WHOLE HOUSE FANS

by

A COMPLETE GUIDE FOR

DO-IT-YOURSELF INSTALLATION

of Cool Attic Models

CX242DDWT

CX302DDWT

CX24BD2SPD

CX30BD2SPD

CX36BD2SPD

THANK YOU for your purchase of a Cool Attic Whole House Fan.

Your new fan is easy to install and will operate efficiently and be trouble-free

for many years to come. Should you have any problem with the installation

or operation of your fan, please call our toll-free customer service line at

1-800-433-1626. We welcome your call and will do everything we can to

help you complete the installation of your Cool Attic Whole House Fan.

VENTAMATIC, LTD. P.O. BOX 728, MINERAL WELLS, TX 76068-0728 • PHONE 800-433-1626 FAX 940-325-9311 • WWW.BVC.COM • E-MAIL: BVC@BVC.COM

A leader in the ventilation industry for over 60 years, Ventamatic, Ltd. oers a complete line of air movement

products for commercial, industrial, agricultural, and residential use sold under these ne names:

®

®

PLEASE READ AND SAVE

THESE INSTALLATION INSTRUCTIONS

THIS FAN IS INTENDED FOR RESIDENTIAL USE ONLY

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY, OBSERVE THE FOLLOWING:

DO NOT USE Models CX242DDWT, CX302DDWT, CX24BD2SPD,

1.

CX30BD2SPD, CX36BD2SPD WITH ANY SOLID STATE VARIABLE SPEED

CONTROL DEVICE (RHEOSTAT).

Use this unit only in the manner intended by the manufacturer. If you have any

2.

questions, contact the manufacturer.

Before servicing or cleaning this unit, switch the power off at the service panel and

3.

lock out to prevent power from being switched on accidentally.

Installation work and electrical wiring must be done by qualified people in

4.

accordance with all applicable codes and standards, including fire-rated

construction.

Sufficient air is needed for proper combustion and exhausting of gasses through

5.

the flue (chimney) of fuel burning equipment to prevent back-drafting. Follow the

heating equipment manufacturers' guidelines and safety standards such as those

published by the National Fire Protection Association (NFPA) and the American

Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) and

local code authorities.

When cutting or drilling into walls or ceilings, do not damage electrical wiring and

6.

other hidden utilities.

7.

To avoid injury from fiberglass insulation, wear long sleeves, rubber gloves,

goggles, and a respirator mask both in the attic and below when cutting and

removing sheet rock from the shutter opening.

CAUTION

1.

This fan is intended for general ventilating use only. Do not use it to exhaust

hazardous or explosive materials or vapors.

2.

This unit has an unguarded impeller. Do not use in locations easily accessible to

people or animals.

3.

Do not operate fan when a fire is burning in the fireplace.

PAGE 2

INSTALLING YOUR WHOLE HOUSE FAN

BEFORE BEGINNING INSTALLATION, PLEASE READ INSTRUCTIONS

THOROUGHLY.

PRELIMINARY STEPS

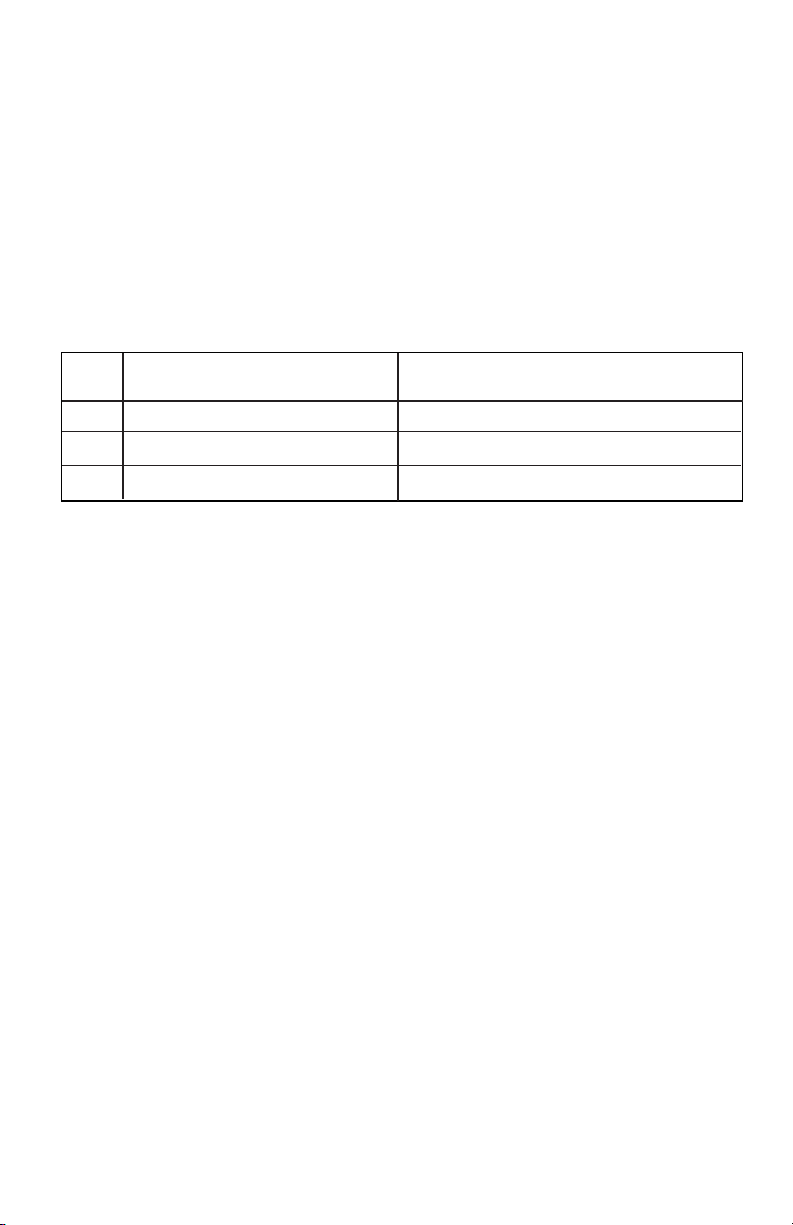

1. Review the Attic Air Exhaust Requirements in the chart below.

Whole House Fans are designed to pull in fresh, cool air from the outside through

open windows in your home. Hot air that is in the home is pulled up through the

fan and into the attic, and then exhausted through vents in the roof, undereaves,

soffits or gables. This exhaust ventilation is measured in Net Free Area (NFA).

For your Whole House Fan to operate properly, you must have adequate

NFA as listed in the chart below.

FAN

SIZE

SQUARE FOOTAGE OF

AREA TO BE VENTILATED

NFA (Net Free Area)

EXHAUST REQUIRED

24" up to 1800 sq ft (1 story) 8 to 10 sq ft (1152 to 1440 sq in)

30" 2000 to 3000 sq ft (1 story) 10 to 12 sq ft (1440 to 1728 sq in)

36" over 3200 sq ft (1 story) 12 to 14 sq ft (1728 to 2016 sq in)

2. Assemble the following tools and materials. They will be used

during the installation procedure.

TOOLS NEEDED:

• Tape measure

• Marker or pencil

• Circular saw, saber saw, or keyhole saw

• Hand saw

• Electric drill

• Screwdrivers (slotted & Phillips)

• Hammer

• Utility knife

• 6 to 8 ft. stepladder

• Goggles, rubber gloves, respirator mask

MATERIALS NEEDED:

• 11/2 pounds of #12d (3") common nails or #16 box nails (about 100 nails)

• Sixteen to twenty 1

• Twelve to sixteen 1

• Lumber of the same dimension and type (i.e., 2" x 6", 2" x 8" etc.) as your ceiling joists

to frame the shutter opening. The length of the lumber will depend on the size of your fan.

• Two 8-ft pieces of lumber of the same type as your ceiling joists (i.e., 2" x 6", 2" x 8" etc.).

Two 8-ft sections will be enough to face even the largest fan.

• Wiring Supplies:

UL-listed junction boxes that meet local code requirements.

3-conductor Romex cable with ground.

1/2" ring shank drywall nails

1/2" #8 decking screws

3. Read through the 9 Installation Steps on the following pages before

beginning installation.

PAGE 3

STEP 1: SELECT THE INSTALLATION SITE

1. Select the location for your new Whole House Fan. Usually, locating the fan in a central hallway

produces the most uniform airflow.

2. Once you have selected the installation site, check the attic immediately above the site to be sure

that there are no ducts, piping or wiring obstructing the installation area. Also, the installation

site should allow a minimum of 36” of unobstructed space between the attic floor and the roof.

READ THE FOLLOWING BEFORE PROCEEDING WITH STEP 2:

The fan and shutter MUST

be installed horizontally; they will not function in a vertical position.

Decide whether you will use a “Joist-In” or “Joist-Out” installation (described below):

Joist-In Installation Method

If you choose this method, you will leave the ceiling joists intact. Please note that this method

requires another attic access since the fan will not fit through the shutter opening with the joist

in place. Special Note regarding Model CX36BD2SPD: The Joist-In Installation method may

be used ONLY if the joist centers are 24” apart or greater AND if there is enough space

between the involved joist(s) and any wall(s).

Joist-Out Installation Method

If you choose this method, you will remove a section of a ceiling joist.

STEP 2: PREPARE THE SHUTTER OPENING

Remove all insulation from the attic floor

above the installation site (be sure to take

proper precautions—gloves, goggles,

respirator mask), using the "rough opening

to cut" dimension in the chart at right.

SHUTTER DIMENSION CHART

FAN

SIZE

24" 23 3/4 x 25 1/2 28 x 29 3/4

30" 29 1/4 x 32 27 1/4 x 29 3/4 31 1/2 x 34

36" 37 1/4 x 33 1/2 35 x 31 1/4 39 1/4 x 35 3/4

ROUGH

OPENING

25 1/2 x 27 3/4

INSIDE SHUTTER

DIMENSIONS

WARNING: BE SURE TO USE THE ROUGH OPENING DIMENSIONS IN THE CHART

FOR THIS STEP. DO NOT use the dimension of the fan frame OR the inside/outside

shutter dimensions.

(Note: the shutter opening will be identical regardless of the mounting method you choose.)

Follow the instructions below for the installation method you have chosen.

Joist-In Installation

To prepare the shutter opening, align the center of the stationary shutter vein with the

center of the ceiling joist that crosses the approximate center of the shutter opening.

OR

Draw a line on the ceiling marking the rough opening size of the shutter frame. Make

sure that the dimensions you have marked are accurate and that the corners are square.

Joist-Out Installation

1. To prepare the shutter opening, drill two 1/4” holes (from the attic floor down through

the ceiling) at the two corners that are aligned with one of the joists (Figure 1).

2. On the ceiling side, draw a straight line between the two drilled holes. Using this line

as a guide, mark the other three sides (Figure 2) of the shutter opening using the rough

opening specifications in the Shutter Dimension Chart. Check to make sure that the

dimensions are accurate and that the corners are square.

3. From the ceiling side, drill two more 1/4” holes (Figure 1) at the remaining two corners.

FIGURE 1 (Joist-Out Installation Only) FIGURE 2

drill first two holes from attic

mark ceiling

OUTSIDE SHUTTER

DIMENSIONS

PAGE 4

drill second two holes from ceiling

STEP 3: CUT THE SHUTTER OPENING

1. Using a saber saw or keyhole saw, cut

through the ceiling along the lines you have

FIGURE 3

drawn, being careful not to cut the joists.

To be absolutely sure that you will not cut

through a joist, you may also use a circular

saw with the shoe adjusted to a cutting

depth equal to the depth of the drywall.

(Figure 3)

2. Carefully remove the drywall from the

shutter opening.

STEP 4: CUT THE CEILING JOIST

(Skip this step if you are using the Joist-In Installation method.)

1. BEFORE you cut the ceiling joist, it is best

that the joist from which you are

FIGURE 4

bridge pieces

removing a section be secured on either

side with a “bridge” (Figure 4). Doing so

will give extra support to the joist as you

cut it and will also help prevent the

drywall from cracking. To secure the

joists you may use the 2” x 6” pieces of

lumber that you will use later to construct

the facing. Place the bridge pieces

perpendicular to the joists about 6”

ceiling joist marked and cut 1

outside the edges of shutter opening

1/2"

outside the sides of the shutter opening,

being sure to allow enough room to use a handsaw or power saw comfortably and accurately.

Although you may nail the bridge pieces to the joists with #12d nails, it will be easier for you to

remove them later if you fasten them with 2 1/2” deck screws.

2. Mark the cut lines on the joist to be cut (Figure 4). The cut lines should be 1 1/2” outside the

edges of the shutter opening (this will allow for framing the opening, described in Step 5). Be

certain that the cut lines are square (perpendicular to the joist) so that you will be able to fit the

headers tightly against the joist and the shutter opening. After carefully measuring and marking

each cut line, you may cut the joist.

STEP 5: FRAME THE SHUTTER OPENING

1. To frame in the shutter opening you will use lumber that is of the same dimension as your

ceiling joists (i.e., 2” x 6”, 2” x 8”, etc) and #12d common nails. Figure 5A shows the framing

for a Joist-Out Installation; Figure 5B shows the framing for a Joist-In Installation.

2. On the ceiling side of the installation fasten the sheetrock around the edges of the framed

opening. Use 1 1/2” ring shank drywall nails.

3. Remove the two bridges across the ceiling joists. Save this lumber to build the facing around the

framed shutter opening.

Note: Any gaps between the headers and the joists should be sealed with caulk or foam insulation

to enable your fan to draw properly.

FIGURE 5A (Joist-Out Installation) FIGURE 5B (Joist-In Installation)

framing pieces framing pieces

PAGE 5

STEP 6: INSTALL THE FACING

1. Cut the end pieces of the facing from the 2” x 6” pieces of lumber you used as the bridges. The

end facing pieces should be the same length as the width of the shutter opening.

2. Cut the sides of the facing from the 2” x 6” lumber. The length of the side facing pieces should

be equal to the length of the shutter opening plus 11” (two times the width of the 2” x 6”

lumber, which is actually 5 1/2” wide).

3. Use #12d common nails to anchor the facing pieces in place (Figure 6A Joist-Out or 6B

Joist-In). You are now ready to mount your Whole House Fan to its supporting ceiling frame.

FIGURE 6A (Joist-Out Installation)

FIGURE 6B (Joist-In Installation)

facing pieces facing pieces

STEP 7: PREPARE AND INSTALL THE FAN ASSEMBLY

Prepare the Fan Assembly

Cool Attic Whole House Fans are carefully packed and “assembled” at the factory in such a way as

to prevent shipping damage. Before you install the fan assembly in your attic, you must prepare the

fan by re-assembling it.

Belt Drive Models: The factory has secured the motor and motor

base to the bottom of the tubing frame with two 1/4-20 bolts. Remove

‰

the bolts and remount the motor and motor base to the top of the cross

bars (Figure 7A below). Position the fan belt on the pulleys and adjust

the fan belt to a minimum tension—about a 1/2” deflection (at right).

Direct Drive Models:

The factory has installed the fan blade upside down to prevent shipping

1/2" DEFLECTION

damage. Loosen the set screws holding the fan blade in place. Invert the fan blade. Retighten the

set screws. The blade must be firmly secured and the hub must be flush with the end of the shaft

before attempting to operate your fan.

Install the Fan Assembly

1. Push the fan assembly diagonally up through the shutter opening. If you have chosen a Joist-In

Installation, you will need to use some other attic access for the fan since the fan will not fit

through the shutter opening with the joist in place. Place the fan housing on top of the facing,

as shown in Figure 7A (belt drive) and Figure 7B (direct drive).

Note: To provide a good seal between the fan housing and the facing and to minimize

vibration noise, you may wish to install a felt strip or foam tape between the fan frame and the

facing.

2. Center the fan assembly on the facing and draw alignment marks around the wooden fan

assembly base.

3. Toenail the fan assembly to the facing using 2 1/2” deck screws or #12d common nails. Be

sure to check as you anchor each corner that the fan assembly has not moved off the alignment

marks you have drawn.

FIGURE 7A (Belt Drive Model)

FIGURE 7B (Direct Drive Model)

hub must be flush with end of shaft

PAGE 6

STEP 8: INSTALL THE SHUTTER

FIGURE 8 FIGURE 9

1. The shutter itself is 7/8” larger all

around than the shutter opening.

Draw alignment marks (Figure 8)

on the ceiling to indicate the outer

edges of the shutter frame. Use the

Shutter Dimension Chart on page

4 for size.

2. Install the shutter using the wood screws

provided with your fan (Figure 9).

STEP 9: WIRING INSTRUCTIONS

Warning: Before proceeding with Step 9, disconnect the power supply at the service entrance or

switch off the appropriate circuit breaker.

Note: Use 3-conductor wire with ground (not furnished). All wiring supplies and installations must

meet all requirements of local electrical and fire codes. Wire to 115-120V, 60 Hz current only.

1. Install the switch in a UL-listed wiring box in a wall near the fan (typically in a hallway).

2. Refer to Figure 10 to wire all models. Cool Attic Whole House Fans have two fixed speeds

(high and low). The center position on the rocker switch is the “off” position.

3. Connect the hot line from your power supply to the center terminal (terminal #2) of the

two-speed switch.

4. Connect the black wire from the motor (the high-speed line) to terminal #3 of the rocker

switch.

5. Connect the red wire from the motor (the low-speed line) to terminal #1 of the rocker switch.

6. Before turning on power, rotate the fan blade by hand to be sure that there are no tools or

other materials in its path.

7. Your Whole House Fan is now ready to operate.

FIGURE 10

RED - LOW SPEED

BLACK - HIGH SPEED

WHITE - COMMON

INCOMMING POWER

SUPPLY 120V / 60 HZ

WHITE

GREEN

1 2 3

HI-OFF-LOW

BROWN

BLACK (HI)BLACK

RED (LOW)

WHITE

GROUND

CAPICITOR ATTACHED

AT FACTORY

BROWN

FAN

MOTOR

OPERATING INSTRUCTIONS

Whole House Fans cool your home by pulling in fresh, cooler air from the outside through open

windows and doors. In a two-story home, windows should be opened on one level only for most

efficient cooling. DO NOT operate your Whole House Fan without open doors or windows. An

added benefit of Whole House Fans is that they reduce attic temperatures, which in turn, reduces

energy costs as well as wear and tear on roofing components.

If your home has a fireplace, be sure that the flue damper on the fireplace is closed to prevent

chimney soot from being drawn into the house by the fan. DO NOT operate the fan when a fire is

burning in the fireplace.

PAGE 7

Ventamatic, Ltd. Limited Warranty

1.

Ventamatic, Ltd. extends this warranty to the original retail purchaser of its model or, if this unit is

purchased and installed by a new home builder, then to the original owner of the home. No

subsequent purchaser of the unit or of a home in which it is installed is entitled to any of the

benefits of this warranty.

2.

This product is warranted against defects in materials and workmanship for a period of ten (10)

years from the date of original retail purchase. No other parts or components are warranted.

There is no warranty for defects caused by abuse, faulty installation, or the like. Repairs or

replacement parts supplied under this warranty are warranted only for the period of this warranty;

that is, ten (10) years from the date of the original retail purchase of the unit.

3.

In the event of a defect or malfunction, we will replace or repair the defective part or component

only and return the new or repaired part to you freight prepaid. You must bear all other expenses

incurred in obtaining repairs, including labor required for field repair or replacement, and the cost

of shipping the defective part to us. You must also bear the cost of repair to or replacement of any

part or component and the shipping charges incurred for the repair or replacement and return to

you of any part or component not covered by this warranty, including parts or components

damaged by you.

4.

The company reserves the right to demand and receive written evidence of the date of purchase

before undertaking to perform its obligations under this warranty. You should, therefore, retain

your sales slip and attach a copy of it to the warranty claim.

5.

In order to obtain the repair or replacement of this unit, you must select one of the following

methods:

A. Return to factory.

Return postage prepaid only the part or component which you believe to be defective

to the following address:

Ventamatic, Ltd

100 Washington Street

Mineral Wells, TX 76067

Complete and enclose a written claim and attach a copy of your sales slip or other

proof of purchase.

B. Return to retail dealer.

If the retail dealer from whom you purchased this unit stocks replacement parts or

components, you may return a part or component which you believe to be defective

to that dealer for replacement.

Caution: Only a limited number of our retail dealers stock replacement parts. If your

dealer does not, you must return the part to the factory following the procedure described

in paragraph "A" above.

6.

There is no informal dispute settling mechanism available in the event of a controversy involving

this warranty.

7.

Any and all implied warranties which may exist terminate upon the expiration of this warranty ten

(10) years from the date of the original retail purchase. Some states do not allow limitations on

how long an implied warranty lasts, so this limitation may not apply to you.

8.

Ventamatic, Ltd. is not liable to you for incidental or consequential damages arising out of a defect

or malfunction of a unit or its installation or out of any alleged breach of this warranty. Some states

do not allow the exclusion or limitation of incidental or consequential damages, so this limitation

may not apply to you.

9.

This warranty gives you specific legal rights and you may also have other rights which may vary

from state to state.

PAGE 8

©2009 Ventamatic, Ltd WHF INSTALL INS

Loading...

Loading...