RP6-JM03-61

RP6 SENSOR BOARD

RP6 Sensor board

©2013 AREXX Engineering and JM3 Engineering

www.arexx.com

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 1

Impressum

©2012 AREXX Engineering

Nervistraat 16

8013 RS Zwolle

The Netherlands

Tel.: +31 (0) 38 454 2028

Fax.: +31 (0) 38 452 4482

This manual is protected by the laws of

Copyright. It is forbidden to copy all or part

of the contents without prior written

authorization!

Product specifications and delivery contents

are subject to changes. The manual is

subject to changes without prior notice.

You can find free updates of this manual on

http://www.arexx.com/

“RP6 and AREXX” are registered trademarks from AREXX Engineering.

All other trademark are the property of their owners. We are not responsible for

the contents of external web pages that are mentioned in this manual!

Information about limited warranty and responsibility

The warranty granted by AREXX Engineering is limited to the replacement or repair of the

Module and its accessories within the legal warranty period if the default has arisen from

production errors such as mechanical damage or missing or wrong assembly of electronic

components except for all components that are connected via plugs/sockets.

The warranty does not apply directly or indirectly to damages due to the use of the robot.

This excludes claims that fall under the legal prescription of product responsibility.

The warranty does not apply in case of irreversible changes (such as soldering of other

components, drilling of holes, etc.) of the module or its accessories or if the module is

damaged due to the disrespect of this manual!

It cannot be guaranteed that the supplied software will satisfy individual expectations or

will run completely error-free and without any interruption. Moreover the software can be

freely changed and is loaded into the unit by the user. Therefore the user carries the full

risk regarding the quality and performance of the unit including all software.

AREXX Engineering guarantees the functionality of the supplied application examples

provided the respect of the conditions specified in the data sheet. If the SAM-04-LAN or the

PC software turns out to be faulty or insufficient, the customer carries all costs for service,

repair or correction.

Please note the relevant license agreements on the CD-ROM!

The exclamation mark attracts the attention of the user to important

instructions that must be adhered to. If you make a mistake in this part, it

can lead eventually to the destruction of the robot or its accessories and

even endanger your health or that of your environment!

The "Information" symbol draws the attention to useful tips and tricks or

background information. It is not always essential to understand

everything but it is often very useful.

Symbols

The manual uses following symbols:

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 2

Safety recommendations

IMPORTANT:

Prior to using this robot arm for the first time, please read this manual thoroughly up to

the end! They explain the correct use and inform you about potential dangers! Moreover

they contain important information that might not be obvious for all users.

- Check the polarity of the batteries or power supply.

- Keep all products dry, when the product gets wet remove the power directly.

- Remove the batteries or power when you are not using the product for a longer period.

- Before taking the module into operation, always check it and its cables for damage.

- If you have reason to believe that the device can no longer be operated safely,

disconnect it immediately and make sure it is not unintentionally operated.

- Do not operate the module in rooms or under unfavourable conditions.

- This module is equipped with highly sensitive components. Electronic components are

very sensitive to static electricity discharge. Only touch the module by the edges and

avoid direct contact with the components on the circuit board.

Normal use

This module is developed to use with robots, which allows you to determine basic behaviour patterns and

reactions of the robot to external influences yourself.

The module was developed as an experimental platform for all electronic technicians with interest in robotics. In

practical tests, it visualises the influence and effects of software parameters as well as physical parameters via

the corresponding sensor technology. Any use other than that described above is not permitted.

The product is not a toy and should be kept out of reach of children under 14 years of age! It may only be used

in closed, dry indoor rooms. The product must not get damp or wet. Use other than that described above can

lead to damage to the product and may involve additional risks such as short circuits, fire, electrical shocks etc.

Content

Impressum 2

Safety recommendations 3

Robot configuration with the RP6 Sensor Board 4

Introduction 5

Manual 6

Circuit 19

PCB layout 23

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 3

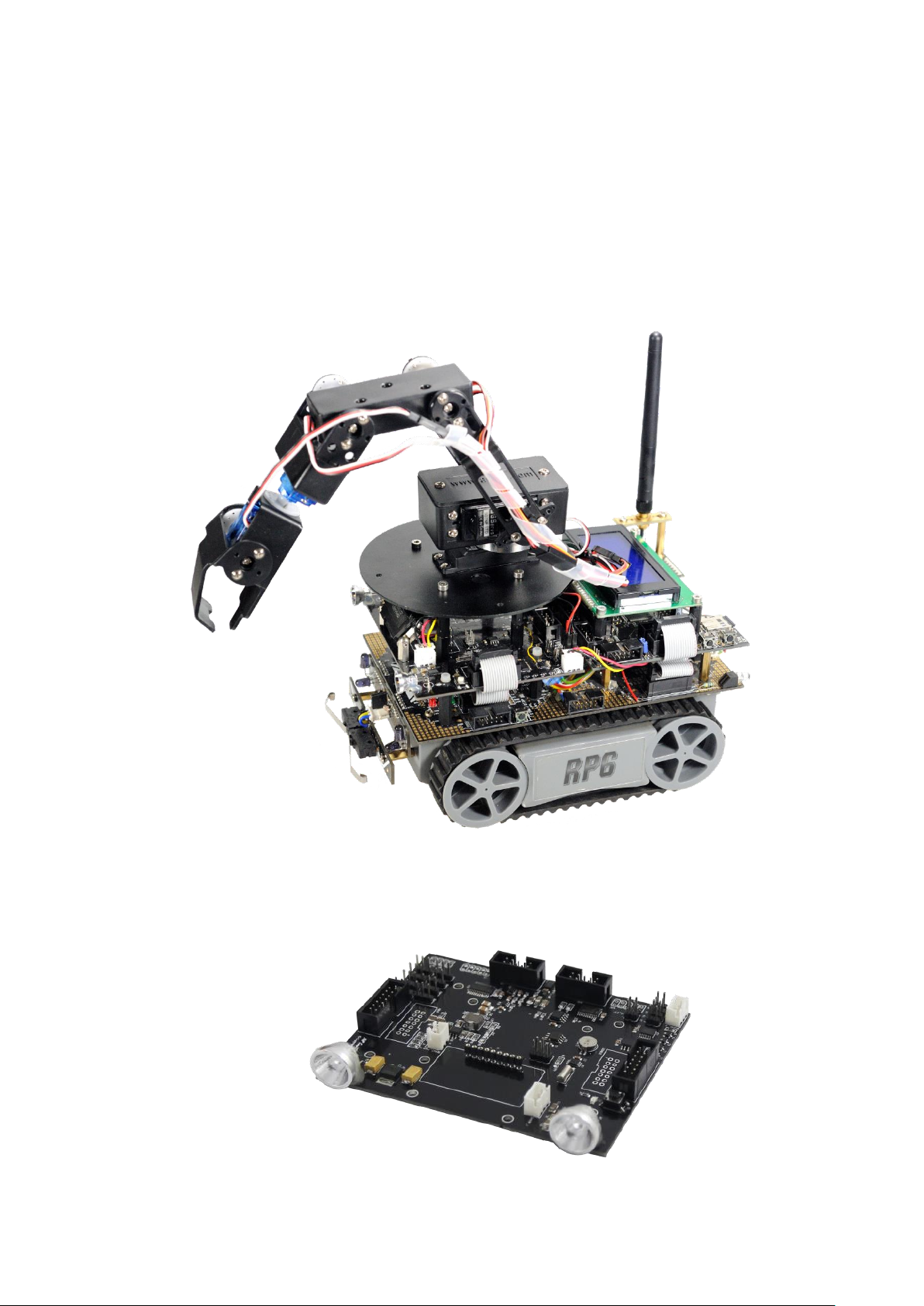

RP6V2/RP6WIFI – RP6_Sensor&I/O Board

Picture shows the RP6 with RP6WiFi Control board, the RP6_Sensor&I/O Board, Sharp Sensor

and a part of the AREXX Robot Arm RA2-HOBBY.

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 4

Introduction

What can I do with the RP6_Sensor&I/O Board?

The RP6_Sensor&I/O Board enables all versions of the RP6 Robots, but it is primarily designed for the

RP6V2 and RP6WIFI.

It provides the capabilities to measure signals and gives control over the sensor power consumption.

Together with the RP6V2 and RP6WIFI board you can send sensor data back to the ‘Command Center’

(PC Program) - e.g. compass heading, outside temperature, pitch & role angle. You can also command

new headings e.g. turn by 20°to left side.

The Servo Controller can drive up to 8 servos to command e.g. a Robot Arm (picture see front page),

which can be mounted on the IO Board. A switched regulator (5V 3 Amp.) can be switched on and off

by software.

The Sharp sensor measures distances very accurate, e.g. for autonomous route decision – or if it looks

downwards you can detect stairs or the table edge. There are two interfaces available, e.g. one at the

front and one at the rear.

The LED controller can control the brightness of the head LEDs and the Rear LED (if installed). Blinking

of the LEDs in case of turning to the right or left side is also easily possible.

The RTC can generate an interrupt waking up the RP6 at a programmed time from a sleep mode.

The yaw rate Gyro tells you if you try to turn into a direction, but you are blocked by obstacles - so you

can modify the strategy case by case turning into the other side

You can also add I2C based small modules (e.g. GPS) to the board which can be switched on/off by

software.

There are many, many new options you can develop for your RP6 – be creative!

Configuration and setup

The I/O board is designed to support best a master / slave configuration of the control board and the

base board, but it is not limited to.

This description provides guidance for the mater/slave configuration. The base board (SLAVE) controls

all drive relevant algorithms like ACS, move control, speed detection, etc. and gets the ‘move’ relevant

sensor input data like Gyro, Sharp-Front and -Rear. The control board (MASTER) gets input from the

sensors, e.g. compass heading and commands turns and speed via I2C to the base board. Commands

received via WIFI from the PC Remote Control Program will be executed to e.g. drive the servos or

switching the light ON or OFF. The RTC time and date can be set via WIFI as well.

From XBUS the board gets the 5V power supply and the I2C bus signal SDA and SCL to control all

functions. In addition, the extension board needs the ‘power-on’ signal from the base board (PWRON).

The analog signals from the Sharp sensor at the Front and Rear (if installed) and the gyro should be

measured by the base board directly. Therefore you need to add 4 wires to the base board (see

description further down in chapter 4). Alternatively, the Sharp Rear sensor analog signal (ADC4) goes

to the RP6WIFI control board (ADC connector PIN3), if this analog input should be used differently, you

can remove jumper J6 to disconnect the signal.

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 5

1.1. Board overview

3.3V regulator

I2C Hotswap

2 Digital-I/O

with GND pins

LED headlight

Distance sensor option

Sharp (front)

Temp. sensor

I2C Expansion modules

e.g. GPS I2C module

Gyro Yaw

LED driver

4 CH Power switch

RTC & recharge-able

battery -Attention – not

user serviceable!

Button & LED

compass

LED output

connectors

Sharp sensor

port (rear)

CAM I2C & PWR

VSS PIN – no short

protection!

ADC -

connector

I/O –

connector

3D Compass

Servo_PWR Input

Attention – no revers

polarity protection!

5.0V regulator

(servo supply)

Servo connectors

8 Ch. PWM OUT

‚Jumper‘

for interrupts

The RP6_Sensor&I/O Board provide multiple possibilities to add ‘sensors’ and actuators to the RP6.

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 6

On board there are:

- 2 x Sharp Sensor ports with power ON/OFF capability (front K5) / rear K3)

- 1 x I2C Expansion module port and 5V power ON/OFF capability MOSFET (K28)

- 8 x Servo output with separate power supply (5V / 3A)and ON/OFF capability

- 8 x PWM outputs

- 1 x CAM interface (CAM_IF) e.g. for a CMUcam3/CMUcam4 and power switch capability

The serial link can be attached to the RP6WIFI board (e.g. UART1).

The header provides an I2c bus interface (hot swap) which can be used for other module

extensions or the planned CAM module with I2C bus.

- I2C hot swap bus (allows to switch off I2C modules, if not needed and save power,

e.g. CAM and I2C extension)

- Temp sensor LM75BD (I2C)

- 1 button and LED (control via s/w)

- 3D Magnetometer / 3D Accelerometer for 3D compass function (I2C)

- Yaw Gyro (analog)

- Real Time Clock with date (rechargeable backup battery) I2C bus (can generate interrupt)

- LED driver I2C bus (smart functions)

2 LED headlights (controlled via LED driver)

2 LED for backlight of RP6 (K10)

Display illumination port (connector K7)

2 LED ports free (connector K2, K4)

- 2 x free Digital I/O lines (input can generate interrupt; connector I/O_EXT)

- Patchfield_1 to get access to I/O lines form Control board

- Patchfield_2 to get access to ADC lines form Control board

- Jumper J2, J3, J4, J5, J6 to disconnect Interrupt lines from connector pins

1.2. RP6 – Setup

The setup for the RP6 mainboard requires two additional steps:

Hint: The changes requiring basic soldering skills!

i. Soldering the header (1 x 8 Pins) into the mainboard.

ii. Connecting power to the Servo

The best is to use a separate battery for the servo power supply (SERVO_PWR), but it

works also from internal battery, if you make a connection with the Power Cable from the

Kit between the 8 Pin header on the mainboard and Servo Power plus on the

RP6_Sensor&I/O Board (JST XH connector).

iii. Then follow the steps from RP6V2 in chap. 1.3 (except Servo power supply)

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 7

1.3. RP6V2– Setup

ADC1

ADC0

1.3.1. Signals to be connected to the mainboard

The following signals need to be wired from the main board if you want to use the signals.

a. ADC0 -> PIN_1 USRBUS1 (Sharp front)

b. ADC1 -> PIN_2 USRBUS1 (Gyro)

c. ADC4 -> PIN_5 USRBUS1 (Sharp rear)

d. PWRON -> PIN_3 USRBUS1

The following options are possible:

i. Connecting the Sharp Front & Rear sensor to ADC0 – in this case you have to switch the

Sharps sensors alternately on (time –multiplex) and read out ADC0. The Gyro sensors will be

read from ADC1.

ii. The RP6V2 provides two connectors to connect analog signals ADC0 and ADC1 to the main

board (see picture below).

Make the wire connection from the USRBUS1 PIN_1 (SHARP_Front) and USRBUS1

PIN_5 (SHARP_Rear) to ADC0 header and the USRBUS1 PIN_2 (Gyro) to ADC1 header.

HINT: To connect both ADC signals from the Sharp sensors will only work, if they

are not powered on at the same time! If you want to use the Sharp sensors in a

different application mode then they should be connected to ADC inputs of the

control board.

iii. Alternatively you can solder wires on the back of the mainboard PCB from USRBUS1 to the

signal of the header – which looks more professional.

Hint: The changes requiring average soldering skills!

Do some soldering test before, if you doesn’t feel well enough with such changes.

It is important to use a soldering iron with a slim tip.

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 8

iv. The PWRON signal is the general enable/disable signal for the MOSFETS.

+UB and GND

Wire from Y3 to PWR

+UB

GND

Make the wire connection from the USRBUS1 PIN_3 to PWR signal on the main board.

HINT: To power a sensor you must select the specific sensor (see chap 3.2 Hardware

Register) and set the PWRON signal to logic 1.

1.4. Servo Power:

The best is to use a separate battery for the servo power supply (SERVO_PWR), but it works also from

internal battery, if you make a connection with the Power Cable from the Kit between the 8 Pin header

on the mainboard and Servo Power plus on the RP6-Sensor&I/O Board.

Hint: For the exact pin out of the 8 pin header please refer to the manual of the

RP6V2.

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 9

2 SW – Package for RP6_Sensor&I/O board working with the RP6WIFI

2.1 C++ and C-Source code support

Together with the RP6_Sensor&I/O board the door into the C++ word has been opened for the

RP6 Robot - and this in an easy way – no worry!

The C++ language is a superset of the C language or vice versa the C++ language is an extension

of the C-language, but more powerful and structured – more rigid in the compiler checks.

All in all it gives a better readable code and better protection against side effects of your software

design (e.g. enums and the use of name space definitions for the modules instead of tons of

#defines) - and of course with C++ you can combine C-code and Assembler-code.

Special advantages, will be given if you have multiple instances of e.g. a device driver like a UART

which saves memory. The developed code is also easier to port to a new system.

The used Extended Embedded C++ excluded by purpose the following C++ features, which

doesn’t make sense on an embedded system:

1.) RTTI

2.) Exceptions

Refer also to: http://www.iar.com/Products/IAR-Embedded-Workbench/Technology/Languagestandards/

The GCC makefile to compile your existing C-Code and the Libs from the RP6V2 or RP6WIFI

board and the C++ code from the Sensor & IO board with examples are included.

The software can be edited and complied with Visual Studio 2010 Express (free download at

Microsoft) – the makefile is included. Other editors can be used as well.

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 10

Here an example how to add in C-code in the C++ world (taken from the Demo Program):

Sensor

Address

LSM303 Accelerometer

0x32

LSM303 Magnetometer

0x3C

MAX7311AUG / TCA9555 IO-Expansion

0x40

TCA6507 LED Driver

0x8A

LM75 Temperature Sensor

0x90

DS1339U Real Time Clock

0xD0

PCA9685 PWM Controller

0x88

/**********************************************************************\

* IO Extension Demo Program

* main.cpp

* v 1.1.0

\**********************************************************************/

extern "C"

{

#include "RP6M256.h"

#include "RP6M256Lib.h"

#include "RP6M256uart.h"

#include "RP6I2CmasterTWI.h"

#include "Yourcode.h" <- include your C-code modules inside 'extern "C"'!

}

#include "ioExt.h" <- include your C++-code modules outside of 'extern "C"'!

. . . . // some code is not shown here

int main() __attribute__((noreturn));

int main()

{

initRP6M256(); <- function calls of C-code modules

I2CTWI_initMaster(400);

initLCD();

clearLCD();

// init RP6 Io Extension

ioExt::Initialize(); <- function calls of C++-code modules (with namespaces)

// set RTC test date and time in local structure

ioExt::rtc.setDay(07);

ioExt::rtc.setMonth(03);

ioExt::rtc.setYear(2013);

ioExt::rtc.setHour(23);

ioExt::rtc.setMinute(59);

ioExt::rtc.setSecond(55);

. . . // more code

2.2 I2C bus addresses

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 11

2.3 Hardware Control Register

Sensor/Item

I2C Address

Port #

I2C Module - ON/OFF

0x40

0.0

Sharp_Front_PWR - ON/OFF

0x40

0.1

Sharp_Rear_PWR - ON/OFF

0x40

0.2

Ready Signal I2C buffer (TCA4311A) - Input

0x40

0.3

LED Drive (TCA6507) - ENABLE

0x40

0.4

CAM PWR - ON/OFF

0x40

0.5

Gyro SLEEP/PWR (PD_2) - ON/OFF

0x40

0.6

Gyro TEST (ST_2) – ON/OFF

0x40

0.7

I2C OUT - ENABLE

0x40

1.0

I/O (IO_EXT_PIN1; free)

0x40

1.1

I/O (IO_EXT_PIN2; free)

0x40

1.2

Servo Output inverted (PCA9685) - ENABLE

0x40

1.3

Servo PWR - ON/OFF

0x40

1.4

Magnetometer data ready (LSM303) – DRYD (Input)

0x40

1.5

LED (D2) – ON/OFF

0x40

1.6

Switch (S1) input

0x40

1.7

Jumper

Description

populated

RTC Interrupt (DS1339) routed to INT3

J2

0R0 (SMD 0805)

Magnetometer INT1 (LSM303) to INT1

J3

0R0 (SMD 0805)

MAX7311 interrupt routed to INT2

J4

0R0 (SMD 0805)

Magnetometer INT2 (LSM303) to INT3

J5

0R0 (SMD 0805)

Sharp Rear (ADC4) routed to PIN3

of the ADC Connector

J6

0R0 (SMD 0805)

Hint: If you have more than one I2C Bus module or IC on the buffered I2c bus, then

always all modules must be powered on to read data!!!

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 12

2.4 IOExtDemo SW

Provides a base implementation to control the Sensor & IO board. A display 2 x 16 char will be

supported. The description is within the source code.

Source code files for both boards are included in the package (see src folder). The software can be

complied with Visual Studio 2010 Express (free download at Microsoft) – the makefile is included.

The makefile supports the existing C- code libs from the RP6V2 and RP6WIFI and combined this

with the C++ code from the sensor boards in an easy way.

Load the IoExtDemo.hex file into the RP6WIFI control board. The source code (included in the

package) for the demo software can be complied with Visual Studio 2010 Express (free download

at Microsoft) – the makefile is included.

The following messages will be shown on the LCD (Pressing SW1 RP6WIFI board will move to the

next screen):

1. StartScreen: RP6 IO Extension Demo Program

followed with Date (08.03.2013)

and Time (starting from 00:00:00)

2. Accelerometer: P (Pitch angle in 1/10 degree)

R (Pitch angle in 1/10 degree)

3. Compass: Hd (heading in degree)

Compass calibration (use SW2 on the RP6WIFI board):

1.) Press S1 after aligning the robot to North,

2.) Align to East followed and press S1

3.) Same for South and West to calibrate compass.

After calibration is completed the status LED should switch of.

HINT: Ferro-magnetic material will influence the result in heading

quality!!!

4. Temperatur: T (in degree C)

5. LED: SW2 toggles all LEDs ON/OFF

6. Servo: SW2 toggles between 2 PWM values

-45 deg and +45 deg

Keep in mid this is only a basic implementation to show how the IC shall be initialized and to

compute some data, e.g. the 2D-Compass application is included. The source code should be

adapted to your RP6V2 / RP6 software. Further documentation please refer to the source.

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 13

2.5 RP6-RC Demo SW (Remote Control)

At first start an

error message can

be displayed here,

because there is

no config- file.

This will be created

automatically.

If you click on ‘Use Keyboard (WASD)’ than the

control is via the keys W A S D.

Disabling will enable the joystick as control

automatically.

The RP6 Robot and the RP6WIFI board together enables you to control the RP6 Robot remotely so you can ‘drive’ the robot via a Joystick or WASD keys on the key pad - right, left, forward,

backward and turns. The joystick should be moved as straight as possible to the directions left,

right forward or backward.

The current version is a demonstration PC program and associated RP6 Base and WIFI hex-flies.

Other functions like sensor data transmission and Light ON/OFF can be added by the user (source

code will be made available).

Source code files for both boards are included in the package (see src folder). The software can be

complied with Visual Studio 2010 Express (free download at Microsoft) – the makefile is included.

The make file supports the existing c- code libs from the RP6V2 and RP6WIFI and combined this

with the C++ code from the sensor boards in an easy way.

2.5.1 Configuration and setup

2.5.1.1 RP6 Base

Load the ‘RP6Base_I2CSlave.hex’ file with the Robot Loader into the RP6v2.

2.5.1.2 RP6WIFI

Load the ‘rp6RcDemo.hex’ with the Robot Loader into the RP6.WIFI control board.

2.5.1.3 PC-Remote Program

Copy the folder ‘pc’ on your desktop, open the folder ‘pc’ and run the ‘RP6-RC.exe’ program.

You should see the following window:

The files EXE-file and the 2 DLL’s must be in the same folder!

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 14

Switch the RP6 ON and run the application, then type your RP6 IP into the Hostname field and

Your Robot IP !

Status message –

remote control active

after enabling the

remote control !

click on the connect button and click on the box to ‘Enable Remote Control’.

You should see the following:

After the connection has been accepted, you get some signals reported from the RP6, which

are:

1.) Depth signal (if a Sharp sensor in the front is installed)

2.) Speed of right and left chain (actual speed)

3.) Battery voltage

4.) ACS state information

5.) MoveState ( 1 == Remote Control)

In the command field (Send Command) you can type in commands which will be sent to the

RP6WIFI board.

Keep in mind, currently there is no command coded on the RP6WIFI board in this version to

the demonstrator program.

Optional there are status messages displayed on the LC Display is connected.

2.5.1.4 PC Requirements

PC with WINDOWS VISTA / 7 operation system

WIFI access; Robot WIFI IP assigned

Optional: Joystick – e.g. Logitech connected to the PC.

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 15

HINT: The Firewall Program can refuse the connection – please allow the

Robot IP in your network.

2.5.1.5 Robot Requirements

RP6 Robot with RP6WIFI Board

optional: RP6_Sensor&I/O Board, Sharp Sensor, display (min: 2 lines with

16 characters

3. Detailed descriptions of the integrated circuits see datasheets

- LM75BM Temp. Sensor

- LSM303DLHC Magnetometer and Accelerometer

- DS1339U33 RTC

- MAX7311AUG I/O digital

- TCA6507 LED Driver

- LY330ALH Gyro Yaw

- PCA9685 PWM Servo controller

4. Connector PIN-OUT

4.1. Connectors to Board:

XBUS: VSS_1 = PIN 4, 6

VDD_1 = PIN 3, 5

GND = PIN 1, 2,

14

SDA = PIN 12

SCL = PIN 10

INT1 = PIN 8

INT2 = PIN 11

INT3 = PIN 9

MRESET = PIN 13

I/O (K17):

USRBUS: ADC0 = PIN 1 (Sharp front)

ADC1 = PIN 2 (Gyro)

ADC4 = PIN 5 (Sharp Rear)

PWR = PIN 3

ADC (K18): ADC4 = PIN 3

(Sharp rear -

alternative PIN)

PD5 = PIN 9 (I2C OUT -

Enable

alternatively)

Hint: The signal name PD5 on the Sensor Bord was derived from the Control M32

board. PIN 9 of the I/O header on the M256 Board is labeled as PB6

(IO_PWM/T0/T1).

The signal ADC4 on the Sensor Board was derived from the Control M32

board. PIN 3 of the ADC header on the M256 Board is labeled as ADC9

(ADC_IO2/CMP).

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 16

4.2. Connectors on Board:

K2: (LED)

PIN 1 = P2

PIN 2 = VDD_1

K3: (Sharp Rear)

PIN 1 = ADC4

PIN 2 = VDD_1

PIN 3 = Load (100 Ohm)

K4: (LED)

PIN 1 = P1

PIN 2 = VDD_1

K5: (Sharp Front)

PIN 1 = ADC0

PIN 2 = VDD_1

PIN 3 = Load (100 Ohm)

K7: (Display. Illumination)

PIN 1 = P0

PIN 2 = VDD_1

K10: (LED Out)

PIN 1 = P3

PIN 2 = P4

K28: (I2C)

PIN 1 = Load

PIN 2 = VDD_1

PIN 3 = SCLOUT

PIN 4 = SDAOUT

PIN 5 = SCL_M

PIN 6 = SDA_M

K12: (PWM OUT)

PIN 1 = PWM0

PIN 2 = PWM1

PIN 3 = PWM2

PIN 4 = PWM3

PIN 5 = PWM4

PIN 6 = PWM5

PIN 7 = PWM6

PIN 8 = PWM7

K6: (SERVO_1)

PIN 1 = PWM15

PIN 2 = Servo_PWR

PIN 3 = GND

K11: (SERVO_2)

PIN 1 = PWM14

PIN 2 = Servo_PWR

PIN 3 = GND

K29: (SERVO_4)

PIN 1 = PWM13

PIN 2 = Servo_PWR

PIN 3 = GND

K30: (SERVO_3)

PIN 1 = PWM12

PIN 2 = Servo_PWR

PIN 3 = GND

K31: (SERVO_6)

PIN 1 = PWM11

PIN 2 = Servo_PWR

PIN 3 = GND

K32: (SERVO_5)

PIN 1 = PWM10

PIN 2 = Servo_PWR

PIN 3 = GND

K33: (SERVO_8)

PIN 1 = PWM9

PIN 2 = Servo_PWR

PIN 3 = GND

K34: (SERVO_7)

PIN 1 = PWM8

PIN 2 = Servo_PWR

PIN 3 = GND

K19: (Dig-I/O)

PIN 1 = I/O1.2

PIN 2 = GND

PIN 3 = I/O1.1

PIN 4 = GND

M1; (I2C Module Interface):

PIN 1 = VDD_1

PIN 2 = SDLOUT

PIN 4 = SDAOUT

PIN 5 = LED

PIN 6 = Input button S1

PIN 9 = GND (switched)

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 17

4.3. Rechargeable Battery

The Battery will be recharges automatically while the IO Board is in use (RP6 is switched on).

Overloading is not possible.

Hint: You must enable the Trickle charger in the RTC (DS1339 – 2kOhm and Diode). Refer

to the source IOExtDemo Software and/or the datasheet of the DS1339!

Hint: There should be no need to replace this battery! Recharging will occure during

normal operation of the Robot. The data will be kept over several weeks.

5. Technical data

5.1. Supply voltage / current consumption (bus not active, no other connections rather than supply

voltage and GND).

VDD (PIN3, XBUS) = 5,0 V ± 2%

IDD = 15,00 mA ± 5,0mA

5.2. Servo Power Supply input voltage.

VSensor_PWR ≤ 10,0 V

ISensor_PWR ≤ 3,0 A average; peak load up to 5,0 A

depending on servo load

5.3. Gyro:

Vout = Vout(0) ± 10mV / dps ± 2%

Vout(0) = 2,5 V ± 2% (no motion)

Range = approx. 200dps max

5.4. Power switches:

Iout max = 0.5 A / continuous each channel / peak 1,0A

(5V regulator on base board might be limiting if all

4 channels are active at the same time.)

5.5. I2C Bus speed max. 400kHz

5.6. All other data according to IC data sheets (see chap. 3.)

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 18

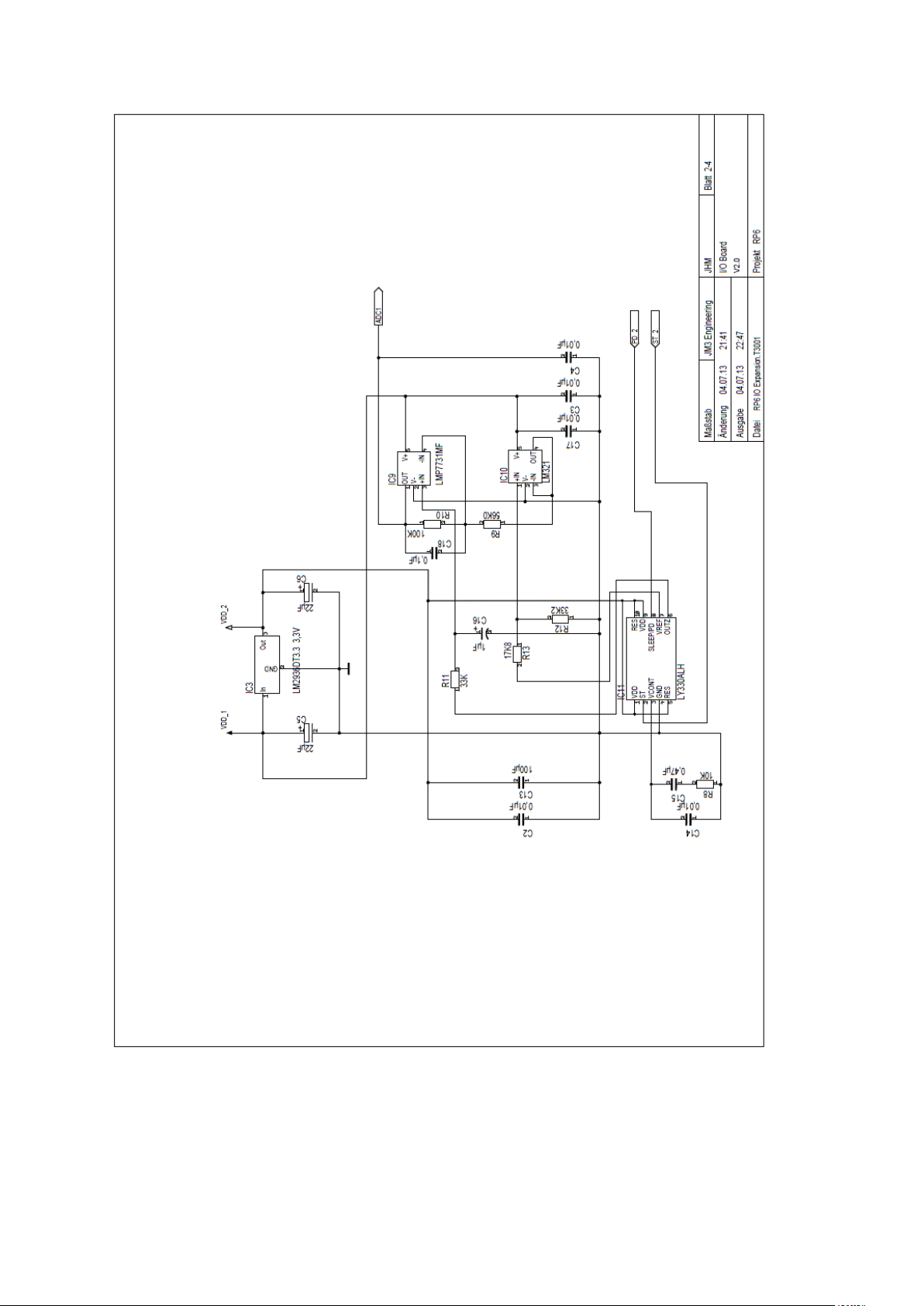

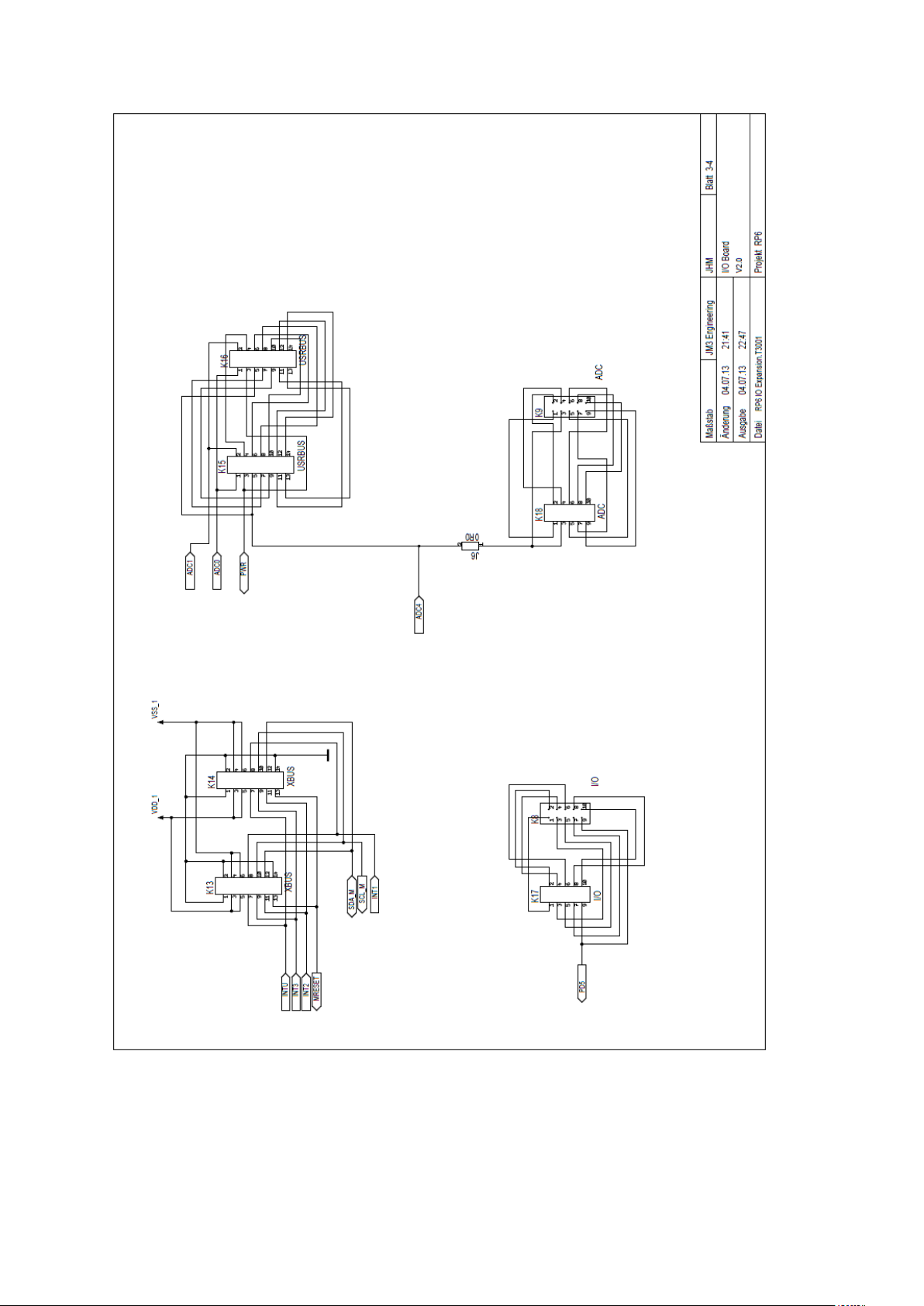

RP6 SENSOR BOARD CIRCUIT DIAGRAM

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 19

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 20

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 21

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 22

RP6 SENSOR BOARD PCB LAYOUT

AREXX Engineering & JM3 Engineering

Version: 1.20 Apr. 20, 2014 page: 23

Loading...

Loading...