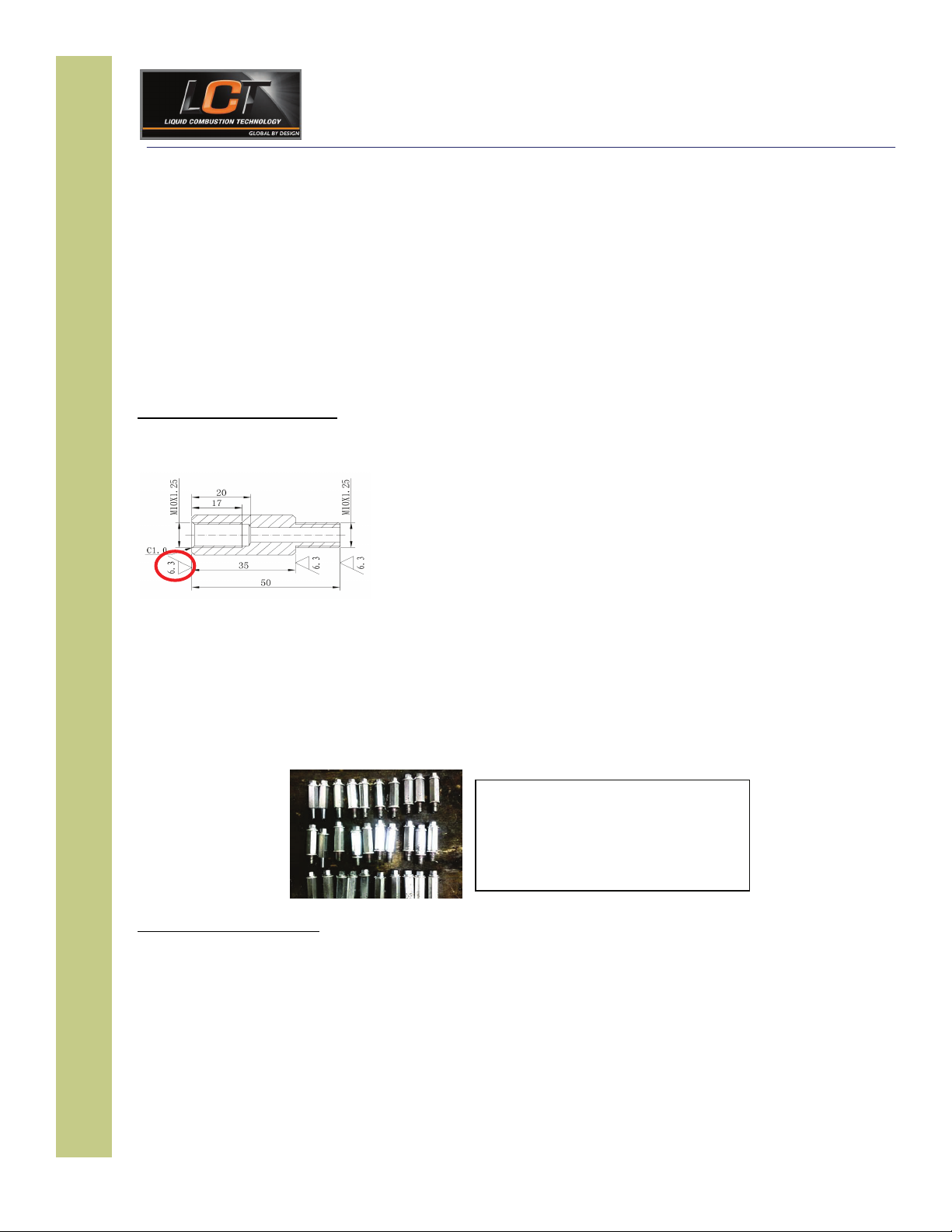

Oil Seepage from 35mm Drain Tube Reported by customer. After internal inventory audit, seepage was confirmed. Further Investigative Analysis determined:

35mm Oil Tube Face (crush washer engagement area) does not meet surface finish drawing specification of

6.3um

Short Term Corrective Action:

LCT recommends increasing drain bolt torque to 23lb-ft to allow crush washer to fill excessive ridges/valleys

caused by the out of specification surface finish:

Phone: 864.660.8036

Fax: 864.834.6670

E-mail: dougglass@lctllc.com

Capability study was conducted on 30pc of Oil Drain Tubes removed from inventory product

Engines were filled with oil and monitored over a 24hr period

5pcs of the 30 were observed to have an oil witness mark below oil drain bolt (35mm drain tube

side)

Oil Drain Tubes were removed from engines and service Oil Drain Tubes (with correct surface fin-

ish) installed and torqued and engines were placed back into inventory

Removed Oil Drain Plugs were then torqued to 23lb-ft and pressurized in a submerged state to

look for joint seal failure. No failures were observed after torque was increased to 23lb-ft

Long Term Corrective Action:

Currently working with supplier to determine root cause of oil drain tube missing the facing operation

Will update with full 8D report once final root cause has been determined

Containment Activities:

Inventory audits were conducted with product in South Carolina warehouse

Product with May 25th date code (>15000 engine serial number) was discovered to have the “non faced”

machining condition

Product from August 6th (<8000 engine serial number in August) was discovered to have correct machined

face surface area

Total engine exposure based on the 5/30 statistical sample—5689

30pc Oil Drain Tube Samples

- Samples were torqued to 23lb-ft

- Samples were pressurized and submerged

- No leaks were detected

Loading...

Loading...