Page 1

A SAFETY MESSAGE A

The product for which you have requested

information or repiacement parts is not a

current product. The repiacement modeis

incorporate product designs, safety features,

safety instructions or warnings which repre

sent the latest “State Of The Art” develop

ments. For your safety and those around you

please contact your nearest Ariens/Gravely

Dealer for a demonstration of the current

product safety provisions and features.

■

.^M

■

lens

Sno-Thro

Owner/Operator Manual

MODELS

006 - SS322 007 - SS522 008 - SS322E

009 - SS522E 301 - SS322 303 - SS522

038076 Orig.4/96

Printed in USA

Page 2

<^4tens

Thank You

Ariens outdoor power equipment is

engineered to be the best from start to

finish. We have one fundamental belief:

Value is not measured solely by price;

value is a durable, easy-to-use machine

that performs season after season.

This manual and the engine manual are

your guides. By following the instructions

and procedures in them, your Ariens

equipment will serve you well for many

years. The care you give this equipment

will determine your overall satisfaction and

its service life.

Safety is up to you. Obey all correct

operating practices and procedures for

this equipment. Prevent serious injury or

death. Three reasons safety is important:

1. Accidents disable and kill.

Your Satisfaction Is Important

Questions? Please follow these helpful steps:

1. Always Refer to Your Owner/Operator or

Engine Manual First.

a) Its detail will guide you through safe and

proper operation and maintenance.

b) It contains specifications on your model of

equipment.

c) If your questions are not answered in these

manuals, go to step number two.

2. Contact Your Ariens Dealer.

a) Our dealers will be happy to supply any

service or advice required to keep your

equipment operating at peak efficiency.

b) A factory trained staff is available to

support your equipment needs. They stock

genuine Ariens parts and lubricants;

manufactured with the same precision and

skill as the original equipment.

c) If your questions are not resolved by the

support staff, ask for the manager or owner.

d) When contacting your Ariens Dealer supply

your equipment or attachment model and

serial numbers.

______________________

2. Accidents can be avoided.

3. Accidents always cost.

Ariens proudly offers one of the finest

warranties in the business. Contact your

Ariens Dealer with any questions,

comments or orders. Ariens equipment for

the world is made in the USA.

Crafted in

America

Since 1933

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects or

other reproductive harm.

Page 3

Table of Contents

o4rlenst

Section

Page

Section 1: Introduction

The Manual

Service and Replacement Parts

Product Registration........................................1

Disclaimer..........................................................1

Section 2: Safety

Safety Alert Symbol

Signal Words

Practices and Laws...........................................2

Required Operator Training

Safety Decais and Locations

Personal Safety

Operational Safety.............................................5

Maintenance and Senrice Safety

Section 3: Assembly

Dealer Preparation

Delivery

Section 4: Operation

Standard Controls............................................10

Impeller

Impeller Clutch Bail..........................................10

Ignition Switch.................................................10

Primer Bulb......................................................10

Choke Control Knob

Recoil Starter Handle......................................10

Discharge Chute Deflector

Discharge Chute...............................................12

Pre-Start............................................................12

Starting and Shut Off

Controls and Features

Throwing Snow.................................................13

........................................................

......................

____________

..........................................

.....................................................

.............................

...........................

.................................................

.....................

_________

............................................

..............................................................

_________

.............................................................

.......................................

..............................

.......................................

.....................................

10

1

1

10

12

12

13

Section

Page

Section 5:

General Maintenance

Filling Fuel Tank..............................................14

Service Position

Engine Cooling................................................14

Clutch and Brake

Drive Belt

Discharge Chute Deflector.............................16

Transport..........................................................16

2

2

2

3

4

«t

6

_

y

7

9

№

100S

Storage.............................................................16

Accessories.....................................................16

Maintenance Schedule

Section 6: Specifications

Model................................................................18

Engine..............................................................18

Fuel ................................................................ 18

Electric Start Option

Snow Clearing Width

OL0700

Snow Throwing Distance

Chute................................................................18

Size and Weight

Handlebar.........................................................18

Impeller

Drive Belt

Wheels..............................................................18

Warranty...........................................................19

............................................................

..............................................

............................................

.........................................................

...................................

.......................................

......................................

..............................................

.........................................................

________

...............................

14

15

16

17

18

18

18

18

18

18

#

Ariense Sno-Thro* Orig. 4/96

Page 4

Sno-Thro Models

Model 938006 (SS322)

3 HP 22” Single Stage

Serial Number 000101 and up

Model 938007 (SS522)

5 HP 22” Single Stage

Serial Number 000101 and up

Model 938008 (SS322E)

3 HP 22" Single Stage, Electric Start

Serial Number 000101 and up

Model 938009 (SS522E)

5 HP 22” Single Stage, Electric Start

Serial Number 000101 and up

Model 938301 (SS322) Export

3 HP 22" Single Stage

Serial Number 000250 and up

Model 938303 (SS522) Export

5 HP 22” Single Stage

Serial Number 000101 and up

o

All rights rasarvad. No part of this publication may ba raproducad, transmittad,

O Copyright 1996 Arlant Company

transcribad, storad In a ratrlaval systam, or translatad Into any languaga In any form

by any maans without tha writtan parmisslon of Arlans Company

Prlntad In U.S.A.

o

Arl«iii» Snd'Thro* OHg. 4/96

Page 5

SECTION 1: INTRODUCTION

<?4

Contents

• The Manual

• Service and Replacement Parts

• Product Registration

• Disciaimer

Introduction

The Manual

Before you operate your unit, carefully

and completely read manuals supplied

with unit. The contents wili provide you

with an understanding of safety

instructions and controis during normai operation and

maintenance of your unit. Graphics are provided to heip

you understand the text.

Ail reference to left, right, front, or rear are given from

operator standing in operation position and facing the

direction of forward travei.

Transfer |

model & serial .

label from '

product I

registration .

here. I

Service and

Replacement Parts

When ordering replacement parts or

making service inquiries, know the

Model and Serial numbers of your unit

and engine.

Record Unit Model and Serial numbers here.

Record Engine Model and Serial numbers here.

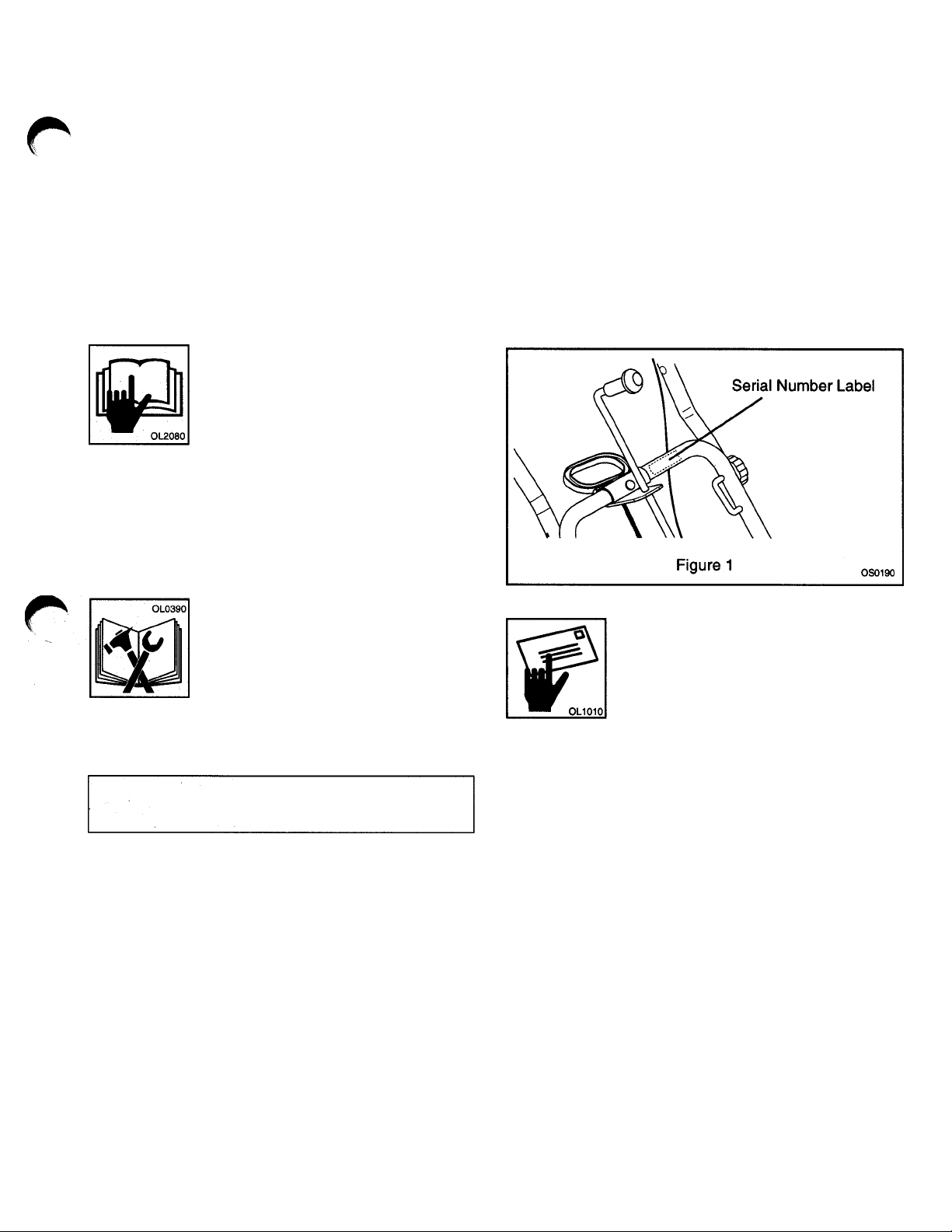

Numbers are located on the product registration form in

the unit Literature Package. They are printed on a Serial

Number Label (see Figure 1).

Product Registration

A warranty registration card must be

filled out by the Ariens dealer, signed,

and returned at sale. This form

activates the warranty. The replacement

of any part on this unit with anything other than an

Ariens authorized replacement part may adversely affect

the performance, durability, or safety of this unit and may

void the warranty. Claims meeting requirements during

limited warranty period will be honored. To guarantee

full warranty service, make sure your registration card

has been returned to Ariens Company.

Disclaimer

Ariens Company is hereinafter referred to as Ariens.

Ariens reserves the right to discontinue, make changes

to, and add improvements upon its products at any time

without public notice or obligation. Ariens disclaims

liability for any claims or damages, whether regarding

property, personal injury or death arising out of the use

of unauthorized replacement parts. The descriptions

and specifications contained in this manual were in

effect at printing. Equipment described within this

manual may not be identified as either standard or

optional. Illustrations may not be applicable to your unit.

Ariens® Sno-Thro® Orig. 4/96

Page 6

SECTION 2: SAFETY

<A

Contents

• Safety Alert Symbol

• Signal Words

• Practices and Laws

• Required Operator Training

Safety

• Safety Decals and Locations

• Personai Safety

• Operational Safety

• Maintenance and Service Safety

Safety Alert Symbol

This is a safety alert symbol. It means:

• ATTENTION!

A

• YOUR SAFETY IS INVOLVED!

When you see this symbol:

• BECOME ALERT!

• OBEY ITS MESSAGE!

Signal Words

The safety alert symbol is used with the following signal

words and colors to alert you to safety messages. They

are used in safety decals on the equipment and with

proper operation and procedures in this manual. They

alert you to the existence and relative degree of hazards.

Understand the safety message. It contains important

information about personal safety on or near the unit.

EXTREME HAZARD

Adanger

Awarning

ACAUTION •A'»!'"

For your safety and the safety of others read and

follow A DANGER, A WARNING, and A CAUTION

messages found in manuals and on safety decals.

• Avoid!

• ACT WILL RESULT in

serious injury or death.

HAZARD

• Avoid!

• ACT CAN RESULT in

serious injury or death.

POTENTIAL HAZARD

• ACT MAY RESULT in

injury.

Notations

NOTE : General reference information for proper

operation and maintenance practices.

IMPORTANT: Specific procedures or information

required to prevent damage to unit or attachment.

A WARNING

IMPROPER OPERATION of this

ft]. 1 f

_ •

hlTt

unit can result in serious injury or

death. Before starting the engine.

OL2080

OL1350

OL1021

follow these three steps:

1. Read and understand this

manual and all safety decals on

unit or attachment.

2. Keep children and people away

when operating unit.

3. Clear area before operation.

n

Practices and Laws

Practice usual and customary safe working precautions,

for the benefit of yourself and others. Understand and

follow all safety messages. Be alert to unsafe conditions

and the possibility of minor, moderate, or serious injury

or death.

Information in this manual does not replace any safety

rules and laws in your area. Before operating this unit,

learn all applicable rules and laws in your area.

Required Operator Training

Original purchaser of unit was instructed by seller on

safe and proper operation and use. If this unit is to be

used by someone other than original purchaser (loaned,

rented, sold) ALWAYS provide this manual and any

needed safety training before operation.

Ariens® Sno-Thro® Orig. 4/96

Page 7

P

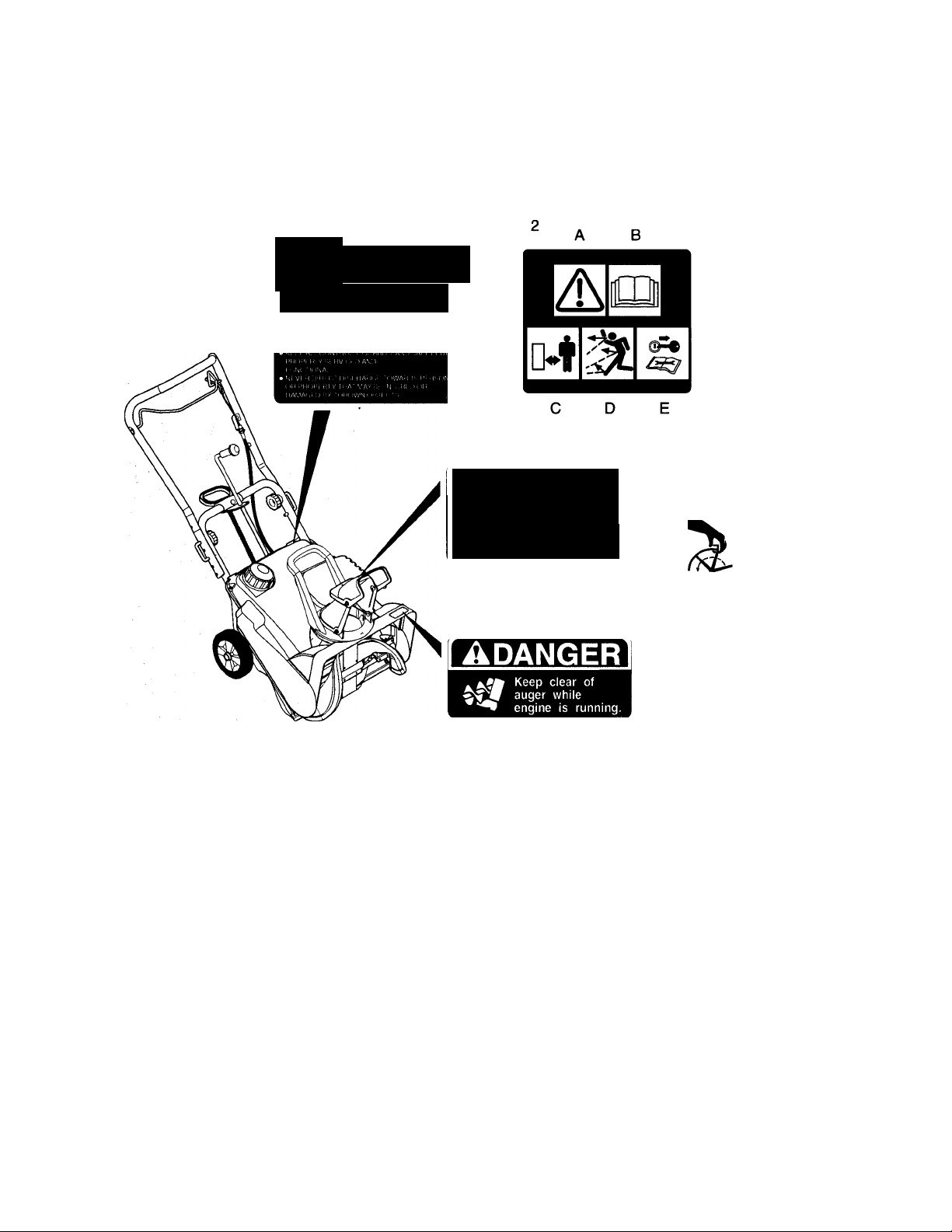

Safety Decals and Locations

ALWAYS replace missing or damaged Safety Decals.

Refer to Figure 2 for Safety Decal locations.

SAFETY

A

INSTRUCTIONS

TO AVOID POSSIBLE INJURY READ

OWNERS MANUAL AND UNDERSTAND

PURPOSE OF ALL SAFETY ALERTS.

1. SAFETY INSTRUCTIONS

2. SAFETY INSTRUCTIONS (938301,303)

A. Attention! Your safety is involved!

B. Read Owner/Operator Manual.

C. Keep people away from unit during

operation.

D. Always stand clear of discharge area

E. Shut off engine and remove key before

maintenance.

3. DANGER! Rotating Parts

A DANGER

I- ROTATING

PARTS

remove ignition

key before clearing

4. Safety Decal (938301,303)

A. Attention! Your safety is involved!

B. Read Owner/Operator Manual.

C. Keep hands away from rotating parts.

D. Shut off engine and remove key before

maintenance.

5. DANGER! Keep Clear of Auger

6. Safety Decal (938301,303)

A. Attention! Your safety is involved!

B. Read Owner/Operator Manual.

C. Keep feet away from rotating parts.

D. Shut off engine and remove key before

maintenance.

B

A

D

B

A

D

6

Ariens® Sno-Thro® Orig. 4/96

Figure 2

Page 8

Personal Safety

Responsible Operators

• Only trained adults may operate

unit

• Training includes actual operation

• Clearly understand instructions

• Be alert! Conditions can change

No Drugs

NEVER operate unit after or during

consumption of medication, drugs or

alcohol. Safe operation requires

complete and unimpaired attention at

all times.

No Alcohol

NEVER aliow anyone to operate unit

when their alertness or coordination is

impaired.

Safety Gear

Wear safety gear to protect body.

DO NOT wear loose clothing or jeweiry

that may get caught in rotating parts.

Wear adequate winter outer garments.

Rotating Parts

Movement of Impeller and other parts

can cut off body parts. Keep away from

rotating parts while parts are in motion.

Hot Surfaces

DO NOT touch parts which might be hot

from operation. Before maintenance,

adjustments or service, allow parts to

cool.

Avoid Pinch Points

ALWAYS keep hands away from all

pinch points.

Exhaust Fumes

Fumes from engine exhaust can cause

injury or death.

Gloves

Wear gloves to protect hands from

sharp edges.

Protective Footwear

NEVER wear open sandals or canvas

shoes during operation. Wear footwear

that will improve footing on slippery

surfaces.

Safety Goggles

Wear safety goggles to protect eyes

from thrown objects.

Entanglement

NEVER place hands, body parts or

clothing inside or near any moving

parts.

mL/

y . OL054C

0

OL1410

Ventilation

DO NOT run engine in enclosed area.

ALWAYS provide good ventilation and

wait until hazard has been removed.

Explosive Fuel

Fuel is highly flammable and its vapors

are explosive. Handle with care. Use

an approved (RED) fuel container.

Fuel Tank

No smoking. No sparks. No flames.

ALWAYS allow engine to cool.

NEVER fill tank when engine is running

or hot from operation.

NEVER Fill Fuel Tank indoors. Fill fuel

tank outdoors from approved (RED) fuel

container.

Replace Fuel Cap securely and wipe up

spilled fuel.

Ariens® Sno-Thro® Orig. 4/96

Page 9

r

Operational Safety

Rules of Operation

KNOW Unit before starting engine.

Understand;

Child Safety

Keep children out of work area and

under watchful care of an adult.

c

OL0340

• How to operate all controls

• Functions of all controls

• How to STOP in an Emergency

• Braking & steering characteristics

• Turning radius and clearances

Speed Ranges

DO NOT clear snow at too fast a rate.

DO NOT change engine governor

setting or over speed engine.

Walk Around Inspection

Complete a walk around inspection of

unit and work area to understand:

• Area of operation

• Your unit

• All safety decals

Visual Obstruction

Dust, smoke, fog, etc. can reduce

vision and cause an accident. Operate

equipment only with good visibility and

light.

n

Hazardous Slopes

DO NOT attempt to operate on steep

slopes.

Use Extreme caution on slopes.

Unit Roll-Away

DO NOT park unit on an incline and

leave unit unattended.

Clearances

ALWAYS check overhead and side

clearances carefully before operation.

Clearly mark potential obstructions

before seasonal changes.

ALWAYS be aware of traffic when

operating along streets or curbs. Set up

safety signs and/or flags.

OL1021

A

Clear Area

Keep area of operation clear of all toys,

pets, doormats, wire and debris to

avoid thrown objects which may result

in injury.

Work Area

ALWAYS be sure of your footing. Avoid

slippery surfaces. Walk; NEVER run.

Tip Over

DO NOT operate near drop offs,

ditches or embankments. Unit can

suddenly turn over if a wheel is over

the edge of a cliff or ditch, or if an edge

caves in. Avoid uneven and rough

terrain.

Safe Distances

Keep people away from unit during

operation.

Ariens® Sno-Thro® Orig. 4/96

Thrown Objects

Deflected materials can cause injury

and property damage. DO NOT

discharge directly onto paved or gravel

surfaces.

Discharge Area

ALWAYS stand clear of discharge area

during operation.

ALWAYS position Discharge Chute and

Deflector in safe direction and angle

before starting engine. ALWAYS

provide a safe, secure area for material

being discharged.

Page 10

\

OL0866

s

STOP

Clearing Debris & Blockages

ALWAYS disengage Impeller, stop

engine, remove key and wait for all

moving parts to stop before you: leave

operators position, unclog unit, make

repairs or adjustments or inspections.

Check for and repair any damage

before restart.

Run unit a few minutes after throwing

snow to prevent freeze-up of Impeller.

Electric Starter

Use only approved extension cords and

receptacles when starting units

equipped with Electric Starter.

Si

K.0610

_________

Engine

Before maintenance, adjustments or

service (except where specifically

recommended):

Shut off engine

^

Allow engine to cool

Transport

Disengage Impeller, and shut off engine

when unit is being transported.

Ol

Si

KJ

STOP

02»

OL0870

Maintenance and

Service Safety

Abnormal Vibrations

Stop unit and engine immediately,

remove key and wait for all moving

parts to stop. Check for and repair any

damage before restart. Check for and

tighten any loose hardware before

restart.

Parking

Never leave a running unit unattended.

ALWAYS shut off engine.

ALWAYS remove key to prevent

unauthorized use when unit is not in

operation.

Safety Devices

NEVER operate unit without guards

and other safety devices in place and

functional.

Check Clutch and Brake function

frequently as instructed in Assembly

Section.

Storage

NEVER store unit, with fuel in fuel tank,

inside a building where ignition sources

(pilot lights, hot water or space heaters,

clothes dryers, etc.) are present.

Allow engine to cool before storage in

any enclosure.

If storing for an extended period, clean

unit thoroughly and see Engine Manual

for proper storage.

Ariens* Sno-Thro* Orig. 4/96

Page 11

SECTION 3: ASSEMBLY

Contents

• Dealer Preparation

• Delivery

Assembly

Dealer Preparation

Customer Note - Your Ariens Dealer is expected to

complete these preparation steps and review important

information, including this manual, with .you before or

upon delivery of unit or attachment.

The preparation information is included here so that you

and your dealer may review it together.

TW

ÜmRNING

ELECTRIC SHOCK can result in

serious injury or death and/or damage

to equipment.

>

Tools Required

Open-end wrench: 7/16"

DO NOT remove wire from spark plug

while engine is running.

Handlebar

1 Unit is in handlebar “fold” position for shipping

(Figure 3).

2. Keep customer in mind and adjust Upper Handle

Bar higher or lower by selecting alternate holes for

“J” bolts (Figure 4).

3. Unfold Upper Handlebar.

4. Tighten Knobs to secure Upper Handlebar in

place.

Package Contents

Literature Package and Ariens Sno-Thro (Figure 3).

f

Ariens® Sno-Thro® Orig. 4/96

Page 12

Discharge Chute Crank (938006,009)

To install Discharge Chute Crank (Figure 6);

9. Remove Nut from bolt that holds Recoil Starter

Handle Bracket in place.

10. Pull the Chute Crank Assembly up so hole in

Chute Crank Bracket fits behind/under Lower

Handle Bar and over bolt end.

NOTE: DO NOT pull Chute Crank Assembly up too far.

If Chute Crank Bracket goes past Lower Handle Bar,

48T Gear and Spacer will fall off into unit.

11. With Crank Knob straight up and Discharge Chute

straight forward, check that 48T Gear meshes with

12T Pinion at Space and Tooth Identification

Marks. Align if necessary.

6. Remove Rear Cap Screw and Nut from rear of

Discharge Chute (Figure 5).

7. Tip Discharge Chute up and install hardware just

removed.

8. Tighten hardware at rear of Discharge Chute first,

then at sides.

1.

Nut

2.

Recoil Starter Handle Bracket

3.

Chute Crank Shaft

4.

Crank Knob

5.

Chute Crank Bracket

6.

Lower Handle Bar

7.

Space & Tooth Identification Marks

Spacer

8.

9.

48T Gear

10. 12T Pinion

11. Cotter Pin

Figure 6

Ariens» Sno-Thro» Orig. 4/96

Page 13

12. Insert Cotter Pin (taped to Chute Crank Assembly)

through 48T Gear and Chute Crank Shaft. Minor

movement of the Crank Shaft or Discharge Chute

Handle may be needed to align holes.

13. Rotate Chute Crank to access Cotter Pin and

secure Pin by bending ends over.

14. Reinstali Nut, securing Chute Crank and Starter

Handie Brackets to Lower Handle Bar.

№

Engine Fuel

A WARNING

Hardware

21. Check for loose hardware.

Walk Around Inspection

22. Walk around unit and check for leaking, damaged,

or missing parts. Make necessary repairs before

operation.

Clutch and Brake

A WARNING

UNIT ROLL AWAY can result in serious injury or

death. Check and test Clutch and Brake before

each operation.

EXPLOSIVE VAPORS and

FLAMMABLE FUEL can result in

serious injury or death. Handle fuel

with care. ALWAYS Use an

approved (RED) fuel container.

No Smoking!

0

0

0

IMPORTANT: 2 cycle engines require that oil be mixed

with fuei. Failure to mix oil with gasoiine will result in

seizure and severe damage to engine. DO NOT use

gasohol or gasoline containing alcohol because alcohol

will cause internal parts to deteriorate. See Engine

Manual for Correct type and grade of fuel.

No Lighted Materials!

No Open Flame!

Allow engine to cool before servicing.

OL1410

15. Put unit in open area.

16. Clean Fuel Cap and area around

Fuel Cap to prevent dirt form

entering Fuel Tank. Remove Cap.

23. Ensure there is some slight, noticeable slack in the

Control Cable Inner Wire when Impeller Clutch Bail

is disengaged (released position). Bail should travel

6-3/4 to 7-1/4" (17.1-18.4 cm) before Handlebar

contact.

24. Ensure there is a noticeable increase in resistance

1 to 1-1/2“ (2.5-3.8 cm) before Impeller Clutch Bail

contacts Handlebar.

25. Check that Impeller stops within 5 seconds after

releasing Impeller Clutch Bail.

Delivery

Using the Owner/Operator Manual, instruct customer on

controls and operation of equipment. Emphasize safety

and discuss Safety Precautions. Give customer

Owner/Operator Manual. Advise customer to thoroughly

read and understand it.

Explain recommended lubrication and maintenance of

equipment. Advise customer on adjustments.

Fill out Original Purchaser Registration Card and return

to Ariens. Place Model and Serial Number on page in

the front of this manual.

17. Mix 50 parts fuel to 1 part oil.

№+i

OStW Mix 2 Cycle Engine

Lubricant is recommended.

soQi

18. Fill fuel tank with mixture. Tank capacity is 1.2

quarts (1.1 liters).

NOTE: Fuel mixture left standing for prolonged periods

wili begin to separate; thoroughly shake mixture before

using.

19. Replace Fuel Cap and tighten.

20. ALWAYS clean up any spilled fuel.

Ariens® Sno-Thro® Orig. 4/96

Warranty

Explain Ariens Limited Warranty Policy.

Page 14

SECTION 4: OPERATION

<t4

Contents

• Standard Controls

• Pre-Start

Operation

• Starting and Shut Off

• Controls and Features

' Throwing Snow

Standard Controls

See Figure 9 for Control and Feature locations.

Impeller

During snow removal, Impeller propels unit forward while

collecting snow. Forward speed will vary according to

snow depth and moisture content.

Impeller Clutch Bail

Squeeze Impeller Clutch Bail against

Handlebar to engage Impeller. Unit will

move fonward and throw snow. Release

Bail to disengage and brake Impeller

IMPORTANT: Check impeiler to be sure it

is not frozen. If belt squeals when Clutch

Bail is engaged. Impeller is frozen.

Release Clutch Bail and move equipment

to a heated area to thaw.

IMPORTANT: Check Clutch/Brake

function before each use. If Impeller does

not stop quickly when Impeller Clutch Bail

is released or there is no noticeable

increase in Bail force before contacting

Handlebar, adjust as directed in

Maintenance Section, or repair before

operating unit.

Choke Control Knob

When pulled out (away from Impeller

Housing), Choke Control Knob chokes off

air to engine for easier start. When pushed

in. Control Knob allows for normal

operation.

IMPORTANT: ALWAYS push Control Knob in (towards

Impeller Housing) after engine start.

Recoil Starter Handle

When pulied. Recoil Starter Handle will turn engine over.

Ignition Switch

See Figures 7 and 8.

Ignition Switch is operated by a removable Key. It has

two positions:

^ "Stop" Position

(2) Run Position

Primer Bulb

Push Primer Bulb in to add fuel for easier

engine start (Figure 8).

10

Ariens® Sno-Thro® Orig. 4/96

Page 15

1. Impeller Clutch Bail

Chute Crank (938007,009)

2.

Recoil Starter Handle

3.

4. Handlebar Knob

Chute Deflector Handle

5.

6. Air Intake ^

Chute Deflector

7.

8.

Discharge Chute

Impeller Housing

9.

Impeller

10.

Scraper Blade

11.

12. Discharge Chute Rotation Handle

Fuel Tank and Cap

13.

14. Cowl

Impeller Control Cable

15.

Figure 9

Ariens* Sno-Thro* Orig. 4/96

11

Page 16

Discharge Chute Deflector

ALWAYS position Discharge Chute Defiector in safe

direction and angie before starting engine. Use Handle

at rear of Defiector to position Defiector at desired

height. DO NOT throw snow any higher than necessary.

IMPORTANT: If Chute Deflector does not stay in set

position, adjust as directed in Maintenance Section, or

repair before operating equipment.

Discharge Chute

Discharge Chute rotates 220°. Rotate Chute with

Deflector Chute Handle or crank chute with Defiector

Chute Handie ON Models 938007,009 only. (Figure 10)

IMPORTANT: DO NOT force frozen Chute controls.

Start engine and run for 3-5 minutes to thaw. If still

frozen, take to warm place until controls are free.

Starting and Shut Off

Starting

1. Turn discharge chute straight ahead.

2. Push Primer Bulb 2 or 3 times for cold engine.

NOTE: When temperature is below -15° F additional

priming may be needed.

3. Pull choke control out to "Choke" position (Figure 7).

NOTE: A warm engine requires less choking than a cold

engine.

4. Insert Key into Ignition Switch.

5. Turn key to run position.

6. Grasp starter handle and pull rope out slowly until it

pulls harder, this is compression stroke, let rope

rewind slowly (Figure 8).

7. Pull rope with a rapid continuous full arm stroke. Let

rope rewind slowly.

IMPORTANT: DO NOT let Starter Handle snap against

Starter Handle Bracket.

8. Repeat until engine starts. (If engine does not start,

refer to Engine Manual.)

9. When engine has started, open Choke slowly by

gradually pushing Choke Control in.

Pre-Start

IMPORTANT: Before engine start check Impeller to be

sure it is not frozen. With key in "Stop" position,

squeeze Impeller Clutch Bail to Engaged position and

pull Recoil Starter Handle. If Impeller is frozen, (cannot

pull Starter Handle) move unit to a heated area and thaw

to prevent possible damage.

Shut Off

1. Run Impeller a few minutes after use to prevent

freeze-up of Impeller.

2. Release Impeller Clutch Bail and allow Impeller to

stop.

3. Turn Ignition Switch to "Off" position.

4 Remove key.

12

Ariens® Sno-Thro® Orig. 4/96

Page 17

1. Switch Box

2. Starter Button

3. Female End of Power Cord

Figure 11

Controls and Features

Electric Starter

Optional on models 938006, 007, 301,303 (Figure 11).

IMPORTANT: Electric starter is not equipped with a

thermal cutout switch. DO NOT crank engine for more

than 20 seconds. Always allow electric starter to cool

down for 10 minutes or electric starter damage will

result.

1. Follow Starting and Shut Off steps 1 -5.

2. Connect female end of power cord to Switch Box.

3. Plug male end of power cord into 120 volt AC

receptacle.

4. Push Starter Button to crank engine.

5. When engine starts, release Starter Button and

, disconnect Power Cord from receptacle first, then

from Switch Box.

6. Gradually push in choke control knob to housing.

Throwing Snow

Lift the Handlebar only high enough to propel unit

forward. Do not lift so high to allow snow to kick back

from under unit.

To clear an area, run unit in an overlapping

series of paths. For large areas start in

middle and throw snow to each side so you

do not have to move snow more than once.

ALWAYS direct snow away from area to be

cleared and with direction of wind.

Ariens* Sno-Thro* Orig. 4/96

13

Page 18

SECTION 5: GENERAL MAINTENANCE

<т4

Contents

• Filling Fuel Tank

• Service Position

• Engine Cooling

• Clutch & Brake

• Drive Belt

• Chute Deflector

Transport

Storage

’ Engine Trouble Shooting

General Maintenance

• Maintenance Schedule

• Accessories

Ariens Dealers will provide any service which may be

required to keep your unit operating at peak efficiency.

Should engine service be required, it can be obtained

from an Ariens dealer or an authorized engine

manufacturer's service center.

Ш

Filling Fuel Tank

A WARNING

EXPLOSIVE VAPORS and

FLAMMABLE FUEL can result in

serious injury or death. Handle fuel with

care. ALWAYS use an approved (RED)

fuel container.

No Smoking!

0

0

1. Add fuel to Fuel Tank as needed.

2. Put unit in open or well ventilated area.

IMPORTANT: 2 cycle engines require that oil be mixed

with fuel. Failure to mix oil with gasoline will result in

seizure and severe damage to engine. DO NOT use

gasohol or gasoline containing alcohol because alcohol

will cause internal parts to deteriorate. See Engine

Manual for correct type and grade of fuel.

Ш+4

50Э1

No Lighted Materials!

No Open Flame!

«

OL1410

OLU10 Allow engine to cool before maintenance.

3. Stop engine and allow to cool.

4. Clean Fuel Cap and surrounding area

to prevent dirt form entering Fuel Tank.

5. Remove Cap.

Mix 50 parts fuel to 1 part oil. We

6.

recommend OSten Mix a 2 Cycle

Engine Lubricant.

Fill fuel tank with mixture. Tank

OL0840

7.

capacity is 1.2 quarts (1.1 liters).

NOTE; Fuel mixture left standing for prolonged periods

will begin to separate; thoroughly shake mixture before

use.

8. Replace Fuel Cap and tighten.

9. ALWAYS clean up any spilled fuel.

Service Position

Tip unit forward onto front of Impeller housing for

service. Assure unit is secure and will not tip over. Strap

and clamp onto bench if needed.

A CAUTION

When equipment is tipped up onto housing, remove

enough fuel so that no spillage will occur.

Engine Cooling

Engine is air cooled. Air must circulate freely around

engine from Air Intake (Figure 12) to cooling fins on

cylinder head and block, to prevent overheat.

A WARNING

HOT SURFACES can result in

serious injury or death. DO NOT

touch parts which are hot from

operation. ALWAYS allow parts to

____________

Every 10 hours of operation or every year (more often if

conditions require) remove cooling shrouds and clean

cooling fins. Clean external surfaces of engine of dust,

dirt and oil deposits which can contribute to improper

cooling. See Engine Manual.

IMPORTANT: DO NOT operate engine with cooling

shrouds removed, this will overheat engine and cause

damage.

9L21S2.

cool.

14

Ariens® Sno-Thro* Orig. 4/96

Page 19

Clutch and Brake

Impeller Control Cable Adjustment

For Brake to function properly, there must ALWAYS be

some slight, noticeable slack in the Control Cable Inner

Wire when the Impeller Clutch Ball is disengaged

(lowered position). This allows Extension Spring to pull

Idler Arm/Brake, braking Belt. Bail should travel 6-3/4 to

7-1/4“ (17.1-18.4 cm) before contacting Handlebar. If

Brake does not stop Impeller within 5 seconds of

releasing Impeller Clutch Bail, Inner Wire slack must be

adjusted.

A properly adjusted Clutch must show a noticeable

increase in resistance (caused by stretch of Control

Cable Spring) before Impeller Clutch Bail contacts

Handlebar. At factory adjustment, increase occurs 1 to

1-1/2" (2.5-3.8 cm) from Handlebar. As Drive Belt seats

and wears, increase in resistance will occur closer to

Handlebar contact. If no resistance occurs. Inner Wire

slack must be adjusted.

To adjust Inner Wire (Figure 12);

• Use Adjusting Nuts on Control Cable to remove

almost all slack in Inner Wire.

IMPORTANT: If there is still no resistance, the Idler

Position must be adjusted.

NOTE: It may be desirable to leave extra slack in the

Control Cable Inner Wire so Bail resistance is not

uncomfortably strong when held up against the

Handlebar.

6. Start engine and ensure Impeller does not rotate

when Impeller Clutch is disengaged.

7. Repeat the above steps until proper adjustment is

achieved.

IMPORTANT: If adjustment cannot be achieved, the

Drive Belt must be replaced.

8. Replace Cowl.

1. Control Cable Inner Wire

2. Adjusting Nuts

#

Idler Position Adjustment

For proper operation, the Idler must be as close as

possible to the Drive Belt when the Impeller Clutch Bail

is disengaged (lowered position), but not so close that it

causes Impeller rotation. To adjust the Idler position

(Figure 13):

1. Shut off engine, allow to cool, and remove Cowl.

ROTATING PARTS can result in

serious injury or death. ALWAYS

keep hands and feet away. DO NOT

wear loose clothing or scarves that

may get caught in rotating parts.

2. Ensure Control Cable Inner Wire has slack when

Impeller Clutch Bail is disengaged (lowered

position).

3. Ensure Belt Fingers are properly adjusted (see

Drive Belt Replacement).

4. Loosen Idler hardware, reposition Idler along Slot in

Idler Arm, and tighten hardware.

5. Check for proper Impeller Clutch Bail resistance.

Figure 12

1.Extension Spring

2.Idler Arm/Brake

3.ldler

4.Slot

5.Belt Finger

B.Impeller Clutch Control Cable & Spring

7.Drive Belt

8.Impeller Drive Pulley

9.Cap Screw & Washer on Impeller Shaft

Ariens® Sno-Thro® Orig. 4/96

Figure 13

15

Page 20

Drive Belt

To replace drive belt (Figure 13):

1. Remove Cowl and disconnect Extension Spring on

Idler Arm/Brake.

2. Remove Cap Screw and Washer from end of

Impeller Shaft and pull off Impeller Drive Pulley.

Remove old Belt and install new one.

3.

4. Replace parts in reverse order checking to be sure

there is 1/32 to 1/16“ (1-1.6 mm) clearance

between Belt Finger and back side of Belt with

Impeller Clutch Bail engaged.

Discharge Chute Deflector

If Discharge Chute Deflector does not stay in set position

during operation adjust chute by:

• Tightening Fasteners evenly until Deflector stays in

position (Figure 14).

NOTE: Use a #T30 Torx Drive or a 3/16" (.19 cm) wide

Straight Screwdriver to tighten.

Storage

Run the unit with Impeller Clutch engaged a few minutes

after each use to free unit of any loose or melting snow.

Keep all nuts, bolts and screws tight and be sure unit is

in safe working condition. Check all hardware at regular

intervals.

Never store unit with fuel in tank inside a building where

fumes may reach an open flame or spark.

Allow engine to cool before storage in any enclosure.

Be sure to drain fuel or run the fuel tank dry before

storage.

It is possible to hang the unit on a wall.

Engine trouble shooting

PROBLEM

Probable Cause

Engine will not crank

Check if Key Switch is in run position

Check for a bad starter or connections.

Check for electrical problems.

Transport

Equipment should be shut off when transporting. To

transport equipment to or from an area to be cleared,

press down on handlebar enough to raise front of SnoThro slightly off surface and push or pull unit.

Engine will not start

Check for electrical problems.

Check for engine ignition problems - see Engine

Manufactures Service Manual.

Engine stops.

Check fuel supply. Use only clean fuel.

Check spark.

Engine power, noise, idle and shut down.

See Engine Manufactures Service Manual.

Accessories

737001 Electric Start (3 HP)

737002 Electric Start (3 HP)-Canada

738001 Electric Start (5HP)

16

Ariens® Sno-Thro® Orig. 4/96

Page 21

Maintenance Schedule

The chart below shows the recommended service

schedule that should be performed on a regular basis.

More frequent service may be required due to working

conditions (heavy loads, high ambient temperatures,

dusty conditions, airborne debris).

See Engine maintenance instructions in Engine Manual.

Page 22

SECTION 5: SPECIFICATIONS

<t4

Contents

• Specifications • Warranty

Specifications

Sno-Thro

Model Number 938006

938301 938303

Description SS322 SS522

Engine

Engine Power - HP (KW) - 2 Cycle

Engine Operating Fast Idle Speed - RPM 4300 3600 4300 3600

Engine Displacement - in (cc)

Fuel

Fuel to Oil Mix

Fuel Tank Capacity - qt (Liters)

Fuel Filter Neck Inside Dia. - in (cm)

120V Electric Start Option

Snow Clearing Width - Cu. in (cm)

Snow Throwing Distance - ft (meters)

Chute

Chute Rotation Angle

Chute Rotation Control at Handlebar No

Chute Inside Dia - in (cm)

Handlebar

Operator Present Impeller Clutch/Brake Control

Folding Handlebar

Handlebar Adjustable For Height

Size & Weight

Handlebars Max. Extended Height - in (cm)

Minimum Folded Height - in (cm)

-----------------------------------------------------X.

Length - in (cm)

Minimurn Folded Length - in (cm)

Width - in (cm)

Weight - lbs (Kg)

Impeller

Impeller Dia - in (cm)

Impeller Speed - RPM

Drive Belt

Single “V”

Construction

Material

Wheels

Wheel Size - in (cm)

----------^--------------------------------------------------

3 (2.24)

6.0 (98) 8.46(139)

1

58 (26.4) 73 (33.2)

1120

938007

5 (3.73)

See Engine Manual for type and grade

1.2 (1.1)

2.8 (7.1)

Yes

22 (56)

3-30 (0.9-9.1)

007Yes/303 No No

6.0(15.2)

40.8(104)

25.8 (65.5)

43.2(110)

34.5 (87.6)

22 (56)

9.0 (23)

1100

3L Section

Raw Edge

Kevlar Cord

7.0 X 1.5(18x3.8)

938008 938009

SS322E

3 (2.24) 5 (3.73)

6.0 (98) 8.46(139)

50:1

220°

Yes

Yes

Yes

60 (27.2)

1120

Yes

1 75 (38.5) 1

1 1100 1

SS522E

Installed |

Yes

18

Ariens® Sno-Thro® Orig. 4/96

Page 23

QUALITY

QUALITY

PRODUCTS

GUARANTEE

Aricn& Company hereby warrants to Uie original consumer purchaser that products nunufactuied

by Ai iciix ('on)pun> will Iv free from defects in material and woi kmanship TOR A PERIOD

OF i 1\ E t5) YT \RS FROM THE DATE OF PURCHASE, LX( T.PT AS NOTED BELOW.

PROTECTION PLAN

• The Company will provide for the replacement of any part found upon examination by the Company to be

2^

LAB OR

defective. Such repair or replacement will be free of charge to the purchaser (labor and parts) for two years

(24 months) from the date of purchase. Ariens manufactured parts (but not labor) will be free of charge for

an additional three years (36 months) thereafter.

This warranty is subject to the following exceptions and limitations:

PURCHASER RESPONSIBLITIES RENTAL USE - ALL PRODUCTS

• Maintenances: minor adjustments per owners manual • NINETY DAYS LABOR & PARTS

• Notification of need for warranty service

• TransDortation to/from olace of warrantv reoair ^

PRODUCT REGISTRATION

• Return of registration card required to validate warranty

PURCHASED COMPONENTS & NORMAL WEAR

• Two year labor and parts on purchased components

i.e., (tractor drive train components manufactured by

Dana, Eaton, Foote, Sundstrand and any plastic and

electrical components, wire harness, bags, boots, tubes,

etc.).

• Two year labor and parts on normal wear items i.e.,

(belts and rubber components, bearings, cables,

controls, clutches, tines, etc.).

BATTERY WARRANTY PRORATED

• One to six months - free replacement

• Seven to twelve months - 50% credit

• Thirteen to twenty-four months - 25% credit

WARRANTY- COMMERCIAL PRODUCTS

• One year parts and labor

• Product labeled commercial/professional

• Household use - 5 year limited warranty applies

„ . ,A. , t . CONSUMER PRODUCT-PUT TO COMMERCIAL,

• NINETY DAYS LABOR & PARTS

SERVICE PARTS & ACCESSORIES

• NINETY DAYS LABOR & PARTS

SERVICE

• For warranty service, contact any Ariens Distributer

or Dealer. For the name and location of the Ariens

Distributer or Dealers in your area, and for further

warranty information, write or call Ariens Company.

ENGINES, ENGINE ACCESSORIES, & PEERLESS

PRODUCTS

• Covered only by manufacturer’s warranty

EXCLUSIONS

• No warranty is extended to blades, mower vanes, skid

shoes, runners, scraper blades, shear bolts, light bulbs,

headlights and any equipment which has been altered,

misused, misassembled, improperly adjusted,

neglected, or damaged by accident.

• No warranty is extended for service completed by

anyone other than an authorized distributor or dealer.

• No warranty is extended on any parts that are not

genuine Ariens service parts.

• Ariens Company reserves the right to incorporate

any changes in design into its products without

obligation to make such changes on products

previously manufactured.

A

s

PAR TS

«PA RTS

Crafted In

America

Since 1933

#

DISCLAIMER OF FURTHER WARRANTY

There is no other express warrsnty. Implied warranties, including

any warranty of merchantability or fitness for a particular purpose,

are limited to the duration of this written warranty, and are excluded

to the extent permitted by law. Thera are no warranties which extend

beyond the description of the product contained herein.

In no event shall the company be liable for indirect, special or

consequential damages (such as loss of anticipated profits)

Ariens® Sno-Thro® Orig. 4/96

in connection with the consumer's use of the product.

This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state. Some states do not allow

the exclusion of incidental or consequential damages, or limitations

on how long an implied warranty lasts, so the above limitation and

exclusions may not apply to you.

19

Page 24

94leiì&

655 West Ryan Street • RO. Box 157 • Brillion, Wl 54110-0157 • 414-756-2141 • Fax 414-756-4421

Ask Your Dealer For Information On

These Other Fine Arlens Products

• Front and Rear Tine Tillers

• Walk-Behind Lawn Mowers

• Zero-Turning Radius Mowers

• Rear Engine Riding Mowers

• Yard and Garden Tractors

• Commercial Waik-Behind and Riding Mowers

• Sno-Thros

Loading...

Loading...