Page 1

Design Soccer Robot

SOCCER ROBOT

MANUAL: Model SR-129

© AREXX - THE NETHERLANDS 2006

- 1 -

Page 2

Contents

1. Product information SOCCER ROBOT 3

2. Tools 4

3. Parts list 6

4. Assembly instructions 8

5. Final assembly 18

6. Troubeshooting 18

7. SOCCER ROBOT game 19

8. How does the SOCCER ROBOT move 19

9. Information about gears 20

© (April 2006, Manual): AREXX Engineering (NL).

All rights reserved. Reprinting any part of this manual is strictly forbidden without the written approval of the

European Importer:

AREXX Engineering - Zwolle (NL).

Manufacturer and Dealer are not responsible for the consequences of improper use, assembly mistakes and or

operation of this product as a result of ignorance of this manual. If necessary, the contents of this manual can be

changed any time without prior notice.

European Importer:

AREXX Engineering

ZWOLLE The Netherlands

© AREXX - HOLLAND & CHINA

- 2 -

Technical support:

WWW.AREXX.COM

Page 3

1. PRODUCT INFORMATION SOCCER ROBOT

Play your own World Championships of Soccer Robots!

Before the games begin, first you have to assemble the SOCCER ROBOT.

When the SOCCER ROBOT is ready, you can start your own Soccer

Championships. First however, an extensive training is necessary because it

is not so easy to control this funny, six-legged robot. The controller has two

switches to control the two motors. These two motors send the robot in any

direction you like.

The performances of this fast robot will certainly appeal to you. In this manual

we will show you all robot movements, so you really will get to know the

functions of this SOCCER ROBOT.

Specications:

Power voltage : 3V (2 Penlite Batteries of 1,5V

(Batteries are not included in this kit)

Power consumption : Approx. 300 mA max

Height : 100 mm

Length : 160 mm

Width : 90 mm

Cable length controller : 1.5 meter

Warning

* When you open the plastic bags of the parts the return right is no longer valid

* Before you start assembling, first read the complete instruction manual

* Be careful with tools and always keep them away from little children!

* Keep this product out of reach of children and do not build this kit when children are

in the neighbourhood, the tools and parts are dangerous for children

* Check the polarity of the batteries when you insert them

* Keep the batteries dry and when the robot gets wet, remove the batteries and let the

soccer robot dry for some time

* Remove the batteries when you are not using the robot for a longer period

- 3 -

Page 4

2. TOOLS

We strongly suggest to read this chapter rst before assembling the product

Assemble the robot in the exact order as described in this manual. This way you will

avoid assembly mistakes. If you assemble in the correct order and study the picture on

the packaging so now and then, you will build a perfectly functioning robot in no time.

All parts fit perfectly, so there is absolutely no need to use force. Work calmly and read

the complete manual before you start to assemble this robot.

Small hammer

With the correct tools

you already solved

half the job!

Long nose plier

Detaching parts from a frame

Assembly of shafts and gears

Screwdriver set

Always use the correct size

for each screw

We recommend to use electronic pliers (150 mm).

When a part is fixed to a plastic

frame you have to detach it with

a diagonal cutter or ahobby knife.

Make sure that you do not cut in the

part itself and remove all burrs neatly.

Important !

Do not detach parts from the

frame before you need them.

Be always very careful when you assemble shafts and

gears. When possible always try to push the gear on the

shaft with your hands. When you need to use a hammer,

always put a piece of wood between the hammer and the

gear or shaft, so you do not damage things.

- 4 -

Page 5

Self-tapping screws (Parker)

thickness

A self-tapping screw looks similar to a wood screw.

When you screw it in a hole, it can cut the threads

at the same time. Never try to screw it down all the

way for a first time, because it may easily become

stuck or you will damage its head.

Tapping screws always have a sharp point

sometimes with a small carve. The best way

is to screw it in and out a bit.

1 Screw in

2 Screw out a bit

3 Screw in further and continue

step 1 and 2

Do not screw a tapping screw in and out to often because the screw hole may become

enlarged and the screw will loose all grip and proper function.

Screws and nuts

Nut

Length

Lock nut

In a moving environment, screws and nuts must be tightened properly. A lock nut is a

special nut with nylon inside which will lock itself automatically.

Another easy way to lock a screw is to use ordinary fingernail polish. A big advantage

of nail polish is that you always can loosen it quite easily again. A professional way to

lock a screw is to use for example locktite a sort of glue especially made for screws,

but it is very difficult to unlock such a screw afterwards.

The size of a screw is expressed by thickness and length. A screw with the marking M2 x 10

means 2mm thick. The length of the thread is 10mm. A M2 nut means it is used for a M2 screw

so the nut always corresponds with the screw thickness.

Lock nut fixation

To lock the lock nut in a proper way, use a plier or

the spanner which is supplied in this kit.

See drawing on the left!

- 5 -

Page 6

3. PARTS LIST SOCCER ROBOT

Please check all parts before you start assembly:

Self-tapping screw

M2,3 x 5 2 pcs.

M2,3 x 8 2 pcs.

Screw short

M3 x 10 4 pcs.

Screw small

Screw middle

M3 x 20 2 pcs. M3 x 35 3 pcs.

M2 Nut

M3 Nut

Screw long

Lock nut

M2,6 x 6 5 pcs.

Pinion gear Flatspur gear

2 pcs.

Motor holder Crank

2 pcs.

Spacer 5mm

with pinion

2 pcs.

2 pcs.

Spacer 10mm Spacer 25mm Shaft 85mm

M2 x 0,5 8 pcs.

Flatspur gear

with boss

2 pcs.

Spring washer

M2

10 pcs.

14 pcs.

Collar nut

6 pcs.

9 pcs.

Crown gear

with pinion

2 pcs.

Hexadiagonal tool

1 pcs.

Washer M3

2 pcs.

Motor

2 pcs.

Wrench

M2 & M3

1 pc.

Spring washer

M3

4 pcs.

Ball

6 pcs.

Screw shaft for leg

2 pcs. 1 pc. 2 pcs. 2 pcs.

2 pcs.

Screw shaft

thick

Screw shaft

thin

- 6 -

2 pcs.

6 pcs.

Shaft 22mm Cable holder

2 pcs.

4 pcs.

1 pc.

Page 7

Side panel

Controller top

Controller bottom

2 pcs. (Left and Right)

Leg

middle

2 pcs. 4 pcs. 4 pcs.

Battery holder

1 pc.

Felt

Leg

front and rear

Cable set Switch PCB

1 pc. 1 pc.

1 pc. 1 pc.

Foot

6 pcs.

Sticker

Joint strip

Kicker

1 pc.

1 pc.

- 7 -

1 pc.

Page 8

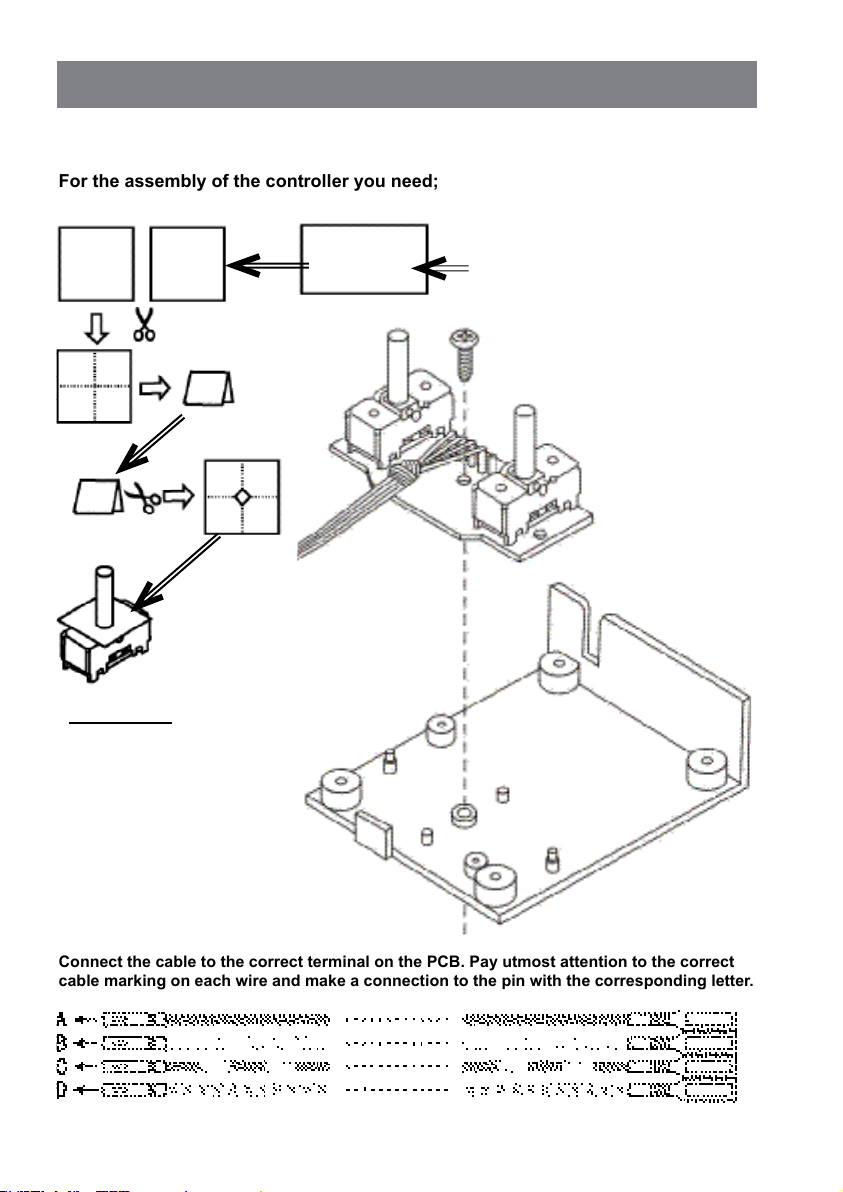

For the assembly of the controller you need;

4. ASSEMBLY INSTRUCTIONS SOCCER ROBOT

Connect the cable to the correct terminal on the PCB. Pay utmost attention to the correct

cable marking on each wire and make a connection to the pin with the corresponding letter.

Controller assembly

WARNING:

Do NOT put the batteries into the

battery holder yet. Wait until the

robot is completely assembled.

When you create a short cut and

the batteries are already placed,

you can start a fire or get hurt by

the extreme heat of the

batteries.

1 pc. Felt

1 pc. Switch PCB

1 pc. Cable set

1 pc. Controller bottom

1 pc. Tapping screw 2.6x6mm

To make a felt cover for the switches,

please follow the arrows.

Attach the PCB to the controller bottom

with the tapping screw 2.6x6

- 8 -

Page 9

Final assembly of the Controller :

For the final controller assembly you need;

Install the battery bottom with the

4 tapping screws M2.6 x 6mm.

Attach the sticker

Finally, we install the

battery holder with the

2 tapping screws

M2.3 x 8mm

The completed

CONTROLLER

Connect the battery wires to the correct

+ and - terminals on the PCB (see drawing)

and PCB marking.

Black = - (Blk)

Red = + (Red)

Assemble the controller as shown on the pictures blow

and in numerical order

:

1 pc. Assembled controller bottom

1 pc. Battery holder

2 pcs. Tapping screw 2.3x8mm

1 pc. Controller top

1 pc. Sticker

4 pc. Tapping screw 2.6x6mm

IMPORTANT

Be sure that the cables are guided

through the correct holes.

Motor cable

Battery cable

- 9 -

Page 10

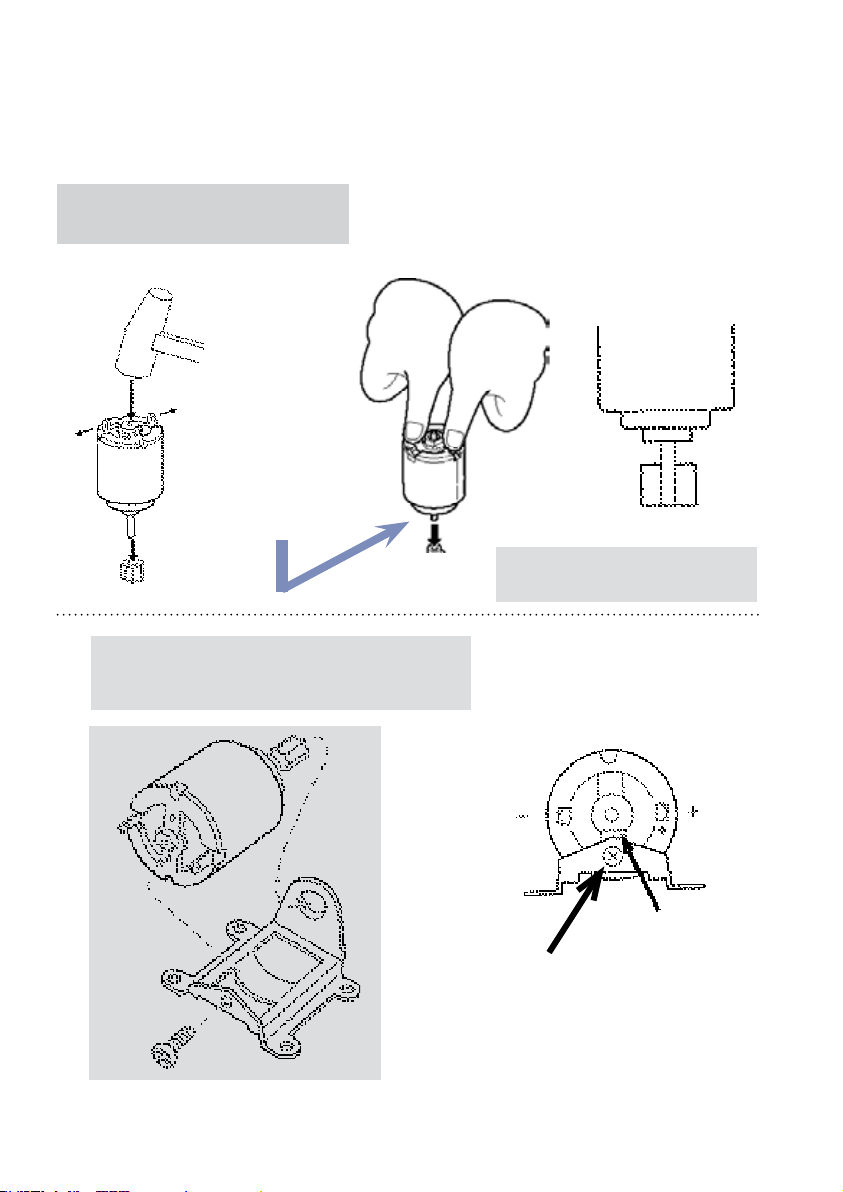

Assembly of the motors:

To assemble the motors you need;

2 pcs. Motor

2 pcs. Pinion gear

2 pcs. Motor holder

2 pcs. Tapping screw M2.3 x 5mm

Assemble the gear to the motor shaft as

shown on the picture below.

MAKE 2 SETS!

Hit slightly with the hammer,

do not hit the terminals!

OR BETTER:

Push the gear on the shaft

with your hands.

Be careful not to damage the gear or motor shaft.

When you use a hammer, be very gentle and put a piece

of wood between hammer and gear or better use a plastic

hammer. Best way is to push the gear on the shaft with your

hands.

Attach the motors to the motor holder with a tapping

screw M2.3 x 5 mm.

MAKE 2 SETS!

The shaft must be fully pushed into

the gear !

- 10 -

Flat part is faced down

Be sure the motor is fixed

properly with the 2.3 x 5 mm

tapping screw.

Page 11

Assembly of the side panels:

For the assembly of the side panels you need;

ATTENTION

Screw the lock nuts real tight!

Keep the lock nut in position by holding it with a plier

or a well-fitting spanner

Shaft

3x22mm

Screw long M3x20

2 pcs. Side panel L&R

2 pcs. Gear with boss

2 pcs. Crank

2 pcs. Shaft 3x22mm

2 pcs. Spacer 5mm

2 pcs. Screw shaft (thick)

2 pcs. Screw shaft (thin)

2 pcs. Lock nut

2 pcs. Screw long M3x20

4 pcs. Nut M2

Make two sets

Crank

Crank

Spacer 5mm

Shaft

3x22mm

Crank

First please read page 5 how to screw a lock nut.

Make 2 sets.

Assemble the left panel in the

same way as the right panel.

Nut

M2

The boss

is on the

other site

Big hole

Gear with boss

Lock nut

Screw shaft thick

Screw shaft thin

- 11 -

Page 12

Assembly of the gears:

For the assembly of the gears you need;

Asssemble the gears and motor as shown on the

drawing below.

Assemble in numerical order.

4 pcs. Screw M2 x 5mm

2 pcs. Assembled side panels L & R

2 pcs. Flat spur gear with pinion

2 pcs. Crown gear with pinion

8 pcs. Screw M2

8 pcs. Nut M2

8 pcs. Spring washer M2

2 pcs. Screw shaft long

2 pcs. Washer M2

2 pcs. Nut M2

Washer M2

Screw shaft

long

Nut M2

4 pcs. Spring washer

Flat spur gear

Crown gear

4 pcs. Nut M2

Assemble the left and right side in the same way

MOTOR

- 12 -

Page 13

Final side pannel assembly:

For the final side panel assembly you need;

3 pcs. Screw M2 x 32mm

Spacer 10mm

2 pcs. Spacer 25mm

Kicker

2 pcs. Assembled side panel L and R

3 pcs. Screw M3 x 32mm

5 pcs. Nut M3

2 pcs. Spacer 25mm

2 pcs. Spacer 10mm

1 pcs. Cable holder

1 pcs. Kicker

Cable holder

2 pcs. Nut M3

Spacer 10mm

Attach the two side

panels together.

After this step we will name this assembled part the CHASSIS.

- 13 -

Top view

3 pcs. Nut M3

Page 14

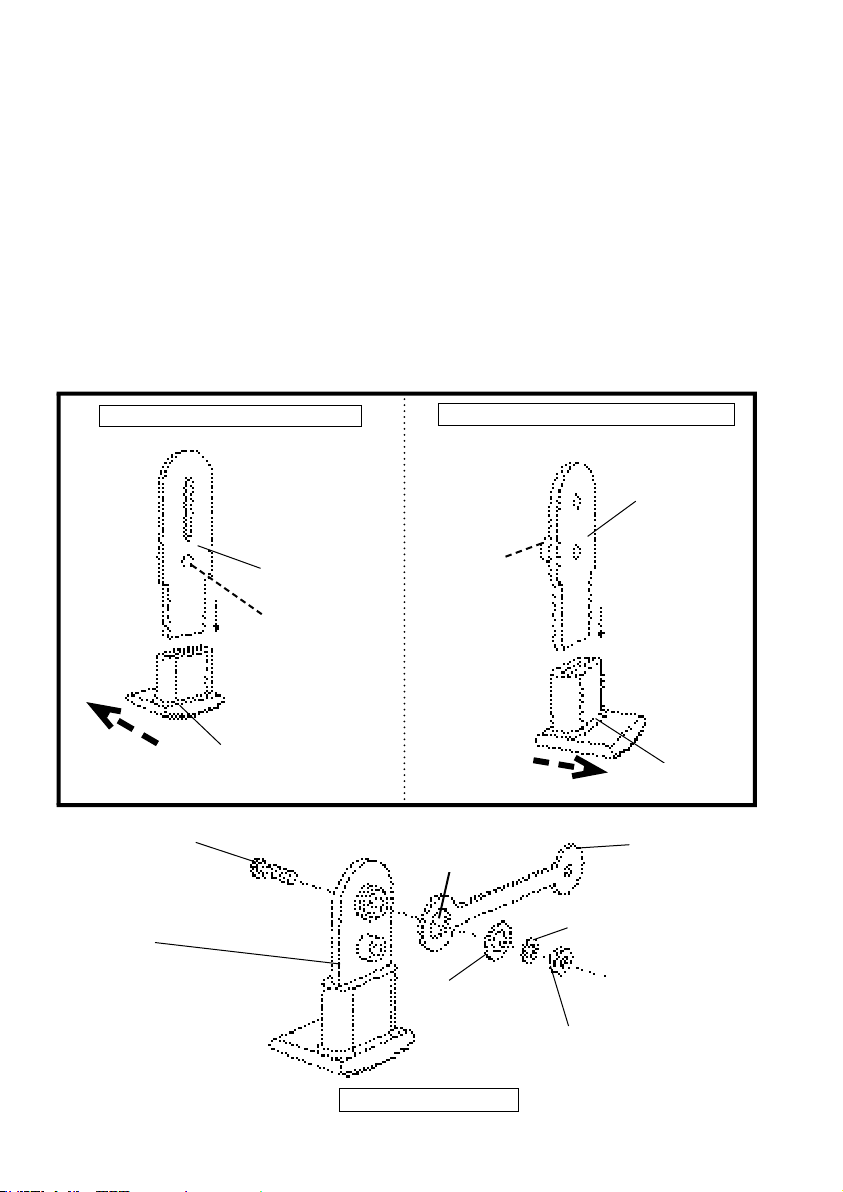

Leg assembly:

For the leg assembly you need;

Assemble the parts as shown on the drawings below:

6 pcs. Rubber feet

4 pcs. Leg short (front and back)

2 pcs. Leg long (middle)

4 pcs. Screw M3 x 10mm

4 pcs. Nut M3

4 pcs. Spring washer M3

4 pcs. Washer M3

4 pcs. Joint strip

Assemble 2 middle legs:

!

Screw M3

Front and

rear leg

Middle leg

(long)

Boss on

other side

Rubber Feet

Make 4 sets in total (2 front & 2 rear):

Boss on

this side

!

Large hole !

Spring washer M3

Washer M3

Front and rear

legs

(short)

Rubber feet

Joint strip

Make 4 sets

- 14 -

Nut M3

Page 15

Assembly of the front legs:

Front leg

Shaft 85mm

Spacer 5mm

Joint strip

Collar

Spacer

10mm

Spacer 5mm

Spacer 10mm

Collar

Collar screw

Front leg

For the assembly of the front legs you need;

Assemble the front legs on the left side and right side as shown

on the drawing. Also notice the small detail-drawing!

The assembly of the front legs is

for the left and right side exactly

the same.

1 pc. Chassis

2 pcs. Assembled front leg

2 pcs. Shaft 85mm

2 pcs. Spacer 5mm

2 pcs. Spacer 10mm

2 pcs. Collar

- 15 -

Page 16

Assembly of the rear legs:

Shaft 85mm

Spacer 10mm

Joint strip

Spacer 5mm

Collar

Collar

For the assembly of the rear legs you need;

1 pc. Chassis

2 pcs. Assembled rear leg

1 pc. Shaft 85 mm

2 pcs. Spacer 10mm

2 pcs. Collar

Rear leg

- 16 -

Page 17

Assembly of the middle legs:

Assemble the middle legs to the left and right side as shown on the drawings:

THE COMPLETED

SOCCER

ROBOT!

Washer

Washer

Collar

Collar

For the assembly of the middle legs you need;

1 pc. Chassis

2 pcs. Middle leg

2 pcs. Washer M3

- 17 -

Page 18

5. FINAL ASSEMBLY

Wiring of the motors

IMPORTANT: Please check the correct marking on the wires!

Notice the correct polarity (+ & -) of the controller cable:

A = + Rear motor

B = - Rear motor

C = + Front motor

D = - Front motor

+

+

-

Battery installation

Insert the batteries into the battery holder.

Notice the correct polarity (+ & -) of the batteries.

6. TROUBLESHOOTING

Problem: Check:

The motors are not running.

No leg movement.

The robot movements do not correspond

with the controller

• Check the batteries, are they really full

• Check the battery polarity (+ and -).

• Check the wires on the switch PCB.

• Check the wires on the motors.

• Check the gears and especially the lock nuts

(tighten them a bit more or less).

• Check the side panels, all gears and their position

(rotate motor pinion by hand).

• Check all wire markings and connections

• Change motor wire + & - so they will rotate in reverse.

• Change motor wires from front motor to rear motor

Finally pass the wires

through the cable holder

- 18 -

Page 19

7. SOCCER ROBOT GAME

In this chapter we describe some soccer robot games you can play:

SOCCER FIELD

A great field for our game is a ping pong table (table

tennis table). Make some fences around it and make

goals for both sides. Now you can a game with 2

robots or when you have only 1 robot try to make as

many goals as you can in 5 minutes.

SOCCER GAME

First make teams with 1 or 2 players and shoot the ball in the opponents goal as often as

possible during a certain period of time.

SOCCER POOL GAME

For this you need about 10 table tennis balls. Try to shoot as many goals as possible in

5 minutes of time using all balls. You also can number the balls and try to make a the highest

score counting the numbers on the balls!

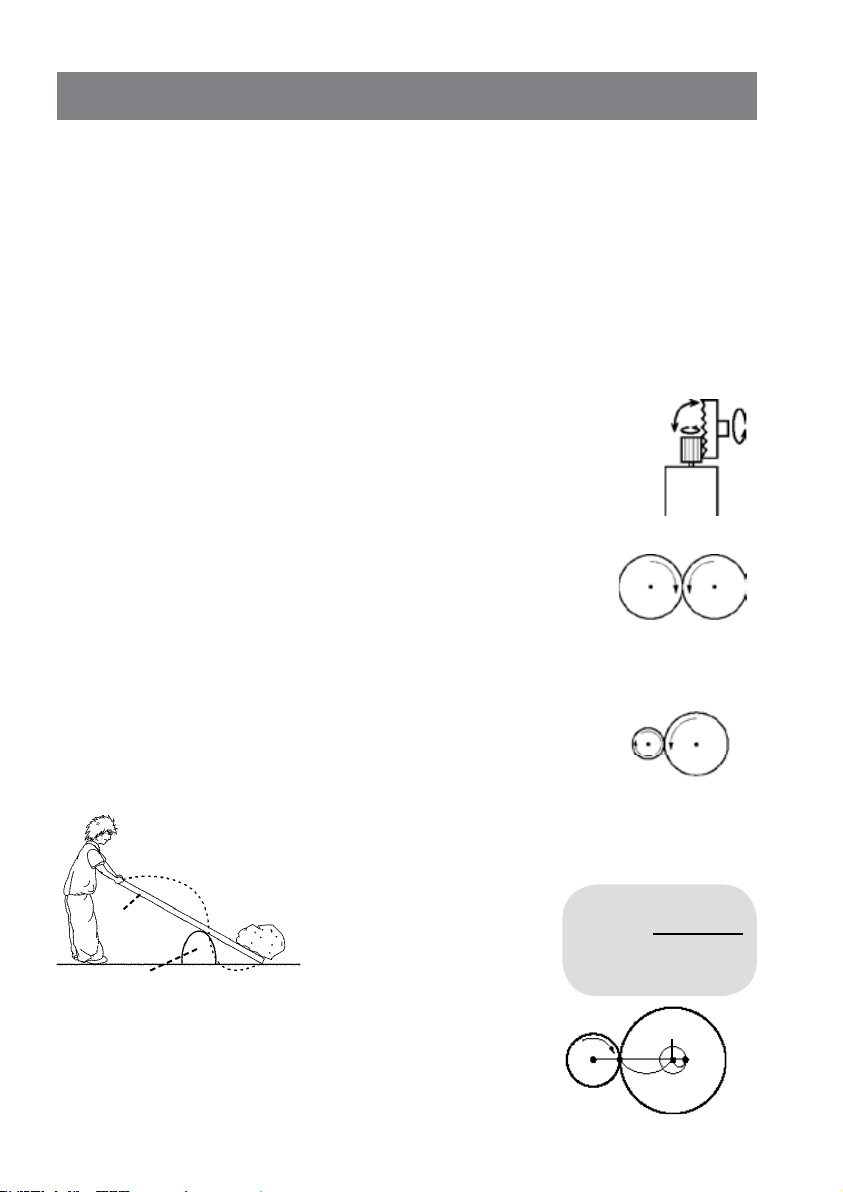

8. HOW DOES THE SOCCER ROBOT MOVE?

On the next page you find some background information about gears. Here we explain how the

soccer robot can walk with his six feet.

Crank Mechanism

Crank

Joint

strip

When the robots does not function well yet or when the gears do not have a good grip, please

check the troubleshooting table on page 18. Please check all assembly steps again.

When your robot still does not function well, just take it apart and assemble it again. Check and

double check all assembly steps by studying each drawing. This way you might find the problem.

The SOCCER ROBOT can walk because of the

presence of the crank. The crank converts a

rotational movement into a reciprocating movement.

The robot is constructed in a way that the front and

rear legs only make a forward and backward

movement.

The middle leg is designed to make a vertical slide

movement, the crank circular movement is directly

Leg

conveyed to the toe of the middle leg.

So when the middle leg goes up, the front and back

legs go backwards and the robot moves forward.

- 19 -

Page 20

9. INFORMATION ABOUT GEARS

The mechanics of the SOCCER ROBOT consists of two parts. The first part is the gear

box, which takes care that the power from the motor shaft is converted to the crank.

The second part is to convert the rotation of the crank into a movement of the feet.

The transmission of power

Gears, transmission belts, shaft, crank, chains: They all can transmit power.

In the soccer robot four gears transfer the motor power into the crank. Such a transmission is called a gear box. The power is transmitted by the teeth of the gears. At the

same time three conversions take place:

a. Change in rotating direction

b. Change in rotating speed

90º

c. Change in torque

a. Change in rotating direction

When two gears are connected, there will be a change in rotation direction. One gear will rotate clockwise, the other gear will rotate counterclockwise.

Clockwise

Counter

clockwise

b. Change in rotation speed

The change in rotating speed depends on the relation of the teeth in

the gear. As an example we describe a gear with 10 teeth and a gear

with 40 teeth. When the first gear (10 teeth) makes a full rotation, the

second gear 40 (teeth) only makes a quarter of a rotation. So before the second gear

makes a full rotation, the first gear already makes four rotations. You may understand

that this effect also changes the rotating speed.

c. Change in torque

The torque can be seen as a lever construction with a

fulcrum. Imagine a person who lifts a stone with a lever.

10

Teeth

The person who lifts the lever

Lever

Fulcrum

A

B

must use more power when the

distance A gets shorter or when

the distance B gets longer.

Motor rotatio

Gear ratio =

Number of

last gear rotation

40

Teeth

This is about the same for gears. The power on the teeth

increases on the inner side of the gear. For that function

we are using spur gears.

- 20 -

Fulcrum

A

B

Loading...

Loading...