Page 1

EZRider

Owner/Operator Manual

-------

1.

MODELS

008 -1540

009 - 1648

010-1540

m

01533600 Orig. 1/98

Printed in USA

Page 2

CT^iens

ThankŸQU

Ariens outdòór power equipment is

engineered to pé thé best tròni

finish. We hâve one

. Value /s pot meesured solely, by.price;. .

value is à dursòiéreasy-^^ .

that performs season after season.

This manuat and thè engine manual aré.

your guidés. By following the instructí^

and procedures in therh, your Ariens

equipment will serve you wet! for many

years: The care you give this unit will

detérminé your overall satisfaction and its .

servicéíife. . . . \

Safety is up to you: Obey all correct

operating practices and procedures for this

Unit. ' Prevent serious injury or death: :

Three reasons safety is important:

1. Accidents can disable, and kill

Your Satisfaction Is Important

Questions? Please follow these helpful steps:

1. Always Refer to Your Owner/Operator or

Engine Manual First.

a) Its detail will guide you through safe and

proper operation and maintenance.

b) It contains specifications on your model.

c) If your questions are not answered in these

manuals, go to step number two.

2. Contact Your Ariens Dealer.

a) Our dealers will be happy to supply any

sen/ice or advice required to keep your unit

operating at peak efficiency.

b) A factory trained staff is available to support

your equipment needs. They stock genuine

Ariens parts and lubricants manufactured

with the same precision and skill as the

original.

c) If your questions are not resolved by the

support staff, ask for the manager or owner.

d) When contacting your Ariens Dealer supply

your model and serial numbers.

_________________

2. Accidents can be avoided^

3. Accidents always cost. .

Ariens proudly offers one of the finest: .

. warranties in the business. Contact your

Ariens .Dealer with any questions, .

comments or. orders. Ariens equipment for

. the world is made in the USA- - -

Crafted In

America

Since Í93.3

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects

or other reproductive harm.

Page 3

<t4

TABLE OF CONTENTS

Models

Model 915008

1540.15 HP Briggs & Stratton, 40” Deck

Model 915009

1648.16 HP Briggs & Stratton, 48” Deck

Model 915010

1540,15 HP Kohler, 40” Deck

Section 1: Introduction

The Manual.......................................

Service and Replacement Parts

Product Registration

Disclaimer........................................

Section 2: Safety

Safety Alert Symbol

Signal Words..............................

Practices and Laws

Required Operator Training ..

Safety Decals and Locations

Safety Precautions

Section 3: Operation

Controls and Features.....................................8

Pre-Start

Starting and Shut-Off

Operation

Mowing.............................................................12

Parking............................................................13

Mowing Tips

.........................................................

........................................................

...................................................

......................

..................

...................

....................

....................................

2

2

2

2

3

4

11

12

12

13

Section 4: General Maintenance

Service Position

Fuel Tank

Hardware.........................................................14

Engine

.............................................................

Engine Cooling

Engine Oil

Belts

................................................................

Lubrication

Tire Pressure

Hydraulics and Transaxles

Sharpening Mower Blades

Battery.............................................................17

Adjustments

Transport........................................................21

Cleaning and Storage

.............................................

........................................................

..............................................

.......................................................

.....................................................

..................................................

...........................

............................

...................................................

...................................

Section 5: Specifications

Models.............................................................22

Engine

.............................................................

Tires.................................................................22

y

100S

OL0700

Hydrostatic System

Dimensions.....................................................22

Weight

.............................................................

Waranty...............................Inside Back Cover

.......................................

________

14

14

15

15

15

15

16

17

17

17

19

21

22

22

22

Ariens* EZRider™ Orig. 1/98

Page 4

All rights reserved. No part of this publication may be reproduced, transmitted,

(0 Copyright 1998 Arlens Company

transcribed, stored In a retrieval system, or translated Into any language In any form by

any means without the written permission of Ariens Company

Ariens® EZRider™ Orig, 1/98

Page 5

SECTION 1

<t4

Introduction

The Manual

Before you operate your unit, carefully

and completely read manuals

supplied with the unit. The contents

1800

OL

of safety instructions and controls during normal

operation and maintenance. Graphics are provided to

help you understand the text.

All reference to left, right, front or rear are given from

the operator sitting in the operation position and facing

the front of the unit.

will provide you with an understanding

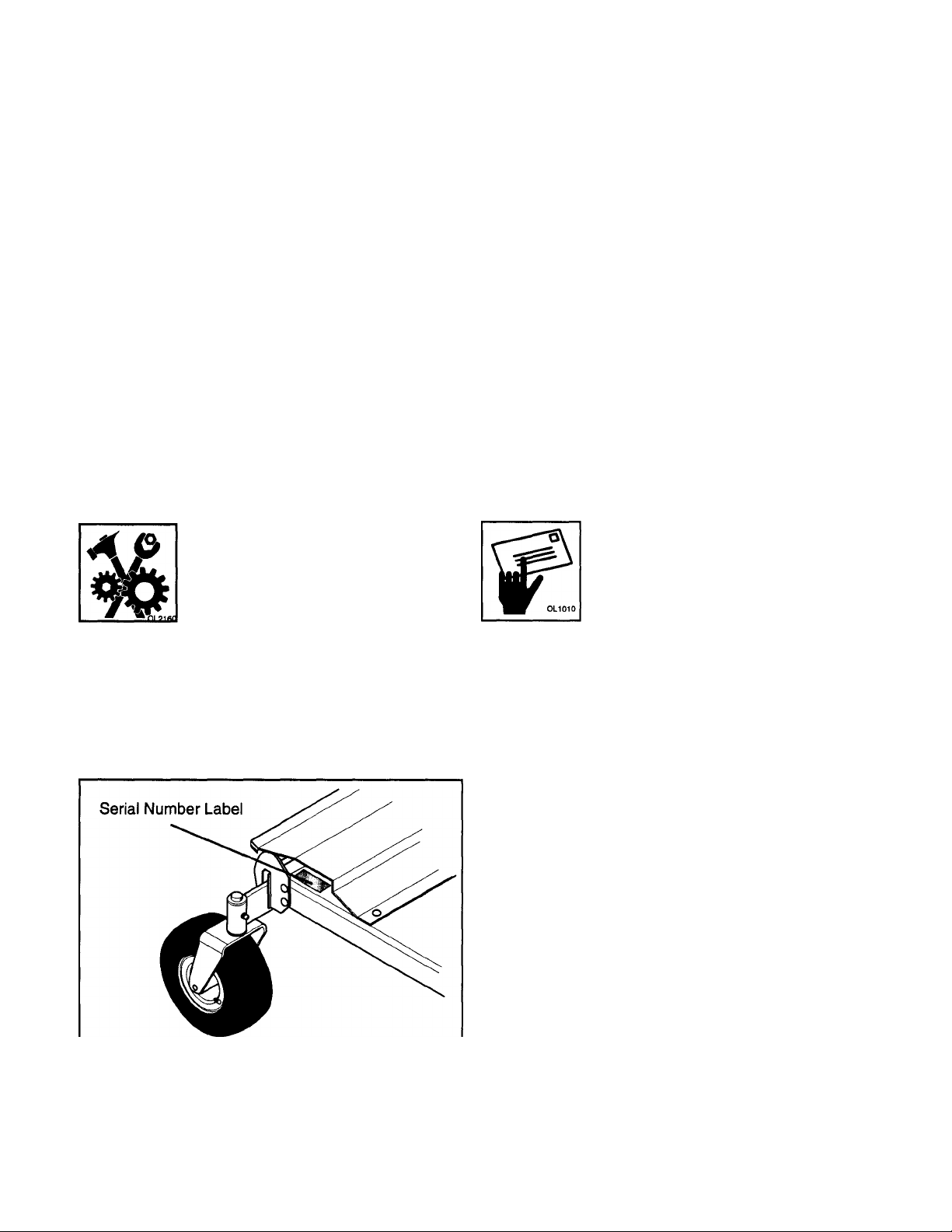

Service and

Replacement Parts

When ordering replacement parts or

making service inquires, know the

I

---------------

I Transfer |

. Model & Serial .

i Number Label I

I from product I

. registration .

I here. I

I

____________

Model and Serial Numbers of your

1

unit and attachment. Numbers are

located on the product registration

card in the attachment literature

package. They are printed on a Serial

Number Label, located on the frame

of the attachment (Figure 1).

1

Record numbers on this page for convenience and

quick reference.

Unit Model and Serial Numbers:

Attachment Model and Serial Numbers:

Product Registration

A warranty registration card must be

filled out by the Ariens dealer, signed,

and returned at sale. This card

activates the warranty. The

replacement of any part on this unit with anything other

than a Ariens authorized replacement part may

adversely affect the performance, durability, or safety

of this unit and may void the warranty. Claims meeting

requirements during limited warranty period will be

honored. To guarantee full warranty service, make

sure your registration card has been returned to

Ariens.

Ariens® EZRider'“ Orig. 1/98

Figure 1

Disclaimer

Ariens Company is hereinafter referred to as Ariens.

Ariens reserves the right to discontinue, make

changes to, and add improvements upon its products

at any time without public notice or obligation. Ariens

disclaims liability for any claims or damages, whether

regarding property, personal injury or death arising out

of the use of unauthorized replacement parts. The

descriptions and specifications contained in this

manual were in effect at printing. Units described

within this manual may not be identified as either

standard or optional. Illustrations may not be

applicable to your unit.

Page 6

SECTION 2

<t4

Safety

Safety Alert Symbol

This is a Safety Alert Symbol. It means:

• ATTENTION!

• YOUR SAFETY IS INVOLVED!

----------

2!:i2d When you see this symbol:

• BECOME ALERT!

• OBEY ITS MESSAGE!

Notations

NOTE: General reference information for proper

operation and maintenance practices.

IMPORTANT: Specific procedures or information

required to prevent damage to unit or attachment.

Signal Words

The Safety Alert Symbol is used with the Signal Words

DANGER, WARNING, and CAUTION to alert you to

safety messages.

They are used in Safety Decals on the unit and with

proper operation procedures in this manual. They alert

you to the existence of and relative degree of hazards.

Understand the safety message. It contains important

information about personal safety. For your safety and

the safety of others ALWAYS read, understand, and

follow all ADANGER, AWARNING, and ACAUTION

messages.

A DANGER

IMMINENTLY HAZARDOUS SITUATION which,

if not avoided, will result in death or serious injury.

POTENTIALLY HAZARDOUS SITUATION which,

if not avoided, could result in death or serious injury.

IMPROPER OPERATION of this unit

can result in death or serious injury.

m

Before starting engine, follow these

three steps:

1. Read and understand this manual

and all safety decals on unit or

attachment.

2. Keep children and people away

when operating unit.

3. Always clear area before operation

of unit.

iL

Practices and Laws

Practice usual and customary safe working

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate or serious injury or death.

Information in this manual does not replace any safety

rules or laws in your area. Before operating this unit,

learn all applicable rules and laws in your area.

A CAUTION

POTENTIALLY HAZARDOUS SITUATION which,

if not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

Required Operating Training

Original purchaser of unit was instructed by seller on

safe and proper operation and use. If this unit is to be

used by someone other than original purchaser such

as loaned, rented or sold, ALWAYS provide this

manual and any needed safety training before

operation.

Ariens® EZRider™ Orig. 1/98

Page 7

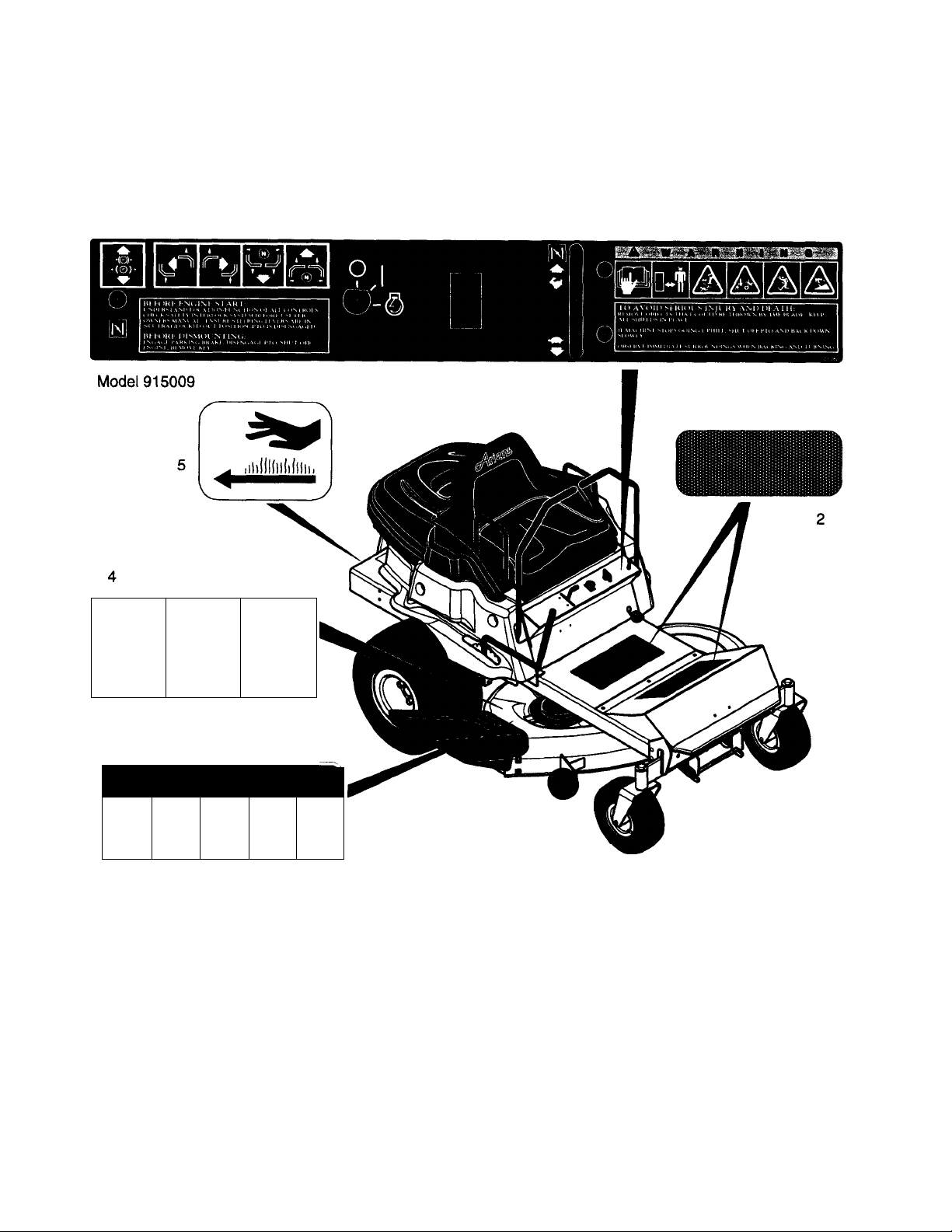

Safety Decals and Locations

ALWAYS replace missing or damaged Safety Decals.

Refer to Figure 2 for Safety Decal Locations.

Models 915008,010

A

II Jt

r ADANGER 1

3=^

V

____

D-t

«n*M J

1. WARNING Decal

2. Safety Tread Foot Board Cover

3. DANGER Rotating Blade

4. WARNING Guards

5. Hot Surface.

Ariens» EZRider™ Orig. 1/98

Figure 2

Page 8

Unit Safety

Walk Around Inspection

Complete a walk around inspection of

unit and work area to understand:

• Work area

• Your unit

• All safety decals

Clearances

ALWAYS check overhead and side

clearances carefully before operation.

Safety Guards and Devices

ALWAYS keep protective structures,

guards, and panels in good repair, in

place and securely fastened.

NEVER modify or remove safety

devices.

Discharge Covers

ALWAYS keep discharge cover or

complete grass catcher in place and

in proper working condition.

ALWAYS be aware of traffic when

operating along streets or curbs.

Work Area

Keep children and people away.

Keep children out of work area and

under watchful care of a responsible

adult.

Clear Work Area

Keep area of operation clear of all

toys, pets, and debris. Thrown objects

can cause injury.

Avoid Falls

Check for weak spots on dock, ramps

or floors. Avoid uneven work areas

and rough terrain.

Slippery Surfaces

Avoid siippery surfaces. ALWAYS be

sure of your footing.

Safety Interlock System

Safety Interlock System must function

properly. DO NOT operate unit if

operator presence controi is damaged

or disabled.

Modification

NEVER modify, alter, or permit

anyone to modify or alter the unit or

its components.

Brakes

Check brake operation frequently.

Adjust and service as required.

No Step

DO NOT step on rotary mower deck.

DO NOT operate on wet grass to

avoid siiding.

Visual Obstruction

Dust, smoke, fog, etc. can reduce

vision and cause an accident.

Operate unit only when there is good

visibility and light.

Safety Surfaces

Keep all nonskid surfaces clean.

Replace safety treads if worn,

damaged, or missing.

Ariense EZRider™ Rev. 1/97

Page 9

jLuaiü

Operational Safety

Rules of Operation

Understand:

• How to operate all controls

• The functions of all controls

• How to STOP in an Emergency

• Braking and steering characteristics

• Turning radius and clearance

Child Safety

NEVER allow children to operate, play

on or near unit.

Be alert and shut-off unit if children

enter area.

Pre-Start

Before starting engine: disengage

PTO, place unit in neutrai, lower

attachment, and set parking brake (if

applicable).

Avoid Tip over

Avoid uneven and rough terrain.

DO NOT operate near drop offs,

ditches, or embankments. Unit can

suddenly turn over if a wheel is over

the edge of a cliff or ditch, or if an

edge caves in.

DO NOT try to stabilize unit by putting

foot on ground.

Hazardous Slopes

DO NOT operate on steep slopes.

Operate up and down slopes, not

across slopes.

DO NOT operate on side hill slope of

more than 10°.

DO NOT operate on a downhill slope

of more than 15°.

AVOID starting and stopping on a

slope.

Speed Ranges

DO NOT operate at too fast a rate.

DO NOT change engine governor

settings or over speed engine. Slow

down and turn corners slowly.

PTO Control

Disengage PTO when attachment is

not in use. ALWAYS turn off power to

attachment when transporting,

crossing drives, etc.

No Riders

NEVER carry passengers.

Reverse

DO NOT operate in reverse uniess

absolutely necessary. ALWAYS

backup slowly. ALWAYS look down

and behind, before and while backing.

Keep all movement on slopes slow

and gradual. Use a slow speed to

avoid stops or shifts on slopes.

DO NOT make sudden changes in

speed or direction.

Traction

DO NOT turn on slopes unless

necessary, and then, turn slowly and

gradually down the slope.

If tires lose traction, turn off PTO, and

proceed slowly straight down slope.

If you cannot back up the slope or feel

uneasy, DO NOT mow it.

Ariens» EZRider’“ Rev. 1/97

Page 10

fol

OL0663

St

STOP

Shut-Off

ALWAYS disengage PTO, stop unit

and engine, remove key and allow

moving parts to stop.

Engage parking brake before leaving

operator’s position.

OL0220

Abnormal Vibrations, Foreign Objects, Clogged Unit

Immediately shut off unit.

INSPECT for any damage or loose

parts and repair before restart.

Parking

NEVER leave a running unit

unattended. ALWAYS shut off engine

before leaving unit.

ALWAYS remove key to prevent

unauthorized use.

Personal Safety

Responsible Operators

• Only trained adults may operate unit

• Training includes actual operation

No Drugs or Alcohol

NEVER operate unit after or during

the use of medication, drugs or

alcohol. Safe operation requires your

complete and unimpaired attention at

all times.

NEVER allow anyone to operate this

unit when their alertness or

coordination is impaired.

Safety Gear

Wear adequate safety gear,

protective gloves and footwear.

OL

NEVER wear open sandals or canvas

shoes during operation.

Unit Roli-Away

DO NOT park unit on a slope unless

absolutely necessary. When parking

on a slope always cock or block the

wheels. ALWAYS set parking brake.

Protect eyes, face and head from

objects that may be thrown from unit.

>L

Wear appropriate hearing protection.

a

Avoid Sharp Edges

Sharp edges can cut. Movement of

parts can cut off fingers or a hand.

Wrap blade(s), wear gloves and use

extreme caution when servicing.

IMPORTANT: On multi-blade

mowers, rotation of one blade will

cause all blades to rotate.

Avoid Rotating Parts

ALWAYS keep hands and feet away

from all rotating parts during

operation. Rotating parts can cut off

body parts

Ariens® EZRider™ Rev. 1/97

Page 11

Avoid Pinch Points

ALWAYS keep hands away from all

pinch points.

Maintenance and

Service Safety

^ r»i no

.0100 -

Avoid Hot Surfaces

DO NOT touch unit parts which might

be hot from operation. Allow parts to

cool before attempting to maintain,

adjust or service.

Avoid Entangiement

NEVER place your hands or any part

of your body or clothing inside or near

any moving part while unit is running.

DO NOT wear loose clothing or

jewelry and tie back hair that may get

caught in rotating parts.

Safe Distances

Keep children and people away from

unit during operation.

Avoid Thrown Objects

Deflected materials can cause injury

and property damage. DO NOT point

discharge at anyone or discharge

directly onto paved or gravel surfaces.

Always stand clear of the discharge

area when operating this unit.

loi

OL0863

B

0)

St

If*.

■ i* f

STOP

0

OL1410

Prepare Unit

Before making any inspections,

repairs, etc.: disengage PTO, stop

unit and engine, remove key, allow

moving parts to stop.

Allow hot parts to cool.

Service Position

ALWAYS block wheels and know all

jack stands are strong and secure

and will hold weight of unit during

maintenance.

Expiosive Fuei

Fuel is highly flammable and its

vapors are explosive. Handle with

care. Use an approved fuel container.

No smoking. No sparks. No flames.

ALWAYS allow engine to cool before

servicing.

NEVER fill fuel tank when engine is

running or hot from operation.

NEVER fill or drain fuel tank indoors.

Replace fuel cap securely and clean

up spilled fuel.

Avoid Exhaust Fumes

Fumes from engine exhaust can

cause injury or death.

Ventiiation

DO NOT run engine in an enclosed

area. Always provide good ventilation

and wait until hazard has been

removed.

Ariens» EZRider'“ Rev. 1/97

Replacement Parts

ALWAYS maintain unit in safe

operating condition. Damaged or

worn out muffler can cause fire or

explosion.

Hardware

Keep hardware, especially blade

attachment bolts, tight.

Page 12

Battery

Avoid Electric Shock. DO NOT

reverse battery connections.

Explosive Gases!

Poisonous battery fluid contains

sulfuric acid and its contact with skin,

eyes, or clothing can cause severe

burns.

Transport

NEVER push or pull (tow) unit with

another vehicle. Transmission

damage will occur.

Use extra care when loading or

unloading unit onto trailer or truck.

Block wheels and secure unit chassis

to transport vehicle. NEVER secure

from rods or linkages that could be

damaged.

0

0

QUÛ&Q

No flames. No sparks. No smoking

near battery. ALWAYS wear safety

glasses and protective gear near

battery.

______

DO NOT TIP battery beyond a 45°

angle in any direction.

ALWAYS keep batteries out of reach

of children.

Hydraulics

HYDRAULIC FLUID WILL CAUSE

SEVERE BURNS. Fluid in the

hydraulic system can penetrate the

skin and cause death or serious

injury.

Cleaning

Keep unit free of grass, leaves, or

other debris. Clean up oil or fuel spills.

DO NOT transport machine while

engine is running.

Attachments and

Accessories

Use only attachments or accessories

designed for your unit.

Check attachment components

frequently. If worn or damaged,

replace with manufacturer’s

recommended parts.

Avoid Tipover

Use extra care with grass catchers

and other attachments. These can

change the stability of the unit. Use

only approved hitch points.

Clearances

ALWAYS be aware of attachments

when turning. ALWAYS allow

adequate clearance between

attachments, personnel, and other

objects.

DO NOT transport with attachment in

the lowered (operating) position

Storage

For unit storage or extended storage:

• NEVER store with fuel in fuel tank,

inside a building where any ignition

sources are present

• Allow engine to cool completely

A

ALWAYS lower attachment when unit

is parked or stored.

Load Capacity

Know the weight of loads. Limit loads

to those you can safely control and

the unit can safely handle.

Ariens® EZRider'" Rev. 1/97

Page 13

SECTION 3

Operation

Controls and Features

See Figure 3 for Controls and Features locations.

Travel-Steering Control Levers

The Travel-Steering Control Levers are used to star,

stop, steer and control the travel direction of the unit.

Neutral Lock

To start, lock unit in neutral by pushing

both Travel-Steering Control Levers

outward -to each side- from centered

(neutral) position (Figure 4).

Straight Forward

Push the Travel-Steering Control Levers

SLOWLY forward the same distance from

the centered (neutral) position. The further

you move the levers, the faster the unit will

travel forward. (Travel-Steering Control

Levers have quick response timing.)

Straight Backwards (Reverse)

Pull the Travel-Steering Control Levers

back the same distance from the centered

(neutral) position. The further you move the

levers, the faster the unit will travel in

reverse.

Turns

Move one Travel-Steering Control Lever forward and

the other backward. Pushing the lever forward from the

centered position moves the unit forward on that side;

pulling the lever back from the centered position moves

the unit backward on that side.

1. Left Lever further forward that Right

Lever: turns unit to the right.

2. Right Lever further forward that Left

Lever: turns unit to the left.

Throttle Lever

(Also Choke Lever on 1540 models)

The Throttle Lever is used to change the speed of the

engine.

^ ^ Moving the lever to the “FAST” position

increases the engine speed.

Moving the lever to the “SLOW”

position decreases engine speed.

Ignition Switch

The Ignition Switch is operated with a

removable key. The switch may be

turned clockwise from the “OFF”

position to the “START” position then

the key will spring back to the “RUN"

position.

“OFF” Position: Ignition system is shut down.

“RUN” Position: All controls are operable.

“START” Position: Starter turns over the engine.

To start the engine the key must be in the “START”

position. To stop the engine, turn the key to the “OFF”

position.

Choke Control

N

1648 Modeis: The engine is choked by pulling Choke

control out to “CHOKE" position.

1540 Modeis: The engine is choked by moving the

Throttle Lever to the “CHOKE” position.

Parking Brake

To engage the Parking Brake, lift up on

knob and pull forward until it stops.

To disengage Parking Brake, lift up on

knob and push backward until it stops.

If one or both of the rear wheels do not

turn easily, check brake to assure it is

disengaged.

NOTE: Engine will shut off if control levers are taken

out of neutral with brake engaged.

Ariens» EZRider" Orig. 1/98

Page 14

1. Operator’s Seat

2. Travel-Steering Control Levers

3. Battery Compartment

4. Choke Control (1648 Models)

5. Ignition Switch

6. PTC Switch

7. Throttle Lever (also Choke

Control for 1540 Models)

8. Parking Brake Knob

9. Mower Deck Attachment Lift Lever

10. Foot Rest

11. Anti-Scalp Rollers

12. Mower Deck Attachment

13. Discharge Chute

14. Engine Shroud Cover

Figure 3

10

Ariens» EZRider™ Orig. 1/98

Page 15

Neutral Lock Position

Figure 4

Power Take Off (PTO) Switch

The Power Take Off Switch is used to engage and

disengage the attachment.

---------

When the PTO Switch is pulled out, it is in

the “ON” position and the attachment is

^ engaged.

When the PTO Switch is pushed in, it is in

^ the “OFF” position and the attachment is

disengaged.

Transmission Dump Vaives

Closing the Dump Valves allows the unit to by pushed

by hand. Dump Valves must be open to drive unit.

IMPORTANT: NEVER push or pull (tow) the unit with

another vehicle. Use a truck or trailer when transporting

or transmission damage can occur.

To Open the Dump Valves: Lift up on the Dump Valve

Rod and pull rearward until the expanded section of the

rod comes through the hole in the trailer hitch. Push the

rod back down to lock it into position (Figure 5).

To Close the Dump Valves: Lift up on the Dump Valve

Rod and push it back fon/vard.

1. Dump Valve Rod

2. Trailer Hitch

Figure 5

Pre-Start

Attachment Lift Lever

To raise the attachment, move the lever to

iWl'Ih the right to unlock It and pull up on lever.

I|||X To lower the attachment, move the lever to

the right to unlock It and push lever down.

Maximum cutting height is 5"; lowest cutting height is

1.38". Intermediate positions allow selection of cutting

heights between these values.

Safety interiock System

The engine must shut off if the operator leaves the seat

while the Travel-Speed Control Levers are In any

position other than the “NEUTRAL LOCK” position and

the PTO Switch is in the “ON” position.

Check Tires

Before each use, make a visual check of tires.

Check Engine Oil

Check that the engine oil is at proper level using

dipstick. Fill or change per instructions in General

Maintenance.

Check Seat Adjustment

Be sure all controls can be reached safely from

operator’s position. If seat needs adjustment, refer to

Adjustments.

Test Operation of All Controls

A CAUTION

Check function of all controls before starting engine.

All safety devices and guards must be in position

and operating properly or injury may result.

Ariens* EZRider'“ Orig. 1/98

11

Page 16

Starting and Shut-Off

See Figure 3 for Controls and Features Locations.

Starting

1. The operator must be seated.

2. Travel-Steering Control levers must be in the

“NEUTRAL LOCK” position (Figure 4).

3. The PTO Switch must be in the “OFF" position.

4. If the engine is cold, apply choke. See Engine

Manual for detailed instructions.

5. Set Throttle to proper starting position (see Engine

Manual).

6. Turn the ignition switch key clockwise to the

“START” position. Release the key when the

engine starts.

7. As soon as the engine starts, adjust choke as

needed. Wait until the engine is running smoothly

before operating the unit.

Shut-Off

1. With both Travel-Steering Control Levers pulled

back to centered (neutral) position, bring unit to a

complete stop on level ground.

2. Put PTO in the “OFF” position.

3. Move the Throttle Lever to “SLOW”.

4. Turn the Ignition Key to “OFF”.

5. Engage the Parking Brake.

Operation

See Figure 3 for Controls and Features Locations.

NOTE: This unit is equipped with an internal

combustion engine. DO NOT use equipment on or near

any unimproved, forest-covered or brush-covered land

unless exhaust system is equipped with a spark

arrestor meeting applicable local, state or federal laws.

A spark arrestor, if it is used, must be maintained in

effective working order by operator.

Speed

DO NOT operate and too fast a rate.

Sudden forward or backward movement in TravelSteering Control Lever(s) and fast speeds can

cause injury or death.

Move one or both Travel-Steering Control Lever(s)

forward and backward SLOWLY until you learn how to

operate the unit properly. The further you move the

levers, the faster the unit will travel.

NOTE: This unit is designed to be highly

maneuverable and responds quickly to movement of

the Travel-Steering Control Levers. Practice operation

of the controls in a flat open area until you are

comfortable with their operation. ALWAYS start and

backup slowly and make turns with caution.

Mowing

To mow with the unit:

1. Adjust deck to desired height.

2. Move Throttle Lever to about half speed.

3. Pull the PTO Switch to the “ON” position to engage

the mower.

4. Move the Throttle Lever fon/vard to full engine

speed.

5. Move Travel-Steering Control Levers forward to

mow.

IMPORTANT: NEVER engage the PTO if the mower is

plugged with grass or other material. This may cause

damage to the PTO Belt.

12

Ariens® EZRider™ Orig. 1/98

Page 17

Parking

MACHINE ROLL AWAY can cause injury or death.

ALWAYS engage Parking Brake when leaving unit

unattended.

Stop engine and remove key before cleaning or

servicing unit.

To park, stop the unit and engage the Parking Brake.

Always take all possible precautions when leaving unit

unattended.

Mowing Tips

The following tips will help you to mow safely, achieve

maximum performance from you unit and maintain the

desired appearance of your lawn.

NOTE: Clean mower pan after each use. DO NOT

allow grass clumps or a coating of grass and debris to

collect inside of mower pan. Avoid operation over bare

ground intermittent with grass cutting as this causes

dirt and grass to collect and cake under pan surface.

Grass should be cut when it si dry, not when it is wet

from dew, rain or watering. Wet grass tends to pack

inside mower pan and will not discharge, mulch or bag

properly, especially if height of cut is set too low.

Keep mower blades sharp. Dull blades will tear grass

and a white cast will result over a freshly cut lawn. The

tips of the grass blades will then turn brown.

A new lawn has soft blades of grass and a high

moisture content. It is important to cut a new lawn with

sharp blades.

Proper leveling and pitch of the rotary mower pan is

needed for a smooth even lawn. If the pitch of the

mower pan is reversed or inadequate, grass will be cut

twice, resulting in frayed grass ends. Too much pitch

will cause an uneven cut.

Upon first use of mower, cut the grass at a longer

length than usual. This will prevent scalping due to the

irregularities in the lawn.

To insure the most complete and even cut, overlap

each swath.

Plan your cutting so that you always trim with the left

side of the mower pan.

Following the same pattern each time you mow the

lawn can develope ridges. Change direction in mowing

pattern (when possible) to prevent ridges.

Generally, grass should be cut at about 1-1/2” long in

the spring and not less than 2” long in the hot summer

weather.

Lower unit speed at turns to prevent scuffing.

If grass is high, or if it contains a high degree of

moisture, cut it first with the mower pan set high. Cut

the grass a second time, with the mower pan set lower,

for a better distribution of clippings and a cleaner cut.

For thick, lush or heavy growth lawns do not set the

cutting height too low. Grass cut too short may die.

When the mower pan is set too low, the mower pan will

drag on the grass and restrict air flow, causing a

reduction in the discharge of grass clippings.

Discharge grass clippings away from borderline objects

(sidewalks, driveways, fences) when cutting grass.

Discharge grass clippings over cut grass when not

cutting borderlines. This will prevent buildup of grass

clippings on uncut areas.

Adjust Anti-Scalp Rollers properly for smooth

appearance in cut (see Adjustments).

Mow with engine set a full throttle to maintain proper

blade speed and air flow for discharge of clippings.

NOTE: Grass catcher components are subject to wear,

damage and deterioration which could expose moving

parts or allow objects to be thrown. Frequently check

components and replace with manufacturer’s

recommended parts when necessary.

Ariens» EZRider™ Orig. 1/98

13

Page 18

SECTION 4

<A

General Maintenance

Ariens Dealers will provide any service which may be

required to keep your unit operating at peak efficiency.

Should engine service be required, it can be obtained

from an Ariens Dealer or an authorized engine

manufacturer’s service center.

ALWAYS turn PTO Switch “OFF”, place TravelSteering Control Levers in “NEUTRAL LOCK”

position, set Parking Brake, turn ignition switch

“OFF”, wait for moving parts to stop, and remove

wire from spark plug before any maintenance or

adjustment.

Service Position

Place the unit on a flat, level surface. ALWAYS stop

engine and disengage PTO. Assure unit is secure and

will not tip over. Strap and clamp onto lift if used.

A CAUTION

3. Tilt seat forward.

4. Clean the fuel cap and the area around the fuel cap

to prevent dirt from entering the fuel tank (Figure

6).

Remove enough fuel so that no spillage will occur.

DO NOT touch engine or drive parts which are hot

from operation. Allow such parts to cool before

servicing.

Fuel Tank

Fuei is highly flammable and its vapors are

expiosive. Handle with care.

NO smoking, NO sparks, NO flames.

Add fuel to the fuel tank as needed. See the Engine

Manuai for the correct type and grade of fuel.

To add fuel to the fuel tank:

1. ALWAYS place unit in open or well ventilated area.

2. Stop engine and allow to cool for 2 minutes.

5. Remove the cap from the fuel tank.

6. Fill the fuel tank. Use care; do not spill fuel.

7. Replace the cap on the fuel tank and tighten.

8. ALWAYS clean up any spilled fuel before staring

engine.

9. Lower Seat.

Hardware

Keep all nut, bolts and screws tight and be sure

equipment is in safe working condition. Check all

hardware at regular intervals.

14

Ariens« EZRider™ Orig. 1/98

Page 19

Engine

Correct maintenance can increase the life of the

engine. See Engine Manual for information on the

operation and maintenance of the engine.

IMPORTANT: DO NOT change engine governor

setting or over speed engine.

To access engine;

1. Flip seat forward.

2. Unhook Engine Shroud Cover latch.

3. Push in on clips located under seat and lift Cover

up and off unit. Place aside (Figure 6).

4. After engine service is complete, replace and

fasten Engine Shroud Cover.

Engine Cooling

Each day before operation, every 12 hours, or more

often if conditions require, check the following:

1. Check the level of oil in the engine. NEVER

operate the engine when oil level is below the add

mark.

2. Check air cleaner element. Dirt can decrease the

flow of air to the engine.

3. Check the air cooling system on the engine. Debris

can decrease the flow of air to the engine.

IMPORTANT: DO NOT operate engine with cooling

fins plugged or removed; this will cause overheating

and engine damage.

Engine Oil

IMPORTANT: DO NOT over fill. Oil level must not

exceed Full (F) mark. Overheating and engine damage

will occur. Be sure engine is level when adding oil.

7. Replace oil cap and dipstick.

8. Clean up any spilled oil.

Change Engine Oil

To drain engine crankcase oil:

1. Open the valve, located on the left side of the

engine at the back of the unit. The oil will drain

through a tube under the back of the frame.

2. Close valve when drained.

Belts

MOVING PARTS can cut or amputate body parts.

ALWAYS wait for moving parts to stop before

maintenance or service of unit.

Mower Drive Beit Replacement

Refer to Figure 7.

1. Disconnect main idler spring from frame.

2. Remove belt from electric clutch and mower pan.

3. Install new belt in reverse order, checking for belt

alignment and clearance.

4. Connect main idler spring to frame.

Check and Add Engine Oil

The engine crankcase oil should be checked daily or

every 5 hours of operation. Oil level MUST be

maintained in safe operating range on dipstick at all

times or engine damage will result (see Engine

Manual).

To Check Engine Crankcase Oil;

1. Park unit on a flat, level surface. Place TravelSteering Control Levers in neutral and set brake.

2. Stop engine and remove Engine Shroud Cover.

3. Clean debris away from oil cap.

4. Remove oil cap and dipstick. Wipe oil off dipstick

with a clean cloth. Replace dipstick until cap

bottoms on tube.

5. Remove dipstick again and observe oil level. Oil

should be at the Full (F) mark.

6. If low, add oil at oil fill opening and bring oil level up

to the Full (F) mark.

Ariense EZRider“ Orig. 1/98

Rotary Mower Belt Replacement

Refer to Figure 7.

1. Remove mower drive belt.

2. Remove sheave covers.

3. Remove idler spring.

4. Remove belt.

5. Reverse procedure for installation.

Transaxle Belt Replacement

1. Remove transaxle idler spring from frame.

2. Remove belt from belt from transaxles (Figure 8).

3. Remove belt from engine sheave.

4. Install new belt in reverse order, checking for belt

alignment and clearance.

5. Connect transaxle idler spring.

15

Page 20

Clutch Shaft Belt Replacement

1. Remove transaxle belt (Figure 8).

2. Remove clutch shaft idler spring from frame.

3. Remove belt from engine sheave.

4. Remove belt from clutch sheave.

5. Install new belt in reverse order, checking for belt

alignment and clearance.

5. Connect clutch Idler spring to frame.

6. Reinstall transaxle belt.

Lubrication

Apply a small amount of oil to the pivot points as

required for smooth and proper operation.

Grease the fittings on the front wheel spindles, the idler

arms, and the steering controls every 50 hours of

operation (Figures 8 and 9).

Apply astenMIx Hl-Temp Grease or equivalent to the

lube fittings. Order P/N: 00036800 - Three pack of 3

oz. cartridges or 00036700 - Ten pack of 14 oz.

cartridges.

1. Clutch Shaft Idler

2. Clutch Shaft Belt

3. Transaxle Idler

4. Transaxle Belt

5. Idler Springs

6. Mower Drive Belt

7. Mower Drive Idler

8. Main Idler Spring

Figure 8

16

Figure 9

OE0031

OE0192

Ariens« EZRider™ Orig. 1/98

Page 21

Tire Pressure

Before each use, make a visual check of tires. The

correct air pressure is 10-12 psi (65-83 kN/m^).

Battery

Hydraulics and Transaxles

HYDRAULIC FLUID WILL CAUSE SEVERE

BURNS. Fluid in the hydraulic system can penetrate

the skin and cause serious injury or death.

Keep body and hands away from pin holes or

nozzles which expel hydraulic fluid when under

pressure. Use paper or cardboard and not hands to

search for leaks.

Make sure all hydraulic fluid connections are tight

and all hydraulic hoses and lines are in good

condition before applying pressure to the system.

Foreign fluid injected into the skin must be surgically

removed within a few hours by a doctor familiar with

this form of injury or gangrene may result.

Transaxle Fluid

The transaxle fluid is a lifetime oil which need not be

changed over the unit life.

Sharpening Mower Blades

ELECTRIC SHOCK may result in injury and/or

damage to unit.

DO NOT allow objects to come into contact with

both terminals at the same time.

REVERSE CONNECTIONS may result in sparks

which can cause serious injury. ALWAYS connect

positive (+) lead of charger to positive (+) terminal,

and negative (-) lead to negative (-) terminal.

ALWAYS connect positive (+) cable FIRST, and

negative (-) cable SECOND.

EXPLOSIVE GASES from battery can cause death

or serious injury. ALWAYS keep open flames,

sparks, or smoking materials away from batteries.

POISONOUS BATTERY FLUID contains sulfuric

acid and its contact with skin, eyes, or clothing can

cause severe chemical burns. ALWAYS wear safety

glasses and protective gear near battery.

DO NOT TIP any battery beyond a 45° angle in any

direction.

ALWAYS KEEP BATTERIES OUT OF REACH of

children.

ACAUTION

MOVING PARTS AND SHARP BLADES can cut or

amputate body parts.

ALWAYS use sturdy gloves or padding to protect

hands when working with mower blades.

1. Shut off the engine and unit. Remove the ignition

key. Remove the ignition wire from the spark plug.

2. Remove the locknuts, flat washers, and blades

from the spindle shafts.

3. Sharpen the beveled edges of the blades in a

straight line. DO NOT change the angle of the

beveled edge. If more than 0.5 inch (12.7 mm) are

removed from the width of a blade, discard the

used blade. Make sure the sharpened blades are

balanced. Balance must be held within 1.3 in. oz.

4. Put the blades, washers, and locknuts back on the

spindle shafts.

5. Tighten lock nuts to a torque of 60 ft. lbs. (82 Nm).

6. Put the ignition wire back on the spark plug.

Battery Electrolyte First Aid

Follow First Aid directions for contact with battery fluid.

• External Contact: Flush with water.

• Eyes: Flush with water for at least 15 minutes

and get medical attention immediately!

• Internal Contact: Drink large quantities of water.

Follow with Milk of Magnesia, beaten egg or

vegetable oil. Get medical attention immediately!

IMPORTANT: In case of internal contact, DO NOT

induce vomiting.

Ariens® EZRider™ Orig. 1/98

17

Page 22

Battery Removal

Remove battery from unit before servicing (Figure 10).

To remove the battery from the unit:

1. Remove the four screws at the front of the seat

support; use a 7/16” wrench.

2. Pull the control panel forward.

3. Remove wing nut from the Battery Rod and remove

the rod.

4. Disconnect the negative (-) cable first.

5. Disconnect the positive (+) cable second.

6. Lift the battery out of the unit and place battery on

a bench or other well ventilated area where an acid

spill will not create damage.

When service is finished, reinstall battery into unit and

connect positive (+) cable first, then negative (-) cable.

Electrolyte Level

Every 25 hours or each week, check the electrolyte

level of each cell by removing caps one at a time. The

electrolyte level should be at level indicator. Use

distilled water to fill each cell if needed.

IMPORTANT: When distilled water is added to battery

during freezing weather, it must be charged to mix

water with electrolyte or water will remain at top and

freeze.

Battery Charger

Under normal conditions the engine alternator will have

no trouble keeping the battery charged. When unit has

not been operated for an extended period of time and

the battery has been completely discharged, a battery

charger will be required for recharging.

Before using a charger, an attempt can be made to

recharge the battery using the engine alternator by

jump starting the unit and allowing the engine to run.

Charging

FROZEN BATTERIES CAN EXPLODE and result in

death or serious injury.

DO NOT charge a frozen battery. Let the battery

thaw out before putting on a charger.

ALWAYS follow information provided on battery by

battery manufacturer. Contact battery manufacturer for

extensive instructions to charge battery.

To charge:

1. Remove battery from unit per removal instructions

above.

2. Remove caps and fill each cell to level indicated

with electrolyte at 1.230 ± specific gravity and 80° F

(27° C).

3. Let battery stand for one half hour.

4. Check electrolyte level and add more if necessary.

5. Connect positive (+) lead of charger to positive (+)

terminal of battery.

6. Connect negative (-) lead of charger to negative (-)

terminal of battery.

7. Charge the battery at two and a half amps for ten

hours or until all cells are gassing freely and the

specific gravity is constant over three 30 minute

intervals.

8. Immediately after charging, check electrolyte level.

If low, add distilled water to bring cell(s) up to

required level.

9. Reinstall battery into unit and connect positive (+)

cable first, then negative (-) cable.

18

Ariens® EZRider™ Orig. 1/98

Page 23

Jump Starting

Jump starting, battery charging or replacement is

required when the starter motor will not crank the

engine.

To jump start engine:

1. Ensure battery is not frozen. If the fluid is frozen,

remove battery from unit and allow it to thaw before

charging.

2. The unit used for jump starting should have a 12

volt battery with at least 500 cold cranking amperes

and a negatively grounded system.

UNIT MOVEMENT can result in death or serious

injury. NEVER jump start unit directly to the starter

or starter solenoid. Unit can move forward or

backward and injure the person jump starting unit.

3. Connect the positive (+) jumper cable to the

positive terminal of the discharged battery.

4. Connect the other end of the same jumper cable to

the positive (+) terminal of the booster battery.

5. Connect one end of the second jumper cable to the

negative (-) terminal of the booster battery.

6. Make the final jumper cable connection to the

engine block or the furthest ground point away from

the discharged battery.

7. Follow Starting and Shut-Off steps in Operation

section.

8. Remove jumper cables in the reverse order of their

connection. Remove cable from: the ground point,

then the negative (-) terminal of the booster battery,

then the positive (+) terminal of the booster battery,

and finally the positive (+) terminal of the

discharged battery.

Adjustments

Ahens recommends that adjustments be made by the

Ariens dealer. Should the decision be made to make

the following adjustments on the unit yourself, Ariens

recommends calling the dealer for answers to any

questions that might arise.

Neutral Adjustment (Speed Control Lever)

1. Stop the engine. Remove the ignition key. Push the

PTO knob in the “OFF” position.

A CAUTION

PREVENT personal injury! ALWAYS KNOW that

jack(s) or blocks used are stable, strong and will

support the weight of the unit.

Place jack(s) under rear transaxles only. If jack(s)

are not available, place support blocks under both

transaxles at the rear of unit.

Raise the rear drive wheels off the floor. Remove

3.

side shrouds. Place aside for replacement.

Start the engine and run it at part throttle.

Loosen the two lock nuts holding the Speed

Control Arm (Figure 11).

Turn and loosen the connection to the Speed

Control Arm with the Flange Bushing untii the

wheel stops rotating.

Lock the Speed Control Arm in place by tightening

the two lock nuts.

8. Repeat procedure for other side of unit.

Ariens® EZRider™ Orig. 1/98

19

Page 24

Parking Brake Adjustment

There are two knob positions for the Parking Brake.

“ON" or Engaged - Pull the knob up and fonward.

“OFF” or Disengaged - Pull the knob up and push

backward.

To adjust the “ON” position:

1. Pull the Parking Brake knob up in the travel slot

until the nut on the rod can pass through the

keyway. The knob can now be pulled forward.

2. Turn the nut on the rod threads until the rod can

not move backward when it is dropped in the travel

slot. The rod will now stay in the “ON” or Engaged

position.

Seat Adjustment

Lift up and tilt seat fonvard to locate seat adjustment

screws on the seat plate. Loosen the two front and two

back screws that hold the rear springs. Slide operator

seat forward or rearward as desired. Retighten screws

as required.

Mower Level (Side to Side)

NOTE: A wood block (about 1" square by 5“ long) may

be used under pan for blade measurement. Wrap block

with masking tape, mark tape with cutting edge of

blade and measure distance from end of block to

mark(s). (This method avoids errors by having to read

any measurements under pan.)

To Check Side to Side Level:

1. Position unit on a smooth, flat, level surface. Set

tire pressure properly.

2. Position blade(s) side to side, measure distance of

blade tips to floor at right and left side of mower

pan (Figure 12). Rotate blade(s) 180° and check

again. The measurement should be equal within

1/8" side to side.

To Adjust Side to Side Level:

1. Loosen nut on height adjuster (Figure 13).

2. Turn height adjuster nut clockwise on low side of

mower pan to raise low side one half the difference

in height. Turn height adjuster nut counterclockwise

on high side to lower high side the other one half of

the height difference.

20

Ariens® EZRider™ Orig. 1/98

Page 25

Mower Pitch

Proper blade pitch is when the blade tip, measured

from the bottom surface, is 1/8" to 1/4" lower at front of

mower pan than when same tip is at rear of mower pan

(Figure 14).

Front of Unit

TTTT

— 4

Anti-Scalp Rollers

Secure rollers in top position for average lawn mowing.

Use lowest roller position when mowing in higher

cutting height or rough terrain to guard against most

scalping. Use top roller position when cutting at lowest

cutting height.

For a smooth appearance, cut lawn using frame

suspended models with anti-scalp rollers. Keep anti

scalp roller adjusted to the minimum 1/2” above flat,

hard, smooth surface.

NOTE: Rollers are intended for anti-scalping, not for

controlling cutting height.

1. Cutting Edges

2. Ground Level

3. Front Blade Height

4. Rear Blade Height

Figure 14

To Adjust pitch loosen flange lock nuts and slide

adjusting tabs up or down to achieve proper pitch

(Figure 13).

Mower Height

Adjusting hanger hooks equally raises or lowers the

mower pan and changes cutting height.

To adjust:

1. Loosen upper nuts on hanger hooks and turn lower

nuts equally clockwise to lower or counterclockwise

to raise rear of rotary mower. With mower

attachment lift in highest position, front blade height

should measure 5" from ground level.

2. Secure hanger hooks by tightening nuts.

Mower Belt

The mower belt idler system Is designed to provide

constant tension on the belt.

Transport

Equipment should be shut off when transporting. To

move unit without the engine running, open the Dump

Valves (refer to Controls and Features). Close the

Dump Valves before operating.

IMPORTANT: NEVER push or pull (tow) the unit with

another vehicle. Use a truck or trailer when transporting

or transmission damage can occur.

Cleaning and Storage

IMPORTANT: NEVER spray unit with water or store

unit outdoors to aid in prevention of rust or corrosion.

Water can seep into sealed bearings, which are sealed

against dirt and debris only, causing reduced

component life.

Keep all nuts, bolts and screws tight and be sure

equipment is in safe working condition. Check all

hardware at regular intervals.

Never store equipment with fuel in tank inside a

building where fumes may reach an open flame or

spark. Allow engine to cool before storing in any

enclosure.

Ariens» EZRider™ Orig. 1/98

21

Page 26

EZRider Specifications

Model

Engine

15 HP Briggs&Stratton 16 HP Briggs&Stratton

Model Number

Type

Speed

Fuel Tank Capacity

Crankcase Capacity 56 oz. (1.66 liters)

Fuel Type

Lubricant Type

915008

28P777-0647E1

915009 915010

303777-114281

OHV

3250 rpm

3.5 gals. US (13.3 liters)

4 pts. (1.9 liters)

See Engine Manual

See Engine Manual

Tires

Rear

Front

Pressure (all tires)

18 X 8.50-8 4 ply rating

11.0x4.00-5

10to12psi (83 to103kN/m*)

Hydrostatic System

Lubricant Type

20W-50

Speeds @ 3200 rpm

Fon/vard

Reverse

0 to 5.7 mph (9.1 km/hr)

0 to 4.1 mph (6.6 km/hr)

Speeds @ 2900 rpm

Forward

0 to 5.2 mph (8.4 km/hr)

Reverse 0 to 3.6 mph (5.8 km/hr)

Length

Width

Height

Weight

52 in (132 cm) 60 in (152.4 cm) 52 in (132 cm)

588 ibs. (267 kg)

71.88 in (182.5 cm)

44.7 in (113.5 cm)

628 Ibs. (385kg) 588 Ibs. (267 kg)

15 HP Kohler

PS-41531

64 oz. (1.89 liters)

22

Arlense EZRider'“ Orig. 1/98

Page 27

QUALITY

QUALITY

PRODUCTS

Ariens will be fre^

PROTECTION PLAN

• The Company will provide for the replacement of any part found upon examination by the Company to be

defective. Such repair or replacement will be free of charge to the purchaser (labor and parts) for two years

LABOR

w

PUKCHASKD

*WEAR

(24 months) from the date of purchase. Ariens manufactured parts (but not labor) will be free of charge for

an additional three years (36 months) thereafter.

PURCHASER RESPONSIBLITIES

• Maintenance & minor adjustments per owners manual

• Notification of need for warranty service

• Transportation to/from place of warranty repair

PRODUCT REGISTRATION

• Return of registration card required to validate warranty

PURCHASED COMPONENTS & NORMAL WEAR

• Two year labor and parts on purchased components

i.e., (tractor drive train components manufactured by

Dana, Eaton, Foote, Sundstrand and any plastic and

electrical components, wire harness, bags, boots, tubes,

etc.).

• Two year labor and parts on normal wear items i.e.,

(belts and rubber components, bearings, cables,

controls, clutches, tines, etc.).

BATTERY WARRANTY PRORATED

• One to six months - free replacement

• Seven to twelve months - 50% credit

• Thirteen to twenty-four months - 25% credit

WARRANTY- COMMERCIAL PRODUCTS

• One year parts and labor

• Product labeled commercial/professional

• Household use - 5 year limited warranty applies

GUARANTEE

ÎARS FROM

This warranty is subject to the following exceptions and limitations:

RENTAL USE-ALL PRODUCTS

• NINETY DAYS LABOR & PARTS

CONSUMER PRODUCT - PUT TO COMMERCIAL,

INDUSTRIAL, INSTITUTIONAL USE

• NINETY DAYS LABOR & PARTS

SERVICE PARTS & ACCESSORIES

• NINETY DAYS LABOR & PARTS

SERVICE

For warranty service, contact any Ariens Distributor

or Dealer. For the name and location of the Ariens

Distributor or Dealers in your area, and for further

warranty information, write or call Ariens Company.

ENGINES, ENGINE ACCESSORIES, & PEERLESS

PRODUCTS

• Covered only by manufacturer’s warranty

EXCLUSIONS

• No warranty is extended to blades, mower vanes, skid

shoes, runners, scraper blades, shear bolts, light bulbs,

headlights and any equipment which has been altered,

misused, misassembled, improperly adjusted,

neglected, or damaged by accident.

• No warranty is extended for service completed by

anyone other than an authorized distributor or dealer.

• No warranty is extended on any parts that are not

genuine Ariens service parts.

• Ariens Company reserves the right to incorporate

any changes in design into its products without

obligation to make such changes on products

previously manufactured.

A

&

PARTS

c4lcns.

Crafted in

Amarica

Since 1933

DISCLAIMER OF FURTHER WARRANTY

There is no other express warranty. Implied warranties, including

any warranty of merchantability or fitness for a particular purpose,

are limited to the duration of this written warranty, and are excluded

to the extent permitted by law. There are no warranties which extend

beyond the description of the product contained herein.

In no event shall the company be liable for indirect, special or

consequential damages (such as loss of anticipated profits)

in connection with the consumer's use of the product.

This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state. Some states do not allow

the exclusion of incidental or consequential damages, or limitations

on how long an implied warranty lasts, so the above limitation and

exclusions may not apply to you.

OL1243 9/97

Page 28

(T^lens

655 West Ryan Street • RO. Box 157 • Brillion, Wl 54110-0157 • 920-756-2141 • Fax 920-756-4421

Ask Your Dealer For Information On

These Other Fine Ariens Products

• Front and Rear Tine Tillers

• Walk-Behind Lawn Mowers

• Zero-Turning Radius Mowers

• Rear Engine Riding Mowers

• Yard and Garden Tractors

• Commercial Walk-Behind and Riding Mowers

• Sno-Thros

Loading...

Loading...