Argantix XDS 30-500, XDS 40-375, XDS 50-200, XDS 50-300, XDS 80-62 User And Programming Manual

...Page 1

Revision L

February 2007

Copyright 2002-2007

By California Instruments

All rights reserved.

P/N 5005-981

XDS Series

DC Power Supply

User and Programming

Manual

Series II

TEL: +1 (858) 677-9040

FAX: +1 (858) 677-0940

Email: sales@argantix.com

Web Site: http://www.argantix.com

Advanced Test Equipment Rentals

www.atecorp.com 800-404-ATEC (2832)

®

E

s

t

a

b

l

i

s

h

e

d

1

9

8

1

Page 2

User and Programming Manual

User and Programming Manual

P/N 5005-981

DC Power Supplies

Argantix

XDS Series II

Copyright 2002-2007, California Instruments, Rev L.

Argantix is a registered trademark of California Instruments Corporation.

Specifications subject to change without notice.

XDS Series 2

Page 3

User and Programming Manual

SAFETY SUMMARY

This power supply contains high voltage and current circuits that are potentially lethal.

Because of its size and weight, electrical and mechanical stability must be ensured. The

following safety guidelines must be followed when operating or servicing this equipment.

These guidelines are not a substitute for vigilance and common sense. If this power supply is

not used as specified in this manual, the protection provided by this equipment may be

impaired. California Instruments assumes no liability for the customer's failure to comply with

these requirements.

BEFORE APPLYING POWER

1. Check the units input rating on the type label and verify the correct voltage is applied to the unit

(for example 208 V L-L, 3 Phase).

2. The chassis and cabinet of this power supply must be grounded to minimize shock hazard. A

chassis ground is provided at the input terminal block. This is located at the back of the cabinet

on the right hand side (looking at the back of the unit). The chassis ground must be connected

to an electrical ground through an insulated wire (green/yellow) of sufficient gauge.

3. The XDS Series power supplies do not have internal AC mains disconnect. Instead, protection is

provided by fuses. The on/off button only engages or disengages the bias supplies, it does not

disconnect the AC mains to the unit. It is strongly recommended to use a suitably rated

circuit breaker or mains disconnect device with branch protection rating per local

electrical codes between point of connection and the XDS unit AC input.

FUSES

Use only fuses of the specified current, voltage, and protection speed.

DO NOT OPERATE IN A VOLATILE ATMOSPHERE

Do not operate the power supply in the presence of flammable gases or fumes. This product is

designed to operate in a controlled environment. Do not expose to rain or snow.

DO NOT TOUCH ENERGIZED CIRCUITS

Disconnect the power cable before servicing this equipment. Even with the power cable disconnected,

high voltage can still exist on some circuits. Discharge these voltages before servicing. Allow at least

30 minutes for all internal circuits to discharge before removing the top cover. Only qualified service

personnel may remove covers, replace components or make adjustments.

DO NOT SERVICE ALONE

Do not remove covers, replace components, or make adjustments unless another person, who can

administer first aid, is present.

DO NOT EXCEED INPUT RATINGS

Do not exceed the rated input voltage or frequency. Additional hazards may be introduced because of

component failure or improper operation.

DO NOT MODIFY INSTRUMENT OR SUBSTITUTE PARTS

Do not modify this instrument or substitute parts. Additional hazards may be introduced because of

component failure or improper operation.

MOVING THE POWER SUPPLY

When moving the power supply, observe the following:

1. Remove all AC power to unit.

2. Note that the handles are provided to pull instrument out of 19" instru men t cab in et and are

not designed to support the weight of the unit.

3. Use two people to prevent injury.

SURFACE STABILITY

Operate the power supply only on a level surface.

XDS Series 3

Page 4

User and Programming Manual

Electrical Safety Symbols Used in This Manual

4 XDS Series

Page 5

User and Programming Manual

WARRANTY INFORMATION

CALIFORNIA INSTRUMENTS CORPORATION warrants each instrument manufactured by them

to be free from defects in material and workmanship for a period of five years from the date of

shipment to the original purchaser. Excepted from this warranty are fuses and batteries that

carry the warranty of their original manufacturer where applicable. CALIFORNIA

INSTRUMENTS will service, replace, or adjust any defective part or parts, free of charge, when

the instrument is returned freight both ways prepaid, and when examination reveals that the fault

has not occurred because of misuse, abnormal conditions of operation, user modification, or

attempted user repair. Equipment repaired beyond the effective date of warranty or when

abnormal usage has occurred will be charged at applicable rates. CALIFORNIA INSTRUMENTS

will submit an estimate for such charges before commencing repair, if so requested.

SERVICE PROCEDURE

If a fault develops, notify CALIFORNIA INSTRUMENTS at support@argantix.com or its local

representative, giving full details of the difficulty, including the model number and serial number.

On receipt of this information, service information or a Return Material Authorization (RMA)

number will be given. Add the RMA number furnished to the shipping label. Pack the instrument

carefully to prevent transportation damage, affix label to shipping container, and ship freight

prepaid to the factory. CALIFORNIA INSTRUMENTS shall not be responsible for repair of

damage due to improper handling or packing. Instruments returned without RMA No. or freight

collect may be refused at California Instruments discretion. All XDS Series Instruments repaired

will be returned freight collect, Ex Works CALIFORNIA INSTRUMENTS, 9689 Towne Centre

Drive, San Diego, CA 92121-1964. If requested, an estimate of repair charges will be made

before work begins on repairs not covered by the Warranty.

DAMAGE IN TRANSIT

The instrument should be tested when it is received. If it fails to operate properly, or is damaged

in any way, a claim should be filed immediately with the carrier. The claim agent should obtain a

full report of the damage, and a copy of this report should be forwarded to us by fax or email

(Fax: 858 677 0940, Email: support@argantix.com

an estimate of repair cost and repair the instrument when authorized by the claim agent. Please

include model number and serial number when referring to the instrument.

). CALIFORNIA INSTRUMENTS will prepare

SPARE PARTS

To order spare parts, user manuals, or determine the correct replacement part for your California

Instruments products, please contact the Customer Service department by phone at + 1 858 404

6936, press 2 or by email support@argantix.com

.

XDS Series 5

Page 6

User and Programming Manual

Table of Contents

1

Introduction .................................................................................................................................. 10

1.1 General Description ............................................................................................................................. 10

1.2 Bench Top use .................................................................................................................................... 11

1.3 Equipment Rack use ........................................................................................................................... 11

2 Specifications ............................................................................................................................... 12

2.1 Electrical .............................................................................................................................................. 12

2.2 Measurements .................................................................................................................................... 15

2.3 Environmental ..................................................................................................................................... 17

2.4 Mechanical .......................................................................................................................................... 17

2.5 Agency Approvals ............................................................................................................................... 18

2.6 Remote Control Interfaces .................................................................................................................. 18

2.7 Protection ............................................................................................................................................ 19

2.8 Controls and Indicators ....................................................................................................................... 19

2.9 Parallel Operation ................................................................................................................................ 19

2.10 Factory Configuration Options ......................................................................................................... 20

2.11 -LC Option ....................................................................................................................................... 20

3 Installation and Functional Test ................................................................................................... 21

3.1 Inspection ............................................................................................................................................ 21

3.2 Location and Mounting ........................................................................................................................ 21

3.3 Input / Output Connectors ................................................................................................................... 22

3.4 Wire Sizing and Lug Size .................................................................................................................... 25

3.5 AC Input Wiring ................................................................................................................................... 26

4 Front Panel Operation ................................................................................................................. 28

4.1 Functional Controls ............................................................................................................................. 28

4.2 How to examples... .............................................................................................................................. 31

4.3 Setting the Power on Initialization Values ............................................................................................ 33

4.4 Operating Modes ................................................................................................................................. 34

4.5 Special Features ................................................................................................................................. 35

5 Model Configurations ................................................................................................................... 37

5.1 Available Configurations ...................................................................................................................... 37

5.2 Changing Configurations ..................................................................................................................... 38

5.3 Stand Alone Configuration .................................................................................................................. 40

5.4 Parallel Mode ...................................................................................................................................... 40

5.5 RPV Mode ........................................................................................................................................... 43

5.6 RPC Mode ........................................................................................................................................... 43

6 Principle of Operation .................................................................................................................. 44

6.1 General ............................................................................................................................................... 44

6.2 Overall Description .............................................................................................................................. 44

6.3 Bias Power Supply (A7) ....................................................................................................................... 47

6.4 Power Module (A9 through A11) ......................................................................................................... 48

6.5 Controller Module (A3) ........................................................................................................................ 50

7 Calibration .................................................................................................................................... 52

7.1 Calibration Equipment ......................................................................................................................... 52

7.2 Routine Calibration .............................................................................................................................. 53

7.3 Non-Routine Calibration ...................................................................................................................... 56

6 XDS Series

Page 7

User and Programming Manual

8 Service ......................................................................................................................................... 59

8.1 General ............................................................................................................................................... 59

8.2 Basic Operation ................................................................................................................................... 59

8.3 Module Removal ................................................................................................................................. 62

8.4 Controller Jumper Settings .................................................................................................................. 65

8.5 Replaceable Parts ............................................................................................................................... 67

9 Remote Control ............................................................................................................................ 70

9.1 Introduction ......................................................................................................................................... 70

9.2 XDSGUI Program Requirements ......................................................................................................... 71

9.3 RS232C Interface ................................................................................................................................ 71

9.4 Optional IEEE Interface ....................................................................................................................... 73

9.5 XDSGUI Installation ........................................................................................................................... 74

9.6 Trouble Shooting - RS232C ................................................................................................................ 75

9.7 Trouble Shooting - IEEE-488 / GPIB ................................................................................................... 78

9.8 Software Registration .......................................................................................................................... 79

10 Introduction to SCPI ................................................................................................................. 80

10.1 Conventions Used in This Manual ................................................................................................... 80

10.2 The SCPI Commands and Messages ............................................................................................. 80

10.3 Using Queries .................................................................................................................................. 83

10.4 Structure of a SCPI Message .......................................................................................................... 83

10.5 SCPI Data Formats ......................................................................................................................... 85

10.6 Programming Tips ........................................................................................................................... 86

11 SCPI Command Reference ...................................................................................................... 87

11.1 Subsystem Commands ................................................................................................................... 87

11.2 Measurement Subsystem ................................................................................................................ 88

11.3 Source Subsystem .......................................................................................................................... 90

11.4 Output Subsystem ........................................................................................................................... 95

11.5 Display Subsystem .......................................................................................................................... 97

11.6 System Commands ......................................................................................................................... 98

11.7 Common Commands .................................................................................................................... 100

12 Programming Examples ......................................................................................................... 107

12.1 Introduction ................................................................................................................................... 107

12.2 Programming the Output ............................................................................................................... 107

12.3 Making Measurements .................................................................................................................. 108

13 Status Registers ..................................................................................................................... 109

13.1 Power-On Conditions .................................................................................................................... 109

13.2 Standard Event Status Group........................................................................................................ 110

13.3 Status Byte Register ...................................................................................................................... 110

13.4 Examples ...................................................................................................................................... 111

Appendix A: SCPI Command tree .................................................................................................... 112

Appendix B: SCPI Conformance Information ................................................................................... 113

Appendix C: Error Messages ............................................................................................................ 114

Index .................................................................................................................................................. 115

XDS Series 7

Page 8

User and Programming Manual

List of Figures

Figure 1-1: XDS Series DC Power Supply .......................................................................................................... 10

Figure 3-1: Location of rear panel connectors. .................................................................................................... 24

Figure 3-2: DC Output bus bar studs. ................................................................................................................. 25

Figure 3-4: Toroid Installation, -400V input model. .............................................................................................. 26

Figure 3-5: Outline Drawing XDS DC Supply ...................................................................................................... 27

Figure 4-1: Front Panel View ............................................................................................................................... 28

Figure 4-2: Shuttle Knob ..................................................................................................................................... 29

Figure 5-1: XDS Configuration Jumper Locations ............................................................................................... 38

Figure 5-2: XDS Controller Jumper Locations – Front view, far side of PWB. ..................................................... 39

Figure 5-3: Master / Auxiliary Interconnect Cable Diagram ................................................................................. 40

Figure 5-4: Parallel Cable Interconnect Accessory .............................................................................................. 41

Figure 5-5: XDS 30KW System Connections ...................................................................................................... 42

Figure 6-1: DC Power Supply Block Diagram - -IF option shown ........................................................................ 45

Figure 6-2: XDS DC Supply Simplified Block Diagram ........................................................................................ 46

Figure 6-3: Power Module Block Diagram ........................................................................................................... 48

Figure 7-1: Test Equipment Hookup for Routine Output and Measurement Calibration ...................................... 53

Figure 7-2: Calibration Adjustments .................................................................................................................... 54

Figure 8-1: Assembly Location ............................................................................................................................ 62

Figure 8-2: XDS Controller Jumper Locations – Front view, far side of PWB. ..................................................... 66

Figure 8-3: Replaceable Fuse Locations ............................................................................................................. 69

Figure 9-1: XDSGUI Main screen ........................................................................................................................ 70

Figure 9-2: Rear Panel View ............................................................................................................................... 73

Figure 9-3: GPIB Address Selection Switch ........................................................................................................ 73

Figure 9-4: System Properties Dialog Box .......................................................................................................... 76

Figure 9-5: Advanced Port Settings Dialog Box .................................................................................................. 76

Figure 9-6: COM Port Properties Dialog Box ...................................................................................................... 76

Figure 9-7: NI PCI-GPIB Settings ........................................................................................................................ 78

Figure 9-8: NI PCI-GPIB Advanced Settings Dialog ............................................................................................ 78

Figure 10-1: Partial Command Tree .................................................................................................................... 81

Figure 10-2: Command Message Structure ........................................................................................................ 83

Figure 13-1: Power Supply Status System Model ............................................................................................. 109

8 XDS Series

Page 9

User and Programming Manual

List of Tables

Table 3-1: Rear Panel Input and /Output Connectors ......................................................................................... 22

Table 3-2: Output Connection Description .......................................................................................................... 22

Table 3-3: Input Connection Description ............................................................................................................. 23

Table 3-4: RS232C Connector J20 ..................................................................................................................... 23

Table 3-5: Analog I/O Connector J22 .................................................................................................................. 23

Table 3-6: Auxiliary I/O Connector (Isolated ) – J21 ............................................................................................ 24

Table 3-7: Minimum Wire Size Table .................................................................................................................. 25

Table 4-1: Factory Default Power on Settings ..................................................................................................... 33

Table 5-1: XDS Controller Configuration Options ................................................................................................ 37

Table 5-2: Configuration Jumper Settings - Mode ............................................................................................... 38

Table 7-1: Calibration Equipment ........................................................................................................................ 52

Table 7-2: Load Resistors and Current by model ................................................................................................ 52

Table 7-3: Calibration Adjustment Reference by number .................................................................................... 55

Table 7-4: Calibration Adjustment Reference by location left to right .................................................................. 55

Table 8-1: Basic Symptoms ................................................................................................................................ 59

Table 8-2: Poor Output Voltage Accuracy ........................................................................................................... 59

Table 8-3: Poor Output Voltage Regulation ......................................................................................................... 59

Table 8-4: No Output and No Lights on Front Panel ........................................................................................... 60

Table 8-5: No Output But "Display" Is On ........................................................................................................... 60

Table 8-6: DC Controller Configuration Jumper Settings - Mode ........................................................................ 65

Table 8-7: DC Controller Jumper configurations - Power Level ........................................................................... 65

Table 8-8: DC Controller Jumper configurations - OVP mode ............................................................................. 65

Table 8-9: Replaceable Parts .............................................................................................................................. 68

Table 8-10: Power Module Output Capacitance .................................................................................................. 68

Table 11-1: Mode query result decoding ............................................................................................................. 92

Table 11-2: Display Mode Command Encoding .................................................................................................. 97

Table 11-3: Bit Configuration of Standard Event Status Enable Register ......................................................... 101

Table 11-4: Bit Configuration of Standard Event Status Register ...................................................................... 102

Table 11-5: *RST Default Parameter Values ..................................................................................................... 104

Table 11-6: Status Registers - Power on Conditions ......................................................................................... 104

Table 11-7: Bit Configuration of Status Byte Register ....................................................................................... 106

Table 13-1: Bus Error Messages ....................................................................................................................... 114

XDS Series 9

Page 10

User and Programming Manual

1 Introduction

1.1 General Description

Figure 1-1: XDS Series DC Power Supply

The Argantix XDS Series of DC Programmable Power Supplies are designed specifically for

laboratory test and systems applications requiring single output, variable DC voltage and current

with good ripple and regulation characteristics. The XDS Series comes in a 3U chassis and can

operate in constant current or constant voltage mode with auto crossover feature. Available

Power levels are 5kW, 10kW and 15kW.

Simple front panel controls enable the voltage and current limit to be changed. Measurements of

voltage, current, peak current and power can also be read from the front panel LED displays.

The front panel contains a output on/off button for controlling the DC supply output and an LED

indicator that informs the operator of the output status at all time.

The left hand side LED display is used to display the programmed voltage as well as the

measured output voltage. The LED display to the right is used to program the current or to

display measured current, peak current or power. The display SELECT button can be used to

set the desired display mode.

A standard RS232C and optional IEEE 488 interface is available for applications that require

remote control and measurements. While operated remotely, the front panel can be locked out

and the remote control status is indicated by a REMOTE LED.

A power on/off switch can be used to turn the DC supply on or off.

Note: This user manual applies to the XDS models series II with the 5005-720-1

controller assembly. For first generation XDS DC models with controller

assembly 5005-708-1, refer to user manual P/N 5005-980 instead. First

generation XDS models typically do not have the air vents in the front

panel.

10 XDS Series

Page 11

User and Programming Manual

1.2 Bench Top use

The XDS Series DC Supply may be used as a bench top unit provided adequate provisions are

made to protect the end-user from touching the output terminals. To this end, output covers are

provided on all XDS units. These covers must be installed during use and may only be removed

when the unit is not in use and disconnected from AC mains.

Adequate air flow must be maintained at all times so care should be taken not to block the front,

top and side air intakes or the rear air exhaust. Leave at least 4" of clearance at the back of the

unit to allow proper airflow.

1.3 Equipment Rack use

The XDS Series uses a 19" cabinet with rack ears and can be installed in a standard equipment

rack. Due to the weight of the unit however, it must be properly supported by either a shelf or L

brackets on both sides. The rack ears are not designed to support the full weight of the XDS unit

when installed in a cabinet but only to prevent it from sliding out.

Contact Argantix customer support (support@argantix.com

specific cabinets depths.

Proper airflow must be maintained in the instrument cabinet and the rear of the cabinet should

not be closed off by a door but rather a perforated screen allowing adequate airflow. It is also

important to leave enough clearance above each unit as some of the air intake is on the top

cover.

Note: For optimal cooling, it is recommended to leave a 1.75" (1 U) space above

each XDS unit.

This space may be covered by a louvered cover plate to allow some air intake from the front of

the cabinet. When planning cabinet space, allow for 4U per DC supply.

If insufficient rack space is available, the top vents may be blocked off by stacking units directly

on top of each other but maximum power may not be available at maximum ambient temperature

due to over temp fault.

) for information on rack mount kits for

XDS Series 11

Page 12

User and Programming Manual

2 Specifications

All specifications at 23 5C unless noted otherwise.

2.1 Electrical

2.1.1 AC Line Input

Standard: -208: 208 VAC L-L -10% to 230VAC L-L +10 %

Options: -400: 400VAC L-L ± 10 %

-480: 480VAC L-L ± 10 %

Frequency: 50 to 60 Hz ± 3 Hz

Phases: 3-phase, 3-wire plus safety ground

Power Factor: > 0.65 typical.

2.1.2 Maximum Line Input Current per Phase at Low Line

Current 5 KW 10 KW 15 KW

Standard -208 27A 54A 81A

Options -400

-480:

Recommended circuit protection per phase. (CB)

Standard -208 30A 60A 90A

Options -400

-480:

2.1.3 Output Power

DC Power: 5 KW, 10 KW or 15 KW depending on model. See section 2.1.5.

2.1.4 Output Voltage

Voltage Range:

Voltage Programming:

XDS 30-XXX 0 - 30 V 0.01 V ± 0.08 V

XDS 40-XXX 0 - 40 V 0.01 V ± 0.08 V

XDS 50-XXX 0 - 50 V 0.02 V ± 0.16 V

XDS 80-XXX 0 – 80 V 0.02 V ± 0.16 V

XDS 100-XXX 0 - 100 V 0.1 V ± 0.2 V

XDS 150-XXX 0 - 150 V 0.1 V ± 0.4 V

XDS 250-XXX 0 - 250 V 0.1 V ± 0.8 V

18A

18A

20A

20A

Maximum power is available at full-scale voltage.

See section 2.1.5

Model Range Resolution Accuracy

36A

36A

40A

40A

54A

54A

60A

60A

12 XDS Series

Page 13

User and Programming Manual

XDS 300-XXX 0 - 300 V 0.1 V ± 0.8 V

XDS 400-XXX 0 - 400 V 0.1 V ± 1.6 V

XDS 600-XXX 0 - 600 V 0.2 V ± 1.6 V

Noise and Ripple:

See section 2.1.5

Line Regulation: < 0.1% of V Range

Load Regulation: < 0.1% of V Range

External Sense External Voltage Sense mode.

Maximum voltage drop allowed at load terminals is 5% of voltage

range.

Note: For 600V models, maximum drop allowed is 3% (20Vdc).

OVP Range: 0 to 110 % of V Range

Transient Response: A 30% step load will recover to within 2% of voltage range value

within 2 msec.

Stability: +/- 0.05% of max. rating for 8 Hrs. at fixed line, load and temp

after 30 minutes warm up period

2.1.5 Ranges, Noise and Ripple

Model

XDS 30-167

XDS 30-333

XDS 30-500

XDS 40-125

XDS 40-250

XDS 40-375

XDS 50-100

XDS 50-200

XDS 50-300

XDS 80-62

XDS 80-125

XDS 80-187

XDS 100-50

XDS 100-100

XDS 100-150

XDS 150-33

XDS 150-66

XDS 150-100

XDS 250-20

XDS 250-40

XDS 250-60

XDS 300-17

XDS 300-33

XDS 300-50

XDS 400-12

XDS 400-25

XDS 400-37

1

Maximum RMS Ripple < 2 x typical value shown.

Power

Max.

5

10

15

5

10

15

5

10

15

5

10

15

5

10

15

5

10

15

5

10

15

5

10

15

5

10

15

Volts

Max.

30

30

30

40

40

40

50

50

50

80

80

80

80

80

80

150

150

150

250

250

250

300

300

300

400

400

400

Output

Amps

Max.

167

333

500

125

250

375

100

200

300

62.5

125

187.5

50

100

150

33.3

66.7

100

20

40

60

17

33.3

50

12.5

25

37.5

RMS Ripple

Typical1

15 mV

15 mV

15 mV

15 mV

15 mV

15 mV

15 mV

15 mV

15 mV

25 mV

25 mV

25 mV

25 mV

25 mV

25 mV

25 mV

25 mV

25 mV

100 mV

100 mV

100 mV

100 mV

100 mV

100 mV

250 mV

250 mV

250 mV

Peak-Peak

Ripple typ.

90 mV

90 mV

90 mV

90 mV

90 mV

90 mV

90 mV

90 mV

90 mV

250 mV

250 mV

250 mV

250 mV

250 mV

250 mV

300 mV

300 mV

300 mV

400 mV

400 mV

400 mV

400 mV

400 mV

400 mV

2 V

2 V

2 V

XDS Series 13

Page 14

User and Programming Manual

XDS 600-8

XDS 600-17

XDS 600-25

2.1.6 Output Current

Current Range: See section 2.1.5

Current Programming:

Resolution: Shown in column 3 by model.

XDS 30-167

XDS 30-333

XDS 30-500

XDS 40-125

XDS 40-250

XDS 40-375

XDS 50-100

XDS 50-200

XDS 50-300

XDS 80-62

XDS 80-125

XDS 80-187

XDS 100-50

XDS 100-100

XDS 100-150

XDS 150-33

XDS 150-66

XDS 150-100

XDS 250-20

XDS 250-40

XDS 250-60

XDS 300-17

XDS 300-33

XDS 300-50

XDS 400-12

XDS 400-25

XDS 400-37

XDS 600-8

XDS 600-17

XDS 600-25

Line Regulation: < 0.1% of I Range

5

10

15

600

600

600

8.33

17

25

250 mV

250 mV

250 mV

2 V

2 V

2 V

Accuracy: Accuracy shown in last column as % of Full Scale (FS) from 100

% programmed to 0% programmed.

Model Range Resolution Accuracy

0 - 167 A

0 - 333 A

0 - 500 A

0 - 125 A

0 - 250 A

0 - 375 A

0 - 125 A

0 - 250 A

0 - 375 A

0 - 62.5 A

0 - 125 A

0 - 187.5 A

0 - 50 A

0 - 100 A

0 - 150 A

0 - 33.3 A

0 - 66.7 A

0 - 100 A

0 - 20 A

0 - 40 A

0 - 60 A

0 - 16.7 A

0 - 33.3 A

0 - 50 A

0 – 12.5 A

0 – 25.0 A

0 – 37.5 A

0 - 8.3 A

0 - 16.7 A

0 - 25 A

0.1 A

0.1 A

0.2 A

0.1 A

0.1 A

0.2 A

0.1 A

0.1 A

0.1 A

0.02 A

0.1 A

0.1 A

0.02 A

0.1 A

0.1 A

0.01 A

0.02 A

0.1 A

0.005 A

0.01 A

0.02 A

0.005 A

0.01 A

0.02 A

0.005 A

0.01 A

0.02 A

0.003 A

0.005 A

0.01 A

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

Load Regulation: < 0.1% of I Range

Stability:

14 XDS Series

+/- 0.05% of max. rating for 8 Hrs. at fixed line, load and temp

after 30 minutes warm up period

Page 15

User and Programming Manual

2.2 Measurements

Voltage

Model Range Resolution Accuracy

XDS 30-XXX 0 - 30 V 0.01 V ± 0.05 V

XDS 40-XXX 0 - 40 V 0.01 V ± 0.05 V

XDS 50-XXX 0 - 50 V 0.02 V ± 0.1 V

XDS 80-XXX 0 - 80 V 0.02 V ± 0.1 V

XDS 100-XXX 0 - 100 V 0.1 V ± 0.2 V

XDS 150-XXX 0 - 150 V 0.1 V ± 0.3 V

XDS 250-XXX 0 - 250 V 0.1 V ± 0.5 V

XDS 300-XXX 0 - 300 V 0.1 V ± 0.5 V

XDS 400-XXX 0 - 400 V 0.1 V ± 0.5 V

XDS 600-XXX 0 - 600 V 0.2 V ± 1.0 V

Current

Model Range Resolution Accuracy

XDS 30-167

XDS 30-333

XDS 30-500

XDS 40-125

XDS 40-250

XDS 40-375

XDS 50-100

XDS 50-200

XDS 50-300

XDS 80-62

XDS 80-125

XDS 80-187

XDS 100-50

XDS 100-100

XDS 100-150

XDS 150-33

XDS 150-66

XDS 150-100

XDS 250-20

XDS 250-40

XDS 250-60

XDS 300-17

XDS 300-33

XDS 300-50

XDS 400-12

XDS 400-25

XDS 400-37

XDS 600-8 0 - 8 A 0.003 A ± 0.013 A

0 - 167 A

0 - 333 A

0 - 500 A

0 - 125 A

0 - 250 A

0 - 375 A

0 - 100 A

0 - 200 A

0 - 300 A

0 - 66 A

0 - 125 A

0 - 187 A

0 - 50 A

0 - 100 A

0 - 150 A

0 - 33 A

0 - 66 A

0 - 100 A

0 – 20 A

0 - 40 A

0 - 60 A

0 - 17 A

0 - 33 A

0 - 50 A

0 – 12.5 A

0 - 25 A

0 – 37.5 A

0.1 A

0.1 A

0.2 A

0.1 A

0.1 A

0.1 A

0.1 A

0.1 A

0.1 A

0.02 A

0.1 A

0.1 A

0.02 A

0.1 A

0.1 A

0.01 A

0.02 A

0.1 A

0.005 A

0.01 A

0.02 A

0.005 A

0.01 A

0.02 A

0.005 A

0.01 A

0.02 A

± 0.3 A

± 0.5 A

± 1 A

± 0.3 A

± 0.5 A

± 0.5 A

± 0.3 A

± 0.5 A

± 0.5 A

± 0.1 A

± 0.3 A

± 0.3 A

± 0.1 A

± 0.3 A

± 0.3 A

± 0.05 A

± 0.1 A

± 0.3 A

± 0.025 A

± 0.05 A

± 0.1 A

± 0.025 A

± 0.05 A

± 0.1 A

± 0.025 A

± 0.05 A

± 0.1 A

XDS Series 15

Page 16

User and Programming Manual

XDS 600-17

XDS 600-25

0 - 17 A

0 - 25 A

0.005 A

0.01 A

± 0.025 A

± 0.05 A

Power

Model Range Resolution Accuracy

All 0 - 5 KW

0 -10 KW

0 - 15 KW

1 W

2 W

5 W

± 0.3 % FS

Peak Current

Model Range Resolution Accuracy

All See current table See current table See accuracy in

current table

+ 3 x resolution

16 XDS Series

Page 17

User and Programming Manual

2.3 Environmental

Temperature Coefficient

Voltage Set Point: 0.02%/C of V Range

Current Set Point: 0.03%/C of I Range

Ambient Temperature

Operating: 0° to 40° C / 32° to 104° F

Storage: -40° to 75° C /-40° to 167° F

Humidity: 0 to 80 % RH, non condensing

Cooling: Forced Air. Front, side and top air intake, rear exhaust.

Altitude

Operating: 2000 meters max.

Storage: 6000 meters max.

2.4 Mechanical

Dimensions: Width: 19.00 “/ 482.6 mm

Depth: 22.19”/ 563.3 mm

(excluding bus bars and cover)

Height: 5.25”/133.35 mm

Unit Weight: 15 kW model: Net: 90 Lbs. / 40.8 Kg.

Gross: 125 Lbs. / 56.7 Kg

10 kW model: Net: 70 Lbs. / 31.8 Kg.

Gross: 105 Lbs. / 47.6 Kg

5 kW model: Net: 50 Lbs. / 22.7 Kg.

Gross: 85 Lbs. / 38.6 Kg

Material: Chassis: Steel. (Anodized)

Top cover: Aluminum (Anodized)

Front panel Aluminum (Anodized)

Cooling: Forced air, side and top intake, rear exhaust

Acoustic Noise Level:

(Measured at 1 meter

from front of unit).

Internal Construction: Modular construction.

Rear Panel

Connections:

Rack Mounting Unit must be supported by shelf or brackets when mounted in 19"

5 KW: < 55 dBA

10KW: < 60 dBA

15KW: < 65 dBA

AC Power Input, DC power out, RS232, GPIB (option), Analog

Programming (option)

cabinet.

No provisions for rack slides are made on instrument.

XDS Series 17

Page 18

User and Programming Manual

2.5 Agency Approvals

CE Mark:

GENERAL: IEC 61326-1, 1998

SAFETY: IEC 61010-1, 2001

EMC: EN55011, Class A, Group 1

IEC 61000-4-2, 1995 IEC 61000-4-4, 1995

IEC 61000-4-5, 1995 IEC 61000-4-6, 1996

IEC61000-4-8, IEC 61000-4-11, 1994

2.6 Remote Control Interfaces

Standard:

Digital

9 pin D-Shell connector

Handshake: CTS, RTS

Data bits: 8

Stop bits: 1

Baud Rate: 19200

SCPI Syntax

Analog

Input: 0 - 10 VDC / 0 – 5 VDC for 0 to full scale voltage (RPV) or

Input impedance 10 KOhm

Accuracy: 0.5 %

See section 5 for details.

Output: Auxiliary drive output signal.

See section 5 for details.

Remote

Inhibit

-IF Option: GPIB Interface is part of -IF Option

IEEE-488 IEEE-488 Interface option:

IEEE-488 (GPIB) talker listener

RS232C Interface:

Shuts down output. Factory default operation is output disabled with contact

closure or logic low input. Operation mode can be inverted to shut down when

connection is broken/interrupted using SYST:CONF and SYST:SAVE

commands.

Connects to J22 pin 1 and 14 (Iso com) on rear panel.

current limit (RPC) .

Subset: AH1, L3, RL2, SH1, T8

IEEE-488.2 SCPI Syntax

18 XDS Series

Page 19

User and Programming Manual

2.7 Protection

Over temperature shut down

Short circuit protection

Overload protection

Over voltage

Voltage sense lines open.

2.8 Controls and Indicators

Controls: Voltage Setting: Digitally encoded rotary knob

Current Setting: Digitally encoded rotary knob

Measurement

Select

Output on/off: Push button

Power on/off: Toggle Switch

Indicators: Display: Dual, seven segment LED's

LED’s for: Output on/off

Constant Current mode

Constant Voltage mode

Remote Interface state

Selected Measurement: Curr, Peak Curr, Power

Push button

2.9 Parallel Operation

Two or more XDS power supply of the same model number (voltage range and power level must

match) may be combined to create a higher power system. This requires one master unit

(default) and one or more auxiliary units (-AUX).

The maximum number of XDS units that can be paralleled is 5 (1 master + 4 auxiliary units).

The following specifications apply to multi-box XDS configurations:

Parameter

Current Range: Multiply by number of XDS units.

Current Programming:

Accuracy: Multiply by number of XDS units.

Resolution: Same as single XDS unit.

Current Sharing Within 2 % of combined current range.

Current ripple Multiply by number of XDS units

XDS Series 19

Page 20

User and Programming Manual

2.10 Factory Configuration Options

All XDS models can be factory configured with the options shown below. Configuration changes

can be made in the field if needed. Refer to Chapter 5 for details on changing configuration

settings.

Option Configuration

none Stand-alone and Master operation.

-AUX Auxiliary configuration. Can be used with Master XDS unit to increase

power level.

-RPV10 Stand-alone operation with analog voltage programming, 0 – 10 V.

-RPV5 Stand-alone operation with analog voltage programming, 0 – 5 V.

-RPC10 Stand-alone operation with analog current limit programming, 0 – 10 V.

-RPC5 Stand-alone operation with analog current limit programming, 0 – 5 V.

2.11 -LC Option

The –LC option reduces the output capacitance of each DC power module. This results in

improved rise and fall times compared to a standard XDS unit. The output noise and ripple

specification is increased by a factor of 2 when adding the –LC option. This option is available

only on models with voltage ranges of 100V and below. The –LC option must be ordered at time

of initial orders. This option cannot be retrofitted.

-LC Option Output capacitance with LC option

Capacitance per 5 KW module.

30V 11200 uF 44000 uF

40V 7800 uF 30000 uF

50V 7800 uF 24000 uF

80V 3000 uF 7800 uF

100V 940 uF 4400 uF

Note: -LC option is available only on 30V, 40V, 50V, 80V and 100V output voltage range models.

Standard Unit

Capacitance per 5 KW module.

20 XDS Series

Page 21

User and Programming Manual

3 Installation and Functional Test

3.1 Inspection

Inspect the shipping carton for possible damage before unpacking the unit. Carefully unpack the

equipment.

Save all packing materials until inspection is complete. Verify that all items listed on the packing

slips have been received. Visually inspect all exterior surfaces for broken knobs, connectors or

meters. Inspect for dented or damage exterior surfaces. External damage may be an indication of

internal damage. If any damage is evident, immediately contact the carrier that delivered the unit

and submit a damage report. Failure to do so could invalidate future claims.

3.2 Location and Mounting

Bench Use

The XDS Series DC Supply may be used as a bench top unit provided adequate provisions are

made to protect the end-user from touching the output terminals. To this end, output covers are

provided on all XDS units. These covers must be installed during use and may only be removed

when the unit is not in use and disconnected from AC mains.

Adequate air flow must be maintained at all times so care should be taken not to block the top

and side air intakes or the rear air exhaust. Leave at least 4" of clearance at the back of the unit

to allow proper airflow.

Rack Use

The XDS Series uses a 19" cabinet with rack ears and can be installed in a standard equipment

rack. Due to the weight of the unit however, it must be properly supported by either a shelf or L

brackets on both sides. The rack ears are not designed to support the full weight of the XDS unit

when installed in a cabinet but only to prevent it from sliding out. Four screws, two on each side

of the front panel, should be used to secure the unit in place.

Proper airflow must be maintained in the instrument cabinet and the rear of the cabinet should

not be closed off by a door but rather a perforated screen allowing adequate airflow.

NOTE: The unit should be provided with the proper ventilation. The top, rear and

both sides of the unit should be free of obstructions. A 1.75" (1 U) spacing

between units mounted in the same cabinet is recommended.

XDS Series 21

Page 22

User and Programming Manual

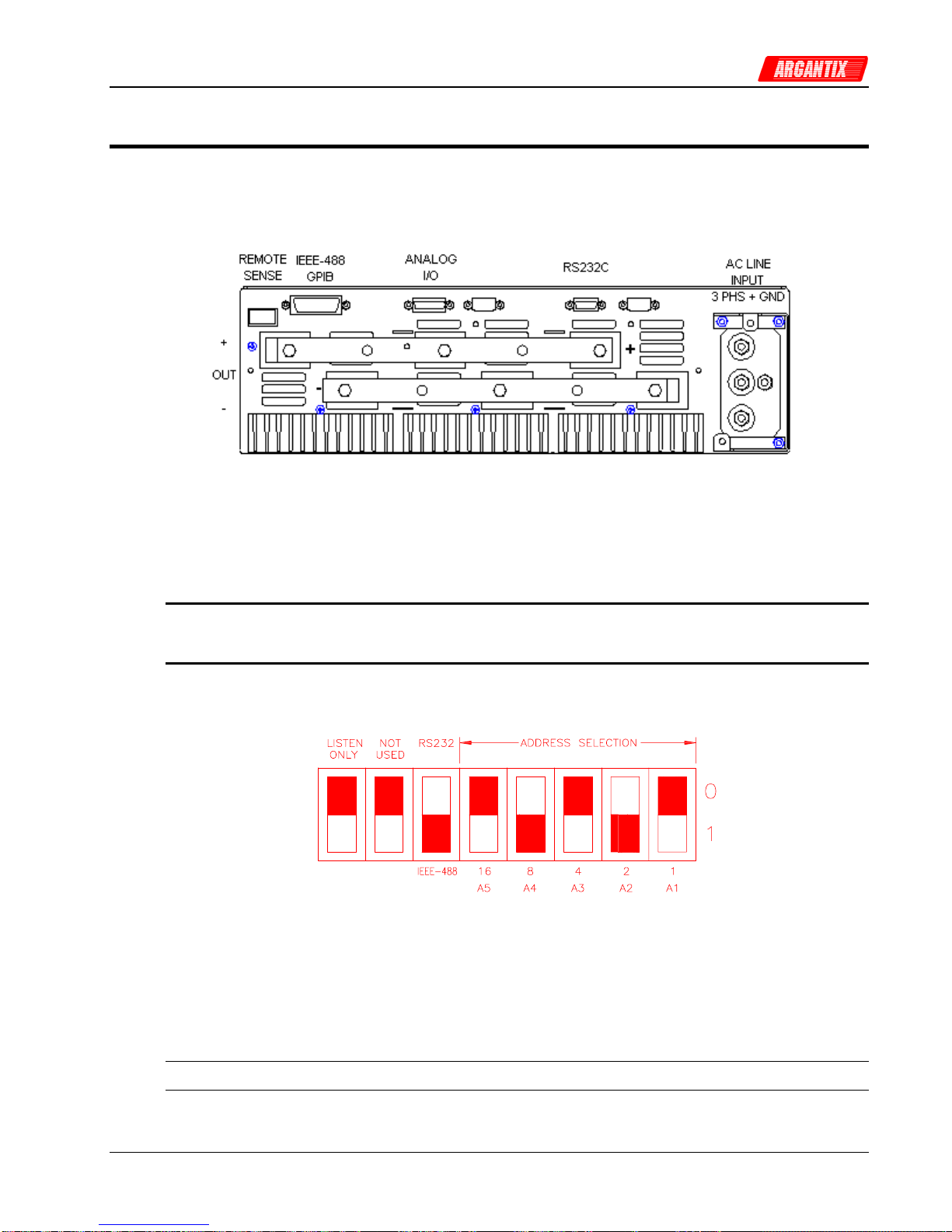

3.3 Input / Output Connectors

Table 3-1 lists all external connections for the XDS Series. Table 3-2 and Table 3-3 provide input

and output connector descriptions.

NOTE: DO NOT REVERSE THE EXT. SENSE CONNECTION POLARITY OR

DAMAGE TO THE XDS SUPPLY WILL RESULT.

For permanently connected equipment, a readily accessible disconnect device shall be

incorporated in the fixed wiring. For equipment connected through an outlet socket, the outlet

must be installed near the equipment and must be easily accessible.

NOTE: For proper connection to the mains, a suitable circuit breaker or fuse is

required. The rating will depend on the units' nominal AC input voltage. If a

fuse is used, a suitable disconnect device should be installed to allow AC

input to be removed from the supply.

NOTE: When connecting the AC Input wiring, DO NOT APPLY MORE THAN 32

INCH POUND (equivalent to 2.67 lbf feet or 3.62 Nm) of torque to the input

terminal connection studs and screws.

Table 3-1: Rear Panel Input and /Output Connectors

Connector

AC Input Function Connects To

L1 – AC in

L2 – AC in

L3 – AC in

CHASSIS - GND

Primary AC Power Input 208 - 230 VAC nominal (Std)

400 VAC nominal

480 VAC nominal

Limit torque applied to 32 inch pound force/

2.7 foot pond force / 3.6 Nm.

DC Output Function Connects To

Positive Bus Bar

Negative Bus Bar

DC output User Load

Table 3-2

Other Function Table

Isolated Analog I/O Control Interface (option) DB15, J22, Table 3-5

RS232 Control Interface DB9, J20, Table 3-4

Auxiliary I/O Misc. DB9, J21, Table 3-6

Remote Inhibit Output shut-off DB15, J22, Table 3-5

IEEE-488 Control Interface (option) GPIB 24 pin, J23. See IEEE-488 standard

for pin out.

Table 3-2: Output Connection Description

Supply Type Connection Description

For Output voltages <= 60V

Bus Bar with threaded Stud. (Do not exceed 10 foot

pound force / 13.5 Nm of torque when tightening

nuts of bus bars)

For Output Voltages > = 80V Bus Bar with threaded Stud and a rear safety cover

22 XDS Series

(Do not exceed 10 foot pound force / 13.5 Nm of

torque when tightening nuts of bus bars)

Page 23

User and Programming Manual

Table 3-3: Input Connection Description

AC In. Designator Dir. Connection Description

1 ØA Input 10-32 Threaded Stud

2 ØB Input 10-32 Threaded Stud

3 ØC Input 10-32 Threaded Stud

4 GND 10-32 Threaded Stud

Table 3-4: RS232C Connector J20

J20, Pin Designator Dir. Description

1 Not used N/C

2 TxD Output Transmit data

3 RxD Input Receive data

4 Not used N/C

5 Common Common

6 Not used N/C

7 CTS Input Clear to send

8 RTS Output Request to send

9 Not used N/C

Table 3-5: Analog I/O Connector J22

J22, Pin Designator Dir. Description

1 ON / OFF Input ON/OFF (Remote Inhibit).

Mode 0: Switch/relay contacts or a direct short

between this terminal and ISO RTN (pin 10) will turn

off the power supply.

Mode 1: A logic high or a disconnect between this

terminal and ISO RTN (pin 10) will turn off the power

supply.

The mode can be set over the RS232C or GPIB bus

using the SYST:CONF command and retained at

power on using the SYST:SAVE command.

2 Not used N/C

3 Not used N/C

4 V/I PROG

10V

Input

Isolated

Remote analog programming. Using a 0-10VDC

source referenced to pin 10 or 14 (ISO RTN/COM)

will program the output voltage or current from 0 to

100%. Mode is determined by controller settings.

5 Not used N/C

6 Not used

7-9 Not used N/C

10 ISO RTN Isolated Return path. Internally connected to pin 14.

11 V/I PROG 5V Input

Isolated

Remote analog programming. Using a 0-5VDC

source referenced to pin 10 or 14 (ISO RTN/COM)

will program the output voltage or current from 0 to

100%. Mode is determined by controller settings.

XDS Series 23

Page 24

User and Programming Manual

J22, Pin Designator Dir. Description

11 Not used N/C

12 Not used N/C

13 Not used N/C

14 ISO COM Isolated Return path to be used with pins V/I PROG 5V and

V/I PROG 10V. Internally connected to pin 10.

15 Not used N/C

Table 3-6: Auxiliary I/O Connector (Isolated ) – J21

J21, Pin Designator Dir. Description

1 Not used N/C

2 ISO COM Isolated Return path to be used with pin 6.

3 Not used N/C

4 Not used N/C

5 Not used N/C

6 I MON Output Output current monitor.

7 Not used N/C

8 Not used N/C

9 Not used N/C

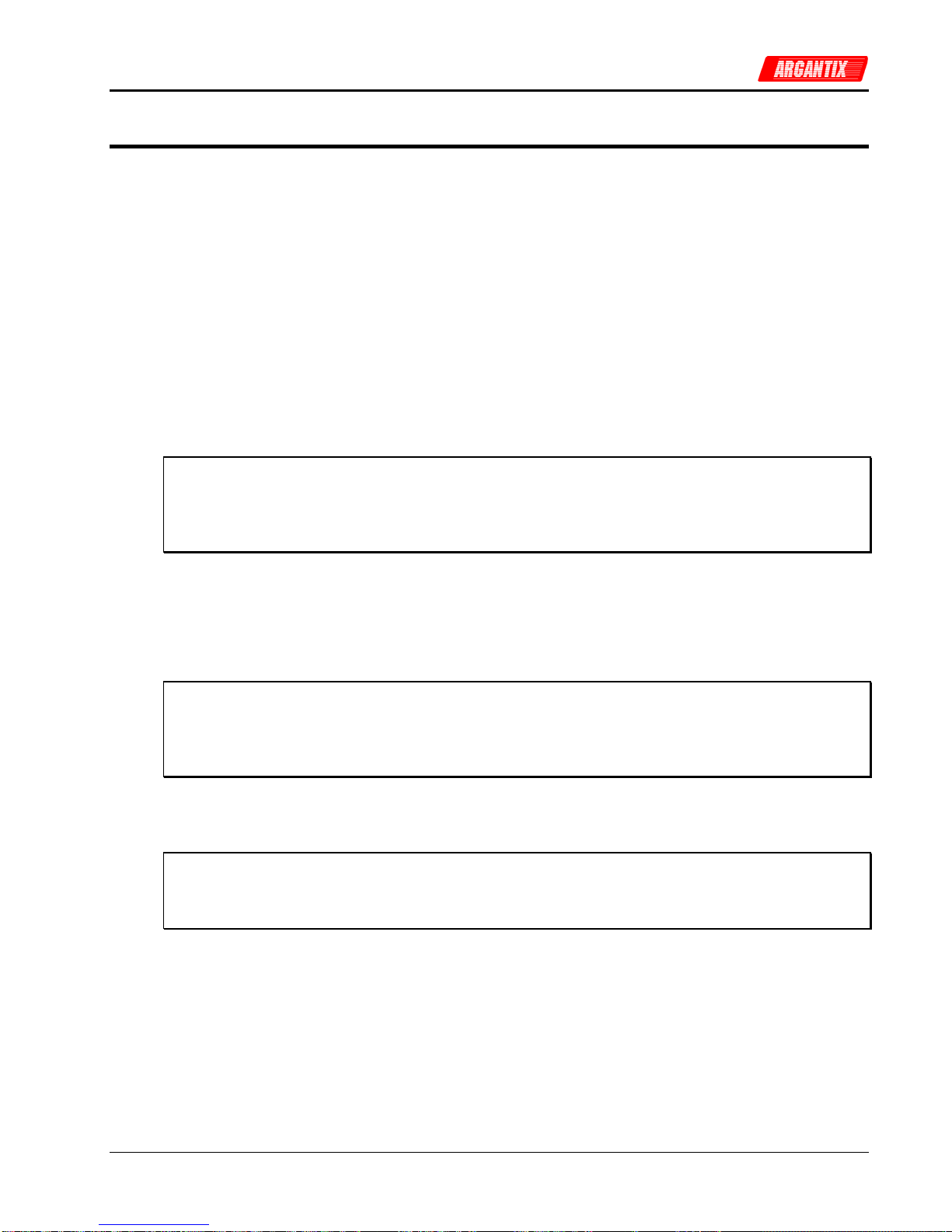

Figure 3-1: Location of rear panel connectors.

24 XDS Series

Page 25

User and Programming Manual

3.4 Wire Sizing and Lug Size

The DC output is available from a set of copper bus bars, one for the positive terminal, out for the

negative terminal. Each bus bar has two screw studs, (Penn Engineering, HFHB-0518-24, see

www.pennfast.com

recommended ring-lug size that mates with these 5/16-18 thread studs for connecting output

wiring is 5/16” (standard) or 8M (metric). The wire gauge and ring-lug crimp size must be

matched. Crimp ring lugs are generally available from Tyco/AMP and catalog vendors like

Mouser, Digikey etc. See paragraph 3.5 for AC input wire lug size.

) to which a set of two nuts and lock washers are attached. The

Figure 3-2: DC Output bus bar studs.

Care must be taken to properly size all conductors for the input and output of the power supply.

Table 3-7 bellow gives minimum recommended wire size for the input. This table is derived from

the National Electrical Code and is for reference only. Local laws and conditions may have

different requirements. The table is for copper wire only.

Table 3-7: Minimum Wire Size Table

Size Temperature Rating of Copper Conductor

AWG

MCM

14 20 20 25 25

12 25 25 30 30

10 30 35 40 40

8 40 50 55 55

6 55 65 70 75

4 70 85 95 95

3 85 100 110 110

2 95 115 125 130

1 110 130 145 150

0 125 150 165 170

00 145 175 190 195

000 165 200 215 225

0000 195 230 250 260

60 C 75 C 85 C 90 C

Types Types Types Types

RUW, T, TW UF FEPW,M R, RHW,

RUH, THW, THWN,

XHHW, USE, ZW

Current Rating

V, MI TA, TBS, SA, AVB,SIS,

FEP, FEPB, RHH, THHN,

XHHW

For higher ratings wires can be paralleled or refer to the National Electrical Code.

XDS Series 25

Page 26

User and Programming Manual

3.5 AC Input Wiring

All XDS models require 3 phase AC input. A neutral

connection is not available, as the XDS only requires a

delta input. If only three-phase Wye AC power is available,

verify the correct Line-to-Line voltage and connect only the

phase wires.

The Safety Ground connection MUST be made to the stud

marked with the earth ground symbol.

The AC input wires must be terminated with ring lugs (AC

input stud size is ¼”-20 thread, M4 metric) of at least ¼” (7

mm) diameter. See Figure 3-3.

Before attaching wires to line input terminals, wires must

pass-thru strain relief on the safety cover. Always install

the AC input safety cover and strain relief provided with the

unit. The ground wire should be longer than the three

power phase wires by at least 1 inch.

3.5.1 EMI Toroid Installation – 400V Models

To meet CE Mark conducted emissions, models with 400V AC input must have the supplied

ferrite toroid installed on the AC input wiring as shown. Loop the three phase conductors through

the supplied toroid 4 times (4 turns). This means they loop around the outside of the toroid one

time. This should be done before passing the AC input wires through the safety cover strain relief

and attached them to the AC input terminal studs on the rear of the XDS unit.

Figure 3-3: AC Input Terminals

Wind 3 line

input wires 4

turns thru

toroid.

26 XDS Series

Figure 3-4: Toroid Installation, -400V input model.

Page 27

User and Programming Manual

XDS Series 27

Figure 3-5: Outline Drawing XDS DC Supply

Page 28

User and Programming Manual

4 Front Panel Operation

4.1 Functional Controls

The front panel can be divided in a small number of functional areas:

Status Indicator lights

Shuttle knobs

LED displays

Button controls

4.1.1 Status Indicator Lights

Seven green LED status indicators are located on the front panel. These LED’s correspond to

the following conditions:

CV MODE Indicates the DC Supply is operating in the Constant Voltage

CC MODE Indicates the DC Supply is operating in the Constant Current

OUTPUT The Output LED indicates the status of the OUTPUT. The output

CURR Illuminates when the LED display shows the programmed or

PK CUR Illuminates when the LED display shows the measured peak

PWR Illuminates when the LED display shows the measured power.

Figure 4-1: Front Panel View

mode.

mode.

is controlled by the OUTPUT ON/OFF button located directly

below the LED. When the Output LED is not lit, the output

voltage is not present at the output terminals regardless of the

voltage setting.

measured current.

current.

28 XDS Series

Page 29

User and Programming Manual

REMOTE The REMOTE LED indicates that the unit is in remote control

mode. If the RS232C interface is used, the REMOTE state can

be enabled by the controller using the SYST:REM command.

Any time the REMOTE LED is lit, the front panel of the XDS

Series unit is disabled. There is no LOCAL button that allows

the user to regain control of the front panel. The SYST:LOC

command will enable the front panel controls. When using the

optional IEEE interface, the remote /local state is controlled by

the REN (Remote Enable) interface line.

4.1.2 Shuttle knobs

Counter Clockwise

clockwise

DECREASE INCREASE

There are two shuttle knobs located below the LED displays which are used to change settings

for voltage and current. The left shuttle always controls the voltage. The right shuttle always

controls the current.

4.1.3 Buttons

There are only two buttons on the front panel. One is used to toggle the Output State, the other to

toggle display modes for the right hand side segment LED. The following is a description of

these buttons:

KEY DESCRIPTION

OUTPUT ON/OFF The OUTPUT ON/OFF button will toggle the output on or off.

SELECT The SELECT button selects the function of the right Shuttle knob

Figure 4-2: Shuttle Knob

The LED above the button will light when the output is on. No

output voltage will be present when the OUTPUT ON/OFF

button is off despite the level of voltage programmed.

and the LED display. The right hand Shuttle knob will program

the current limit and the display will show its value in the current

mode. The display will revert back to showing the measured

current after 3 seconds from the last movement of the shuttle.

The SELECT button also allows selection of the desired

measurement function readout. Available selections are:

Current (Also puts the shuttle in Current Limit set mode)

Peak Current

Power

Measurements are updated 2 times per second. The display

mode is indicated by the LED’s above the segment LED display.

Note that voltage measurements are available through the

Voltage LED.

XDS Series 29

Page 30

User and Programming Manual

4.1.4 LED Segment Displays

Settings and measurements are shown on two 4 digit, 7 segment LED displays. The voltage

display shows the programmed voltage as the user turns the left knob. After releasing the knob

for about 3 seconds, this display reverts back to displaying the measured output voltage. The

right hand LED display is a multi purpose display. For setup purposes, it always displays the

Current limit setting. After about 3 seconds on inactivity, this display switches to the selected

measurement parameter. The SELECT button will define the operating mode or the selected

measurement parameter for the right hand display.

30 XDS Series

Page 31

User and Programming Manual

4.2 How to examples...

This section covers some common tasks that are often performed with an DC power supply.

These examples are written in a How to... format and provide step by step instructions on how to

set up the DC supply for a specific task.

4.2.1 Set the Output

Output parameters are Voltage and Current Limit.

1. Disable the output by pressing the OUTPUT button. The LED above the button will turn off.

2. Use the left shuttle to set the output voltage. Clockwise will increase the output, counter

clockwise will reduce the output. The display above the shuttle will show the voltage setting.

3. Use the right shuttle to set the current limit. The SELECT button will define the function of the

right hand side LED display.

4. Enable the output by pressing the OUTPUT button.

4.2.2 Slew Output Values

The output parameters can be slewed using the shuttles.

1. Enable the output by pressing the OUTPUT button. The LED above it will turn on.

2. Use the left shuttle to set the output voltage. Clockwise will increase the output, counter

clockwise will reduce the output. The display above the shuttle will show the voltage setting.

3. Use the right shuttle to set the current limit. The LED’s located above the display will indicate

the selected measurement display function.

XDS Series 31

Page 32

User and Programming Manual

4.2.3 Display Measurement Data

Measurements are always active and can be displayed as follows:

1. For voltage, the left display always displays the measured output voltage unless the knob

is turned. As the knob is turned, the programmed voltage will be displayed instead. After

releasing the knob for about 3 seconds, the display reverts back to the measured

voltage.

2. All other measurements can be displayed by using the SELECT button to toggle through

the available measurements. The LED’s above the LED segment display indicates the

current selection. The knob only affects the current limit set.

3. Moving the right shuttle knob will interrupt the selected measurement and put the display

back in Current Limit adjust mode.

4.2.4 Control the Output

The Output can be disabled or enabled using the ON/OFF button as follows:

1. Pressing the OUTPUT button when the output LED is on will turn off the DC supply output.

The programmed voltage setting will remain at the last program value.

2. Pressing the OUTPUT button again will engage the output and the output will revert to the

last programmed value.

4.2.5 Measure Peak Inrush Current

The peak current measurement function of the XDS Series uses a sample and hold circuit to

track the highest peak current found until reset. The peak current sample and hold circuit is reset

any time the user toggles away from the peak current display mode to a different measurement

using the SELECT button.

The peak inrush current for a unit under test can be measured using this function as follows:

1. Program the output to zero volts and turn off the output using the ON/OFF button.

2. Use the SELECT button to display the present peak current value.

3. Use the SELECT button again to toggle to any other measurement readout. This will

effectively reset the peak current sample and hold circuit to zero amps.

4. Use the left shuttle knob to set the voltage to the nominal supply voltage of the unit under

test.

5. Use the OUTPUT ON/OFF button to apply the programmed voltage to the unit under test.

6. Use the SELECT button to display the measured peak current value.

32 XDS Series

Page 33

User and Programming Manual

4.3 Setting the Power on Initialization Values

The power supply is shipped with default factory settings when the unit is powered up. The

factory settings are:

Parameter Factory default setting

Voltage 0.0 Volt

Current limit Maximum available current.

Display mode Voltage and Current measurement

Output state OFF

Local / Remote State Local. Front panel unlocked.

Table 4-1: Factory Default Power on Settings

It is possible to change the power on initialization values in one of two ways:

1. Using the RS232 or optional IEEE-488 interface and the supplied XDSGUI program.

2. Using the front panel.

To change the power on initialization values from the front panel, proceed as follows:

1. Set the unit up in the desired way from the front. (Voltage, current limit, output state, display

mode).

2. Press and hold the SELECT key (normally toggles LED display mode).

3. While holding the SELECT key, press the OUTPUT ON/OFF key. This will save the present

front panel settings in non-volatile memory register (NVM) no 7 and assign this register as

the power on register.

4. Release both keys. Note that as step 2 is executed, the display mode will toggle. This means

the display mode after power up is different from how the unit was set up. To avoid this, just

toggle the display till one position before the desired power on mode first and then execute

steps 2-4.

5. This procedure can be repeated as often as needed by the user.

To change the power on initialization values over the bus, proceed as follows:

1. Set the unit up in the desired way using the relevant bus commands.

2. Save the new setup you want to make the power-on setting to one of the 8 setup registers

using the *SAV <n> command. (n = 0 through 7)

3. Assign the register as the Power-on register using the SYST:PON <n> command where <n>

is register used in step 2.

XDS Series 33

Page 34

User and Programming Manual

4.4 Operating Modes

The XDS Series can operate in one of two modes of operation, voltage mode or current mode

with automatic cross over.

Voltage Mode (CV) mode In this mode of operation, the output voltage of

the DC supply is regulated as long as the

current limit set is not exceeded. If the current

limit is reached due to the load condition, the

DC supply crosses over to constant current

mode by reducing the output voltage as needed

to maintain the set current limit level.

Constant Current (CC) mode In this mode of operation, the output current of

the DC supply is regulated as long as the

voltage set is not reached. If the output voltage

reaches the set voltage, the DC supply crosses

over to the constant voltage mode by reducing

the output current as needed to maintain the set

voltage level.

The currently active mode is always indicated by the CV and CC status LED's on the front panel

and may also be queried through he remote control interface. The mode can not be changed by

the user. It is determined by the load condition and the programmed values for voltage and

current limit.

34 XDS Series

Page 35

User and Programming Manual

4.5 Special Features

The XDS Series offers some special features, which are explained in this section

4.5.1 Remote Inhibit / Remote Shutdown

The output of the DC supply can be controlled using a discrete input. This input is available on

connecter J22 at the rear panel of the XDS unit.

The Remote Inhibit or Remote Shutdown can be configured over the bus to operate in one of two

modes:

RI Mode Description

0 Active Low. A TTL logic low signal level or switch closure between pin 1 and

pin 10 of J22 will DISABLE the output. This will override the front panel

OUTPUT ON/OFF button or remote output state.

This is the default mode.

1 Active High. A TTL logic low signal level or switch closure between pin 1 and

pin 10 of J22 will ENABLE the output. This will override the front panel

OUTPUT ON/OFF button or remote output state.

The SYST:CONF bus command may be used to set the polarity mode for the Remote Inhibit

shutdown input. Once set, send the SYST:SAVE command so the new mode is retained at power

up.

4.5.2 Bleeder circuit

The DC supply has an amplifier that can source but can’t sink current. Under a no-load condition

the output voltage will remain unless there is a provision to bleed the voltage from the storage

capacitors across the output terminals. The XDS Series DC supply has a bleeder circuit that

when activated will drop the output from its present value to a value closer to zero volts in

approximately 150 milliseconds under a no-load condition. Actual times may vary by voltage

range model.

This special bleeder circuit will activate when the output voltage is programmed to a value that is

10% lower than its prior voltage setting. For example if the output is set to 80 volts the bleeder

will not activate if the voltage is programmed to 75 volts. If it is programmed to 40 volts however,

it will activate since 40 volts is more than 10 % less than 80 V. Once activated, the bleeder circuit

stays active until the voltage drops to 44 volts (110% of new setting). The bleeder circuit will

work with either internal or RPV programming.

4.5.3 Over Voltage Protection (OVP)

The XDS Series offers an over voltage protection mode. This mode protects the power supply

from over voltage damage.

The Over Voltage Protection (OVP) is controlled by the voltage measurements and as such

reacts to the measured output voltage rather than the programmed value.

When the actual output voltage exceeds the OVP level the controller will disable the output and

program the output to zero volts.

When operated from the front panel, the OVP level is fixed at 110% of the available voltage

range. When operated over the remote control interface, the OVP trip level can be set by the user

XDS Series 35

Page 36

User and Programming Manual

as a percentage of voltage range. Allowable range is 0 to 110%. Bus operation also allows the

OVP mode to be turned on (enabled) or off (disabled).

If the output voltage exceeds the set trip level and the OVP mode is enabled, the power supply

will generate a -300, Device specific error and turn off the output. The mode is enabled with the

VOLT:PROT:STAT command. The OVP mode provides another level of protection in addition to

the volt:high user setting which prevents programming commands or front panel inputs above this

level to be accepted.

36 XDS Series

Page 37

User and Programming Manual

5 Model Configurations

5.1 Available Configurations

The XDS controller can be reconfigured for various modes of operation. Generally, the mode of

operation is factory set at the time of shipment and is indicated on the model number tag by a

configuration option suffix. The following configurations are available.

Configuration Configuration

Option Suffix

Master None Normal mode of operation. A single XDS unit in

Auxiliary -AUX Set to operate as an auxiliary unit to another XDS

Master, remote

programming, Voltage

Master, remote

programming, Voltage

Master, remote

programming, Current

-RPV5 Stand-alone mode with voltage controlled by

-RPV10 Stand-alone mode with voltage controlled by

-RPC5 Stand-alone mode with current limit controlled by

Description

either 5, 10 or 15 KW power configuration. Both

voltage and current limit are controlled from the

front panel or over the bus.

master unit. This allows parallel operation of up to

5 identical XDS units for higher power systems.

The master unit controls auxiliary units. Voltage

and current cannot be set from the front panel or

over the bus. Measurements are still available

however.

external analog DC voltage input signal. Full-scale

voltage required 5 VDC input. Current limit can be

set from the front panel or over the bus.

external analog DC voltage input signal. Full-scale

voltage required 10 VDC input. Current limit can be

set from the front panel or over the bus.

external analog DC voltage input signal. Full-scale

voltage required 5 VDC input. Voltage can be set

from the front panel or over the bus.

Master, remote

programming, Current

XDS Series 37

-RPC10 Stand-alone mode with current limit controlled by

external analog DC voltage input signal. Full-scale

voltage required 10 VDC input. Voltage can be set

from the front panel or over the bus.

Table 5-1: XDS Controller Configuration Options

Page 38

User and Programming Manual

5.2 Changing Configurations

Factory configured models are pre-configured and calibrated for their indicated mode of

operation. If a unit has to be redeployed for a different application than originally purchased for,