Page 1

cT^tiens

A SAFETY MESSAGE A

The product for which you have requested

information or replacement parts is not a current

product. The replacement models incorporate

product designs, safety features, safety

instructions or warnings which represent the latest

“State Of The Art” developments. For your safety

and those around you please contact your nearest

Ariens/Gravely Dealer for a demonstration of the

current product safety provisions and features.

Series

Walk Behind

Lawn Mowers

Owner’s

Manual

PRINTED IN USA

PART NO. 011670J

1-96

Page 2

A Message to Ariens Customers...

Welcome to the world of Ariens equipment. We are

pleased that you have selected Ariens and sincerely

believe you have purchased the best equipment

available. The care you give your new Ariens

equipment will determine the satisfaction and service

life you will obtain from it. Use this manual and the

engine manual supplied as your guide. By observing

the instructions and suggestions in these manuals,

your Ariens equipment will serve you well for many

years.

Your Ariens dealer will be happy to supply any

service or advice which may be required to keep your

Ariens equipment operating at peak efficiency. He

stocks genuine Ariens parts and lubricants,

manufactured with the same precision and skill as the

original equipment. His trained staff is kept well

informed on the best methods of servicing Ariens

equipment and is ready and able to serve you. If

Safety Alert Symbol and Notations

engine repairs or services are required, they can be

obtained from an Ariens dealer or from an authorized

engine manufacturer’s service center. If service is

required, be prepared to supply the service person

with the Model Number and Serial Number of the

equipment and engine, as well as a full description of

the problem encountered.

NOTE: The descriptions and specifications contained

in this manual were in effect at the time the manual

was approved for printing. Ariens Company reserves

the right to discontinue models without notice and

without incurring obligation. The equipment described

within this manual may not be identified as either

standard or optional and the various illustrations may

not all be applicable to your particular unit. If you

have questions, always check with your Ariens

dealer.

The following safety notations are used throughout

this manual to call attention to special information or

operating procedures. Understand the message in

each notation and be alert to unsafe conditions and

the possibility of personal injury.

NOTE: A NOTE points out general reference

information regarding proper operation and

maintenance practices.

IMPORTANT: An IMPORTANT statement indicates

specific procedures or information that is required to

prevent damage to the machine or its attachments.

This safety alert symbol is used to

attract your attention! PERSONAL

A

SAFETY — IS INVOLVED! When you see

this symbol -BECOME ALERT - HEED

ITS MESSAGE.

A

A

A

DANGER: Indicates an imminentiy

hazardous situation that, if not avoided,

wiii resuit in death or serious injury.

WARNiNG: indicates a potentiaiiy

hazardous situation that, if not avoided,

couid resuit in death or serious injury.

CAUTION: indicates a potentiaiiy

hazardous situation that, if not avoided,

may resuit in minor moderate injury.

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects or

other reproductive harm.

OL0010

Page 3

Contents

Models

Safety Alert and Notations

Safety Precautions................................................................... 3

Safety Decals...............................................................................5

Controls and Features

Operation.....................................................................................7

Lubrication and Maintenance............................................12

Adjustments.............................................................................21

Storage ......................................................................................23

Service Manual

Troubleshooting......................................................................24

Specifications

Dealer Preparation

Accessories................................................................................34

Warranty

Specific Model and Serial Numbers are on a label

located on the frame of your mower and on a label

located on the product registration form. Record and

transfer the label from the product registration to

place indicated below. Use these numbers whenever

parts or service is required.

.......................................................................

...........................................................................

................................................................

...................................................................................

Model Number.

Serial Number.

....................................................

.............................................................

TRANSFER

MODEL SERIAL

LABEL FROM

PRODUCT

REGISTRATION

i

6

24

25

31

35

Model 911065 (LM230sp)

4 Cycle,Kawasaki 5 HP

Recoil, Self-Propelled

Serial Number 000101 and up

Model 911067 (MM223)

4 Cycle, Tecumseh Centura 5 HP

Recoil, Push

Serial Number 000101 and up

Model 911068 (MM224sp)

4 Cycle, Tecumseh Centura 5.5 HP

Recoil, Self Propelled

Serial Number 000101 and up

Model 911069 (LM225SP)

4 Cycle,Briggs & Stratton Diamond Plus 5.5 HP

Recoil, Self Propelled

Serial Number 000101 and up

Model 911070 (LM226SP) - Swivel

4 Cycle,Briggs & Stratton Diamond Plus 5.5 HP

Recoil, Self-Propelled

Serial Number 000101 and up

Model 911071 (LM227SP) - Swivel

4 Cycle,Tecumseh Vector 6 HP

Electric Start, Self Propelled

Serial Number 000101 and up

Model 911072 (LM228SP)

4 Cycle, Tecumseh Vector 6 HP

Recoil, Self Propelled

Serial Number 000101 and up

Model 911073 (LM229sp) - Swivel

4 Cycle, Tecumseh Vector 6 HP

Recoil, Self Propelled

Serial Number 000101 and up

Model 911304 (LM21)

4 Cycle, Briggs & Stratton Quantum 5 HP

Recoil, Push

Serial Number 001001 and up

Model 911311 (LM21s)

4 Cycle, Briggs & Stratton Quantum 5 HP

Recoil, Self Propelled

Serial Number 001001 and up

© Ariens Company-All Rights Reserved

Page 4

Models (Continued)

Model 911312(LM21sm)

4 Cycle, Tecumseh Vector 6 HP

Recoil, Self-Propelled

Serial Number 000101 and up

Model 911313 (LM21S)

4 Cycle, Tecumseh Vector 6 HP

Recoil, Self Propelled

Serial Number 000101 and up

Model 911314 (LM21sw) - Swivel

4 Cycle, Tecumseh Vector 6 HP

Recoil, Self Propelled

Serial Number 000101 and up

Model 911315 (LM21se)

4 Cycle, Tecumseh Vector 6 HP

Electric Start, Self Propelled

Serial Number 000101 and up

Model 911316 (LM21SCSW)

Self Propelled

Serial Number 000101 and up

Model 911317 (LM21scsw) - Swivel

4 Cycle, Kawasaki 5 HP

Recoil, Self Propelled

Serial Number 000101 and up

Model 911318 (LM21S)

2 Cycle, Tecumseh 5 HP

Recoil, Self Propelled

Serial Number 000101 and up

Model 911319 (LM21SW)

4 Cycle Briggs & Stratton Quantum 5 HP

Recoil, Self Propelled

Serial Number 000101 and up

Model 911469(LM232sp)

4 Cycle, Briggs & Stratton Diamond Plus 5.5 HP

Recoil, Self-Propelled

Serial Number 000101 and up

Model 911470 (LM233sp) - Swivel

4 Cycle, Briggs & Stratton Diamond Plus 5.5 HP

Recoil, Self-Propelled

Serial Number 000101 and up

Model 911471 (LM234sp) - Swivel

4 Cycle, Tecumseh Vector 6 HP

Electric Start, Self Propelled

Serial Number 000101 and up

Model 911472 (LM235sp)

4 Cycle, Tecumseh Vector 6 HP

Recoil, Self-Propelled

Serial Number 000101 and up

Model 911473 (LM236sp) - Swivel

4 Cycle, Tecumseh Vector 6 HP

Recoil, Self-Propelled

Serial Number 000101 and up

Page 5

Safety Precautions

Training

Read and understand this Owner’s Manual and

engine manufacturer’s instructions before operating

unit. Be thoroughly familiar with controls and proper

use of equipment. Know how to disengage controls

and stop unit quickly in an emergency.

Understand and follow each Danger, Warning,

Caution and Instructional decal installed on mower.

NEVER allow children to operate mower. DO NOT

allow adults to operate it without proper instruction.

Keep the area of operation clear of all persons,

particularly children and pets.

Safe operation of this equipment requires your

complete and unimpaired attention at all times. DO

NOT operate unit after or during the consumption of

medication, drugs or alcohol.

Preparation

Thoroughly inspect and clear work area of objects

which might be picked up and thrown. Remove all

stones, sticks, wires, and other foreign objects.

minutes before removing fuel cap. Replace gasoline

tank cap securely and clean up any spilled fuel

before starting engine.

DO NOT start the engine or operate mower with the

Side Discharge Opening Cover or the Side Discharge

Deflector removed. NEVER operate the engine with

the Rear Door open unless the Grass Bag is in place.

Doing so may result in serious injury due to Blade

contact or thrown objects. When mulching the Side

Discharge Opening Cover must be installed and the

Rear Door fully closed whenever the engine is

operating.

Operation

Keep equipment in good condition. Keep all shields in

place and safety devices operating properly.

Operate unit only when there is good visibility and

light.

DO NOT put hands or feet near, or under, rotating

parts. Keep clear of the discharge opening and

mower pan at all times. NEVER open the Rear Door

without the Grass Bag in place when the engine is

operating.

Wear sturdy footwear. DO NOT operate mower

barefoot or when wearing open sandals or canvas

shoes. DO NOT wear loose clothing that may get

caught in rotating parts of unit.

NEVER attempt to make any adjustments to unit

while engine is running (except where specifically

recommended). DO NOT make cutting height wheel

adjustment while engine is running.

Gasoline is highly flammable and its vapors are

explosive. Handle with care. Use an approved (RED)

gasoline container.

NEVER allow smoking materials, sparks or flame

(match, pilot light, etc.) near mower or gasoline

container.

Check fuel supply before starting engine. DO NOT fill

gasoline tank indoors, when engine is running, or

while engine is still hot. Allow engine to cool several

Open doors if unit is run in garage, exhaust fumes

are dangerous. DO NOT run engine in an enclosed

area.

DO NOT operate mower in wet grass. Always be

sure of your footing, keep a firm hold on handlebar

and walk, never run.

Do not operate mower on gravel or on loose material

such as sand. Stop mower when crossing gravel

drives, walks, or roads. Objects may be picked up

and thrown, causing damage or injury.

NEVER direct discharge of material toward

bystanders nor allow anyone near equipment while

unit is in operation. The operator is responsible for

the safety of bystanders.

Be familiar with area of operation. Stay alert for

holes, rocks, roots and hidden hazards in area of

operation. Keep away from drop-offs.

Page 6

Safety Precautions (Continued)

Mow across face of slopes, never up and down. Be

especially cautious when changing direction on

slopes. DO NOT mow steep slopes.

Engine/Blade Control feature on mower will cause

engine and blade to stop whenever operator releases

control on handlebar. If feature fails to operate,

disconnect spark plug wire and adjust or have it

repaired before using unit.

Stop engine, wait for moving parts to stop, remove

ignition wire and secure away from spark plug before

attempting to; unclog discharge chute, when making

any repairs, adjustments, inspections or cleaning

unit.

DO NOT touch equipment parts which might be hot

from operation. Before attempting to maintain, adjust

or service allow such parts to cool.

If equipment vibrates abnormally, stop engine at

once, wait for moving parts to stop and remove wire

from spark plug. Abnormal vibration is a warning of

trouble. Repair any damage before restarting unit.

(See your Ariens Dealer.)

After striking a foreign object, stop engine, wait for

moving parts to stop and remove wire from spark

plug. Thoroughly inspect unit for any damage and

repair damage before restarting and operating unit.

Take all possible precautions when leaving unit

unattended. Remove and keep wire away from spark

plug to prevent accidental starting or unauthorized

use. (On electric start units, remove key or unplug

battery.)

DO NOT change engine governor setting or over

speed engine.

Keep all nuts, bolts and screws tight and be sure

equipment is in safe working condition. Check all

hardware at regular intervals.

Check grass bag for wear and/or deterioration.

Replace only with Ariens original equipment

replacement part for safety.

Before tipping mower to work or clean underside.

Disconnect ignition wire and secure away from spark

plug. Follow instructions in Lubrication and

Maintenance Section of this manual.

To reduce fire hazard and overheating, keep

equipment free of grass, leaves, debris or excessive

lubricants.

Worn out mufflers are more than just a noise

nuisance and should be replaced immediately.

Continued use could result in fire or explosion.

Follow engine manufacturers safety instructions

when servicing engine.

NEVER store equipment with gasoline in tank inside

a building where fumes may reach an open flame or

spark. Allow engine to cool before storing in any

enclosure.

Refer to Storage Section of this Owner’s Manual for

important instructions if unit is to be stored for

extended periods.

Maintenance and Storage

Use only attachment or replacement parts designed

for your unit. See your Ariens Dealer.

#•

Page 7

A WARNING

STOP ENGINE BEFORE ATTACHING

OR REMOVING GRASS BAG.

1. Under normal usage bag material is sub

ject to deterioration and wear. Bag should

be checked periodically and replaced

when necessary.

2. Replace bag with Ariens original service

part only.

3. Do not store grass in bag. Empty bag

completely and make sure bag is kept

dry.

(ON BAG) 07893200

(911065,069,070,071,072,073

304,311,313,314,315,317,

318,469,470,471,472,473)

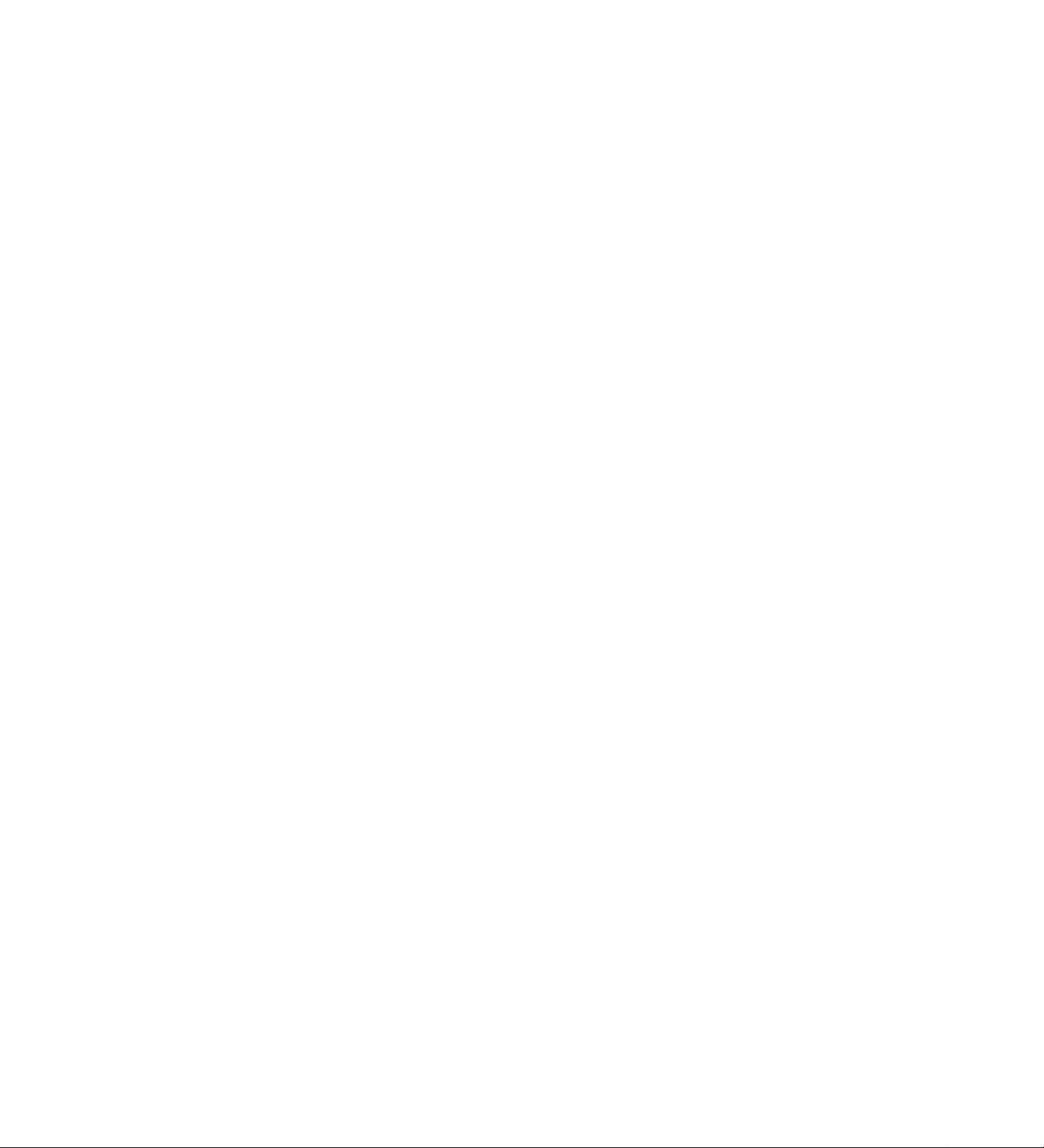

Safety Decals

AIIA Mil PH

; MM MMt it

• ENGINE MUST BE STOPPED

BEFORE CLEARING DISCHARGE.

• BLADE MUST BE STOPPED

WHEN DOOR IS OPENED.

07759200

(911065,067,068,069,070,071,072,

073,469,470,471,472,473)

▲WARNING

Do not operate mower unless

guards are in operating

position or bagger is attached.

07893700

(911065,067,068,069,070,071,072,

073,469,470,471,472,473)

(07722800)

(911304,311,312,313,

314,315,317,318,319)

Figure 1: Safety Decals

5

07874200

(911065,067,068,069,070,071,

072,073,469,470,471,472,473)

Page 8

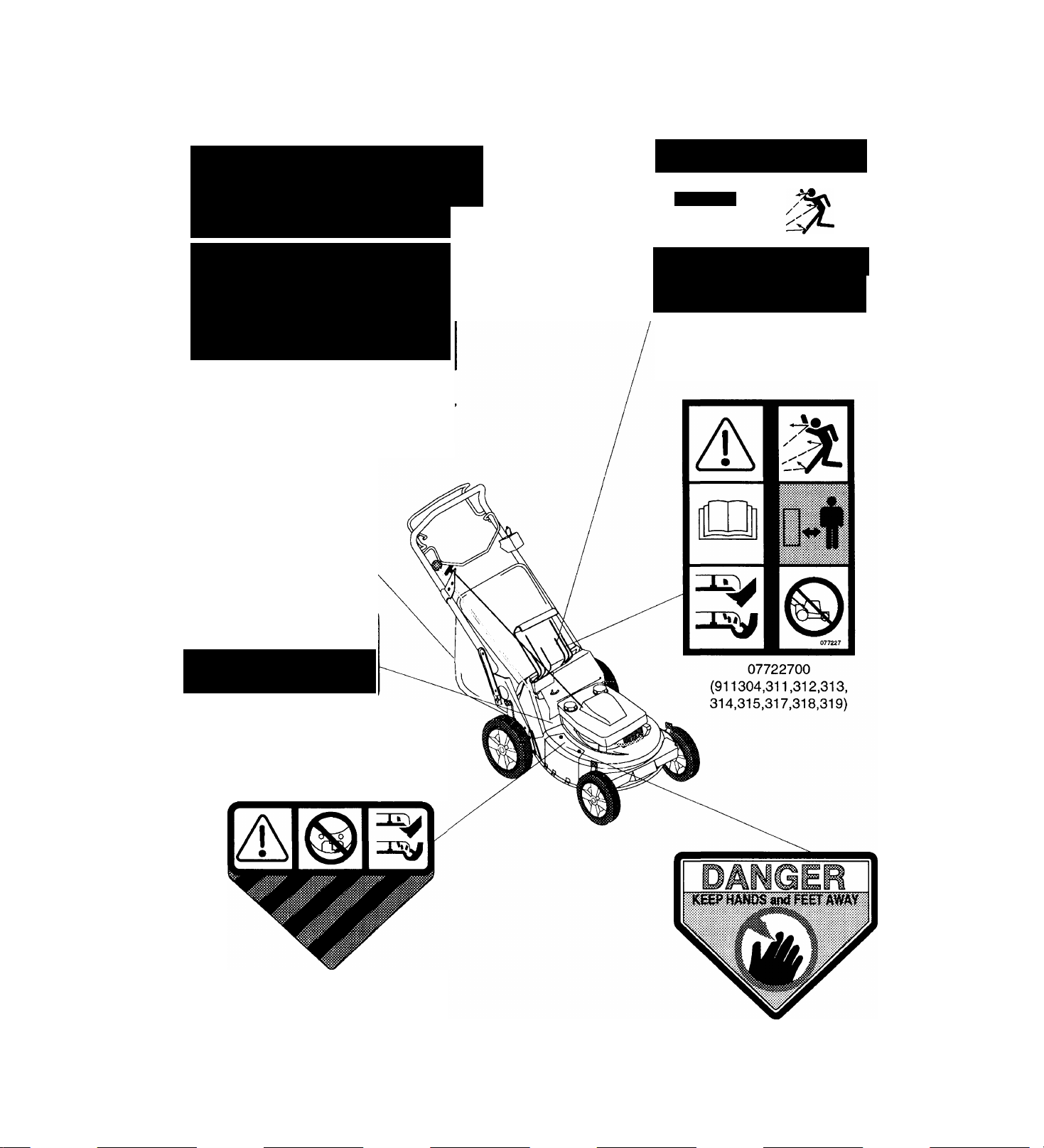

Controls and Features

12

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

1.

Engine Control

Electric Start Control (Electric Start Models)

Speed Selector (Self Propelled Models)

Primer

Side Discharge Opening Cover

Side Discharge Deflector

Cutting Height Levers (Wheel Adjustors)

Rear Door

Adjustable and Folding Handlebars

Grass Bag

Rewind Starter

Wheel Drive Control (Self Propelled Models)

Cutting Height Levers (Wheel Adjustors - See Page 9 For Swivel Wheel Models)

Mulch Master™ Plug

Throttle Control (Professional Models)

Figure 2: Control and Feature Locations

Page 9

Operation

PRE-STARTING

• Check that engine crankcase oil is at proper level

using dipstick. Fill or change as per instructions

in Lubrication and Maintenance Section. Two

cycle engines require that oil be mixed with fuel.

NOTE: This product is equipped with an internal

combustion engine. DO NOT use on or near any

unimproved, forest or brush covered land unless the

exhaust system is equipped with a spark arrester

meeting applicable local, state or federal laws. A

spark arrester, if used, must be maintained in

effective working order by the operator. See your

Ariens Dealer or engine manufacturer’s service

center.

CAUTION: Make sure all hardware is

tight, aii safety devices in place and all

A

adjustments made correctly.

Check air cleaner for dirt. Clean as required. See

Lubrication and Maintenance Section of this

manual.

Fuel

WARNING: Gasoline is highly flammable

A

and must be handled with care. Allow

engine to cool several minutes before

removing fuel tank cap. Never fill tank

when engine is running or is hot from

operation. DO NOT allow open flame,

matches, or smoking in area. DO NOT

over fill. Allow about 1/4” of tank space

for fuel expansion. Wipe up any spills

and allow vapors to dissipate before

starting engine. Use approved (Red)

gasoline container.__________________

W) approved oil. One gallon of gasoline requires 2.5

ounces of oil.

IMPORTANT: Observe the recommended gasoline

to oil mixing ratio to prevent engine damage.

To assure thorougn mixing of gasoline and oil, fill

container partially with gasoline, add oil, shake

container vigorously, add remainder of gasoline into

container and shake vigorously

Handlebar Height

Handlebar adjusts to four positions by selecting holes

in braces. Select a safe comfortable height and place

pin through hole in brace that is closest to that height.

Refer to Adjustment Section. (On professional

models, 911065 and 911317 nuts and carriage bolts

replace pin). Adjust handlebar to a safe, comfortable

operator height according to instructions in

Adjustments Section of this manual.

Mower Configurations

WARNING: DO NOT operate mower

unless either side discharge opening

A

To configure your mower for bagging, side discharge

or mulching, proceed as follows:

Bagging: Lift rear door, place bar of grass bag frame

on lip of mounting flange and lower rear door. If

necessary, lift rear of grass bag frame to lock in

position.

cover or side discharge deflector is

instalied. Objects may be picked up and

thrown causing damage or personal

injury. Never operate engine with rear

door open unless grass bag is in place.

NOTE: To prevent foreign particles from entering

tank while filling: wipe dust, dirt and debris from

around cap before removing it.

• Check fuel supply.

For 4 cycle engine, fill fuel tank with a good grade of

fresh lead free gasoline. DO NOT use premium,

gasohol, or mix gasoline with oil. (Use of lead free

gasoline produces fewer combustion deposits.

For 2 cycle engine, the recommended gasoline to oil

ratio is 50:1. For every 50 parts of gasoline, mix one

part Boating Industry Association two cycle (BIA TC-

Be sure there are no openings between bag and

mounting surface after installing bag, if necessary

clear bag mounting surface of debris.

To,remove grass bag, lift rear door. Then with

handle, lift bag up off mounting flange and close rear

door.

CAUTION: Objects may be thrown.

Check Grass Bag frequently for wear or

A

deterioration. Replace worn or

damaged bag with Ariens original

equipment replacement part only.

Page 10

Operation (Continued)

Side Discharge: With grass bag removed, remove

two lock nuts and washers that secure side discharge

opening cover to mower. Lift cover to free tabs from

slots and remove cover from mower.

Position holes in side discharge deflector over studs

on mower with tab on rear edge of deflector placed

onto edge of discharge opening. Secure deflector

with cover hardware.

CAUTION: NEVER direct discharge of

A

Muiching: With grass bag removed and side

discharge opening cover installed, install the

Mulchmaster Plug by the handle with the beveled

face to the left. Open rear door and insert

Mulchmaster Plug. Rear door will close flush with

proper insertion.

For maximum mulching performance, install the

mulchmaster mulching kit. Installation instructions

are provided in the accessory kit.

material toward bystanders nor allow

anyone near equipment while unit is in

operation.

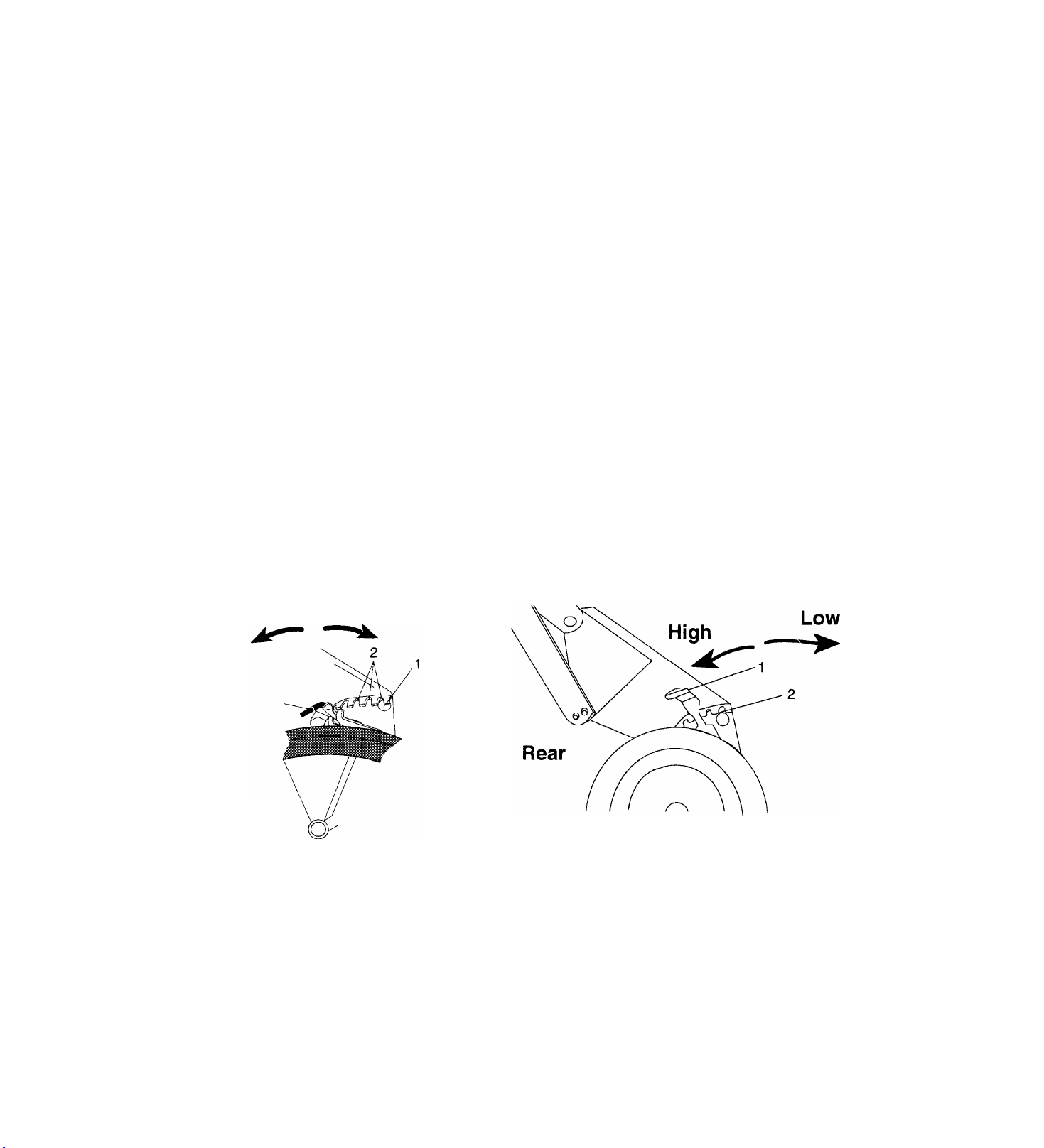

Cutting Height - Standard Models

DANGER: To avoid inadvertent biade

A

A

To change cutting height, move Cutting Height levers

one notch at a time on each wheel until desired

height of cut is obtained.

NOTE: Each Wheel on mower must be set at the

same height for a level cut.

Low Setting = 1-1/4" cut grass length.

Second Notch = 1 -3/4" cut grass length.

Third Notch = 2-1/8" cut grass length.

Fourth Notch = 2-5/8" cut grass length.

Fifth Notch = 3" cut grass length.

High Setting = 3-1/2" cut grass length.

contact, NEVER attempt to make any

cutting height adjustments while

engine is running.

CAUTION: On self-propelled models,

both rear wheels must be positioned at

same height or traction drive may not

clutch or operate properly.

r

Low

Front

r

High

1. Cutting Height Lever

2. Notch

Figure 3: Cutting Height Levers (Wheel Adjusters)

r

Page 11

Operation (Continued)

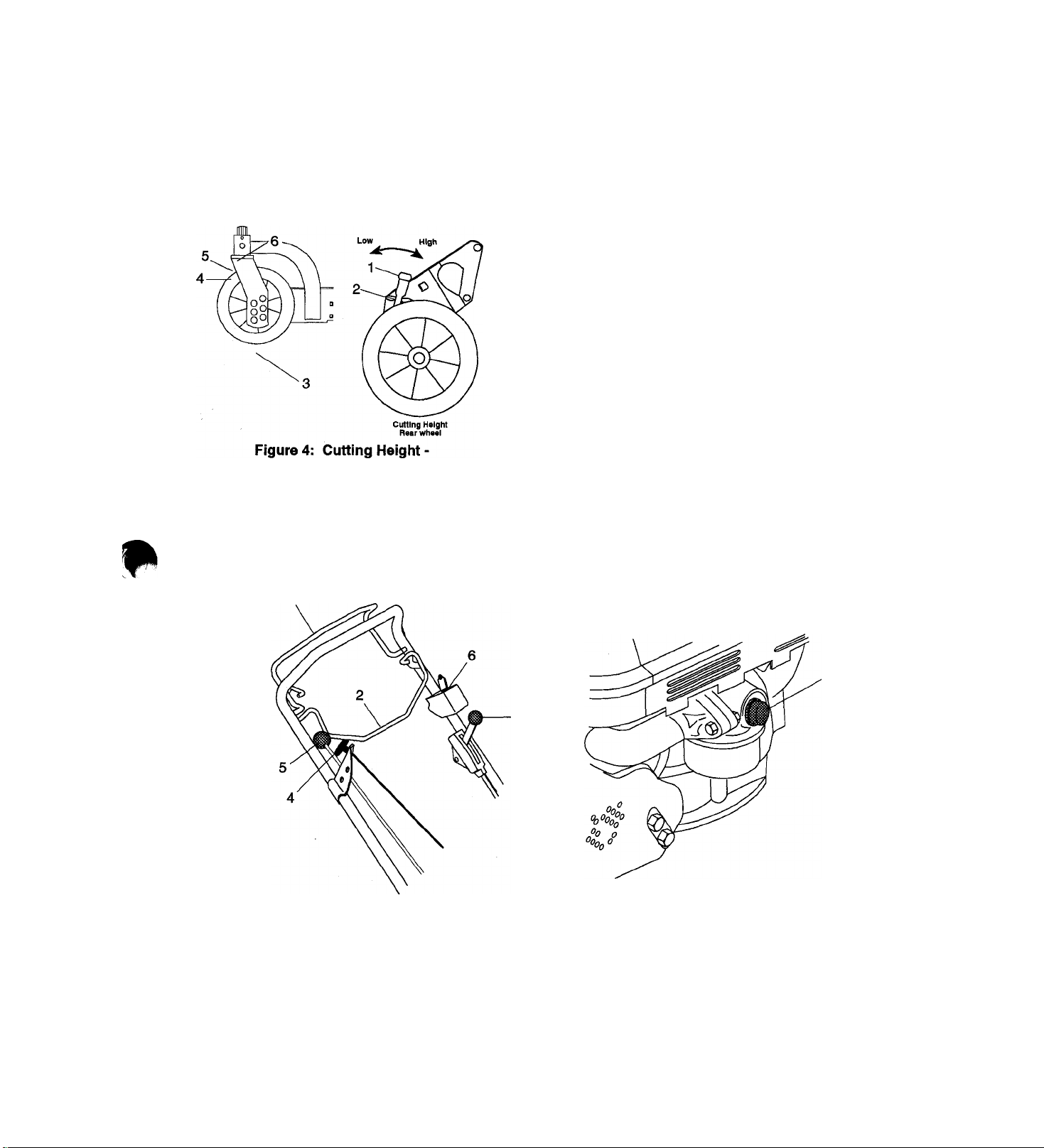

Cutting Height - Swivei Models

To change front wheel cutting height, insert clevis pin

into the holes that corresponds to the desired cutting

height. (Figure 4).

Swivel Models

STARTING

To change rear wheel cutting height, move cutting

height levers one notch at a time until the desired

cutting height is obtained. (Figure 4)

1. Cutting Height Lever

2. Notches

3. Clevis Pin & Swivel Height Adjustment Holes

4. Grease Fitting

5. Swivel Lock Hole (Clevis Pin Thru To Lock)

6. Lynch Pin Storage Hole (Clevis Pin Thru To

Swivel)

WARNING: DO NOT attempt to start

your engine at this time. Familiarize

A

yourself with controls to see what they

do, how they work and thoroughly read

and understand entire Operator's

Manual first.

1. Wheel Drive Control (Self Propelled Model)

2. Engine Control

3. Primer

4. Rewind Starter

5. Speed Selector (Self Propelled Model)

6. Key Switch (Electric Start Model)

7. Throttle Control (Professional Models Only)

Figures: Controls

Page 12

Operation (Continued)

Primer

To start a cold engine, push Primer bulb three

times.

Throttle

For engines with a choke, place throttle control in

the choke position. Once the engine has started,

place throttle in the high speed detent.

NOTE: It is not necessary to prime or choke a warm

engine.

Engine/Blade Control

The engine is equipped with a switch, that stops

the engine ignition, and a brake, that stops the

engine (blade), within 3 seconds after the

operator releases the Engine Control. The

Engine Control must be held against the

handlebar in order to start the engine as well as

during mowing operations to keep the engine

running. Releasing the control during operation

stops the engine and blade.

CAUTION: Function of Engine/Blade

A

Control should be checked regularly

per instructions in Adjustments Section

of this manual. Improper function of

control could contribute to operator or

bystander injury.

(Recoil may be used to start the engine. The key

must be in the on position.) "

Wheel Drive Control (self-propelled models)

CAUTION: Holding Wheel Drive Control

A

of self-propelled models against

handlebar, when attempting to start

mower, will propel mower forward.

On self-propelled models, with engine running,

slowly squeeze and hold Wheel Drive Control

against handlebar to propel mower forward.

Release Wheel Drive Control to stop forward

motion.

Speed Selector (self-propelled models)

Speed Selector is used to select variable forward

travel speeds of mower.

Lowest speed is when Speed Selector is pulled all

the way to rear and highest speed is provided when it

is pushed all the way forward.

With Speed Selector set at a slow travel speed and

engine running, engage Wheel Drive Control, then

increase speed with Speed Selector to a safe

comfortable walking pace. Once speed has been

selected. Speed Selector should remain in this

position, if not, adjust speed control bell crank spring

tension per instructions in Adjustments Section.

r

Rewind starter

Grasp Rewind Starter handle and pull rope out

slowly until it pulls harder (this is the compression

stroke) and let rope rewind slowly. Then pull rope

with rapid continuous full arm stroke to start

engine and allow rope to rewind slowly.

IMPORTANT: DO NOT let starter rope snap back

against bracket.

Repeat above instructions until engine starts. (Refer

to engine manufacturer’s instructions.)

NOTE: Start engine (blade) on a hard level surface

that is free of debris. To start on lawn, push down on

handlebar to allow blade to rotate above grass.

Electric Start

On electric start models, turn the key with the

Engine Control held against the handlebar.

Stopping

Release control, and allow engine to cool. On

electric start models turn key to off position after

releasing controls

CAUTION: Remove wire from spark

plug to prevent accidental starting or

A

unauthorized use of mower.

Operating Tips

The following tips will help you to mow safely,

achieve maximum performance from your mower and

maintain the appearance of your lawn.

When Bagging, be sure to release Engine/Blade

Control before attempting to remove and empty grass

bag. Empty bag before it becomes overloaded, clogs

mower and/or affects performance.

10

Page 13

Operation (Continued)

mowing. By changing direction of mowing (when

CAUTION: If clog or obstruction prevents

grass flow, release Engine/Blade Control

A

and disconnect spark plug wire before

attempting to clear away any clogs.

CAUTION: On swivel wheel models when

mowing on slopes it is recommended that

A

the lynch pin be positioned thru the swivel

lock hole. If wheels are in the swivel

position and control handles are released

the mower may "free roll" downhill. Never

mow on steep slopes.

possible) you can prevent this.

When using side discharge, turn clockwise (right turn)

when beginning to mow large open areas. This

discharges clippings away from borderline objects

(sidewalks, driveways, fences, etc.). After making a

clockwise pass, mow in a counterclockwise (left turn)

direction. This discharges clippings evenly over cut

grass. Continuous clockwise mowing will cause a build

up of clippings, preventing a uniform cut. Also, plan

cutting so that you always trim with the ieft side of

mower when using side discharge.

Restarting engine will be easier if mower is allowed to

completely discharge clippings before stopping engine.

On electric start model, if starter will not cycle because

of grass buildup under deck, rotate blade with rewind

starter to clear blockage.

Be sure your mower blade is sharp. A dull blade will tear

grass blades. This usually results in a white cast over a

freshly cut lawn. Later, tips of grass blades will turn

brown.

A new lawn has much softer blades of grass and has a

higher moisture content. It is important for this type of

lawn to be cut with sharp blades.

Cutting height will vary with different types of grass,

climate and individual preference. Generally, grass

should be cut about 1-1/2” long in spring, and not less

than 2” long in hot summer weather.

If grass is high, or if it contains a high degree of

moisture, cut it first with mower set high and then cut it

with mower set lower. This gives better distribution or

collection of clippings and provides a clean second cut.

A good fertilization program and frequent watering will

keep your lawn weed free and green all year long. Due

to variations in climate, soil and grass varieties, contact

your local garden supply dealer, park or golf course

superintendent, or county agent to obtain specific

information pertaining to your area.

NOTE: Be sure to empty grass bag and clean mower

pan after each use. A dirty unit may not bag and/or cut

grass properly.

Do not allow grass clumps or a coating of grass and

debris to collect inside of grass bag or mower pan.

Avoid operating over bare ground intermittent with grass

cuttings as this causes dirt and grass to collect and cake

under pan surface as well as in grass bag. To tip mower

for cleaning under side of pan refer to Lubrication and

Maintenance section of this manual.

Grass bag should be washed with hose and allowed to

dry. Washing grass bag prevents debris buildup, that

will clog mesh of bag, which will prevent proper air

circulation and bagging of grass.

Mulching Tips

Height of cut should not be set too low on thick, lush

lawns. Such grass, if cut too short, may die. This also

applies to springy, heavy growth lawns. If blade is set

too low, mower pan will drag on grass and restrict air

flow thus reducing discharge or collection of clippings.

Grass should be cut when it is dry; not when it is wet

from dew, rain or from watering. When wet, grass tends

to pack inside mower pan or chute and will not

discharge, mulch or bag properly, especially if height of

cut is set too low.

To insure most complete and even cut, overlap each

swath.

Following the same pattern each time you mow your

lawn can develop ridges at right angles to direction of

For best performance, it is recommended that the height

of cut for your mower be set at, or as near as possible

to, 3 inches and that not more than 1 inch of grass is

removed per cutting. This can be controlled easier by

obsen/ing the “Mulching Zone Decal” (Part No. 077123).

The decal serves as a height gage for measuring the 1

inch maximum per cutting range.

Grass should be cut when it is dry, not when it is wet

from dew, rain, or from watering. When wet, the grass

will tend to ball and pack inside the mower pan and will

not disperse evenly. If the grass does not disperse

evenly, it is probably because too much grass is being

removed per cutting, the grass is too wet, or the travel

speed is too fast.

11

Page 14

Lubrication and Maintenance

Ariens Dealers will provide any service which may be

required to keep your mower operating at peak

efficiency. Should engine repair or service be

required, it can be obtained from an Ariens Dealer or

an authorized engine manufacturer’s service center.

WARNING: Stop engine, wait for moving

parts to stop, and remove wire from

A

A

spark plug (keep wire away from plug to

prevent accidental starting) before

attempting any lubrication or

maintenance procedures.

CAUTION: DO NOT touch engine or

parts which are hot from operation.

Allow such parts to cool before

servicing

General

Mower does not require any lubrication. Wheel

assemblies are .designed for long life without

additional lubricatiori. (The professional models

911065 and 911317 has zerk fittings on drive carrier

and rear axle).

Service Positions

Pi

Figure 6: Handlebar Service Position

NOTE: On the models with Kawasaki engines,

remove the side discharge deflector, if so equipped,

prior to tipping the machine.

NOTE: A piece of plastic bag may be used to seal

fuel tank opening when tipping mower. To seal,

remove fuel tank cap, cover fuel tank opening with

plastic, replace and tighten cap securely before

tipping mower. Be sure to remove plastic before

attempting to operate mower.

A handlebar service position is provided, for tipping

the unit, for convenient cleaning and service

operations.

To place handlebar into the handlebar service

position, remove braces from pins, rotate handlebar

forward and place pins into holes of braces. See

Figures 6 and 13.

NOTE: Nuts and bolts replace pins on Professional

Models.

IMPORTANT: When tipping to service engine or unit,

use the following service positions for the brand and

type of engine on your mower:

Tecumseh Vector and Centura Engines; place

handlebar into handlebar service position and tip

machine to the rear.

Briggs & Stratton Quantum and Diamond Plus

Engines; place handlebar into handlebar service

position and tip the machine to the left, opposite the

side descharge deflector.

Kawasaki Engines; place handlebar into handlebar

service position and tip machine to the right, side

discharge deflector side.

WARNING: Gasoline is highly flammable

A

IMPORTANT: If 4 cycle engine becomes “flooded”

due to tipping, clean air cleaner. Gasoline, drawn into

cylinder may wash cylinder wall and shorten engine

life. If cylinder wall becomes washed with gasoline,

remove spark plug, put one teaspoon of oil in

cylinder, turn engine over a few times and replace

spark plug.

and must be handled with care.

Engine Oil (4 cycle engines)

Use a high quality detergent oil classified “For API

Service SF or SG” with a single viscosity SAE30.

Capacity is approximately 1-1/4 pints. Detergent oils

keep engine cleaner and retard formation of gum and

varnish deposits. DO NOT add anything to

recommended oil.

Checking

The engine crankcase oil should be checked daily or

every five (5) hours of operation.

To check oil, place mower on flat, level surface. Wipe

all debris from around oil fill cap.

12

Page 15

Lubrication and Maintenance (Continued)

To check oil, place mower on flat, level surface. Wipe

all debris from around oil fill cap.

Turn cap, remove dipstick from engine and wipe oil

off dipstick. Insert dipstick into fill hole and turn slowly

until cap bottoms firmly. Remove dipstick and

observe oil level. If low, add fresh clean oil (of same

type and viscosity as is in engine) to bring oil level to

full (F) mark. Replace dipstick being sure to tighten

cap firmly.

IMPORTANT: DO NOT over fill. Level must not

exceed full (F) mark. Oil level MUST be maintained in

safe operating range on dipstick at all times or engine

damage will result.

Changing Oil

IMPORTANT: Change engine crankcase oil after

first two (2) hours of operation, thereafter, change oil

every twenty fiye hours of operation (more often in

dusty dirty conditions).

NOTE: Run engine just prior to changing oil. Oil will

flow more freely and carry away more contaminant’s

when warm.

Place mower into the Service Position specified for

your brand and type of engine. (See Service

Positions section). Professional models 911065 and

911317 remain in the operator’s position. Attach oil

drain hose to end of engine oil drain. Place a

suitable container under oil fill, remove oil fill cap with

dipstick and allow oil to drain into container.

Place machine back onto wheels, add fresh clean oil

to proper level and be sure to replace oil fill cap with

dipstick.

4 Cycle Briggs & Stratton

Quantum & Diamond Plus Engine

1. Oil Fill Cap and Dipstick

2. Air Cleaner

3. Spark Plug and Wire

4. Fuel Cap and Tank

13

Page 16

Lubrication and Maintenance (Continued)

4 Cycle Tecumseh Engine

Centura Engine

1. Oil Fill Cap and Dipstick

2. Air Cleaner

3. Spark Plug and Wire

4. Fuel Cap and Tank

Air Cleaner

IMPORTANT: DO NOT run engine with air cleaner

removed. Operating engine with dirty air cleaner for

only a brief time can cause engine damage.

14

Page 17

Lubrication and Maintenance (Continued)

Inspect air cleaner every 10 hours of operation or

every month, whichever occurs first.

When dirty, filter elements should be removed and

cleaned per the following instructions.

NOTE: Inspect air cleaner more often if unit is used

under dirty dusty conditions.

A

CAUTION: Periodically clean muffler

and manifold areas to remove all grass,

dirt and combustible debris. If engine

muffler is equipped with spark arrester

screen assembly, remove every 50

hours for cleaning and inspection.

Replace if damaged.

To inspect and/or clean remove cover and filter

element(s) and/or cartridge from air cleaner body.

NOTE: Clean air cleaner cover and body before

installing clean or new components.

Foam Filter Element (Pre-cleaner) - Wash foam

elements in warm water with detergent. Rinse

thoroughly until all traces of detergent are eliminated,

squeeze (don’t wring) away excess water and air dry.

Soak foam element in clean fresh oil, wrap in paper

towel or rag and squeeze out excess oil.

Cartrldge/Or Paper Filter Element - Clean by

tapping gently on flat surface. Replace if it is very

dirty or becomes distorted.

Engine Cooling

The engine is air cooled. Air must circulate freely

around engine and over cooling fins on cylinder head

and block to prevent overheating.

Once a year or every one hundred (100) operating

hours (more often if conditions require) clean engine

fins and external surfaces of engine of dust, dirt, and

oil deposits which can contribute to improper cooling.

IMPORTANT: DO NOT operate engine with blower

housing removed - this will cause overheating and

engine damage.

Spark Plug

Spark plug should be cleaned or replaced (if

necessary) and gap reset to .030” every 100 hours of

operation or yearly whichever comes first.

To clean, remove debris from area around spark plug

base, remove spark plug from engine, scrape and

wash with a commercial solvent. DO NOT blast

clean.

NOTE: Sparking can occur if wire terminal does not

fit firmly on spark plug. Reform terminal if necessary.

Muffler

Worn out mufflers are more than just a noise

nuisance and should be replaced immediately.

Continued use could result in fire or explosion.

Mower Blade

CAUTION: Use sturdy gloves or

padding to protect hands when working

A

Regularly check mower blades for wear and that lock

washer is fully compressed by cap screw (requires

25-30 foot pounds of torque on cap screw.

with mower blades.

15

Page 18

Lubrication and Maintenance (Continued)

WARNING: Stop engine, wait for

A

When blade needs sharpening, block blade to

prevent rotation, remove cap screw(s), lock washer(s)

and blade from shaft.

Sharpen both ends of blade at original angle (25

degrees), removing equal amounts of material from

each end to maintain proper blade balance. New

blades are balanced to within 1.3 inch ounces at

factory, DO NOT grind around corner at tip of blade.

moving parts to stop and remove wire

from spark piug before attempting any

maintenance procedures.

If cutting edge of blade cannot be sharpened in a

straight line to within 1/8 of an inch of its end, replace

blade with Ariens replacement blade only. Blades

are available through your Ariens Dealer.

Install blade, lock washer(s) and tighten cap screw(s)

until lock washer is fully compressed (requires 25-30

foot pounds of torque on nuts).

NOTE: The 01172300 mulching blade is the only

blade to be used with the mulchmaster insert dome.

IMPORTANT: If mower is used under sandy soil

conditions, replace blades when air lifts become

eroded through at end.

Cutting Edge 4. Idler

1.

Square Corner

2.

3. Air Lift Erosion

4. Air Lift

Reverse Lift

5.

Figured: Mower Blade

16

Blade

1.

Cap Screws,Lock Washer,

2.

& Flat Washer

Drive Belt

3.

Figure 9: Mower Blade Replacement

Page 19

Lubrication and Maintenance (Continued)

IMPORTANT: Use battery supplied only. DO NOT

attempt to “jump start” mower.

To charge with battery charger, connect charger plug

to mating plug on battery (not engine) and plug

charger into 120 volt Alternating Current (A.C.) outlet.

Charge for 24 to 48 hours (battery may be charged

for up to 72 hours with no harmful effects).

An engine run time of at least 8 hours is required to

charge a fully discharged battery.

Swivel Lubrication (swivel models)

DANGER: To avoid inadvertent biade

1. Drive Belt

A

contact, NEVER attempt iubrication or

maintenance procedures whiie the

engine is running.

Figure 10: Drive Beit

Drive Belt (self propelled models)

To remove drive belt, position right hand rear wheel

Height Adjustment lever in first notch and left hand

rear wheel Height Adjustment lever in third notch.

This provides clearance between friction wheel and

drive disk.

Remove belt from idler, drive disk and engine pulley.

Pull belt through opening under mower pan and over

blade.

Check idler for free rotation of pulley and movement

of pivot.

Replace drive belt in reverse order being sure that

belt seats in pulley grooves with idler positioned on

back (flat) side of belt.

Battery (electric start model)

CAUTION: Do not put battery in fire or

mutilate; battery may burst or release

A

toxic materiais. Do not short circuit;

battery may cause burns.

NOTE: Use Ariens multi-purpose grease (part

number 000150) or a good grade of general purpose

grease. Grease swivels every 10 hours of use.

NOTE: Lynch pin must be in the swivel lock hole

while lubricating.

Swivel Lock Hole

A 12 volt, 2.5 ampere hour sealed lead acid battery is

supplied with unit. Engine alternator will normally

keep battery fully charged with a 3 to 5 minute

start/run cycle.

17

Page 20

Lubrication and Maintenance (Continued)

Chart 1 shows the recommended service schedule that should be performed on a regular basis. More frequent

service may be required due to working condition, (i.e. Heavy Loads, high ambient temperatures, dusty

conditions or when airborne debris are present.) See the engine manual for maintenance instructions. Use chart

2 to record the actual hours on the hourmeter and the date at which each service item is performed.

MAINTENANCE SCHEDULE

SERVICE PREFORMED

Check Engine Oil

Check Belt Drive

Check Air Cleaner

General Lubrication

Check Drive Control

Check Mower Blade

Check Fasteners

Check Engine/Blade Controls

Check Bag Wear

DAILY

•

•

•

•

•

TIME INTERVALS BETWEEN SERVICE

10 HRS.

•

•

•

•

Chart 1

Always use genuine Ariens service parts and accessories to ensure your machines peak

performance.

18

Page 21

MAINTENANCE RECORD

■o

o

c

o

o

o

o

c

(0

c

0)

(0

■o

c

(0

£

o

SERVICE TO BE PERFORMED

General Lubrication

Check the Fasteners

Check Drive Control

Check Bag Wear

TIME INTERVALS BETWEEN SERVICE

LU

LLI LJU

LU

LU

LU

LU LU

LU

LU

LU

LU

LU

CM

■c

o>

<0

U

(0

o

n

3

Always use genuine Ariens service parts and accessories to ensure your machines peak performance.

Page 22

MAINTENANCE RECORD

■o

0)

3

c

o

o

o

o

c

(0

c

0)

+-*

c

■ <5

■o

c

(0

SERVICE TO BE PERFORMED

General Lubrication

Check the Fasteners

Check Drive Control

Check Bag Wear

TIME INTERVALS BETWEEN SERVICE

■o

o

c

o

o

CM

■c

es

sz

O

o

CM

(0

o

3

Always use genuine Ariens service parts and accessories to ensure your machines peak performance.

Page 23

Adjustments

• For storage, remove braces from pins, rotate

WARNING. Stop engine, wait for moving

parts to stop and remove wire form

A

spark plug (keep wire away from plug to

prevent accidental starting) before

attempting any adjustment procedures.

handlebar forward and place pins into holes

further up on braces.

NOTE: Nuts and bolts replace pins on Professional

models.

CAUTION: DO NOT change engine

governor setting or over speed engine.

A

"Operate engine at the governed no

load speed recommended by the Ariens

Company only." DO NOT exceed this

speed as personal injury may result.

Handlebar

• Holes in handlebar braces provide four height

positions, a service and (except on professional

models 911065 and 911317) a storage position.

• To adjust to a safe comfortable operating height,

use one of four hole positions; 1,2,3, or 4 in order

of increasing height, in brace on both sides of

mower and place pin through hole in brace. (On

professional models 911065 and 911317) use

hole positions 1 & 3,1 & 4, 2 & 3 or 2 & 4.)

Refer to illustration.

• To place handlebar into the handlebar service

position, remove braces from pins, rotate

handlebar forward and place pins into holes of

braces. See Figures 6 and 12.

Engine/Blade Control

• Engine Control must stop engine ignition, at a

point 3/4”-1 1/4” from handlebar as control is

released. To check, start engine and slowly

release Control until engine stops firing.

• Measure distance between handlebar and control

at the point that engine stopped firing.

• Turn cable nuts at handlebar mount clockwise if

measurement is more than 11/4" or

counterclockwise if measurement is less than ^

3/4". Turn nuts against mount to lock in position.

1.

Hole No. 1 5. Pin

Hole No. 2

2.

3. Hole No. 3 7.

4. Hole No. 4 8.

Figure 12: Handlebar Height

6. Brace

Professional Brace

Storage Position

21

1.

Engine Control

2. Handlebar

Cable Nuts

3.

4.

Mount

Figure 13: Engine Control

Page 24

Adjustments (Continued)

Drive Wheel (self propelled model)

• When the Wheel Drive Control is squeezed

toward the handlebar the extension spring,

located at the bottom end of the traction cable,

must start to extend when the control is between

1" and 1 -1/2" away from the handlebar. To

check, squeeze the Wheel Drive Control toward

the handlebar until the spring starts to open.

• Measure the distance between the Wheel Drive

Control and handlebar at the handlebar

indentation.

• To obtain the proper adjustment turn the cable

nuts at either the handlebar end or the bottom

end of the traction cable. Tighten the nuts

against the bracket to lock in position.

Speed Control Bell Crank

• To adjust, remove cover, fully compress the

helical spring lockwashers with lock nut and then

back lock nut off one half turn. Align notch in

L.H. side of cover with bolt and secure with knob.

1. Lock Nut

2. Helical Spring Lockwashers

3. Speed Control Bell Crank

4. Speed Control Rod

1. Traction Cable

2. Handlebar Indentation

3. Cable Nuts

4. Wheel Drive Control

Figure 14: Wheel Drive Control

Figure 15: Speed Control Bell Crank

22

Page 25

A

storage

WARNING: Never store mower in an

enclosed area where fuel fumes may

reach flame, sparks, pilot lights, or an

ignited object. Drain fuel outdoors away

from any ignition source. Use only

approved (Red) fuel container.

Remove Grass Bag and clean out all debris prior to

storage. Grass Bag may be stored in position on

mower. Keep Grass Bag dry during storage.

On electric start models, fully charge battery and

store in a cool dry location. (Refer to Battery in

Lubrication and Maintenance Section.)

Your authorized Ariens Dealer is trained and

equipped to service your mower. A periodic

checkup by your dealer will help reduce your

maintenance costs.

Inspect mower for visible signs of wear, breakage or

damage. Order any parts required and make

necessary repairs to avoid delays when beginning

use again.

Service Manual

Service manuals are available for owners who wish

to perform some of their own maintenance and

service operations. Should a complete service

manual be desired, order by referring to the model

and serial number of your machine.

When ordering parts always include the model and

serial number of your unit to assure prompt service.

A parts manual is included in your literature package

to make ordering of service parts easier.

When storing mower for an extended period, refer to

engine instruction for proper engine storage

procedures.

Clean unit thoroughly. Touch up all areas to prevent

rust. Matching touch up paint is available from your

Ariens Dealer. Store mower in a cool, dry protected

location.

Mail Request to: Ariens Service

655 West Ryan Street

P.O. Box 157

Brillion,WI 54110-0157

Walk Behind Mower Model Number.

Walk Behind Mower Serial Number.

23

Page 26

Trouble Shooting

1. Engine won’t start

Low or empty gas tank.

Spark plug wire attached.

Engine/brake control cable deattached or broken.

Engine/brake control cable adjusted properly.

Engine/brake control bail engaged.

Discharged battery.

2. Self-propelled drive does not engage

Drive belt not in position.

Drive belt in good condition.

Rear wheels in the same cutting height.

Friction Wheel engagement adjusted properly.

Friction wheel in good condition.

Idler and idler spring installed properly.

Traction drive cable deattached or broken.

Traction drive bail engaged.

Bearings in good condition.

Debris in gear set.

24

Page 27

Specifications

Model No.

Description Name

Length

Height

Width

Weight Actual

911065

LM230sp

60.5 153.7 CM

37.75 96 CM

23” 58.4 CM

113 Lbs

Engine - Manufacturer Kawasaki

- Cycles

Four

- HP (3600 rpm) 5.0 HP

Fuel Tank Cap.

1.4 Qt.

Fuel Unleaded

Primer Bulb N/A

Throttle/Choke Control

Standard

Starting Recoil

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Cap.

Air Cleaner

Engine Oil Type Spark Plug

Differential

Variable Speeds - MPH

Cast Iron Sleeve

Standard w/Oil Filter

2850+ - 150

19 Oz.

Dual Element

SAE. 30

.30

Standard

0-4 MPH

0-6.4 KMPH

Mower Deck Gauge

14 Gauge Stamped

Steel Steel

Baked Powder Paint

Cutting Width

Cutting Height

Standard

21” 53.3 CM

6 Positions

1.00” - 3.25” 1.25” - 3.5”

2.5 - 8.3 Cm

911067

MM223

60.5 153.7 CM

37.75” 96 CM

23” 58.4 CM

72 Lbs.

Tecumseh

Four

5.0 HP

1.5 Qt.

Unleaded

Standard

N/A

Recoil

Aluminum

Standard

2850-1--150

27 Oz.

911068

MM224SP

60.5” 153.7 CM

37.75” 96 CM

23” 58.4 CM

92.5 Lbs,

Tecumseh

Four

5.5 HP

1.5 Qt.

Unleaded

Standard

N/A

Recoil

Aluminum

Standard

2850-I--150

27 Oz.

Paper Element Paper Element

SAE. 30

.30

N/A

N/A

SAE. 30

.30

Standard

0-3.5 MPH

0-5.6 KMPH

16 Gauge Stamped

16 Gauge Stamp

Steel

Standard

21” 53.3 CM

Standard

21” 53.3 CM

6 Positions 6 Positions

1.25”-3.5”

‘3.2-8.9 CM

‘3.2-8.9 CM

Folding Handlebar Standard

One Piece

Adjustable Handle Bar

Front Wheel Dia.

Rear Wheel Dia.

Side Discharge

Bagger

4 Position

7.0” 17.8 CM

10.0” 25.4 CM

Standard

Standard

Accessory

Dethatcher

Mulchmaster Plug

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Accessory

= Part of Base Model

711024 N/A

*

711028

•k

■ k

711033

711032

711034 711034

711035

25

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

N/A (Rear Opt)

Optional

•k

711028

N/A

711030

711033

711032

711035

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

N/A (Rear Opt)

Optional

711024

k

711028

N/A

711030

711033

711032

711034

711035

Page 28

Specifications

Model No.

Description Name

Length

Height

Width

Weight Actual

Engine - Manufacturer

- Cycles

- HP (3600 rpm)

Fuel Tank Cap.

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Cap.

Air Cleaner

Engine Oil Type

Spark Plug

Differential

Variable Speeds - MPH

Mower Deck Gauge

Baked Powder Paint

Cutting Width

Cutting Height

911069/911469

LM225sp/LM232sp

60.5 153.7 CM

37.75 96 CM

23” 58.4 CM

99.5 Lbs

Briggs & Stratton

Four

5.5 HP

1.6 Qt.

Unleaded

Standard

N/A

Recoil

Cast Iron Sleeve

Standard

2900 +-100

20 Oz.

Dual Clean

SAE. 30

.30

Standard

0-4 MPH

0-6.4 KMPH

14 Gauge Stamped

Steel

Standard

21” 53.3 CM

6 Positions

1.25”- 3.5”

‘3.2-8.9 Cm

911070/911470 911071/911471

LM226sp/LM233sp LM227sp/LM234sp

60.5 153.7 CM

37.75” 96 CM

23” 58.4 CM

102.5 Lbs.

Briggs & Stratton

Four

5.5 HP

1.6 Qt.

60.5” 153.7 CM

37.75” 96 CM

23” 58.4 CM

108.5 Lbs.

Tecumseh

Four

6.0 HP

1.5 Qt.

Unleaded Unleaded

Standard

N/A

Recoil

Cast Iron Sleeve

Standard

2900+ -100

20 Oz.

Dual Clean

SAE. 30

.30

Standard

0-4 MPH

0-6.4 KMPH

14 Gauge Stamped

Steel

Standard

21” 53.3 CM

6 Positions

1.25” - 3.5”

‘3.2-8.9 CM

Standard

N/A

Electric/Recoil

Aluminum

Standard

2850 +-150

27 Oz.

Paper Element

SAE. 30

.30

Standard

0-4 MPH

0-6.4 KMPH

14 Gauge Stamped

Steel

Standard

21” 53.3 CM

6 Positions

1.25” - 3.5”

‘3.2-8.9 CM

Folding Handlebar

Adjustable Handle Bar

Front Wheel Dia.

Rear Wheel Dia.

Side Discharge

Bagger

Accessory

Dethatcher

Mulchmaster Plug

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Accessory

= Part of Base Model

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

Standard

Standard

711024

•k

711028

*

•k

711033

711032

711034

711035

26

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

Standard

Standard

N/A

к

711028

к

к

*

711032

711034

711035

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

Standard

Standard

N/A

к

711028

к

к

к

711032

711034

711035

Page 29

Specifications

Model No.

Description Name

Length

Height

Width

Weight Actual

Engine - Manufacturer

- Cycles Four

- HP (3600 rpm) 6.0 HP

Fuel Tank Cap. 1.5 Qt.

Fuel Unleaded

911072/911472

LM228sp/LM235sp

60.5 153.7 CM

37.75 96 CM

23” 58.4 CM

99.5 Lbs

Tecumseh

911073/911473

LM229sp/LM236sp

60.5 153.7 CM

37.75 96 CM

23” 58.4 CM

102.5 Lbs.

Tecumseh

Four

6.0 HP

1.5 Qt.

Unleaded

Primer Bulb Standard Standard

Throttle/Choke Control N/A

Starting

Recoil

Cylinder Bore Aluminum

N/A

Recoil

Aluminum

Pressurized Oil System Standard Standard

Governed RPM

Crank Case Cap.

2850+ -150 2850-1--150

27 Oz.

27 Oz.

Air Cleaner Paper Element Paper Element

Engine Oil Type .

Spark Plug

SAE. 30

.30

SAE. 30

.30

Differential Standard Standard

Variable Speeds - MPH 0-4 MPH

i

Mower Deck Gauge

0-6.4 KMPH

14 Gauge Stamped

Steel

0-4 MPH

0-6.4 KMPH

14 Gauge Stamped

Steel

Baked Powder Paint Standard Standard

Cutting Width 21” 53.3 CM 21” 53.3 CM

Cutting Height 6 Positions

1.25”- 3.5”

3.2-8.9 CM

6 Positions

1.25” - 3.5”

3.2-8.9 CM

Folding Handlebar Standard Standard

One Piece One Piece

Adjustable Handle Bar 4 Position 4 Position

Front Wheel Dia. 7.5” 19.1 CM

7.5” 19.1 CM

Rear Wheel Dia. 10.5” 26.7 CM 10.5” 26.7 CM

Side Discharge

Standard Standard

Bagger \ Standard Standard

1

Accessory

Dethatcher

Mulchmaster Plug

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

1 Rear Roller Kit

711024

* it

711028 711028

* *

it

711033

N/A

*

*

711032 711032

711034 711034

Mulching Accessory 711035 711035

Part of Base Model

27

Page 30

Specifications

Model No.

Description Name

Length

Height

Width

Weight Actuai

Engine - Manufacturer

- Cycles

- HP (3600 rpm)

Fuel Tank Cap.

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Cap.

Air Cleaner

Engine Oil Type

Spark Plug

Differential

Variable Speeds - MPH

Mower Deck Gauge

Baked Powder Paint

Cutting Width

Cutting Height

911304 911311

LM21

60.5 153.7 CM

LM21S LM21sm

60.5 153.7 CM

37.75 96 CM 37.75” 96 CM

23” 58.4 CM

81.5 Lbs

Briggs & Stratton

Four

5.0 HP

1.5 Qt.

Unleaded

N/A

Standard

Recoil

Aluminum

Standard

2900+ -100

20 Oz.

Paper Element

SAE. 30

.30

N/A

N/A

23” 58.4 CM 23” 58.4 CM

96.5 Lbs. 97.2 Lbs.

Briggs & Stratton

Four

5.0 HP

1.5 Qt.

Unleaded

N/A

Standard N/A

Recoil

Aluminum

Standard

2900-I--100

20 Oz.

Paper Element

SAE. 30

.30

Standard

0-4 MPH

0-6.4 KMPH

14 Gauge Stamped

Steel

Standard

21” 53.3 CM

6 Positions

1.25”- 3.5”

3.2-8.9 CM

14 Gauge Stamped

Steel

Standard

21” 53.3 CM

6 Positions

1.25”-3.5”

3.2-8.9 CM

911312

60.5” 153.7 CM

37.75” 96 CM

Tecumseh

Four

6.0 HP

1.5 Qt.

Unleaded

Standard

Recoil

Aluminum

Standard

2850+ -150

27 Oz.

Paper Element

SAE. 30

.30

Standard

0-4 MPH

0-6.4 KMPH

16 Gauge Stamped

Steel

Standard

21” 53.3 CM

6 Positions

1.25”-3.5”

3.2-8.3 CM

Folding Handlebar

Adjustable Handle Bar

Front Wheel Dia.

Rear Wheel Dia.

Side Discharge

Bagger

Accessory

Dethatcher

Muichmaster Plug

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Accessory

= Part of Base Model

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

Standard

Standard

N/A

711027

711028

*

*

711033

711032

711034

711035

28

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

Standard

Standard

711024

711027

711028

*

ic

711033

711032

711034

711035

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

N/A (Rear Opt)

Optional

711024

711027

711028

N/A

711030

711033

711032

711034

■k

Page 31

Specifications

Model No.

Description Name

Length

Height

Width

Weight Actual

Engine - Manufacturer

- Cycies Four

- HP (3600 rpm)

Fuel Tank Cap.

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

Pressurized Oil System

Governed RPM

Crank Case Cap.

Air Cleaner

Engine Oil Type

Spark Plug

Differential

Variable Speeds - MPH

Mower Deck Gauge

Baked Powder Paint

Cutting Width

Cutting Height

911313

LM21S

60.5 153.7 CM

37.75 96 CM

23" 58.4 CM

99.5 Lbs

Tecumseh

6.0 HP

1.5 Qt.

Unleaded

Standard

N/A

Recoil

Aluminum

Standard

2850 +-150

27 Oz.

Paper Element

SAE. 30

.30

Standard

0-4 MPH

0-6.4 KM PH

14 Gauge Stamped

Steel

Standard

21” 53.3 CM

6 Positions

1.25”- 3.5”

3.2-8.9 CM

911314

LM21SW

60.5 153.7 CM

37.75” 96 CM

23” 58.4 CM

102.5 Lbs.

Tecumseh

Four

6.0 HP

1.5 Qt.

Unleaded

Standard

N/A

Recoil

Aluminum

Standard

2850+ - 150

27 Oz.

Paper Element

SAE. 30

.30

Standard

0-4 MPH

0-6.4 KMPH

14 Gauge Stamped

Steel

Standard

21” 53.3 CM

6 Positions

1.25” - 3.5”

3.2-8.9 CM

911315

LM21se

60.5” 153.7 CM

37.75” 96 CM

23” 58.4 CM

105.5 Lbs.

Tecumseh

Four

6.0 HP

1.5 Qt.

Unleaded

Standard

N/A

Electric/Recoil

Aluminum

Standard

2850+ -150

27 Oz.

Paper Element

SAE. 30

.30

Standard

0-4 MPH

0-6.4 KMPH

14 Gauge Stamps

Steel

Standard

21” 53.3 CM

6 Positions

1.25” - 3.5”

3.2-8.9 CM

Folding Handlebar

Adjustable Handle Bar

Front Wheel Dia.

Rear Wheel Dia.

Side Discharge

Bagger

Accessory

Dethatcher

Mulchmaster Plug

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Accessory

= Part of Base Model

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

Standard

Standard

711024

711027

711028 711028

*

*

711033

711032

711034

711035

29

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

Standard

Standard

N/A

711027

*

it

it

711032

711034

711035

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

Standard

Standard

711024

711027

711028

it

it

711033

711032

711034

711035

Page 32

Specifications

Model No.

Description Name

Length

Height

Width

Weight Actual

911316 911317

LM21SCSW LM21SCSW

60.5 153.7 CM

37.75” 96 CM

23” 58.4 CM 23” 58.4 CM

88 Lbs

Engine - Manufacturer N/A

- Cycles

- HP (3600 rpm)

Fuel Tank Cap.

Fuel

Primer Bulb

Throttle/Choke Control

Starting

Cylinder Bore

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Pressurized Oil System N/A

Governed RPM

Crank Case Cap.

Air Cieaner

Engine Oil Type

Spark Plug

Differential

Variable Speeds - MPH

Mower Deck Gauge

Baked Powder Paint

Cutting Width

Cutting Height

N/A

N/A

N/A

N/A

N/A

Standard Standard

0-4 MPH

14 Gauge Stamped

Standard Standard

21” 53.3 CM

6 Positions

60.5 153.7 CM 60.5 153.7CM

37.75” 96 CM 37.75” 96CM

113 Lbs

Kawasaki

Four

5.0 HP

1.4 Qt.

Unleaded

N/A

Standard

Recoil

Cast Iron Sleeve

Standard w/Oil Filter

2850+ - 150

19 0z.

Dual Element

SAE. 30

.30 .30

0-4 MPH 0-3.5 MPH

0-6.4 KMPH

0-6.4 KMPH

14 Gauge Stamped

Steel

Steel

21” 53.3 CM

6 Positions

1.25” - 3.5”

1.25”- 3.5”

3.2-8.9 CM 3.2-8.9 CM

911318 911319

LM21S

LM21SW

60.50 153.7CM

37.75” 96CM

23” 58.4 CM

23” 58.4CM

99 Lbs. 99.5 Lbs.

Tecumseh

Briggs & Stratton

Two Four

5.0 HP 5.0 HP

1.5 Qt.

Unleaded/Oil (50:1)

Standard

N/A

Recoil

Aluminum

Standard

3200+ - 150

N/A

Paper Element

N/A

1.5 Qt.

Unieaded

N/A

Standard

Recoil

Aluminum

Standard

2900 100

20 Oz.

Paper Element

SAE.30

.30

Standard

Standard

0-4 MPH

0-5.6 KMPH

14 Gauge Stamped

Steel

Standard

21” 53.3 CM

6 Positions

1.25” - 3.5”

3.2-8.9 CM

0-6.4 KMPH

14 Gauge Stamped

Steel

Standard

21” 53.3 CM

6 Positions

1.25” - 3.5”

3.2-8.9 CM

Folding Handlebar

Adjustable Handle Bar

Front Wheel Dia.

Rear Wheel Dia.

Side Discharge

Bagger

Accessory

Dethatcher

Mulchmaster Plug

Leaf Shredder

Side Discharge Chute

Rear Bagger

Swivel Wheel Kit

Rear Discharge Chute

Rear Roller Kit

Mulching Accessory

= Part of Base Model

Standard

One Piece

Standard

One Piece

4 Position 4 Position

7.5” 19.1 CM

10.5” 26.7 CM

7.5” 19.1 CM

10.5” 26.7 CM

Standard Standard

Standard

N/A

Standard

N/A

711027 711027

711028

•k

■k

711033

711032

711034

711028

*

•k

711033

711032

711034

711035 711035

30

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

Standard

Standard

711024

*

711028

*

•k

711033

Standard

One Piece

4 Position

7.5” 19.1 CM

10.5” 26.7 CM

Standard

Standard

N/A

711027

711028

■k

*

711033

711032 711032

711034

711035

711034

711035

Page 33

Dealer Preparation

Consumer Note: Your Ariens Dealer is expected to

complete these preparation steps and review

important information, including this manual, with you

before or upon delivery of unit.

The preparation information is included here so that

you and your dealer may review it together.

NOTE: All references to “Left", “Right”, “Front” and

“Rear” are given from operator’s position.

WARNING: Failure to follow all

instructions could result in personal

A

Instructions contained in this manual apply to several

models of mower. Use the instructions that apply to

your unit.

injury and/or damage to mower. Remove

wire from spark plug before attempting

any adjustment or assembly procedure.

Tools Required:

None

Package Contents - All Models (except

where noted).

Side Discharge Chute (not included

in 911067 and 911068)

IMPORTANT: Engines are shipped without oil in

engine crankcase. Refer to Lubrication and

Maintenance Section for filling instructions.

Step 1

Remove the mower and other components from

shipping container.

31

Page 34

Dealer Preparation

step 2

Unfold the handlebar. Select a safe comfortable

handlebar operating height, place hole in braces onto

pins on both sides of mower. (Refer to Adjustments

Section.)

On Professional models, nuts and bolts are used to

secure handlebar.

1. Speed Selector Rod

2. Speed Control Bell Crank

3. Washer

4. Hair Pin

5. Swivel

1. Handlebar Height Adjustment Holes

Figure 16: Handlebar Set-up

Step 3 (Self Propelled Models)

On self propelled models, Speed Selector rod is

shipped on handlebar with hardware in position.

Remove hair pin and washer, insert bent end of rod

through hole in swivel of speed control bell crank,

place washer onto rod and retain with hair pin.

Figure 17: Speed Selector

Step 4

Assemble grass bag onto bag frame by sliding bag

over frame (longest side of bag is top and goes over

long side of frame).

32

3. Bag Molding

Figure 18: Grass Bagger

Page 35

Dealer Preparation (Continued)

Secure bag to each side of bag frame by separating

molding on bag enough to slide frame into molding.

Be sure molding is completely seated on all four

sides of bag frame.

To install grass bag or side discharge deflector on

mower refer to Pre-Starting in Operation Section of

this manual.

WARNING: DO NOT operate mower

unless either side discharge opening

A

cover or side discharge defiector is

instaiied. Objects may be picked up and

thrown causing damage or personai

injury. Never operate engine with rear

door open uniess grass bag is in piace.

Step 5 (electric start models)

On electric start models, battery was charged before

unit was shipped but may start mower only a few

times because of long term self discharge. Fully

charge battery before delivery of mower to customer.

(Refer to instructions in Lubrication and Maintenance

ection.)

Step 6

Engine/Blade Control feature on this mower must

cause engine and blade to stop within 3 (three)

seconds whenever operator releases control on

handlebar. Control was adjusted at factory but must

be checked according to instructions in Adjustments

Section of this manual.

Step 8

Complete Walk Behind Lawn Mower Warranty

Registration Form and mail original copy to Ariens

Company.

Warranty is registered under model and serial

number found on decal on mower pan.

Step 9

Using the Owner’s Manual, instruct customer on

controls and operation of unit. Emphasize safety and

discuss the Safety Precautions.

Explain recommended lubrication and maintenance

of the unit.

IMPORTANT: Remind customer to change oil in 4

cycle engine crankcase after first two (2) hours of

operation.

Advise customer on adjustments, demonstrate how to

install grass bag, deflector and discharge opening

cover.

Explain Ariens Company, Limited Warranty Policy,

and fill out Original Purchaser Registration Card,

Parts and Repair Manual Order Form and return to

Ariens Company. Place Model and Serial Number on

page (1) of this manual.

Give customer his Owner’s Manual and engine

manufacturer’s instructions. Advise him to thoroughly

read and understand them.

Step 7

Oil air cleaner precleaner per instructions in

Lubrication and Maintenance section of this manual

before delivery to customer.

33

Page 36

Accessories

Enhance your Walk Behind Lawn Mower with these Ariens Accessories.

71102400 Dethatcher

71102700

71102800

71102900

71103000 Grass Bag

71103200

71103300

71103400 Rear Roller

71103500

Be sure to always use genuine Ariens parts to keep your

walk behind lawn mower running like new.

Mulchmaster Plug

Leaf Shredder

Side Discharge Deflector

Rear Discharge Chute

Swivel Wheel

Mulching Accessory

34

Page 37

AraENS

PRODUCTS

GUARANTEE

LIMITED

WARRANTY

PROTECTION PLAN

e The Company will provide for the replacement of any

part found upon examination by the Cotnpany to be

defective. Such repair or replacement will be free of

charge to the purchaser (labor and parts) for two years

(24 months) from the date of purchase. Arlens

manufadured parts (but not labor) will be free of charge