Page 1

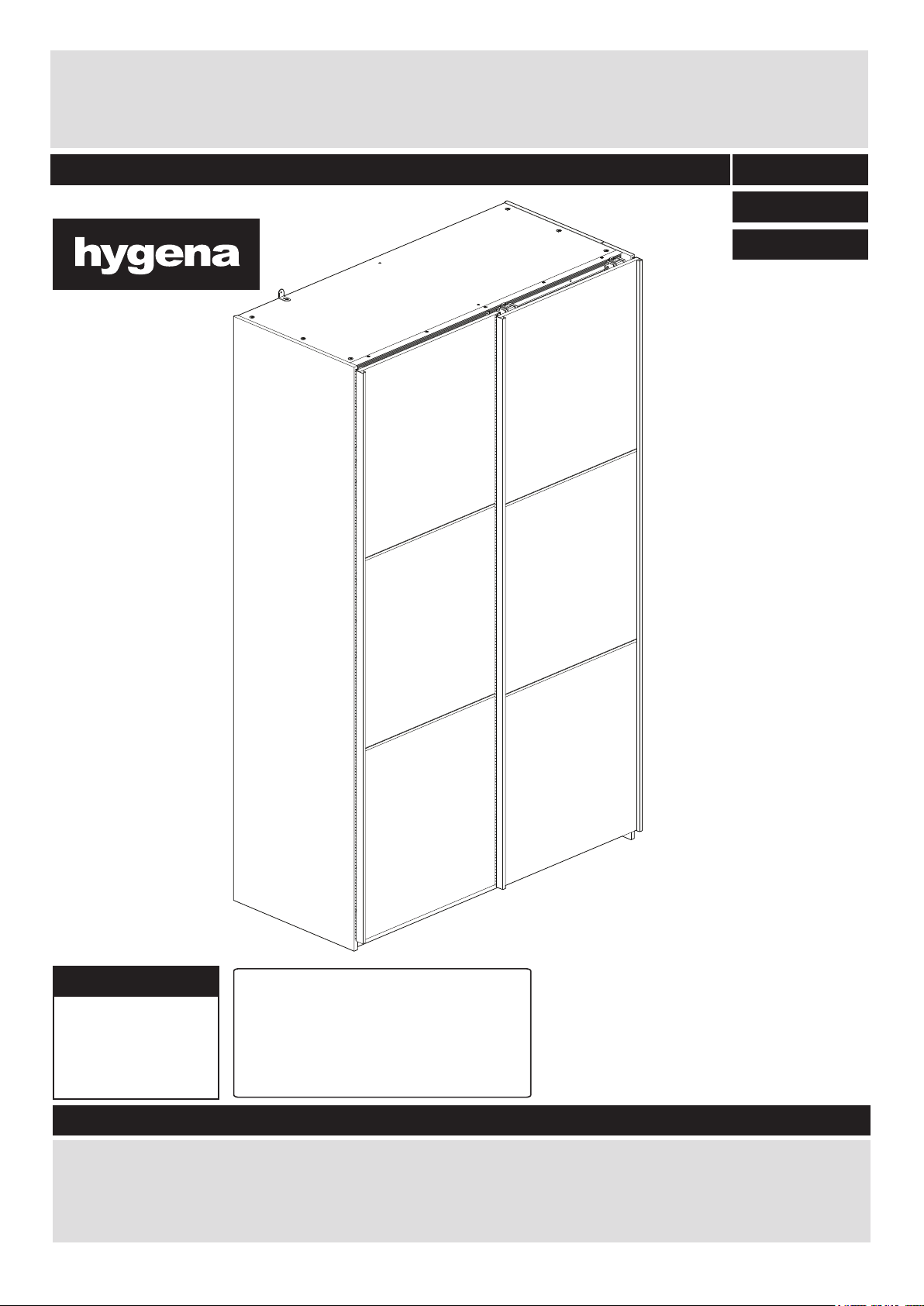

Bergen 120 Foil/ foil

Assembly Instructions- Please keep for future reference

DR8250050

258/1417

257/1740

258/5963

Dimensions

Width - 120cm

Depth - 59.5cm

Height - 199.8cm

Tip : To prevent damage,

we recommend that you

build your unit on the

carton(s) it was packed in.

258/1417 OAK

258/5963 WAL

257/1740 WHT

Important – Please read these instructions fully before starting assembly

If you need help or have damaged or missing parts, please visit: www.argos-support.co.uk

or email: Help@ClickSpares.co.uk (quoting your original order number)

Alternatively, call the Spares Helpline on: 0370 112 1928

For any other queries please contact the Customer Helpline on: 0345 640 2020

Issue 3 - 05/11/15

Page 2

Safety and Care Advice

Important – Please read these instructions fully before starting assembly

• Check you have all the

components and tools listed on

pages 2 and 3.

• Remove all fittings from the

plastic bags and separate them

into their groups.

• Keep children and animals

away from the work area, small

parts could choke if swallowed.

• Make sure you have enough

space to layout the parts before

starting.

Care and maintenance

• Only clean using a damp cloth

and mild detergent, do no use

bleach or abrasive cleaners.

• Do not stand or put weight on

the product, this could cause

damage.

• Assemble the item as close

to its final position (in the same

room) as possible.

• Assemble on a soft level

surface to avoid damaging the

unit or your floor.

• Parts of the assembly will be

easier with 2 people.

• From time to time check that

there are no loose screws on

this unit.

•To reduce the

likelihood of

damaging your

product please

ensure that your

power drill is set on a low torque

setting.

• Dispose of all packaging

carefully and responsibly.

• This product should not be

discarded with household

waste. Take to your local

authority waste disposal centre.

Handy Hints

• Assemble all parts and bolts

loosely during assembly, only

once the product is complete

should you fully tighten the bolts

Instruction video

• This manual is provided with an additional instruction

video. If the icon on the right is displayed at a particular

step in the manual, Follow the link: http://nlink.nu/vid02

Or scan the QR code on the left with your phone.

• Regularly check and ensure

tightend properly.

See page 2 for link

to instruction video!

Note: if required the next

page can be cut out and used

as reference throughout the

assembly. Keep this page with

these instructions for future

reference.

2

Page 3

Components - Panels

For damaged or missing parts, please visit:

www.argos-support.co.uk or email: Help@ClickSpares.co.uk

Please check you have all the panels listed below

Left side

1

(199.8 x 52.9cm)

P2883

Top

5

(117 x 51cm)

P1883

Plinth x2

7

(117 x 6cm)

P7883

Right side

2

(199.8 x 55.8cm)

P2882

Upright

3

(190.3 x 49cm)

P2886

Bottom

6

(117 x 51.1cm)

P1884

8

Shelf x2

(57.7 x 48.8cm)

P1886

Foldy back x2

4

(193 x 59cm)

BO3429

Segment x4

9

(61.3 x 65cm)

P3189

Segment middle x2

10

(61.3 x 65.1cm)

P3259

3

Page 4

Components - Fittings

For damaged or missing parts, please visit:

www.argos-support.co.uk or email: Help@ClickSpares.co.uk

Please check you have all the fittings listed below

Note: The quantities below are the correct amount to complete the assembly. In some cases more fittings

may be supplied than are required.

1/2

A

FK1005

Confirmat screw x 4 (5x40mm)

D

FK1309

Screw x 20 (4x12.5mm)

G

FK1052

Double locking screw x 3 (5x66.5mm)

J

FK1248

Corner connector, white x 2

M

FK1235

L-Bracket x 1

P

PM1823

B

Locking screw x 18 (5x24mm)

E

Plug, Nylon x 32 (5x9mm)

H

Wood dowel x 4 (8x30mm)

K

Hanger rail support, gray x 4

N

Nail holder x 1

Q

FK1011

C

Screw x 49 (4x15mm)

FK1082

F

Nail x 60

FK1411

I

Large locking nut x 24 (15x12mm)

FK1217

L

Peg, brown x 1

FK1419

O

Connecting plate x 4

PM1613

R

FK1400

FK1515

FK1012

15mm

FK1234

FK1236

PK1613

Hanger rail x 2

(569mm)

S

Door handle x 3 (1952mm)

V

OR

Allen key x 1 (3mm)

PM1652B

FK1013

Guide rail x 1, metal (1169mm)

T

Brush x 3 (1952mm)

W

PM1652C

ZF99936

Wall plug (6mm) and parkerscrew x 1

Guide rail x 1, plastic(1169mm)

U

Door trim x 1 (1952mm)

PM1652D

4

Page 5

Components - Fittings

Please check you have all the fittings listed below

Note: The quantities below are the correct amount to complete the assembly. In some cases more fittings

may be supplied than are required.

A

2/2

AA

Screw x 2 (3.5x35mm)

AD

Screw x 2 (4x14mm)

AG

End stop x 2

AJ

Back guide part x 2

ZF9997I

ZF9997J

ZF9997G

ZF9998D

AB

Screw x 6 (3.5x25mm)

AE

Spacer x 1

AH

Stop guide rail x 2

AK

Sliding door connecting plate x 2

ZF9997K

ZF9997F

ZF9997H

ZF9997B

AC

ZF9997L

Screw x 33 (4x15mm)

AF

ZF9997E

Tapping block for guide rail x 2

AI

ZF9997C

Front guide part x 2

AL

ZF9997A

Sliding door connecting bracket x 2

Tools required

Phillips screwdriver

(medium & large)

Stairs

Drill

Flatblade screwdriver

(medium)

Piercer

(small)

Spirit level

5mm Suitable drill bit

5mm Suitable drill bit

Setsquare

Ruler - Use this ruler to help correctly identify the screws

105

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

110 115 120 125 130 135 140 145 150 155 160 165 170

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

0 1 2 3 4 5 6

Eye protection

(when using a

hammer or drill)

Small

hammer

Ruler/tape

measure

Scissors

5

Page 6

Assembly Instructions

BBBBBBBBBBBBBBBBBBB

K

Step 1

a:

Cabinet assembly

a: Screw 9 locking screws

into the holes on back

B

of the left side 1.

AB

D

D

Mount hanger rail support

K, fasten with 1 screw D.

Screw D into the board

between two predrilled

holes.

Mount tapping block for

guide rail f with two

screws b.

b: Screw 9 locking screws

B into the holes on back

of the right side 2 .

Mount hanger rail

support K, fasten with 1

screw D. Screw D into

the board between two

predrilled holes.

Mount tapping block for

guide rail f with two

screws b.

AF

b:

AB

AB

AF

AF

AB

K

Finished

front edge

D

K

AF

AB

1

AB

Finished

front edge

2

C: Mount hanger rail

support K on the

upright 3, fasten with

screw D 1x. Screw D

into the board between two

predrilled holes

Turn over.

Mount hanger rail

support K on the

upright 3, fasten with

screw D 1x. Screw D

into the board between two

predrilled holes.

6

c:

D

K

3

Finished

front edge

Page 7

Assembly Instructions

5

687

IIIIIIIIIIIIIIIIIIH

H

Step 1

Cabinet assembly

d: Insert 6x small locking

nuts I into the top 5.

Make sure the ‘arrow’ on

I is pointing towards the

hole in the edge of the

top 5.

e: Insert 6x small locking

nuts I into the bottom 6.

Make sure the ‘arrow’ on

I is pointing towards the

hole in the edge of the

bottom 6.

d:

Finished

front edge

e:

plain chipboard

Finished

front edge

f: Insert 6x small locking

nuts I into the shelf 6.

2x.

Make sure the ‘arrow’ on

I is pointing towards the

hole in the edge of the

bottom 6.

g: Insert 4x wooden

dowelsJ into the

plinth 7. 2x.

f:

g:

2x

Finished

front edge

2x

Finished

front edge

77

Page 8

Assembly Instructions

V

GGG

6

3

1

885

5

365

AAA

388

6

Assembly Instructions

Step x

Step 1

Xxxxxx

Cabinet assembly

x: x

h: Attach top 5 with 2x

confirmat screws A to the

upright 3. Use allenkeyV.

Attach bottom 6 with 2x

confirmat srews A to the

upright 3

x: xx

i: Attach 2x the shelf 8 to

the upright 3 with 3x

double locking screws G.

Use a screwdriver to turn

6x locking nuts clockwise

to lock.

.

Finished

front edge

h:

Plain chipboard

i:

j: Attach the left side 1

with 9x double locking

screws G on the top 5,

shelf 8 and the

x: xxx

bottom 6.

Use a screwdriver to turn

9x locking nuts clockwise

to lock.

Finished

front edge

Finished

front edge

Plain chipboard

j:

Plain chipboard

8

8

Page 9

Assembly Instructions

JJCCFFF

JCC

767

7

6

282

544N6

2

F

C

N

F

Step 1

Cabinet assembly

k: Attach 2x the plinth 7

between the left site 1

and the right side 2.

Note: that the finished side

properly placed.

Attach the right side 2

with 9x double locking

screws G on the top 5,

shelf 8 and

the bottom 6.

k:

Use a screwdriver to turn 9x

locking nuts clockwise to

lock.

Mount corner connector J

with 2 screws C on the

plinth 7 and bottom 6.

l: Attach 2x foldy back 4

to back of cabinet with

the coloured surface facing

the inside of the cabinet

using 60x nails F and

22x screws C.

Use nail holder N to hold

the nails F vertical and at

correct distance as you

secure the

2x foldy back 4.

Nails F should be spaced

about 150mm apart.

Finished

front edge

Finished side

l:

Important:

Cabinet MUST

be ‘square’ when

Finished

front edge

back is attached.

Stand up the unit!

2 people required to

stand up the unit.

9

9

Page 10

Assembly Instructions

AD

P

P

AG

AG

M

CCC

C

C

C

Q

AHAHABABABABAB

AA

AA

R

8

8

123

123

6

5

AD

Q

AD

AG

Q

P

K

AB

AA

R

6

7

AH

R

Step 1

Cabinet assembly

m: Position L-Bracket M

onto top 5 , by using 1x

screw C.

Position metal guide rail Q

onto top 5 , fix with 5x

screws C.

Attach 2x end stop g on

the end of the guide rail Q

with 2x screws d.

Place 2x hanger rail P into

hanger rail support K.

A

x2

B

x5

C

x5

C

m:

n: Position plastic guide

rail R onto bottom 6 , fix

with 5x screws b.

Attach 2x stop guide rail

h on the end of the

guide rail R., mount with

2x screws a.

A

C

x x

. . . . .

n:

B

x7

D

10

10

x 5

Page 11

Assembly Instructions

E

E

CCCUUCCCCCCCCCCCCCCCCCC

S

99999

9

Step 2

3 Segment slide door left

a: Put 8x nylon plug E

into the segment 9. Use

a small hammer.

Repeat this step.

b: Mount door trim U with

3x screws C on segment

9.

Note: there should be no

gap between doorsegment

9 and door trim U.

a:

2x

b:

c: Mount segment middle

2 with 3x screws C

on door trim U.

Mount segment 9

with 4x screws C on door

trim U.

d: Mount door handle S

on segment 9 with

4x screws C and on

middle segment 0 with 3x

screws C.

No Gap

between metal profiles

and door panel!

c:

10

d:

Note: there should be no

gap between doorsegment

0 and door handle S.

10

11

Page 12

Assembly Instructions

S

T

AKAKACACACACAC

AJ

AJ

AC

ACACAC

TOODDDD

S

AE

AC

AJ

AC

999

9

Step 2

3 Segment slide door left

e: Mount 2x connecting

plate O, each with 2x

screws D on segment

9 and 2x screws D

on middle segment 0.

Remove protective film

from door handle S.

Stick 1x brush T onto

door handle S by partially

removing the cover from

adhease as brush is

applied.

f: Upside.

Mount 2x Sliding door

connecting plate k

squarely by using the guidemarks in the plate, each

with 6x screws c on

segment 9.

Attach 1x spacer e with

1x screw c on the brush

side sliding door connecting

plate k.

See page 2 for link

to instruction video!

e:

10

Please remove

the protective film!

f:

g: Underside.

Mount 2x back guide

part j , each with 2x

screws c on segment

9.

12

g:

x2

Page 13

Assembly Instructions

AJ

AJ

RRR

9

9

Step 3

Place left slide door

2 People are required for

step 3a and 3b.

a: Hook the 2x back guide

part j into the plastic

guide rail R.

See page 2 for link

to instruction video!

a:

10

a: Detail.

The hook of the back guide

part j should be in the

front guide of the plastic

guide rail R

13

Page 14

Assembly Instructions

QQQ

Q

AKAKAK

9

9

Step 3

Place left slide door

b: Hook Sliding door

connecting platek

on metal guide rail Q.

b:

10

b: Detail.

The wheel of the sliding

door connecting plate k

should be in the front guide

of the metal guide rail Q.

To lock the door, lock the

Sliding door connecting

plate k on the guide

railQ with the locking pawl.

push the yellow

lock pin to

secure part k to rail

14

Page 15

Assembly Instructions

E

E

CCCUUCCCCCCCCCCCCCCCCCC

S

9

999

9

9

Step 4

3 Segment slide door left

a: Put 8x nylon plug E

into the segment 1. Use

a small hammer.

Repeat this step.

b: Mount door trim U with

3x screws C on segment

1.

Note: there should be no

gap between doorsegment

1 and door trim U.

a:

2x

b:

c: Mount segment middle

2 with 3x screws C

on door trim U.

Mount segment 1

with 4x screws C on door

trim U.

d: Mount door handle S

on segment 1 with

4x screws C and on

middle segment 2 with 3x

screws C.

No Gap

between metal profiles

and door panel!

c:

10

d:

Note: there should be no

gap between doorsegment

1 and door handle S.

10

15

Page 16

Assembly Instructions

S

T

AC

AI

ACACAC

AC

999

ACACAC

AC

T

O

O

DDD

D

T

AL

AL

S

S

10

9

AI

AI

Step 4

3 Segment slide door

right

e: Mount 2x connecting

plate O, each with 2x

screws D on segment 9

and 2x screws D on

middle segment 0 .

Remove protective film

from door handle S.

Stick 2x brush T onto 2x

door handle S by partially

remove the cover from

adhease as brush is

applied.

f: Upside.

Mount 2x sliding door

connecting bracket l

squarely by using the

guidemarks in the plate,

each with 6x screws c

on segment 9.

See page 2 for link

to instruction video!

e:

Please remove

the protective film!

f:

g: Underside.

Mount 2x front guide

part i , each with 2x

screws c on segment 9.

16

g:

x2

Page 17

Assembly Instructions

R

RAIR

9

9

Step 5

Place right slide door

a: Hook the 2x front guide

part i into the plastic

guide rail R.

See page 2 for link

to instruction video!

a:

10

a: Detail.

The hook of the front guide

part i should be in the

rear guide of the plastic

guide rail R

17

Page 18

Assembly Instructions

QQQ

Q

ALALAL

9

9

Step 5

Place right slide door

b: Hook the sliding door

connecting bracketl

on metal guide rail Q.

a:

10

b: Detail.

The wheel of the sliding

door connecting bracket

l should be in the rear

guideof the metal guide

rail Q.

To lock the door, lock the

sliding door connecting

bracket l on the

guide rail Q with the

locking pawl.

18

Page 19

MMW

L

L

Assembly Instructions

Step 6

Place cabinet

a: Use to 1x wall plug W

to mount L-Bracket M on

the wall,

please see last page for

more information.

a:

b: Before adjusting the

doors, use a spirit level to

check if the base of this

unit is level front-to-back

and side-to-side in the

three positions shown.

Use pegs L to square

your unit. Knock peg L in,

as far as you require,

under the ends of the unit

and thensnap off flush with

the panel.

b:

SNAP!

19

Page 20

A Guide to - Wall Mounting & Fixings

Important note:

If plastic wall plugs

are supplied with your

product:

- these are only suitable for

use in masonry walls.

If you are in any doubt about

the correct wall plugs for

your wall, seek professional

advice.

Failure of the product due to

using incorrect fixings is the

responsibility of the installer.

Important: When drilling into walls always

check that there are no hidden wires or pipes etc.

Make sure that the screws and wall plugs being used

are suitable for supporting your unit. Consult a qualified

tradesperson if you are unsure.

Hints:

1: General rule: Always use a larger screw and wall plug

if you are not sure.

2: Ensure you use the recommended drill bit to match the wall

plug and hole size.

3: Ensure you drill the hole horizontally, do not force the drill or

enlarge the hole.

4: Take extra care when drilling high walls, ceilings and ceramic

tiles. Ensure wall plugs are inserted beyond the thickness of

the ceramic tiles to avoid the tiles splitting or cracking.

5: Ensure wall plugs are well fitted and are a tight fit in the

drilled hole.

Types of walls

No.1 “General Purpose” wall plug

Generally aerated blocks should not

be used to support heavy loads, use

a specialist fitting in this case. For light

loads, general purpose wall plugs can

be used.

No.2 “Plasterboard” wall plug

You can use one of the following types of wall plug if your walls are made

of brick, breeze block, concrete, stone or wood.

No.3 “Cavity Fixing” wall plug

For use with plasterboard partitions or

hollow wooden doors.

No.4 “Cavity Fixing-Heavy Duty”

wall plug

No.5 “Hammer Fixing” wall plug

For use with walls stuck with

plasterboard. The hamemr fixing allows

it to be fixed to the wall rather than the

plasterboard. Always check the fixing

is secure to the retaining wall.is secure to the retaining wall.

No.6 “Shield Anchor” wall plug

Heavy loads

For use when attaching light loads on

to plasterboard partitions.

Care &

Maintenance

For use when fitting or supporting

heavy loads such as shelving, wall

cabinets and coat racks.

Safety: Always check the fitting

and location to ensure your safety

in and around the home.

For use with heavier loads such as TV

& HiFi speakers and satelite dishes etc.

Fitting: From time to time check

the fitting to ensure the wall plugs

or screws do not become loose.

Loading...

Loading...