Page 1

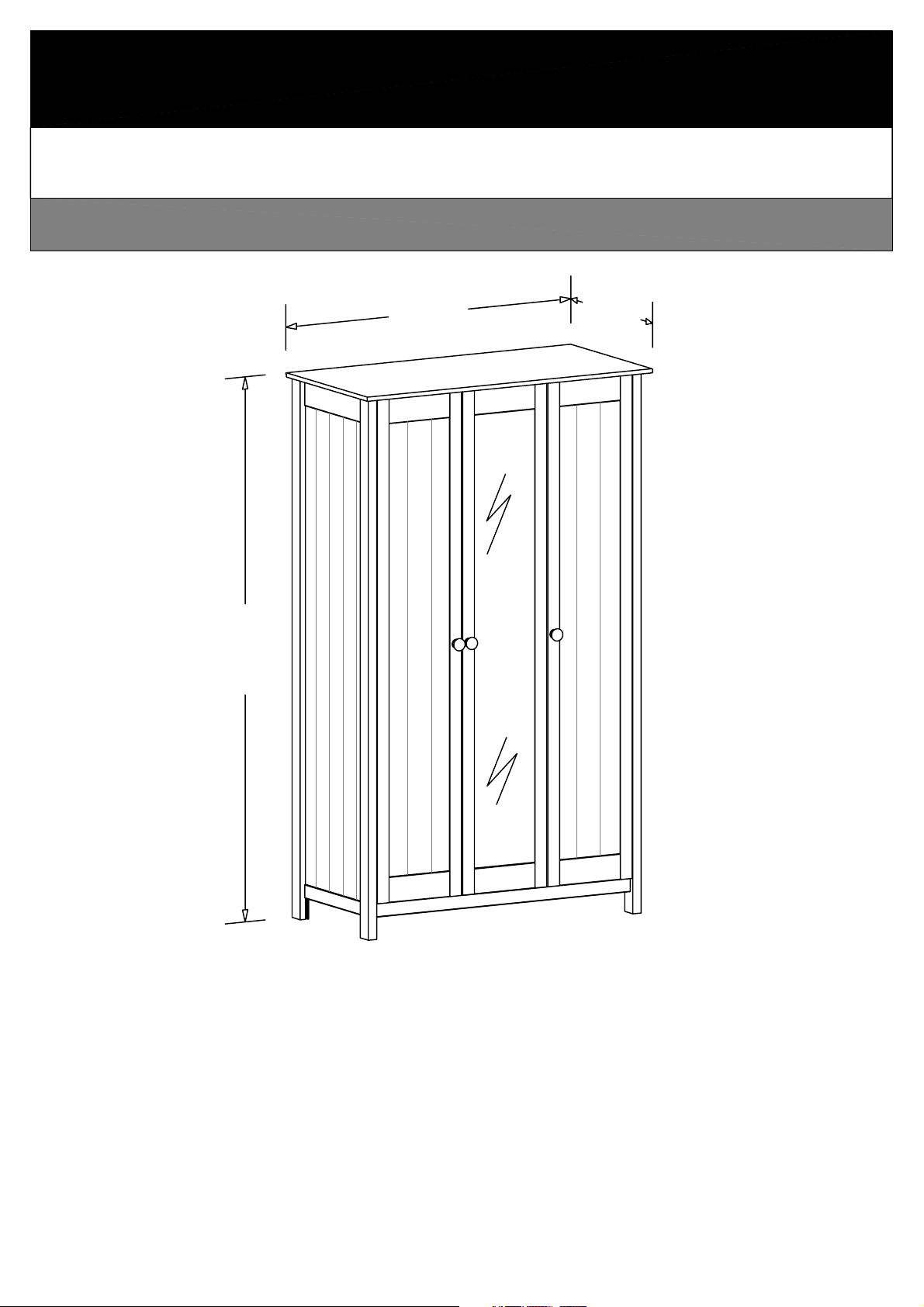

Scandinavia

3 door robe w. mirror

1799mm

1070mm

530mm

Page 1 of 21

Scandinavia 3 door robe w. mirror

Page 2

Please sort out all parts before you begin to assemble the item.

This to make sure you always use the correct part.

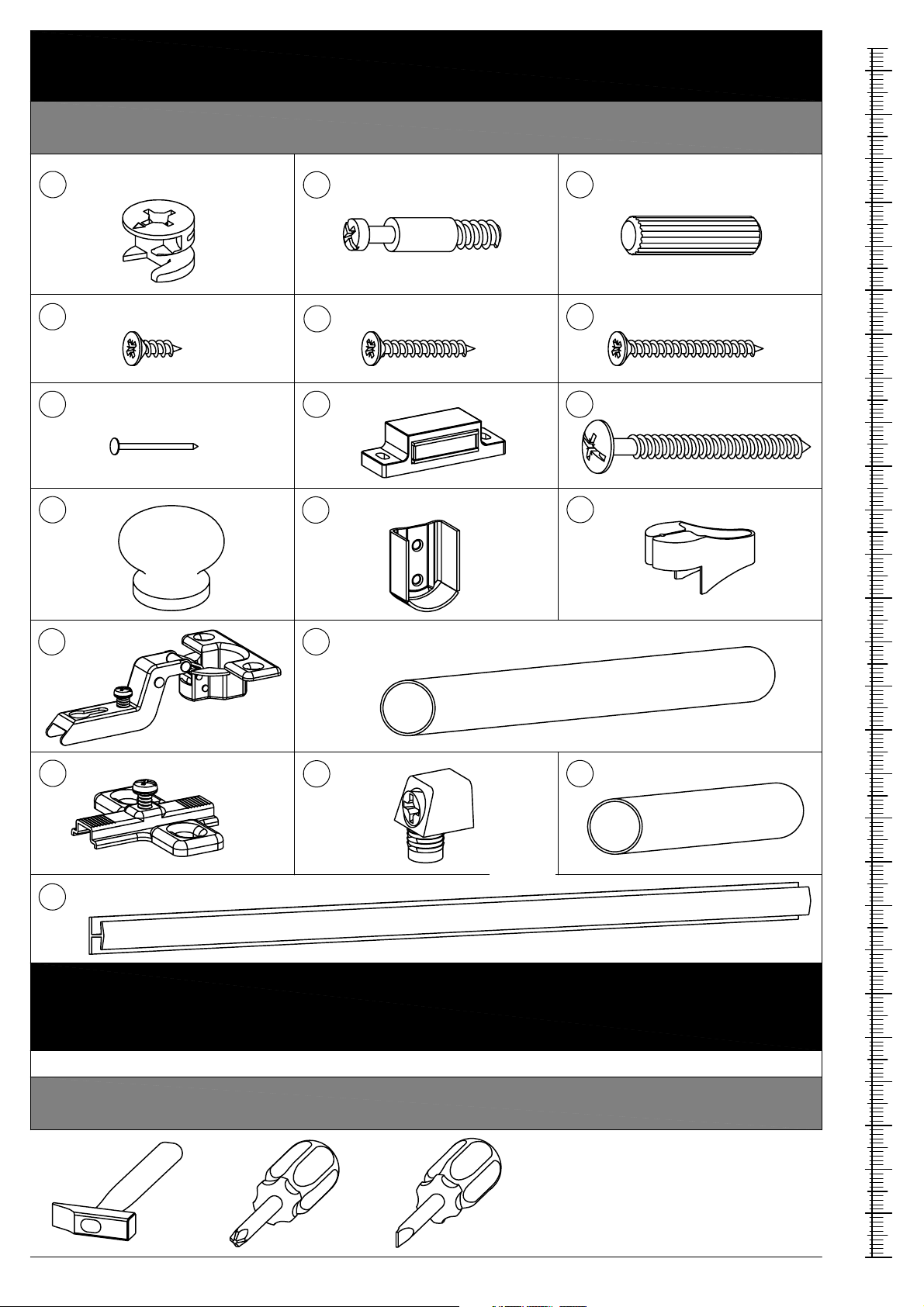

Fittings contained in the Box.

A

D

G

12 pcs.

40 pcs.

30 pcs.

Cam - ø15 x 12mm

Screw - ø3,5 x 12mm

Nail - 1,2 x 20mm

B

E

H

12 pcs.

12 pcs.

3 pcs.

Bolt - ø6,5 x 24/11mm

Screw - ø3,5 x 25mm

Magnet

C

F

J

4 pcs.

3 pcs.

3 pcs.

Dowel - ø8 x 30mm

Screw - ø3,5 x 35mm

Screw - ø5 x 50mm

MM

270

260

250

240

230

220

210

200

190

180

3 pcs.

K

Knob

ø40 x 30mm

9 pcs.

N

Cup hinge

9 pcs.

P

1 pcs.

S

Cross plate

Joining strip - 1653mm

L

O

Q

4 pcs.

1 pcs.

4 pcs.

Hanging rail cup

Hanging rail - ø16 x 636mm

Miniblock

M

R

1 pcs.

Nail guide

1 pcs.

Hanging rail

16 x 302mm

170

160

150

140

130

120

110

100

90

80

70

Hazard Warning !

Keep small components out of the reach of children.

Fittings A, B, C, D, E, F, G and J are shown in their actual dimensions.

Tools Needed.

Page 2 of 21

Scandinavia 3 door robe w. mirror

60

50

40

30

20

10

0

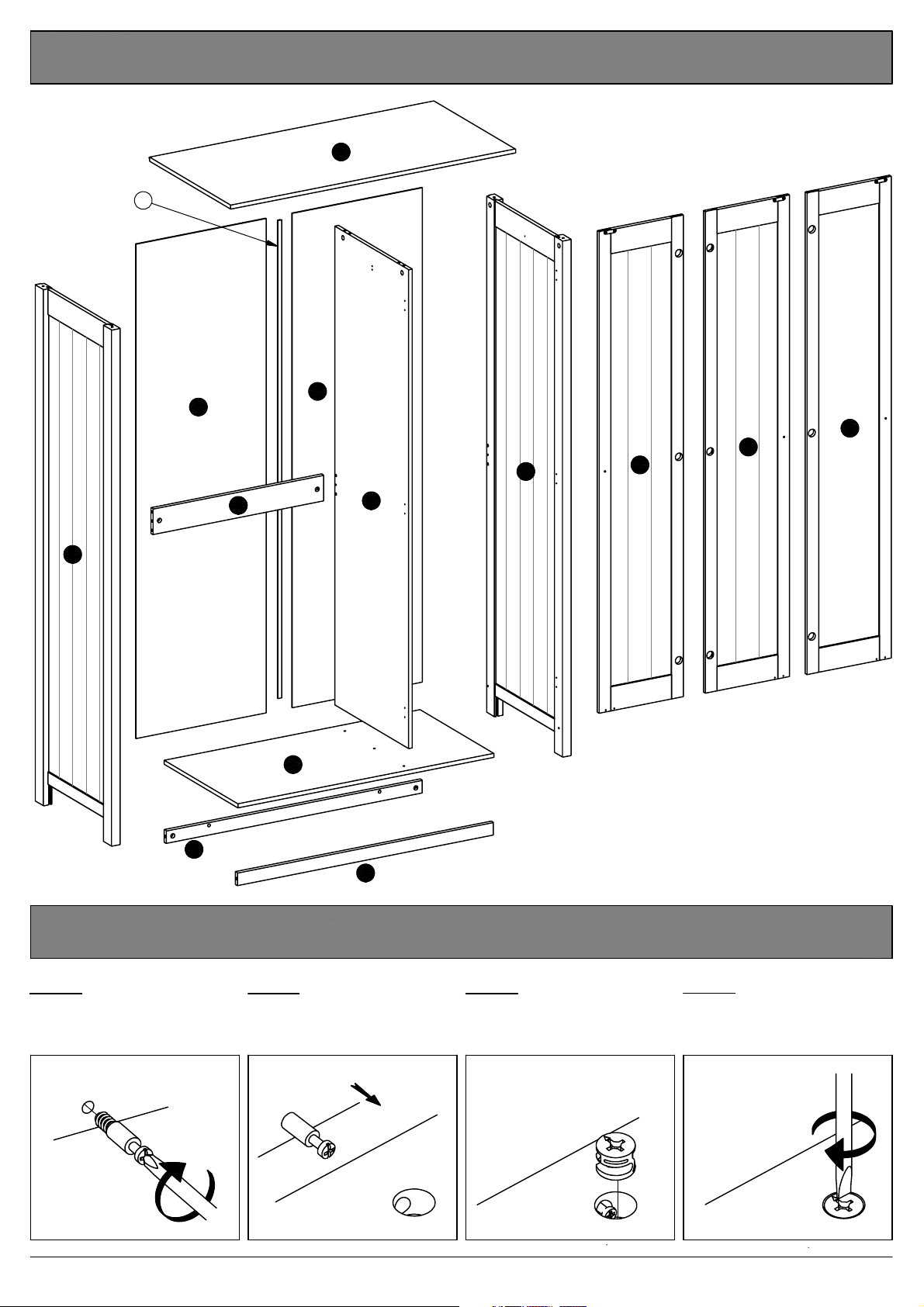

Page 3

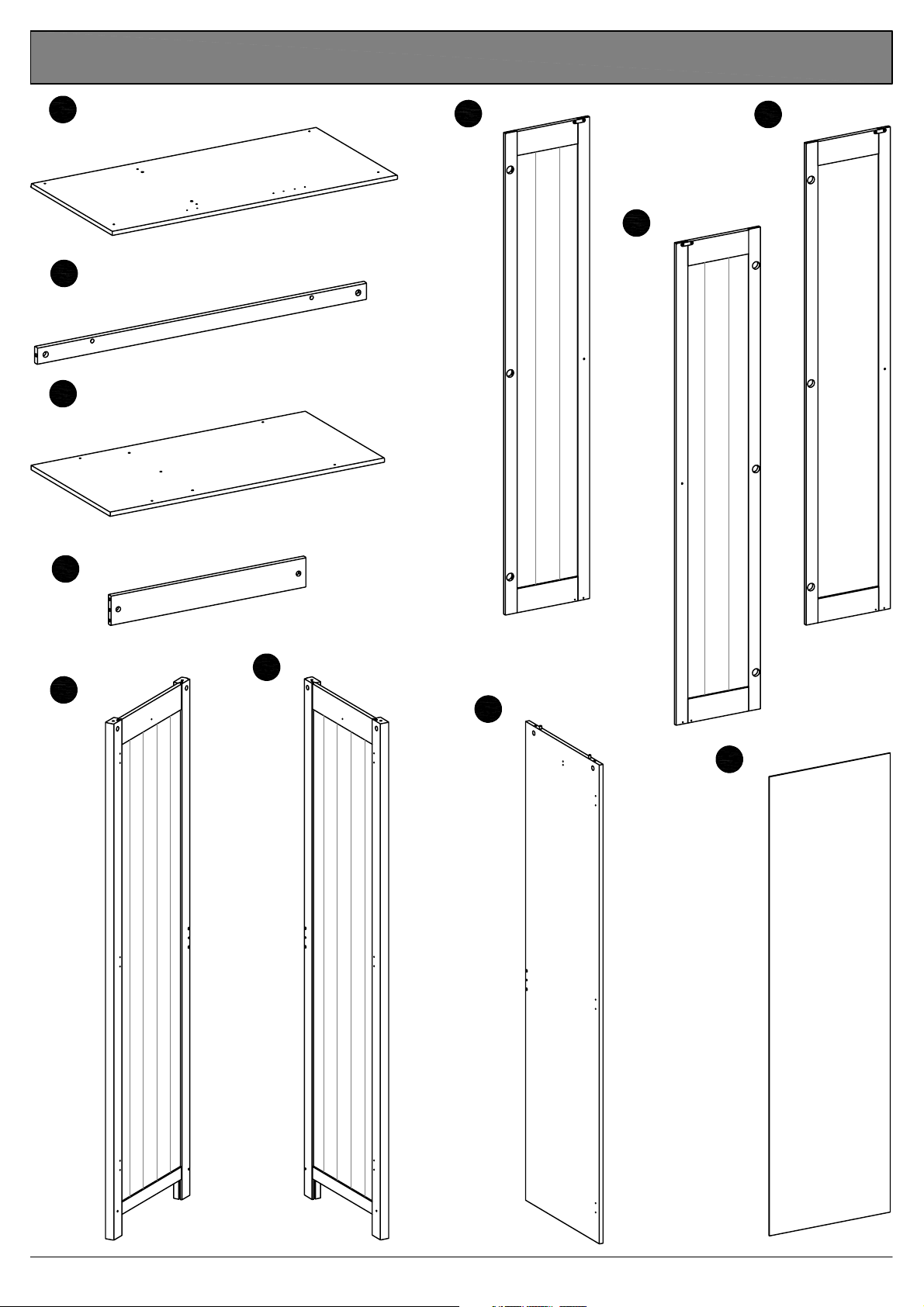

Wooden parts contained in the box.

Top

1

1 pcs.

8

1 pcs.

Door, right

10

1 pcs.

Door w. mirror

2

2 pcs.

3

1 pcs.

4

1 pcs.

5

1 pcs.

Plinth

Bottom

Support Rail

Side, left

960 x 45mm

960 x 480mm

640 x 90mm

1 pcs.

1070 x 530mm

Side, right

6

7

1 pcs.

m

m

6

1

3

x

6

6

6

1

Divider

9

1 pcs.

Door, left

m

m

6

1

3

x

6

6

6

1

m

m

6

1

3

x

6

6

6

1

m

m

8

9

4

x

5

8

7

1

m

m

8

9

4

x

5

8

7

1

m

m

0

8

4

x

6

5

6

1

11

2 pcs.

Back

m

m

8

8

4

x

0

1

7

1

Page 3 of 21

Scandinavia 3 door robe w. mirror

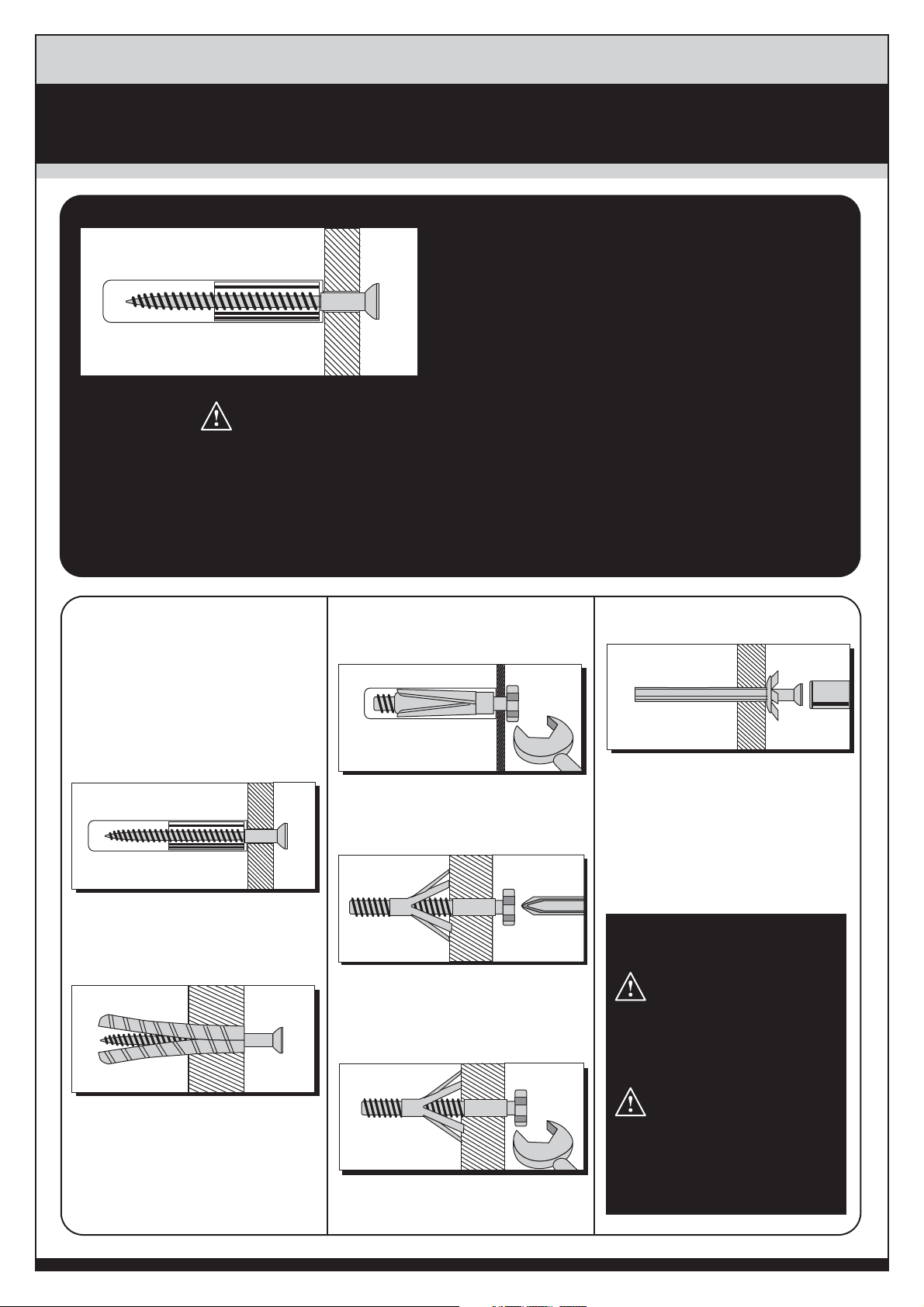

Page 4

A Guide to

Scandinavia 3 door robe w.mirror

Wall Mounting & Fixings

IMPORTANT:

When drilling into walls always check that there are no

hidden wires or pipes etc. Make sure that the screws and

wall plugs being used are suitable for supporting your unit.

Consult a qualified tradesperson if you are unsure.

HINTS:

1) General Rule Always use a larger screw and wall plug if you are not sure.

2) Ensure you use the recommended drill bit to match the wall plug and hole size.

3) Ensure you drill the hole horizontally, do not force the drill or enlarge the hole.

4) Take extra care when drilling high walls, ceilings and ceramic tiles. Ensure the plug is fitting below the ceramic

tile to avoid splitting or cracking.

5) Ensure wall plugs are well fitted and are a tight fit in the drilled hole.

Types Of Walls

You can use one of the following types

of wall plug if your walls are made of

brick, breeze block, concrete, stone,

wood or plaster board.

No.1 "Standard" Wall Plug

General Wall Materials

These come in various sizes and are made

from plastic or sometimes wood fiber.

No.2 "General Purpose" Wall Plug

Aerated / Breeze Block

No.3 "Shield Anchor" Wall Plug

Heavy Loads

For use with heavier loads such as TV

& HiFi Speakers and Satellite Dishes etc.

No.4 "Cavity Fixing" Wall Plug

For use with plaster board partitions or

hollow wooden doors.

No.5 "Cavity Fixing - Heavy Duty"

Wall Plug

No.6 "Hammer Fixing" Wall Plug

For use with walls stuck with plaster

board. The hammer fixing allows it to

be fixed to the wall rather than the plaster

board. Always check the fixing is secure

to the retaining wall.

CARE & MAINTENANCE

SAFETY

Always check the fitting and

location to ensure your safety in

and around the home.

Generally aerated blocks should not be

used to support heavy loads, use a

specialist fitting in this case.

For light loads, a General Purpose Plug

can be used.

For use when fitting or supporting heavy

loads such as shelving, wall cabinets,

coat racks.

Page 4 of 21

FITTING

From time to time check the fitting

to ensure the wall plugs or screws

do not become loose.

Page 5

Key diagram.

S

11

11

1

10

8

6

9

4

5

3

2

7

2

Function of cam & bolt.

Step 1:

Fix the Bolt to the

wooden Panel.

1

Step 2:

Push the wooden Panel

with the attached Bolt onto

the other wooden Panel.

2

Page 5 of 21

Step 3:

Place the Cam into the

Hole, arrow pointing

towards the Bolt.

Step 4:

Tighten: Turn the Cam to

the Right.

34

Scandinavia 3 door robe w. mirror

Page 6

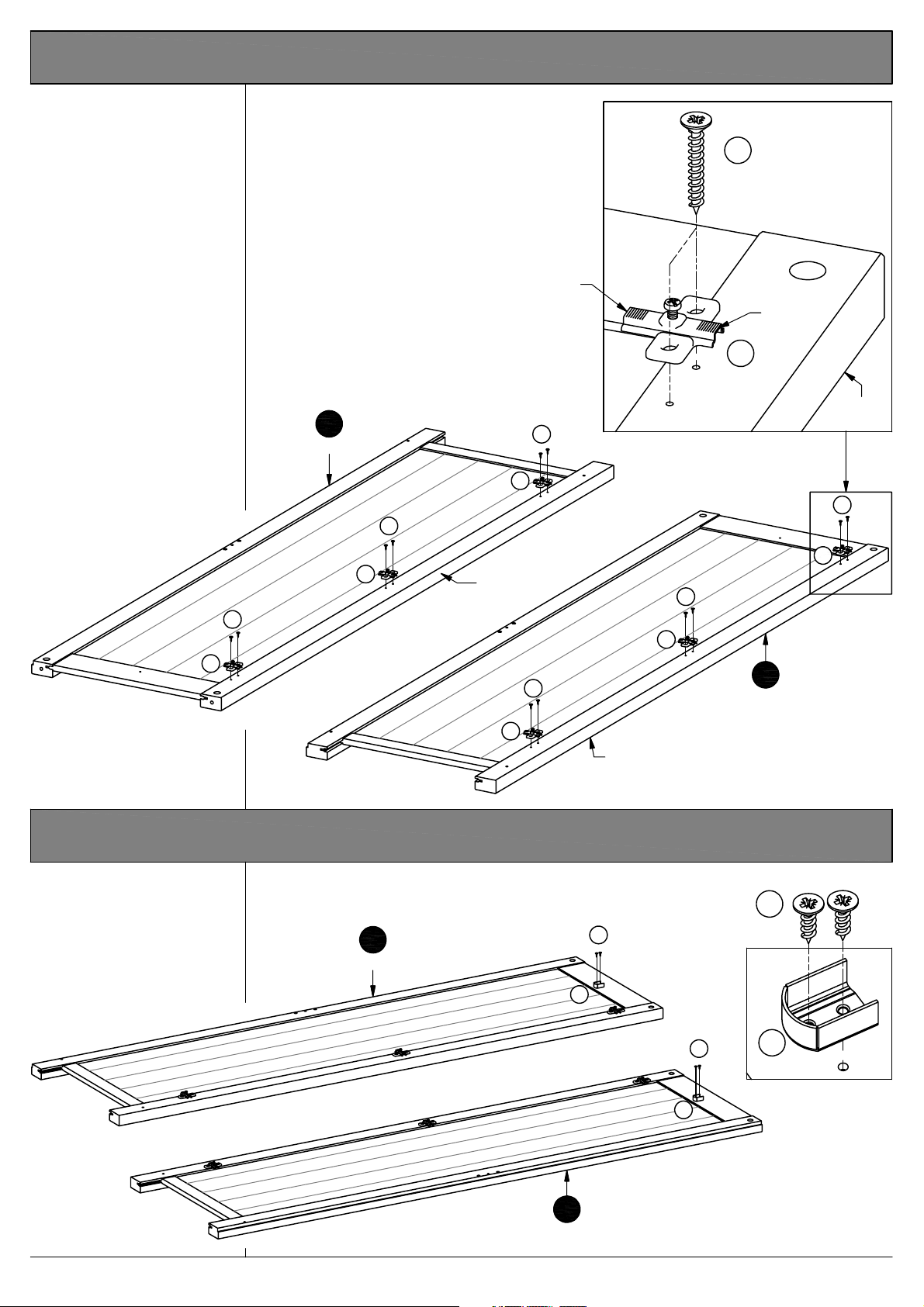

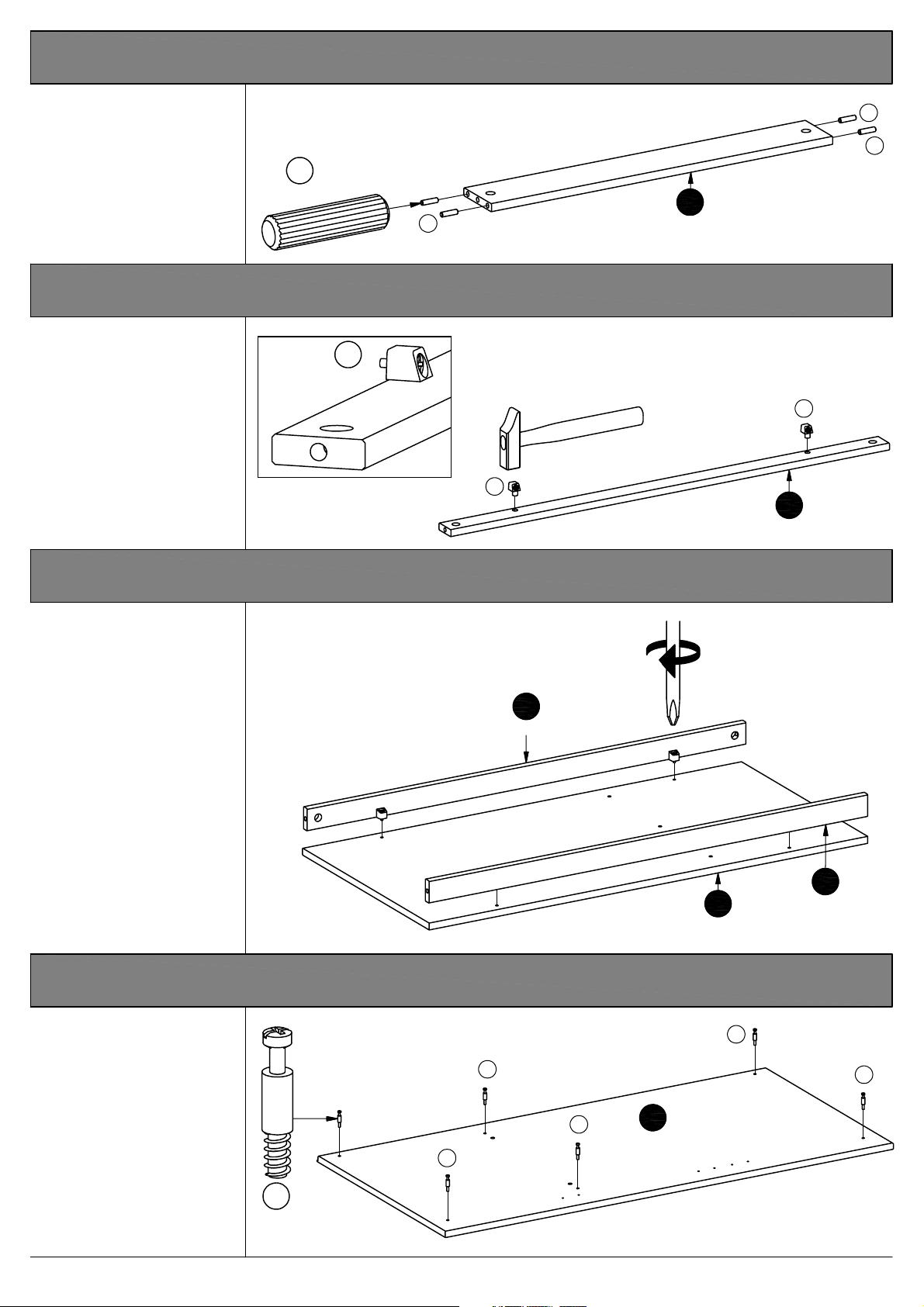

1. Mounting the cross plates to the sides.

Fix the cross plates

"P" to the sides "5"

and "6" using screws

"E" into the holes

indicated.

It is important that the

cross plates is placed

exactly as shown.

The short end of the

cross plates must

point towards the front

edge of the sides.

See fig. 1.1

Fig. 1.1

E

12 Pcs.

Long end

Short end

P

6 Pcs.

Front

5

Side, left

E

P

E

P

Front

E

P

E

P

E

P

E

6

Side, right

P

Front

2. Mounting the hanging rail cups to the sides.

Fix the hanging rail cups

"L" onto the sides "5"

and "6" using screws

"D" into the pre-drilled

holes.

See fig. 2.1

6

Side, right

D

L

D

L

D

4 Pcs.

L

2 Pcs.

Fig. 2.1

Page 6 of 21

5

Side, left

Scandinavia 3 door robe w. mirror

Page 7

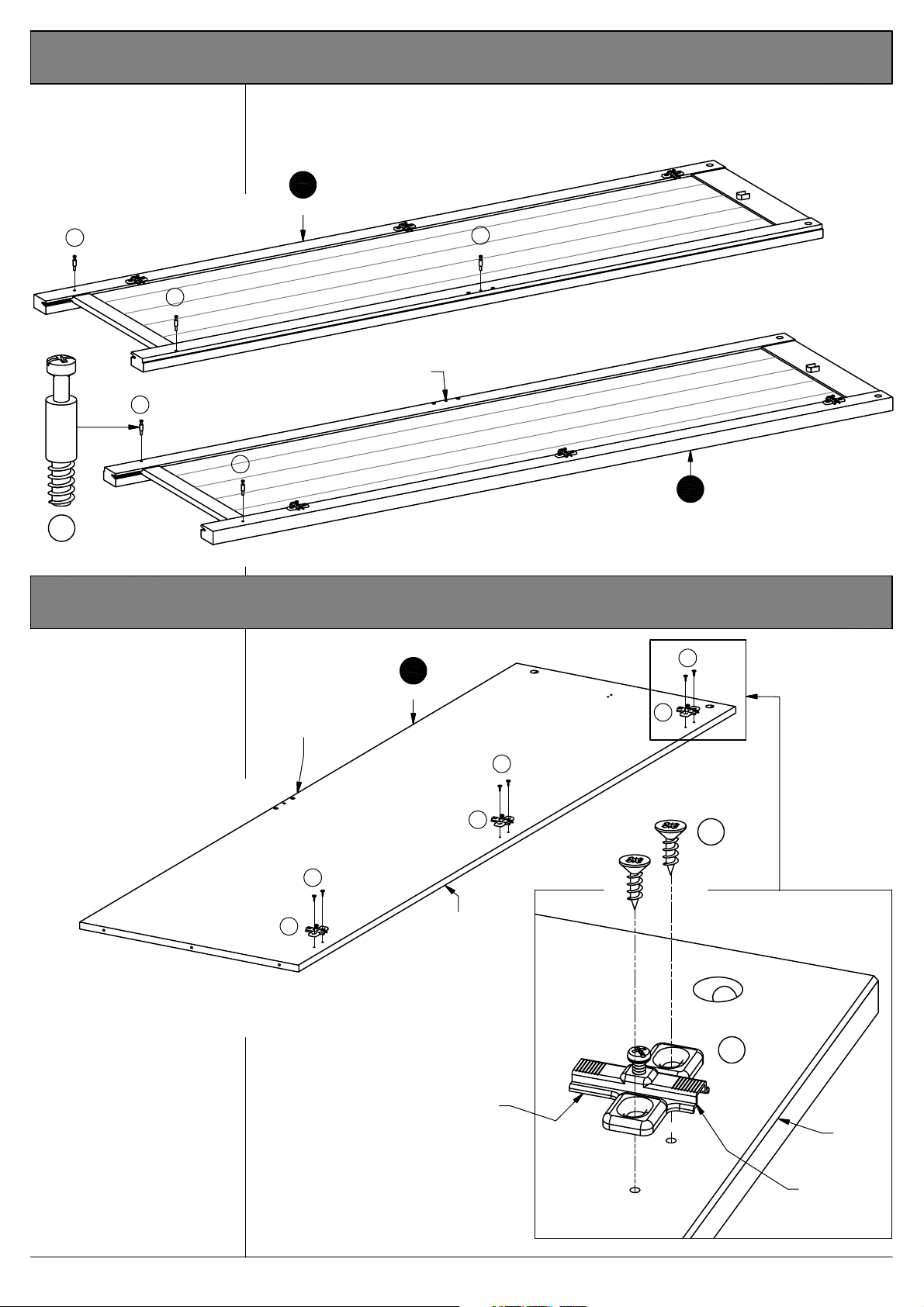

3. Mounting the bolts to the sides.

Screw the bolts "B"

into the holes

indicated on the sides

"5" and "6".

5

Side, left

B

B

B

NO Bolt here

B

B

B

5 Pcs.

4. Mounting the cross plates to the divider.

Fix the cross plates "P"

to the divider "7" using

screws "D".

It is important that the

cross plates is placed

exactly as shown.

Holes = Back

7

Divider

D

6

Side, right

D

P

The short end of the

cross plates must point

towards the front edge

of the divider.

See fig. 4.1

P

D

6 Pcs.

D

P

Front

Fig. 4.1

P

3 Pcs.

Long end

Front

Short end

Page 7 of 21

Scandinavia 3 door robe w. mirror

Page 8

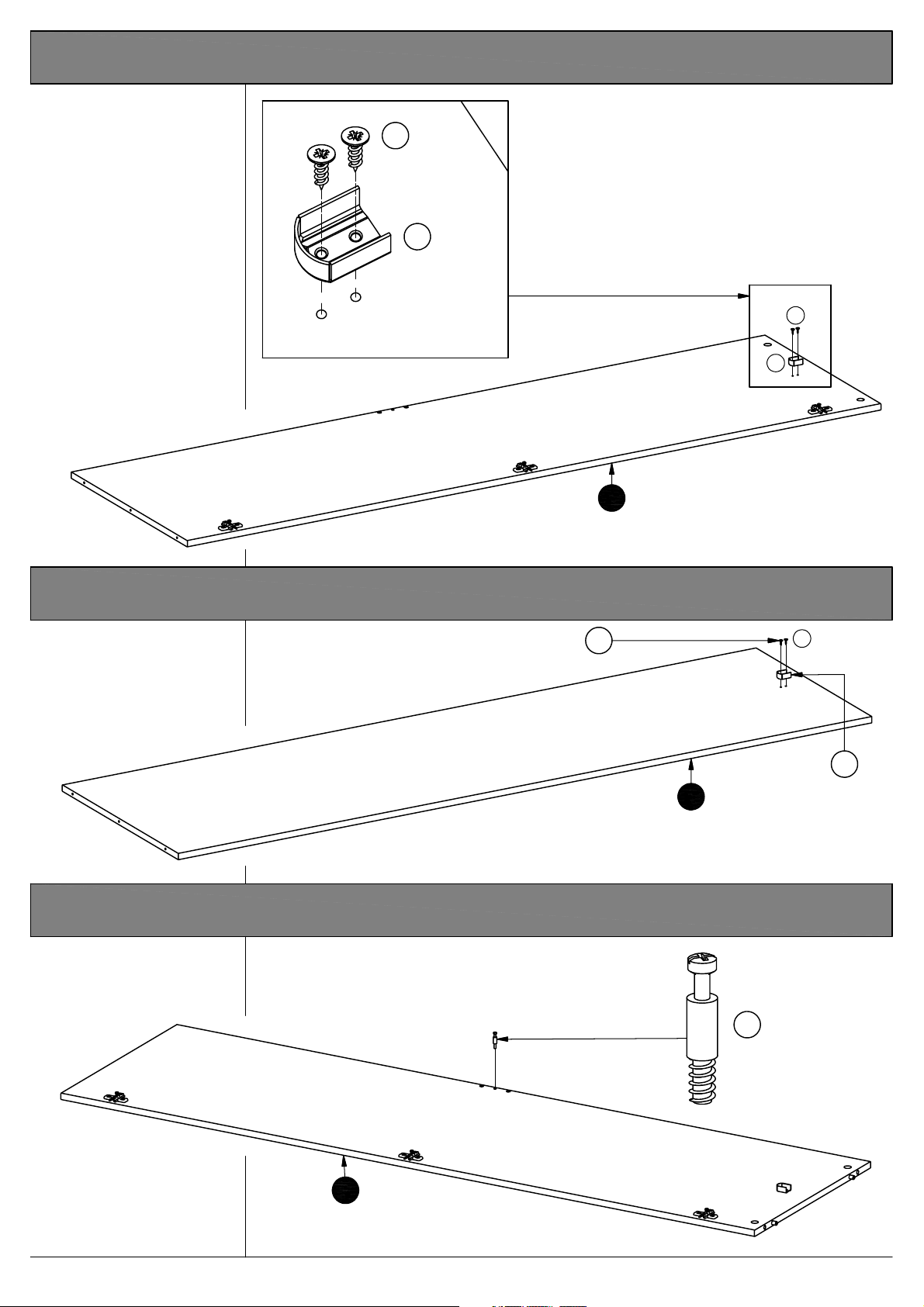

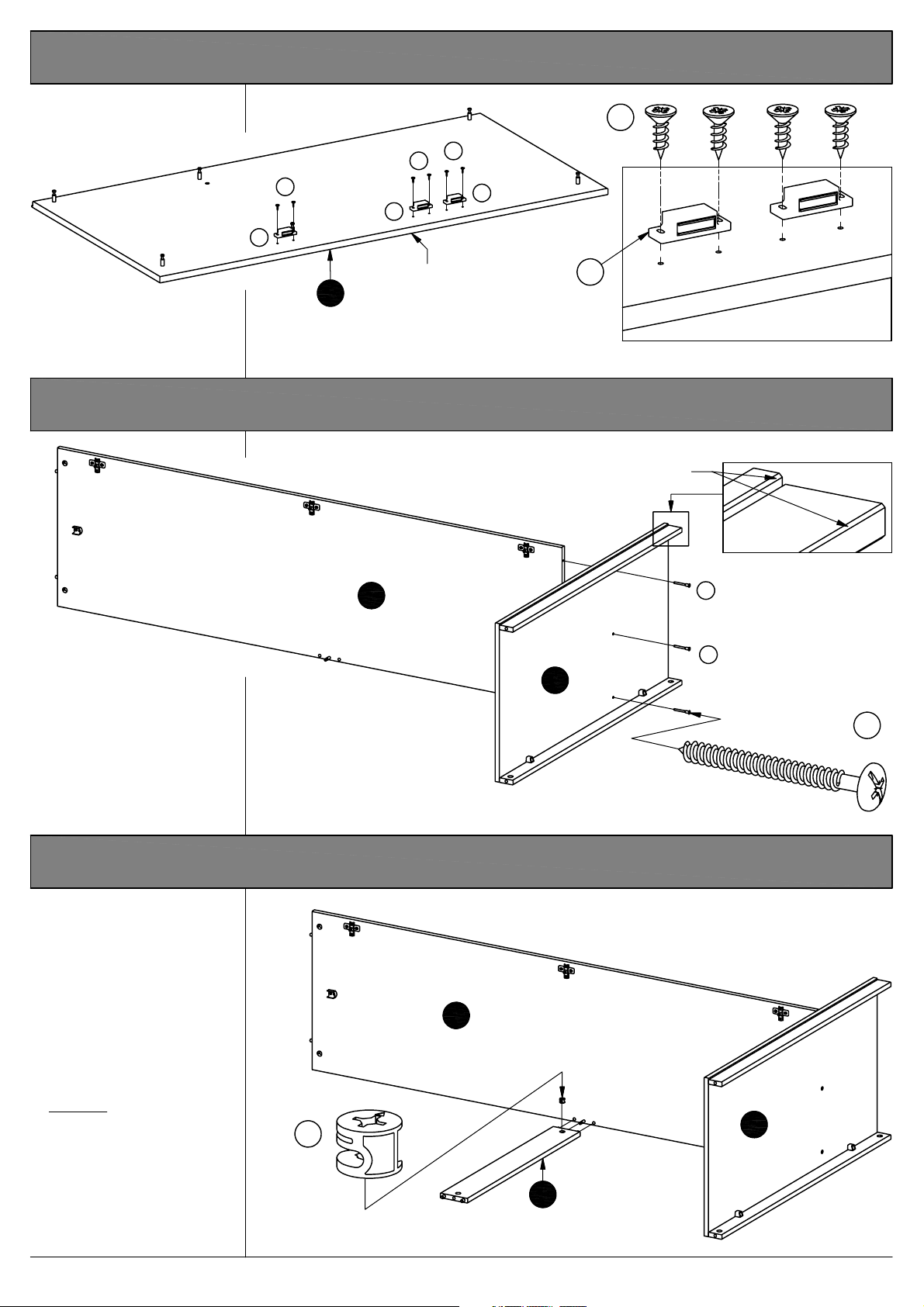

5a. Mounting the hanging rail cup to the divider.

Fix the hanging rail cup

"L" onto the left hand

side of the divider "7"

using screws "D" into

the pre-drilled holes.

See fig. 5a.1

Fig. 5a.1

D

2 Pcs.

L

1 Pcs.

D

L

7

Divider

5b. Mounting the hanging rail cup to the divider.

Fix the hanging rail cup

"L" onto the right hand

side of the divider "7"

using screws "D" into

the pre-drilled holes.

See fig. 5a.1

D

2 pcs.

7

Divider

6. Mounting the bolt to the divider.

Screw the bolt "B" into

the hole indicated on

the divider "7".

1 Pcs.

D

L

1 pcs.

B

7

Divider

Page 8 of 21

Scandinavia 3 door robe w. mirror

Page 9

7. Adding the dowels to the support rail.

Knock the dowels "C"

into the holes indicated

on the support rail "4".

C

4 Pcs.

C

8. Adding the miniblocks to the plinths.

Knock the miniblocks

"Q" into the holes

indicated on both the

plinths "2".

Q

4 Pcs.

Fig. 8.1

Q

4

Support Rail

Q

2

2 Pcs.

C

C

Plinth

9. Mounting the plinths to the bottom.

Fix the plinths "2" to

the bottom "3" using

the screws in the

miniblocks "Q".

2

Plinth

10. Mounting the bolts to the top.

Screw the bolts "B" into

the holes indicated on

the top "1".

B

3

Bottom

B

2

Plinth

B

B

6 Pcs.

B

Page 9 of 21

B

1

Top

Scandinavia 3 door robe w. mirror

Page 10

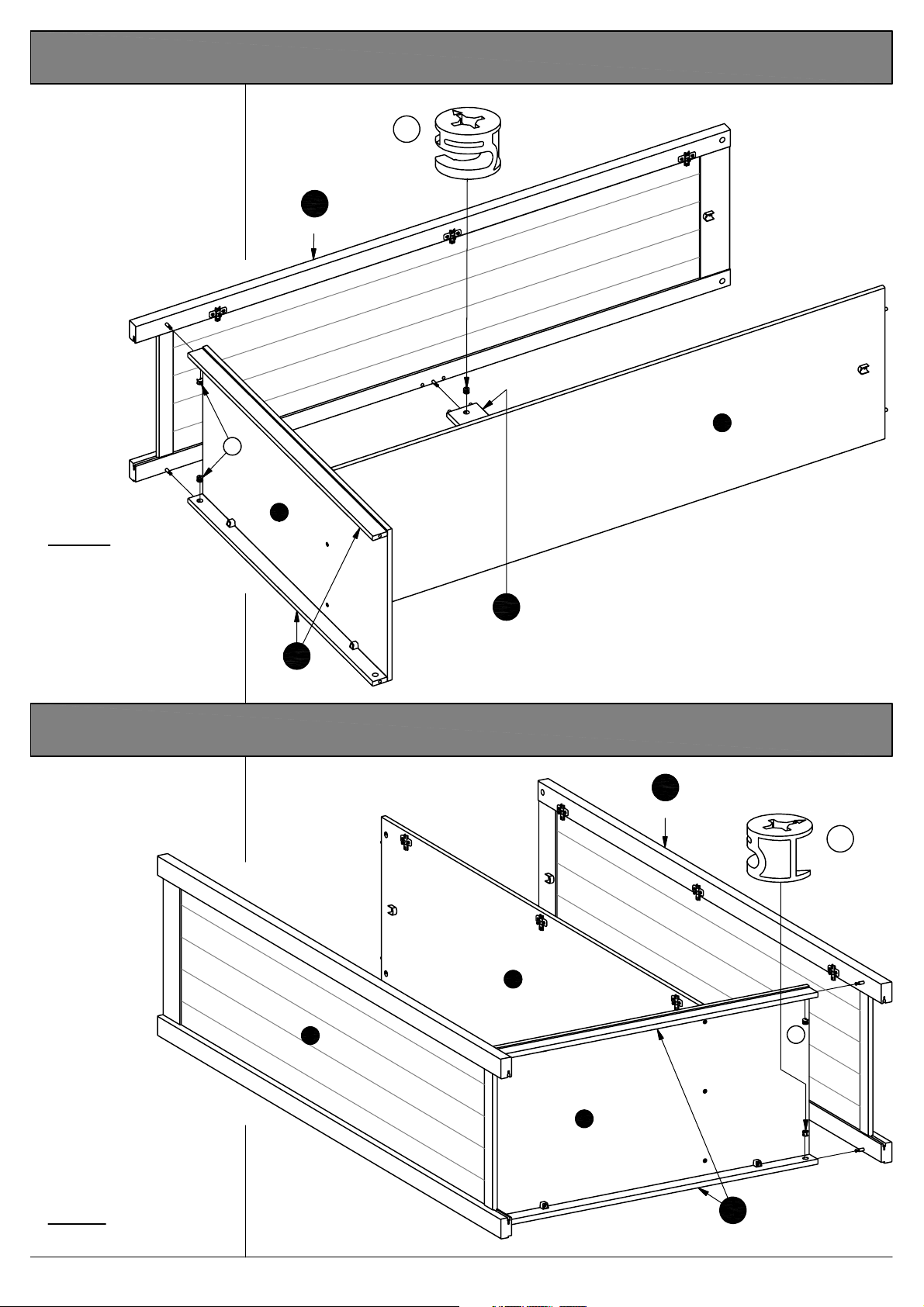

11. Mounting the magnets to the top.

Fix the magnets "H" to

the top "1" using screws

"D" into the pre-drilled

holes.

It is important that the

magnetic part points

towards the front edge of

the top. See fig. 11.1

D

D

D

H

H

Front edge

H

1

Top

D

6 Pcs.

H

3 Pcs.

12. Assembling the bottom to the divider.

Chamfer = Front

Fig. 11.1

7

Divider

Fix the divider "7" to the

bottom "3" using

screws "J".

Make sure to turn the

bottom as shown. The

chamfered edge should

point towards the front.

See fig 12.1

3

Bottom

13. Adding the support rail to the divider.

Press the support rail "4"

onto the divider "7".

See page 4 "Function of

the cam & bolt".

Place the cam "A" into

the hole indicated, arrow

pointing towards the

divider / bolt.

7

Divider

Fig. 12.1

J

J

J

3 Pcs.

Tighten:

Turn the cam to the right.

A

1 Pcs.

Page 10 of 21

3

Bottom

4

Support rail

Scandinavia 3 door robe w. mirror

Page 11

14. Adding the side to the plinths and the support rail.

Press the side "5" onto

the plinths "2" and the

support rail "4".

See page 4 "Function of

the cam & bolt".

Place the cams "A" into

the holes indicated,

arrows pointing towards

the side / bolt.

Tighten:

Turn the cams to the

right.

5

Side, left

A

3

A

3 Pcs.

7

4

Support rail

2

Plinth

15. Adding the right hand side to the plinths.

Press the side "6" onto the

plinths "2".

See page 4

"Function of the

cam & bolt".

Place the cams "A" into

the holes indicated,

arrows pointing towards

the side / bolt.

7

5

3

6

Side, right

A

2 Pcs.

A

Tighten:

Turn the cams to the right.

Page 11 of 21

2

Plinth

Scandinavia 3 door robe w. mirror

Page 12

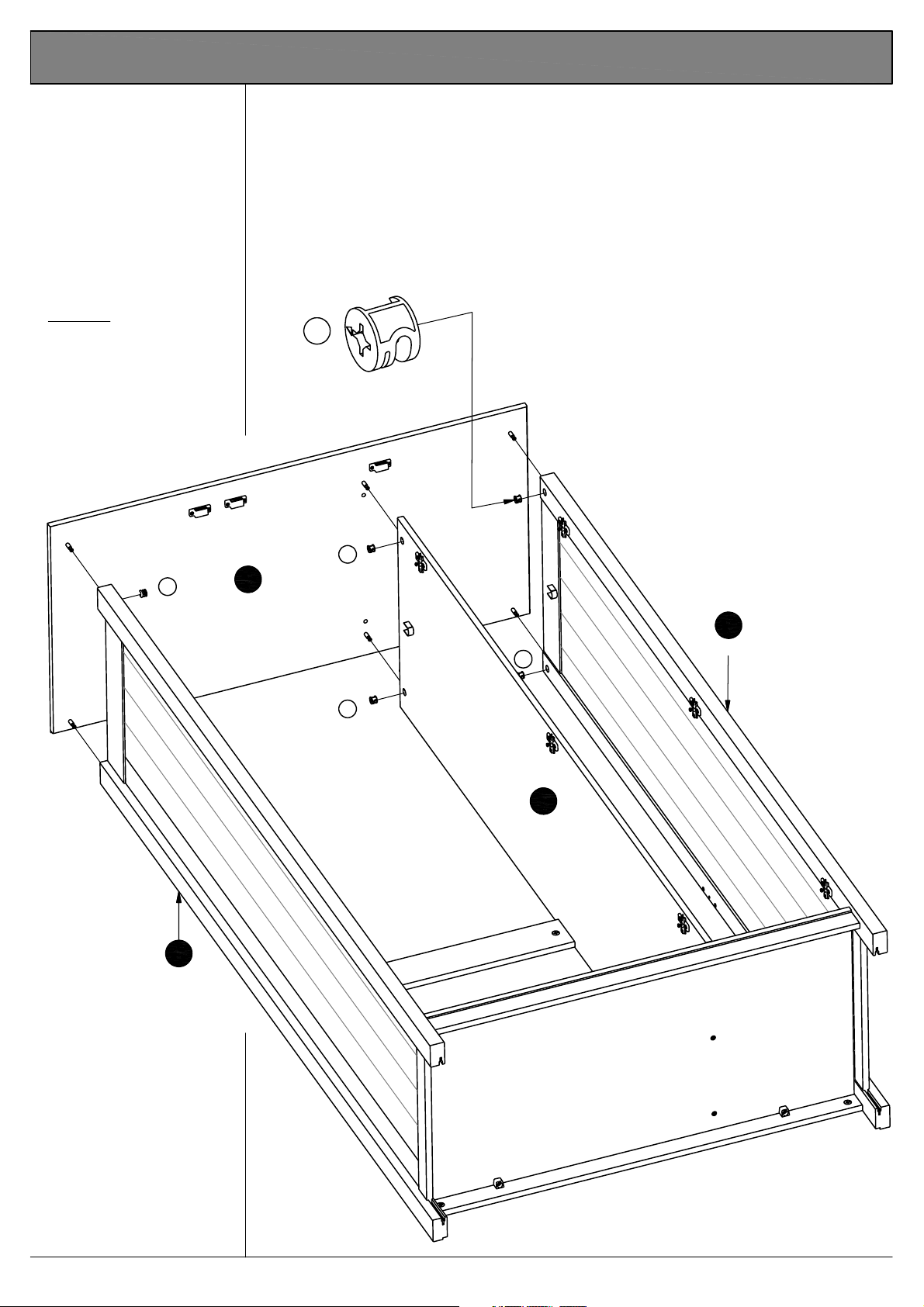

16. Assembling the top to the sides.

Lower the top "1" onto

the sides "5" and "6" and

the divider "7".

See page 4 "Function of

the cam & bolt".

Place the cams "A" into

the holes indicated,

arrows pointing towards

the top / bolt.

Tighten:

Turn the cams to the

right.

A

6 Pcs.

A

5

Side, left

1

Top

A

6

A

A

Side, right

7

Divider

Page 12 of 21

Scandinavia 3 door robe w. mirror

Page 13

17. Adding the back to the carcass.

Place the back "11" into

the rabbet of the top "1"

and the side "6".

Ensure there is NO GAP

between the side and the

back, NOR between the

top and the back.

Fasten the back with

nails "G" along the top.

Use the nail guide "M" see fig. 17.4

The angle between the

top and the side must be

90 degrees. Fig. 17.2

To accomplish this,

ensure there is NO GAP

between the side and the

back.

Fasten the back along

the side and the bottom.

Use the nail guide as

shown in fig. 17.5.

Fig. 17.2

Fig. 17.4

Fig. 17.1

M

Rabbet = Back

1

Top

G

G

11

Back

M

5

G

4

90a

G

3

G

Fig. 17.5

6

Side, right

Page 13 of 21

Rabbet = Back

Fig. 17.3

Scandinavia 3 door robe w. mirror

Page 14

18. Adding the back and the joining strip to the carcass.

Place the joining strip

"S" onto the back.

See fig. 18.1

11

S

11

Fig. 18.1

Place the back into the

rabbet of the top "1" and

the side "5".

Ensure there is NO GAP

between the side and the

back, NOR between the

top and the back.

Fasten the back along

the top. Use the nail

guide - see page 12, fig.

17.4.

Ensure there is NO GAP

between the side and the

back.

1

S

Joining strip

11

fig. 18.2

G

11

Back

1

11

90a

1

G

5

G

Fasten the back along

the side and the bottom.

Use the nail guide - see

page 12, fig. 17.5

Fix the back onto the

support rail "4" using

screws "D".

See fig. 18.3

Fig. 18.3

D

2 Pcs.

4

D

G

G

14 Pcs.

G

Page 14 of 21

Scandinavia 3 door robe w. mirror

Page 15

19. Mounting the cup hinges to the doors.

Lower the cup hinges

"N" into the holes

indicated on the doors

"8", "9" and "10".

Fix the hinges using

screws "D".

Fig. 19.1

D

8

Door, right

D

N

D

N

D

N

D

N

9

Door, left

N

D

D

10

Door w. mirror

N

N

D

N

D

N

D

18 Pcs.

Fig. 19.1

N

9 Pcs.

Page 15 of 21

Scandinavia 3 door robe w. mirror

Page 16

20. Mounting the doors to the carcass.

When placing the doors,

the magnet catches

MUST point upwards.

Step 1

Place the adjustment

hole of the cup hinge at

the level of the fixing

screw. Push the cup

hinge towards the cross

plate - placing the fixing

screw in the wider part

of the adjustment hole.

It is very IMPORTANT to

catch ALL of the fixing

screws.

Step 2

Push the door / cup

hinge inwards - placing

the fixing screw in the

narrow end of the

adjustment hole.

Step 3

Tighten the fixing

screws of ALL of the

cross plates.

Fig. 20.1

Fig.

20.2

Cross plate

1

Adjustment

hole

2

Fixing screw

Adjusting

screw

Page 16 of 21

10

3

Scandinavia 3 door robe w. mirror

Page 17

21. Mounting the knobs & adding the hanging rails.

Lower the hanging rails

"O" and "R" into the

hanging rail cups "L".

O

Hanging rail

Fig. 21.1

R

Hanging rail

Fix the knobs "K" to

the doors using

screws "F".

F

K

F

K

F

K

Fig. 21.2

3 Pcs.

Page 17 of 21

F

K

3 Pcs.

Scandinavia 3 door robe w. mirror

Page 18

22a. Adjusting the doors from side to side.

MAKE SURE THE

WARDROBE IS PLACED

ON A PLANE SURFACE

BEFORE YOU BEGIN

ADJUSTING THE HINGES.

Step 1

Loosen the fixing screw.

Step 2

To adjust the door away

from the side (towards the

other door / the centre) turn the adjusting screw

to the right.

Step 3

To adjust the door

towards the side (away

from the other door / the

centre) - turn the

adjusting screw to the

left.

Step 4

Either continue

adjustment on page 18 step 2 - or tighten the

fixing screws of ALL of

the cross plates.

Fig.

1

22a.1

Fixing screw

2

3

Adjusting

screw

Adjusting

screw

Page 18 of 21

4

Cross plate

Fixing screw

Scandinavia 3 door robe w. mirror

Page 19

22b. Adjusting the doors forwards or backwards.

Step 1

Loosen the fixing screw.

Step 2

Push the cup hinges / the

door back OR forth to

adjust. The doors should

level with the front edge

of the sides.

Step 3

Tighten the fixing screws

of ALL of the cross

plates.

Fig.

1

22b.1

Fixing

screw

2

3

Cross plate

Adjustment hole

Page 19 of 21

Fixing

screw

Scandinavia 3 door robe w. mirror

Page 20

22c. Adjusting the doors up or down.

Step 1

Loosen the two screws

"E"/"D" of each cross

plate, BUT ONLY as

much as it will allow the

cross plate to move up

and down.

Step 2

Adjust the cross plate /

the door.

Step 3

Tighten the screws

"E"/"D" of ALL of the

cross plates.

Fig.

22a.1

1

Cross Plate

"E"/"D"

2

3

"E"/"D"

Page 20 of 21

"E"/"D"

Scandinavia 3 door robe w. mirror

Page 21

Dear Customer

This unit complies with BS 7449: (1991).

Manufacturer (or supplier): Argos MK9 2NW

Model No. : 6423801 Scandinavia 3 door robe w. mirror

Date: 10-10-2007

Keep these instructions for further use.

This unit contains film backed glass of a nominal thickness of 4 mm

If a glass component is chipped or broken replace with glass of the type described on this

label. Consult the manufacturer, retailer or agent with regard to obtaining a manufacturing

specification and shape for replacement glass quoting the model Number and date.

.

WARNINGS !

(1) Do not place very hot or very cold items against or in close proximity to glass surfaces

unless an adequately thick insulating material is used to prevent such items from coming

into contact with the glass.

(2) Do not strike the glass with hard or pointed items.

(3) When cleaning glass panels or mirrors use a damp cloth or leather with washing up

liquid or soft soap if necessary; do not use washing powders or any other substances

containing abrasives since these substances scratch glass.

(4) Do not sit or stand upon horizontal glass surfaces.

(5)) If you are not sure the furniture is put together right please get professional help as

wrong assembled furniture can cause damages on yourself or others.

Please note that the product you have purchased is a natural living timber.

Just like nature itself, wood varies in shape and colour. Knots, vein patterns, resin pockets

and colour differences contribute to giving the piece of furniture its beauty and form - a

natural part of solid wood.

Although the tree has been cut down and dried, it is still alive and therefore will react to

high and low temperatures, light, humidity, drought and time.

In cold and dry periods, the wood contracts which may lead to small cracks in the piece of

furniture. The reverse happens in warm and humid periods where the wood expands and

this may result in slight unevenness.

The colour of the wood also changes with time, particularly if the furniture is placed in a

light place. This is a natural process and part of owning a piece of furniture made of solid

wood.

Any flexing that has occurred during transport will re-correct it self once this product is

correctly assembled.

Re-tighten all joints of the furniture after six months.

Page 21 of 21

Scandinavia 3 door robe w. mirror

Page 22

Scandinavia - 3 Door Robe w

. Mi

rror

A

ssembly Instructi

on

s

- Please k

eep for future reference

642/3801

643/8401

Dimension

Width - 107cm

Depth - 53c

Height -

Import

s

m

179.9cm

- Please r

an

t

ead these instructions

If you need help or have dam

fully before starting assembly

aged or missing parts, call the

Customer Helpline: 08456 400800

Issue 2 - 01/04/12

Page 23

!

Important

S

a

f

e

t

-

Please r

y

and

C

a

r

e

A

d

v

i

c

e

ead these instructions fully before starting assembl

y

Check you have all t

com

ponents and tools listed

pages 2

Remove all fittings from t

plastic bags

into their gr

Keep children

away from the work area, small

parts could choke if swallowed

Make sure you have enough

space to layou

starting

Care

Only clean using a damp clot

and mild detergen

bleach or abrasive cl

and 3

.

and s

oups.

and animal

t the parts before

.

and maint

he

on

he

eparate the

s

enance

t, do no us

eaners

m

.

e

.

Do not stand on

the pr

oduct, this could

cause dam

Assemble the item as clos

to its final position (in the same

room) as possible.

Assemble on a soft leve

surface to avoid damaging the

un

it or your floor

Parts of the assembly will be

easier with 2

From time to time check tha

h

here are no loose screws

t

this uni

age

t.

.

.

people

.

l

e

on

t

We do no

use of powe

dr

inserting screws

as this could damage the unit.

Only use

Dispose of all packaging

carefully

This product should not be

discar

waste. Take to your loca

authority waste disposal centre

ded with

recomm

ill/drivers

hand screwdrivers

and res

ponsibly.

household

t

end the

r

for

l

,

.

.

K

eep these instructions for further use.

This product complies with BSEN

Manufacturer (or s

Argos LTD. MK9 2NW.

WARNINGS

Do not place very hot or very

cold items

proximity to glass surfaces

unless an

insulating material is used to

prevent such items from

coming contact with the glass

against or in close

adequately thick

!

upplier)

:

.

14749

hard or pointed items.

.

Do not strike the glass with

Batch No/ Date of m

If a glass com

stop using the pr

m

anufacturer or supplier.

anufacture:

ponent is chipped or broken,

oduct

When cleaning glass

use a damp cloth or leather with

washing up liquid or soft soap if

necessary; do not use washing

powders or any other substances

containing abrasives since these

substances scratch the glass.

Note:

if r

page can be cut out and used

as reference throughou

assembly. K

these instructions for future

reference.

and consul

equired the nex

eep this page wit

t the

panels

t

t t

he

h

1

Page 24

If you have damaged or missing components

C

o

m

ponen

t

s

-

P

ane

l

s

call the

Please check you have all the panels listed below

Customer Helpline: 08456 400800

,

Plinth x 2

2

1

Top

(96 x 4.5cm)

Bottom

3

(

107 x 53cm

(96 x 48cm)

4

S

upport rail

)

(64 x 9cm)

8

Right doo

(

166.6 x 31.6cm

r

)

9

Left

(

166.6 x 31.6cm

doo

r

)

5

Left side

(

178.5 x 49.8cm

)

6

Right side

(

178.5 x 49.8cm

)

7

Divider

(

165.6 x 48cm

)

11

Back x 2

(

171 x 48.8cm

)

Mirror doo

10

(

166.6 x 31.6cm

r

)

2

Page 25

C

o

m

ponen

t

s

-

F

i

tt

i

ng

s

Please check you have all the fittings listed belo

Note:

The quantities below are correct am

may be s

A

D

14mm Screw x

G

16mm Nail x

J

M

upplied than are r

Cam x 12

42

30

H

anging rail cup x

equired.

B

Locking pin x

E

25mm Screw x

H

K

4

oun

t to complete the assembly

12

12

w

M

agnet x 3

Cup hi

nge x 9

. In some cases more fittings

C

30mm Dowel x 4

F

35mm Screw x

I

L

N

3

K

Cross plate x

nob x 3

9

636mm Hanging rail x 1

O

Miniblock x

R

Wall strap x

U

Tools requir

ed

Philips screwdrive

(medium & large

Flatblade screwdrive

(medium)

Suitable drill bit

(for use with wall plug

302mm Hanging rail x 1

P

4

50mm Screw x

S

2

Wall plug x 2

3

Q

20mm Screw x

T

Washer x 4

2

1653mm Joining strip x 1

Sma

ll

hamme

r

Ruler/tape

measur

e

)

r

r

Drill

0

10

70

50

60

40

30

20

8090100 110

150

120

130

140

Eye protection

)

(when using

ha

mmer or glue)

a

Ruler

0

3

- Use this ruler to help correctly identify the screws

55

35

30

5

10

25

15

20

50

45

40

65

60

75

70

9080

85 95

100

105

110

115 125

120

130

135

145 155 165

140

150

160

170

Page 26

C

o

m

ponen

U

t

s

-

K

e

1

y

D

i

ag

r

a

m

3

11

10

6

7

9

8

11

5

4

2

F

un

c

t

i

on

Step 1

:

Fix the locking pin to

the wooden panel.

1

B

2

o

f

C

a

m

and

Step 2

:

Push the wooden panel with

the attac

onto the other wooden panel.

hed locking pin

2

Lo

ck

i

ng

Step 3

:

Place the cam into t

hole, arrow pointing

towards the locking pin

3

P

i

n

he

Step 4

:

Tighten: Turn the cam to

t

he righ

t.

.

4

A

4

Page 27

A

ss

e

m

b

l

y

I

n

s

t

r

u

c

t

i

on

s

Step 1

M

ounting the cross

plates to the sides

Fix the cross plates

the sides

the screws

holes indicated.

5

&

E

.

L

6

using

into the

to

It is important that the

cross plates are placed

exactly as shown

The short

end of the

cross plates must poin

.

t

towards the front edge of

the sides

.

Step 2

M

ounting the

rail cups to the sides.

Fix the hanging rail cups

J

onto the sides

6

and

using screws

into the pre-dr

hanging

5

illed holes

D

.

J

5

Side, lef

6

Side, righ

D

t

t

E

L

E E

L

E

L

E

L

Side, righ

Fron

6

t

Long end

t

Short end

E

L

Fron

t

L

E

L

Fron

t

D

J

D

Step 3

M

ounting the locking

pins to the sides

Screw the locking pins

B

into the holes

indicated on the sides

5

and

Note:

Insert locking pin

B

as far as shown

not over tighten

5

.

.

6

.

.

Do

s

J

5

Side, lef

B

6

Side, righ

B

B

B

B

B

t

Side, lef

5

t

t

Page 28

A

ss

e

m

b

l

y

Step 4

Adding the miniblocks

to the plinths

.

I

n

s

t

r

u

c

t

i

on

O

s

Inser

t the miniblocks

into the holes indicated on

2

the plinths

.

O

Step 5

M

ounting the plinths

to the bottom

Fix the plinths

bottom

screws in the miniblocks

.

O

Note the chamfer

.

3

using the

2

to the

.

Chamfer = Front

O

O

2

Plinth

O

Plinth

2

Plinth

O

2

2

Plinth

3

Bottom

Step 6

M

ounting the cross

plates to the divider

Fix the cross plates

the divider

screws

indicated

It is important that the

cross plates are placed

exactly as shown

The short

cross plates must poin

7

D

into the holes

.

end of the

towards the front edge of

the divider

.

.

L

to

using the

.

t

Holes = Back

7

Divide

r

D

L

D

L

Fron

t

D

L

D

L

Long end

Fron

Short end

t

6

Page 29

A

ss

e

m

b

l

y

Step 7

M

ounting the

rail cups to the divider.

Fix the hanging rail cup

J

onto the left

of the divider

screws

pre-drilled holes

hanging

D

into the

hand side

7

using

.

I

n

s

t

r

u

c

t

i

on

D

s

J

D

J

7

Divide

r

Step 8

M

ounting the

rail cups to the divider.

Fix the hanging rail cup

J

onto the right

of the divider

screws

pre-drilled holes

hanging

D

into the

hand side

7

using

.

Step 9

M

ounting the locking

pin to the divider.

Screw the locking pins

B

into the hole indicated

7

on the divider

.

D

J

7

Divide

r

B

D

J

B

Note:

Insert locking pin

B

as far as shown

not over tighten

7

.

.

Do

7

Divide

r

Page 30

A

ss

e

m

b

l

y

I

n

s

t

r

u

c

t

i

on

s

Step 10

Adding the dowels to

the support rail.

Knock the dowels

he holes indicated on the

t

s

upport rail

C

into

.

4

Step 11

M

ounting the locking

pins to the top.

Screw the locking pins

B

into the holes indicated

1

on the top

Note:

Insert locking pin

B

as far as shown

not over tighten

.

s

.

Do

.

C

4

S

B

upport ra

1

T

op

C

B

il

C

C

Step 12

M

ounting the magnets

to the top.

Fix the m

the top

D

into the pre-drilled

holes.

It is important that t

m

agnetic part points

towards the front edge of

the top.

agnets

1

using screws

H

to

he

T

1

op

D

D

D

H

H

D

H

H

Front edge

8

Page 31

A

ss

e

m

b

l

y

Step 13

Assembling the bottom

to the divider

.

I

n

s

t

r

u

c

t

i

on

s

Chamfer = Front

Fix the divider

bottom

P

Make sure to turn the

bottom as shown. The

3

.

chamfered edge s

poin

t towards the fron

7

to the

using screws

hould

t.

Step 14

Adding the support rail

to the divider

Press the support rail

onto the divider

See

page 4 "Function of

cam and locking pin".

.

7

.

7

Divide

P

4

7

Divide

r

r

3

Bottom

P

P

Place the cam

hole indicated, arrow

pointing towards the

A

into the

divider / locking pin.

To tighten cam: Turn to

he right using a

t

screwdriver.

Step 15

Adding the side to the

plinths

rail

Fit the side

plinths

s

See

cam and locking pin".

Place the cams

the holes indicated

arrows pointing towards

the side / locking pins

To tighten cams: Turn to

he right using a

t

screwdriver.

9

and the s

.

2

upport rail

upport

5

onto the

and the

.

4

page 4 "Function of

A

into

,

.

A

4

S

A

A

5

Side, lef

upport ra

t

il

A

Divide

3

Bottom

7

r

4

2

Plinth

2

Plinth

S

upport ra

il

Page 32

A

ss

e

m

b

l

y

I

n

s

t

r

u

c

t

i

on

s

Step 16

Adding the right

side to the plinths.

Fit the side

2

plinths

See

cam and locking pin".

Place the cams

the holes indicated

arrows pointing towards

the side / locking pins

To tighten cams: Turn to

he right using a

t

screwdriver.

.

page 4 "Function of

hand

6

onto the

A

into

,

.

Step 17

Assembling the top to

the sides

.

5

Side, lef

t

7

Divide

A

r

3

Bottom

6

Side, righ

Plinth

t

A

A

2

1

5

7

and

.

onto

6

A

into

,

.

and

Attach the top

the sides

he divider

t

See

cam and locking pin".

Place the cams

the holes indicated

arrows pointing towards

the top / locking pins

To tighten cams: Turn to

he right using a

t

screwdriver.

page 4 "Function of

A

A

5

Side, lef

t

T

1

op

A

A

7

Divide

r

6

Side, righ

t

10

Page 33

A

ss

e

m

b

l

y

I

n

s

t

r

u

c

t

i

on

s

Step 18

Adding the back to the

carcass.

Place the back

the rabbet of the top

.

and the side

Ensure that there is no

gap betw

the back, nor between the

top

and the back.

Fasten the back with

G

nails

al

The

angle betw

top

and the side must be

6

een the side and

ong the top

een the

90 degrees.

To accomplish this

ensure tha

gap betw

the back

t there is no

een the side and

.

11

into

,

1

.

G

6

Side, righ

R

abbet = Back

t

G

G

11

11

Back

G

90

1

T

op

4

G

o

R

abbet = Back

5

3

G

Fasten the back with

G

nails

al

ong the side

and the bottom.

s

Step 19

Adding the back and the

joining strip to the

carcass.

Place the joining strip

onto the back.

Place the back

11

the rabbet of the top

.

and the side

Ensure that there is no

gap betw

the back, nor between the

top

and the back.

Fasten the back with

G

nails

al

and the bottom.

Fix the back onto the

s

upport rail

screws

5

een the side and

ong the side

4

using

D

.

U

into

1

T

1

op

11

1

6

D

G

G

U

Joining stri

U

11

p

6

11

G

G

D

4

G

11

Back

G

3

5

G

11

Page 34

A

ss

e

m

b

l

y

I

n

s

t

r

u

c

t

i

on

s

Step 20

M

ounting the cup

hinges to the

Fix the cup hi

he holes indicated on the

t

doors

10

Attach the hinges using

screws

8

and

.

D

.

doors

.

nges

9

and

K

into

D

8

Door, righ

D

D

t

D

K

K

D

K

K

K

D

K

D

K

9

Door, lef

t

D

Door w

10

. mirro

r

K

D

K

D

K

12

Page 35

A

ss

e

m

b

l

y

I

Step 21

M

ounting the

the carcass

W

hen placing the

t

he m

agnetic catch plates

must be a

doors

.

a

:

Place the adjustmen

hole of the cup hinge a

t

he level of the fixing

screw. Push the cup

hinge towards the cross

place - placing the fixing

screw in the wider part of

the adjustment hole.

Important:

!

all three of the

fixing screws.

b

:

Push the

hinge inwards - placing

the fixing screw in the

narrow

adjustment hole

doors to

.

t the top of the

Ensure you catch

door / cup

end of the

doors

.

,

t

t

n

s

t

r

u

c

t

i

on

s

a

:

Cro

ss

plat

Adjustment

hol

b

:

e

Fixing scre

e

Adjusti

screw

w

ng

c

:

Tighten the fixing

screws of all three of the

cross plates

.

c

:

13

Page 36

A

ss

e

m

b

Step 22

M

ounting the knobs

adding the hanging

rails.

Lower the

and

rail cups

hanging rails

N

into the

.

J

hanging

l

y

and

I

n

M

s

t

r

u

c

t

i

on

s

Fasten the k

the

doors

10

and

using screws

nobs

8

and

I

to

9

F

.

I

M

F

N

F

I

F

I

9

Door, lef

F

t

Door w

10

. mirro

r

8

Door, righ

I

t

14

Page 37

A

A

ss

e

ss

e

m

m

b

l

b

l

y

I

y

I

n

s

n

s

t

r

t

r

u

c

u

c

t

i

on

t

i

on

s

s

Step 23

Adjusting the

Make sure the wardr

is placed on a level

surface before you

to adjus

Right or left:

Loosen the fixing screw.

1.1

doors

t the hi

Fixing scre

.

begin

nges.

obe

w

To adjus

the left

adjusting screw to the right.

1.2

t the

door towards

hand side - turn the

Adjusting screw

To adjus

he right hand side - turn the

t

adjusting screw to the left.

1.3

t the

door towards

Adjusting screw

1

2

3

Continue adjustment - see 2

or tighten the fixing screw of

the cross plate

1.4

s

Cross plat

-

e

Forwards or backwards

Loosen the fixing screw.

Fixing scre

Up or down

Loosen the two screws of each cro

plate, but only as much as it will allow

the cross plate to move up

w

:

E

E

:

and down

.

Push the cup hinges / the

to adjus

edge of the sides

t. The door should level with the front

.

2.22.1

Adjustment hol

ss

Adjus

t the cross plate

e

door back or fort

/

door.

Fixing scre

Tighten the fixing screws of all the cro

h

plates.

2.3

Fixing scre

Tighten the screws

plates.

3.33.23.1

Cross plat

w

E

w

e

E

of all the cross

ss

Cross plat

15

e

Cross plat

e

Page 38

A

ss

e

m

b

Step 24

Fixing to wall

It is recomm

the wardrobe is fixed

to a wall.

Fix wall straps

of wardrobe usi

screws

D

.

.

ended tha

R

to t

ng

l

y

t

op

I

n

s

t

r

u

c

t

i

on

s

Note:

Wall plugs s

for solid walls only

The correct type of fixing must

be used for your wall, seek

professi

onal advice if in

upplied are

.

doub

t.

With help, move

wardr

obe into position

The wardr

!

is heavy.

Mark fixing holes on wall

and remove wardrobe

Drill 7mm holes and inser

wall plugs

Before drilling,

!

check wall fo

hi

R

eposition wardrobe

and fix wall straps usi

screws

.

Q

Warning:

obe

Lift with care

.

S

Warning:

dden pipe

and cables

.

ng

.

.

.

r

s

t

S

T

Q

Assembly is complete

If you need help or have dam

.

D

T

aged or missing parts, call the

R

Customer Helpline: 08456 400800

Wall

16

Page 39

A Guide to - Wall Mounting & Fixings

Important note:

If plastic wall plugs

are supplied with

product:

your

- these are only suitable for

use in masonry walls.

If you are in any doubt about

the correct wall plugs for

your wall, seek professional

advice.

Failure of the product due to

using incorrect fixings is the

responsibility of the installer.

Types of walls

No.1

“General Purpose” wall plug

Generally aerated blocks should not

be used to support heavy loads, use

a specialist fitting in this case. For light

loads, general purpose wall plugs can

be used.

No.2

“Plasterboard” wall plug

For use when attaching light loads on

to plasterboard partitions.

Care &

Maintenance

No.3

Important

check that there are no hidden wires or pipes etc.

Make sure that the screws and wall plugs be ing used

suitable for supporting your unit. Consult a qualified

tradesperson if you are unsure.

:

When drilling into walls always

are

Hints:

1:

General rule

:

Always use a larger screw and wall plug

if you are not sure.

2: Ensure you use the recommended drill bit to match the wall

plug and hole size.

3: Ensure you drill the hole horizontally, do not force the drill or

enlarge the hole.

4: Take extra care when drilling high walls, ceilings and ceramic

tiles. Ensure wall plugs are inserted beyond the thickness of

the ceramic tiles to avoid the tiles splitting or cracking.

5: Ensure wall plugs are well fitted and are a tight fit in the

drilled hole.

You can use one of the following types of wall plug if your walls are

made of brick, breeze block, concrete, stone or wood.

“Cavity Fixing” wall plug

For use with plasterboard partitions or

hollow wooden doors.

No.4 “

Cavity Fixing-Heavy Duty”

wall plug

For use when fitting or supporting

heavy loads such as shelving, wall

cabinets and coat racks.

No.5 “Hammer Fixing”

For use with walls stuck

plasterboard. The hammer fixing allows

it to be fixed to the wall rather than the

plasterboard. Always check the fixing

is secure to the re tainin g wa ll.

No.6

For use with heavier loads such as TV

& HiFi speakers and satelite dishes etc.

“Shield Anchor” wall plug

Heavy loads

wall plug

with

Safety: Always check the fitting

and location to ensure your safety

in and around the home.

Fitting: From time to time check

the fitting to ensure the wall plugs

or screws do not become loose.

Page 40

Dear Customer

Dear Customer

Please note that the product you have purchased is a

natural living timber.

Just like nature itself, wood varies in shape and colour.

Knots, vein patterns, resin pockets and colour differences

contribute to giving the piece of furniture its beauty and

form - a natural part of solid wood.

Although the tree has been cut down and dried, it is still

alive and therefore will react to high and low

temperatures, light, humidity, drought and time.

In cold and dry periods, the wood contracts which may

lead to small cracks in the piece of furniture. The reverse

happens in warm and humid periods where the wood

expands and this may result in slight unevenness.

The colour of the wood also changes with time,

particularly if the furniture is placed in a light place. This

is a natural process and part of owning a piece of

furniture made of solid wood.

Any flexing that has occurred during transport will

re-correct it self once this product is correctly assembled.

Tighten all joints of the furniture after six months.

Please keep these instructions in a safe place for future

use.

18

Loading...

Loading...