Page 1

Page 2

TABLE OF CONTENTS

Section 1 - Introduction . . . . . . . . . . . . . . . . . 1-3

1.1 The Manual . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 Service and Replacement Parts . . . . . . . 1-3

1.3 Product Registration . . . . . . . . . . . . . . . . 1-3

1.4 Unauthorized Replacement Parts . . . . . . 1-3

1.5 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.6 Technical Service Communications. . . . . 1-3

Section 2 - Safety2-4

2.1 Safety Alerts . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2 Signal Words . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 Notations . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Practices and Laws . . . . . . . . . . . . . . . . . 2-4

2.5 Required Operator Training. . . . . . . . . . . 2-4

2.6 Preparation . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.7 Service Position . . . . . . . . . . . . . . . . . . . . 2-4

2.8 Cleaning and Storage . . . . . . . . . . . . . . . 2-4

2.9 Safety Rules . . . . . . . . . . . . . . . . . . . . . . 2-5

Section 3 - Specifications . . . . . . . . . . . . . . . 3-7

Section 4 - General Maintenance &

Adjustments. . . . . . . . . . . . . . . . . . . . . . . .4-12

4.1 Controls and Features . . . . . . . . . . . . . . .4-12

4.2 Service Positions . . . . . . . . . . . . . . . . . . .4-13

4.3 Filling The Fuel Tank . . . . . . . . . . . . . . . .4-13

4.4 General Lubrication . . . . . . . . . . . . . . . . .4-13

4.5 Mower Belt Adjustment . . . . . . . . . . . . . .4-14

4.6 Clutch and Brake . . . . . . . . . . . . . . . . . . .4-14

4.7 Mower Pan. . . . . . . . . . . . . . . . . . . . . . . .4-15

4.8 Anti-Scalp Rollers . . . . . . . . . . . . . . . . . .4-16

4.9 Vents . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

4.10 Pinion and Steering Adjustment . . . . . .4-17

4.11 Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Section 5 - Engine. . . . . . . . . . . . . . . . . . . . . .5-18

5.1 Engine Troubleshooting. . . . . . . . . . . . . .5-18

5.2 Engine Oil . . . . . . . . . . . . . . . . . . . . . . . .5-19

5.3 Changing Oil . . . . . . . . . . . . . . . . . . . . . .5-19

5.4 Air Cleaner. . . . . . . . . . . . . . . . . . . . . . . .5-19

5.5 Spark Plug . . . . . . . . . . . . . . . . . . . . . . . .5-20

5.6 Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

5.7 Engine Removal . . . . . . . . . . . . . . . . . . .5-20

5.8 Engine Replacement . . . . . . . . . . . . . . . .5-20

Section 6 - Mower Deck . . . . . . . . . . . . . . . . .6-22

6.1 Rotary Mower Belt Replacement. . . . . . .6-22

6.2 Mower Drive Belt Replacement . . . . . . . .6-22

6.3 Mower Blade . . . . . . . . . . . . . . . . . . . . . .6-22

6.4 Mower Pan Removal . . . . . . . . . . . . . . . .6-23

6.5 Linkages for Mower Height/Engagement &

Clutch/Brake . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

6.6 Mower Spindle Removal . . . . . . . . . . . . .6-25

Section 7 - Steering and Controls . . . . . . . . .7-26

7.1 Steering Shaft Gears . . . . . . . . . . . . . . . .7-26

7.2 Speed Selector . . . . . . . . . . . . . . . . . . . .7-27

Section 8 - Brake and Clutch . . . . . . . . . . . . .8-28

8.1 Brake Disassembly . . . . . . . . . . . . . . . . .8-28

8.2 Clutch and Brake Adjustment . . . . . . . . .8-28

Section 9 - Drive Train . . . . . . . . . . . . . . . . . .9-29

9.1 Rear Axle Disassembly . . . . . . . . . . . . . .9-29

9.2 Gear Case Removal . . . . . . . . . . . . . . . .9-29

9.3 Gear Case Replacement . . . . . . . . . . . . .9-30

9.4 Friction Wheel Replacement . . . . . . . . . .9-30

Section 10 - Bagger. . . . . . . . . . . . . . . . . . . . 10-32

10.1 Vane Installation. . . . . . . . . . . . . . . . . . 10-32

10.2 Bagger Assembly. . . . . . . . . . . . . . . . . 10-32

10.3 Lower Boot Installation. . . . . . . . . . . . . 10-33

Section 11 - Electrical. . . . . . . . . . . . . . . . . . 11-34

11.1 Safety Interlock System . . . . . . . . . . . . 11-34

11.2 Troubleshooting . . . . . . . . . . . . . . . . . . 11-34

11.3 Battery (Electric Start Models) . . . . . . . 11-34

2

Page 3

SECTION 1 - INTRODUCTION

1.1 THE MANUAL

It is the purpose of this manual to provide complete

instructions for service, maintenance, disassembly,

repair, and installation of the mechanical components

for the 927 Rear Engine Rider Mowers.

Dealer trained service personnel should use this

manual as a supplement to and reminder of the training

sessions conducted by the company.

Read all information for servicing a part of system

before repair work is started to avoid needless

disassembly.

Operation

Before operation of the unit, carefully and completely

read manuals supplied with the unit. The contents will

provide you with an understanding of safety

instructions and controls during normal operation and

maintenance.

Safety Messages

For your safety and the safety of others always read,

understand, and follow all DANGER, WARNING, and

CAUTION messages found in manuals and on safety

decals.

Directional Reference

All reference to left, right, front, or rear are given from

the operator in the operator position and facing the

direction of forward travel.

1.2 SERVICE AND REPLACEMENT PARTS

When ordering publications, replacement parts, or

making service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product registration form in

the unit literature package. They are printed on a serial

number label, located on the frame of your unit.

Serial Number

1.3 PRODUCT REGISTRATION

A warranty registration card must be filled out, signed,

and returned at the time of purchase. This card

activates the warranty. Claims meeting requirements

during limited warranty period will be honored.

1.4 UNAUTHORIZED REPLACEMENT

PARTS

Use only Ariens replacement parts. The replacement of

any part on this vehicle with anything other than an

Ariens authorized replacement part may adversely

affect the performance, durability, or safety of this unit

and may void the warranty. Ariens disclaims liability for

any claims or damages, whether warranty, property

damage, personal injury , or death arising out of the use

of unauthorized replacement parts.

1.5 DISCLAIMER

Ariens reserves the right to discontinue, make changes

to, and add improvements upon its products at any

time without public notice or obligation. The

descriptions and specifications contained in this

manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations

may not be applicable to your unit.

1.6 TECHNICAL SERVICE

COMMUNICATIONS

Ariens Technical Service communicates information to

the field using Service Letters, Service Bulletins,

Product Notices, and Campaigns. Each

communication signifies a type of information and

priority. The dealer is responsible to carry out the

directive provided in the communication. The types of

communication are:

Service Letter

dealer. Technical information on how to service the

product and product improvements.

Service Bulletin

resolve certain issues or a notification of a policy

change.

Product Notices

located in a certain region. This is a limited distribution

to only those who received the product involved.

Campaigns

product must be updated and are tracked by the

factory until all units are corrected.

- General technical information for the

- Notification to update products to

- Notification of limited product

- Notification of a safety related issue. All

Figure 1

OA0040

3

Page 4

SECTION 2 - SAFETY

2.1 SAFETY ALERTS

Look for these symbols to point out

important safety precautions. They

mean:

Attention!

Personal Safety Is Involved!

Become Alert!

Obey The Message!

2.2 SIGNAL WORDS

The safety alert symbol is used in decals on the unit

and with proper operation procedures in this manual.

They alert you to the existence and relative degree of

hazards.

Understand the safety message. It contains important

information about personal safety on or near the unit.

DANGER:

SITUATION! If not avoided, WILL RESULT in

death or serious injury.

WARNING:

SITUATION! If not avoided, COULD RESULT

in death or serious injury.

CAUTION:

SITUATION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be used

to alert against unsafe practices.

IMMINENTLY HAZARDOUS

POTENTIALLY HAZARDOUS

POTENTIALLY HAZARDOUS

2.3 NOTATIONS

NOTE:

ation and maintenance practices.

IMPORTANT:

required to prevent damage to unit or attachment.

General reference information for proper oper-

Specific procedures o r infor mati on

2.4 PRACTICES AND LAWS

Practice usual and custo mar y safe worki ng

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate, or serious injury or death. Learn applicable

rules and laws in your area.

2.5 REQUIRED OPERATOR TRAINING

Original purchaser of this unit was instructed by the

seller on safe and proper operation. If unit is to be used

by someone other than original purchaser; loaned,

rented or sold, ALWAYS provide this manual and any

needed safety training before operation.

2.6 PREPARATION

Before starting any removal of parts, proper

preparation is very important for efficient work. A clean

work area at the start of each job will allow you to

perform service repairs easily and quickly.

To reduce the incidence of misplaced tools or parts,

place removed components with all attaching hardware

in the disassembly order on a clean work surface.

Organization is a key part of proper reassembly.

T ools, instruments, and parts needed for the job should

be gathered before work is started. Interrupting a job to

locate tools or parts is a needless delay. A list of

required special tools has been included in this

manual.

CAUTION:

spillage will occur. Remove battery to prevent

spillage of electrolyte.

Remove enough fuel so that no

2.7 SERVICE POSITION

Place unit on a flat level surface. ALWAYS stop engine

and disengage clutches. Tip up on the service bar for

ease of access during some procedures. Assure unit is

secure and will not tip over. Strap and clamp onto lift if

used.

IMPORTANT:

bar, undrained gasoline drawn into cylinder may wash

cylinder wall and shorten engine life.

When unit is tipped up onto its service

WARNING:

can cut. Movem ent of par ts can cu t of f fing ers

or a hand. Wear gloves, and use extreme

caution when servicing.

AVOID SHARP EDGES which

2.8 CLEANING AND STORAGE

IMPORTANT:

outdoors to help prevent sealed bearing rust or

corrosion. Water can seep into sealed bearings and

reduce component life. Bearings are sealed against dirt

and debris only.

A unit that is excessively dirty should be cleaned

before work starts. Cleaning will occasionally uncover

trouble sources. Dirt and abrasive dust reduce the

efficient work life of parts and can lead to costly

replacement.

When taking unit out of extended storage:

1. Check for any damage or loose parts. Repair,

replace, or tighten hardware before operation.

2. If a preservative fluid was used in fuel tank, drain

and discard. Fill fuel tank with fresh new fuel.

Never spray unit with water or store unit

2 - 4

Page 5

2.9 SAFETY RULES

Walk Around Inspection

Complete a walk around inspection of unit and work

area to understand:

• Work area.

• Your unit.

• All safety decals.

Work Area

ALWAYS check overhead and side clearances

carefully before operation. ALWAYS be aware of traffic

when operating along streets or curbs.

ALWAYS keep hands and feet within the limits of the

unit.

Keep children, people, and animals away. Keep

children out of work area and under watchful care of a

responsible adult.

Keep area of operation clear of all toys, pets, and

debris. Stay alert for hidden hazards.

DO NOT run engine in an enclosed area. Always

provide good ventilation.

Unit

ALWAYS keep protective structures, guards, and

panels in good repair, in place and securely fastened.

NEVER modify or remove safety devices.

Check Safety Interlock System for proper operation

daily (see Operation section). Do not operate unless

system operates properly.

Operation

Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an Emergency

• Speed ranges

Before starting engine, disengage auxiliary power.

Always back up slowly. Always look down and behind

before and while backing.

Never leave a running unit unattended. ALWAYS shut

off auxiliary power, lower throttle setting, and stop

engine before leaving unit. ALWAYS remove key to

prevent unauthorized use.

Never carry passengers on any part of unit.

Avoid uneven and rough terrain. DO NOT operate near

drop offs, ditches, or embankments. Unit can suddenly

turn over if a wheel is over the edge of a cliff or ditch, or

if an edge caves in.

ALWAYS operate unit in good visibility and light.

Fuel is highly flammable and its vapors can explode.

Use ONLY approved fuel containers.

NO Smoking!

NO Sparks!

NO Flames!

Allow engine to cool before servicing.

NEVER fill fuel tank when engine is running, hot, or unit

is indoors.

Abnormal Vibrations are a warning of trouble. Striking a

foreign object can damage unit. Stop unit and engine.

Wait for all moving parts to stop. Remove wire from

spark plug. Inspect unit and make any necessary

repairs before restart.

Hazardous Slopes

DO NOT operate on steep slopes. Avoid operating on

slopes. When you must operate on a slope, travel up

and down the slope. Never operate cross a slope.

Never operate on a slope greater than 10 degrees.

If tires lose traction, turn off auxiliary power and

proceed slowly straight down slope. Avoid wet

surfaces.

Avoid parking on a slope. If necessary, use wheel

chocks.

DO NOT leave unit unattended on a slope. ALWAYS

use wheel chocks when leaving unit.

Child Safety

NEVER allow children to operate or play on or near

unit. Be alert and shut off unit if children enter area.

Personal Safety

Read and obey all warning, caution, and instructions

on the unit and in provided manuals.

• Only trained adults may operate unit.

• Training includes actual operation.

• Clearly understand instructions.

• Be alert! Conditions can change.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation requires

your complete and unimpaired attention at all times.

NEVER allow anyone to operate the unit when their

alertness or coordination is impaired.

DO NOT operate unit without wearing adequate outer

garments. Wear adequate safety gear and protective

gloves. Wear proper footwear to improve footing on

slippery surfaces.

Protect eyes, face, and head from objects that may be

thrown from unit. Wear appropriate hearing protection.

Avoid Sharp Edges. Sharp edges can cut. Moving

parts can cut or amputate fingers or a hand. Wear

gloves to service unit when handling sharp edges.

ALWAYS keep hands away from any pinch points.

ALWAYS keep hands and feet away from all moving

parts during operation. Moving parts can cut off body

parts.

DO NOT touch unit parts which might be hot from

operation. Allow parts to cool before attempting to

maintain, adjust, or service.

2 - 5

Page 6

Controls

Come to a complete stop before reversing.

Never jerk the control levers. Always use a steady

even action to achieve smooth control.

Always be aware of obstructions that may cause injury

to operator or damage to the unit.

Keep alert with eyes fixed in direction of travel.

Maintenance

ALWAYS maintain unit in safe operating condition.

Damaged or worn out muffler can cause fire or

explosion.

Check the condition of the unit at the end of each day

and repair any damage or defects.

ALWAYS block wheels and know all jack stands are

strong and secure and will hold weight of unit during

maintenance.

Keep nuts and bolts tight and keep equipment in safe

operating conditions.

Before maintenance, adjustments, or service (except

where specifically recommended), shut off engine.

Allow hot parts to cool.

Keep unit free of dirt, stones, and other debris. Clean

up oil or fuel spills.

Storage

DO NOT store unit inside a building with fuel in the fuel

tank where any ignition sources are present. Allow unit

to cool completely.

ALWAYS clean unit before extended storage. See

Engine Manual for proper storage.

Battery

Avoid Electric Shock. DO NOT reverse battery

connections.

Explosive Gases! Poisonous battery fluid contains

sulfuric acid and its contact with skin, eyes, or clothing

can cause severe burns.

No flames. No sparks. No smoking near battery.

Always wear safety glasses and protective gear near

battery.

DO NOT TIP battery beyond a 45

direction.

ALWAYS KEEP BATTERIES OUT OF REACH of

children.

o

angle in any

Transport

Use extra care when loading or unloading unit onto

trailer or truck. Secure unit chassis to transport vehicle.

NEVER secure from rods or linkages that could be

damaged.

Attachments and Accessories

Use only attachments or accessories designed for your

unit.

2 - 6

Page 7

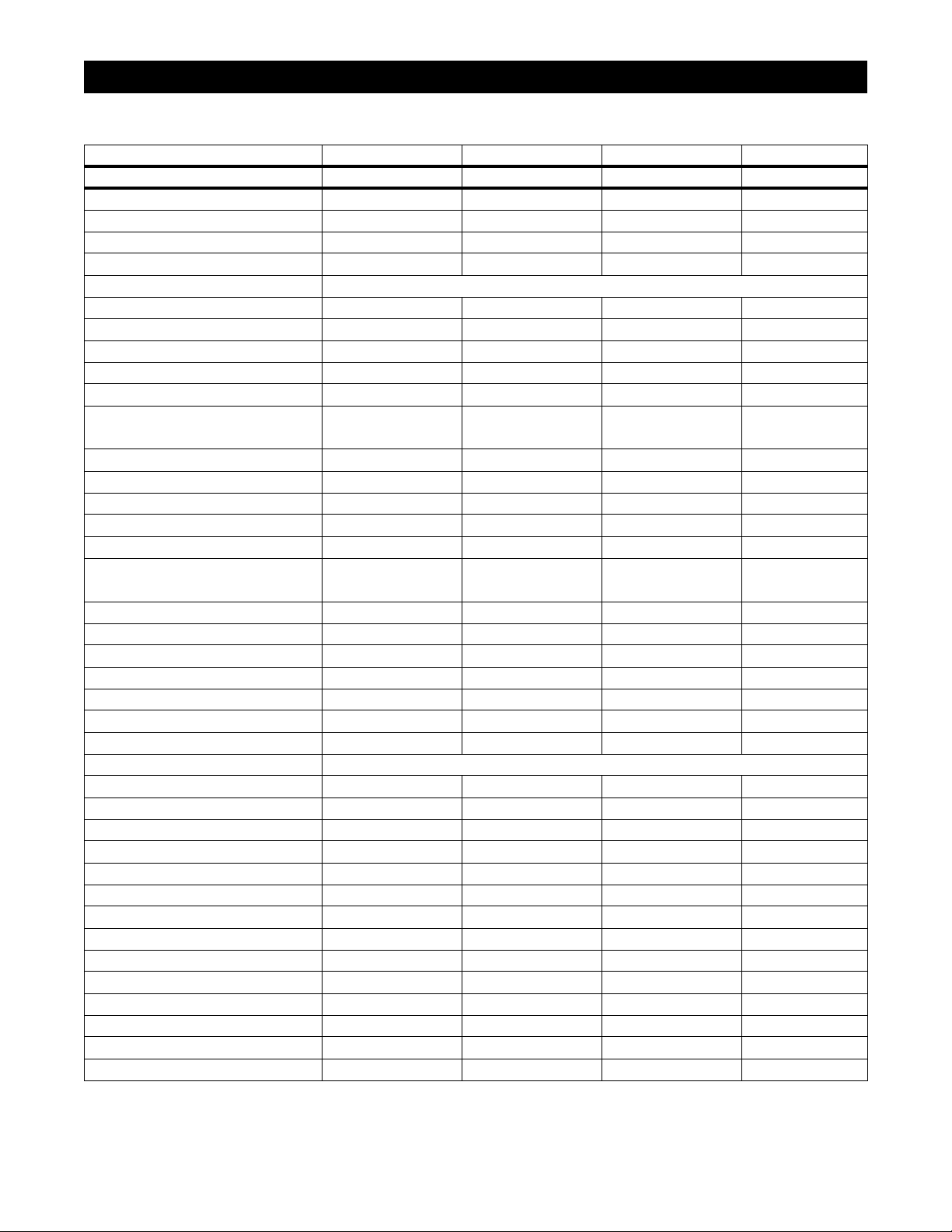

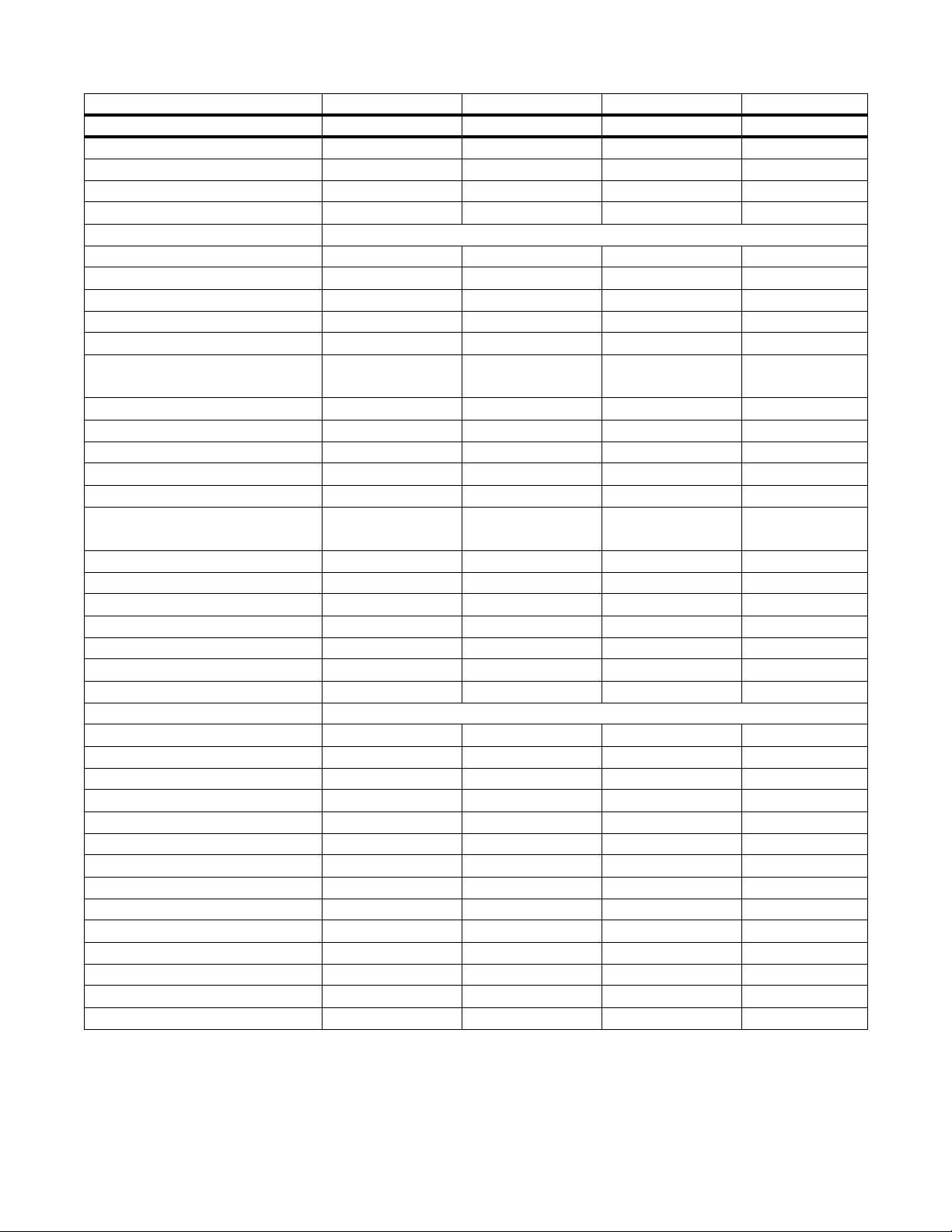

Model Number 927046 927047 927048 927049

Description Name RM 1028E RM 1132E RM 9028E RM 9030E

Battery

Brakes

Steering

Turning Radius - in (cm)

Tire Size

Front

Rear

Engine - Manufacturer

- Cycle

- Horsepower

Starting System

Fuel Tank Cap. -qt (L)

Fuel

Idle RPM

Governed RPM

Crank Case Cap. - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug

Transmission

Speed - Forward Max - mph (kph)

- Reverse Max. - mph (kph)

Trans miss ion Lube

Drive Clutch

Tire Pressure

Front

Rear

Lift System

Power Take Off

Mower Deck - Flex & Float

- High Performance

- Cutting Width - in (cm)

- Cutting Height - in (cm)

- Cut Increments - in (cm)

Bagger

Dethatcher Kit

Front Weight Kit

Leaf Mulcher Kit

Grass Mulcher Kit

SECTION 3 - SPECIFICATIONS

180 CCA 180 CCA 180 CCA 180 CCA

Drum Drum Drum Drum

Gear & Pinion Gear & Pinion Gear & Pinion Gear & Pinion

26 (66) 26 (66) 26 (66) 26 (66)

4.10-3.50x4.00 4.10-3.50x4.00 4.10-3.50x4.00 4.10-3.50x4.00

16.6x5x8.00 16.6x5x8.00 16.6x5x8.00 16.6x5x8.00

Briggs & Stratton Briggs & Stratton Briggs & Stratton Briggs & Stratton

Four Four Four Four

10.0 11.0 9.0 9.0

Electric

Recoil Back-up

3 (2.8) 3 (2.8) 3 (2.8) 3 (2.8)

Unleaded Unleaded Unleaded Unleaded

1800 1800 1800 1800

3250 3250 3250 3250

39 (1.2) 39 (1.2) 39 (1.2) 39 (1.2)

Paper Element

Foam Precleaner

SAE 30 SAE 30 SAE 30 SAE 30

.030" .030" .030" .030"

Sealed Case Sealed Case Sealed Case Sealed Case

1.6-5.5 (2.6-8.8) 1.6-5.5 (2.6-8.8) 1.6-5.5 (2.6-8.8) 1.6-5.5 (2.6-8.8)

2.7 (4.3) 2.7 (4.3) 2.7 (4.3) 2.7 (4.3)

150 Grease 150 Grease 150 Grease 150 Grease

Disc-O-Matic Disc-O-Matic Disc-O-Matic Disc-O-Matic

14 PSI 14 PSI 14 PSI 14 PSI

14 PSI 14 PSI 14 PSI 14 PSI

Manual Manual Manual Manual

Manual Manual Manual Manual

Standard Standard Standard Standard

Standard Standard Standard Standard

28 (71.1) 32 (81.3) 28 (71.1) 30 (76.2)

1.5-3.5 (3.8-11.4) 1.5-3.5 (3.8-11.4) 1.5-3.5 (3.8-11.4) 1.5-3.5 (3.8-11.4)

.5 (1.2) .5 (1.2) .5 (1.2) .5 (1.2)

827026/827013 827026/827013 827026/827013 827020

72701300 72701300 72701300 72701300

72701600 72701600 72701600 72701600

N/A N/A N/A 72703400

72703500 72703600 72703500 72701400

Electric

Recoil Back-up

Paper Element

Foam Precleaner

Electric

Recoil Back-up

Paper Element

Foam Precleaner

Electric

Recoil Back-up

Paper Element

Foam Precleaner

3 - 7

Page 8

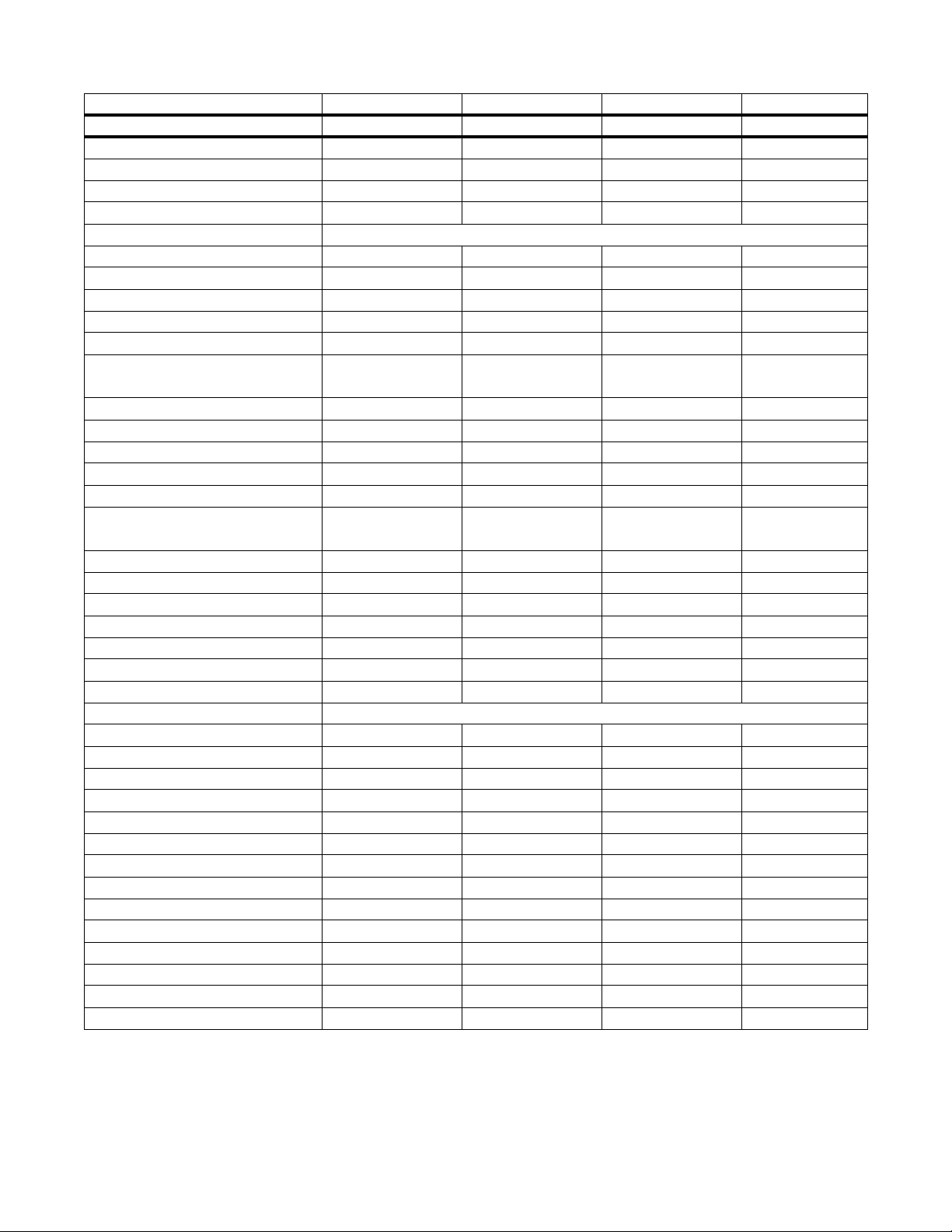

Model Number 927050 927051 927052 927053

Description Name RM 1232E RM 1332 RM 1330 RM 9028

Battery

Brakes

Steering

Turning Radius - in (cm)

Tire Size

Front

Rear

Engine - Manufacturer

- Cycle

- Horsepower

Starting System

Fuel Tank Cap. -qt (L)

Fuel

Idle RPM

Governed RPM

Crank Case Cap. - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug

Transmission

Speed - Forward Max - mph (kph)

- Reverse Max. - mph (kph)

Trans miss ion Lube

Drive Clutch

Tire Pressure

Front

Rear

Lift System

Power Take Off

Mower Deck - Flex & Float

- High Performance

- Cutting Width - in (cm)

- Cutting Height - in (cm)

- Cut Increments - in (cm)

Bagger

Dethatcher Kit

Front Weight Kit

Leaf Mulcher Kit

Grass Mulcher Kit

180 CCA 180 CCA 180 CCA 180 CCA

Drum Drum Drum Drum

Gear & Pinion Gear & Pinion Gear & Pinion Gear & Pinion

26 (66) 26 (66) 26 (66) 26 (66)

4.10-3.50x4.00 4.10-3.50x4.00 4.10-3.50x4.00 4.10-3.50x4.00

16.6x5x8.00 16.6x5x8.00 16.6x5x8.00 16.6x5x8.00

Briggs & Stratton Briggs & Stratton Briggs & Stratton Briggs & Stratton

Four Four Four Four

12.0 13.0 13.0 9.0

Electric

Recoil Back-up

3 (2.8) 3 (2.8) 3 (2.8) 3 (2.8)

Unleaded Unleaded Unleaded Unleaded

1800 1800 1800 1800

3250 3250 3250 3250

39 (1.2) 39 (1.2) 39 (1.2) 39 (1.2)

Paper Element

Foam Precleaner

SAE 30 SAE 30 SAE 30 SAE 30

.030" .030" .030" .030"

Sealed Case Sealed Case Sealed Case Sealed Case

1.6-5.5 (2.6-8.8) 1.6-5.5 (2.6-8.8) 1.6-5.5 (2.6-8.8) 1.6-5.5 (2.6-8.8)

2.7 (4.3) 2.7 (4.3) 2.7 (4.3) 2.7 (4.3)

150 Grease 150 Grease 150 Grease 150 Grease

Disc-O-Matic Disc-O-Matic Disc-O-Matic Disc-O-Matic

14 PSI 14 PSI 14 PSI 14 PSI

14 PSI 14 PSI 14 PSI 14 PSI

Manual Manual Manual Manual

Manual Manual Manual Manual

Standard Standard Standard Standard

Standard Standard Standard Standard

32 (81.3) 32 (81.3) 30 (76.2) 28 (71.1)

1.5-3.5 (3.8-11.4) 1.5-3.5 (3.8-11.4) 1.5-3.5 (3.8-11.4) 1.5-3.5 (3.8-11.4)

.5 (1.2) .5 (1.2) .5 (1.2) .5 (1.2)

827026/827013 827026/827013 827020 827026/827013

72701300 72701300 72701300 72701300

72701600 72701600 72701600 72701600

N/A N/A 72703400 N/A

72703600 72703600 72701400 72703500

Electric

Recoil Back-up

Paper Element

Foam Precleaner

Electric

Recoil Back-up

Paper Element

Foam Precleaner

Electric

Recoil Back-up

Paper Element

Foam Precleaner

3 - 8

Page 9

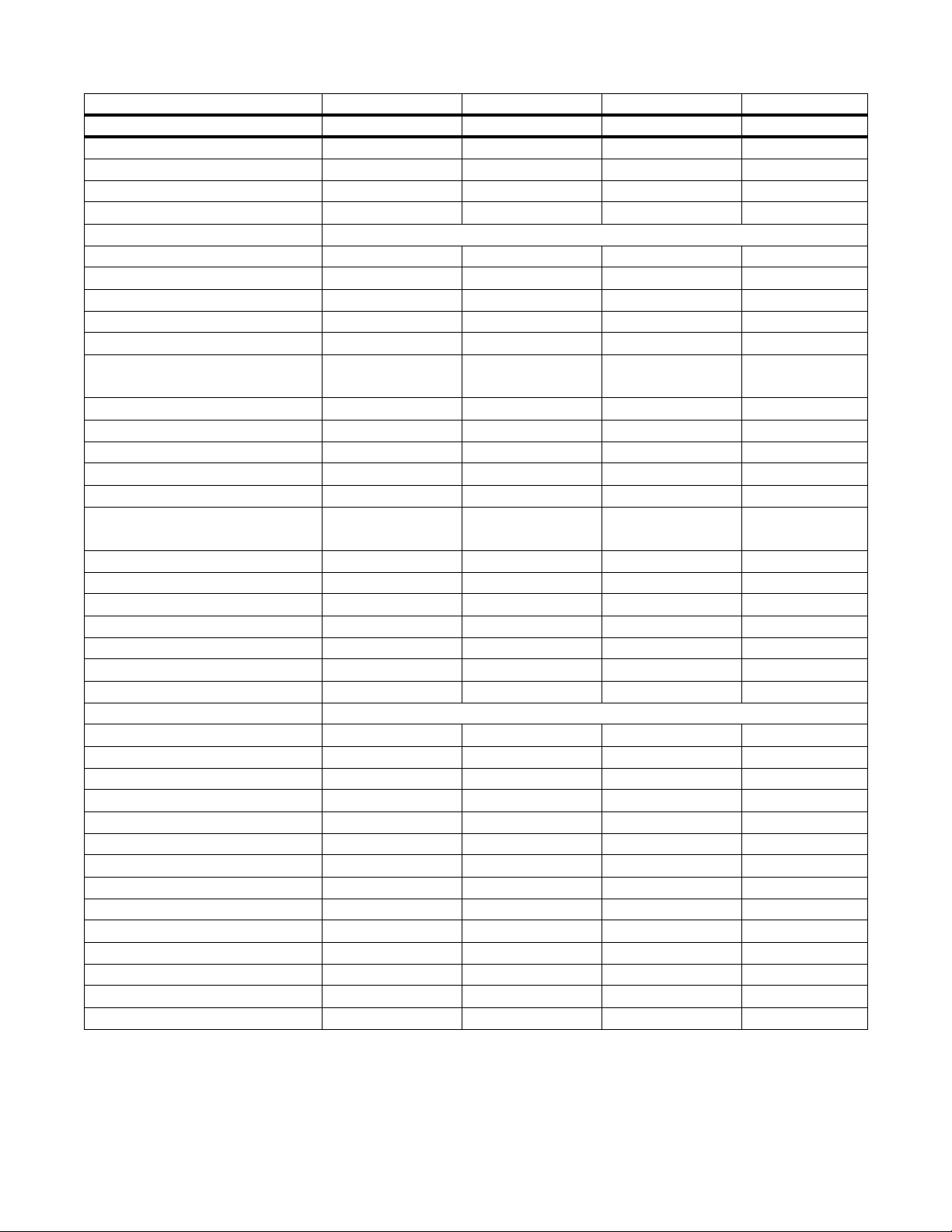

Model Number 927054 927055 927056 927301

Description Name RM 9030 RM 1332 RM 1330 RM 9028E

Battery

Brakes

Steering

Turning Radius - in (cm)

Tire Size

Front

Rear

Engine - Manufacturer

- Cycle

- Horsepower

Starting System

Fuel Tank Cap. -qt (L)

Fuel

Idle RPM

Governed RPM

Crank Case Cap. - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug

Transmission

Speed - Forward Max - mph (kph)

- Reverse Max. - mph (kph)

Trans miss ion Lube

Drive Clutch

Tire Pressure

Front

Rear

Lift System

Power Take Off

Mower Deck - Flex & Float

- High Performance

- Cutting Width - in (cm)

- Cutting Height - in (cm)

- Cut Increments - in (cm)

Bagger

Dethatcher Kit

Front Weight Kit

Leaf Mulcher Kit

Grass Mulcher Kit

180 CCA 180 CCA 180 CCA 180 CCA

Drum Drum Drum Drum

Gear & Pinion Gear & Pinion Gear & Pinion Gear & Pinion

26 (66) 26 (66) 26 (66) 26 (66)

4.10-3.50x4.00 4.10-3.50x4.00 4.10-3.50x4.00 4.10-3.50x4.00

16.6x5x8.00 16.6x5x8.00 16.6x5x8.00 16.6x5x8.00

Briggs & Stratton Briggs & Stratton Briggs & Stratton Briggs & Stratton

Four Four Four Four

9.0 13.0 13.0 9.0

Electric

Recoil Back-up

3 (2.8) 3 (2.8) 3 (2.8) 3 (2.8)

Unleaded Unleaded Unleaded Unleaded

1800 1800 1800 1800

3250 3250 3250 3000 max.

39 (1.2) 39 (1.2) 39 (1.2) 30 (.9)

Paper Element

Foam Precleaner

SAE 30 SAE 30 SAE 30 SAE 30

.030" .030" .030" .030"

Sealed Case Sealed Case Sealed Case Sealed Case

1.6-5.5 (2.6-8.8) 1.6-5.5 (2.6-8.8) 1.6-5.5 (2.6-8.8) 1.5-5.1 (2.4-8.2)

2.7 (4.3) 2.7 (4.3) 2.7 (4.3) 2.5 m(4.0)

150 Grease 150 Grease 150 Grease 150 Grease

Disc-O-Matic Disc-O-Matic Disc-O-Matic Disc-O-Matic

14 PSI 14 PSI 14 PSI 14 PSI

14 PSI 14 PSI 14 PSI 14 PSI

Manual Manual Manual Manual

Manual Manual Manual Manual

Standard Standard Standard Standard

Standard Standard Standard Standard

30 (76.2) 32 (81.3) 30 (76.2) 28 (71.1)

1.5-3.5 (3.8-11.4) 1.5-3.5 (3.8-11.4) 1.5-3.5 (3.8-11.4) 1.5-3.5 (3.8-11.4)

.5 (1.2) .5 (1.2) .5 (1.2) .5 (1.2)

827020 827026/827013 827020 827026/827013

72701300 72701300 72701300 72701300

72701600 72701600 72701600 72701600

72703400 N/A 72703400 N/A

72701400 72703600 72701400 72703500

Electric

Recoil Back-up

Paper Element

Foam Precleaner

Electric

Recoil Back-up

Paper Element

Foam Precleaner

Electric

Recoil Back-up

Paper Element

Foam Precleaner

3 - 9

Page 10

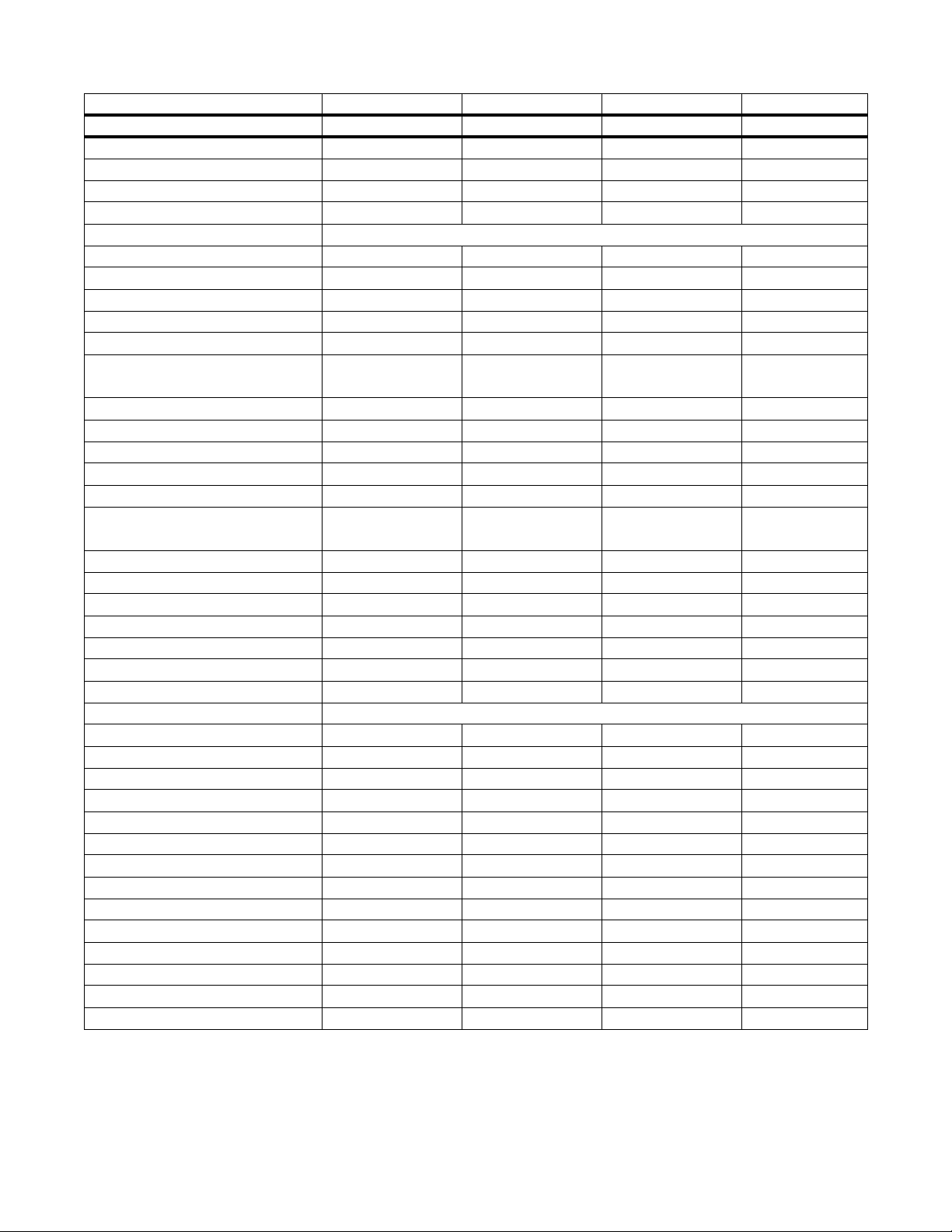

Model Number 927302 927303 927304 927305

Description Name RM 1228E RM 1232E RM 1328 RM 1332

Battery

Brakes

Steering

Turning Radius - in (cm)

Tire Size

Front

Rear

Engine - Manufacturer

- Cycle

- Horsepower

Starting System

Fuel Tank Cap. -qt (L)

Fuel

Idle RPM

Governed RPM

Crank Case Cap. - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug

Transmission

Speed - Forward Max - mph (kph)

- Reverse Max. - mph (kph)

Trans miss ion Lube

Drive Clutch

Tire Pressure

Front

Rear

Lift System

Power Take Off

Mower Deck - Flex & Float

- High Performance

- Cutting Width - in (cm)

- Cutting Height - in (cm)

- Cut Increments - in (cm)

Bagger

Dethatcher Kit

Front Weight Kit

Leaf Mulcher Kit

Grass Mulcher Kit

180 CCA 180 CCA 180 CCA 180 CCA

Drum Drum Drum Drum

Gear & Pinion Gear & Pinion Gear & Pinion Gear & Pinion

26 (66) 26 (66) 26 (66) 26 (66)

4.10-3.50x4.00 4.10-3.50x4.00 4.10-3.50x4.00 4.10-3.50x4.00

16.6x5x8.00 16.6x5x8.00 16.6x5x8.00 16.6x5x8.00

Briggs & Stratton Briggs & Stratton Briggs & Stratton Briggs & Stratton

Four Four Four Four

12.0 12.0 13.0 13.0

Electric

Recoil Back-up

3 (2.8) 3 (2.8) 3 (2.8) 3 (2.8)

Unleaded Unleaded Unleaded Unleaded

1800 1800 1800 1800

2930 max. 2850 max. 3250 3250 max.

39 (1.2) 39 (1.2) 39 (1.2) 39 (1.2)

Paper Element

Foam Precleaner

SAE 30 SAE 30 SAE 30 SAE 30

.030" .030" .030" .030"

Sealed Case Sealed Case Sealed Case Sealed Case

1.4-5.0 (2.3-8.0) 1.4-4.8 (2.3-7.7) 1.6-5.5 (2.6-8.8) 1.6-5.5 (2.6-8.8)

2.4 (3.9) 2.4 (3.9) 2.7 (4.3) 2.7 (4.3)

150 Grease 150 Grease 150 Grease 150 Grease

Disc-O-Matic Disc-O-Matic Disc-O-Matic Disc-O-Matic

14 PSI 14 PSI 14 PSI 14 PSI

14 PSI 14 PSI 14 PSI 14 PSI

Manual Manual Manual Manual

Manual Manual Manual Manual

Standard Standard Standard Standard

Standard Standard Standard Standard

28 (71.1) 32 (81.3) 28 (71.1) 32 (81.3)

1.5-3.5" (3.8-11.4) 1.5-3.5" (3.8-11.4) 1.5-3.5" (3.8-11.4) 1.5-3.5" (3.8-11.4)

.5 (1.2) .5 (1.2) .5 (1.2) .5 (1.2)

827026/827013 827026/827013 827026/827013 827026/827013

72701300 72701300 72701300 72701300

72701600 72701600 72701600 72701600

N/A N/A N/A N/A

72703500 72703600 72703500 72703600

Electric

Recoil Back-up

Paper Element

Foam Precleaner

Electric

Recoil Back-up

Paper Element

Foam Precleaner

Electric

Recoil Back-up

Paper Element

Foam Precleaner

3 - 10

Page 11

Model Number 927306 927307 927308 927310

Description Name RM 9028 RM 1328 RM 1332 RM 1028

Battery

Brakes

Steering

Turning Radius - in (cm)

Tire Size

- Front

- Rear

Engine - Manufacturer

- Cycle

- Horsepower

Starting System

Fuel Tank Cap. -qt (L)

Fuel

Idle RPM

Governed RPM

Crank Case Cap. - oz (L)

Air Cleaner

Engine Oil Type

Spark Plug

Transmission

Speed - Forward Max - mph (kph)

- Reverse Max. - mph (kph)

Trans miss ion Lube

Drive Clutch

Tire Pressure

Front

Rear

Lift System

Power Take Off

Mower Deck - Flex & Float

- High Performance

- Cutting Width - in (cm)

- Cutting Height - in (cm)

- Cut Increments - in (cm)

Bagger

Dethatcher Kit

Front Weight Kit

Leaf Mulcher Kit

Grass Mulcher Kit

180 CCA 180 CCA 180 CCA 180 CCA

Drum Drum Drum Drum

Gear & Pinion Gear & Pinion Gear & Pinion Gear & Pinion

26 (66) 26 (66) 26 (66) 26 (66)

4.10-3.50x4.00 4.10-3.50x4.00 4.10-3.50x4.00 4.10-3.50x4.00

16.6x5x8.00 16.6x5x8.00 16.6x5x8.00 16.6x5x8.00

Briggs & Stratton Briggs & Stratton Briggs & Stratton Briggs & Stratton

Four Four Four Four

9.0 13.0 13.0 10.0

Electric

Recoil Back-up

3 (2.8) 3 (2.8) 3 (2.8) 3 (2.8)

Unleaded Unleaded Unleaded Unleaded

1800 1800 1800 1800

3250 3250 3250 3250

39 (1.2) 39 (1.2) 39 (1.2) 39 (1.2)

Paper Element

Foam Precleaner

SAE 30 SAE 30 SAE 30 SAE 30

.030" .030" .030" .030"

Sealed Case Sealed Case Sealed Case Sealed Case

1.6-5.5 (2.6-8.8) 1.6-5.5 (2.6-8.8) 1.6-5.5 (2.6-8.8) 1.6-5.5 (2.6-8.8)

2.7 (4.3) 2.7 (4.3) 2.7 (4.3) 2.7 (4.3)

150 Grease 150 Grease 150 Grease 150 Grease

Disc-O-Matic Disc-O-Matic Disc-O-Matic Disc-O-Matic

14 PSI 14 PSI 14 PSI 14 PSI

14 PSI 14 PSI 14 PSI 14 PSI

Manual Manual Manual Manual

Manual Manual Manual Manual

Standard Standard Standard Standard

Standard Standard Standard Standard

28 (71.1) 28 (71.1) 32 (81.3) 28 (71.1)

1.5-3.5 (3.8-11.4) 1.5-3.5 (3.8-11.4) 1.5-3.5 (3.8-11.4) 1.5-3.5 (3.8-11.4)

.5 (1.2) .5 (1.2) .5 (1.2) .5 (1.2)

827026/827013 827026/827013 827026/827013 827026/827013

72701300 72701300 72701300 72701300

72701600 72701600 72701600 72701600

N/A N/A N/A N/A

72703500 72703500 72703600 72703500

Electric

Recoil Back-up

Paper Element

Foam Precleaner

Electric

Recoil Back-up

Paper Element

Foam Precleaner

Electric

Recoil Back-up

Paper Element

Foam Precleaner

3 - 11

Page 12

SECTION 4 - GENERAL MAINTENANCE & ADJUSTMENTS

4.1 CONTROLS AND FEATURES

11

10

4

5

3

CACAUTIONUTION

Before starting engine be

sure machine is in neutral

and mower clutch is

disengaged

2

Depress clutch pedal

P

and push latch to set.

6

7

WARNING

TO AVOID SERIOUS INJURY

OR DEATH

Read operator's manual.

Understand location and

function of all controls.

Look down and behind before

and while backing.

Remove objects thatcould be thrown

by the blade.

Avoid sudden turns.

Check interlock system per manual

before use.

Keep all sheilds in place.

Never carry childern.

Keep people and pets away when operating

machine.

Go up and down slopes, not across.

If machine stops going uphill. shut off

1

PTO and back down slowly.

GO

Release parking brake

Depress clutch pedal

Shift to 1st or 2nd speed

Slowly release clutch

Shift to desired speed

STOP

Depress clutch pedal

Depress Brake pedal

Before leaving operator's

position:

Shift to neutral

Engage parking brake

Disengage mower clutch

Stop Engine

Remove ignition key

SERVICING

Wait for all movement to stop

Disconnect spark plug wire

Before tipping unit, drain

gas tank and remove

battery - if electric

6

5

4

3

2

1

N

R

Speed

Selector

Located on

right hand

side of

driver's seat

8

9

12

13

1. Throttle Control

2. Mower Clutch Lever

3. Parking Brake

4. Clutch Pedal

5. Brake Pedal

6. Mower Height Lever

8. Speed Indicator

9. Speed Selector

10.Engine Oil Fill

11.Fuel Tank Fill

12.Mower Pan

13.Roller

7. Ignition Key Switch

Figure 2

OS0792

4 - 12

Page 13

4.2 SERVICE POSITIONS

1. Oil Fill Cap and Dipstick

2. Air Cleaner Cover

3. Spark Plug

4. Oil Drain Plug

5. Fuel Tank

6. Fuel Cap

Figure 3

1

2

3

4

5

6

Ariens Dealers will provide any service or adjustments

which may be required to keep your unit operating at

peak efficiency. Should engine service be required,

contact an Ariens dealer or an authorized engine

manufacturer’s service center.

WARNING:

UP can cause death or serious injury.

ALWAYS stop engine, remove key, wait for

moving parts to stop and remove wire from

spark plug before adjusting or servicing.

HOT SURFACES can result in death or

serious injury.

DO NOT touch parts which are hot from

operation.

ALWAYS allow parts to cool.

ROTATING PARTS can cut off body parts.

Keep hands and feet away. Loose clothing,

long hair or scarves can get caught in rotating

parts and cause death or serious injury.

CAUTION:

or moderate injury and/or damage to the unit.

Before unit is tipped up onto housing, remove

enough fuel so that no spillage will occur.

Remove battery to prevent spillage of

electrolyte.

Service Position

Place unit on a flat level surface. ALWAYS stop engine

and disengage clutches. Tip up on the service bar for

ease of access during some procedures. Assure unit is

secure and will not tip over. Strap and clamp onto lift if

used.

When unit is tipped up onto its service bar, undrained

gasoline drawn into cylinder may wash cylinder wall

and shorten engine life.

4.3 FILLING THE FUEL TANK

FLAMMABLE FUEL and its EXPLOSI VE

VAPORS can result in death or serious injury.

Handle fuel with care. ALWAYS use an

To add fuel to fuel tank (Figure 3):

approved fuel container.

No Smoking ! No lighted Materials!

No Open Flame!

Allow engine to cool before any service.

1. ALWAYS place unit in open or well ventilated area.

2. Stop engine and allow to cool for 2 minutes.

3. Clean fuel cap and surrounding area to prevent dirt

from entering fuel tank.

ACCIDENTAL ENGINE START

FUEL SPILLS may result in minor

4. Remove cap.

IMPORTANT:

DO NOT use gasohol or gasoline

containing alcohol. Alcohol will cause internal parts to

deteriorate. See Engine Manual for correct type and

grade of fuel.

5. Fill fuel tank to within 1/2" (1.3 cm) below bottom of

filler neck with unleaded gasoline.

6. Replace fuel cap and tighten.

7. ALWAYS clean up any spilled fuel.

Maintenance Schedule

The chart below shows the recommended

maintenance schedule that should be performed on a

regular basis. More frequent service may be required

due to working conditions (heavy loads, high ambient

temperatures, dusty conditions, or airborne debris).

See Engine Manual for further maintenance and

troubleshooting information.

4.4 GENERAL LUBRICATION

IMPORTANT:

and after lubrication. Keep grease and oil off belts to

avoid slippage and deterioration.

NOTE:

to the lube fittings. Order P/N: 00036800 - three pack of

3 oz. cartridges or 00036700 - ten pack of 14 oz.

cartridges.

The steering system, front wheels, left rear wheel and

linkage pivot points should be lubricated every

25 hours of operation, or twice each season,

whichever occurs first (Figure 4).

Wipe each grease fitting clean before

Apply Sten Mix Hi-Temp Grease or equivalent

4 - 13

Page 14

4.5 MOWER BELT ADJUSTMENT

Figure 5

1. Steering Gear

2. Adjustment Cap Screw

3. Height Control

4. Height Lever

5. View Quadrant Th rough

Slot

6. Spring Clip

1

2

3

4

5

6

Figure 6

1. Mower Pulley

2. Mower Belt

3. Fixed Idler

4. Clutching Idler

5. Belt Finger

6. Adjustable Clutch Rod

1

2

3

4

5

6

Adjust mower belt after first five (5) hours of operation.

To adjust 28" and 30" mowers (Figure 5):

1. Place height control lever in midnotch position,

depress spring clip and tighten yoke on front of unit

with a 3/4" socket wrench.

2. When tightening cap screw, hold mower clutch

lever so that front edge of lever is positioned in line

with rear edge of forward notch of quadrant.

3. Tighten belt just enough to prevent slippage under

load. Mower clutch lever (when tightening cap

screw) will move slightly to rear of this point when

tension is correct.

To adjust the 32" mower:

1. The 32" mower belt clutch rod should be adjusted

so the compressed spring length is from 5-1/4" to

5-3/8" (13.3 to 13.6 cm) when belt is engaged

(Figure 6).

2. Belt engagement should occur when front edge of

mower clutch is positioned in line with rear edge of

forward notch of quadrant (as viewed through slot

in left side of cowl).

3. Full locked-in engagement should occur when

lever is positioned completely into front notch of

quadrant. (Some resistance should be felt when

moving lever into notch).

Figure 4

4.6 CLUTCH AND BRAKE

Clutch and brake adjustments are dependent upon

each other. If depressing clutch and brake pedal fully

does not stop riding mower and/or hold it on hill, brake

must be adjusted.

1. With speed selector in neutral (N), depress clutch

pedal fully and engage parking brake.

2. Adjust double nuts on clutch rod until carrier yoke

clears neutral stop by 1/8" to 1/4" (3.18 to 6.4 mm).

4 - 14

Page 15

3. Release parking brake and turn both rear wheels

Figure 8

1. Adjustment Cap Screw

2. Adjustment Level

3. Mower Pan

1

2

3

Figure 9

1. Cutting Tip

2. Mower Pan

3. Blade

4. Ground Level

5. Cutting Height

6. Discharge Chute

3

2

1

4

5

6

OT0860

by hand. They should rotate freely in neutral (N)

but not rotate with speed selector in any other

position.

4. Using two 1/2" wrenches (to avoid twisting or

distorting brake band), hold inner adjusting nut with

one wrench and loosen outer lock nut with the

other.

5. Turn rear wheel by hand while tightening inner

adjustment nut until brake band just binds on hub.

Back off adjusting nut by 1-1/2 turns and secure

with locknut.

6. Test by fully depressing clutch pedal and trying to

turn wheels by hand. They should not turn.

5

1. Neutral Stop

2. Brake Rod

3. Clutch Rod

2

1

4. Clutch Adjustment Nuts

5. Brake Adjustment Nuts

6. Brake Band

3

Figure 7

4.7 MOWER PAN

Mower Level (Side to Side)

NOTE:

be used under pan for blade measurement. Wrap block

with masking tape, mark tape with cutting edge of

blade and measure distance from end of block to

mark(s). This method avoids errors by having to read

any measurements under pan.

To level mower pan, turn adjustment cap screw on

adjustment lever clockwise to raise right side or

counterclockwise to lower it (Figure 8).

A wood block (about 1" square by 5" long) may

4

Cutting Height

6

Cutting height range is 1" to 4" (2.5 to 10.1 cm). Place

unit on a smooth, flat, level surface.

1. With blade (s) positioned side to side, measure

2. Rotate blade(s) 180

To correct for difference in height of blade tips from

side to side:

1. Loosen nuts on adjustment levers.

2. Turn lever adjustment screw clockwise on the low

3. Turn lever adjustment screw counterclockwise on

4. Tighten nuts on adjustment levers.

CAUTION:

Rotate mower blade with mower

clutch disengaged (OUT) and take

measurements with mower clutc h enga ged

(ON).

distance of blade(s) tips to floor at right and left

side of mower pan (Figures 8 and 9).

o

and check again. The

measurement should be equal within 1/8" (3.2 mm)

side to side.

side of mower pan to raise the low side to one half

the difference in height.

the high side to lower high side the remaining one

half of the height difference.

4 - 15

Page 16

Mower Pitch and Height

Figure 12

Vents

Proper blade pitch is when the blade tip, measured

from the bottom surface (Figure 10), is 1/4" to 3/8"

(6.4 to 9.9 mm) lower at front of mower pan than when

same tip is at rear of mower pan.

1

2

4

1. Blade Cutting Edges

2. Ground Level

3. Front Blade Height

4. Rear Blade Height

Figure 10

Adjusting front lift link raises or lowers front of mower

pan and changes both cutting height and pitch.

To adjust:

1. Loosen jam nut on front link to allow for movement

of coupling nut.

2. Turn coupling nut clockwise to raise and

counterclockwise to lower front of mower pan.

3. Secure coupling in position by tightening jam nut.

Adjusting rear lift links raises or lowers rear of mower

pan and changes both cutting height and pitch.

To adjust:

1. Loosen both lower jam nuts to allow for movement

of upper jam nuts on lift rods.

2. Turn both upper jam nuts on each lift rod equality

to raise or lower rear of pan.

3. Secure lift rods in position by tightening lower jam

nuts.

3

Front of Unit

OT0850

If proper pitch cannot be obtained with front and rear lift

links:

1. Loosen nut on carriage bolt and remove cap screw

holding lift strap and adjustment strap together.

2. Slide lift strap and adjustment strap together to

raise, or apart to lower rear of pan.

3. Select tapped hole in lift strap that provides proper

adjustment, install cap screw in tapped hole and

tighten nut on carriage bolt to secure.

4.8 ANTI-SCALP ROLLERS

Secure rollers in middle position for average lawn

mowing.

1. Use lowest roller position when mowing in higher

cutting heights and rough terrain to guard against

most scalping.

2. Use highest roller position when cutting at lowest

cutting height.

For smoothest appearing cut when using frame

suspended models with anti-scalp rollers, keep antiscalp rollers adjusted to the minimum 1/2" (12.8 mm)

above flat hard smooth surface after setting height of

cut.

NOTE:

The rollers are intended for anti-scalping, not

for controlling cutting height.

4.9 VENTS

The vents are opened at the factory to increase airflow

into deck for bagging purposes. To open, align the

vents on deck with spindle housing holes (Figure 12).

1

1. Lift Strap

2. Cap Screw-Remove to

Adjust

3

4

2

3. Carriage Bolt

4. Adjustment Strap

Figure 11

4 - 16

Page 17

4.10 PINION AND STEERING

ADJUSTMENT

For ease of access to bottom of unit during service

procedures, your unit may be driven up on ramps or

tipped up onto bagger attachment service bar and

braced securely. (For units without a bagger

attachment, a service bar package is available through

your Ariens Dealer.)

On units with steering adjustment bracket, loosen

lower lock nut and tighten adjustment nut until steering

works smoothly with no play in gears.

Tighten lower lock nut.

2

1

3

1. Bottom of Steering Post

2. Adjustment Nut

3. Lock Nut

Figure 13

4.11 TIRES

NOTE:

proper tire inflation when working under various conditions inflate tires to 14 psi. Use a low pressure tire

gauge for accurate pressure readings.

Keep tires properly inflated at all times. For

4 - 17

Page 18

SECTION 5 - ENGINE

5.1 ENGINE TROUBLESHOOTING

The following troubleshooting chart is to be used to

isolate engine problems and give possible causes and

corrective action responses.

The troubleshooting key is generic and can be used for

several types of engines. Use only those possible

causes and corrective actions that apply to the

unit.

TROUBLE POSSIBLE CAUSES

CORRECTIVE ACTION

(Refer to Key Below)

Black Exhaust 1, 20, 22, 25, 29, 31, 32, 33 repair or replace

Blue/White Exhaust 4, 20, 25, 31, 33, 34 repair or replace

Difficult Starting 1, 5, 7, 8, 9, 10, 20, 21, 22, 29, 31, 32, 33 repair or replace

Erratic Running 1, 7, 8, 9, 10, 20, 21, 23, 26, 29, 33, 59, 62 repair or replace

Excessive Fuel Consumption 1, 20, 22, 23, 25, 39, 31, 32, 33 repair or replace

High Oil Pressure 4, 41 repair or replace

Knocking 22, 26, 29, 31, 33, 36, 46, 59 repair or replace

Loss of Power or System 1, 8, 10, 20, 21, 22, 23, 25, 26, 31, 32, 33 repair or replace

Low Cranking Power 2, 3, 4, 11 repair or replace

Low Oil Pressure 4, 36, 37, 39 repair or replace

Misfiring 10, 20, 25, 26, 28, 29, 32 repair or replace

Overheating 1, 19, 25, repair or replace

Poor Compression 25, 28, 29, 31, 32, 33, 34,59, repair or replace

Starts and Stops 1, 6, 10, 62 repair or replace

see electrical systems

see engine service manual

Vibration 20, 23, 25, 26, 29, 33, 45, 49 repair or replace

Will Not Crank 2, 11, 45 charge battery or replace

Will Not Start 1, 10, 62 repair or replace

see electrical systems

see engine service manual

TROUBLESHOOTING KEY

1 Restriction in air cleaner 22 Incorrect grade of fuel 43 Faulty suction pipe

2 Ba d electrical connection 23 Sticking throttle/restricted movement 44 Choked oil filter

3 Faulty starter motor 24 Exhaust pipe restriction 45 Bad solenoid switch

4 Incorrect grade of lubricating oil 25 Leaking cylinder head gasket 46 Incorrect piston height

5 Low cranking speed 26 Overheating 47 Damaged fan

6 Fuel tank empty 27 Cold running 48 Faulty engine mounting

7 Controls not in correct operation

position

8 Blocked fuel feed line 29 Sticking valves 50 Faulty thermostat

9 Faulty fuel lift pump 30 Incorrect high pressure pipes 51 Restriction in water jacket

10 Choked fuel filter 31 Worn cylinder bores 52 Loose fan belt

11 Battery capacity low 32 Pitted valves and seats 53 Choked radiator

12 Air in fuel system 33 Broken, worn or sticking piston ring(s) 54 Faulty water pump

13 Faulty fuel injection pump 34 Worn valve stems and guides 55 Choked breather pipe

14 Faulty fuel injectors or incorrect type 35 Restriction in air cleaner 56 Damaged valve stem oil deflector (if

15 Incorrect use of cold start

equipment

16 Faulty cold start equipment 37 Insufficient oil in sump 58 Blocked sump strainer

17 Broken fuel injection pump drive 38 Bad/defective oil temperature switch 59 Broken valve spring

18 Incorrect fuel pump timing 39 Oil pump worn 60 Exhaust or vacuum pipe leak

19 Incorrect valve timing 40 Pressure relief valve sticking open 61 Bad or defective water temperature

20 Poor compression 41 Pressure relief valve sticking closed 62 Bad spark plug(s)

21 Blocked fuel tank vent 42 Broken relief valve spring

28 Incorrect tappet adjustment 49 Incorrectly aligned flywheel and/or

flywheel housing

fitted)

36 Worn or damaged bearings 57 Coolant level too low

switch

5 - 18

Page 19

WARNING:

Figure 14

1. Cover

2. Filter Element

3. Paper Element

4. Body

1

2

3

4

wait for moving parts to stop before

attempting any service procedures.

CAUTION:

mower parts which are hot from operation.

Allow such parts to cool before servicing unit.

CAUTION:

bar without draining enough gasoline from

tank to avoid spilling gasoline. On electric

start models, remove battery to prevent

spillage of electrolyte.

Stop engine, remove key and

DO NOT touch engine or riding

DO NOT tip unit up onto service

NOTE:

flow more freely and carry away more contamination

when warm.

Run engine just prior to changing oil. Oil will

1. Drain engine crankcase by removing oil drain plug.

After oil has drained, replace plug.

2. Remove oil fill cap and dipstick.

3. Pouring slowly, fill crankcase with oil. (See

specifications).

4. Check oil level with dipstick. Replace dipstick and

retighten cap.

5.4 AIR CLEANER

IMPORTANT:

cleaner installed on engine.

Never run engine without complete air

WARNING:

must be handled with care.

For ease of access to bottom of unit during service

procedures, your riding mower may be driven up on

ramps or tipped up onto bagger attachment service bar

and braced securely. (For units w ithout a bagger

attachment, a service bar package is available through

your Ariens Dealer).

Gasoline is highly flammable and

5.2 ENGINE OIL

See engine manufacturer’s instructions for proper type,

viscosity and amount required.

The engine crankcase oil should be checked daily or

every five (5) hours of operation. Oil level MUST be

maintained in safe operating range on dipstick at all

times or engine damage will result.

1. Clean all debris away from around oil cap.

2. Remove oil cap and dipstick. Wipe oil off dipstick

with a clean cloth.

3. Replace dipstick until cap bottoms on tube.

Remove dipstick again and observe oil level. Oil

should be at the Full (F) mark.

4. If low, add oil and bring up to the Full (F) mark. DO

NOT over fill. Oil level must not exceed Full (F)

mark.

5. Replace dipstick and cap.

6. Clean up any spilled oil.

IMPORTANT:

when adding oil.

5.3 CHANGING OIL

IMPORTANT:

two (2) hours of operation. Thereafter, change oil every

twenty five hours of operation (more often in dusty dirty

conditions).

DO NOT overfill. Be sure engine is level

Change engine crankcase oil after first

Foam Filter

Inspect filter every twenty-five (25) operating hours

(more often if unit is used under extremely dirty or

dusty conditions).

1. Wash in water and detergent solution and squeeze

(don’t twist) until all dirt is removed.

2. Rinse thoroughly in clear water.

3. Wrap in a clean cloth and squeeze (do not twist)

until completely dry.

4. Saturate with engine oil and squeeze (do not twist)

to distribute oil and remove excess oil.

Paper Filter

Do not attempt to clean or oil filter. Replace once a

year or every 100 operating hours, more often if used

in extremely dusty conditions.

Clean inside of cover and body of filter holder. Replace

filter and cover and secure.

5 - 19

Page 20

5.5 SPARK PLUG

Figure 16 Tecumseh Engine

1. Washer

2. Taptite 5/16-18 x 1-1/2

3. Taptite 5/16-18 x 3/4

4. Inner Bolt Circle

5. Outer Bolt Circle

6. Alternate Hole

1

2

3

4

5

6

1

1

2

Spark plug should be cleaned or replaced (if

necessary) and gap reset to .030" every 100 hours of

operation or yearly whichever comes first.

To clean:

1. Remove debris from area around spark plug base.

2. Remove spark plug from engine.

3. Scrape and wash spark plug with a commercial

solvent. DO NOT blast clean.

4. Replace spark plug.

NOTE:

Sparking can occur if wire terminal does not fit

firmly on spark plug. Replace terminal if damaged.

5.6 MUFFLER

Worn out mufflers should be replaced immediately.

Continued use could result in fire or explo si on.

5.7 ENGINE REMOVAL

1. Disconnect and remove battery.

2. Empty fuel tank.

3. Disconnect spark plug wire.

4. Remove throttle cable and electrical connections

from engine.

5. Remove rear belt finger, drive and mower belts.

6. Remove cap screws securing engine to frame.

7. Remove engine.

5.8 ENGINE REPLACEMENT

Consult parts manual to determine hardw are used on

replacement engine.

NOTE:

various bolt patterns and amounts of hardware (taptites

or cap screws) may be used to secure engine.

The following diagrams outline two styles of hardware.

Depending on horsepower and manufacturer,

1. Engine

2. Idler

3. Drive Belt

4. Drive Disc

Place washers between frame and engine at locations

where tapt ites will be ins talled.

Install two taptites (5/16-18 x 1-1/2) and one taptite

(5/16-18 x 3/4) on inner bolt circle at position shown

below. Torque taptites to 250 in-lbs (15.4 Nm).

1

NOTE:

been previously operated with loose mounting bolts,

If taptite strips out engine base, or if unit has

install a locknut (5/16-18 Gr C toplock). Torque locknut

to 150 in-lbs (9.2 Nm).

2

7

6

5. Mower Pulley

Figure 15

6. Mower Belt

7. Engine Pulley

3

4

5

If taptite (5/16-18 x 3/4) strips out, install in alternate

hole. Torque to 250 in-lbs (15.4 Nm).

IMPORTANT:

Do not use outer bolt circle.

5 - 20

Page 21

Figure 17 Briggs & Stratton Engine

Figure 18

1. Clip

2. Overflow Tube

3. Hose Clamp

4. Throttle Bracket

5. Throttle Lever

6. Throttle Brace

7. Link

8. Shield

9. Brace

10.Grommet

11.V-Belt

12.Mower Belt

13.Idler Arm

14.Spacer

15.Idler

16.Extension Spring

17.Shoulder Stud

18.Engine Pulley

19.Straight Key

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

PA0150

Place washers between frame and engine at locations

where cap screws will be installed.

Using outer bolt circle secure engine to frame with four

cap screws, washers and locknuts.

Torque to 125 in-lbs (7.7 Nm).

NOTE:

18 ft-lbs (13.3 Nm).

On Kawasaki engines torque cap screws to

5 - 21

Page 22

6.1 ROTARY MOWER BELT

Figure 20

1. Mower Pulley

2. Mower Belt

3. Fixed Idler

4. Clutching Idler

5. Belt Finger

6. Adjustable Clutch Rod

1

2

3

4

5

6

REPLACEMENT

1. Disengage (OUT) mower clutch lever.

2. Loosen three nuts securing rear belt finger to back

cover and rotate belt finger counterclockwise to

remove from unit.

3. On 32" mowers, remove mower pulley belt finger,

loosen cap screw on clutching idler and fixed idler

to provide clearance for belt between belt fingers

and idlers.

4. Remove old belt and place new belt in position on

mower and engine pulley.

5. Position rear belt finger with 1/16" (1.5 mm)

clearance between belt and finger, secure rear belt

finger to rear cover by tightening top two nuts first,

then bottom nut (see Adjustments).

6. On 32" mowers tighten cap screws on clutching

idler (with 1/8" (1.5 mm) clearance between belt

and finger) and fixed idler (with tab on mount

engaged in hole of belt finger).

7. Install belt finger at mower pulley with 1/16"

(1.5 mm) clearance between belt and finger (bend

finger as required).

1

7

3

1. Mower Belt

2. Rear Belt Finger

3. Engine Pulley

4. Drive Belt

2

5. Idler Arm

6. Friction Wheel

7. Drive Disc

Figure 19

SECTIO N 6 - MOWER DECK

6.2 MOWER DRIVE BELT REPLACEMENT

1. Remove rear belt finger from back cover and

mower belt from engine pulley.

2. Remove five cap screws with lock washers that

secure friction wheel and guard to hub (this

provides clearance for removal of belt).

3. Place speed selector in neutral (N), release drive

belt from idler and remove it from drive disk and

engine pulley.

6

5

4

4. Install new belt around engine pulley, drive disk

and idler with belt properly sealed in grooves.

5. Secure friction wheel and guard on hub with five

cap screws and lock washers.

6. Install mower belt on engine pulley and secure rear

belt finger to back cover.

7. Adjust mower belt (see section on Mower Belt

Adjustment).

6.3 MOWER BLADE

Regularly check mower blades for wear and that lock

washer is fully compressed by hardware.

28" and 32" decks: Torque cap screw to 25-30 ft-lbs

(34-47 Nm).

When blade needs sharpening:

1. Block blade to prevent rotation.

2. Remove hardware and blade from shaft.

6 - 22

Page 23

3. Sharpen both ends of blade at original angle (25o),

Figure 22

1. Hairpin

2. Front Hanger Pin

3. Rear Links

4. Swivel Bracket

5. Rear Hanger Pin & Hair

Pin

6. Coupling Nut

7. Jam Nut

8. Upper Jam Nut

9. Lower Jam Nut

10.Lift Rod

1

2

3

4

5

6

7

8

9

10

removing equal amounts of material from each end

to maintain proper blade balance. New blades are

balanced to within 1.3 in. oz. at factory. DO NOT

grind around corner at tip of blade. If cutting edge

of blade cannot be sharpened in a straight line to

within 1/8 of an inch of its end, replace blade with

Ariens replacement blade only.

4. Install blade, lock washer, and tighten hardware to

torque listed above.

IMPORTANT:

If mower is used under sandy soil

conditions, replace blades when air lifts become

eroded.

IMPORTANT:

On 28" & 32", when replacing blade,

blade should be 3/8" (9.6 mm) above flange. To

position, turn cap screws on each end of blade tray

until both tips of blade clear flange by 3/8" (9.6 mm) all

the way around pan.

2

3

1. Cutting Edge

2. Square Corner

3. Air Lift Erosion

6.4 MOWER PAN REMOVAL

1. Remove rear belt finger from back cover and

mower belt from engine pulley.

2. Positio n m owe r on fl a t lev el surface. Lower mower

pan with height control lever. (Lowering mower pan

down on blocks will relieve weight on linkage and

make removal of pins easier).

3. Remove hair pin and rear hanger pin from swivel

bracket to disconnect rear link.

4. Remove cotter pin from clutch rod and rod from

clutch link.

5. Remove hair pin and front hanger pin to disconnect

front linkage.

6. On 32" mower, remove hair pins and positioning

arms from front mounting bracket.

7. Remove mower pan from rider.

8. Install mower pan on rider in reverse order.

1

4

Figure 21

6

4. Air Lift

5. Cap Screw

6. Tip of Blade

5

6.5 LINKAGES FOR MOWER HEIGHT/

ENGAGEMENT & CLUTCH/BRAKE

NOTE:

be used under pan for blade measurement. Wrap block

with masking tape, mark tape with cutting edge of

blade and measure distance from end of block to

mark(s). (This method avoids errors by having to read

any measurements under pan.)

A wood block (about 1" square by 5" long) may

6 - 23

Page 24

should not be greater than 3/16". If it is greater

than 3/16" see your Ariens dealer to have it

1

3

4

2

6

5

corrected.

8. To adjust cutting height, see Cutting Height and

Mower Pitch and Height in the Adjustments

section.

NOTE:

Lift strap is used for various diameters of

mower pans and generally does not have to be

adjusted. If replacing mower pan with that of a different

diameter, refer to parts manual for correct front lift arm

9

7

in conjunction with strap adjustment.

Check all linkages for wear or damage and replace as

6

8

10

necessary. (See Figure 22 for Height/Engagement

Linkage and Figure 23 for Clutch/Brake Linkage.)

Check straps and connecting links for alignment and

11

replace as necessary.

17

12

13

14

Check all bushings, cotter pins, roll pins, and hardware

and replace as necessary.

Oil all pivot points to retard wear .

6

1. Spacer Bushing

2. Rod Pivot

3. Rear Lift Link

4. Center Lock jam Nut

5. Rear Mower Hanger

6. Flange Bushing

7. Spacer

8. Lift Strap

16

9. Adjustment Strap

10.Mower Lift Arm

11.Strap

12.Front Lift Link

13.Coupling Nut

14.Front Lift Link

15.Hanger Pin

16.Shoulder Bolt

17.Stop

Figure 22

15

PA0181

To Remove Cowling

1. Remove throttle control knob.

2. Remove two screws securing throttle control to

dash panel.

3. Remove six screws securing dash panel to cowling

and remove dash panel.

4. Unplug wires to key switch.

5. Remove two taptites securing stop to quadrant and

remove stop.

6. Shift mower height lever and mower clutch lever to

deep slots in quadrant and remove cowling.

7. With riding mower positioned on a smooth, flat,

level to its lowest cutting height, rotate one blade

tip to discharge opening and measure distance

from blade tip to surface. Distance from blade tip to

surface should be 1" to 1 1/4". Rotate blade 180

degrees and measure other blade tip. The

difference in measurement between blade tips

15

13

14

12

16

11

32" Mower

28" and

17

30" Mower

20

1. Clutch Arm

2. Link

3. Adjustment Yoke

4. Mower Adjustment

Bracket

5. Taptite

6. Front Anchor

7. spacer Bushing

8. Shaft

9. Shoulder Bolt

10.Clutch Rod

11.Deck Pivot Bracket

10

23

Figure 23

1

2

9

7

8

6

4

13

18

19

21

22

12.Clutch Rod

13.Extension Spring

14.Spacer Bushing

15.Wave Washer

16.Compression Spring

17.Blade Brake

18.Rivet

19.Brake Lever

20.Brake Bracket

21.Pin

22.Brake Link

23.Engagement Link

3

5

PA0190

6 - 24

Page 25

6.6 MOWER SPINDLE REMOVAL

32" Mower

21

20

17

1

19

18

13

15

14

16

13

12

11

7

8

1

28" to 30" Mower

2

3

4

5

6

9

10

1. Mower Pulley

2. Belt Finger

3. Plate

4. Radial Bearing

5. spindle Housing

6. Spindle Shaft

7. Bearing Slinger

8. Retainer Hub

9. Blade Tray

10.Mower Blade

11.Plate

12.Idler Arm with Brake

13.Washer

14.Bearing Spacer

To remove the spindle:

1. Remove two lock nuts securing belt finger to pivot

plate and remove belt finger.

2. Remove jam nut and lockwasher from top of

mower pulley and remove mower pulley.

3. Remove nuts, washer and spring on brake band.

4. Remove fastener from top of brake band and

remove brake band and washer.

5. Remove lock nut and washer on top of idler and

remove idler along with bearing spacer and

washers.

6. Remove capscrew and belt finger from idler arm.

7. Remove idler arm and washer from pivot plate.

15.Idler

16.Washer

17.Brake Band with Idler Arm

18.Fastener

19.Belt Finger

20.Idler

21.Idler Mount

Figure 24

8. Remove jam nut and lockwasher securing blade

and blade tray to spindle and remove blade and

tray.

9. Remove retainer hub and woodruff keys from

spindle shaft along with bearing slinger.

10.Remove capscrews holding spindle housing to

mower pan and remove spindle housing.

11.Press shaft out of spindle housing and remove

bearings inside housing.

12.Inspect all parts for wear or damage and replace

as necessary.

13.Assemble using reverse order.

IMPORTANT:

Jam nuts on both ends of spindle shaft

should be torqued to 50 - 55 ft-lbs (37 - 40 Nm).

PA0210

6 - 25

Page 26

SECTION 7 - STEERING AND CONTROLS

For ease of access to bottom of unit during service

procedures, your unit may be driven up on ramps or

tipped up onto bagger attachment service bar and

braced securely. (For units without a bagger

attachment, a service bar package is available through

your Ariens Dealer.)

7.1 STEERING SHAFT GEARS

To remove steering shaft with gears:

1. Remove roll pin securing steering wheel to shaft

and remove steering wheel and tube.

2. Remove cotter pin from front link on mower pan

and disconnect link. Refer to Mower Pan section

for removal of mower pan.

3. Remove cotter pin from drag link at tie rod arm and

disconnect drag link.

4. Remove four bolts that secure axle bracket to

frame and remove axle from frame.

5. Remove four taptites securing steering bracket to

mower adj ustment br acket. Remove en tire stee ring

assembly out of unit.

6. Check front axle parts for wear and replace as

necessary. Grease before assembly.

7. Assemble in reverse order.

1

2

3

6

4

5

8

9

7

Figure 25

1. Retaining Plate

2. Flange Bushing

3. Steering Bracket

4. Steering Gear

5. Pinion

6. Spacer

7. Drag Link

8. Axle Bracket

9. Axle Assembly

PA0140

7 - 26

Page 27

7.2 SPEED SELECTOR

Carrier Assembly Removal

1. Remove cotter pin attaching shift link to bellcrank

and disconnect shift link from bellcrank.

2. Remove spring from clutch shaft.

3. Remove cotter pin from one end of transfer shaft

and remove transfer shaft from frame.

4. Unhook carrier yoke from clutch shaft and remove

yoke and carrier assembly.

14

13

3

4

5

7

3

1

8

2

6

Disassembly of Carrier

1. Remove locknut and thrust washer from top of

spindle bolt.

2. Remove drive disc assembly from bearing housing

along with ball bearings and sleeve bushing.

3. Remove two flange whizlock screws attaching

yoke to carrier and remove yoke.

4. Remove two flange whizlock screws attaching

bearing housing to carrier and remove bearing

housing.

5. Remove shim washer from spindle bolt.

6. Remove four flange whizlock screws securing disc

adapter to drive disc and remove adapter and

1

spindle bolt.

7. Inspect all parts for wear or damage and replace

as necessary.

8. Assemble in reverse order.

NOTE:

Center lock nut at top of assembly must be

torqued to 45 ft-lbs (61 Nm).

9

10

11

1. Flange Bushing

2. Transfer Shaft

3. Sleeve Bushing

4. Drive Plate Carrier

5. Carrier Yoke

6. Neutral Stop

7. Ball Bearing

8. Sleeve Bushing

12

9. Radial Bearing

10.Drive Disc Adaptor

11.Spindle Bolt

12.Drive Disc

13.Shift Link

14.Bearing Housing

Figure 26

7 - 27

Page 28

SECTION 8 - BRAKE AND CLUTCH

Figure 28

1. Clutch Rod

2. Flange Bushing

3. Lock Nut

4. Clutch Shaft

5. Clutch Bracket

1

2

3

4

5

2

8.1 BRAKE DISASSEMBLY

1. Remove cotter pin securing brake rod to brake

lever

2. Remove nuts and washers securing brake band to

brake lever.

3. Remove cotter pin from pin securing brake lever to

brake bracket.

4. Remove lock nut and lock washer securing friction

wheel hub to pinion shaft and remove brake

assembly.

5. Check all parts for wear and replace as necessary.

6. Assemble in reverse order.

NOTE:

band does not twist.

When resetting brake adjustment be sure brake

6

7

8.2 CLUTCH AND BRAKE ADJUSTMENT

Clutch and brake adjustments are dependent upon

each other. If depressing clutch and brake pedal fully

does not stop riding mower and/or hold it on hill, brake

must be adjusted. See section on Adjustments.

5

1. Brake Rod

2. Compression Spring

3. Brake Bracket

4. Lock Washer

3

4

2

1

5. Pin

6. Brake Band

7. Brake Lever

Figure 27

8 - 28

Page 29

SECTION 9 - DRIVE TRAIN

9.1 REAR AXLE DISASSEMBLY

1. Remove wheel, hub cap, cotter pin, and retainer

from short axle and remove short axle.

2. Remove roll pin in long axle and remove long axle

along with washer on inside of axle.

3. Inspect all parts for wear or damage and replace

as necessary.

4. Assemble in reverse order.

12

11

10

9

1

2

9.2 GEAR CASE REMOVAL

1. Remove wheel, cotter pin, spindle cup and hub cap

from short axle and remove axle.

2. Drive roll pin out of long axle opposite gear case

and remove long axle along with washer inside of

axle bearing.

3. Remove cotter pin from brake rod and remove rod.

4. Remove three flange whizlock screw s from sea l

and remove seal.

5. Remove three cap screws holding gear case to

frame and remove gear case.

7

Figure 29

5

6

8

3

1

2

4

1. Hub Cap

2. Spindle Cup

3. Sleeve Bushing

4. Zerk Fitting

5. Tube

6. Seal

7. Bearing Flange

8. Gear Case-Complete

9. Push Nut

10.Tube

11 .Beari ng Fla nge

12.Radial Bearing

PA0160

9 - 29

Page 30

9.1 GEAR CASE DISASSEMBLY

13

12

15

16

14

11

10

8

1

2

4

4

5

6

7

8

9

Figure 30

3

1. Ball Bearing

2. Breather

3. Cover

4. Needle Bearing

5. Pinion & Gear

6. Spacer

7. Idler Shaft

8. Ball Bearing

9. Pinion Shaft

10.Sleeve Bushing

11.Differential Assembly

12.Guard

13.Friction Wheel

14.Friction Wheel Hub

15.Lock Nut

16.Seal

PA0170

1. Remove locknut from friction disc hub and remove

hub and woodruff key in pinion shaft.

2. Remove flange whizlock screws in cover and using

slots provided pry cover off.

3. Inspect breather in cover and clean or replace.

4. Remove cover gasket.

5. Remove pinion shaft bearing and axle bearing and

inspect for wear.

6. Remove differential assembly and inspect for wear.

7. To test differential assembly insert both axle shafts

and turn one shaft. Other shaft should turn freely in

opposite direction.

NOTE:

When replacing differential, inner spline with

small I.D., should face down inside of gear case.

8. Remove washer from top of pinion shaft.

9. Remove pinion shaft, gear cluster and bearing and

inspect for wear.

10.Remove flat washer under pinion and gear cluster.

1 1.T o remove idler shaft place end of shaft in vise and

tap case with mallet.

12.Check seal and sleeve bushing for wear and

replace if necessary.

13.Remove nuts securing brake bracket to case and

remove bracket. Check for wear.

14.Press out ribbed-neck bolts.

15.Reassemble in reverse order, fill gear case with

8 ounces of Ariens multi-purpose grease,

P/N 00015000.

9.3 GEAR CASE REPLACEMENT

1. Bolt gear case to frame.

2. Insert axle guide tool into gear case from inside of

frame.

3. Slide in long axle and secure with washer and roll

pin. Remove axle guide.

4. Replace seal and secure with flange whizloc k

screws.

5. Insert short axle and rotate to engage springs and

secure with spindle cup, cotter pin and hub cap.

6. Replace brake rod in brake lever and secure with

cotter pin.

9.4 FRICT ION WHEEL REPLACEMENT

See Figure 31-Friction Wheel Wear Guide.

1. Place speed control lever in neutral position.

2. Remove cap screws and lockwasher securing

friction wheel guard and friction wheel to friction

wheel hub. Remove guard and friction wheel.

3. Replace guard on hub temporarily with two cap

screws.

4. Place speed control lever in forward position.

5. Loosen clutch shaft stop and with clutch arm riding

on stop, position stop in slot to give smallest

distance between guard and drive disc. Secure

stop.

NOTE:

This adjustment ensures proper pressure

between drive plate and friction wheel.

6. Remove guard and install new friction wheel and

guard.

9 - 30

Page 31

Friction Wheel Wear Guide

Figure 31

9 - 31

Page 32

SECTION 10 - BAGGER

Figure 33

1. Cover Assembly

2. Upper Boot

3. Bagger Basket

4. Frame Mounting Bracket

1

2

3

4

10.2 BAGGER ASSEMBLY

WARNING:

When operating on slopes, front

weight accessory (P/N 727016) is

recommended. Tip over or complete loss of

steering may result from any combination of

excessive bagger load, operation on slopes,

abrupt turns and speed changes.

10.1 VANE INSTALLATION

Since vanes generally require more power and

generate more, try bagging without vanes first. If

performance is satisfactory , use bagger without vanes.

Generally broad leaf grasses can be cut and bagged