Page 1

Page 2

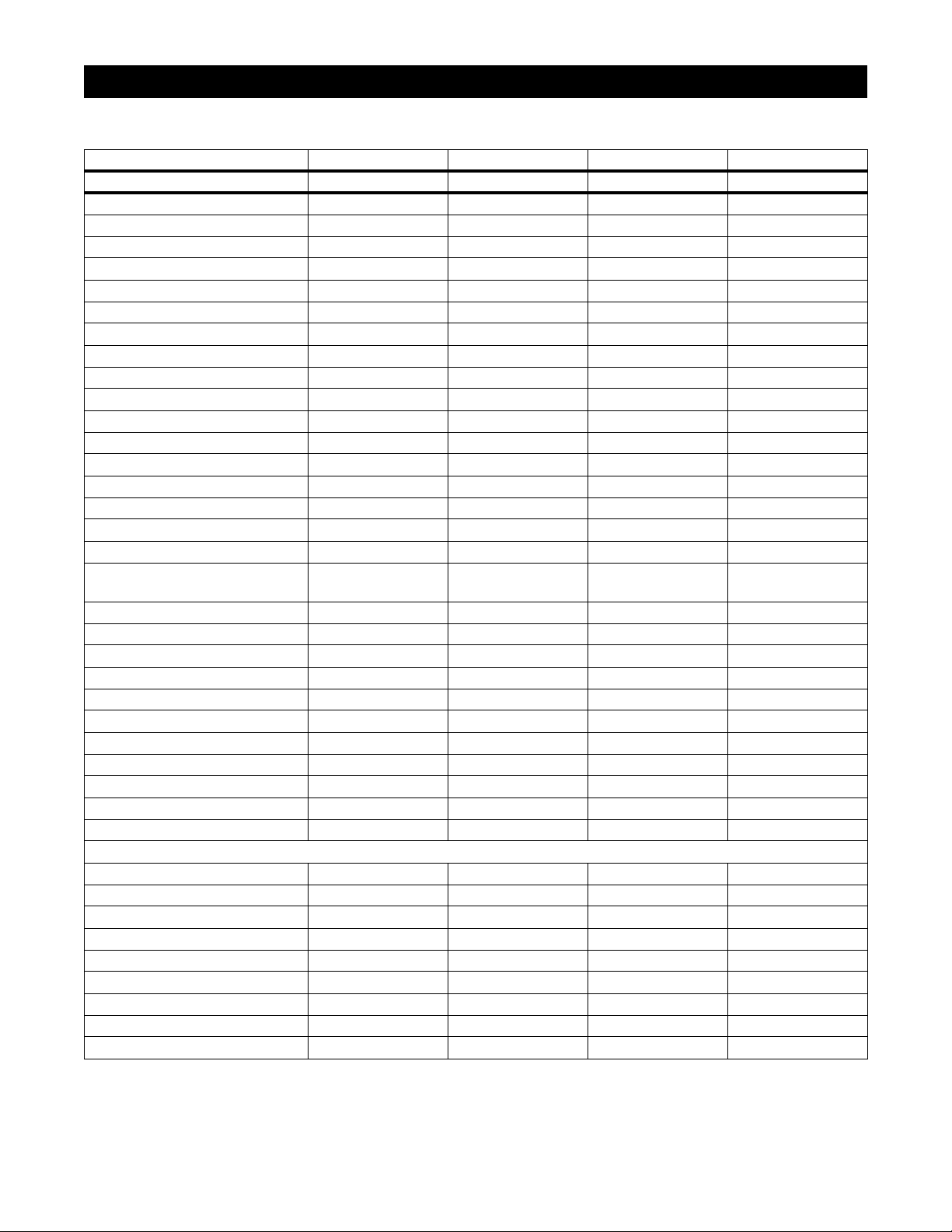

TABLE OF CONTENTS

Section 1 - Introduction . . . . . . . . . . . . . . . . . 1-3

1.1 The Manual . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 Service and Replacement Parts . . . . . . . 1-3

1.3 Product Registration . . . . . . . . . . . . . . . . 1-3

1.4 Unauthorized Replacement Parts . . . . . . 1-3

1.5 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.6 Technical Service Communications. . . . . 1-3

Section 2 - Safety

2.1 Safety Alerts . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2 Signal Words . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 Notations . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Practices and Laws . . . . . . . . . . . . . . . . . 2-4

2.5 Required Operator Training. . . . . . . . . . . 2-4

2.6 Preparation . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.7 Cleaning and Storage . . . . . . . . . . . . . . . 2-4

2.8 Safety Rules . . . . . . . . . . . . . . . . . . . . . . 2-5

Section 3 - Specifications . . . . . . . . . . . . . . . 3-8

Section 4 - General Maintenance &

Adjustments. . . . . . . . . . . . . . . . . . . . . . . .4-21

4.1 Controls and Features . . . . . . . . . . . . . . .4-21

4.2 Service Positions . . . . . . . . . . . . . . . . . . .4-22

4.3 Filling The Fuel Tank . . . . . . . . . . . . . . . .4-22

4.4 General Lubrication . . . . . . . . . . . . . . . . .4-22

4.5 Check Mower Blade. . . . . . . . . . . . . . . . .4-23

4.6 Check Drive Belt . . . . . . . . . . . . . . . . . . .4-23

4.7 Check Engine/Blade Control . . . . . . . . . .4-23

4.8 Check Grass Bag. . . . . . . . . . . . . . . . . . .4-24

4.9 Check Drive Control. . . . . . . . . . . . . . . . .4-24

4.10 Handlebar Adjustment . . . . . . . . . . . . . .4-25

4.11 Speed Control Bell Crank. . . . . . . . . . . .4-25

4.12 Friction Wheel Adjustment. . . . . . . . . . .4-26

Section 5 - Engine. . . . . . . . . . . . . . . . . . . . . .5-27

5.1 Engine Troubleshooting . . . . . . . . . . . . . .5-27

5.2 Engine Service Locations . . . . . . . . . . . .5-28

5.3 Engine Oil . . . . . . . . . . . . . . . . . . . . . . . .5-29

5.4 Air Cleaner. . . . . . . . . . . . . . . . . . . . . . . .5-29

5.5 Engine Cooling. . . . . . . . . . . . . . . . . . . . .5-31

5.6 Spark Plug . . . . . . . . . . . . . . . . . . . . . . . .5-31

5.7 Battery (Electric Start Model). . . . . . . . . .5-31

Section 6 - Mower Deck . . . . . . . . . . . . . . . . .6-32

6.1 Blade Brake/clutch Removal . . . . . . . . . .6-32

6.2 Drive Belt Replacement. . . . . . . . . . . . . .6-33

6.3 Idler Removal. . . . . . . . . . . . . . . . . . . . . .6-33

6.4 Wheels And Adjusters . . . . . . . . . . . . . . .6-33

Section 7 - Handlebars & Controls . . . . . . . .7-37

7.1 Handlebars And Bails . . . . . . . . . . . . . . .7-37

7.2 Speed Control Bell Crank . . . . . . . . . . . .7-37

Section 8 - Electrical. . . . . . . . . . . . . . . . . . . .8-39

8.1 Battery (Electric Start Models). . . . . . . . .8-39

8.2 Wiring Diagram . . . . . . . . . . . . . . . . . . . .8-39

8.3 Continuity Diagram . . . . . . . . . . . . . . . . .8-39

Section 9 - Friction Drive System & Axle. . .9-40

9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . .9-40

9.2 Gear Removal . . . . . . . . . . . . . . . . . . . . .9-40

9.3 Axle Removal. . . . . . . . . . . . . . . . . . . . . .9-40

9.4 Drive Mount Removal . . . . . . . . . . . . . . .9-40

9.5 Drive Mount Disassembly . . . . . . . . . . . .9-40

9.6 Friction Wheel Replacement . . . . . . . . . .9-40

9.7 Drive Disk Removal . . . . . . . . . . . . . . . . .9-41

Section 10 - Gear Drive System & Axle. . . . 10-43

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . 10-43

10.2 Transmission Replacement . . . . . . . . . 10-43

2

Page 3

SECTION 1 - INTRODUCTION

1.1 THE MANUAL

Before operation of unit, carefully and completely read

your manuals. The contents will provide you with an

understanding of safety instructions and controls

during normal operation and maintenance.

All reference to left, right, front, or rear are given from

the operation position, facing the direction of forward

travel.

1.2 SERVICE AND REPLACEMENT PARTS

When ordering replacement parts or making service

inquiries, know the Model and Serial numbers of your

unit and engine.

Numbers are located on the product registration form in

the unit literature package. They are also printed on a

serial number label, located on the frame of your unit

(Figure 1).

Serial Number

Figure 1

1.5 DISCLAIMER

Ariens reserves the right to discontinue, make changes

to, and add improvements upon its products at any

time without public notice or obligation. The

descriptions and specifications contained in this

manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations

may not be applicable to your unit.

1.6 TECHNICAL SERVICE

COMMUNICATIONS

Ariens Technical Service communicates information to

the field using Service Letters, Service Bulletins,

Product Notices, and Campaigns. Each

communication signifies a type of information and

priority. The dealer is responsible to carry out the

directive provided in the communication. The types of

communication are:

Service Letter

dealer. Technical information on how to service the

product and product improvements.

Service Bulletin

resolve certain issues or a notification of a policy

change.

Product Notices

located in a certain region. This is a limited distribution

to only those who received the product involved.

Campaigns

product must be updated and are tracked by the

factory until all units are corrected.

- General technical information for the

- Notification to update products to

- Notification of limited product

- Notification of a safety related issue. All

1.3 PRODUCT REGISTRATION

A warranty registration card must be filled out by the

Ariens dealer, signed, and returned at time of sale. This

card activa tes the warranty. Claims meeting

requirements during limited warranty period will be

honored.

1.4 UNAUTHORIZED REPLACEMENT

PARTS

Use only Ariens replacement parts. The replacement of

any part on this unit with anything other than Ariens

authorized replacement parts may adversely affect the

performance, durability, or safety of this unit and may

void the warranty. Ariens disclaims liability for any

claims or damages, whether warranty, property

damage, personal injury , or death arising out of the use

of unauthorized replacement parts.

1 - 3

Page 4

SECTION 2 - SAFETY

2.1 SAFETY ALERTS

Look for these symbols to point out

important safety precautions. They

mean:

Attention!

Personal Safety Is Involved!

Become Alert!

Obey The Message!

2.2 SIGNAL WORDS

The safety alert symbol is used in decals on the unit

and with proper operation procedures in this manual.

They alert you to the existence and relative degree of

hazards.

Understand the safety message. It contains important

information about personal safety on or near the unit.

DANGER:

SITUATION! If not avoided, WILL RESULT in

death or serious injury.

WARNING:

SITUATION! If not avoided, COULD RESULT

in death or serious injury.

CAUTION:

SITUATION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be used

to alert against unsafe practices.

IMMINENTLY HAZARDOUS

POTENTIALLY HAZARDOUS

POTENTIALLY HAZARDOUS

2.3 NOTATIONS

NOTE:

ation and maintenance practices.

IMPORTANT:

required to prevent damage to unit or attachment.

General reference information for proper oper-

Specific procedures o r infor mati on

2.6 PREPARATION

Before starting any removal of parts, proper

preparation is very important for efficient work. A clean

work area at the start of each job will allow you to

perform service repairs easily and quickly.

To reduce the incidence of misplaced tools or parts,

place removed components with all attaching hardware

in the disassembly order on a clean work surface.

Organization is a key part of proper reassembly.

T ools, instruments, and parts needed for the job should

be gathered before work is started. Interrupting a job to

locate tools or parts is a needless delay.

CAUTION:

spillage will occur. Remove battery to prevent

spillage of electrolyte.

Remove enough fuel so that no

2.7 CLEANING AND STORAGE

WARNING:

can cut. Movem ent of par ts can cu t of f fing ers

or a hand. Wear gloves, and use extreme

caution when servicing.

IMPORTANT:

outdoors to help prevent sealed bearing rust or

corrosion. Water can seep into sealed bearings and

reduce component life. Bearings are sealed against dirt

and debris only.

A unit that is excessively dirty should be cleaned

before work starts. Cleaning will occasionally uncover

trouble sources. Dirt and abrasive dust reduce the

efficient work life of parts and can lead to costly

replacement.

AVOID SHARP EDGES which

Never spray unit with water or store unit

2.4 PRACTICES AND LAWS

Practice usual and custo mar y safe worki ng

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate, or serious injury or death. Learn applicable

rules and laws in your area.

2.5 REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation. If unit is to be used

by someone other than original purchaser; loaned,

rented or sold, ALWAYS provide this manual and any

needed safety training before operation.

2 - 4

Page 5

When taking unit out of extended storage:

1. Check for any damage or loose parts. Repair,

replace, or tighten hardware before operation.

2. If a preservative fluid was used in fuel tank, drain

and discard. Fill fuel tank with fresh new fuel.

2.8 SAFETY RULES

Walk Around Inspection

Complete a walk around inspection of unit and work

area to understand:

• Work area.

• Your unit.

• All safety decals.

Work Area

ALWAYS check overhead and side clearances

carefully before operation. ALWAYS be aware of traffic

when operating along streets or curbs.

ALWAYS keep hands and feet within the limits of the

unit.

Keep children, people, and animals away. Keep

children out of work area and under watchful care of a

responsible adult.

Keep area of operation clear of all toys, pets, and

debris. Stay alert for hidden hazards.

Clear work area of objects which might be picked up

and thrown. Remove all stones, sticks, wires, and other

foreign objects. Tall grass can hide obstacles.

DO NOT run engine in an enclosed area. Always

provide good ventilation.

Unit

ALWAYS keep protective structures, guards, and

panels in good repair, in place and securely fastened.

NEVER modify or remove safety devices.

Check Safety Interlock System for proper operation

daily (see Operation section). Do not operate unless

system operates properly.

Keep equipment in good condition.

ALWAYS keep discharge cover in place.

NEVER operate the engine with the Rear Door open

unless the Grass Bag is in place.

When mulching, the Side Discharge Opening Cover

must be installed and the Rear Door fully closed

whenever the engine is operating.

Operation

Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an Emergency

• Speed ranges

ALWAYS operate unit in good visibility and light.

DO NOT pull mower backwards unless absolutely

necessary. Look down and back before and while

moving backwards.

DO NOT start the engine or operate mower unless

either the Side Discharge Opening Cover or the Side

Discharge Deflector is installed.

Keep the area of operation clear of all persons,

children and pets.

ALWAYS clear area before operation to avoid thrown

objects.

Stop mower if anyone enters the area.

Keep safety devices or guards in place and functioning

properly. NEVER modify or remove safety devices.

ALWAYS keep hands away from all rotating parts

during operation.

Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening and mower pan at

all times. NEVER open the Rear Door without the

Grass Bag in place when the engine is operating.

ALWAYS keep feet and hands away from all rotating

parts during operation. Rotating parts can cut off body

parts.

DO NOT mow at too fast a rate. DO NOT change

engine governor setting or over-speed the engine.

ALWAYS operate unit when there is good visibility and

light.

Use extra care when approaching blind corners,

shrubs, trees, or other objects which may obscure

vision.

ALWAYS be sure of your footing.

Do not operate mower in wet grass. Always be sure of

your footing. Keep a firm hold on handlebar. Walk,

never run.

If equipment vibrates abnormally, stop engine at once,

wait for moving parts to stop and remove wire from

spark plug. Repair any damage before restarting unit.

Avoid uneven work areas and any rough terrain.

Be familiar with area of operation. Stay alert for holes,

rocks, roots, and hidden hazards in area of operation.

Operator could lose footing or balance.

DO NOT operate on steep slopes.

NEVER leave unit unattended on a slope. Chock

wheels if parking on a slope.

Mow across the face of slopes, never up and down. Be

especially cautious when changing direction on slopes.

Remove the key when parking.

Take all possible precautions when leaving unit

unattended.

ALWA YS shut off engine, remove key and remove

spark plug wire to prevent accidental starting or

unauthorized use.

2 - 5

Page 6

Fuel is highly flammable and its vapors can explode.

Use ONLY approved fuel containers.

NO Smoking!

NO Sparks!

NO Flames!

Allow engine to cool before servicing.

NEVER fill fuel tank when engine is running, hot, or unit

is indoors.

Abnormal Vibrations are a warning of trouble. Striking a

foreign object can damage unit. Stop unit and engine.

Wait for all moving parts to stop. Remove wire from

spark plug. Inspect unit and make any necessary

repairs before restart.

Hazardous Slopes

DO NOT operate on steep slopes. Avoid operating on

slopes. When you must operate on a slope, travel up

and down the slope. Never operate cross a slope.

Never operate on a slope greater than 10 degrees.

Child Safety

NEVER allow children to operate or play on or near

unit. Be alert and shut off unit if children enter area.

Personal Safety

Read and obey all warning, caution, and instr uc tions

on the unit and in provided manuals.

• Only trained adults may operate unit.

• Training includes actual operation.

• Clearly understa nd ins tr uc tio ns .

• Be alert! Conditions can change.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation requires

your complete and unimpaired attention at all times.

NEVER allow anyone to operate the unit when their

alertness or coordination is impaired.

Avoid Sharp Edges. Sharp edges can cut. Moving

parts can cut or amputate fingers or a hand. Wear

gloves to service unit when handling sharp edges.

ALWAYS keep hands away from any pinch points.

ALWAYS keep hands and feet away from all moving

parts during operation. Moving parts can cut off body

parts.

DO NOT touch unit parts which might be hot from

operation. Allow parts to cool before attempting to

maintain, adjust, or service.

Keep children out of work area and under the watchful

care of an adult.

NEVER allow children to operate mower.

Turn the mower off if children enter the area.

NEVER direct discharge toward bystanders. The

operator is responsible for the safety of bystanders.

Wear adequate safety gear, protective gloves and

footwear.

Wear sturdy footwear. DO NOT operate mower

barefoot or when wearing open sandals or canvas

shoes.

Always wear safety goggl es or safety gl asses with sid e

shields when operating mower.

NEVER wear loose clothing, jewelry or long hair that

may get caught in rotating parts. Protect eyes, face and

head from objects that may be thrown from unit.

ALWAYS stand clear of discharge when operating unit.

Do not operate mower on gravel or on loose material

such as sand. Stop mower when crossing gravel

drives, walks, or roads, Objects may be picked up and

thrown, causing damage or injury.

Fumes from the engine exhaust can cause death or

serious injury. DO NOT run engine in an enclosed

area.

Service and Adjustments

NEVER attempt to make any adjustments to unit while

engine is running. Stop engine, remove key,

disconnect spark plug wire and wait for all moving parts

to stop before servicing (except where specifically

recommended).

DO NOT make cutting height wheel adjustments while

the engine is running.

On self-propelled models, the wheel drive control will

cause the forward movement of the mower to stop. If

this feature fails to operate, disconnect ignition wire

and repair before using. Wheel drive must be

disengaged when starting engine.

Fuel is highly flammable and its vapors can explode.

ONLY use approved fuel containers.

• NO Smoking!

• NO Sparks!

• NO Flames!

• Allow engine to cool before filling fuel tank.

Check fuel supply before starting engine.

DO NOT fill gasoline tank indoors, when engine is

running, or while engine is still hot.

Allow engine to cool several minutes before removing

fuel cap.

Replace gasoline tank cap securely and clean up any

spilled fuel before starting engine.

Stop engine, wait for moving parts to stop, remove

ignition wire and secure away from spark plug before

attempting to: unclog, repair, adjust, inspect or clean

unit.

To reduce fire hazard and overheating, keep

equipment free of grass, leaves, debris or excessive

lubricants.

2 - 6

Page 7

Battery

Avoid Electric Shock. DO NOT remove wire from spark

plug while engine is running. Do not put battery in fire

or mutilate.

Explosive Gases! Poisonous battery fluid contains

sulfuric acid. Contact with skin, eyes or clothing can

cause severe chemical burns.

No flames, No Sparks, No smoking, near battery.

ALWAYS wear safety glasses and protective gear near

battery.

ALWAYS KEEP BATTERIES OUT OF REACH of

children.

Maintenance

Follow engine manufacturer’s safety instructions when

servicing engine.

Keep all nuts, bolts, and screws tight and be sure

equipment is in safe working condition. Check all

hardware at regular intervals, especially blade

attachment bolts.

Use only replacement parts designed for your unit. See

your Ariens Dealer.

Worn out mufflers are more than just a noise nuisance

and should be replaced immediately. Continued use

could result in fire or explosion.

ALWAYS block wheels and know all jack stands are

strong and secure and will hold weight of unit during

maintenance.

Check grass bag for wear, damage, and/or

deterioration. Replace only with Ariens original

equipment replacement part for safety.

Spark Arrestor

This product is equipped with an internal combustion

engine. DO NOT use on or near any unimproved,

forest or brush covered land unless the exhaust system

is equipped with a spark arrestor meeting applicable

local, state or federal laws. A spark arrestor, if used,

must be maintained in effective working order by the

operator. See your Ariens Dealer or engine

manufacturer’s service center.

Storage

Allow engine to cool before storing in any enclosure.

Refer to Storage Section of the Owner’s Manual for

important instructions if unit is to be stored for

extended periods.

ALWAYS clean unit before extended storage. See

engine manual for proper storage.

DO NOT store unit before extended storage. See

engine manual for proper storage.

DO NOT store unit inside a building with fuel in the fuel

tank where ignition sources are present.

Safety Interlock System

Engine/Blade Control feature on mower will cause

engine and blade to stop whenever operator releases

control on handlebar. If feature fails to operate,

disconnect spark plug wire a nd adjust or have it

repaired before using unit.

Accessories

Use only accessories which have been approved by

Ariens and are properly installed .

2 - 7

Page 8

SECTION 3 - SPECIFICATIONS

Model Number 911044 911045 911046 911047

Description Name LM214SP LM219SP LM217SP LM21SB

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Tecumseh Briggs Tecumseh Tecumseh

Four Four Four Four

5.555.55.5

1.5 (1.4) 1.6 (1.5) 1.5 (1.4) 1.5 (1.4)

Unleaded Unleaded Unleaded Unleaded

Standard Standard Standard Standard

N/AN/AN/AN/A

Recoil Recoil Recoil Recoil

Aluminum Aluminum Aluminum Aluminum

Standard N/A Standard N/A

2850+/-150 2900 2850+/-150 2900

27 (0.8) 20 (0.6) 27 (0.8) 27 (0.8)

Paper Element Paper Element Paper Element Paper Element

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

Standard Standard Standard Standard

0-3.5 (0-5.6) 0-3.5 (0-5.6) 0-3.5 (0-5.6) 0-3.5 (0-5.6)

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 6 Positions 6 Positions

1.2-3.5 (3.2-8.9) 1.2-3.5 (3.2-8.9) 1.2-3.5 (3.2-8.9) 1.2-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.5 (19.1) 7.5 (19.1) 7.5 (19.1) 7.5 (19.1)

10.5 (26.7) 10.5 (26.7) 10.5 (26.7) 10.5 (26.7)

Standard Standard Standard Standard

Standard Standard Standard Standard

With Kit With Kit With Kit With Kit

71102400 71102400 71102400 71102400

71 102700 71102700 71102700 71102700

71 102800 71102800 71102800 71102800

71102900 71102900 71102900 71102900

71103000 71103000 71103000 71103000

71103300 71103300 71103300 71103300

71103200 71103200 71103200 71103200

71103400 71103400 71103400 71103400

71103500 71103500 71103500 71103500

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

3 - 8

Page 9

Model Number 911048 911049 911050 911051

Description Name LM21SC LM21 LM21S LM21

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Briggs Tecumseh Tecumseh Tecumseh

Four Four Four Four

5555.5

1.6 (1.5) 1 (0.9) 1 (0.9) 1 .5 (1.4)

Unleaded Unleaded Unleaded Unleaded

Standard Standard Standard Standard

Recoil Recoil Recoil Recoil

Cast Iron Sleeve Aluminum A luminum Aluminum

N/AN/AN/AN/A

2850 2850 2850 2850

20 (0.6) 21 (0.6) 21 (0.6) 27 (0.8)

Dual Element Paper Element Paper Element Paper Element

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

Standard N/A Standard N/A

0-3.5 (0-5.6) N/A 0-3.5 (0-5.6) N/A

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 6 Positions 6 Positions

1.2-3.5 (3.2-8.9) 1.2-3.5 (3.2-8.9) 1.2-3.5 (3.2-8.9) 1.2-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.5 (19.1) 7.5 (19.1) 7.5 (19.1) 7.5 (19.1)

10.5 (26.7) 10.5 (26.7) 10.5 (26.7) 10.5 (26.7)

Standard Standard Standard Standard

Standard Standard Standard Standard

With KitWith KitWith KitWith Kit

71102400 71102400 71102400 N/A

71 102700 71102700 71102700 71102700

71 102800 71102800 71102800 71102800

71102900 71102900 71102900 71102900

71103300 71103300 71103300 71103300

71103200 71103200 71103200 71103200

71103400 71103400 71103400 71103400

71103500 71103500 71103500 71103500

14 Gauge Stamped

Steel

71103000 71103000 71103000

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

3 - 9

Page 10

Model Number 911052 911053 911054 911055

Description Name LM216S LM21C LM21 AP211 SP

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Tecumseh Briggs Briggs Tecumseh

Four Four Four Four

5.5 5.5 5.5 5.5

1.5 (1.4) 1.6 (1.5) 1 (0.9) 1.5 (1.4)

Unleaded Unleaded Unleaded Unleaded

Standard Standard N/A Standard

Recoil Recoil Recoil Recoil

Aluminum Cast Iron Sleeve Aluminum Aluminum

N/AN/AN/AN/A

2850 2900 3200 2850

27 (0.8) 20 (0.6) 20 (0.6) 21 (0.6)

Paper Element Dual Element Paper Element Paper Element

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

Standard N/A N/A Standard

0-3.5 (0-5.6) N/A N/A 0-3.5 (0-5.6)

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 6 Positions 6 Positions

1.2-3.5 (3.2-8.9) 1.2-3.5 (3.2-8.9) 1.2-3.5 (3.2-8.9) 1.2-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.5 (19.1) 7.5 (19.1) 7.5 (19.1) 7.5 (19.1)

10.5 (26.7) 10.5 (26.7) 10.5 (26.7) 10.5 (26.7)

Standard Standard Standard Standard

Standard Standard Standard Standard

With KitWith KitWith KitWith Kit

N/AN/AN/AN/A

71 102700 71102700 71102700 71102700

71 102800 71102800 71102800 71102800

71102900 71102900 N/A N/A

71103000 71103000 N/A N/A

71103300 71103300 N/A N/A

71103200 71103200 71103200 71103200

71103400 71103400 N/A N/A

71103500 71103500 N/A N/A

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

3 - 10

Page 11

Model Number 911056 911057 911058 911059

Description Name AP212 SP LM2178 SP AP 210 LM220 SP

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Tecumseh Briggs Tecumseh Tecumseh

Four Four Four Four

4.55 45.5

1.5 (1.4) 1.6 (1.5) 1.5 (1.4) 1.5 (1.4)

Unleaded Unleaded Unleaded Unleaded

Standard Standard Standard Standard

Recoil Recoil Recoil Recoil

Aluminum Cast Iron Sleeve Aluminum Cast Iron Sleeve

N/AN/AN/AN/A

2850 2900 3200 2850

21 (0.6) 20 (0.6) 21 (0.6) 27 (0.8)

Paper Element Dual Element Paper Element Dual Element

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

Standard Standard N/A Standard

0-3.5 (0-5.6) 0-3.5 (0-5.6) N/A 0-3.5 (0-5.6)

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 6 Positions 6 Positions

1.2-3.5 (3.2-8.9) 1.2-3.5 (3.2-8.9) 1.2-3.5 (3.2-8.9) 1.2-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.5 (19.1) 7.5 (19.1) 7.5 (19.1) 7.5 (19.1)

10.5 (26.7) 10.5 (26.7) 10.5 (26.7) 10.5 (26.7)

Standard Standard Standard Standard

Standard Standard Standard Standard

With KitWith KitWith KitWith Kit

N/A N/A N/A 71102400

71 102700 71102700 71102700 71102700

71 102800 N/A 71102800 71102800

N/A 71102900 N/A 71102900

N/A N/A N/A 71103000

N/A 71103300 N/A 71103300

71103200 71103200 71103200 71103200

N/A 71103400 N/A 71103400

N/A 71103500 N/A 71103500

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

3 - 11

Page 12

Model Number 911060 911061 911062 911064

Description Name LM221 LM222SP MM221SP MM210

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Tecumseh Tecumseh Tecumseh Tecumseh

Four Four Four Four

5.0 6.0 5.0 4.5

1.5 (1.4) 1.0 (0.9) 1.5 (1.4) 1.5 (1.4)

Unleaded Unleaded Unleaded Unleaded

Standard Standard Standard Standard

N/AN/AN/AN/A

Recoil Recoil Recoil Recoil

Aluminum Cast Iron Sleeve Aluminum Aluminum

Standard Standard Standard Standard

2850+/-150 2850+/-150 2850+/-150 2850+/-150

27 (0.8) 21 (0.62) 21 (0.62) 21 (0.62)

Paper Element Paper Element Paper Element Paper Element

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

N/A Standard Standard N/A

N/A 0-3.5 (0-5.6) 0-3.5 (0-5.6) N/A

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 6 Positions 6 Positions

1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.5 (19.1) 7.5 (19.1) 7.5 (19.1) 7.5 (19.1)

10.5 (26.7) 10.5 (26.7) 10.5 (26.7) 10.5 (26.7)

Standard Standard N/A N/A

Standard Standard Optional Optional

Standard Standard Standard Standard

N/A 71102400 71102400 N/A

* * 71 102700 71102700

71 102800 71102800 71102800 71102800

**N/AN/A

* * 71103000 71103000

71103300 71103300 71103300 71103300

71103200 71103200 71103200 71103200

71103400 71103400 71103400 71103400

71103500 71103500 * *

14 Gauge Stamped

Steel

16 Gauge Stamped

Steel

16 Gauge Stamped

Steel

3 - 12

Page 13

Model Number 911065 911067 911068 911069

Description Name LM230SP MM223 MM224SP DLM225SP

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Kawasaki Tecumseh Tecumseh Briggs & Stratton

Four Four Four Four

5.0 5.0 5.5 5.5

1.4 (1.3) 1.5 (1.4) 1.5 (1.4) 1.6 (1.5)

Unleaded Unleaded Unleaded Unleaded

N/A Standard Standard Standard

Standard N/A N/A N/A

Recoil Recoil Recoil Recoil

Cast Iron Sleeve Aluminum Aluminum Cast Iron Sleeve

Standard Standard Standard Standard

2850+/-150 2850+/-150 2850+/-150 2900+/-100

19 (0.56) 27 (0.8) 27 (0.8) 20 (0.6)

Dual Element Paper Element Paper Element Dual Clean

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

Standard N/A Standard Standard

0-4.0 (0-6.4) N/A 0-3.5 (0-5.6) 0-4 (0-6.4)

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 6 Positions 6 Positions

1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.0 (17.8) 7.5 (19.1) 7.5 (19.1) 7.5 (19.1)

10.0 (25.4) 10.5 (26.7) 10.5 (26.7) 10.5 (26.7)

Standard N/A N/A Standard

Standard Optional Optional Standard

Standard Standard Standard Standard

71102400 N/A 71102400 71102400

****

71 102800 71102800 71102800 71102800

*N/AN/A*

* 71103000 71103000 *

71103300 71103300 71103300 71103300

71103200 71103200 71103200 71103200

71103400 71103400 71103400 71103400

71103500 71103500 71103500 71103500

16 Gauge Stamped

Steel

16 Gauge Stamped

Steel

14 Gauge Stamped

Steel

3 - 13

Page 14

Model Number 911070 911071 911072 911073

Description Name DLM226SP DLM227SP DLM228SP DLM229SP

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Briggs & Stratton Tecumseh Tecumseh Tecumseh

Four Four Four Four

5.5 6.0 6.0 6.0

1.6 (1.5) 1.5 (1.4) 1.5 (1.4) 1.5 (1.4)

Unleaded Unleaded Unleaded Unleaded

Standard Standard Standard Standard

N/AN/AN/AN/A

Recoil Electric/Recoil Recoil Recoil

Cast Iron Sleeve Aluminum A luminum Aluminum

Standard Standard Standard Standard

2900+/-100 2850+/-150 2850+/-150 2850+/-150

20 (0.6) 27 (0.8) 27 (0.8) 27 (0.8)

Dual Element Paper Element Paper Element Paper Element

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

Standard Standard Standard Standard

0-4.0 (0-6.4) 0-4.0 (0-6.4) 0-4 (0-6.4)) 0-4 (0-6.4)

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 6 Positions 6 Positions

1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.0 (17.8) 7.5 (19.1) 7.5 (19.1) 7.5 (19.1)

10.0 (25.4) 10.5 (26.7) 10.5 (26.7) 10.5 (26.7)

Standard Standard Standard Standard

Standard Standard Standard Standard

Standard Standard Standard Standard

N/A N/A 71102400 N /A

****

71 102800 71102800 71102800 71102800

****

****

* * 71103300 *

71103200 71103200 71103200 71103200

71103400 71103400 71103400 71103400

71103500 71103500 71103500 71103500

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

3 - 14

Page 15

Model Number 911075 911076 911077 911078

Description Name DLM21SEW DLM21SEW

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Tecumseh Tecumseh Tecumseh Tecumseh

Four Four Four Four

6.0 5.5 5.5 6.0

1.5 (1.4) 1.5 (1.4) 1.5 (1.4) 1.5 (1.4)

Unleaded Unleaded Unleaded Unleaded

Standard Standard Standard Standard

N/AN/AN/AN/A

Electric/Recoil Recoil Electric/Recoil Electric/Recoil

Aluminum Aluminum Aluminum Aluminum

Standard Standard Standard Standard

2850+/-150 2850+/-150 2850+/-150 2850+/-150

27 (0.8) 27 (0.8) 27 (0.8) 27 (0.8)

Paper Element Paper Element Paper Element Paper Element

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

Standard Standard Standard Standard

0-4 (0-6.4) 0-3.5 (0-5.6) 0-3.5 (0-5.6) 0-4 (0-6.4)

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 6 Positions 6 Positions

1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.5 (19.1) 7.0 (17.8) 7.5 (19.1) 7.5 (19.1)

10.5 (26.7) 10.0 (25.4) 10.5 (26.7) 10.5 (26.7)

Standard Standard Standard Standard

Standard Standard Standard Standard

Standard With Kit With Kit Standard

N/A 71102400 71102400 N/A

* 71 102700 71102700 *

71 102800 71102800 71102800 71102800

* 71102900 71102900 *

* 71103000 71103000 *

* 71103300 71103300 *

71103200 71103200 71103200 71103200

71103400 71103400 71103400 71103400

71103500 71103500 71103500 71103500

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

3 - 15

Page 16

Model Number 911079 911080 911081 911082

Description Name DLM21S DLM21SW SLM21 SLM21S

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Tecumseh Tecumseh Tecumseh Tecumseh

Four Four Four Four

6.0 6.0 5.0 5.5

1.5 (1.4) 1.5 (1.4) 1.5 (1.4) 1.5 (1.4)

Unleaded Unleaded Unleaded Unleaded

Standard Standard Standard Standard

N/AN/AN/AN/A

Recoil Recoil Recoil Recoil

Aluminum Aluminum Aluminum Aluminum

Standard Standard Standard Standard

2800+/-200 2800+/-200 3150+/-200 3150+/-200

27 (0.8) 27 (0.8) 27 (0.8) 27 (0.8)

Paper Element Paper Element Paper Element Paper Element

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

Standard Standard N/A Standard

0-4 (0-6.4) 0-4 (0-6.4) N/A 0-3.5 (0-5.6)

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 6 Positions 6 Positions

1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.5 (19.1) 7.0 (17.8) 7.5 (19.1) 7.5 (19.1)

10.5 (26.7) 10.0 (25.4) 10.5 (26.7) 10.5 (26.7)

Standard Standard N/A N/A

Standard Standard Standard Standard

Standard Standard Standard With Kit

71102400 N/A N/A 71102400

****

71 102800 71102800 71102800 71102800

**N/AN/A

****

71103300 * 71103300 71103300

71103200 71103200 71103200 71103200

71103400 71103400 71103400 71103400

71103500 71103500 71103500 71103500

14 Gauge Stamped

Steel

16 Gauge Stamped

Steel

16 Gauge Stamped

Steel

3 - 16

Page 17

Model Number 911083 911084 911304 911311

Description Name DLM21C DLM21SC LM21 LM21S

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Robin Robin Briggs & Stratton Briggs & Stratton

Four Four Four Four

6.0 6.0 5.0 5.0

1.5 (1.4) 1.5 (1.4) 1.5 (1.4) 1.5 (1.4)

Unleaded Unleaded Unleaded Unleaded

N/AN/AN/AN/A

Standard Standard Standard Standard

Recoil Recoil Recoil Recoil

Cast Iron Sleeve Cast Iron Sleeve Aluminum Aluminum

Standard Standard Standard Standard

2850+/-150 2850+/-150 2900+/-100 2900+/-100

17 (0.5) 17 (0.5) 20 (0.6) 20 (0.6)

Dual Element Dual Element Paper Element Paper Element

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

N/A Standard N/A Standard

N/A 0-4 (0-6.4) 0-4 (0-6.4) 0-4 (0-6.4)

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 6 Positions 6 Positions

1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.0 (17.8) 7.0 (17.8) 7.5 (19.1) 7.5 (19.1)

10.0 (25.4) 10.0 (25.4) 10.5 (26.7) 10.5 (26.7)

Standard Standard Standard Standard

Standard Standard Standard Standard

Standard Standard With Kit With Kit

N/A 71102400 N/A 71102400

* * 71 102700 71102700

71 102800 71102800 71102800 71102800

****

****

71103300 71103300 71103300 71103300

71103200 71103200 71103200 71103200

71103400 71103400 71103400 71103400

71103500 71103500 71103500 71103500

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

3 - 17

Page 18

Model Number 911463 911467 911468 911469

Description Name DLM239 SLM237 SLM238SP DLM232SP

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Robin Tecumseh Tecumseh Briggs & Stratton

Four Four Four Four

6.0 5.0 5.5 5.5

1.5 (1.4) 1.5 (1.4) 1.5 (1.4) 1.6 (1.5)

Unleaded Unleaded Unleaded Unleaded

N/A Standard Standard Standard

Standard N/A N/A N/A

Recoil Recoil Recoil Recoil

Cast Iron Sleeve Aluminum Aluminum Cast Iron Sleeve

Standard Standard Standard Standard

2900+/-100 3200+/-150 3200+/-150 2900+/-100

17 (0.5) 27 (0.8) 27 (0.8) 20 (0.6)

Dual Element Paper Element Paper Element Dual Clean

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

N/A N/A Standard Standard

N/A N/A 0-3.5 (0-5.6) 0-4 (0-6.4)

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 6 Positions 6 Positions

1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.0 (17.8) 7.5 (19.1) 7.5 (19.1) 7.5 (19.1)

10.0 (25.4) 10.5 (26.7) 10.5 (26.7) 10.5 (26.7)

Standard N/A N/A Standard

Standard Standard Standard Standard

Standard Standard Standard Standard

N/A N/A 71102400 71102400

****

71 102800 71102800 71102800 71102800

*N/AN/A*

****

71103300 71103300 71103300 71103300

71103200 71103200 71103200 71103200

71103400 71103400 71103400 71103400

71103500 71103500 71103500 71103500

16 Gauge Stamped

Steel

16 Gauge Stamped

Steel

14 Gauge Stamped

Steel

3 - 18

Page 19

Model Number 911475 911509 911511 911513

Description Name DLM240SP LM21SCH LM21SC LM21

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Robin Robin Robin Briggs & Stratton

Four Four Four Four

6.0 5.4 5.3 4.37

1.5 (1.4) 2.0 (1.9) 2 (1.9) 22 oz. (0.65)

Unleaded Unleaded Unleaded Unleaded

N/A N/A N/A Standard

Standard Standard Standard N/A

Recoil Recoil Recoil Recoil

Cast Iron Sleeve Aluminum Cast Iron Sleeve Aluminum

Standard Splash Pressurized Splash

2900+/-100 3000+/-100 3000+/-100 3000+/-100

27 (0.8) 17 (0.5) 17 (0.5) 22 (0.65)

Dual Element Dual Element Dual Element Paper Element

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

Standard Standard Standard N/A

0-4 (0-6.4) 1.55, 2.98, 3.8

(2.48, 4.77, 6.08)

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 1.25-3.5 6 Positions 6 Positions

1.25-3.5 (3.2-8.9) 1-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.0 (17.8) 8 (20.3) 7.5 (19.1) 7.5 (19.1)

10.0 (25.4) 8 (20.3) 10.5 (26.7) 10.5 (26.7)

Standard Standard Standard Standard

Standard Standard Standard Standard

Standard Standard Standard Standard

71102400 71102400 71102400 71102400

* 71 102700 * *

71 102800 71103700 71102800 71102800

****

****

71103300 71104000 71103300 71103300

71103200 71103200 71103200 71103200

71103400 71103400 71103400 71103400

71103500 71103500 71103500 71103500

14 Gauge Stamped

Steel

0-3.5 (0-5.6) N/A

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

3 - 19

Page 20

Model Number 911514 911515 911516 911517

Description Name LM21S LM21SE LM21SW LM21SC

Engine Manufacture

Cycles

HP (3600RPM)

Fuel Tank Capacity - qt (L)

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Capacity - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug Gap

Differential

Variable Speeds-MPH (KPH)

Mower Deck Gauge

Baked Powder Paint

Cutting Width - in (cm)

Cutting Height - in (cm)

Folding Handlebar

Adjustable Handlebar

Front Wheel Diameter - in (cm)

Rear Wheel Diameter - in (cm)

Side Discharge

Bagger

Mulching Capability

Attachments (* denotes it comes with unit)

Dethatcher

Mulchmaster Package

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Kit

Briggs & Stratton Briggs & Stratton Briggs & Stratton Robin

Four Four Four Four

4.37 4.37 4.37 5.3

22 oz. (0.65) 22 oz (0.65) 22 oz (0.65) 2 (1.9)

Unleaded Unleaded Unleaded Unleaded

Standard Standard Standard N/A

N/A N/A N/A Standard

Recoil Electric/Recoil Recoil Recoil

Aluminum Aluminum Aluminum Cast Iron Sleeve

Splash Splash Splash Pressurized

3000+/-100 3000+/-100 3000+/-100 3000+/-100

22 (0.65) 22 (0.65) 22 (0.65) 17 (0.5)

Paper Element Paper Element Paper Element Dual Element

SAE 30 SAE 30 SAE 30 SAE 30

0.03 0.03 0.03 0.03

Standard Standard N/A Standard

0-4 (0-6.4) 0-4 (0-6.4) N/A 0-3.5 (0-5.6)

14 Gauge Stamped

Steel

Standard Standard Standard Standard

21 (53.3) 21 (53.3) 21 (53.3) 21 (53.3)

6 Positions 6 Positions 6 Positions 6 Positions

1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9) 1.25-3.5 (3.2-8.9)

Standard One Piece Standard One Piece Standard One Piece Standard One Piece

4 Position 4 Position 4 Position 4 Position

7.5 (19.1) 7.0 (17.8) 7.5 (19.1) 7.5 (19.1)

10.5 (26.7) 10.0 (25.4) 10.5 (26.7) 10.5 (26.7)

Standard Standard Standard Standard

Standard Standard Standard Standard

Standard Standard Standard Standard

71102400 71102400 N/A 71102400

* * * 71 102700

71 102800 71102800 71102800 71102800

****

****

71103300 71103300 * 71103300

71103200 71103200 71103200 71103200

71103400 71103400 71103400 71103400

71103500 71103500 71103500 71103500

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

14 Gauge Stamped

Steel

3 - 20

Page 21

SECTION 4 - GENERAL MAINTENANCE & ADJUSTMENTS

4.1 CONTROLS AND FEATURES

12

3

11

1

2

14

8

10

13

1. Engine Control

2. Ignition Switch (Electric Start

Models)

3. Speed Selector (Self-propelled)

4. Primer (Briggs Engine)

5. Side Discharge Cover

6. Side Discharge Deflector

16

7

9

15

7

4

6

5

7. Cutting Height Levers (2 Rear

Wheel Adjusters, 2 Front Wheel

Adjusters

8. Rear Door

9. Adjustable and Folding

Handlebars

10.Grass Bag

11.Recoil

12.Wheel Drive Control

13.Mulchmaster™ Plug

14.Throttle Control (Robin Engines)

15.Handlebar Adjustment Holes

16.Speed Indicator (Self-propelled)

Figure 2

4 - 21

OM0032

Page 22

4.2 SERVICE POSITIONS

Place unit on a flat level surface. ALW AYS stop engine.

Assure unit is secure and will not tip over. Strap and

clamp onto bench if needed.

A handlebar service position is provided for tipping the

unit for cleaning and service (Figure 3). See

Adjustments

IMPORTANT:

use the following service positions for the brand and

type of engine on your mower:

Tecumseh & Robin Engines:

service position and tip machine to the rear.

Briggs & Stratton Intek Engines:

into handlebar service position and tip the machine to

the left, opposite the discharge opening.

Kawasaki:

unit to right.

IMPORTANT:

tipping, clean air cleaner and remove spark plug, put

one teaspoon of oil in cylinder, turn engine over a few

times and reinstall spark plug.

.

Figure 3

WARNING:

UP can cause death or serious injury.

ALWAYS stop engine, remove key, wait for

moving parts to stop and remove wire from

spark plug before adjusting or servicing.

CAUTION:

or moderate injury and/or damage to the unit.

Before unit is tipped up onto housing, remove

enough fuel so that no spillage will occur.

Remove battery to prevent spillage of

electrolyte.

Place handlebar in service position and tip

ACCIDENTAL ENGINE START

FUEL SPILLS may result in minor

When tipping to service engine or unit,

Place handlebar into

Place handlebar

If engine becomes "flooded" due to

OM0210

4.3 FILLING THE FUEL TANK

WARNING: EXPLOSIVE VAPORS

FLAMMABLE FUEL

serious injury. Handle fuel with care.

ALWAYS use an approved fuel container.

No Smoking! No lighted Materials!

No Open Flame!

Allow engine to cool before maintenance.

Gasoline is highly flammable and must be

handled with care. Allow engine to cool

several minutes before removing fuel tank

cap. Never fill tank when engine is running or

is hot from operation. DO NOT allow open

flame, matches, or smoking in area. DO NOT

overfill. Allow about 1/4" of tank space for fuel

expansion. Wipe up any spills and allow

vapors to dissipate before starting engine.

Use approved gasoline container.

To add fuel to fuel tank:

1. Put unit in open or well-ventilated area.

2. Stop engine and allow to cool.

3. Clean fuel cap and surrounding area to prevent

dust, dirt and debris from entering fuel tank.

4. Remove cap.

IMPORTANT:

containing alcohol because alcohol will cause internal

parts to deteriorate. See Engine Manual for correct

type and grade of fuel.

5. Fill fuel tank. (See

6. Replace fuel cap and tighten.

ALWAYS

7.

DO NOT use gasohol or gasoline

Specifications

clean up any spilled fuel.

can result in death or

for tank capacity.)

and its

4.4 GENERAL LUBRICATION

Swivel Lubrication

See Figure 4.

Sten Mix

Apply

lube fittings. Order P/N: 00036800 - 3 pack of 3 oz.

cartridges.

When using Sten Mix Grease for the first time, all

components should be thoroughly cleaned prior to

lubricating.

Hi-Temp Grease or equivalent to the

Commercial Models

Grease fittings on rear axle housing every 25 hours.

(swivel units)

4 - 22

Page 23

2

1

1. Grease Fitting

2. Swivel Lock Hole

Figure 4

OM0210

4.5 CHECK MOWER BLADE

See Figures 5 and 6.

Regularly check mower blades for wear and that lock

washer is fully compressed by cap screw (requires

25-30 ft-lbs (33-40 Nm) of torque on cap screw).

When blade needs sharpening:

1. Block blade to prevent rotation.

2. Remove cap screw, lock washer and blade from

shaft.

3. Sharpen both ends of blade at original angle (25

removing equal amounts of material from each end

to maintain proper blade balance. New blades are

balanced to within 1.3 in. oz. at factory. DO NOT

grind around corner at tip of blade. If cutting edge

of blade cannot be sharpened in a straight line to

within 1/8 of an inch of its end, replace blade with

Ariens replacement blade only.

4. Install blade, lock washer and tighten cap screw

25-30 ft-lbs (33-40 Nm) until lock washer is fully

compressed.

IMPORTANT: If mower is used under sandy soil

conditions, replace blades when air lifts become

eroded.

5

4

3

1

OM0230

OM0240

3

1. Cutting Edge

2. Square Corner

3. Air Lift Erosion

2

4

2

1

4. Air Lift

5. Reverse Lift

Figure 5

4.6 CHECK DRIVE BELT

1

o

),

4

3

1. Blade

2. Cap Screw, Lock

Washer & Flat Washer

3. Drive Belt

4. Idler

Figure 6

2

OM0250

Check drive belt for wear or damage. Replace belt if

worn or damaged.

4.7 CHECK ENGINE/BLADE CONTROL

The engine/blade control must stop the engine and

blade within 3 seconds after the bail is released. If the

engine or blade continues to run, adjust or repair

control immediately.

Engine control must stop engine ignition, at 3/4" to

1-1/4" from handlebar as control is released.

4 - 23

Page 24

To check (Figure 7):

1. Start engine and slowly release control until engine

stops firing.

2. Measure distance between handlebar and control

at the point that engine stopped firing.

3. Turn cable nuts at handlebar mount clockwise if

measurement is more than 1-1/4" or counterclockwise if measurement is less than 3/4".

4. Turn nuts against mount to lock in position.

5

S Hook on

Some Models

4

3

1

2

1

2

1. Engine Control

2. Handlebar

4

3. Cable Nuts

4. Mount

3

Figure 7

3

1

1-1/8" to 1-5/16"

1. Cable Nuts

2. Bracket

3. Spring

2

Figure 8

There must not be slack in cable.

To check, rotate blade in it’s cutting direction (this

draws control rod fully in).

To eliminate slack in cable, turn nuts on cable at

handlebar clockwise.

OM0280

1. Cable Nuts

2. Bracket

3. Spring

4. Spring or "S" Hook

5. Control Rod

Figure 9

4.8 CHECK GRASS BAG

Check bag for wear or damage. Keep bag clean and

dry. Replace only with Ariens original equipment

replacement bag.

4.9 CHECK DRIVE CONTROL

Check operation of drive control. The drive must

disengage completely when the bail handle is

released. Adjust bail travel if necessary. See Figure 10.

When the wheel drive control is squeezed toward the

handlebar, the extension spring, located at the bottom

end of the traction cable, must start to extend when the

control is between 1-1/2" and 2" (3.8 and 5 cm) away

from the handlebar. To check:

1. Squeeze the wheel drive control toward the

handlebar until the spring starts to open.

2. Measure the distance between the wheel drive

control and handlebar at the handlebar indentation.

3. To obtain the proper adjustment, turn the cable

nuts. Turn clockwise if the measurement is more

than 2"; counterclockwise if the measurement is

less than 1-1/2". Tighten the nuts against the

bracket to lock in position. If there is not enough

thread length for adjustment, the opposite end of

the cable can be adjusted.

Three Speed Drive Control

When the wheel drive control bail is squeezed toward

the handlebar, the extension spring must start to

extend when the control bail is between 3-7/8" to 4-1/8"

away from the handlebar. The extension spring is

located at the bottom end of the traction control cable.

4 - 24

Page 25

To check the control cable spring:

Figure 1 1

1. Hole No. 1

2. Hole No. 2

3. Hole No. 3

4. Hole No. 4

5. Handlebar Stud

6. Handlebar Adjustment

Link

7. Professional Bracket

8. Storage Position

OM0271

1

2

3

4

5

6

8

1

2

3

4

7

1. Squeeze the wheel drive control bail towards the

handlebar until the spring starts to open.

2. Measure the distance between the wheel drive bail

to the handlebar indentation.

3. To obtain the proper adjustments turn the control

cable nuts at the handlebar or the bottom of the

control cable anchor against the anchor supports.

2

4

3

1

1. Traction Cable

2. Handlebar

Indentation

3. Cable Nuts

4. Wheel Drive Control

Figure 10

4.10 HANDLEBAR ADJUSTMENT

Holes in handlebar braces provide four height

positions, a service position, and a storage position

(except on profession al mod els ).

Use one of the four holes to adjust handlebar height to

a safe, comfortable position. Place bolt on handlebar

bracket through one of holes 1, 2, 3 or 4 in order of

increasing height (See Figure 11).

NOTE:

On Professional models nuts and bolts replace

pins.

For storage, rotate handlebar forward and place pins

through holes further up braces.

4.11 SPEED CONTROL BELL CRANK

The speed control bell crank holds the speed selector

rod in position after a speed has been set. The spring

washers may become loose with normal wear. If the

speed selector rod does not stay firmly in position,

adjust the speed control bell crank. See Figure 12.

To adjust:

1. Remove cover, fu lly compress the helical spring

lockwashers with lock nut and then back lock nut

off, one half turn.

2. If the speed selector rod is still too loose, tighten

lock nut by small increments until it holds its

position. Tightening the lock nut too much will not

allow the speed selector rod to move at all.

3. Align notch in left hand side of cover with bolt and

secure with knob.

4 - 25

Page 26

1

2

4

3

5

1. Lock Nut

2. Helical Spring

Lockwashers

3. Speed Control Bell

Crank

4. Speed Selector Rod

5. Hair Pin

6. Swivel

Figure 12

6

OM0300

4.12 FRICTION WHEEL ADJUSTMENT

Early Models (Side Pull)

Adjust rear cutting height levers to middle position.

Check to be sure there is slack in the friction wheel

drive cable, if not readjust cable nuts.

Set speed selector at slowest speed and loosen the

two cap screws on drive mount. Hold lever securing

drive cable down toward mower pan and adjust drive

assembly to bring friction wheel to within 1/16" above

drive disk. Tighten cap screws. Check for proper

function of friction wheel and speed selector. Adjust

cable nuts to remove slack.

5

5

3

4

1. Cable Nuts

2. Drive Mount

3. Adjustment Screws

6

4

4. Drive Disk

5. Friction Wheel

6. Battery

Figure 13

1

2

3

2

4 - 26

Page 27

SECTION 5 - ENGINE

5.1 ENGINE TROUBLESHOOTING

The following troubleshooting chart is to be used to

isolate engine problems and give possible causes and

corrective action responses.

The troubleshooting key is generic and can be used for

several types of engines. Use only those possible

causes and corrective actions that apply to the

unit.

TROUBLE POSSIBLE CAUSES

CORRECTIVE ACTION

(Refer to Key Below)

Black Exhaust 1, 20, 22, 25, 29, 31, 32, 33 repair or replace

Blue/White Exhaust 4, 20, 25, 31, 33, 34 repair or replace

Difficult Starting 1, 5, 7, 8, 9, 10, 20, 21, 22, 29, 31, 32, 33 repair or replace

Erratic Running 1, 7, 8, 9, 10, 20, 21, 23, 26, 29, 33, 59, 62 repair or replace

Excessive Fuel Consumption 1, 20, 22, 23, 25, 39, 31, 32, 33 repair or replace

High Oil Pressure 4, 41 repair or replace

Knocking 22, 26, 29, 31, 33, 36, 46, 59 repair or replace

Loss of Power or System 1, 8, 10, 20, 21, 22, 23, 25, 26, 31, 32, 33 repair or replace

Low Cranking Power 2, 3, 4, 11 repair or replace

Low Oil Pressure 4, 36, 37, 39 repair or replace

Misfiring 10, 20, 25, 26, 28, 29, 32 repair or replace

Overheating 1, 19, 25, repair or replace

Poor Compression 25, 28, 29, 31, 32, 33, 34,59, repair or replace

Starts and Stops 1, 6, 10, 62 repair or replace

see electrical systems

see engine service manual

Vibration 20, 23, 25, 26, 29, 33, 45, 49 repair or replace

Will Not Crank 2, 11, 45 charge battery or replace

Will Not Start 1, 10, 62 repair or replace

see electrical systems

see engine service manual

TROUBLESHOOTING KEY

1 Restriction in air cleaner 2 2 Incorrec t grade of fuel 43 Faulty suction pipe

2 Bad electrical connection 23 Sticking throttle/restricted movement 44 Choked oil filter

3 Faulty starter motor 24 Exhaust pipe restriction 45 Bad solenoid switch

4 Incorrect grade of lubricating oil 25 Leaking cylinder head gasket 46 Incorrect piston height

5 Low cranking speed 26 Overheating 47 Damaged fan

6 Fuel tank empty 27 Cold running 48 Faulty engine mounting

7 Controls not in correct operation

position

8 Blocked fuel feed line 29 Sticking valves 50 Faulty thermostat

9 Faulty fuel lift pump 30 Incorrect high pressure pipes 51 Restriction in water jacket

10 Choked fuel filter 31 Worn cylinder bores 52 Loose fan belt

11 Battery capacity low 32 Pitted valves and seats 53 Choked radiator

12 Air in fuel system 33 Broken, worn or sticking piston ring(s) 54 Faulty water pump

13 Faulty fuel injection pump 34 Worn valve stems and guides 55 Choked breather pipe

14 Faulty fuel injectors or incorrect

type

15 Incorrect use of cold start

equipment

16 Faulty cold start equipment 37 Insufficient oil in sump 58 Blocked sump strainer

17 Broken fuel injection pump drive 38 Bad/defective oil temperature switch 59 Broken valve spring

18 Incorrect fuel pump timing 3 9 Oil pump worn 60 Exh aust or vacuum pipe leak

19 Incorrect valve timing 40 Pressure relief valve sticking open 61 Bad or defective water temperature

20 Poor compression 41 Pressure relief valve sticking closed 62 Bad spark plug(s)

21 Blocked fuel tank vent 42 Broken relief valve spring

28 Incorrect tappet adjustment 49 Incorrectly aligned flywheel and/or

flywheel housing

35 Restriction in air cleaner 56 Damaged valve stem oil deflector (if

fitted)

36 Worn or damaged bearings 57 Coolant level too low

switch

5 - 27

Page 28

5.2 ENGINE SERVICE LOCATIONS

1

4

Tecumseh Engine

4

5

2

1

2

3

3

Briggs & Stratton

Professional Engine

1

2

2 Cycle Briggs Engine

1

4

2

Kawasaki Engine

1

2

4

4

6

3

Briggs & Stratton Intek OHV

OM0570

3

OM0550

Robin Engine

1. Oil Fill Cap and Dipstick

2. Air Cleaner

3. Spark Plug and Wire

4. Fuel Cap and Tank

Figure 14

5 - 28

5. Primer

6. Filter

Page 29

5.3 ENGINE OIL

IMPORTANT:

two (2) hours of operation. Thereafter, change oil every

twenty five hours of operation (more often in dusty dirty

conditions). Refer to Engine Manual for oil type and

grade and detailed instructions.

Engine Oil Check and Change

The engine crankcase oil should be checked daily or

every five (5) hours of operation. Oil level MUST be

maintained in safe operating range on dipstick at all

times or engine damage will result.

IMPORTANT:

when adding oil.

See Engine Manual for detailed instructions.

Change engine crankcase oil after first

DO NOT overfill. Be sure engine is level

5.4 AIR CLEANER

Inspect air cleaner every twenty five hours of operation

or every three months, whichever comes first.

When dirty, foam filter elements should be removed

and cleaned. Refer to the following instructions.

NOTE:

under dirty, dusty conditions.

Foam Filter Element

elements in warm water and detergent. Rinse

thoroughly until all traces of detergent are eliminated.

Squeeze (don’t wring) away excess water and air dry.

Soak foam element in clean, fresh oil, wrap in paper

towel or rag, and squeeze out excess oil.

Cartridge -

dirty or becomes distorted.

NOTE:

Inspect air cleaner more often if unit is used

- (Pre Cleaner) - Wash foam

Paper cartridge is to be replaced when it is

DO NOT attempt to clean paper elements.

5 - 29

Page 30

4

Briggs & Stratton

Air Cleaner

1

5

1

2

4

1

Briggs & Stratton Professional Air Cleaner

1

2

4

2

7

5

4

Robin Air Cleaner

1

2

3

5

6

7

5

Tecumseh Air Cleaner

1

4

1. Cover

2. Foam Filter Element (Pre-Cleaner)

3. Felt Filter Element

4. Cartridge

5. Body

6. Base Plate Gasket

7. Base Plate

Figure 15

5 - 30

5

Briggs & Stratton

Air Cleaner

Page 31

5.5 ENGINE COOLING

Figure 17

The engine is air cooled. Air must circulate freely

around engine and over cooling fins on cylinder head

and block to prevent overheating.

Once a year or every one hundred (100) operating

hours (more if conditions require) clean engine fins and

external surfaces of engine of dust, dirt, and oil

deposits which can contribute to improper cooling.

Keep Areas within Heavy Line Clean of all Debris

(Figure 16).

CAUTION:

manifold areas to remove all grass, dirt and all

combustible debris. If engine muffler is

equipped with spark arrester screen

assembly, remove every 50 hours for cleaning

and inspection.

Keep Areas Within Heavy Line Clear of all Debris

Periodically clean muffler and

Figure 16

5.6 SPARK PLUG

Spark plug should be cleaned or replaced and gap

reset to .030" every 100 hours of operation or yearly

whichever comes first.

To clean, remove debris from area around spark plug

base. Remove spark plug from engine. Scrape and

wash with a commercial solvent. DO NOT blast clean.

NOTE:

firmly on spark plug. Reform terminal if necessary.

Sparking can occur if wire terminal does not fit

5.7 BATTERY (ELECTRIC START MODEL)

CAUTION:

mutilate; battery may burst or release toxic

materials. Do not short circuit; battery may

cause burns.

A 12 volt, 2.5 ampere hour sealed lead acid battery is

supplied with unit. Engine alternator will normally keep

battery fully charged with a 3 to 5 minute start/run

cycle.

IMPORTANT:

attempt to "jump start" mower.

If battery discharges, use a 5 to 10 minute start/run

cycle to recharge battery, or use a battery charger (a