Page 1

Educational Design Robot

ROPE DANCER

INSTRUCTION MANUAL: Model WTR-RD1

© 2010 AREXX - THE NETHERLANDS

Page 2

English

CONTENT

1. Product information Rope Dancer 3

2. General assembly information 4

2.1 Parts list Rope Dancer 6

3. Assembly instructions Rope Dancer 7

4. Gears information 13

5. Motors 14

5.1 History of motors 14

5.2 Motor mechanisms 14

© English translation (January 2010): AREXX Engineering (NL).

This description is protected by the laws of copyright. Any partial or total reproduction of the contents

is prohibited without prior written authorisation of the manufacturer:

AREXX Engineering - Zwolle (NL).

The manufacturer and distributor cannot be held responsible for any damages occurred by mishandling,

mounting mistakes or misuse due to a non-respect of the instructions contained in this manual.

The specification, shape and size of the product are subject to change without prior notice.

Worldwide distributor:

AREXX Engineering

Zwolle, The Netherlands

For technical support see:

www.arexx.com

© 2010 AREXX Engineering

2

Page 3

English

1. PRODUCT INFORMATION ROPE DANCER

The Rope Dancer is a robot which can climb over a rope. Then it looks like if

he is dancing because of the movements of the rope. However, before this

robot can climb you have to build it first.

An excellent robot kit for beginners. This battery-controlled kit teaches the

basic principles of robotic mechanics and motion. This simple robot can be

assembled by almost anyone from age 8 and up. Only basic hand tools are

required for the assembly. We already included a screwdriver and a wrench

in this kit.

This robot kit is more than just fun. Assembling, building and following instructions help develop fine motor skills, hand-eye coordination and understanding

technical drawings.

Specifications:

Power source : 3V (2 Penlite AAA Batteries 1.5V, not included)

Current consumption : Approx. 100 mA max.

Height : 140 mm

Length : 170 mm

Width : 85 mm

Warning

- No return is possible after having opened the bags with components and pieces

- Prior to the assembly, read the manual thoroughly.

- Be careful when using tools.

- Keep this kit away from young children during construction and operation.

(They might get hurt by the tools or swallow small components).

- Observe the correct polarity of the batteries.

- Keep the batteries dry. When the Rope Dancer gets wet, remove the batteries and let

the Rope Dancer dry for some time.

- Remove the batteries when you will not use the Rope Dancer for a longer period.

- Children below 14 should only assemble this product with the help of adults.

- Use new batteries and do not MIX batteries (old, new, recharchable) in any way!

3

Page 4

English

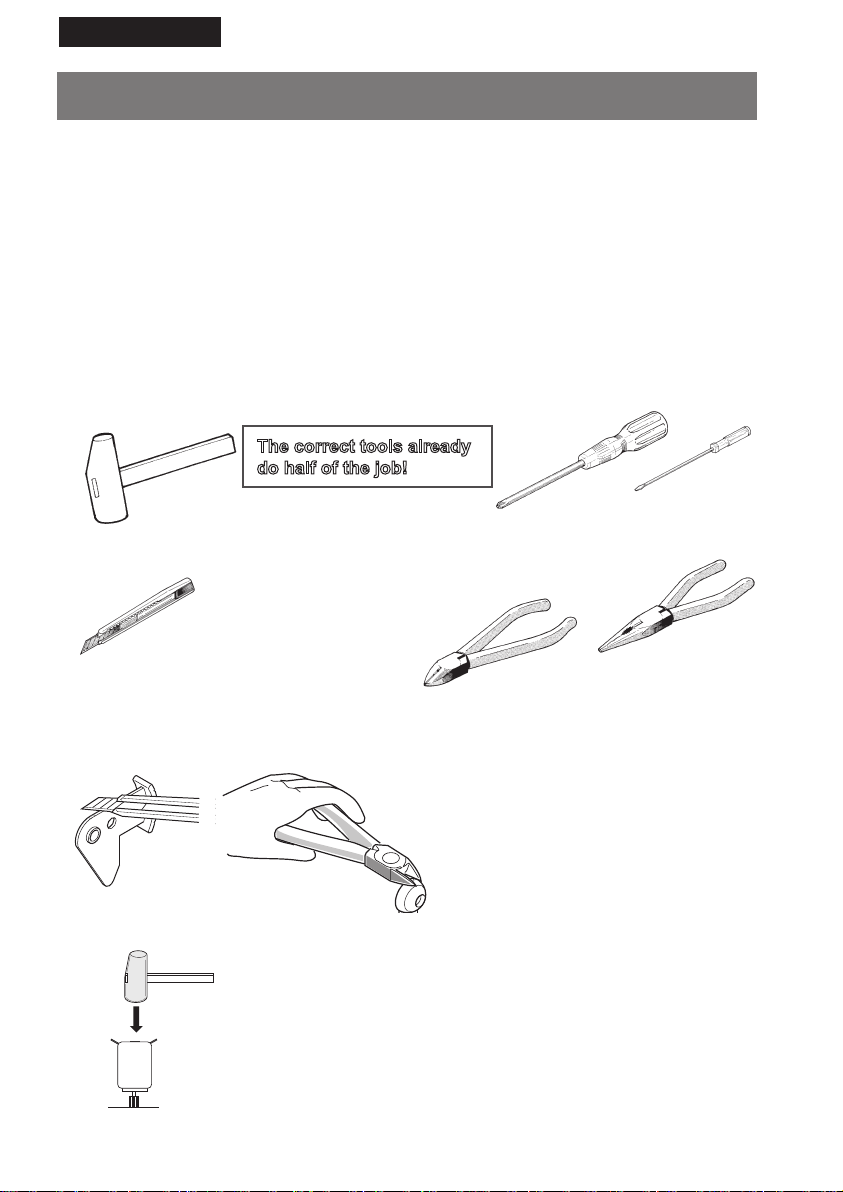

2. GENERAL ASSEMBLY INFORMATION

IMPORTANT: First read all the instructions about the mechanics !

Follow the step-by-step instructions for the mechanical assembly as shown in this

manual. Read and work very accurately, this is the best way to avoid assembly failures.

When you follow the instructions and study the drawings and comments carefully, you

have a big chance the robot will work directly and without any problems.

Also a great help is the picture on the package. You can see very clearly how the robot

should look like. Best is that you only take out the parts from the packages and frames

the moment you need them! Sometimes parts or bags are numbered.

All parts fit perfectly so you do not need to use force assembling this robot!

Do not hurry and once more, best is to read all instructions first before you actually start

the assembly.

Small plastic Hammer

The correct tools already

do half of the job!

Screwdriverset

Always use a good fitting screwdriver size

Hobby knife

WARNING! Be carefull not to cut yourself

when using a hobby knife!

How to cut the plastic parts

Assembly of a gear to an ax

When you install a gear or a pinion to an ax or shaft, like the pinion

to the motor shaft, you must be very careful. Be 100% sure you

put the right gear onto the right ax. Best way is always to press the

gear on the shaft with your hands. When you cannot manage it

this way, use a very small plastic hammer. When you use a hammer, you can protect the gear or the shaft by putting a piece of

wood or carton between the hammer and the part you will hit on.

4

Plier set with cutting plier &

flatnose plier

Best plier size is approx. 150 mm.

To take out the plastic parts from a

frame, use a sharp hobby knife or a

cutting plier. Cut carefully and take

of the bosses with a knife to make it

smooth.

Do not cut parts from a frame

when you do not need them

directly!

Page 5

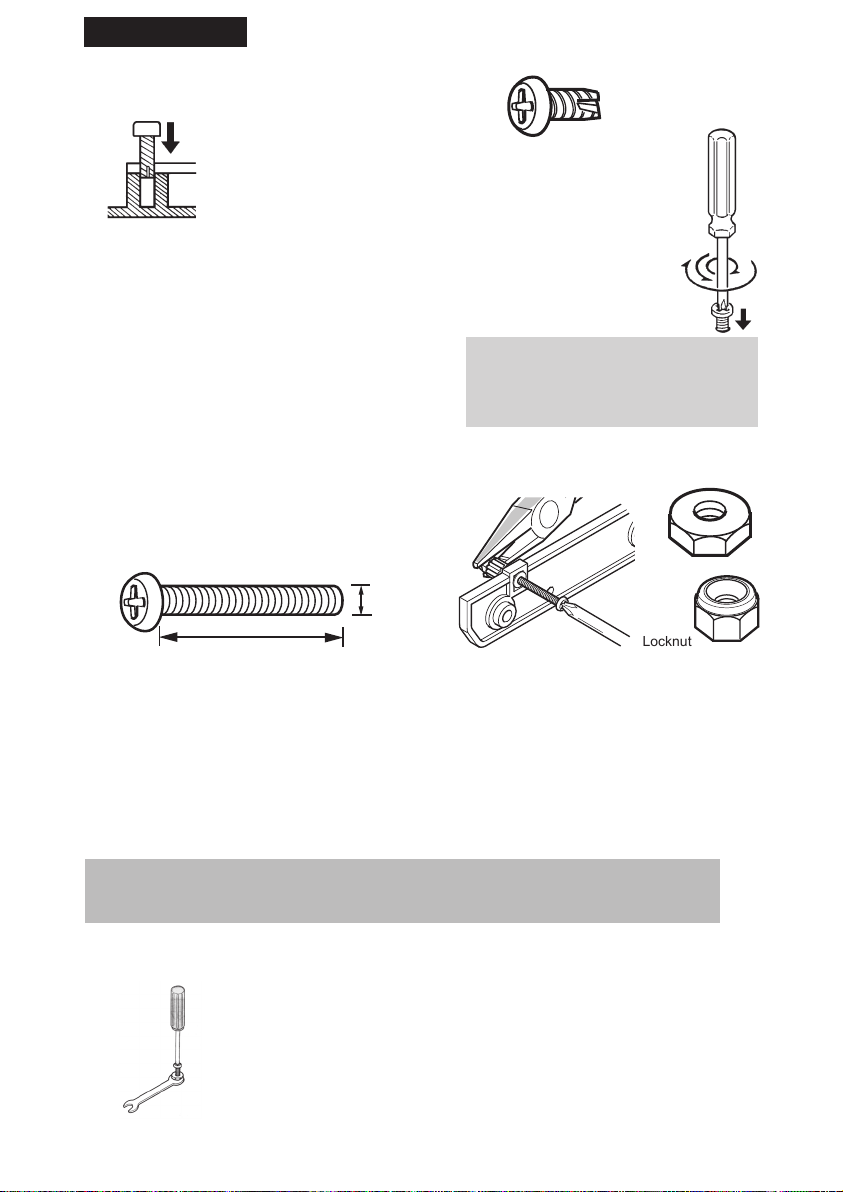

Locknut

English

Self-tapping screws (Parker)

A self-tapping screw looks similar to a wood screw.

When you screw it in a hole, it cuts the threads at

the same time. Never try to screw it down all the

way for a first time, because it may easily become

stuck or you will damage its head.

Tapping screws always have a sharp point,

sometimes with a small carve. They look

almost the same as screws which we use for

wood, only the thread is more fine. The best

way is to screw it in and out a bit.

Do not screw a tapping screw in and out too often because the screw hole may become enlarged and

the screw will loose all grip and proper function.

Screws and nuts

Thickness

Length

1. Screw in

2. Screw out a bit

3. Screw in further and continue

step 1 and 2

Nut

In a moving environment, screws and nuts must be tightened properly. A lock nut is a

special nut with nylon inside which will lock itself automatically.

Another easy way to lock a screw is to use ordinary fingernail polish. A big advantage

of nail polish is that you always can loosen it quite easily again. A professional way to

lock a screw is to use for example locktite, a sort of glue especially made for screws,

but it is very difficult to unlock such a screw afterwards.

The size of a screw is expressed by thickness and length. A screw with the marking M2 x 10

means 2 mm thick. The length of the thread is 10 mm. A M2 nut is used for a M2 screw, so the

nut always corresponds with the screw thickness.

Wrench

This kit includes a small wrench. Please use this wrench

to fit the M2 and M3 nuts in a proper way. You can use it

instead of a plier.

5

Page 6

English

2.1 Parts list ROPE DANCER

Please check all parts before you start the assembly!

M2 x 8

O 8 pcs.

Tapping screws

Roundhead

Thin

M2 x 5

O 2 pcs.

Motor

Pinion gear

O 1 pc.

8 teeth

Spacer

O 3 pc.

Ø 4 - 4mm

Screw middleScrew short

M3 x 14

O 2 pcs.

Roundhead

Thicker

M2.3 x 6

O 5 pcs.

Flat spur gear

with pinion small

O 1 pc.

28 and 10 teeth

Spacer

O 2 pc.

Ø 4 - 6mm

Screw long

M3 x 24

O 2 pc.

Flat spur gear with

pinion middle

O 1 pc.

30 and 10 teeth

Crank

O 2 pcs.

Flathead

countersunk

M3 x 6

O 2 pcs.

Wired

Wired

Nut Lock nut

M2

O 8 pcs.

Roundhead

with flange

M3 x 10

O 3 pcs.

Flat spur gear with

pinion big

O 1 pc.

32 and 10 teeth

RopeMotor

O 1 pc.O 1 pc.

M3

O 4 pcs.

Gear with shaft

O 1 pc.

40 teeth

Wire's

with connector

Complete set

pre-soldered

Motor holder Head

O 1 pc. O 1 pc.

Arm

O 2 pcs.

Battery holder

Wired

Leg

O 2 pcs.

6

Gearbox

side panel 1

Gear coverBody

Switch

Wired

O 1 pc.O 1 pc.O 1 pc.O 1 pc.

Gearbox

side panel 2

O 1 pc.O 1 pc.

Page 7

English

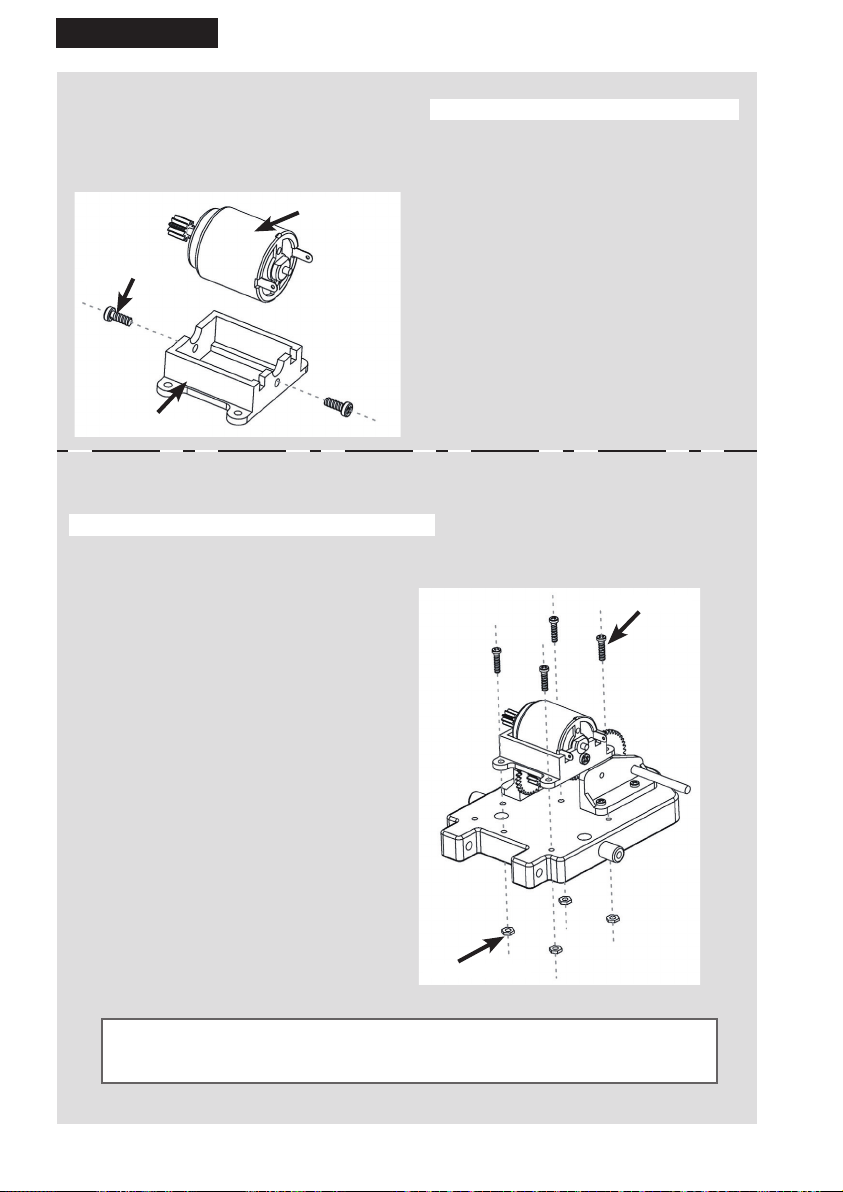

3. ASSEMBLY INSTRUCTIONS ROPE DANCER

First always check and collect all the parts, as mentioned in the parts list, before you start the assembly!

Step 1: Assembly of the gearbox

Assemble the gearbox as shown on the drawing below:

Gearbox

side panel 2

Flatspur gear

28/10

Flatspur gear

30/10

Flat spur gear

32/10

Gearbox

side panel 1

Gear

with shaft

Step 2: Installing the gearbox

To install the gearbox you need:

1 pc. Gearbox from step 1

1 pc. Body

4 pcs. Screw M2 x 8

4 pcs. Nut M2

Install the gearbox on the body as shown on

the drawing:

Screw M2 x 8

For the gearbox assembly you need;

1 pc. Flat spur gear with pinion small

1 pc. Flat spur gear with pinion middle

1 pc. Flat spur gear with pinion big

1 pc. Gearbox side panel 1

1 pc. Gearbox side panel 2

1 pc. Gear with shaft

Assemble the gear parts in order from

1 to 4.

Step 3: Assembly motor pinion

For the motor pinion assembly you need:

1 pc. Motor pinion gear

1 pc. Motor

Put the pinion on the motor shaft as shown in

the drawings:

Place the pinion on the motor shaft and install by SOFTLY

tapping with a small hammer until pinion gear and motor shaft

are flush. The best way to do it, if you have enough force, is to

push the pinion on the shaft by hand, see the drawings below.

Nut M2

Body

Hit slightly with the hammer,

do not hit the terminals!

OR BETTER:

Push the gear on the shaft

with your hands.

The shaft must be fully

pushed into the gear !

7

Page 8

English

Step 4: Motor assembly

For the motor assembly you need:

1 pc. Motor of step 3

1 pc. Motor holder

2 pcs. Screw M2.3 x 6

Motor

Screw M2.3 x 6

Motor holder

Step 5: Installing the motor holder

To install the motor holder you need:

1 pc. Motor holder of step 4

1 pc. Body of step 2

4 pcs. Screw M2 x 8

4 pcs. Nut M2

Assemble the motor holder as shown on

the drawing:

Install the motor on the holder as shown on

the drawing:

Screw M2 x 8

nut M2

After this step,

we will name the partially assembled body: CHASSIS!

8

Page 9

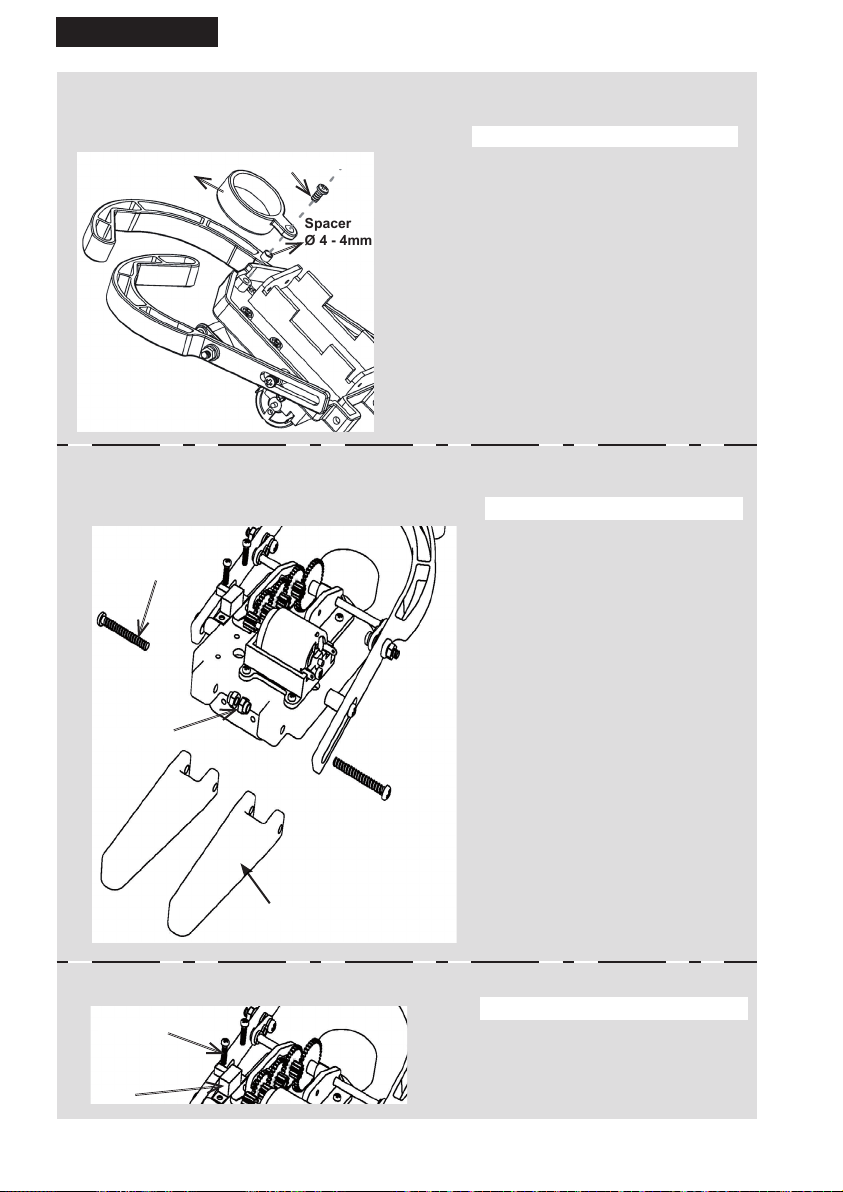

Spacer

Ø 4 - 4mm

Spacer

Ø 4 - 6mm

English

Step 6: Installing the arms

Assemble the arms as shown on the drawing:

Lock nut M3

Screw middle

M3 x 14

Crank

Crank

Screw roundhead

with flange M3 x 10

NOTICE!

Assemble the cranks 180 degrees.

Details are shown on the drawing!

To install the arms you need;

1 pc. Chassis of step 5

2 pcs. Arm

2 pcs. Crank

2 pcs. Spacer Ø 4 - 4mm

2 pcs. Spacer Ø 4 - 6mm

2 pcs. Screw middle size M3 x 14

2 pcs. Lock nut M3

2 pcs. Screw roundhead with

flange M3 x 10

Lock nut M3

Step 7: Installing the battery holder

Flathead screw

countersunk M3 x 6

For the battery holder installation

you need:

1 pc. Chassis of step 6

1 pc. Battery holder

2 pcs. Flathead screw

Countersunk M3 x 6

Battery holder

Install the battery holder as

shown on the drawing:

9

Page 10

Spacer

Ø 4 - 4mm

English

Step 8: Installing the head

Install the head as shown on the drawing:

Head

Screw M3 x 10

Step 9a: Installing the legs

Install the legs as shown on the drawing:

Screw M3 x 24

To install the head you need:

1 pc. Chassis of step 6

1 pc. Head

1 pc. Screw roundhead M3 x 10

1 pc. Spacer Ø 4 - 4mm

To install the legs you need:

1 pc. Chassis of step 8

2 pcs. Leg

2 pcs. Screw long M3 x 24

2 pcs. Lock nut M3

10

Lock nut M3

Leg

Step 9b: Installing the switch

Screw M2 x 5

Switch

To install the switch you need:

1 pc. Chassis of step 9a

1 pc. Switch

2 pcs. Roundhead screw M2 x 5

Page 11

Roundhead screw

M2,3 x 6

Gearbox cover

English

Step 10: Final assembly

Install the gearbox cover as shown on the drawing:

Step 11: The wiring diagram

For the final assembly you need:

1 pc. Chassis of step 9b

1 pc. Gearbox cover

3 pcs. Roundhead screw M2,3 x 6

Connect the wires as shown on picture.

Check the wiring carefull, it should exactly look the same like the drawing below:

11

Page 12

English

Step 12: Inserting the batteries

Place the batteries as shown on the picture:

The way the motor rotates is depending on

the polarity of the batteries!!

Last step: Practice test

Place the Rope Dancers arms around the

rope as shown on the picture and put

the switch in the ON position.

If the Rope Dancer does not move forward, change the polarity of the

batteries!

If the motor does not move at all check:

- Batteries: Are they FULL?

- Wiring: See page 11

- Gears: See page 7

Most likely problems are gear assembly

or poor batteries.

Worst case is that you have to

disassemble the Rope Dancer and

build it all over again.

Let op !

Monteer de vlakke

kant van de motoras

op de juiste manier.

12

Page 13

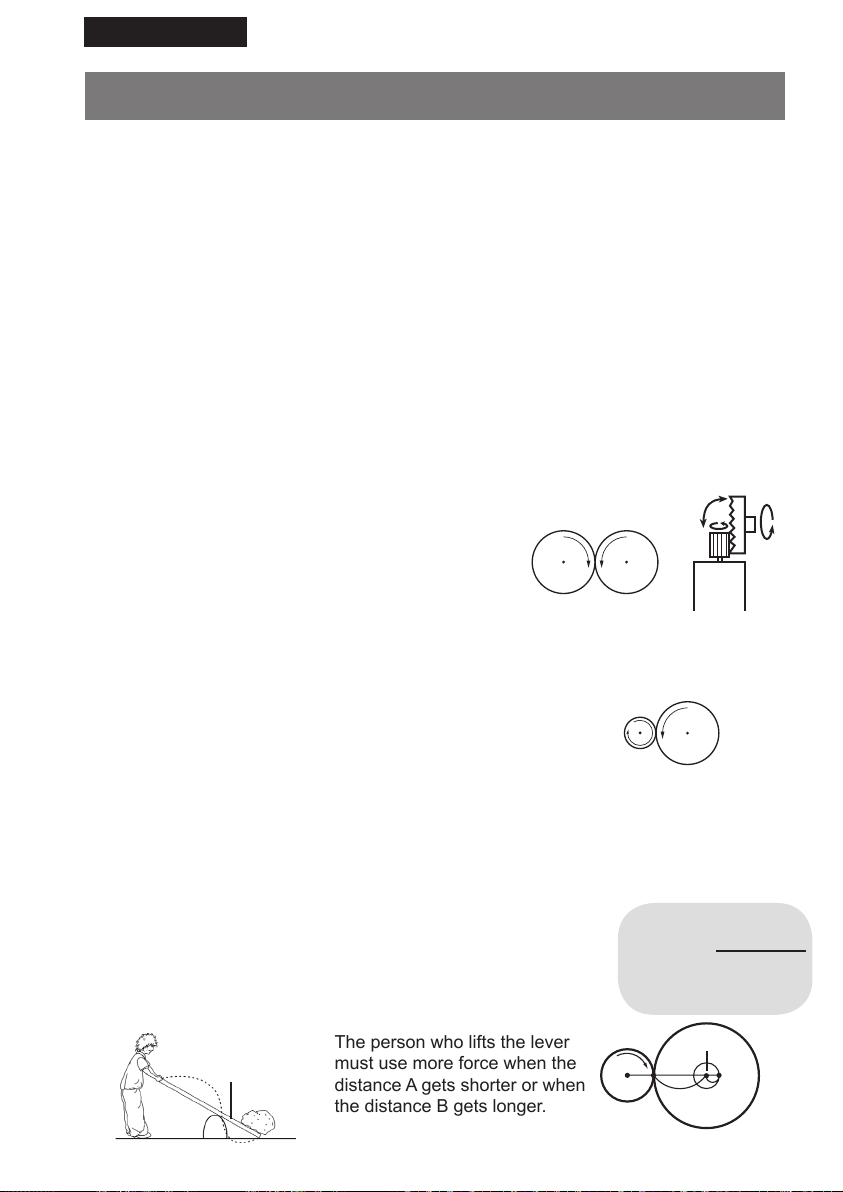

The person who lifts the lever

must use more force when the

distance A gets shorter or when

the distance B gets longer.

English

4. GEARS INFORMATION

The mechanics of the Rope Dancer consists of two parts. The first part is the gearbox,

which takes care that the power from the motor shaft is converted to the crank. The

second part is to convert the rotation of the crank into a movement of the arms.

Transmission of power

Gears, transmission belts, shaft, crank, chains: They all can transmit power. In the

Rope Dancer, four gears transfer the motor power into the crank. Such a transmission

is called a gearbox. The Rope Dancer motor rotates very fast with only a little torque.

However, for the crank we need low rotation speed and high torque. The power is

transmitted by the teeth of the gears. At the same time, three conversions take place:

a. Change in rotating direction

b. Change in rotating speed

c. Change in torque

a. Change in rotating direction

When two gears are connected, there will be a change

in rotation direction. One gear will rotate clockwise,

the other gear will rotate counter-clockwise.

Left rotation

Right rotation

90º

b. Change in rotating speed

The change in rotating speed depends on the relation of the

teeth in the gear. As an example we describe a gear with 10

teeth and a gear with 40 teeth. When the first gear

(10 teeth) makes a full rotation, the second gear (40 teeth)

only makes a quarter of a rotation. So before the second

gear makes a full rotation, the first gear already makes four

rotations. You may understand that this effect also changes the

rotating speed.

c. Change in torque

The torque can be seen as a lever construction with a

fulcrum. Imagine a person who lifts a stone with a lever.

Lever

A

Fulcrum

B

40

Teeth

10

Teeth

Motor rotation

Rotation =

Ratio Rotation last

gear

Fulcrum

B

A

Page 14

English

5. MOTORS

Explanation of motors:

There are many things around us in which motors are used. For example, a mobile

phone uses a motor for the vibration mechanism. A fan inside of a hair dryer is turned

by a motor. Motors are also being used to turn the wheels of a train.

If there were no motors in the world, our present life would not be as

it is.

5.1 History of motors

The prototype of the first electric motor was made by an English physicist, Michael

Faraday, in the beginning of the nineteenth century and was based on the discovery

of electromagnetic induction. Faraday noticed that when electricity ran into a generator

which had the same structure as a motor, it started to turn. On account of the fact that

the generator was invented earlier than the electric motor, this story is probably true.

Around the same period, an American physicist, Joseph Henry, was also working on a

prototype electric motor. However, because Faraday made his research presentation

earlier, he is regarded as the inventor of the motor.

5.2 Motor mechanisms

Electric motors turn by using the power of two different kinds of magnets. One is a

regular magnet (permanent magnets), which you know as a magnet. The other is the

electromagnet which is made by running the electric current through it. Both types of

magnets have north and south poles. The polarity of permanent magnets will not

change; The polarity of electromagnets will switch when the

electric current flow changes direction. Both types of magnets

have the characteristic that like poles they attract each other,

and unlike poles they repel each other.

N

S

N

S

How are magnets used in motors? Common DC motors in small sized plastic

models, such as the Rope Dancer, consist of the following items: permanent magnets,

turning axles, electromagnet cores wrapped with enameled wire, commutators to

change the direction of electric current flow of the electromagnets and brushes to make

contact with commutators. When the electric current is running to the motor from the

outside, the core becomes magnetized.

Then the core starts turning because of

attraction and repulsion, which are created

by the polarity of the electromagnet and the

permanent magnets around it. When the

electromagnet’s south and permanent magnet’s north

attract each other, the core would stop. However, the

electric current flow inside the electromagnet will be

reversed by the commutator. As a result, the electromagnet’s polarity will become the same as the permanent

magnet. Since like poles repel, the core will turn again.

By repeating this cycle, the core will continue to turn. The

axle of the motor is attached to the core and will rotate

as the core turns.

N

S

S

N

14

Loading...

Loading...