Arctic Cat 4000 2021 Service Manual

2021

4000

SERVICE

MANUAL

P/N-2263-107

Table of Contents

General Information/Foreword ............................................... 2

Snowmobile Identification ........................................................2

Recommended Gasoline and Oil .............................................2

Engine Break-In ....................................................................... 3

Drive Belt Break-In ................................................................... 3

Genuine Parts .......................................................................... 3

Varying Altitude Operation........................................................ 3

Preparation for Storage............................................................4

Preparation after Storage.........................................................4

After Break-In Checkup/Checklist ............................................ 5

Engine Specifications...............................................................5

Crankshaft Runout/Repair Specifications ................................5

Electrical Specifications ...........................................................6

Drive System Specifications..................................................... 6

Drive Clutch/Driven Clutch-Related Specifications ..................6

Drive System Components ......................................................6

Track Specifications ................................................................. 6

Torque Conversions ................................................................. 7

Torque Specifications ............................................................... 7

Steering and Body ................................................................... 9

Steering Post............................................................................ 9

Ski ..........................................................................................10

Ski Wear Bar .......................................................................... 11

Spindle ................................................................................... 11

Tie Rod................................................................................... 12

Ski Alignment ......................................................................... 13

A-Arms ...................................................................................14

Ski Shock Absorber................................................................ 15

Seat Assembly ....................................................................... 16

Taillight/Brake Light Assembly................................................ 16

Rear Bumper/Snowflap .......................................................... 16

Windshield/Headlight ............................................................. 17

Headlight Bulb........................................................................ 17

Adjusting Headlight Aim ........................................................ 17

Engine..................................................................................... 18

Engine Removing/Installing.................................................... 18

Assembly Schematic..............................................................25

Engine Servicing .................................................................... 27

Troubleshooting Engine ......................................................... 37

Engine-Related Items ................................................................ 39

Pressure Testing Engine ........................................................39

Liquid Cooling System ........................................................... 39

Cooling System Schematic .................................................... 40

Recoil Starter .........................................................................40

Arctic Power Valve (APV) System..........................................41

Troubleshooting Arctic Power Valve (APV) System ............... 46

Exhaust Controlled Timing (ECT) System.............................. 46

Fuel Systems ......................................................................... 47

EFI System............................................................................. 47

Individual Components........................................................... 47

Self-Diagnostic System/Codes............................................... 49

Fuel Pressure Regulator ........................................................ 50

Throttle Body Assembly .........................................................50

Throttle Cable......................................................................... 51

Fuel Pump..............................................................................52

Troubleshooting Fuel Systems............................................... 54

Electric Oil Pump.................................................................... 54

Gas Tank ................................................................................ 55

Electrical Systems .................................................................56

Ignition System ...................................................................... 56

Throttle Position Sensor ........................................................ 56

Electrical Resistance Tests.................................................... 57

Testing Electric Oil Pump....................................................... 58

Testing Voltage Regulator...................................................... 58

Testing Oil Level Sensor........................................................ 59

Testing Fuel Gauge Sender ................................................... 59

Emergency Stop Switch ........................................................ 59

Starter Relay Solenoid........................................................... 59

Fuse....................................................................................... 60

Ignition Switch ....................................................................... 60

Starter Motor.......................................................................... 60

Troubleshooting Electric Start................................................ 62

Brake Light Switch................................................................. 63

Testing Headlight Switch ....................................................... 63

Testing Handlebar Warmer Elements ................................... 63

Testing Thumb Warmer Element ........................................... 64

Testing Handlebar Warmer/Thumb Warmer Switch............... 64

Testing Tether ........................................................................ 64

Testing Speedometer Sensor ................................................ 64

Testing Shift Switch ............................................................... 65

Drivetrain/Track/Brake Systems ...........................................66

Drive Belt ............................................................................... 66

Drive Clutch ........................................................................... 66

Driven Clutch ......................................................................... 68

Drive Clutch/Driven Clutch .................................................... 70

Drivetrain ............................................................................... 70

Drive Sprockets ..................................................................... 73

Track Tension ........................................................................ 74

Track Alignment..................................................................... 75

Brake System ........................................................................ 76

Brake Lever/Master Cylinder Assembly................................. 80

Troubleshooting Hydraulic Brake System.............................. 81

Troubleshooting Track ........................................................... 82

Troubleshooting Drive Clutch/Driven Clutch.......................... 83

Suspension .............................................................................84

Chassis and Skid Frame Mounting Locations ....................... 85

Servicing Suspension ............................................................ 87

1

General

Information/Foreword

NOTE: General specifications for each 2021 Arctic

Cat Snowmobile can be accessed from the Arctic Cat

Cat Tracker Dealer Communication System.

NOTE: Some illustrations and photographs used in

this section are used for clarity purposes only and are

not designed to depict actual conditions.

This Service Manual contains service and maintenance

information for 2021 Arctic Cat 4000 snowmobile models. The manual is designed to aid service personnel in

service-oriented applications.

This manual is divided into sections that cover specific

snowmobile components or systems and, in addition to

the standard service procedures, include assembling, disassembling, and inspecting instructions. When using this

manual as a guide, the technician should use discretion as

to how much disassembly is needed to correct any given

condition.

The service technician should become familiar with the

operation and construction of the components or systems

by carefully studying the complete manual. This will

assist the service technician in becoming more aware of

and efficient with servicing procedures. Such efficiency

not only helps build consumer confidence but also saves

time and labor.

All Arctic Cat publications and snowmobile decals display the words Warning, Caution, and Note to emphasize

important information. The symbol ! WARNING

identifies personal safety-related information. Be sure to

follow the directive because it deals with the possibility

of severe personal injury or even death. A CAUTION

identifies unsafe practices which may result in snowmobile-related damage. Follow the directive because it deals

with the possibility of damaging part or parts of the

snowmobile. The symbol NOTE: identifies supplementary information worthy of particular attention.

At the time of publication, all information, photographs,

and illustrations were technically correct. Some photographs and illustrations used in this manual are used for

clarity purposes only and are not designed to depict actual

conditions. Because Arctic Cat Inc. constantly refines and

improves its products, no retroactive obligation is incurred.

Snowmobile Identification

The Arctic Cat Snowmobile has two important identification numbers. The Vehicle Identification Number (VIN)

is stamped into the tunnel near the right-side footrest.

The decal also displays pertinent production information.

The Engine Serial Number (ESN) is stamped into the

crankcase of the engine.

These numbers are required to complete warranty claims properly. No warranty will be allowed by Arctic Cat if the engine

serial number or VIN is removed or mutilated in any way.

Recommended Gasoline

and Oil

CAUTION

Do not use white gas or gasoline containing methanol.

Only Arctic Cat-approved gasoline additives should be

used.

RECOMMENDED GASOLINE

The recommended gasoline to use is 91 octane (minimum).

NOTE: If a situation arises in which 91 octane gaso-

line is not available, 87 octane gasoline can be substituted; however, do not prolong the usage of 87 octane

gasoline as it will cause poor engine performance.

In many areas, oxygenates are added to the gasoline.

Oxygenated gasolines containing up to 10% ethanol are

acceptable gasolines.

RECOMMENDED OIL

CAUTION

Any oil used in place of the recommended oil may

cause serious damage.

The recommended oil to use in the oil-injection system is

Arctic Cat C-TEC2 Synthetic 2-Cycle Oil (p/n 8639-118 —

quart), (p/n 7639-840 — gal.), or (p/n 6639-521 — 2.5

gal.) This oil is specially formulated to be used and meets

all of the lubrication requirements of the Arctic Cat

C-TEC2 snowmobile engine.

All materials and specifications are subject to change

without notice.

Product Service and Warranty Department

Arctic Cat Inc.

2

Engine Break-In

The Arctic Cat engine (when new) requires a short

break-in period before the engine is subjected to heavy

load conditions.

The break-in period occurs in two stages. Stage One

occurs during the first 18 minutes of a new engine’s run

time where the ECM provides additional oil to the

engine, along with limiting engine RPM to 6500 RPM.

Stage Two occurs after the completion of Stage One and

eliminates the engine RPM limiter. However, Stage Two

still provides additional oil to the engine for the remainder of 6 hours. This additional oil is less than the amount

added during Stage One.

Premixing fuel and oil during the break-in period is not

required. Due to the oil delivery control strategy of the

electronic oil pump, the oil pump will automatically

compensate and deliver a richer fuel-oil ratio during the

engine break-in period.

Drive Belt Break-In

CLUTCHING

On a normally-aspirated engine as altitude changes,

engine horsepower changes with it. As you go up in altitude, the engine loses horsepower. Because of this, the

continuously variable transmission (CVT) system needs

to be calibrated to compensate for the horsepower loss.

At altitudes above 5000 ft (1524 m), the engine loses

peak horsepower but will also lose horsepower at

engagement speed. For this reason, calibrating the drive

system is usually needed in order to attain acceptable performance. Changing drive clutch engagement speed can

be done several ways. Some of the methods will affect

other characteristics of CVT operation, so you must be

careful what you change. Drive clutch springs are the

most common way to increase engagement speed; however, by simply changing the cam arms to a lighter

weight from the heavier sea level cam arm, you will gain

some engagement speed.

The driven clutch will also play a part in CVT tuning for

high altitude operation. A steeper helix (torque bracket)

angle in the driven clutch will mean a quicker up-shift. A

shallower angle will mean a slower up-shift. If the

up-shift is too quick, due to a very steep helix, RPM will

be pulled down under the peak operating RPM of the

engine (where the horsepower is) and performance will

suffer. The engine may even bog.

Drive belts require a break-in period of 25 miles (40 km).

Drive the snowmobile for 25 miles (40 km) at 3/4 throttle

or less. By revving the engine up and down (but not

exceeding 60 mph [97 km/h]), the exposed cord on the

side of a new belt will be worn down. This will allow the

drive belt to gain its optimum flexibility and will extend

drive belt life.

NOTE: Before starting the snowmobile in extremely

cold temperatures, the drive belt should be removed

and warmed up to room temperature. Once the drive

belt is at room temperature, install the drive belt (see

Drive Belt sub-section in the Drivetrain/Track/Brake

Systems section of this manual).

CAUTION

Running the engine with the drive belt removed could

result in serious engine damage and drive clutch failure.

Genuine Parts

When replacement of parts is necessary, use only genuine

Arctic Cat parts. They are precision-made to ensure high

quality and correct fit.

Varying Altitude Operation

Operating a snowmobile at varying altitudes requires

recalibration of drive system components. Consult the

appropriate specification sheet on Cat Tracker Online.

ENGINE

A normally aspirated engine will generate more horsepower at sea level than it does at higher altitudes. The

reason is that the higher you go, less oxygen is available

for the engine to use during its combustion process. Less

oxygen means it needs less fuel to obtain the correct

air/fuel ratio to operate properly. This is why the fuel

ratio has to be recalibrated. High altitude engines operate

as though they have a lower compression ratio. This,

along with less oxygen and less fuel, means that the

engine generates less horsepower. All of these characteristics will become more evident the higher the altitude.

TRACK

Carefully matching the riding requirements to the type of

track will ensure the maximum use of all available engine

power. Lug height and track durometer are the two main

concerns when selecting a track for various riding styles.

Tracks exist with lug heights from 1.0” up to 2.0” to

accommodate various snow conditions. Generally, the

deeper the snow, the taller the lug. It must be noted that

the installation of any deep-lug track may reduce top end

speed and promote premature wear strip wear in marginal

snow conditions.

Durometer is a measurement of how hard a rubber is. The

lugs on most tracks range between 60 and 80 durometer.

On the durometer scale, the higher the number, the harder

the lugs. For riding in deep powder snow, a softer durometer track works best. The softer rubber allows the track

to “give” a little and pack the snow creating lift rather

than digging its way straight down. When hill-climbing,

the harder lug of an 80 durometer track works the best

due to penetrating the hard snow creating more bite.

Following are basic altitude theories for clutching,

engine, suspension, and track.

3

Preparation for Storage

Prior to storing the snowmobile, it must be properly serviced to prevent corrosion and component deterioration.

11. Clean and polish the hood, console, and chassis with

Cat Cleaner. DO NOT USE SOLVENTS. THE PROPELLENT WILL DAMAGE THE FINISH.

12. Disconnect the battery cables making sure to disconnect the negative cable first; then clean the battery

posts and cables.

1. Clean the seat cushion with a damp cloth and Arctic

Cat Vinyl Protectant.

2. Clean the snowmobile thoroughly by hosing dirt, oil,

grass, and other foreign matter from the skid frame,

tunnel, hood, and belly pan. Allow the snowmobile

to dry thoroughly. DO NOT get water into any part

of the engine.

3. Place the rear of the snowmobile up on a shielded

safety stand; then start the engine and allow to idle.

Spray an Engine Storage Preserver into the intake

until the engine exhaust starts to smoke heavily or

until the engine starts to drop in RPM. Turn engine

off.

CAUTION

Do not run the engine without the belt guard in place

and secured.

4. Plug the exhaust system outlet with steel wool.

5. With the ignition switch in the OFF position:

A. Disconnect the high tension lead from the spark

plug; then remove the plug, connect it to the

lead, and ground on the cylinder head.

CAUTION

Never crank the engine over without grounding the

spark plug. Damage to coil and/or ECM may result.

CAUTION

Sealed batteries require charging if left for extended

non-start periods. Arctic Cat recommends trickle

charging once a month. Follow the manufacturer’s

instructions and cautions.

13. If possible, store the snowmobile indoors. Raise the

track off the floor by blocking up the back end making sure the snowmobile is secure. Loosen the track

adjusting bolts to reduce track tension. Cover the

snowmobile with a machine cover or a heavy, ventilated tarpaulin to protect it from dirt and dust.

14. If the snowmobile must be stored outdoors, position

the snowmobile out of direct sunlight; then block the

entire snowmobile off the ground making sure the

snowmobile is secure. Loosen the track adjusting

bolts to reduce track tension. Cover with a machine

cover or a heavy, ventilated tarpaulin to protect it

from dirt, dust, and rain.

CAUTION

Avoid storing in direct sunlight and using a plastic

cover as moisture may collect on the snowmobile causing corrosion.

Preparation after Storage

B. Pour 29.5 mL (1 fl oz) of SAE 30 petro-

leum-based oil into the spark plug hole and pull

the recoil starter handle slowly about 10 times.

C. Install the spark plug and connect the high ten-

sion lead.

6. Fill the gas tank to its rated capacity; then add Arctic

Cat Fuel Stabilizer to the gas tank following directions on the container for the stabilizer/gasoline

ratio. Tighten the gas tank cap securely.

7. With the snowmobile level, check the lubricant level

in the chain case. If low, add chain lube through the

fill plug hole.

8. Remove the drive belt from the drive clutch/driven

clutch. Lay the belt on a flat surface or slide it into a

cardboard sleeve to prevent warping or distortion

during storage; then clean and inspect the drive

clutch and driven clutch.

9. Apply light oil to the upper steering post bushings and

to the shafts of the shock absorbers; then lubricate the

rear suspension with low-temperature grease.

10. Tighten all nuts, bolts, and cap screws making sure all

calibrated nuts, bolts, and cap screws are tightened to

specifications. Make sure all rivets holding the components together are tight. Replace all loose rivets.

Taking the snowmobile out of storage and correctly preparing it for another season will ensure many hours of

trouble-free snowmobiling. Arctic Cat recommends the

following procedure:

1. Clean the snowmobile thoroughly. Polish the exterior

of the snowmobile.

2. Clean the engine. Remove the cloth from the exhaust

system. Check exhaust system and air silencer for

obstructions.

3. Inspect all control wires and cables for signs of wear

or fraying. Replace if necessary. Use cable ties or

tape to route wires and cables away from hot or rotating parts.

4. Inspect the drive belt for cracks and tears. Check belt

specifications. Replace if damaged or worn. Install

the drive belt.

NOTE: If the old belt is worn but in reasonable con-

dition, retain it with the snowmobile as a spare in case

of emergency.

5. Adjust the throttle cable. Inspect all fuel hoses and

oil hoses for deterioration or cracks; replace if necessary. Make sure all connections are tight.

6. Fill the oil-injection reservoir with the recommended

2-cycle oil; then inspect the spark plug. Replace,

gap, or clean as necessary.

4

7. Tighten all nuts, bolts, and cap screws making sure

all calibrated nuts, bolts, and cap screws are tightened to specifications.

8. If not done during preparation for storage, lubricate

the rear suspension with low-temperature grease.

R Check skid frame and A-arm mounting hardware

for tightness

R Check brake lever travel and adjustment

R Grease all lubrication points

9. Check the coolant level and all coolant hoses and

connections for deterioration or cracks. Add properly

mixed coolant as necessary.

10. Charge the battery; then connect the battery cables

making sure to connect the positive cable first. Test

the electric start system.

11. Inspect the entire brake system, all controls, headlight, taillight, brake light, ski wear bars, and headlight aim; adjust or replace as necessary.

12. Adjust the track to the proper tension and alignment.

After Break-In

Checkup/Checklist

Certain areas require adjustment after the break-in period

in order to obtain peak performance. These areas are the

following:

DRIVE CLUTCH/DRIVEN CLUTCH

ALIGNMENT (OFFSET) — The alignment between

the drive clutch and driven clutch are set at the factory.

Normally, no adjustment is necessary; however, if premature drive belt wear or poor performance is experienced,

the drive clutch/driven clutch alignment must be

checked. See “CHECKING OFFSET” in the Drivetrain

section in this manual.

TRACK TENSION AND ALIGNMENT — A certain

amount of stretch occurs on all tracks during the first 500

miles (800 km). The track must be inspected/adjusted

after the first 50 to 100 miles (80 to 160 km) to the specifications given in the Track Specifications sub-section of

this section and periodically thereafter. If these adjustments aren’t performed, the track may “derail” which

leads to track and slide rail damage.

Along with these major areas, other areas should be

checked and adjusted.

Engine Specifications

ITEM

Engine Number 0962-153

Displacement 397 cc

Bore x Stroke 85 x 70

Compression Ratio 6.60:1

Cooling System Liquid

Ignition Timing (Engine Warm) 19° @ 1750 RPM

Spark Plug (NGK) BPR9ES

Spark Plug Gap 0.028-0.031 in.

Piston Skirt/Cylinder Clearance 0.0041-0.0053 in.

Piston Ring End Gap 0.012-0.0196 in.

Cylinder Trueness Limit 0.004 in.

Piston Pin Diameter 0.8659-0.8661 in.

Piston Pin Bore Diameter 0.8661-0.8665 in.

Connecting Rod Small End Bore 1.0631-1.0634 in.

Connecting Rod Radial Play 0.0001-0.0008 in.

Crankshaft Runout (t.i.r.) 0.002 in. (0,0508 mm)

Crankshaft End Play 0.008 in. (0,2032 mm)

(0.7112-0.7874 mm)

(0.1041-0.1346 mm)

(0.3048-0.49784 mm)

(0,1016 mm)

(21,993-21,998 mm)

(21,998-22-009 mm)

(27.002-27.010 mm)

(0,0025-0,0203 mm)

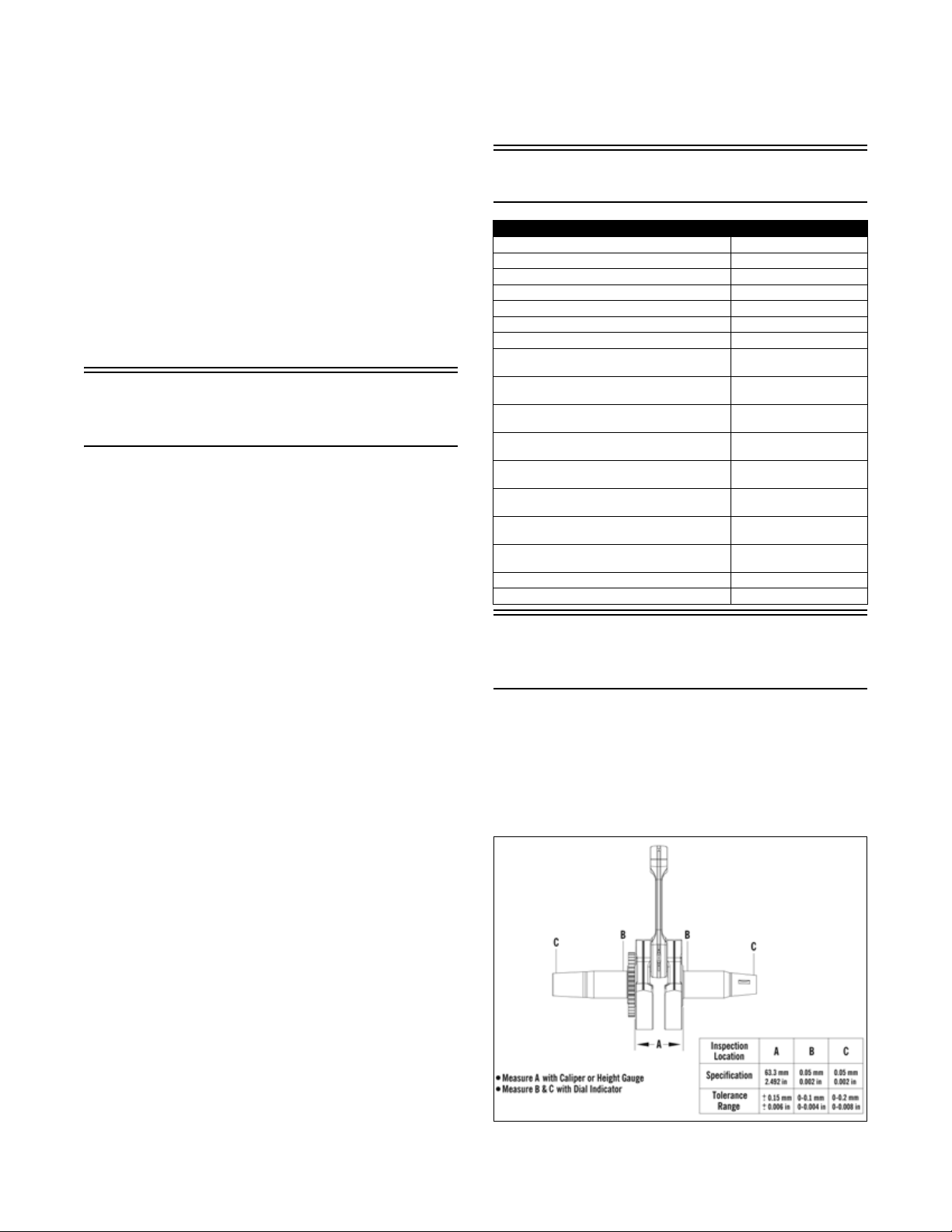

Crankshaft Runout/Repair

Specifications

Refer to the drawing; then find the letter indicating the

specification and refer to the chart within the illustration.

NOTE: From the illustration, note that four check

points are called out: at either end, out on the taper as

shown. The crankshaft is still supported on the outer

shafts using V blocks.

Below is a list of items to check after the break-in period.

The recommended mileage for this inspection is between

100 and 300 miles (160 and 480 km).

R Check drive clutch/driven clutch alignment

R Adjust track tension and alignment

R Check throttle cable tension

R Check engine idle

R Check coolant level

R Check chain case lubricant level

R Check lights (high/low beam, brake light)

R Check safety switch operation

R Check engine compartment for any rubbing com-

ponents

R Check steering hardware for tightness

0755-040

5

Electrical Specifications

(Normally Open Ignition)

Component Test Value + Test Connections -

Spark Plug Cap 4000-6000 ohms cap end cap end

Oil Level Sensor Less than 1 ohm (float end down) terminal terminal

Ignition Switch Less than 1 ohm (key in OFF position) terminal terminal

Ignition Coil (Primary)

Charge Coil (1) 8.8-13.2 ohms black/red green/red

Charge Coil (2) 8.8-13.2 ohms brown/white green/red

Lighting Coil 0.08-0.12 ohm yellow yellow

Ignition Timing Sensor (1) 148-222 ohms green/white brown/green

Ignition Timing Sensor (2) 148-222 ohms green/white brown/green

Fuel Injector 11.4-12.6 ohms terminal terminal

Injection Coil 15.2-22.8 ohms blue/white blue/white

Fuel Pump Coil 1.52-2.28 ohms orange orange

Servomotor 12 DC Volts red/brown (counterclockwise)

Voltage Regulator/Rectifier* 9-15 DC Volts red/blue black

(Secondary)

* Harness plugged in

NOTE: Lighting coil output is unregulated voltage.

Most voltages generated by the ignition system are sufficient to interrupt pacemakers! All technicians, especially

those using pacemakers, must avoid contact with all electrical connections when pulling the recoil starter rope or

after the engine has been started.

0.24-0.36 ohm

5040-7560 ohms

! WARNING

black/white

high tension wire

brown/red (clockwise)

white/blue

ground

brown/red (counterclockwise)

red/brown (clockwise)

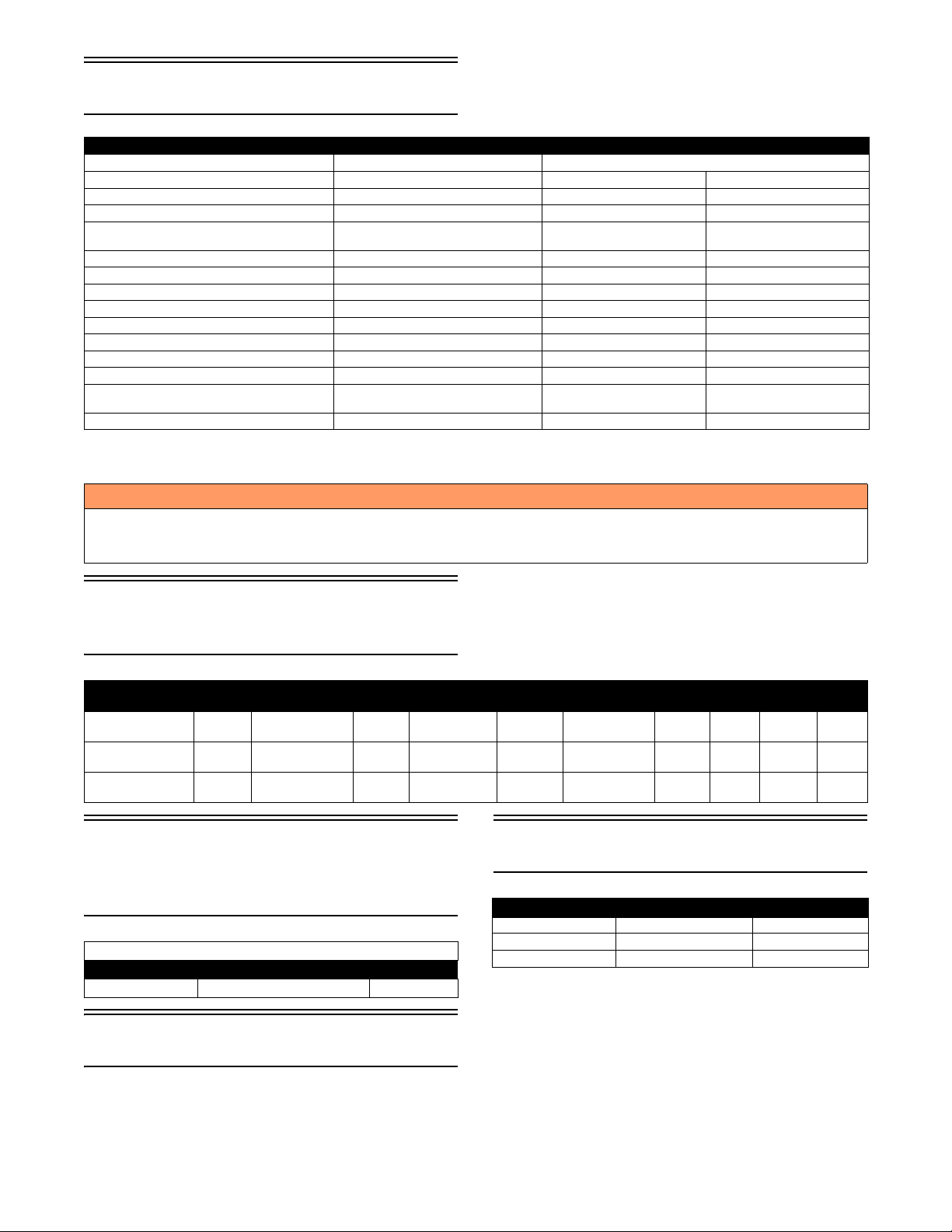

Drive System

Specifications

Model Altitude

Blast ZR 0-3000 ft

Blast LT 0-3000 ft

Blast M 0-3000 ft

(0-915 m)

(0-915 m)

(0-915 m)

Drive Clutch

Spring

700-1115N 11.5 700-1000N 0823-683 3200 ± 100 7500 19T 50T 90

700-1115N 11.5 700-1000N 0823-683 3200 ± 100 7500 19T 50T 90

700-1115N 11.5 700-1000N 0823-683 3200 ± 100 7500 19T 50T 90

Mass

Block

Driven Clutch

Drive Clutch/Driven

Clutch-Related

Specifications

ALIGNMENT BAR

Offset P/N Center-to-Center Offset

0644-654 11.50” 1.39”

Drive System Components

Spring

Drive Belt

Engagement

RPM

Peak

RPM

Top

Gear

Bottom

Gear

Chain

Pitch

Track Specifications

Model Length Lug Height

Blast ZR 121” (3073 mm) 1.0” (25 mm)

Blast LT 146” (3708 mm) 1.6” (41 mm)

Blast M 146” (3708 mm)

NOTE: The track tension on all models should be

20 lb @ 2 inches (9 kg @ 50 mm).

2.0” (50 mm)

A list of drive system components that are available

through the Arctic Cat Service Parts Department can be

found in the Quick Reference Guide. This information

will be useful when doing any fine-tuning on the drive

system.

6

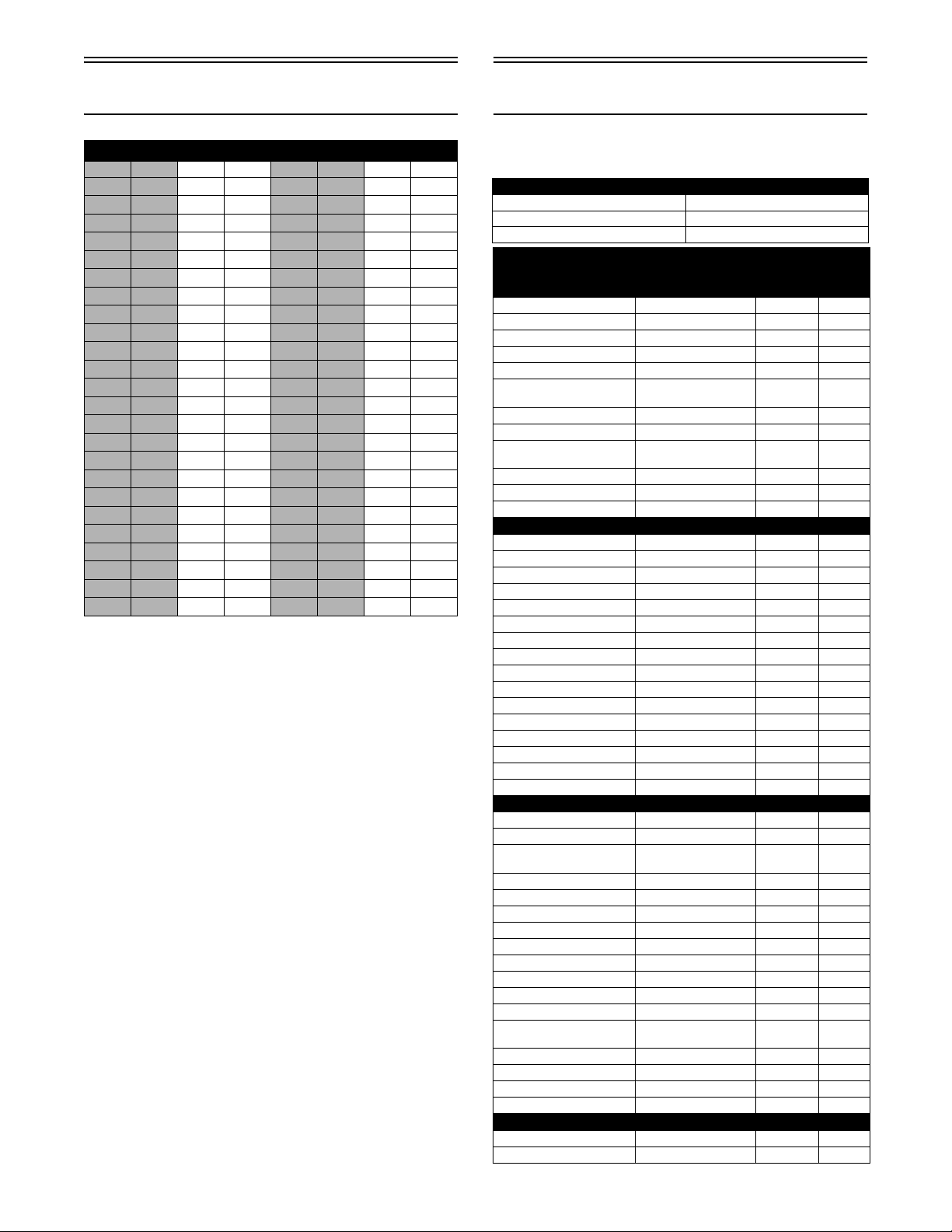

Torque Conversions Torque Specifications

ft-lb N-m ft-lb N-m ft-lb N-m ft-lb N-m

1 1.4 26 35.4 51 69.4 76 103.4

2 2.7 27 36.7 52 70.7 77 104.7

3 4.1 28 38.1 53 72.1 78 106.1

4 5.4 29 39.4 54 73.4 79 107.4

5 6.8 30 40.8 55 74.8 80 108.8

6 8.2 31 42.2 56 76.2 81 110.2

7 9.5 32 43.5 57 77.5 82 111.5

8 10.9 33 44.9 58 78.9 83 112.9

9 12.2 34 46.2 59 80.2 84 114.2

10 13.6 35 47.6 60 81.6 85 115.6

11 15 36 49 61 83 86 117

12 16.3 37 50.3 62 84.3 87 118.3

13 17.7 38 51.7 63 85.7 88 119.7

14 19 39 53 64 87 89 121

15 20.4 40 54.4 65 88.4 90 122.4

16 21.8 41 55.8 66 89.8 91 123.8

17 23.1 42 57.1 67 91.1 92 125.1

18 24.5 43 58.5 68 92.5 93 126.5

19 25.8 44 59.8 69 93.8 94 127.8

20 27.2 45 61.2 70 95.2 95 129.2

21 28.6 46 62.6 71 96.6 96 130.6

22 29.9 47 63.9 72 97.9 97 131.9

23 31.3 48 65.3 73 99.3 98 133.3

24 32.6 49 66.6 74 100.6 99 134.6

25 34 50 68 75 102 100 136

NOTE: Torque specifications have the following tol-

erances:

Tor que Tol eran ce

0-15 ft-lb (0-20 N-m) ±20%

16-39 ft-lb (21-53 N-m) ±15%

40+ ft-lb (54+ N-m) ±10%

Tor qu e

Item Secured to ft-lb N-m

DRIVE SYSTEM

Drive Clutch Engine 51 69.4

Drive Clutch Cover Stationary Sheave 130 176.3

Ring Gear/Damper Drive Clutch 22 29.9

Driven Clutch Driven Shaft 20 27.2

Chain Case (Cap Screw) Chassis 10 13.6

Chain Case (Torx-Head

Screw)

Chain Case Cover Chain Case 108 in.-lb 12.2

Brake Caliper Chassis 25 34

Outside Caliper Housing Inside Caliper

Brake Line Caliper 25 34

Brake Line Master Cylinder 25 34

Brake Caliper Shield Cover 96 in.-lb 10.8

STEERING/FRONT SUSPENSION/CHASSIS

Ski Spindle 35 47.6

Ski Wear Bar 15 20.4

Ski Ski Handle 54 in.-lb 6.1

Steering Support Mounting Block 108 in.-lb 12.2

Steering Post Chassis 20 27.2

Steering Post Cap Riser Block 20 27.2

Tie Rod Steering Post 20 27.2

Tie Rod Spindle Arm 32 43.5

Steering Support Spar 25 34

A-Arm (Upper) Chassis 108 in.-lb 12.2

A-Arm (Lower) Chassis (Front) 65 88.4

A-Arm (Lower) Chassis (Rear) 45 61.2

A-Arm (Upper) Spindle 20 27.2

A-Arm (Lower) Spindle 45 61.2

Shock Absorber A-Arm (Lower) 24 32.6

Shock Absorber Chassis 24 32.6

Wear Strip Rail 50 in.-lb 5.6

End Cap Rail 80 in.-lb 9.2

Idler Wheel/Idler Wheel

Block

Front Arm Rail 52 70.7

Front Arm Tunnel 41 55.8

Idler Arm Tunnel 45 61.2

Front Shock Rail 45 61.2

Front Shock Front Arm 40 54.4

Limiter Strap Limiter Strap 72 in.-lb 8.1

Idler Arm Rear Arm 24 32.6

Rear Wheel Axle Rail 35 47.6

Rear Arm Rail 45 61.2

Rear Shock/Rear Shock

Link

Rear Arm Stop Rail 20 27.2

Rear Shock Idler Arm 40 54.4

Spring Slide Rail 20 27.2

Shock Pivot Front Arm 45 61.2

Wear Strip Rail 50 in.-lb 5.6

End Cap Rail 80 in.-lb 9.2

Chassis 13 17.7

Housing

25 34

REAR SUSPENSION (ZR)

Rail 10 13.6

Shock Pivot 40 54.4

REAR SUSPENSION (LT)

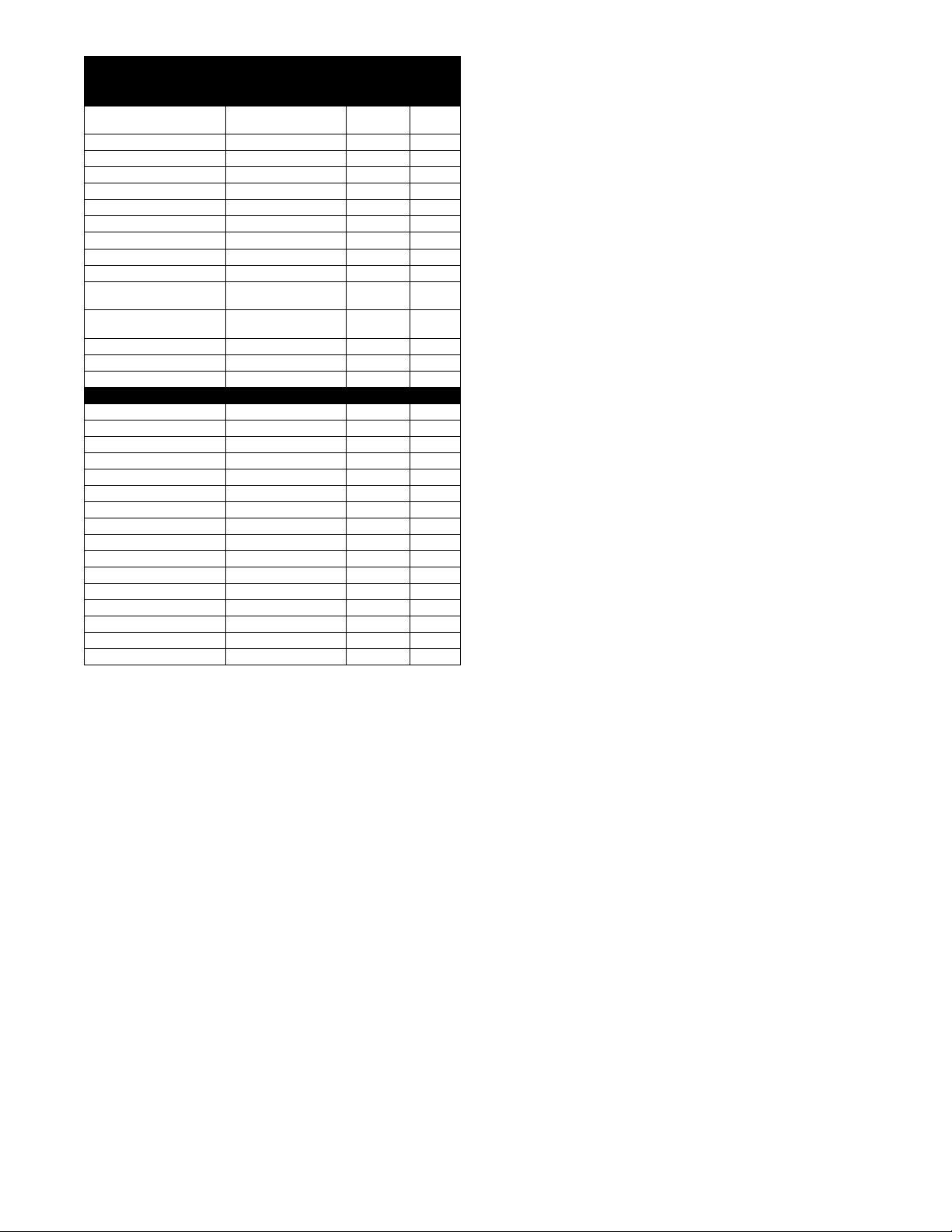

7

Torque

Item Secured to ft-lb N-m

REAR SUSPENSION (LT) (cont.)

Idler Wheel/Idler Wheel

Block

Front Arm Rail 52 70.7

Front Arm Tunnel 41 55.8

Idler Arm Tunnel 45 61.2

Front Shock Rail 45 61.2

Front Shock Front Arm 40 54.4

Limiter Strap Limiter Strap 72 in.-lb 8.1

Idler Arm Rear Arm 24 32.6

Rear Wheel Axle Rail 35 47.6

Rear Arm Rail 45 61.2

Rear Shock/Rear Shock

Link

Rear Shock/Rear Shock

Link

Rear Arm Stop Rail 20 27.2

Spring Slide Rail 20 27.2

Swing Arm Rail 40 54.4

Rail 10 13.6

Front Arm 40 54.4

Idler Arm 40 54.4

REAR SUSPENSION (M)

Wear Strip Rail 50 in.-lb 5.6

Idler Wheel Rail/Shaft 13 17.7

Front Arm Rail 52 70.7

Front Shock Front Arm 24 32.6

Front Shock Rail 52 70.7

Rear Arm Rail 13 17.7

Rear Arm Idler Arm 24 32.6

Track Guide Rear Arm 24 in.-lb 2.7

Rear Axle Rail 24 32.6

Rear Shock Idler Arm 24 32.6

Rear Shock Rear Shock Pivot 24 32.6

Rear Shock Link Rear Shock Pivot 24 32.6

Rear Shock Link Idler Arm 24 32.6

Skid Frame Tunnel 45 61.2

Limiter Strap Limiter Strap 72 in.-lb 8.1

Limiter Strap Rail 15 20.4

8

Steering and Body

This section has been organized into sub-sections for servicing steering and body components; however, some

components may vary from model to model. The technician should use discretion and sound judgment when

removing and installing components.

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is necessary.

SPECIAL TOOLS

A number of special tools must be available to the technician when servicing the steering and body systems.

Description p/n

Handlebar Stand 5639-152

Steering Post Stand 5639-946

NOTE: Special tools are available from the Arctic

Cat Service Parts Department.

Steering Post

SNO-763

5. Remove the nut and washer securing the bottom of

the steering post to the chassis. Discard the nut.

REMOVING

1. Rotate the two quarter turns to the vertical position;

then pull the top of the side panel out and up and off

the skid plate.

2. Remove the Torx screw securing the front of the

hood to the chassis; then loosen the two quarter-turns

securing the hood.

ONS-305

3. Disconnect the hood harness and remove the hood;

then remove the screws securing the front belly pan

to the front frame.

0755-041

6. Remove the two cap screws and nuts securing the tie

rod ends to the steering post. Discard both nuts.

0755-042

7. Remove the cap screws and handlebar caps securing

the handlebar to the top of the handlebar riser; then

remove the two nuts securing the top of steering post

to the chassis. Account for both steering post blocks

and retaining plate.

4. Remove the push rivets securing the right-side steering boot to the chassis. This allows access to the two

tie rod cap screws and nuts.

9

SNO-357

8. Carefully remove the steering post from the snowmobile.

INSTALLING

1. Install steering post into position in the chassis.

Secure the steering post using the existing washer

and a new nut. Tighten to 20 ft-lb (27.2 N-m).

0755-041

2. Secure the tie rod assemblies to the steering post

using two new nuts. Tighten to 20 ft-lb (27.2 N-m).

SNO-763

4. Secure the top of the steering post to the steering

support using the existing retaining plate and nuts.

Tighten to 96 in.-lb (10.8 N-m).

5. Install the handlebar riser and handlebar to the top of

the steering post and secure using the existing caps

and screws. Tighten evenly to 20 ft-lb (27.2 N-m).

SNO-357

6. Position the hood onto the snowmobile and connect

the hood harness connector. Secure using the existing screw and the two quarter-turns.

7. Install the access panels.

0755-042

3. Secure the steering boots to the chassis using the

existing push rivets.

10

Ski

REMOVING

1. Elevate the front of the snowmobile and secure on a

support stand.

2. Remove and discard the cotter pin; then remove the

nut and cap screw securing the ski to the spindle.

NOTE: Note the orientation of the damper for

installation purposes.

3. Remove the ski. Account for the rubber damper,

axle, spacers and washers.

INSPECTING

1. Inspect the ski for cracks or deterioration.

2. Inspect the ski for abnormal bends or cracks.

3. Inspect the wear bar for wear.

4. Inspect all hardware and the spindle bushings for

wear and damage.

5. Inspect the rubber damper for damage or wear.

INSTALLING

1. Slide a washer onto the cap screw used to secure the

ski; then apply low-temperature grease to the shaft

portion of the cap screw and spindle axle.

2. Install the spindle axle and spacers into the spindle;

then position the ski damper into the bottom of the

ski making sure the damper is properly positioned

for the desired ski stance.

0752-477

NOTE: The ski damper must be positioned in the

ski so it is directly under the spindle.

Spindle

0755-083

REMOVING

1. Position the front of the snowmobile on a safety

stand; then remove the ski.

2. Remove the two cap screws and nuts securing the

shock to the chassis and to the lower A-arm.

3. Remove the lock nut securing the tie rod to the spindle arm. Account for the washer on the top side.

3. With the cap screw hole of the ski centered with the

spindle axle, slide the cap screw with washer through

the outside of the ski and spindle assemblies.

NOTE: Install the cap screw so the lock nut will be

located to the inside of the ski and the cotter pin slot

in the cap screw will be horizontal with the ski.

4. Install the remaining washer and lock nut; then

tighten the lock nut to 35 ft-lb (47.6 N-m).

5. Install a new cotter pin from the back side of the ski

cap screw and spread the pin.

Ski Wear Bar

The ski wear bar is a replaceable bar attached to the

underside of the ski. If the snowmobile is operated primarily in deep snow, ski wear bar wear will be minimal;

however, if the snowmobile is operated on terrain where

the snow cover is minimal, the ski wear bar will wear

faster. Arctic Cat recommends that the ski wear bars be

replaced if worn to 1/2 of original diameter.

REMOVING

1. Raise the front of the snowmobile and secure with a

suitable stand.

2. Remove the lock nuts securing the wear bar to the

ski; then remove the wear bar.

INSTALLING

1. Install the wear bar into the ski making sure it is fully

seated using a rubber mallet.

2. Secure the wear bar with lock nuts. Tighten to 15

ft-lb (20.4 N-m).

4. Remove the machine screw and tri-nut securing the

upper A-arm ball joint to the spindle.

5. Remove the lock nut securing the spindle to the

lower A-arm; then using a rubber mallet, remove the

lower arm from the spindle.

INSPECTING

1. Inspect the spindle for excessive wear, cracks, bends,

or imperfections.

2. Inspect the A-arm bushings and axle area for wear.

3. Inspect the ski spindle axle and bearings for wear,

damage, or loose fit. Replace the bearings as a set.

NOTE: Replacing the ski bushings is difficult. The

existing bushings will be damaged during removal. Be

careful, however, not to damage the spindle when removing the bushings. Press the new bushings into the spindle.

INSTALLING

1. Install the lower A-arm into the spindle and loosely

secure using a new lock nut.

2. Loosely secure the upper A-arm ball joint to the

spindle using the existing machine screw and the

tri-nut. Raise the spindle so the upper A-arm is level;

then tighten the new screw securing the ball joint to

the spindle to 20 ft-lb (27.2 N-m).

3. Install the shock and secure using the existing cap

screws and new lock nuts. Tighten to 24 ft-lb (32,6

N-m).

4. Remove the snowmobile from the support stand.

Tighten lower A-arm lock nut to 45 ft-lb (61,2 N-m).

NOTE: The weight of the snowmobile will allow the

lower ball joint to seat into the spindle before tightening the nut.

11

5. Place the tie rod with washer into position on the

spindle arm. Secure with a new lock nut. Tighten to

32 ft-lb (43,5 N-m).

6. Install the ski.

7. Turn the handlebar fully to the right and then to the

left to verify the steering moves freely.

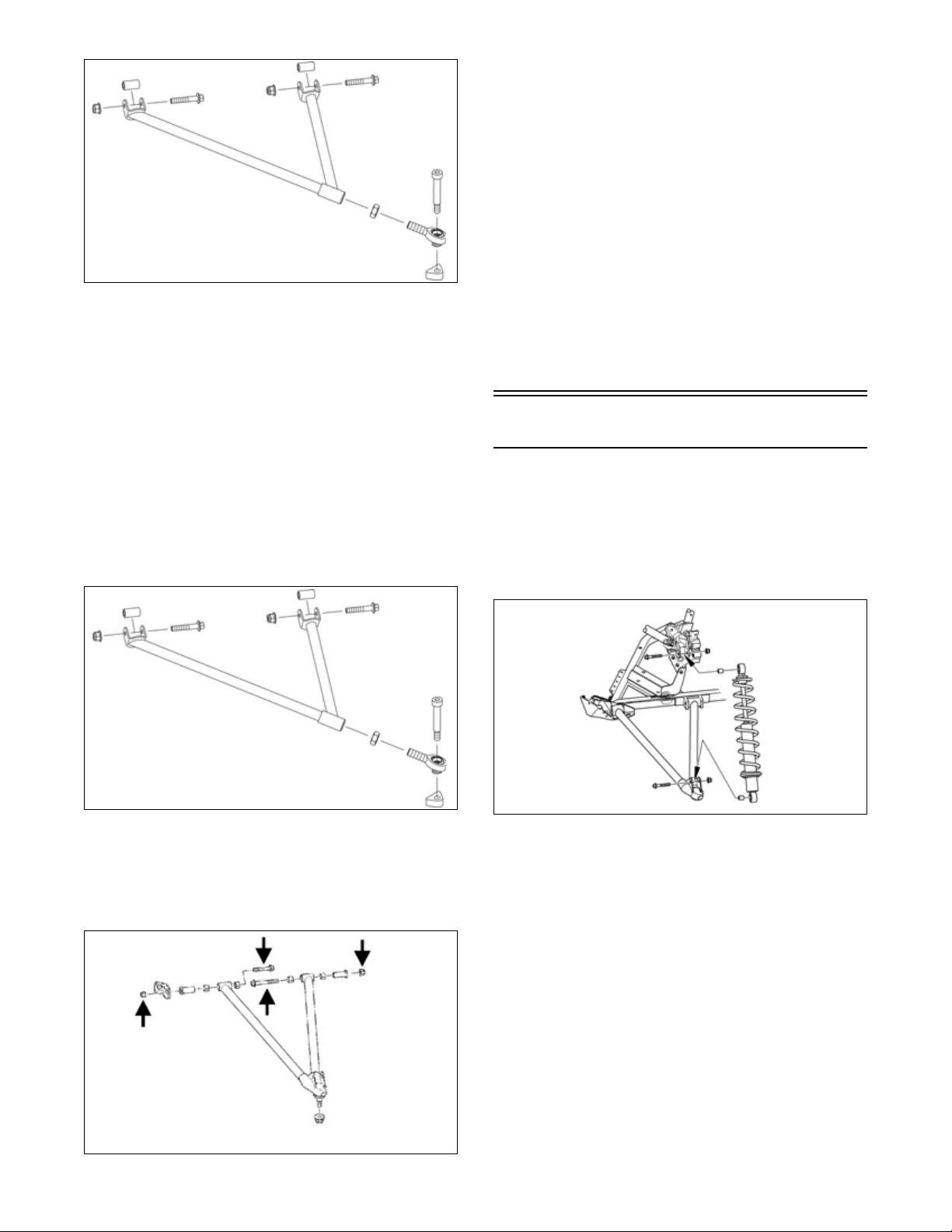

Tie Rod

REMOVING

1. Remove the push rivets securing the right-side steering boot to the chassis. This allows access to the two

tie rod cap screws and nuts.

SNO-763

2. Remove both machine screws and nyloc nuts securing the steering tie rod ends to the steering arm. Discard both nuts.

0755-084

4. Slide the steering tie rod out of the steering boot and

out of the snowmobile.

INSPECTING

1. Inspect the ball joints for damaged threads or wear.

2. Inspect the tie rod for damage, unusual bends, or

wear.

INSTALLING

1. Slide the steering tie rod through the steering boot

and into the snowmobile; then place the steering tie

rod into the spindle arm with the washer. Secure

with a new nyloc nut. Tighten to 32 ft-lb (43,5 N-m).

0755-042

3. Remove the nyloc nuts securing the tie rod ends to

the spindle arms. Account for the washers.

12

0755-084

2. Secure the tie rod to the steering tie rod bracket with

the screw and new nyloc nut. Tighten to 20 ft-lb

(27.2 N-m).

0755-042

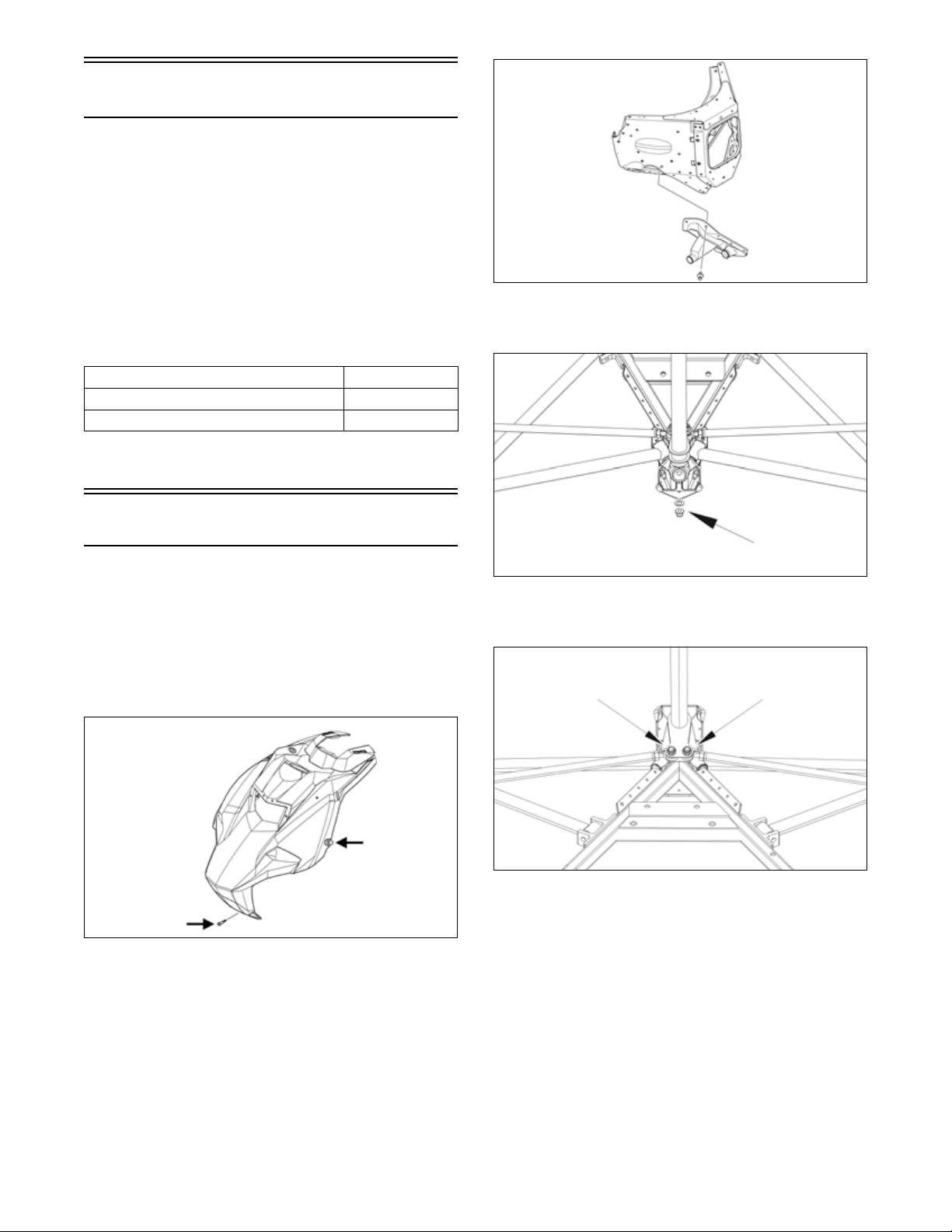

Ski Alignment

CHECKING

NOTE: Track tension and alignment must be properly adjusted prior to checking or adjusting ski alignment. Ski alignment must be performed on a flat,

level surface. Ski toe-out must fall within the range of

1/16-1/4 in (1.6-6.4 mm).

1. Raise the front end of snowmobile just high enough

to keep the skis from contacting the floor.

2. Turn the handlebar to the straight-ahead position.

Visually inspect the handlebar for being centered and

in the straight-ahead position.

3. With the handlebar in the straight-ahead position,

secure the handlebar to prevent the alignment from

becoming disturbed during the remainder of the

alignment procedure.

NOTE: Track tension and alignment must be prop-

erly adjusted prior to placing the straightedge against

the outside edge of the track.

4. Place a long straightedge against the outside edge of

the track so it lies near the inside edge of the left-side

ski.

729-887A

0734-408

6. Place the straightedge against the outside edge of the

track so it lies near the inside edge of the right-side

ski.

729-887B

NOTE: The straightedge should be long enough to

extend from the back of the track to the front of the

ski.

5. Measure the distance from the straightedge to the

left-side ski wear bar bolts in two places: approximately 7-8 in. (18-20 cm) in front of the spindle and

7-8 in. (18-20 cm) behind the spindle. Record the

measurements taken for the left side.

7. Measure the distance from the straightedge to the

right-side ski wear bar bolts in two places: 7-8 in.

(18-20 cm) in front of the spindle and 7-8 in. (18-20

cm) behind the spindle. Record the measurements

taken for the right side.

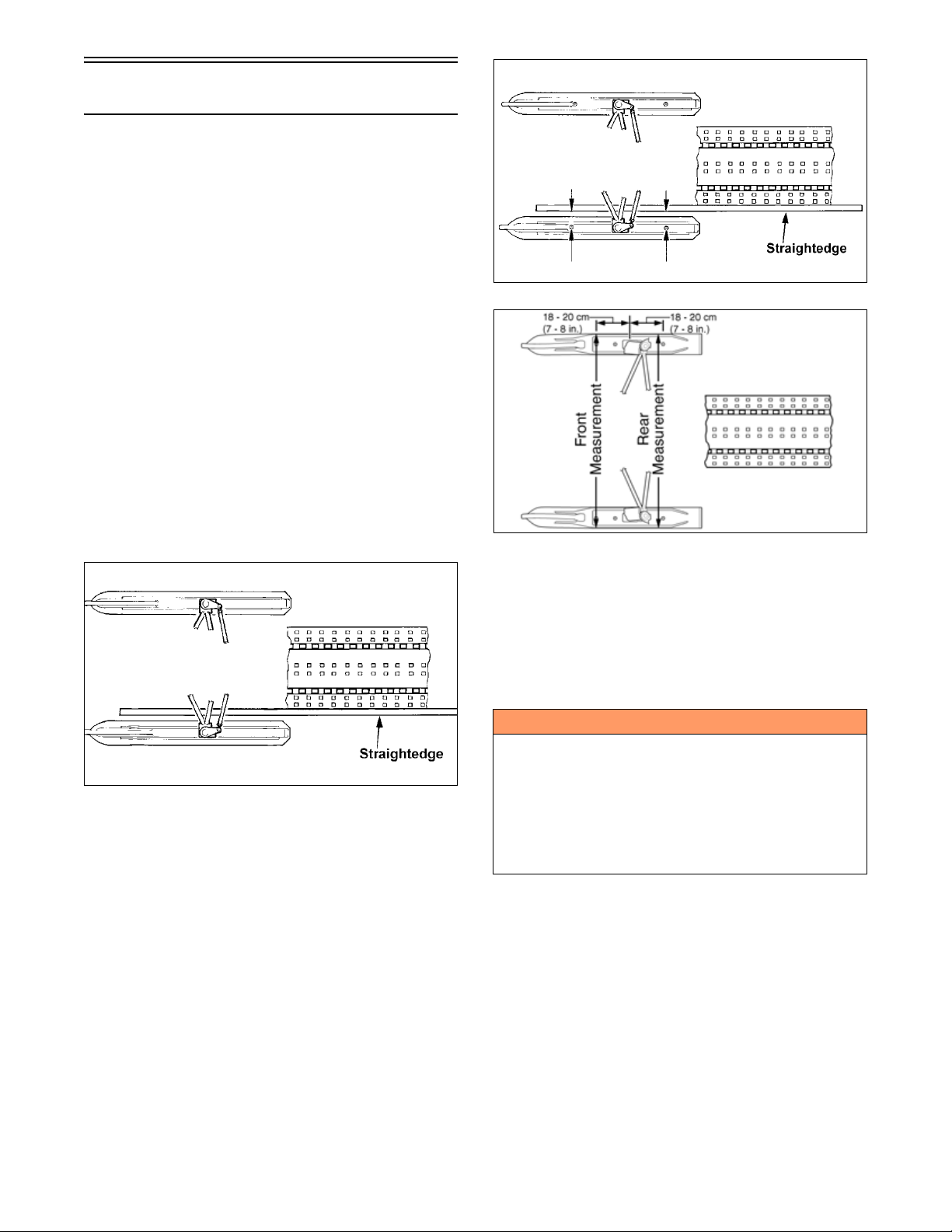

! WARNING

The measurement from the front and rear wear bar bolts

to the straightedge can be equal (ski parallel to the

track), but the front measurement must never be less

(ski toed-in) or poor handling will be experienced. The

front wear bar bolt measurement to the straightedge

must not exceed the measurement from the rear wear

bar bolt to the straightedge (ski toed-out) by more than

5/32 in. (4 mm).

8. If ski alignment is not as specified, adjust the alignment of the ski(s) not parallel to the straightedge.

ADJUSTING

NOTE: The following procedure can be used to

adjust the alignment of either ski.

NOTE: The rivets securing the steering boots will

have to be removed in order to adjust the inner tie rod

ends.

1. Secure the steering tie rod in the centered position.

2. Loosen both spindle tie rod jam nuts on the same

side as the ski to be aligned.

13

3. Using a wrench on the spindle tie rod “flats,” rotate

the spindle tie rod until recommended specification

is attained.

4. Apply blue Loctite #243 to each jam nut thread area;

then tighten the jam nuts against the spindle tie rod.

NOTE: Repeat this procedure on each side (if neces-

sary) until ski toe-out is within specification.

! WARNING

Neglecting to lock the tie rod by tightening the jam nuts

may cause loss of snowmobile control and possible

personal injury.

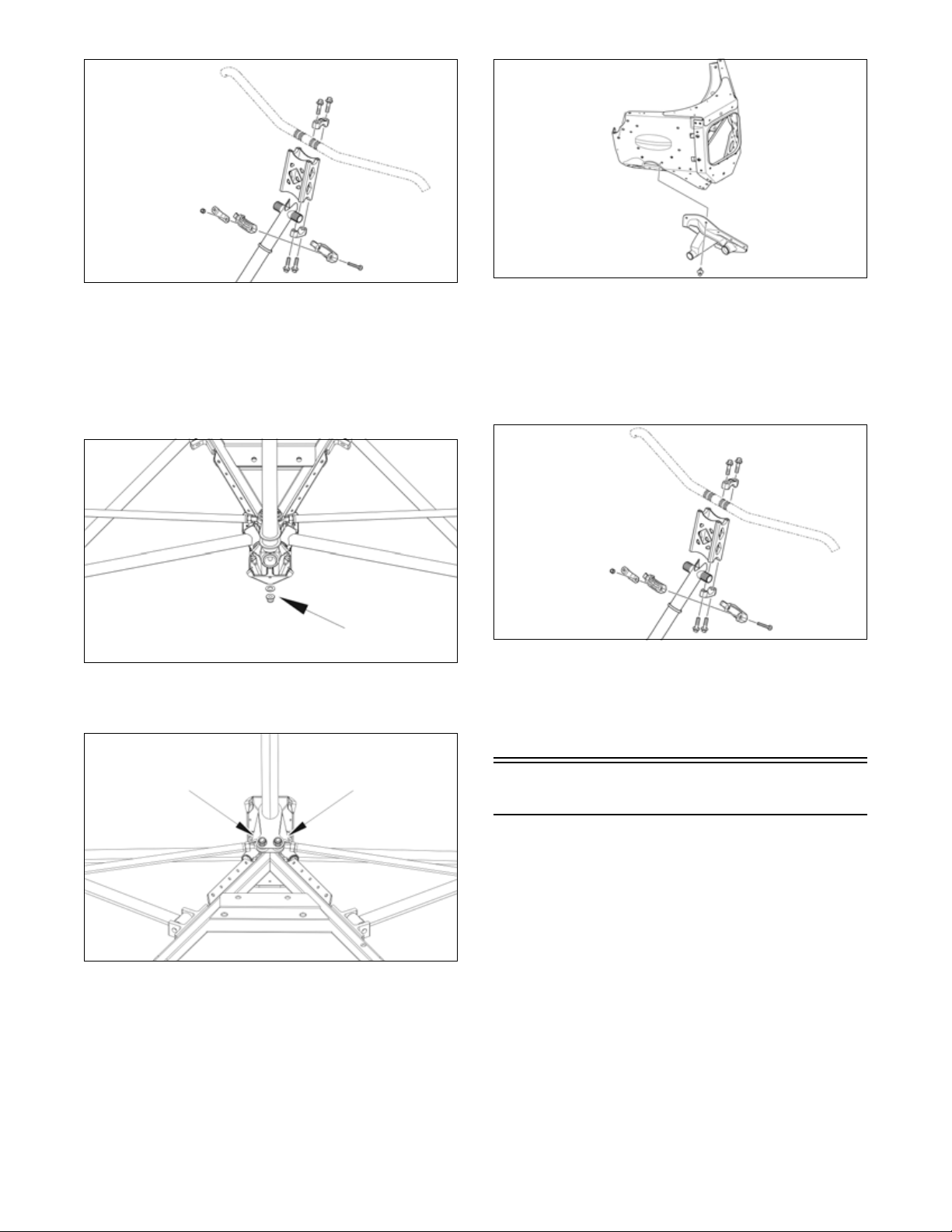

VERIFYING

1. With the handlebar in the straight-ahead position,

verify ski alignment by measuring across from the

outside edge of the left-side wear bar bolts to the outside edge of the right-side wear bar bolts (without

using the straightedge) in two places: approximately

7-8 in. (18-20 cm) in front of the spindle and 7-8 in.

(18-20 cm) behind the spindle.

2. The measurement from in front of the spindle to the

outer edge of the wear bar bolts (without using the

straightedge) must not exceed the rear measurement

by more than 1/16-1/4 in. (1.6-6.4 mm) toe-out.

SNO-763

3. Remove the Torx-head screws securing the front skid

plate to the chassis; then remove the front skid plate.

4. Remove the ski shock absorber.

5. Remove the lock nut, machine screw, and tri-nut

securing the spindle to the A-arms; then using a rubber mallet, remove the lower A-arm from the spindle.

0734-408

! WARNING

The measurement taken in front of the spindle must

never be less than the measurement taken behind the

spindle or poor handling will be experienced. Neglecting to lock the tie rod by tightening the jam nuts may

cause loss of snowmobile control and possible personal injury.

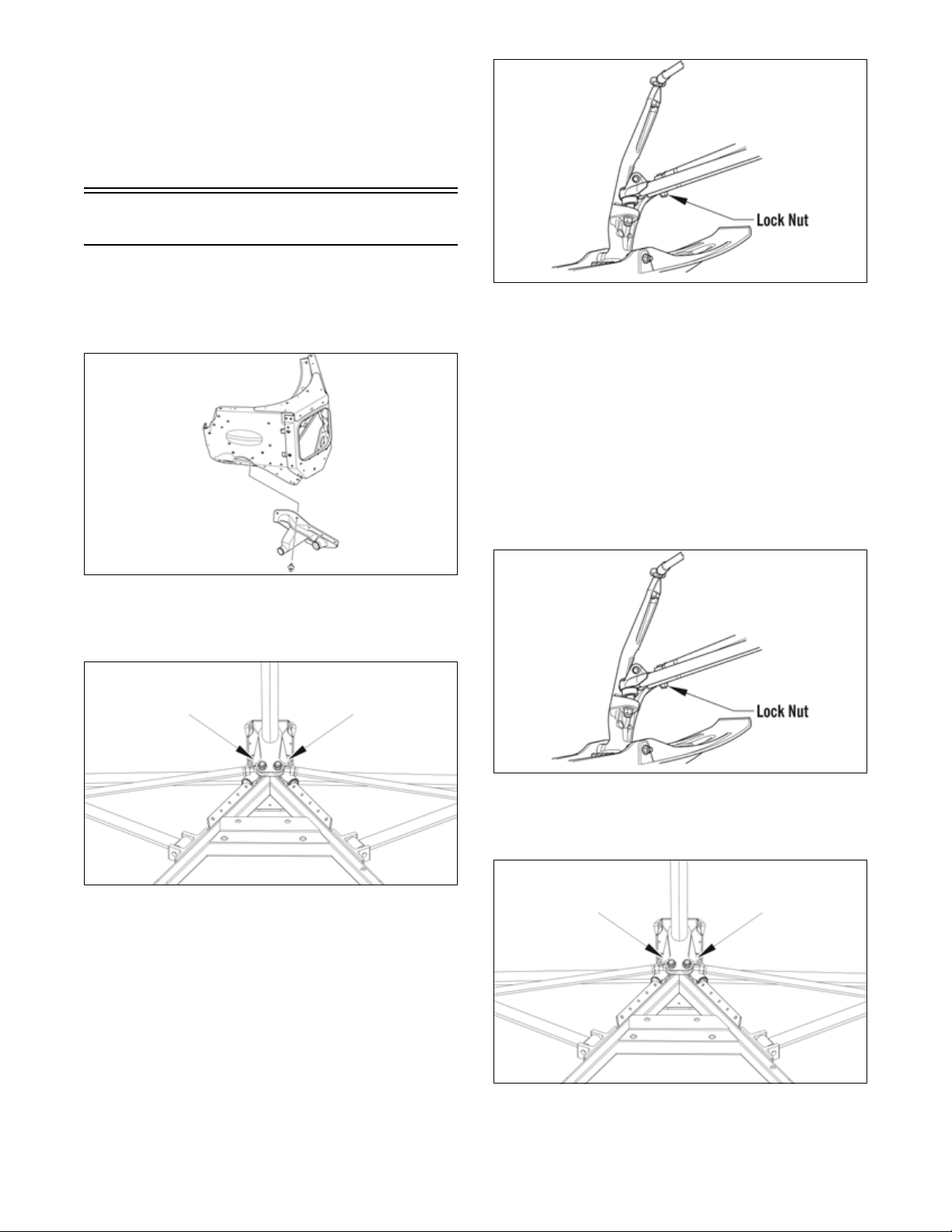

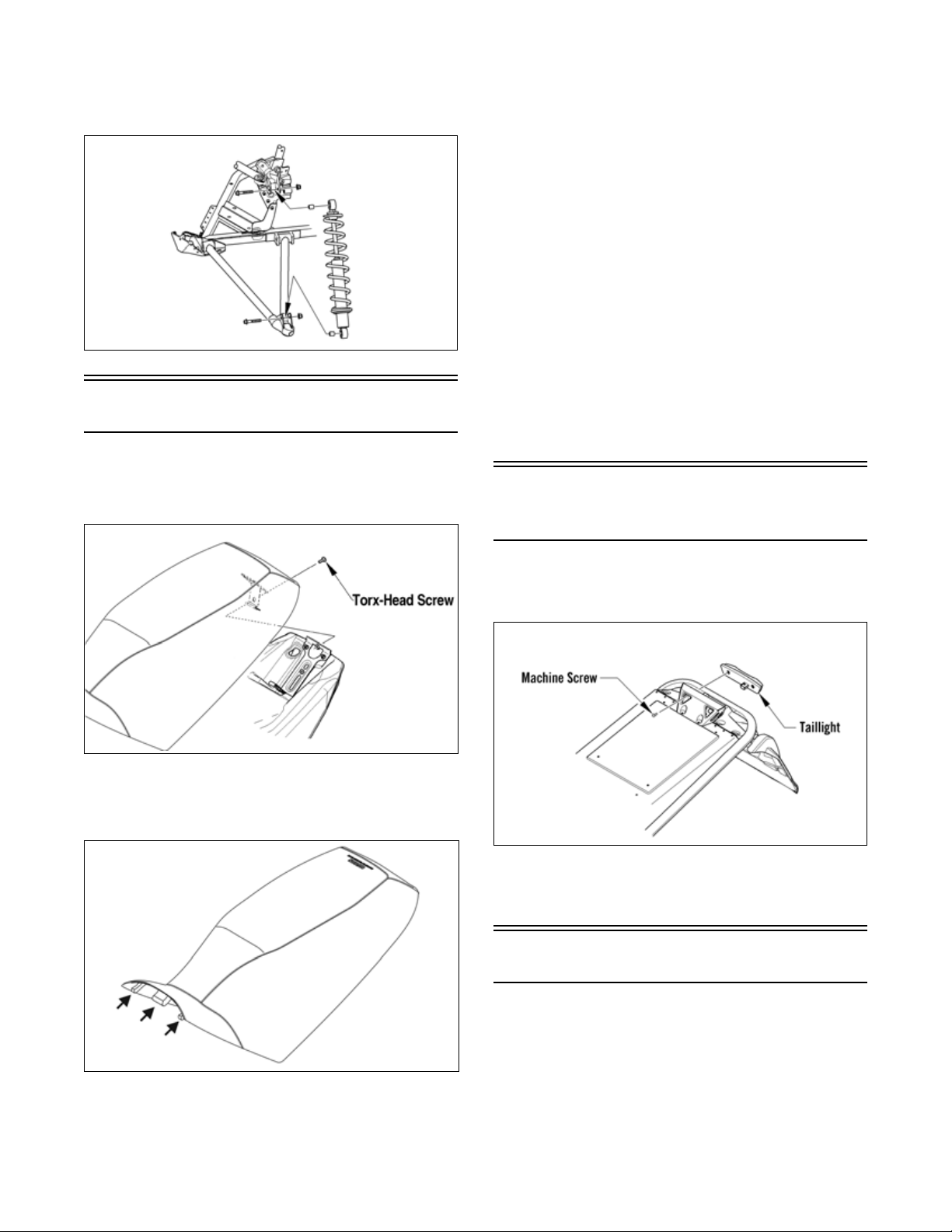

A-Arms

NOTE: Always use new lock nuts when replacing

any steering components.

REMOVING

1. Elevate the front of the snowmobile and secure using

a suitable support stand.

2. Remove the push rivets securing the steering boot to the

chassis; then slide the boot away from the snowmobile.

0755-085

6. Remove the two cap screws and nyloc nuts securing

the lower arm to the chassis; then slide the boot from

the arm and remove the arm.

SNO-226A

7. Remove the two cap screws and lock nuts securing

the upper arm to the chassis.

14

3. Secure the A-arms to the spindle using one new lock

nut, a new machine screw and the existing tri-nut.

Tighten to the lock nut 45 ft-lb (61.2 N-m) and the

machine screw to 20 ft-lb (27.2 N-m).

NOTE: If the upper A-arm ball joint is being

replaced, make sure the ball joint is threaded in as far

as it can. Do not adjust outward or damage to the

A-arm or ball joint can occur.

4. Using a 19 mm wrench, tighten the hex nut against

the upper A-arm securely making sure to keep the

ball joint level with the spindle.

SNO-572

INSPECTING

1. Inspect the arm welded areas for cracks or any signs

of deterioration.

2. Inspect the bearings and axles for wear or damage.

3. Inspect the arm tubing for signs of twisting or bending.

4. Inspect mounting location of the chassis for cracks or

wear.

INSTALLING

1. Place the upper arm into position on the chassis and

secure with the cap screws, axles, and new lock nuts.

Tighten to 108 in.-lb (12.2 N-m).

5. Install the ski shock absorber and secure using the

existing cap screws and new lock nuts. Tighten to 24

ft-lb (32.6 N-m).

6. Install the steering boot and secure using the existing

push-rivets; then place the front skid plate into position. Secure with the Torx-head screws.

Ski Shock Absorber

REMOVING

1. Position the front of the snowmobile on a safety

stand taking all pressure off the skis.

2. Remove the cap screws securing the shock absorber

to the chassis and the lower A-arm; then remove the

shock absorber. Account for all mounting hardware.

SNO-572

2. Slide the lower arm into the steering boot; then place

the arm into position on the chassis with the existing

bushings. Secure with the cap screws and new lock

nuts and tighten to 65 ft-lb (88.4 N-m) (front) and 45

ft-lb (61.2 N-m) (rear).

SNO-226A

0753-180

CLEANING AND INSPECTING

1. Inspect the shock absorber seal area for signs of

excessive oil leakage.

2. Inspect the shock absorber mounting eyelet, bushings, and sleeve for wear or damage.

3. Inspect the threaded shock sleeve for damage or

wear.

INSTALLING

1. Using the shock spring tool, place the spring on the

shock absorber and secure with the retainer.

2. Adjust the retainer nut (spring adjuster) (if applicable) until the specified amount of threads are

exposed between the spring adjuster and the shock

housing (noted in removing) as an initial setting.

15

3. Install the bushings, sleeves, and spacers into each

shock end; then place the shock absorber into position and secure with the cap screws and new lock

nuts. Tighten the lock nuts to 24 ft-lb (32.6 N-m).

0753-180

Seat Assembly

REMOVING/INSTALLING SEAT

1. Remove the cap screw securing the rear of the seat;

then remove the seat.

2. Using a sharp tool, pry out all staples securing the seat

cover to the plastic seat base.

INSTALLING CUSHION

1. Position the cover over the seat foam and seat base.

Check to make sure it is positioned straight.

2. Fold the rear edge of the cushion down and around the

plastic base. Using a staple gun and 1/4 in. (6 mm) staples, staple the rear flap of the cushion to the plastic

base in the same areas as the original staples were

located. Position staples 1 in. (25 mm) apart.

3. Fold the sides of the cushion down around the bottom

edge of the plastic seat base. Position the staples in the

same area as the original staples were located.

NOTE: Note the cushion fit. If any wrinkles are

noted, remove by pulling the cushion material in the

appropriate direction before securing with staples.

4. Fold the front cushion material back and onto the plastic seat base. Check for wrinkles and secure with staples and two screws.

5. Install the seat assembly.

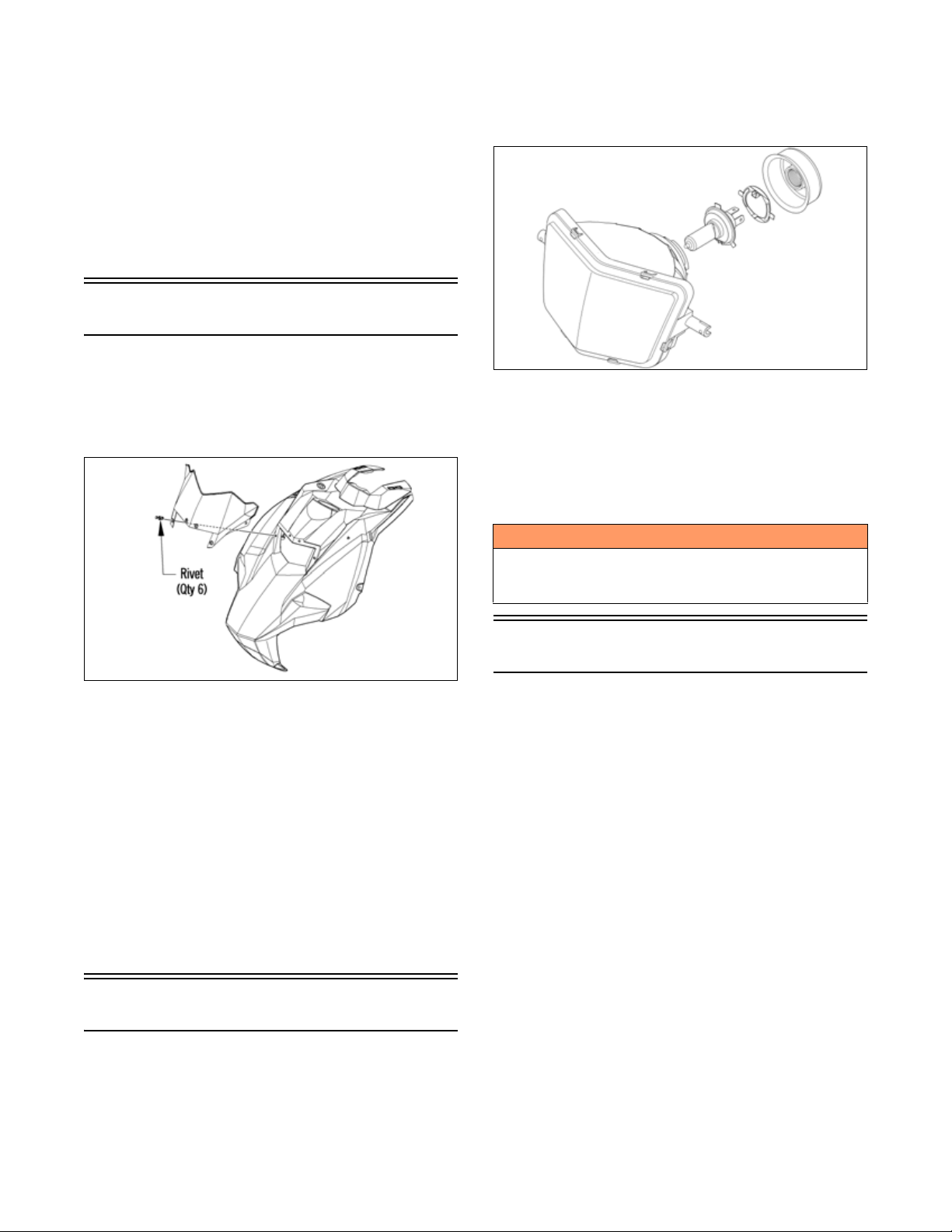

Taillight/Brake Light

Assembly

ONS-332

2. Route the front tab on the seat through the seat-base

hold-down bracket; then install the seat and secure

using the cap screw.

1. Remove the two machine screws securing the taillight to the taillight support; then disconnect the taillight harness connector.

SNO-511

2. Connect the taillight harness connector; then secure

the taillight to the taillight support with the two

machine screws. Tighten to 48 in.-lb (5.4 N-m).

Rear Bumper/Snowflap

REMOVING BUMPER

1. Remove all rivets securing the bumper to the chassis.

ONS-328

RE MOVING CUSHION

1. Remove the seat assembly.

16

INSTALLING BUMPER

1. Align the holes in the bumper with the existing holes

in the tunnel; then using new rivets, secure rear

bumper to the tunnel.

REMOVING SNOWFLAP

1. Remove the screws, washers, and nuts securing the

snowflap to the chassis.

2. Remove the snowflap.

INSTALLING SNOWFLAP

1. Position the snowflap with the mounting holes in the

chassis.

2. Secure the snowflap to the chassis using the existing

screws, washers, and nuts. Tighten to 62 in.-lb (7

N-m).

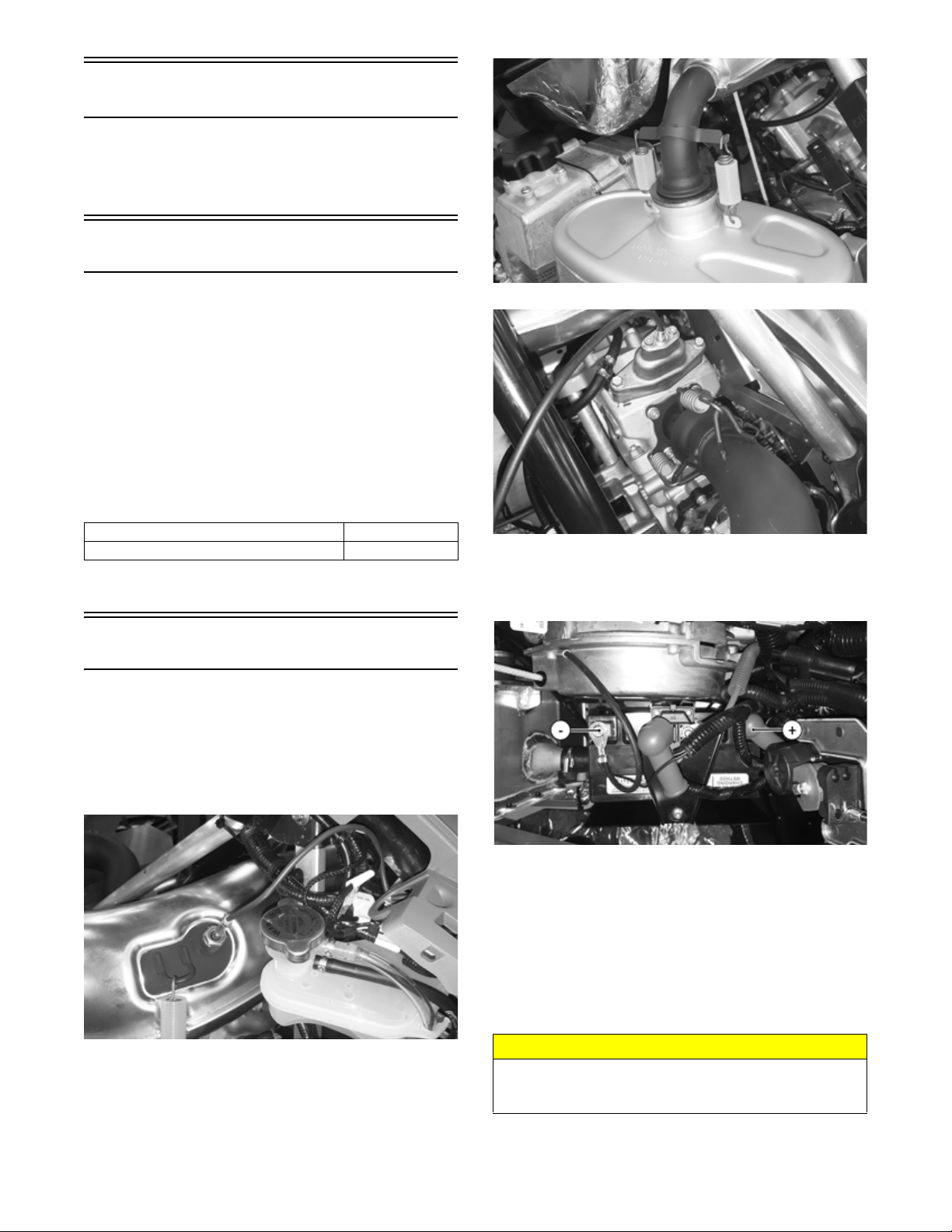

Windshield/Headlight

1. Disconnect the harness from the back of the bulb;

then remove the rubber boot.

2. Rotate the spring retainer securing the bulb in the

headlight; then carefully remove the bulb.

REMOVING

1. Remove both access panels and the hood.

2. Remove the rivets securing the windshield to the

hood. Remove the windshield.

0753-240

3. Disconnect the harness from the back of the bulb.

4. Remove the two pins securing the outer portion of

the headlight; then remove the screw securing the

lower portion of the headlight. Remove the headlight

from the hood.

INSTALLING

1. Install the headlight assembly into the hood tabs and

secure using the existing pins and screw.

2. Connect the harness to the bulb.

3. With the windshield in position, secure the windshield to the hood using the rivets. Tighten securely.

4. Install the hood and both access panels.

ONS-389

3. Install the bulb and retainer; then rotate the retainer

clockwise until it properly locks in place.

4. Install the rubber grommet; then connect the headlight harness connector to the bulb.

5. Check headlight aim (see Adjusting Headlight Aim

in this sub-section).

! WARNING

Do not operate the snowmobile unless headlight beam

is adjusted properly. An incorrectly adjusted beam will

not provide the operator the optimum amount of light.

Adjusting Headlight Aim

The headlight can be adjusted for vertical aim of the

HIGH/LOW beam. The geometric center of LOW beam

zone is to be used for vertical aiming.

1. Position the snowmobile on a level floor so the headlight is approximately 25 ft. (7.62 m) from an aiming

surface (wall or similar surface).

NOTE: There should be an “average” operating load

on the snowmobile when adjusting headlight aim.

2. Measure the distance from the floor to midpoint of

the headlight.

3. Using the measurement obtained in step 2, make a

horizontal mark on the aiming surface.

4. Make a vertical mark intersecting the horizontal mark

on the aiming surface directly in front of the headlight.

Headlight Bulb

NOTE: The bulb portion of the headlight is fragile.

HANDLE WITH CARE. When replacing the headlight bulb, the bulb assembly must first be removed

from the housing. Do not touch the glass portion of

the bulb. If the glass is touched, it must be cleaned

with a dry cloth before installing.

5. Engage the brake lever lock and start the engine.

Select the headlight dimmer switch LOW beam position. DO NOT USE HIGH BEAM.

Observe the headlight beam aim. Proper aim is when the

6.

most intense beam is centered on the vertical mark 5 cm

(2 in.) below the horizontal mark on the aiming surface.

7. Adjust the headlight using the adjusting screw on the

backside of the headlight housing until correct aim is

obtained. Shut the engine off; then disengage the

brake lever lock.

17

Engine

NOTE: Whenever a part is worn excessively,

cracked, or damaged in any way, replacement is necessary.

Engine Removing/Installing

This engine sub-section has been organized to show a

progression for removing/installing the Arctic Cat

engine. For consistency purposes, this sub-section shows

a complete and thorough progression; however, for efficiency it may be preferable to remove only those components needing to be addressed. Also, some components

may vary from model to model. The technician should

use discretion and sound judgment.

SPECIAL TOOLS

A number of special tools must be available to the technician when performing service procedures in this engine

section.

Description p/n

Drive Clutch Puller 0744-062

NOTE: Special tools are available from the Arctic

Cat Service Parts Department.

Removing

NOTE: For assembling purposes, note cable tie

locations securing the harness and cables to the chassis.

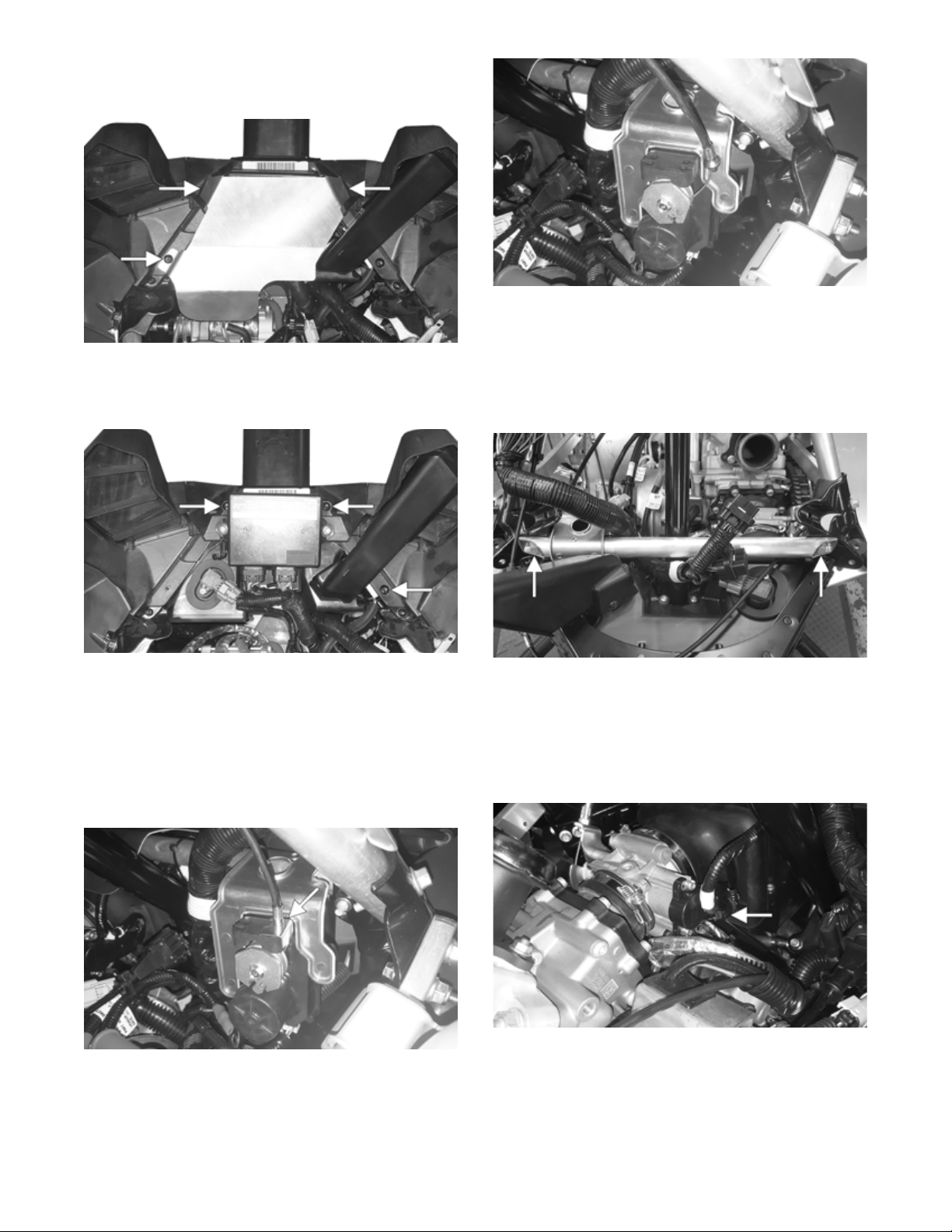

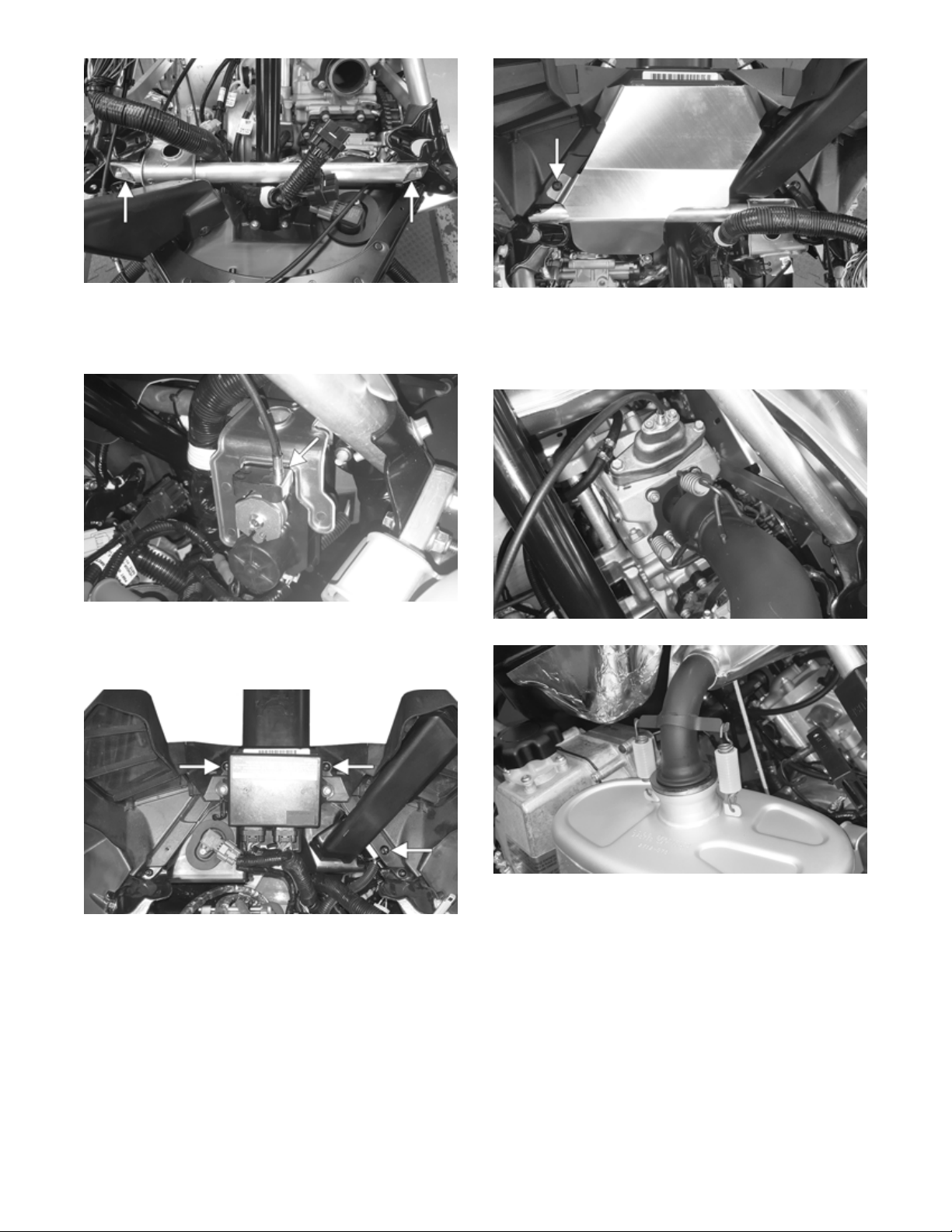

ZR-457

ZR-456

3. Disconnect the battery cables; then remove the screw

securing the battery hold-down bracket. Remove the

battery.

1. Remove both access panels and the hood; then

remove the exhaust temperature sensor from the

expansion chamber.

ZR-458

2. Remove all springs securing the expansion chamber

and resonator; then remove the expansion chamber

and resonator.

18

ZR-386

4. Remove the cap screw and washer securing the

driven clutch and slide the driven clutch (along with

the drive belt) off the driven shaft. Account for the

offset washers.

5. Remove the cap screw and washer securing the drive

clutch to the crankshaft.

6. Using Drive Clutch Puller, tighten the puller.

Remove the drive clutch.

CAUTION

Never attempt to substitute any other drive clutch puller

for the recommended puller or severe clutch or crankshaft damage will occur.

NOTE: If the drive clutch will not release, sharply

strike the head of the puller. Repeat this step until the

clutch releases.

7. Remove the screw securing the heat shield to the

chassis; then remove the heat shield from the two

front locating pins and remove the heat shield.

ZR-461

8. Disconnect the ECM; then remove the screws securing the right and left-side fascia panels to the chassis.

Remove the panels and ECM as an assembly.

ZR-414

12. Remove the cap screws and lock nuts securing the

shock mount bracket support to the shock mount

brackets; then remove the shock mount bracket support.

NOTE: Take care to not drop the spar inserts and

nuts when removing the support.

ZR-460

9. Remove the cap screws securing the PTO-side front

spar to the steering support and shock mount bracket;

then remove the spar.

NOTE: Take care to not drop the spar inserts and

nuts when removing the spar.

10. Remove the servomotor cable holder; then pull the

cable housing down and out of the servomotor.

ZR-413

11. Slide each cable end out of the slot of the clutch; then

disconnect the connector from the servomotor.

ZR-454

13. Drain the engine coolant (see Liquid Cooling System

in the Engine-Related Items section).

14. Loosen the two clamps securing the throttle body to

the intake manifold and the intake boot. Remove the

cable tie securing the TPS harness; then disconnect

the TPS connector.

ZR-415

15. Loosen the two clamps securing the throttle body

coolant hoses to the engine. Carefully remove the

throttle body and set aside.

19

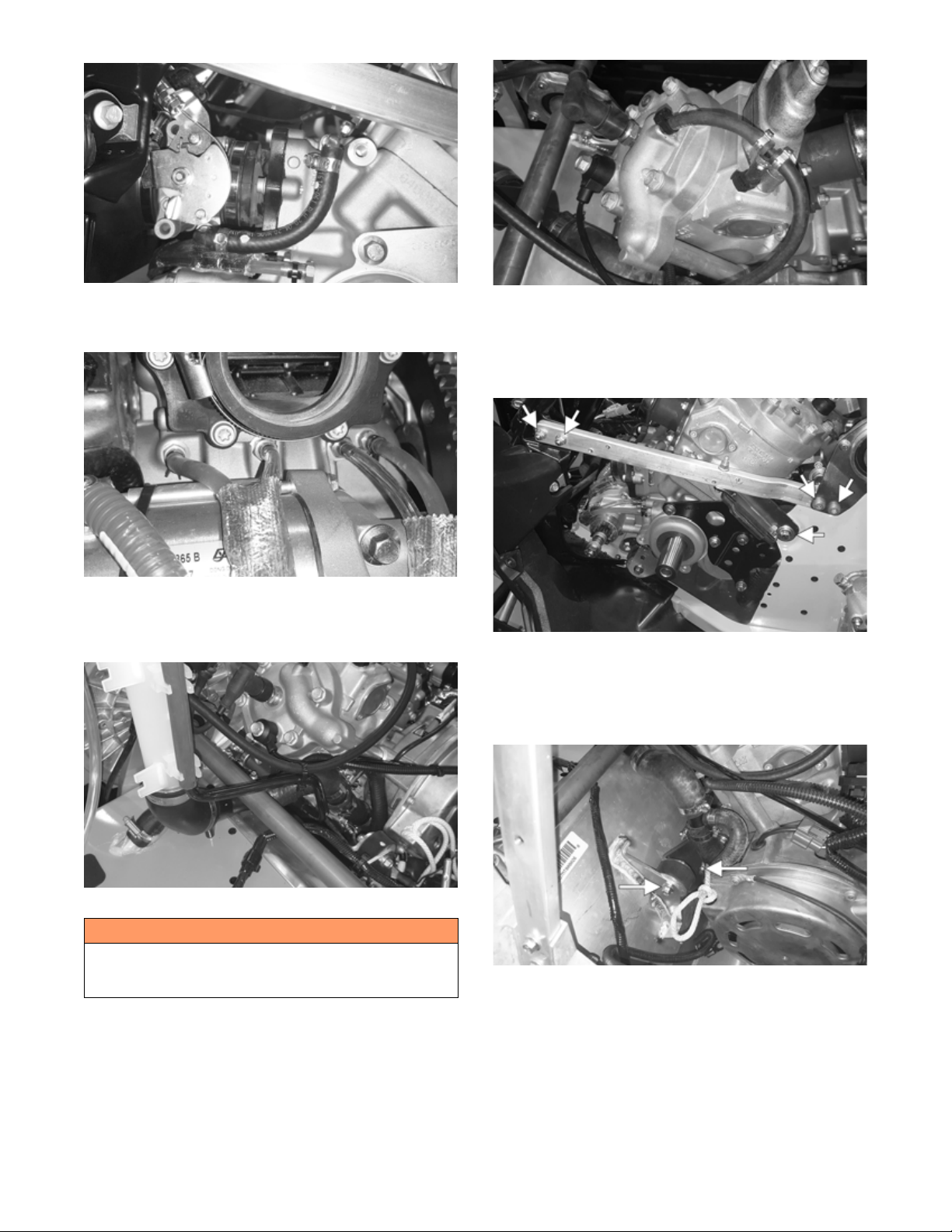

ZR-451

16. Loosen the two clamps securing the oil lines from

the engine. Pull the hoses from the oil fittings.

ZR-459

17. Remove the fuel line from the fuel pump and the fuel

rail. Remove the cable tie securing the coolant vent

hose to the line. Remove the fuel line.

ZR-452

19. Disconnect the harness connectors. Secure the harness out of the way.

20. Remove the cap screws and nuts securing the

left-side chassis support. Remove the support.

ZR-450

21. Loosen the clamp securing the coolant hose to the

rear of the engine. Remove the hose from the engine.

22. Remove the cap screw securing the MAG-side

bracket to the chassis.

ZR-453

! WARNING

The hose may be under pressure; remove it slowly to

release the pressure. Place an absorbent towel around

the connection to absorb gas.

18. Loosen the clamps securing the cylinder and cylinder

head vent hoses. Remove the hoses and the spark

plug cap from the spark plug.

20

ZR-448

23. Remove the two cap screws and nuts securing the

front engine bracket to the chassis.

ZR-449

24. Carefully remove the engine assembly from the

chassis; then remove the cap screws and nuts securing the engine brackets to the engine.

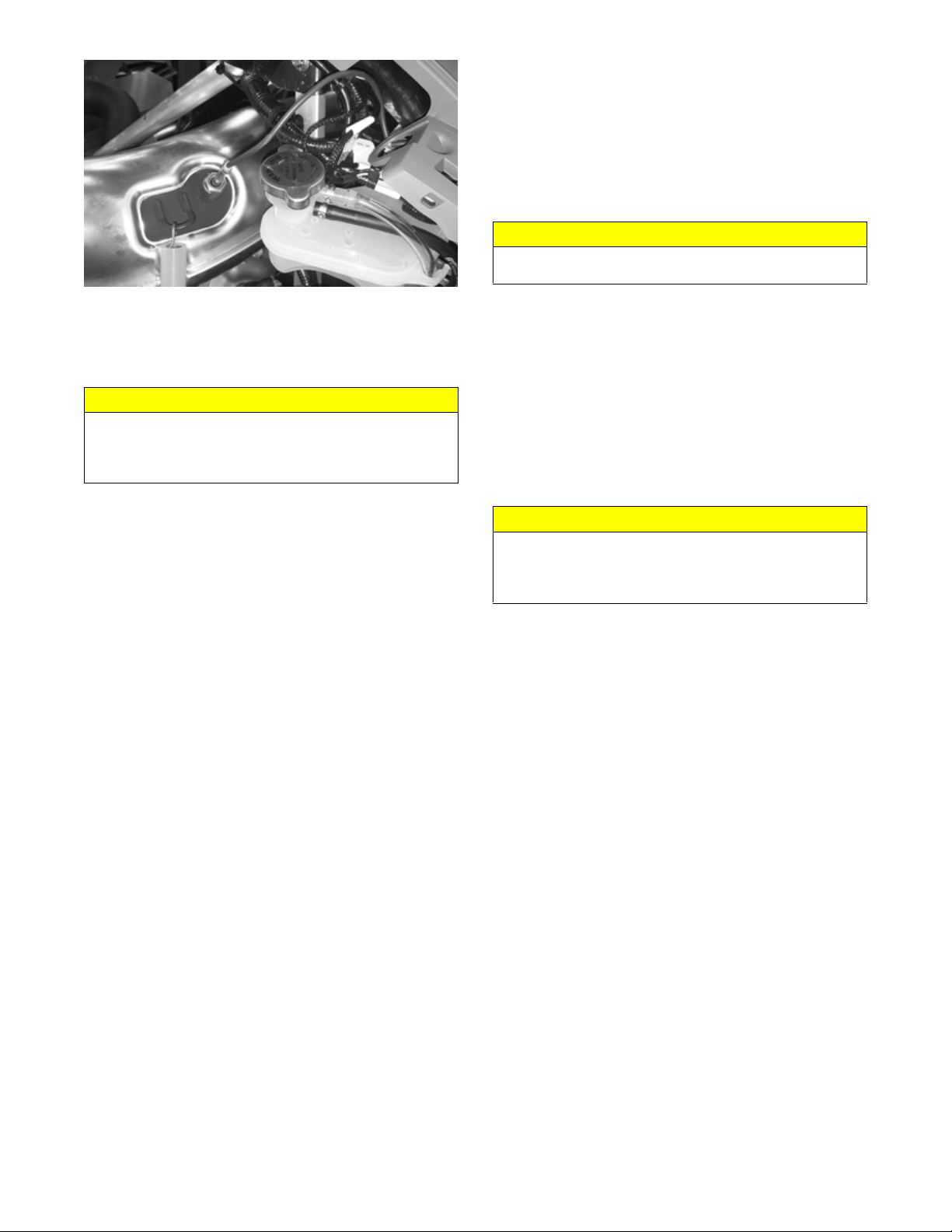

Installing

ONS-388

4. Secure the starter motor to the front of the engine

using four new cap screws. Tighten to 25 ft-lb (34

N-m).

5. Carefully lower the engine into the engine compartment aligning the brackets and mounts with the

mounting locations.

1. Secure the PTO-side engine mount to the engine

using four new cap screws. Tighten to 20 ft-lb (27.2

N-m).

ONS-386

2. Secure the MAG-side engine mount to the engine

using two new nuts. Tighten to 20 ft-lb (27.2 N-m).

6. Install the coolant hose to the rear of the engine using

the existing hose clamp. Tighten securely.

7. Secure the engine mount to the chassis using a new

cap screw. Tighten to 20 ft-lb (27.2 N-m).

ZR-448

8. Secure the front engine bracket to the chassis using

the existing cap screws and new nuts. Tighten to 35

ft-lb (47.6 N-m).

ONS-387

3. Secure the front engine mount assembly to the

engine using the existing cap screws and two new

nuts. Tighten to 20 ft-lb (27.2 N-m).

ZR-449

9. Install the left-side chassis support with the front two

and rear two mounting locations in the chassis.

Loosely secure using the existing cap screws and

new nuts.

21

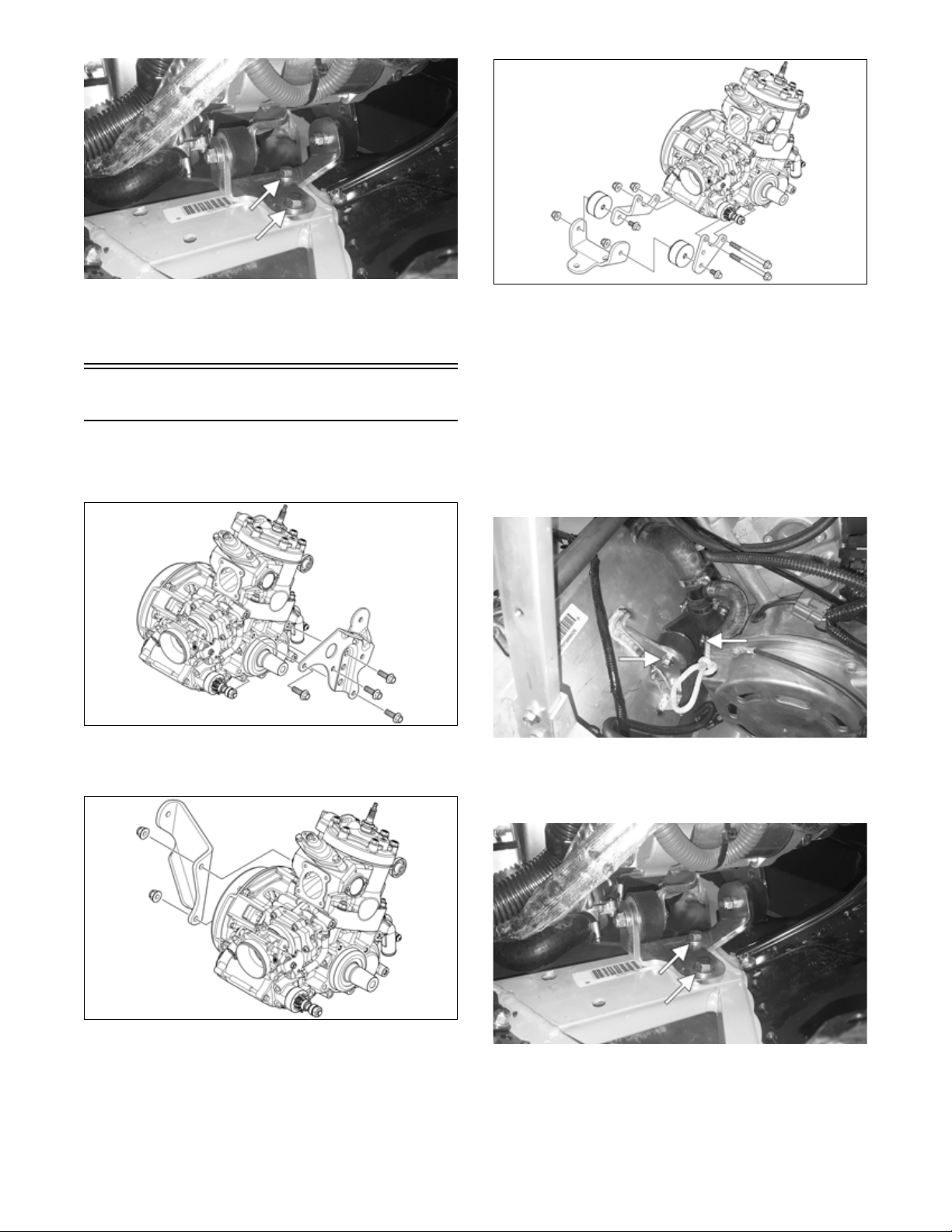

10. Secure the support bracket (through the chassis) to

the engine mount using a new cap screw and the

existing washer. Tighten to 20 ft-lb (27.2 N-m).

11. Secure the front two cap screws to 96 in.-lb (10.8

N-m) and the rear two cap screws to 20 ft-lb (27.2

N-m).

16. Before connecting the wiring harness plug-ins, clean

the connectors and apply dielectric grease to the

seals; then connect all harness connectors making

sure all wiring and coolant hoses are routed properly

as noted in removing. Secure using cable ties.

ZR-464

ZR-450

12. Install the left-side front spar and secure using the

existing cap screws. Tighten to 25 ft-lb (34 N-m).

13. Install the four oil hoses to the engine and secure

using the existing clamps.

ZR-459

14. Position the throttle body assembly between the

intake assembly and the intake manifold. Secure

using the existing clamps. Tighten securely.

15. Install the coolant hoses from the throttle body to the

fittings on the engine. Secure using the existing

clamps. Tighten securely.

17. Connect the knock sensor connector to the main harness; then install the spark plug cap.

18. Install the cylinder and cylinder head vent hose.

ZR-452

19. Install the fuel line to the fuel rail until it fully clicks

onto the rail. Pull back on the fuel line to make sure

it is fully seated; then install the fuel line into the side

of the coolant bottle. Cable tie the coolant vent hose

to the fuel line.

ZR-451

22

ZR-453

20. Install the shock mount bracket support; then using

new lock nuts, secure the support to the shock mount

brackets and tighten to 20 ft-lb (27.2 N-m).

ZR-454

21. Insert the servomotor cable end into the front slot in

the clutch; then connect the servomotor connector.

Secure the cable with the holder.

ZR-413

22. Install the fascia panels (with ECM) and secure to

the chassis using the existing screws. Tighten

securely. Connect the ECM.

ZR-455

24. Install the resonator and secure with the springs; then

place the expansion chamber and gaskets into position and secure to the exhaust manifold and resonator

with the springs.

ZR-456

ZR-460

23. Position the heat shield onto the two front locating

pins; then secure it to the chassis with the screw.

Tighten securely.

ZR-457

25. Install the exhaust temperature sensor into the expansion chamber. Tighten to 34 ft-lb (46.2 N-m).

23

ZR-458

26. Place the drive clutch with drive belt into position on

the crankshaft and secure with the cap screw (threads

coated with oil) and high-collar washer. Tighten to

51 ft-lb (69,4 N-m).

CAUTION

When installing the drive clutch, do not tighten the

clutch cap screw with any kind of impact tool. Tighten

cap screw using a hand torque wrench only. Failure to

do so could result in stationary sheave damage.

NOTE: Before installing the drive clutch, be sure to

wipe clean both the crankshaft and clutch mounting

tapers using a clean towel.

27. Install the driven clutch on the driven shaft and

secure using the existing washer and cap screw.

Tighten to 20 ft-lb (27.2 N-m). Install the drive belt.

28. Fill the cooling system (see Liquid Cooling System

in the Engine-Related Items section).

29. Place the hood into position on the front end and

secure with the screw; then connect hood harness.

Install the side access panels.

CAUTION

Never run the engine with the hood harness disconnected or damage to the electrical system will result.

30. Start the engine and warm up to operating temperature; then verify that all components are functioning

properly and that coolant is circulating through the

cooling system properly.

31. After running the engine to the proper operating temperature, shut the engine off; then open the access

panels and inspect for any signs of coolant, gasoline,

or oil leakage.

32. Allow the engine to cool; then check the coolant

level and add coolant as necessary. Verify the tightening torque of the drive clutch.

CAUTION

If the engine had a major overhaul or if any major component was replaced, proper engine break-in procedures must be followed (see the General Information

section) or severe engine damage may result.

24

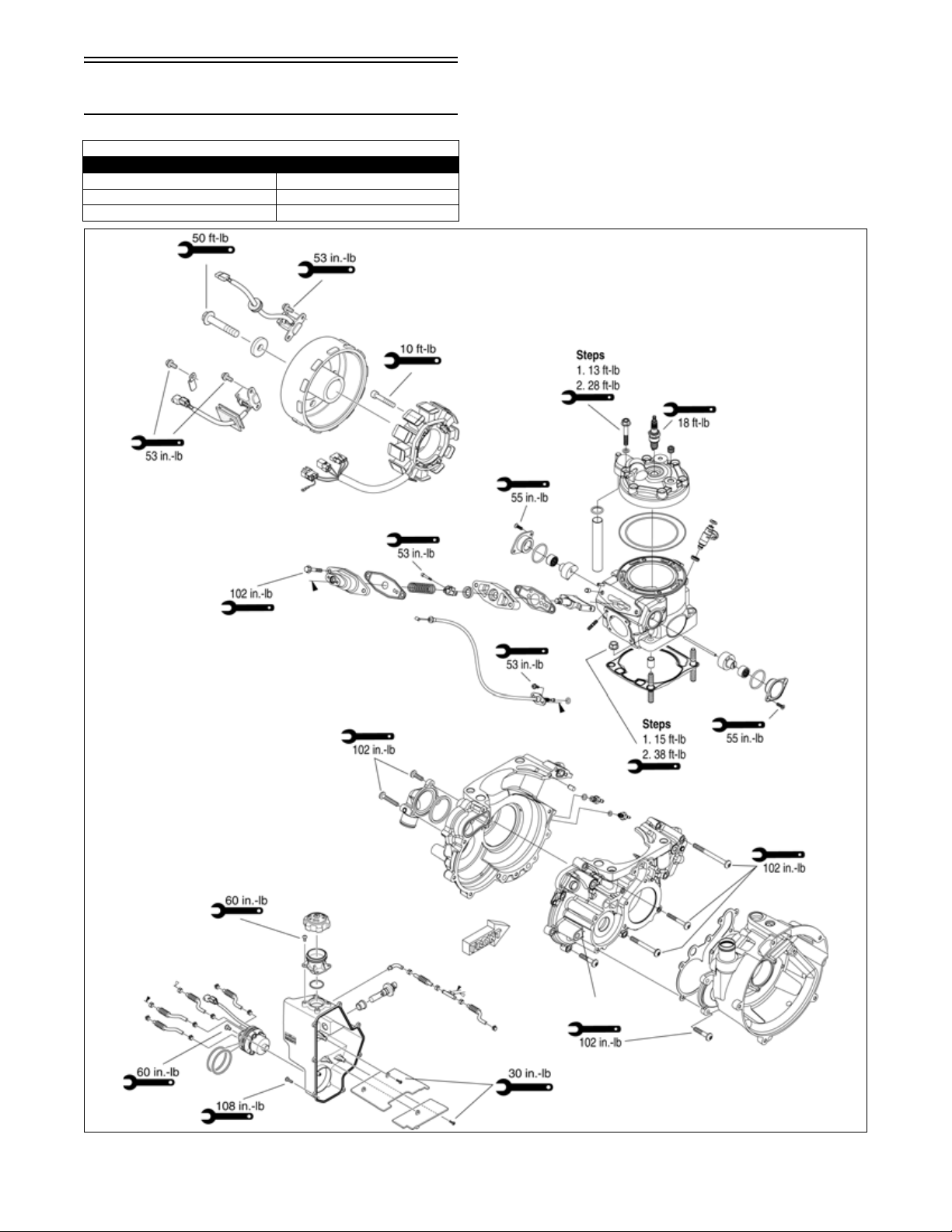

Assembly Schematic

Torque Specification Tolerances

Tor que Tol era nce

0-15 ft-lb (0-20 N-m) ±20%

16-39 ft-lb (21-53 N-m) ±15%

40+ ft-lb (54+ N-m) ±10%

400cc21_1

25

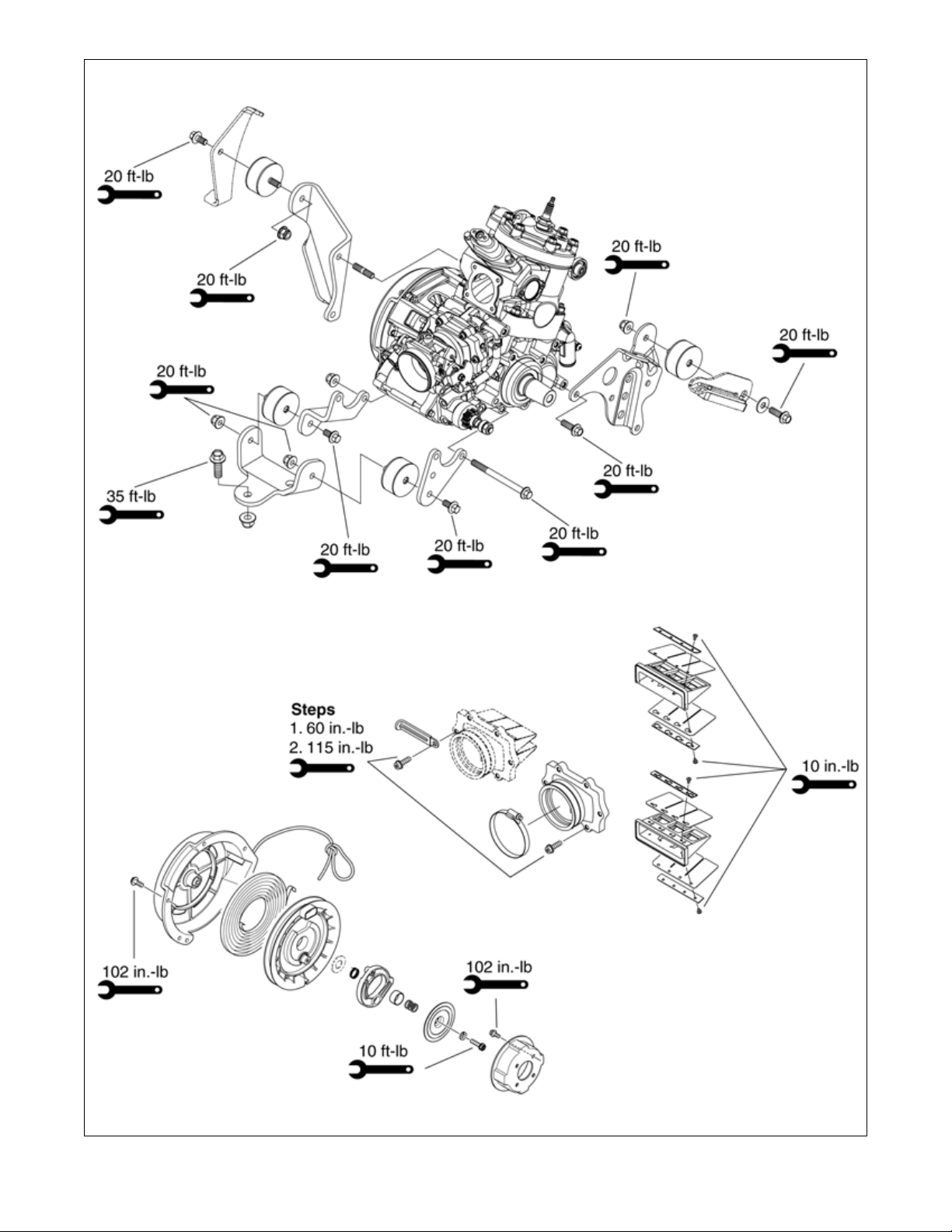

26

400cc21_2

Engine Servicing

This engine sub-section has been organized to show a

progression for servicing the Arctic Cat 4000 engine. For

consistency purposes, this sub-section shows a complete

and thorough progression; however, for efficiency it may

be preferable to disassemble only those components

needing to be addressed. Also, some components may

vary from model to model. The technician should use

discretion and sound judgment.

SPECIAL TOOLS

A number of special tools must be available to the technician when performing service procedures in this engine

section.

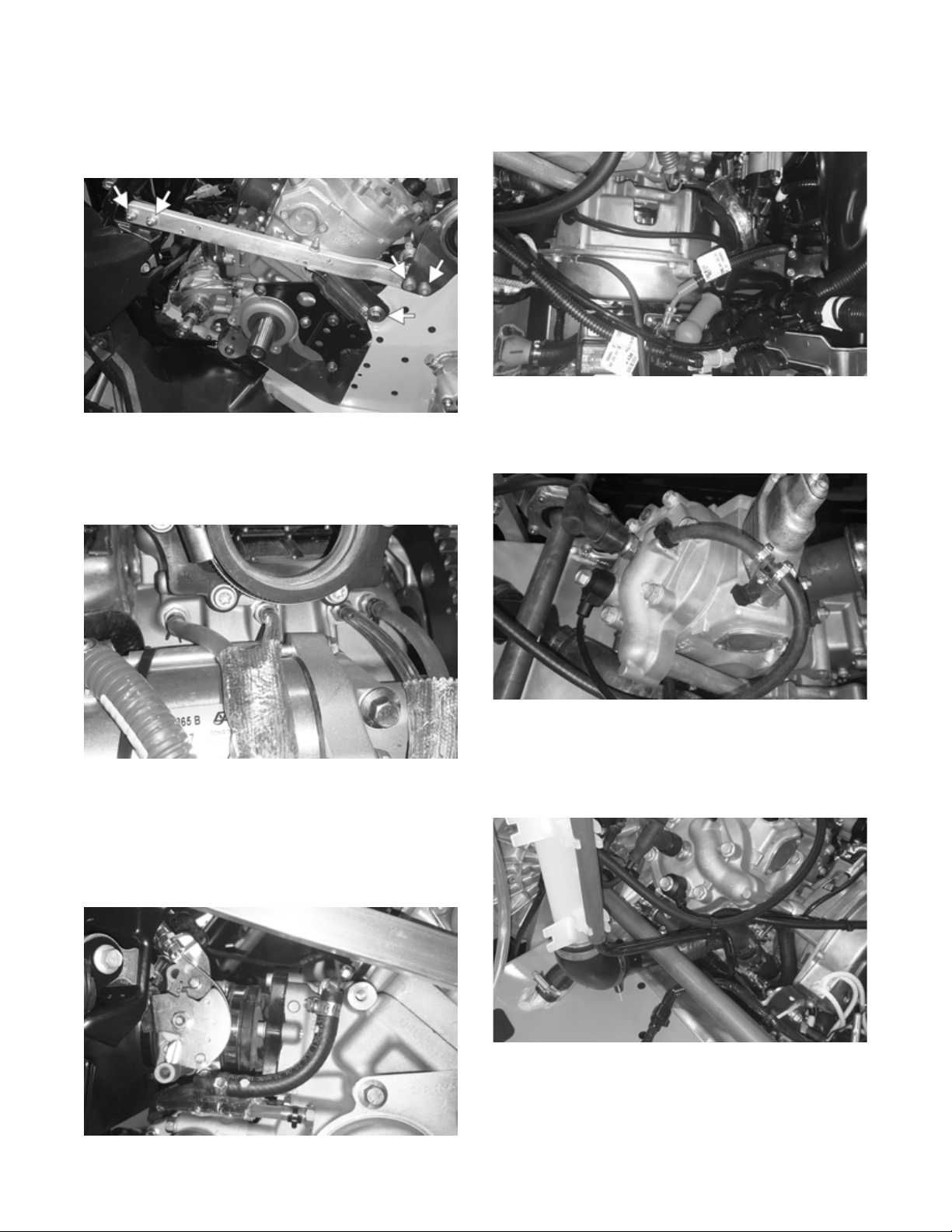

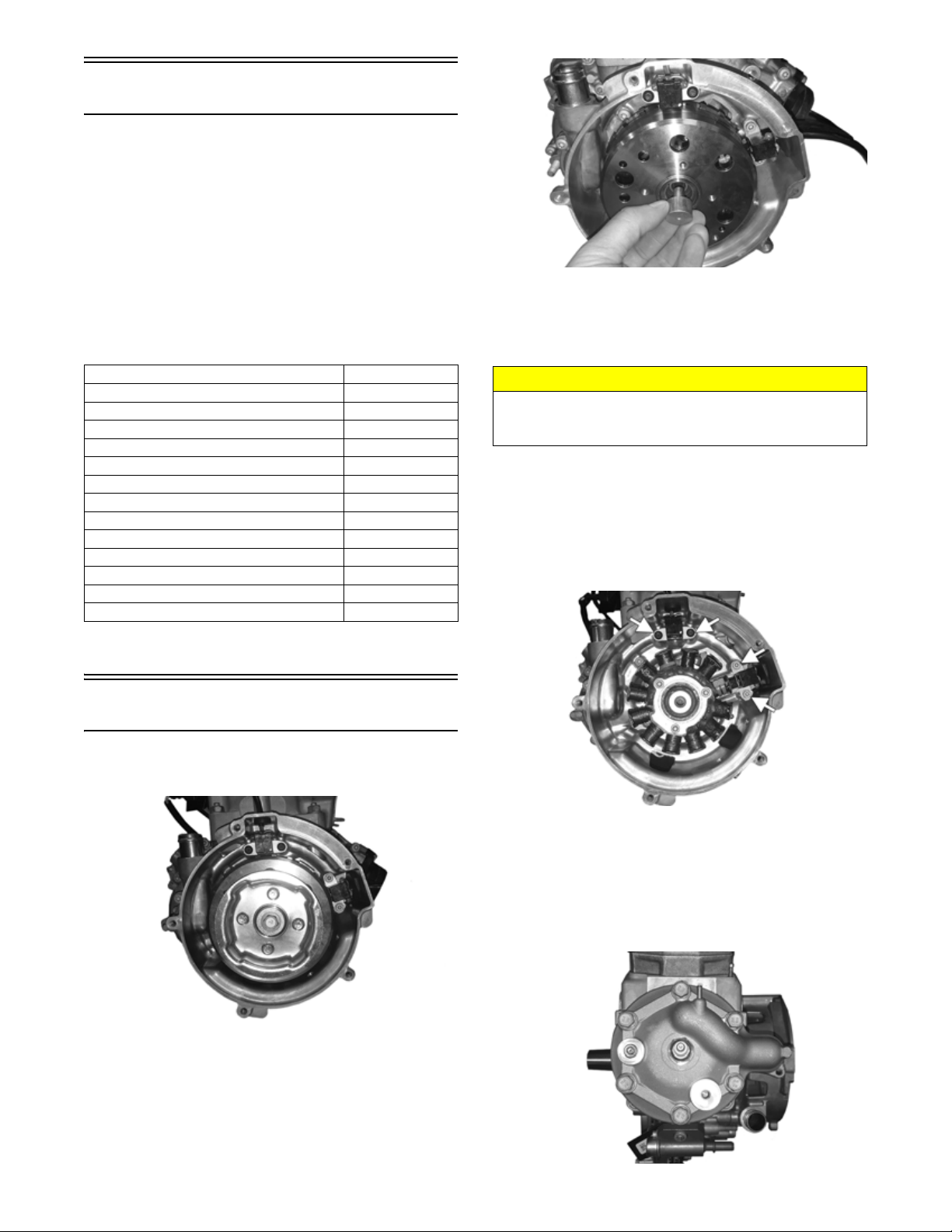

CWI-151

3. Using Flywheel Puller or suitable substitute, remove

the flywheel from the crankshaft by tightening the

puller bolt using an pneumatic gun. Account for the

key.

Description p/n

Ball Hone 0644-294

Flywheel Puller 0744-040

Flywheel Puller Insert 0644-567

Extractor Nut (Medium) 0643-074

Oil Seal Protector Tool 0644-219

14 mm Cylinder Wrench 0644-625

Piston Pin Puller 0644-328

Surface Plate 0644-016

Water Pump Bearing and Seal Tool Kit 0644-557

V Blocks 0644-535

Vacuum Test Pump 0644-131

Crankshaft Install and Removal Tool 0744-112

6 mm Adapter 0644-310

NOTE: Special tools are available from the Arctic

Cat Service Parts Department.

Disassembling

1. Remove the flywheel cap screw and washer; then

remove the cap screws securing the recoil cup.

CAUTION

To prevent damage to the crankshaft, do not thread

puller bolts more than 1/2 in. (12.7 mm) into the flywheel. Damage to the stator may result.

NOTE: To ensure the cleanliness of the flywheel

magnets, place the flywheel (with the magnets facing

upward) on a clean bench.

4. Remove the screws securing the timing sensors and

the ground wire. Remove the sensors and account for

the harness grommets.

CWI-152

5. Remove the screws securing the stator to the engine

housing. Route the stator lead wires out of the housing. Remove the stator assembly.

CWI-150

2. Install the Flywheel Puller Insert onto the end of the

crankshaft.

6. Remove the cap screws securing the cylinder head to

the cylinder. Remove the head and account for the

two O-rings and the coolant tube.

CWI-153

27

7. Remove the screws securing the engine housing to

the crankcase. Remove the housing and account for

the housing gasket and the dowel pins.

CWI-154

8. Remove the cap screw securing the fuel rail to the

cylinder. Remove the fuel rail and the injector.

Account for two O-rings.

CWI-158

11. Using Piston Pin Puller and medium Extractor Nut,

remove the piston pin from the piston.

CAUTION

DO NOT use any type of punch to drive the piston pin

free of the piston; damage may result. Use a piston-pin

puller only.

12. Lift the piston clear of the connecting rod and

remove the piston shims and bearing.

CWI-156

9. Remove the nuts securing the cylinder to the crankcase; then remove from the crankcase by lifting

straight up off the studs. Account for a gasket and the

alignment pins.

CAUTION

When removing the cylinder, be sure to support the piston to prevent damage to the crankcase and piston.

CWI-157

10. Remove the piston-pin circlips from the piston.

CWI-159

13. Remove the screws securing the intake manifold.

Remove the intake manifold and reed valve assembly.

CWI-155

14. Remove the cap screw and washers securing the

water pump impeller. Carefully remove the impeller

from the shaft.

28

Loading...

Loading...