Arctic Cat 2007 Operator's Manual

2007

2007

Snowmobile

Operator’s

Manual

p/n 2257-617

LIMITED WARRANTY

Arctic Cat Inc. (hereinafter referred to as Arctic Cat) extends a limited w arranty on each new Arctic Cat

Snowmobile it manufactures and on each part and accessory manufactured or sold by Arctic Cat. The

warranty is extended to the original retail purchaser only on parts and accessories sold through an

authorized Arctic Cat Snowmobile dealer. Warranty on snowmobiles is extended to the original retail

purchaser; however, the balance of the unused warranty may be transferred to a second party.

Arctic Cat warrants only the products it manufactures and/or sells and does not warrant that other

products will function properly when used with an Arctic Cat Snowmobile or will not damage the Arctic

Cat Snowmobile. Arctic Cat does not assume any liability for incidental or consequential damages.

Arctic Cat will repair or replace, at its option, free of charge (including any related labor charges), any

parts that are found to be warrantable in material or workmanship. This repair work MUST be done by

an authorized Arctic Cat Snowmobile dealer. No transportation charges, rental charges, or

inconvenience costs will be paid by Arctic Cat. The warranty is validated upon examination of said

parts by Arctic Cat or an authorized Arctic Cat Snowmobile dealer. Arctic Cat reserves the right to

inspect such parts at its factory for final determination if warranty should apply.

The warranty periods are as follows:

1. For snowmobiles used for recreational purposes:

—If purchased between May 1 and November 30, warranty expires ONE (1) YEAR from

December 1 of the current year.

—If purchased between December 1 and April 30, ONE (1) YEAR from the date of sale.

2. For snowmobiles used for commercial purposes (including rental operations), ONE (1) YEAR

from the date of sale.

3. SIX (6) MONTHS from date of sale for batteries on a full exchange basis and 50% exchange for

the remaining SIX (6) MONTHS of the first year.

4. THIRTY (30) DAYS from date of sale for all dealer installed service parts and accessories.

5. UNTIL EXPIRATION OF THE NEW PRODUCT WARRANTY for all eligible replacement parts.

Exclusions to this warranty include normal wear, abuse (i.e. a track run on marginal snow conditions

without proper lubrication or additional idler wheels), and the following parts:

Fuel Filter Light Bulbs Windshield Drive Clutch/Driven Pulley Wear Parts

Drive Belt Wear Bars Water Pump Belt Brake Pads

Wear Strips Fan Belt Spark Plugs Torn or Punctured Upholstery

The following will VOID Arctic Cat’s warranty:

1. Failure to perform the proper break-in procedure and all operator related maintenance, storage

procedures, and service as recommended in the Operator’s Manual.

2. Repairs and/or adjustments by anyone other than an authorized Arctic Cat Snowmobile dealer.

3. Use of an improper fuel mixture ratio.

4. Use of improper carburetor main jets.

5. Use of improper gasoline, lubricating oils, or spark plugs.

6. An accident or subjecting the snowmobile to misuse, abuse, or negligent operation.

7. Any modification or removal of parts (i.e. air-intake silencer, muffler, etc.) unless instructed to do

so by Arctic Cat.

8. Use of the snowmobile in any wa y for racing purposes.

9. Removal of the engine for use in another vehicle.

10. Removal or mutilation of the Vehicle Identification Number or Engine Serial Number.

11. Use of parts not sold or approved by Arctic Cat.

12. Track and tunnel damage resulting from either ice stud or hooker plate installation.

13. Damage due to improper transportation.

In consideration of the foregoing, any implied warranty is limited in duration to the various warranty

periods set forth. This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state and country to country. Some states do not allow limitations on how long

an implied warranty lasts, so the above limitations may not apply to you.

Table of Contents

Limited Warranty..................Inside Front Cover

Foreword.........................................................1

Declaration of Confo rmity ...............................2

Snowmobile Safety Rules...............................3

General Information...................................4-30

Snowmobile Identification...........................4

Control Locations ................................ .......4

Tipped Snowmobile....................................7

Gasoline-Oil ...............................................8

Engine Break-In (2-Stroke Mo dels)...........10

Engine Break-In (660 cc/1100 cc

Z1 Models) ...................................... .....10

Indicator Lights (Carbure ted Models/

Bearcat W/T Non-Turbo/

Panther 660)................................. ........11

Low Oil Warning Light

(Standard 2-Stroke Models )..................11

Low Oil Pressure Warning Light

(Bearcat W/T Non-T urbo/

Panther 660 Mo dels)............................11

Coolant T emperature

Warning Light (Carbureted Models/

Bearcat W/T Non-Turbo/

Panther 660)................................. ........12

Charging System Warning Light

(660 cc Models)................................... .12

Check Engine Light (Bearcat W/T

Non-T u rbo/P anther 660 Models)...........12

Speedometer/Tacho meter Indicator

Lights (Crossfire/F-Series/Jaguar Z1/

M-Series/660 cc Turb o Models)............12

Diagnostic Codes/Check Engine

(2-Stroke Models).................................15

Diagnostic Codes/Check Engine

(Jaguar Z1)...........................................16

Handlebar Tilt.......................................... .17

Handlebar Tilt

(F-Series - STD)....................................17

Handlebar Tilt (F-Series L XR/Sno Pro/

Jaguar Z1)........................................... .18

Exhaust System ...................................... .19

Air-Intake Silencer....................................19

Battery (Electric Start Models)..................19

Cooling System (Liquid).......................... .20

Drive Clutch and Driven Pulley.................20

Drive Clutch/Driven

Pulley Alignment...................................21

Drive Chain Tension. ......................... ........21

Fuel Pump................................................22

Gas T ank Shut-Off V alv e...........................22

Shock Absorbers (Standard Gas).............22

Shock Absorbers (Rebu ildable Gas).........22

Deep-Lug Trac k........................................23

Hacksaw Tr ack......... ......................... ........23

T rac k Studs.............................................. .23

Reverse Transmission ...................... ........24

Reverse Transmission (Crossfir e/

F-Series/Jaguar Z1/

M-Series Models).................................25

Towing ......................................................26

Adjustable Backrest .................................26

Removable Rear Seat ..............................26

Removable Se at (Crossfire/M-Series

Models) ........................................ ........27

Removable/Ad justable Seat

(F-Series/Jaguar Z1)............................27

Arctic Pow er V alv e (APV) System.............28

Exhaust Controlled Timing

(ECT) System (600/800/1000 cc).........29

Operating Instructions............................ ..31-39

Starting and Stopping Engine...................31

High RPM Operation

(660 cc Models)....................................35

Braking (Hydraulic Brak e Models)............35

Emergency Stopping................................36

Throttle/Ignition Monitor Switch

(2-Stroke/J aguar Z1 Models)................37

Varying Altitude Oper ation........................39

Lubrication...............................................40-45

Standard Chain Case...............................40

ACT Drive Gear Case...............................41

Front Suspens ion ................................. ....43

Speedometer Drive Adapter.....................44

Rear Suspension......................................45

Maintenance............................................46-93

Periodic Maintenance Chec klist................46

Fuel System .............................................47

Checking Engine Oil Level

(660 cc Models)....................................48

Checking Engine Oil Le vel (J aguar Z1).....49

Changing Engine Oil

(660 cc Models)....................................49

Changing Engine Oil/Filter (Jagu ar Z1).....50

Adjusting Carburetor (Single)...................52

Adjusting Carburetors (Twin) ....................54

Selecting Carburetor Main Jet (s)..............58

Spark Plugs (1100 cc Z1) .........................59

Spark Plugs..............................................59

Checking/Adjusting Valve Clearance

(660 cc/1100 cc Z1)..............................62

Charging Battery

(Electric Start Models)..........................62

Fuses (660 cc Models) .............................64

Fuses (1100 cc Z1)...................................65

Engine Heater (660 cc Models)................66

Mechanical Brake System........................66

Hydraulic Brake System...........................68

Drive Belt................................ ..................72

T rac k Tension............................................76

T rac k Alignment........................................78

Suspension ..............................................79

Lights........................................................83

Ski Wear Bars...........................................89

Adjusting Ski Stance(M-Series/

Bearcat 570 Models) ............................90

Rail Wear Strips........................................91

Axial Fan Belt (37 0 cc Models)..................91

Accessory Belt (660 cc Models)................92

Perf ormance Tips................................... .......94

Preparation For Stor age...........................95-97

Preparation After Storage........................98-99

U.S. EPA Emission Control

Statement/Warra nty Cove rage...............100

Change of Address, Own ership ,

or Warranty Transfer...............................101

Warranty Procedure/

Owner Responsibility.......Inside Back Cover

REFERENCE INFORMATION

Write the appropriate information for your Arctic Cat Snowmobile in the spaces

below.

Always use these numbers when referring to your snowmobile.

Model: ________________________________________________

Date of Purchase: _______________________________________

Vehicle Identification Number: _____________________________

Engine Serial Number: ___________________________________

Your Arctic Cat Dealer: _____________________________________

Address: ________________________________________________

Phone: __________________________________________________

! WARNING

A snowmobile is a very high performance vehicle. Because it does accelerate rapidly and is capable of very high speeds, it should not be operated by

a novice or an inexperienced operator. Never accelerate rapidly or drive at

high speed beyond the limits of visibility or without being totally familiar

with the terrain and what lies in front of you. Obey speed limits and never

operate at speeds that do not allow adequate maneuvering and stopping

distances. Read and study the entire Operator’s Manual and Safety Handbook.

Failure to follow this warning could result in personal i njury to yourself or

others.

PERSONAL INJURY

• To avoid injury to yourself and others, NEVER operate the snowmobile without first

reading and understanding this manual and the Snowmobile Safety Handbook; then

follow the instructions and heed the warnings given.

• USE COMMON SENSE.

• DON’T DRINK and DRIVE.

• STAY IN CONTROL at ALL TIMES.

• TELL Y OUR FRIENDS. If y ou see a friend operating a snowmobile recklessly, at excessive speeds, while intoxicated, or in other unsafe ways, don’t wait until it is too late to

warn of the consequences of snowmobile misuse. Such conduct endangers everyone.

TAKE AN ACTIVE ROLE IN THE SAFETY OF YOURSELF AND OTHERS.

PARTS AND ACCESSORIES

When in need of replacement parts, oil, or accessories for your Arctic Cat Snowmobile, be sure to only use GENUINE ARCTIC CAT PARTS, OIL, AND ACCESSORIES. Only genuine Arctic Cat parts, oil, and accessories are engineered to meet the

standards and requirements of your Arctic Cat Snowmobile. For a complete list of

accessories, refer to the current Arctic Cat Accessory Catalog. An Illustrated Parts

Manual is available through your local Arctic Cat Snowmobile dealer.

1

FOREWORD

Congratulations! You have chosen a quality Arctic Cat Snowmobile designed

and manufactured to give dependable service. Be sure, as the owner/operator of

an Arctic Cat Snowmobile, to become thoroughly familiar w ith its basic operation, maintenance, and off-season storage procedures. Read this manual and the

accompanying Snowmobile Safety Handbook before operating the snowmobile

to learn safe and proper use of your new Arctic Cat Snowmobile. Always operate

the snowmobile within your level of skill and current terrain conditions.

The Operator’s Manual, Snowmobile Safety Handbook, and Snowmobile Decals

display the words Warni ng, Caution, and Note to emphasize important information. The symbol ! WARNING identifies personal safety-related information. Be sure to follow the directive because it deals with the possibility of severe

personal injury or even death. The symbol ! CAUTION identifies unsafe

practices which may result in snowmobile-related dama ge. Follow the directive

because it deals with the possibility of damaging part or parts of the snowmobile.

The symbol

NOTE: identifies supplementary information worthy of particu-

lar attention.

This manual covers operator-related maintenance, operating instructions, and

off-season storage instructions. If major repair or service is ever required, contact

an authorized Arctic Cat Snowmobile dealer for professional service.

At the time of publication, all information and illust rations were technically correct. Some illustrations used in this manual are used for clarity purposes only and

are not designed to depict actual conditions. Because Arctic Cat Inc. constantly

refines and improves its products, no retroactive obligation is incurred.

This Operator’s Manual should be considered a permanent part of the snow mobile and must remain with the snowmobile at the time of resale. If the snow mobile changes ownership more than once, contact Arctic Cat Inc., Service

Department, P.O. Box 810, Thief River Falls, MN 56701, for proper registration

information. This manual was prepared by the Product Service and Warranty

Department of Arctic Cat Inc.

Every Arctic Cat Snowmobile meets or exceeds the standards of the Snowmobile

Safety and Certification Committee and displays the SSCC decal. Arctic Cat Inc.

endorses and encourages the safe use of all snowmobiles. Always wear a helmet

and eye protection. Drive with caution, observe all state and local regulations,

and respect the rights of others. ISMA members like Arctic Cat do their part to

improve trails, sponsor events, and gene rally support the spo rt of snowmobili ng.

As a member of the National Snowmobile Foundation, Arctic Cat Inc. promotes

snowmobiling through education, charity, and research programs.

© 2006 Arctic Cat Inc.

Printed in U.S.A.

2

DECLARATION OF CONFORMITY

Application of council directives: EMC Directive 89/336/EEC

EC Machinery Directive 98/37/EC

Issued by European Commission.

Type of Equipment: Snowmobile

Brand Name: Arctic Cat

Model Numbers:

Standards to which conformity is declared:

EMC: EN 50082-1/ 1992, EN 50081-1

MACHINERY: EN 292-1, EN 292-2, EN 953, EN 1050, EN 954-1

Manufacturer (if not issuing agent): Arctic Cat Inc.

601 Brooks Ave. S.

Thief River Falls, MN

56701 USA

I, the undersigned, hereby declare that the equipment specified above conforms to the

directive(s) and standard(s) as specified.

Fred Bernier

Manager, Product Testing & Certification

S2007ACAAAUSG S2007CFH36USO S2007M1LEKUSO S2007F8HTSUSO

S2007ACAAAUSO S2007CFHSPUSO S2007M1LSPUSO S2007F1LEFUSB

S2007ZAAFCUSO S2007CFL36USB S2007M1LPRUSO S2007F1LEFUSG

S2007ZAALXUSO S2007CFL36USG S2007F5CEFUSB S2007F1LEFUSO

S2007ZADFCUSO S2007CFL36USO S2007F5CEFUSG S2007F1LLXUSB

S2007ZADLXUSO S2007CFLSPUSO S2007F5CEFUSO S2007F1LLXUSG

S2007BCDLTUSL S2007M6D1EUSB S2007F5CLXUSB S2007F1LLXUSO

S2007BCFWTUSL S2007M6D1EUSG S2007F5CLXUSG S2007F1LEPUSB

S2007BCFTWUSL S2007M6D1EUSO S2007F5CLXUSO S2007F1LEPUSG

S2007BCFAWUSL S2007M6D3EUSB S2007F6DEFUSB S2007F1LEPUSO

S2007PAAFCUSB S2007M6D3EUSG S2007F6DEFUSG S2007BCDLTOSL

S2007PADFCUSB S2007M6D3EUSO S2007F6DEFUSO S2007BCFWTOSL

S2007PAFTOUSB S2007M8H1EUSB S2007F6DLXUSB S20077BCFTWOSL

S2007PAFLCUSB S2007M8H1EUSG S2007F6DLXUSG S2007PAAFCOSB

S2007ACFTTUSB S2007M8H1EUSO S2007F6DLXUSO S2007PADFCOSB

S2007ACFTLUSG S2007MBH3EUSB S2007F6DEPUSB S2007PAFTOOSB

S2007ACFTBUSB S2007M8H3EUSG S2007F6DEPUSG S2007ACFTLOSG

S2007ACFTRUSG S2007M8H3EUSO S2007F6DEPUSO S2007CFC36OSB

S2007Z1NJGUSB S2007M8HEKUSB S2007F8HEFUSB S2007CFHSPOSO

S2007Z1NJGUSG S2007M8HEKUSG S2007F8HEFUSG S2007CFLSPOSO

S2007Z1NJGUSR S2007M8HEKUSO S2007F8HEFUSO S2007F5CLXOSG

S2007CFC36USB S2007M8HSPUSO S2007F8HLXUSB S2007F6DEPOSG

S2007CFD36USB S2007M1L3EUSB S2007F8HLXUSG S2007F8HEPOSO

S2007CFD36USG S2007M1L3EUSG S2007F8HLXUSO S2007F1LEPOSB

S2007CFD36USO S2007M1L3EUSO S2007F8HEPUSB S2007Z1NJGOSR

S2007CFH36USB S2007M1LEKUSB S2007F8HEPUSG

S2007CFH36USG S2007M1LEKUSG S2007F8HEPUSO

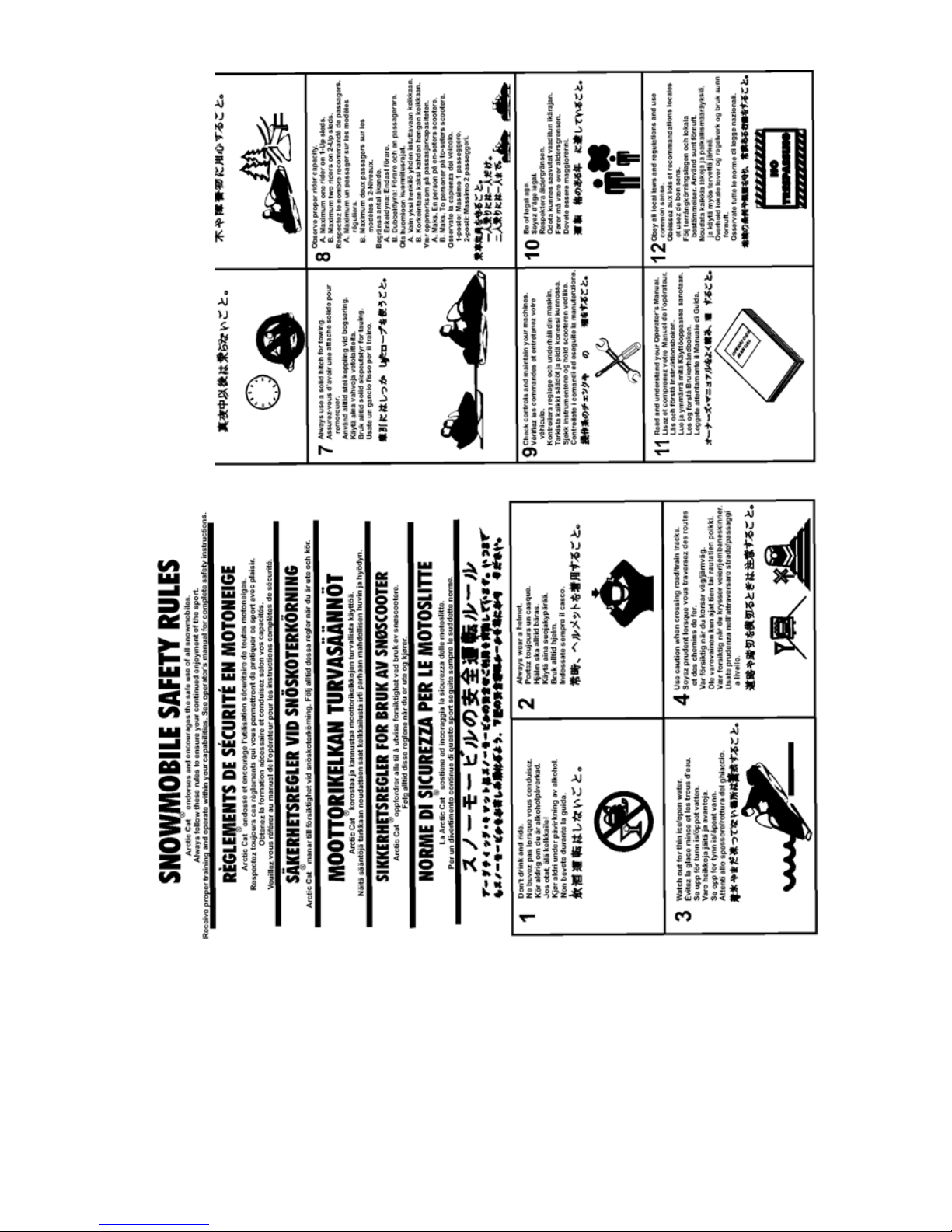

SNOWMOBILE SAFETY RULES 3

SNOWMOBILE SAFETY RULES

4 GENERAL INFORMATION

GENERAL INFORMATION

SNOWMOBILE

IDENTIFICATION

The Arctic Cat Snowmobile has two

important identification numbers. The

Vehicle Identification Number (VIN)

is stamped into the tunnel near the

right-side footrest. The Engine Serial

Number (ESN) is stamped into the

crankcase of the engine.

0726-383

These numbers are required by the

dealer to complete warranty claims

properly. No warranty will be allowed

by Arctic Cat Inc. if the engine serial

number or VIN is removed or mutilated in any way.

Always provide the snowmobile

name, VIN, and ESN when contacting

an authorized Arctic Cat Snowmobile

dealer for parts, service, accessories,

or warranty. If the complete engine

must be replaced, ask the dealer to

notify Arctic Cat for correct registration information.

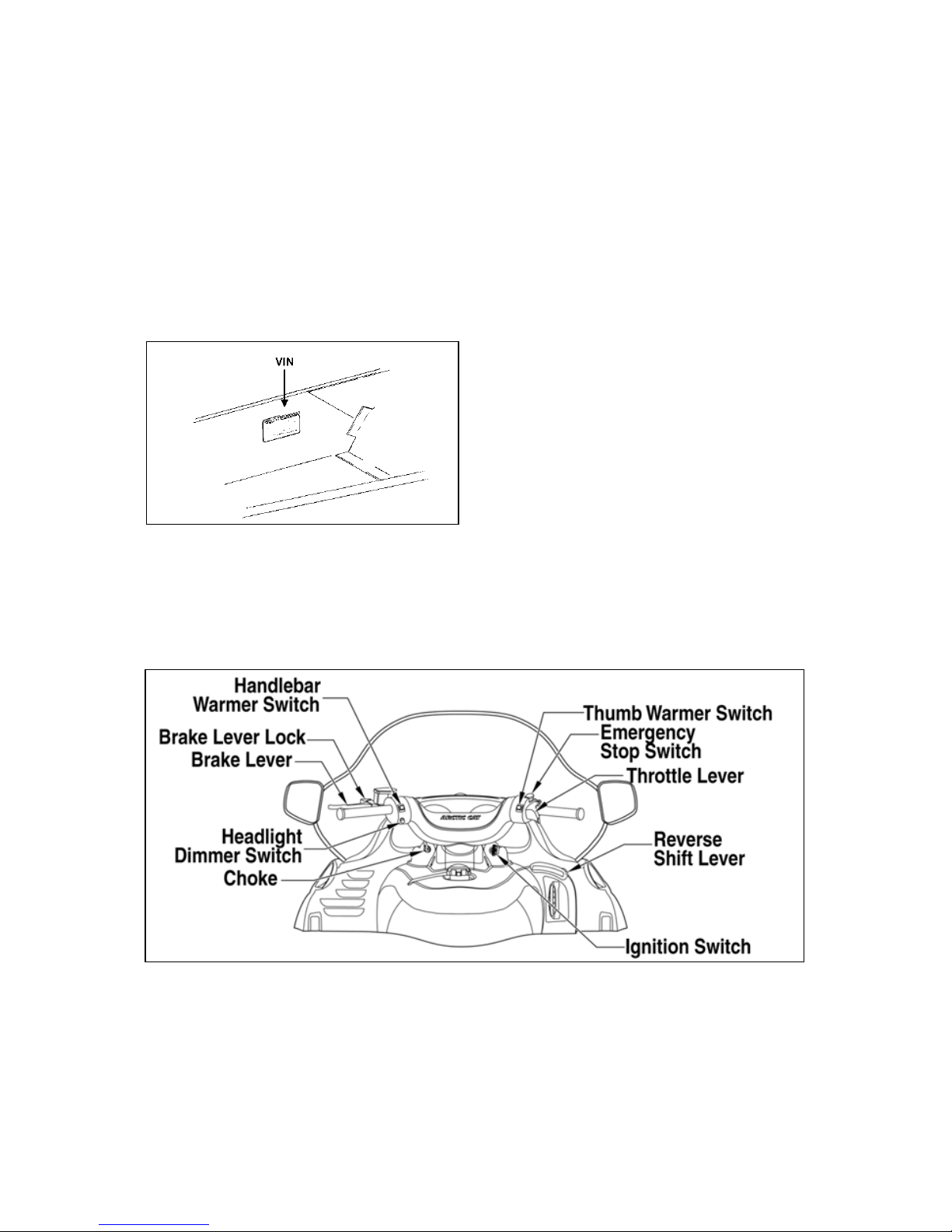

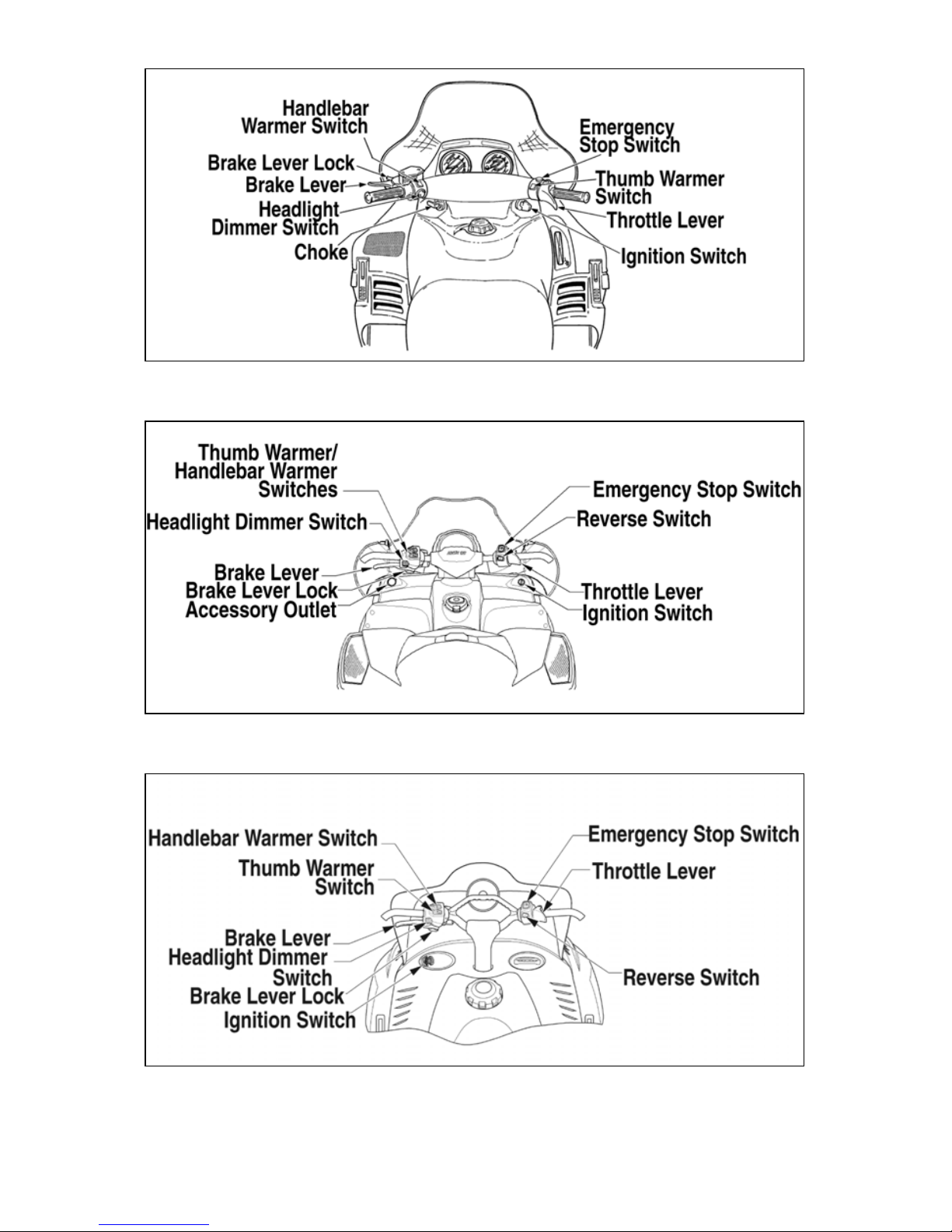

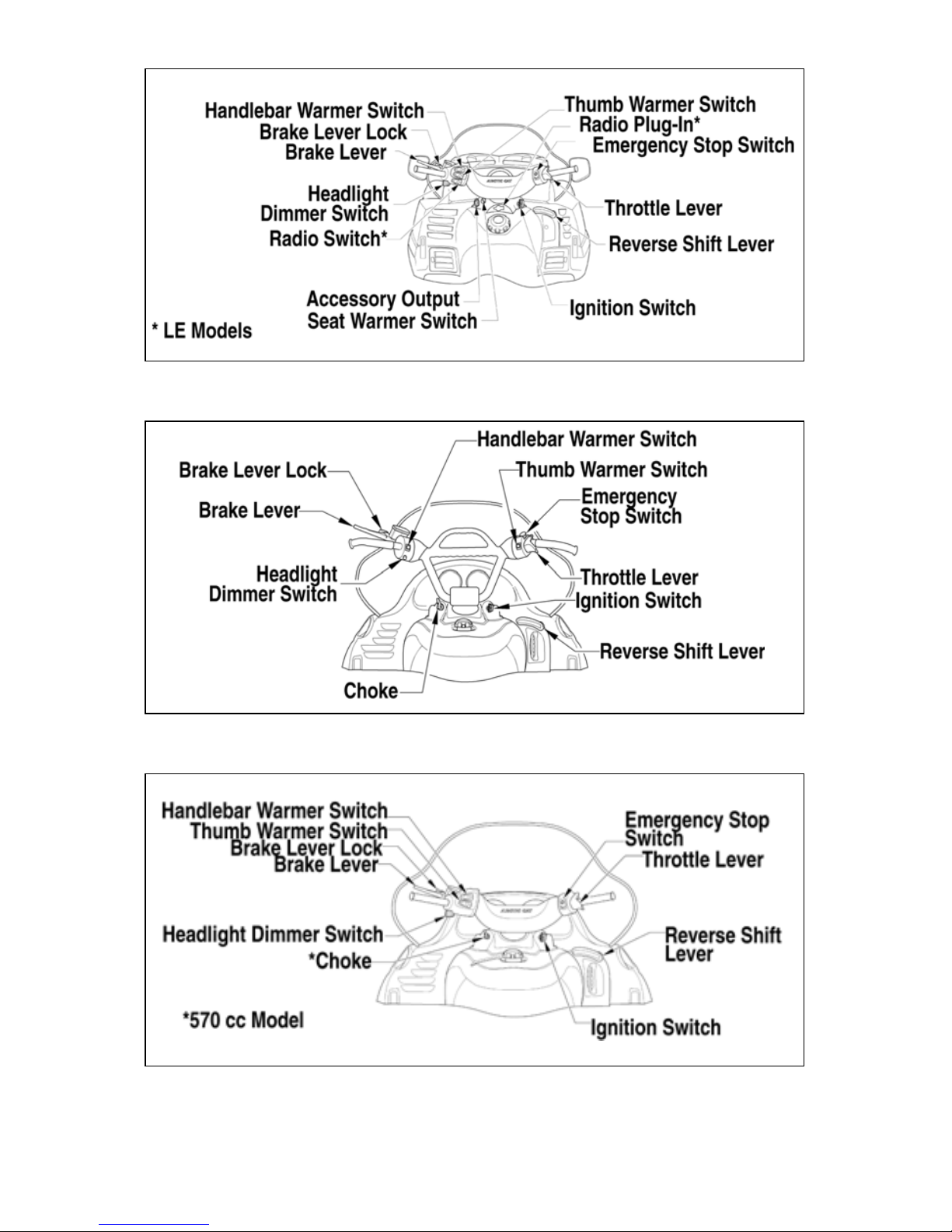

CONTROL

LOCATIONS

Shown are the typical control locations for Arctic Cat snowmobiles.

Location of a specific control will

vary according to model.

Panther 370 Model

739-592D

GENERAL INFORMATION 5

Z Models

734-268A

F-Series/Jaguar Z1 Models

741-375B

Crossfire/M-Series Models

741-633A

6 GENERAL INFORMATION

T660/Bearcat Wide Track Models

741-632A

Bearcat 570 Model

740-586A

Panther 570/660 Models

741-634A

GENERAL INFORMATION 7

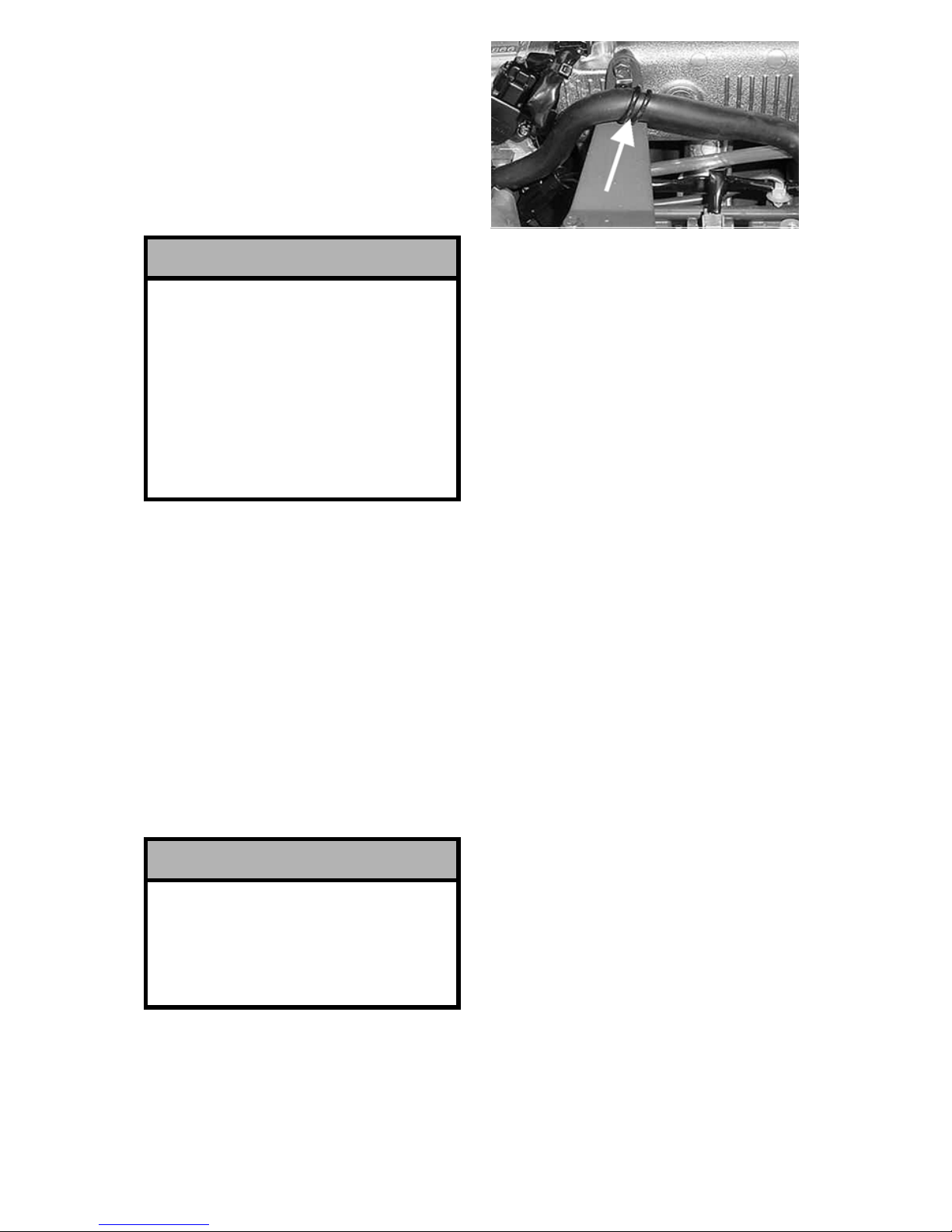

TIPPED SNOWMOBILE

Tipping a snowmobile on its side is

sometimes desirable for maintenance

purposes; however, on a 660 cc model,

Arctic Cat recommends NOT TIP-

PING IT ON ITS SIDE IN EXCESS

OF A 70° ANGLE.

If a 660 cc model is tipped on its side

in excess of a 70° angle or if it has

been upside down at all, return the

snowmobile to the upright position

and use the following procedure:

1. With the ignition switch in the

OFF position, remove the engine

to air-intake silencer hose at the

engine. If oil is present, proceed

to step 2. If no oil is present,

install the hose and start the

engine.

AO224B

2. Remove the air-intake silencer

from the engine. If oil is present

in the air-intake silencer, proceed

to step 3. If no oil is present,

install the air-intake silencer and

the engine to air-intake silencer

hose; then start the engine.

NOTE: Prior to doing step 3,

clean the air s ilencer thoroughly .

3. Remove the spark plugs from the

engine and cover the spark plug

holes with a rag (see Spark Plugs

in this manual). With the emergency stop button in the down

(OFF) position, turn the ignition

switch to the START position.

4. Allow the engine to turn over for

approximately 10 seconds. If oil

was noted coming from the spark

plug holes during this procedure,

repeat the process until all oil has

been discharged from the cylinders.

5. Install the spark plugs, spark plug

wires, air-intake silencer, and the

engine to air-intake silencer hose.

NOTE: The engine should

now be safe to operate.

! CAUTION

The 660 cc models should not be

tipped on their sides in excess of

a 70° angle for any reason, as

engine oil may seep into the

upper engine through the airintake system. Severe engine

damage could result if the engine

is run with oil in the upper

engine.

! CAUTION

Care must be taken when installing the hose that it does not sag

below the entrance/exit ends. If

there is a “valley” in the hose,

freezing may occur.

8 GENERAL INFORMATION

GASOLINE-OIL

Recommended

Gasoline (Carbureted

Models)

The recommended gasoline to use in

these snowmobiles is 87 minimum

octane regular unleaded. In many

areas, oxygenates (either ethanol or

MTBE) are added to the gasoline.

Oxygenated gasolines containing up

to 10% ethanol or up to 15% MTBE

are acceptable gasolines; however,

whenever using oxygenated gasolines,

the carburetor main jet must be one

size larger than the main jet required

for regular unleaded gasoline. For

example, if a 400 main jet is recommended for regular unleaded gasoline,

a 410 main jet must be installed if

using an oxygenated gasoline.

When using ethanol blended gasoline,

it is not necessary to add a gasoline

antifreeze since ethanol will prevent

the accumulation of moisture in the

fuel system.

Recommended

Gasoline (EFI Models)

The recommended gasoline to use in

these snowmobiles is 87 minimum

octane regular unleaded. In many

areas, oxygenates (either ethanol or

MTBE) are added to the gasoline.

Oxygenated gasolines containing up

to 10% ethanol or up to 15% MTBE

are acceptable gasoline. Do not use

gasolines containing methanol.

Recommended

Injection Oil

The recommended oil to use in the oilinjection system is Arctic Cat 50:1

Injection Oil (for standard models) or

Arctic Cat Synthetic APV 2-Cycle Oil

(for APV models). These oils are specially formulated to be used either as

an injection oil or as a pre-mix oil (for

break-in) and meets all of the lubrication requirements of the Arctic Cat

snowmobile engine.

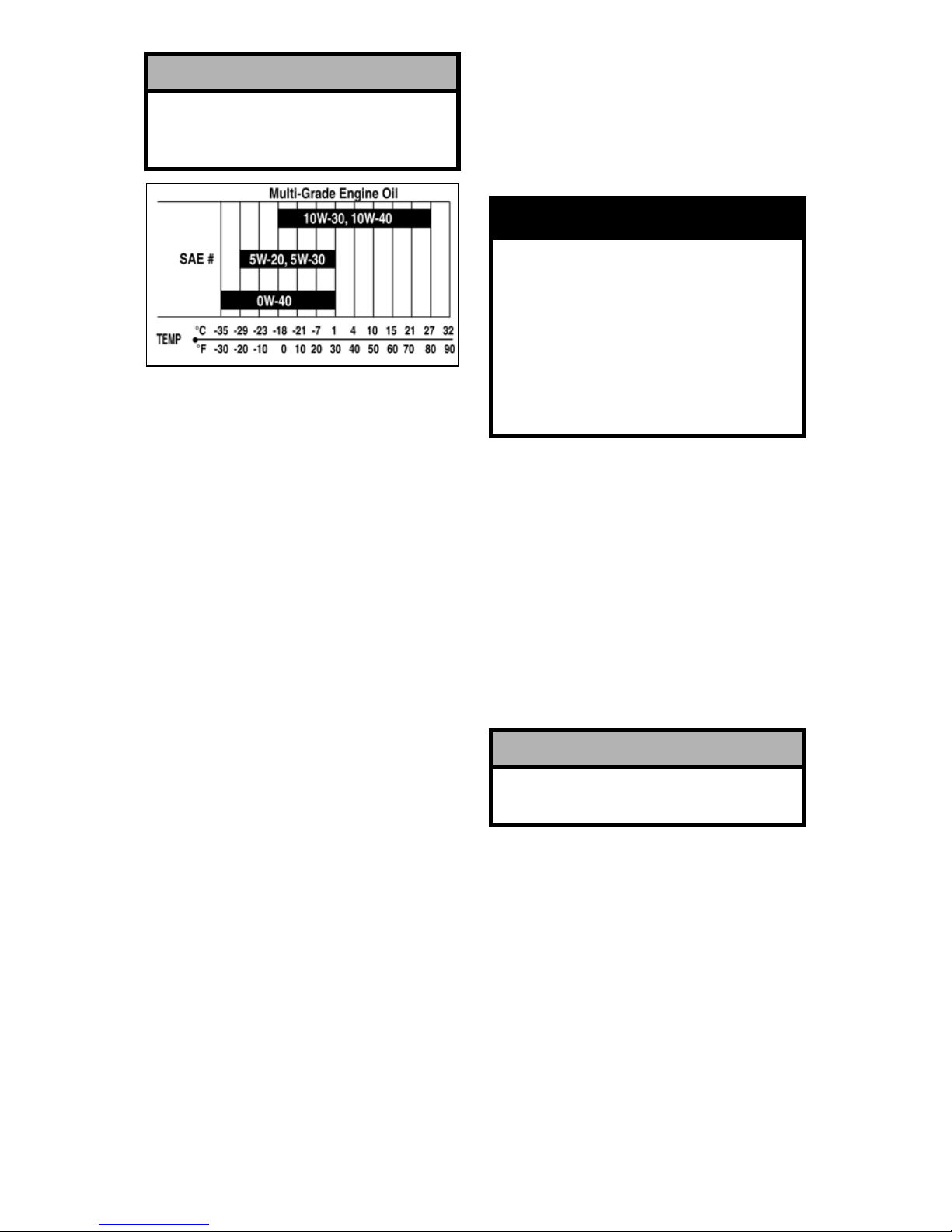

Recommended Engine

Oil (660 cc STD)

NOTE: See the accompanying

Specifications sheet for specific

details on recommended engine

oil.

The recommended oil to use is a

multi-grade oil calibrated to the ambient temperature at which the engine is

run. See the viscosity chart for details.

! CAUTION

Do not use white gas or gasolines containing methanol. Only

Arctic Cat approved gasoline

additives should be used.

! CAUTION

Do not use white gas or gasoline

containing methanol. Only Arctic Cat approved gasoline additives should be used.

! CAUTION

Any oil used in place of the recommended oil could cause serious engine damage.

GENERAL INFORMATION 9

OILCHARTD

After the engine break-in period, the

engine oil should be changed every

2500-3000 miles on standard 660 cc

models.

Recommended Engine

Oil (660 cc Turbo/

1100 cc Z1)

The recommended oil to use is Synthetic Turbo 0W-40 Oil (p/n 3639-

510).

After the engine break-in period, the

engine oil should be changed every

2500-3000 miles on the 1100 cc Z1

model and every 2000 miles on 660 cc

Turbo models and before prolonged

storage.

Filling Gas Tank

Since gasoline expands as its temperature increases, the gas tank must be

filled to its rated capacity only . Expansion room must be maintained in the

tank particularly if the tank is filled

with cold gasoline and then moved to

a warm area.

Also, if the snowmobile is to remain

on a trailer after filling the gas tank,

the bed of the trailer must be maintained level to prevent gasoline from

draining out through the gas tank vent

hose.

Break-In Gas/Oil

Mixing Instructions

(2-Stroke Models)

Before mixing gasoline and oil, make

sure the oil is at room temperature

(20° C/68° F). Use a U.L. approved

22.7 l (6 U.S. gal.) gasoline container

for mixing the gasoline and oil. To

properly mix the fuel at a 100:1 ratio,

use the following procedure:

1. Pour gasoline into the gasoline

container until approximately half

full.

2. Pour 236 ml (8 fl oz) of the recommended 2-cycle oil into the

gasoline container.

3. Install cap on gasoline container

and shake the mixture vigorously.

! CAUTION

Any oil used in place of the recommended oil may cause serious damage.

! WARNING

Always fill the gas tank in a wellventilated area. Never add gasoline to the snowmobile gas tank

near any open flames or with the

engine running. DO NOT SMOKE

while filling the gas tank. Do not

sit on the snowmobile without

first installing the gas tank cap.

! CAUTION

Never mix oil and gasoline in the

snowmobile gas tank.

10 GENERAL INFORMATION

4. Fill the gasoline container with

gasoline; then cap the gasoline

container and shake the mixture

vigorously.

5. Using a fine-mesh screened funnel, pour the fuel mixture from

the gasoline container into the

snowmobile gas tank.

ENGINE BREAK-IN

(2-Stroke Models)

The Arctic Cat engine (when new or

rebuilt) requires a short break-in

period before the engine is subjected

to heavy load conditions. Arctic Cat

requires that the first tankful of fuel be

premixed at a 100:1 ratio in all oilinjection models.

During the break-in period, a maximum of 1/2 throttle is recommended;

however, brief full-throttle accelerations and variations in driving speeds

contribute to good engine break-in.

After one (1) tankful break-in period,

the snowmobile may be taken to an

authorized Arctic Cat Snowmobile

dealer for a checkup. This checkup is

at the discretion and the expense of the

snowmobile owner.

ENGINE BREAK-IN

(660 cc/1100 cc Z1

Models)

The Arctic Cat engine (when new or

rebuilt) requires a short break-in

period before the engine is subjected

to heavy load conditions.

This engine does not require any premixed fuel during the break-in period.

To ensu re trouble-free operation, careful adherence to the following breakin guidelines will be beneficial.

* With occasiona l full-throttle operation.

! WARNING

Always fill the gas tank in a wellventilated area. Never add gasoline to the snowmobile gas tank

near any open flames or with the

engine running. DO NOT SMOKE

while mixing fuel or filling the

gas tank.

! CAUTION

DO NOT exceed the one (1) tankful limitation of a 100:1 gas/oil

break-in mixture. Continuous

use of a gas/oil mixture, unless

consistently operating in

extremely cold conditions (-26°C/

-15°F or colder), could cause

spark plug fouling and excessive

carbon buildup. A 100:1 gas/oil

mixture must be used in conjunction with the oil-injection

system to ensure adequate

engine lubrication in extremely

cold conditions.

! CAUTION

DO NOT use premixed fuel in the

snowmobile gas tank. Engine

damage will occur.

0-200 miles 1/2 Throttle

(45 MPH-max)

200-400 miles 1/2-3/4 Throttle

400-600 miles 1/2-3/4 Throttle *

GENERAL INFORMATION 11

To ensure proper engine break-in on

the 1100 cc Z1 and 660 cc models,

Arctic Cat recommends that the

engine oil and filter be changed after

200-500 miles. This service is at the

expense of the snowmobile owner.

INDICATOR LIGHTS

(Carbureted Models/

Bearcat W/T NonTurbo/Panther 660)

Indicator lights are incorporated

within the speedometer.

LOW OIL WARNING

LIGHT (Standard 2Stroke Models)

The Low Oil Warning Light is

designed to alert the snowmobile

operator when the oil in the oil injection reservoir gets below a prescribed

level; however, it is highly recommended that a visual verification of

the oil level in the reservoir be done

prior to operating the snowmobile.

Once the Low Oil Warning Light ill uminates during operation of the snowmobile, the operator must periodically

monitor the level of oil in the reservoir

and must fill the reservoir the next

time gasoline is added to the gas tank.

The “alert level” of the Low Oil Warning Light is approximately equal to 1

tankful of gasoline under normal operating conditions.

LOW OIL PRESSURE

WARNING LIGHT

(Bearcat W/T NonTurbo/Panther 660

Models)

The Low Oil Pressure Warning Light

indicates engine oil pressure, not the

oil level; however, if the oil level is

low, it may affect oil pressure. The

light should illuminate each time the

ignition switch is turned to RUN or

START, and it should go out wh en the

engine starts. If the light illuminates

while the engine is running, oil pressure has been lost and the engine will

automatically shut off.

If oil pressure is lost, use the following

procedure:

1. Check the oil level.

NOTE: To ensure an accurate

reading, the snowmobile should

be on level ground.

2. If the oil level is below the lower

mark on the oil level stick, add

only enough recommended oil to

raise the level between the upper

and lower marks. DO NOT overfill the crankcase with oil.

3. After adding oil if the engine

starts, oil pressure should be normal.

If the engine does not start, take the

snowmobile to an authorized Arctic

Cat Snowmobile dealer.

12 GENERAL INFORMATION

COOLANT

TEMPERATURE

WARNING LIGHT

(Carbureted Models/

Bearcat W/T NonTurbo/Panther 660)

If the coolant temperature is at the

maximum running temperature, the

coolant temperature warning light will

flash a warning (alert). If the coolant

temperature is above the maximum

running temperature, the coolant temperature warning light will cease

flashing and will remain constantly

illuminated.

CHARGING SYSTEM

WARNING LIGHT (660

cc Models)

The Charging System Warning Light

is designed to warn the operator if the

battery charging system is not functioning. The light should illuminate

each time the key is turned to RUN or

START, and it should go out when the

engine starts. If the light stays illuminated or it illuminates while the

engine is running, the battery is not

being charged, and the snowmobile is

running on battery reserve power only.

If the Charging System Warning Light

illuminates, you should, as soon as

possible, take the snowmobile to an

authorized Arctic Cat Snowmobile

dealer for service. If not under warranty, this service is at the discretion

and expense of the snowmobile owner.

The engine WILL NOT RUN without battery power.

CHECK ENGINE LIGHT

(Bearcat W/T NonTurbo/Panther 660

Models)

The Check Engine Light is controlled

by the ECU and may illuminate for a

number of reasons. The light should

illuminate each time the key is turned

to RUN or START, and it should go

out when the engine starts. If the light

stays illuminated or it illuminates

while the engine is running, the ECU

is receiving input that is outside of its

established parameters. If the Check

Engine Light illuminates, take the

snowmobile to an authorized Arctic

Cat Snowmobile dealer for service. If

not under warranty, this service is at

the discretion and expense of the

snowmobile owner.

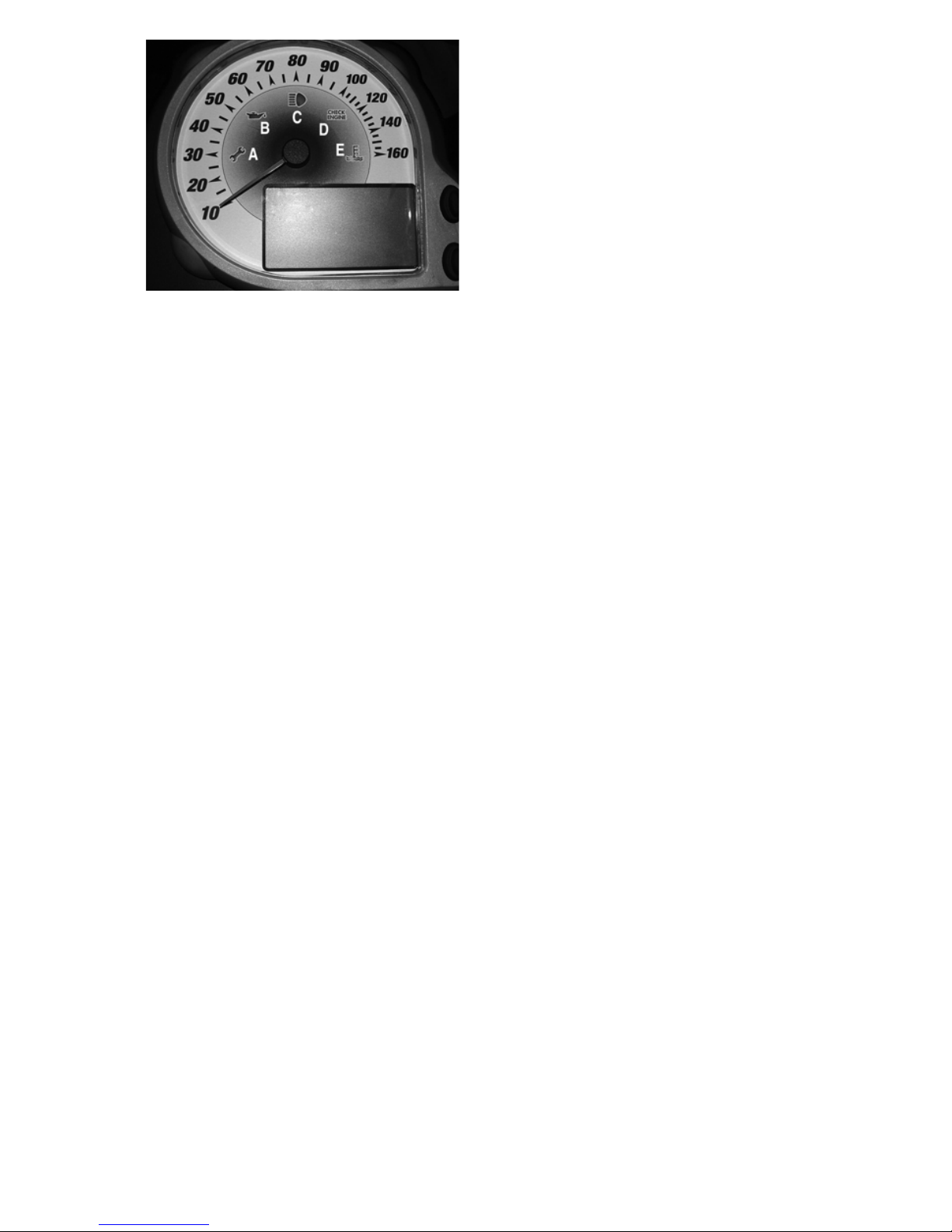

SPEEDOMETER/

TACHOMETER

INDICATOR LIGHTS

(Crossfire/F-Series/

Jaguar Z1/M-Series/

660 cc Turbo Models)

This snowmobile is equipped with a

combination speedometer/tachometer.

Indicator lights are incorporated

within the speedometer/tachometer.

Also incorporated into the speedometer/tachometer is a digital readout

screen.

! CAUTION

At this point, take precautionary

measures such as changing to

loose snow terrain, shutting the

engine off (allowing the engine to

cool down), and checking coolant level. If unable to either determine or remedy the problem,

take the snowmobile to an authorized Arctic Cat Snowmobile

dealer for service.

GENERAL INFORMATION 13

ZJ001A

A. Chassis Control Unit

B. Oil Pressure/Low Oil

C. High Beam

D. Check Engine

E. Coolant Temperature

Top Button

By pushing the top button once (lower

right-hand side of the speedometer/

tachometer), the RPM and MPH will

be displayed (one on the readout

screen and one with the needle). By

pushing the button once again, the

functions will be reversed.

By pushing the top button (with speed

being displayed) for more than two

seconds, the display will show

between standard mph or metric kph.

Release the button when desired display appears.

By pushing and holding the top button, maximum RPM will be displayed

on the readout screen. The maximum

RPM readout will reset when the

engine is shut off.

Bottom Button

By pushing the bottom button once,

the readout screen will display hourmeter or trip-meter/odometer; by

pushing the button once again, the two

functions will be reversed. T o reset the

trip meter with the trip meter displayed, push and hold the bottom button until the display is cleared. The

hour-meter readout will not reset.

Chassis Control Unit

On electric start models, the icon

should illuminate each time the key is

turned to RUN or START, and it

should go out when the engine starts.

If the light stays illuminated (on electric start models) or it illuminates

while the engine is running, the CCU

is receiving input that is outside of its

established parameters. If the CCU

icon illuminates indicating an error,

take the snowmobile to an authorized

Arctic Cat Snowmobile dealer for service. If not under warranty, this service is at the discretion and expense of

the snowmobile owner.

Coolant Temperature

Warning Light

If the coolant temperature is at the

maximum running temperature, the

coolant temperature warning light will

flash a warning (alert). If the coolant

temperature is above the maximum

running temperature, the coolant temperature warning light will cease

flashing and will remain constantly

illuminated.

14 GENERAL INFORMATION

Low Oil Warning Light

(Crossfire/F-Series/MSeries Models)

The Low Oil Warning Light is

designed to alert the snowmobile

operator when the oil in the oil injection reservoir gets below a prescribed

level; however, it is highly recommended that a visual verification of

the oil level in the reservoir be done

prior to operating the snowmobile.

Once the Low Oil Warning Light ill uminates during operation of the snowmobile, the operator must periodically

monitor the level of oil in the reservoir

and must fill the reservoir the next

time gasoline is added to the gas tank.

The “alert level” of the Low Oil Warning Light is approximately equal to 1

tankful of gasoline under normal operating conditions.

Oil Pressure Warning

Light (Jaguar Z1/660

cc Turbo Models)

The Oil Pressure Warning Light indicates engine oil pressure, not the oil

level; however, if the oil level is low , it

may affect oil pressure.

The light should illuminate each time

the ignition switch is turned to RUN

or START, and it should go out when

the engine starts. If the light illuminates while the engine is running, oil

pressure has been lost and the engine

will automatically shut off.

If oil pressure is lost, use the following

procedure to check the oil level:

NOTE: On the 660 cc Turbo

models, to ensure an accurate

reading, the snwomobile should

be on level ground.

1. On the 660 cc Turbo models,

check the oil level. If the oil level

is below the lower mark on the oil

level stick, add only enough recommended oil to raise the level

between the upper and lower

marks. DO NOT overfill the

crankcase with oil.

2. On the Jaguar Z1 with the engine

off, remove the engine oil level

stick and wipe it clean. Without

screwing it in, set the stick back

in the oil tank. Remove it and

observe the oil level on the stick.

If the oil level is at or below the

ADD mark on the oil level stick,

add only enough recommended

oil to raise the level to the NORMAL range. DO NOT overfill the

reservoir with oil.

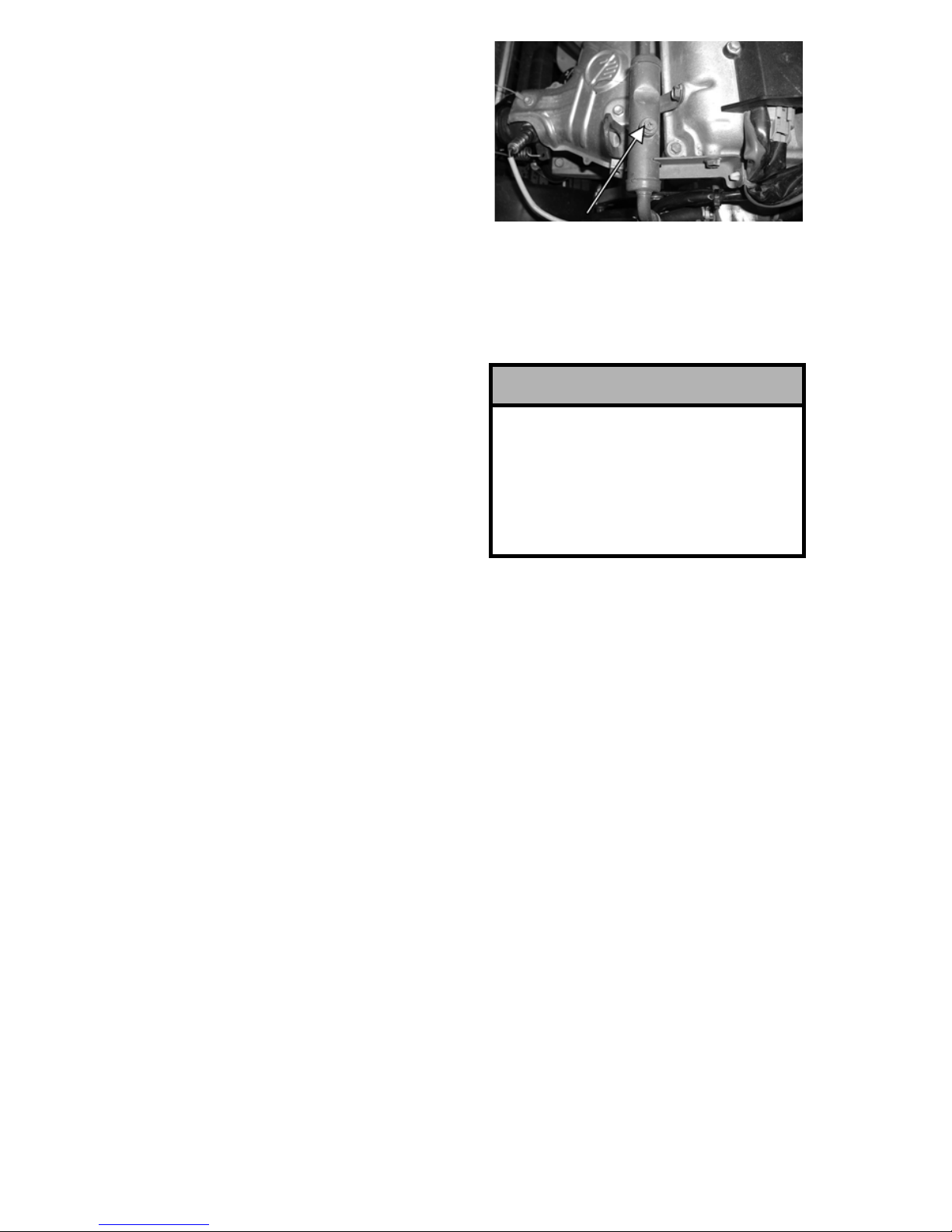

3. On the Jaguar Z1, open the air

bleed bolt located on the oil pump

(beneath the coolant tank) to

purge air from the oil hose.

! CAUTION

At this point, take precautionary

measures such as changing to

loose snow terrain, shutting the

engine off (allowing the engine to

cool down), and checking coolant level. If unable to either determine or remedy the problem,

take the snowmobile to an authorized Arctic Cat Snowmobile

dealer for service.

GENERAL INFORMATION 15

ZJ004A

NOTE: When air can no longer

be heard, purging from oil pump

bleed, tighten the bleed bolt to

1.05 kg-m (7.5 ft-lb).

4. Start the engine. The warning

light shuld go out within five seconds.

If the engine does not start, take the

snowmobile to an authorized Arctic

Cat Snowmobile dealer.

Check Engine Light

The Check Engine Light is controlled

by the ECU and may illuminate for a

number of reasons.

NOTE: The light should illuminate each time the key is turned

to RUN or START, and it should

go out when the engine starts.

If the light stays illuminated or it illuminates while the engine is running,

the ECU is receiving input that is outside of its established parameters. If

the Check Engine Light illuminates,

take the snowmobile to an authorized

Arctic Cat Snowmobile dealer for service. If not under warranty, this service is at the discretion and expense of

the snowmobile owner.

DIAGNOSTIC CODES/

CHECK ENGINE (2Stroke Models)

If the coolant temperature is at or

above 80° C (176° F), the coolant temperature light will flash a warning

(alert). If the coolant temperature is at

or above 93° C (200° F), the check

engine light will cease flashing and

will remain constantly illuminated.

NOTE: At t his point , the op erator should take precautionary

measures such as changing to

loose snow terrain and/or

checking coolant level.

Additional codes are flashed by the

check engine light. Refer to the following chart for diagnostic code

sequences.

NOTE: On single-digit codes

(2, 4, etc.), the number in dicated

will flash in an uninterrupted

sequence. On double-digit

codes (1-2, 2-1, etc.), the first

number indicated will flash in an

uninterrupted sequence, there

will be a short pause, and the

second number indicated will

flash in an uninterrupted

sequence.

! CAUTION

If unable to either determine or

remedy the problem, take the

snowmobile to an authorized

Arctic Cat Snowmobile dealer for

service.

16 GENERAL INFORMATION

DIAGNOSTIC CODES/

CHECK ENGINE

(JAGUAR Z1)

These diagnostic codes are flashed by

the check engine light. Refer to the

following chart for diagnostic code

sequences.

NOTE: On single-digit codes

(2, 3, etc.), the number in dicated

will flash in an uninterrupted

sequence. On double-digit

codes (1-1, 1-2, etc.), the first

number indicated will flash in an

uninterrupted sequence, there

will be a short pause, and the

second number indicated will

flash in an uninterrupted

sequence.

Number of

Flashes

Trouble

1-2

(Check

Engine Light)

Failure in ignition coil.

1-6

(Check

Engine Light)

Incorrect adjustment/

failure in APV cable.

1-7

(Check

Engine Light)

Failure in exhaust tem-

perature sensor.

1-8

(Check

Engine Light)

Failure in servomotor.

2

(Check

Engine Light)

Failure in injector(s).

2-1

(Check

Engine Light)

Fail ure in knock sen-

sor.

2-3

(Check

Engine Light)

Fail ure in knock con-

trol system.

4

(Check

Engine Light)

Open or short circuit in

barometric pressure

sensor.

5

(Check

Engine Light)

Open or short circuit in

intake air temperature

sensor.

6

(Check

Engine Light)

Open or short circuit in

water temperature

sensor.

7

(Check

Engine Light)

Open or short circuit in

throttle position sen-

sor.

Steady Flash

(Coolant

Temperature

Light)

Coolant Temperature

Above 80° C (176° F).

Constant On

(Coolant

Temperature

Light)

Coolant Temperature

Above 93° C (200° F).

Number of

Flashes Trouble

1

(Check Engine

Light)

Failure in the fuel sys-

tem.

1-1

(Check Engine

Light)

Fail ure in speed sen-

sor.

1-2

(Check Engine

Light)

Fai lure in coil (#1).

1-3

(Check Engine

Light)

Fai lure in coil (#2).

1-4

(Check Engine

Light)

Failure in ISC valve.

1-5

(Check Engine

Light)

Fai lure in oxygen sen-

sor.

1-9

(Check Engine

Light)

Fail ure in camshaft

position sensor.

2

(Check Engine

Light)

Failure in injector (#2).

GENERAL INFORMATION 17

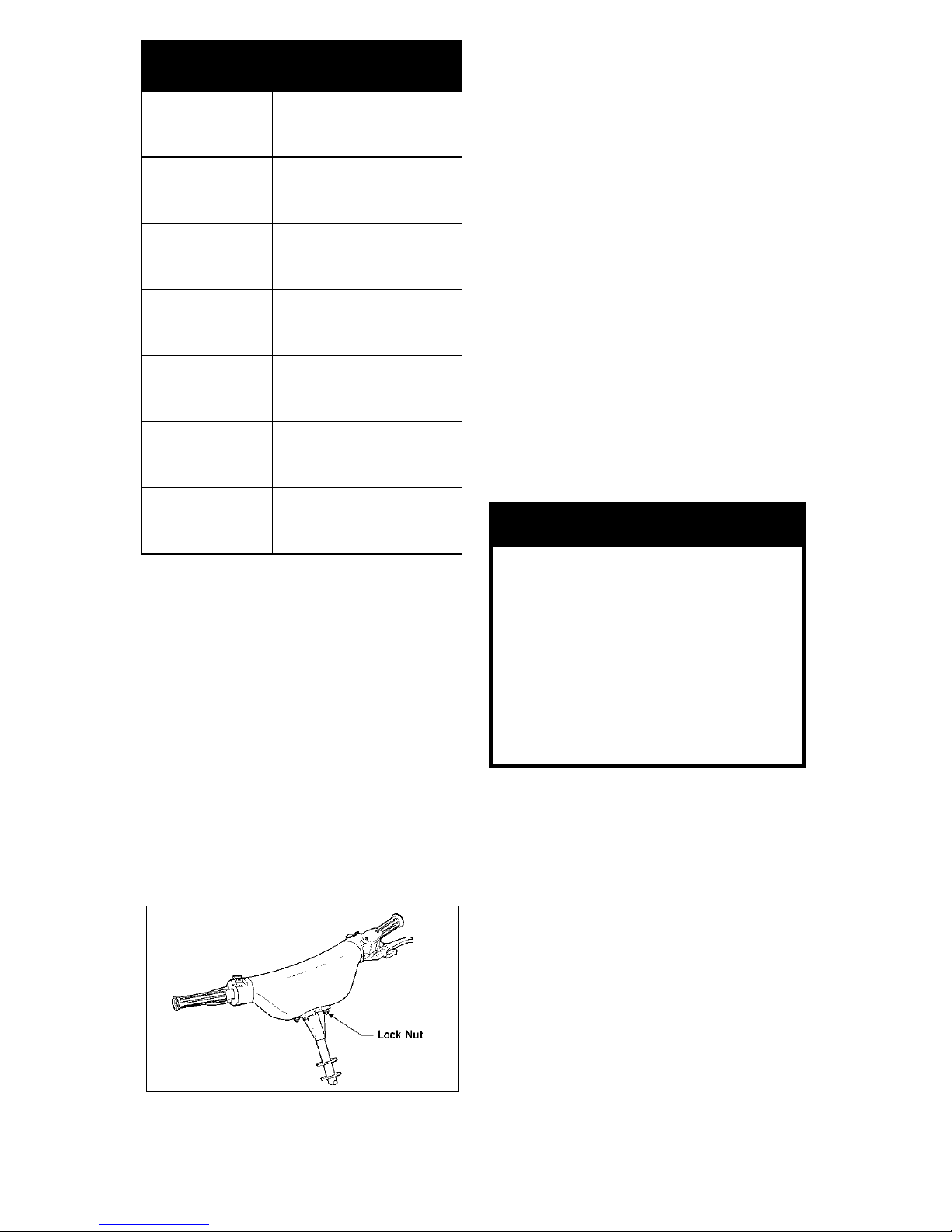

HANDLEBAR TILT

The handlebar can be adjusted to the

position providing the operator with

the most comfort. To adjust the handlebar, use the following procedure:

NOTE: It may be necessary to

remove the handlebar cover for

this procedure.

1. Loosen the four lock nuts securing the handlebar caps and block

to the steering post.

0734-406

2. Adjust the handlebar up or down

to operator’s desired tilt; then

tighten the lock nuts evenly and

securely . Check steering for maximum right/left turning capabilities.

3. Recheck lock nuts; tighten

securely.

NOTE: Recommended torque

value of loc k n uts is 2.5 kg -m (18

ft-lb).

NOTE: Do not adjust the handlebar to a position that allows

the brake fluid to be below the

low mark on either side of the

master cylinder.

HANDLEBAR TILT

(F-Series - STD)

The handlebar can be adjusted to the

operator’s preference. To adjust the

handlebar, use the following procedure:

1. Loosen the eight cap screws

securing the handlebar caps to the

riser and the riser to the steering

post.

3

(Check Engine

Light)

Failure in injector (#1).

4

(Check Engine

Light)

Failure in barometric

pressure sensor.

5

(Check Engine

Light)

Open or short circuit in

intake manifold air tem-

perature sensor.

6

(Check Engine

Light)

Open or short circuit in

water temperature sen-

sor.

7

(Check Engine

Light)

Open or short circuit in

throttle position senso r.

8

(Check Engine

Light)

Open or short circuit in

manifold air pressure

sensor.

9

(Check Engine

Light)

Failure in crankshaft

position sensor.

Number of

Flashes

Trouble

! WARNING

Tighten lock nuts according to

specifications to prevent unexpected “movement” of the handlebar during operation over

rough terrain and DO NOT position handlebar so steering (maximum right/left turning capabilities) or throttle and brake controls are affected.

18 GENERAL INFORMATION

735-501B

2. Adjust the handlebar up or down

to operator’s desired tilt, tighten

the cap screws evenly to 3.5 kg-m

(25 ft-lb), and check steering for

maximum right/left turning capabilities.

NOTE: Do not adjust the handlebar to a position that allows

the brake fluid to be below the

low mark on either side of the

master cylinder.

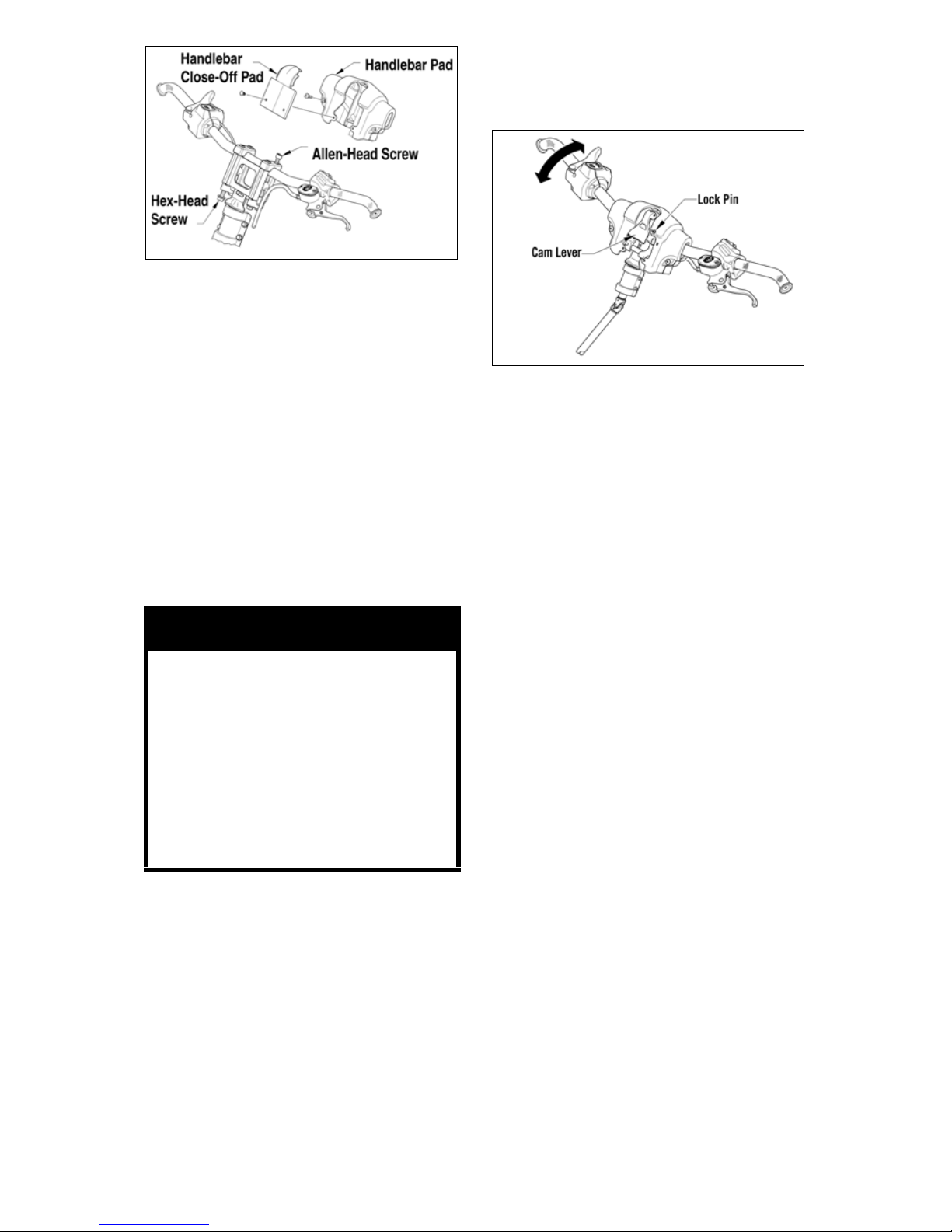

HANDLEBAR TILT

(F-Series LXR/Sno Pro/

Jaguar Z1)

The handlebar can be adjusted to the

operator’s preference. To adjust the

handlebar, use the following procedure:

1. Press inward on the lock pin to

release the cam lever and “flip”

the cam lever up.

0741-427

2. Adjust the handlebar up or down

and/or rotate the handlebar to

operator’s desired position; then

press down on the cam lever until

the lock pin is properly positioned

and locked. Check steering for

maximum right/left turning capabilities.

NOTE: At this point, gently lift

the cam lever without pressing

in on the lock pin. If the cam

lever cannot be lifted, the lock

pin is secure.

NOTE: Do not rotate the handlebar to a position that allows

air to enter the brake system.

3. Test the handlebar to ensure that it

does not rotate within the riser

block. If it does not rotate, proceed to step 4. If it does rotate,

release the cam lever and rotate

the cam lever clockwise; then

press down on the cam lever until

the lock pin is properly positioned

and locked. Repeat this procedure

until the handlebar is properly

secured.

! WARNING

Tighten cap screws according to

specifications to prevent unexpected “movement” of the handlebar during operation over

rough terrain. DO NOT offset the

handlebar so steering (maximum right/left turning capabilities) are altered or throttle and

brake controls will be affected.

GENERAL INFORMATION 19

4. After the handlebar is “locked” in

position, release the cam lever and

rotate it one turn clockwise; then

press down on the cam lever until

it “locks” in place.

NOTE: At this point, gently lift

the cam lever without pressing

in on the lock pin. If the cam

lever cannot be lifted, the lock

pin is secure.

EXHAUST SYSTEM

The exhaust system is designed to

reduce noise and to improve the total

performance of the engine. If any

exhaust system component is removed

from the engine and the engine is run ,

severe engine damage will result.

AIR-INTAKE SILENCER

Used in conjunction with the fuel

intake system is a specially designed

air-intake silencer. The purpose of the

silencer is to quiet the intake of fresh

air. Since the fuel intake system is calibrated with the air-intake silencer in

place, the engine must never be run

with the silencer removed. Performance will not be improved if the airintake silencer is removed. In contrast,

severe engine damage will occur.

BATTERY (Electric

Start Models)

It is extremely important that the battery be maintained at full charge at all

times and that the battery connections

be clean and tight. If charging the battery becomes necessary, refer to

Charging Battery section of this manual.

! CAUTION

If at any time the lock pin will

not engage into the locked position, do NOT operate the snowmobile. Take the snowmobile to

an authorized Arctic Cat dealer

for service.

! WARNING

Care must be taken to securely

lock the handlebar cam lever to

prevent unexpected “movement” of the handlebar during

operation over rough terrain. DO

NOT offset the handlebar so

steering (maximum right/left

turning capabilities) are altered

or throttle and brake controls

will be affected.

! CAUTION

These snowmobiles are not

designed to be operated in dusty

conditions. Operating the snowmobile in dusty conditions will

result in severe engine damage.

20 GENERAL INFORMATION

COOLING SYSTEM

(Liquid)

Some snowmobiles are equipped with

a closed liquid cooling system for

engine cooling. The cooling system

should be inspected daily for leakage

and damage. Also, the coolant level

should be checked daily. If leakage or

damage is detected, take the snowmobile to an authorized Arctic Cat Snowmobile dealer for service. If not under

warranty, this service is at the discretion and expense of the snowmobile

owner.

When filling the cooling system, use

an ethylene glycol-based coolant/

water mixture which will satisfy the

coldest anticipated weather conditions of your area in accordance with

the coolant manufacturer’s recommendations. While the cooling system is

being filled, air pockets may develop;

therefore, run the engine for five to ten

minutes after the initial fill, shut the

engine off, and then fill the cooling

system to approximately 51 mm (2 in.)

below the filler neck on 2-stroke models or to just below the FULL mark on

660 cc/1100 cc Z1 models.

NOTE: The 660 cc models are

equipped with a coolant “bleed

screw” on the purge tank

(located on the front-top of the

engine). After starting the

engine (and with the tank cap on

and tight), open the bleed screw

slightly to allow trapped air to

escape. Continue until no air is

apparent; then tighten the

screw.

AO353A

NOTE: Use a go od qu alit y, ethylene glycol-based, automotivetype antifreeze.

DRIVE CLUTCH AND

DRIVEN PULLEY

The drive clutch and driven pulley do

not require lubrication; therefore, no

special maintenance is required by the

snowmobile owner.

However, the drive clutch and driven

pulley should be disassembled,

cleaned, and inspected by an authorized Arctic Cat Snowmobile dealer

after every 800 miles of operation or

at the end of the snowmobiling season

whichever occurs first. This service is

at the discretion and expense of the

snowmobile owner.

! CAUTION

After operating the snowmobile

for the initial 5-10 minutes, stop

the engine, allow the engine to

cool down, and check the coolant level. Add coolant as necessary.

GENERAL INFORMATION 21

When operating the snowmobile at

high altitudes, it may be necessary to

change certain component parts of the

drive clutch. See an authorized Arctic

Cat Snowmobile dealer for further

information.

DRIVE CLUTCH/

DRIVEN PULLEY

ALIGNMENT

The parallelism and the offset between

the drive clutch and driven pulley are

set at the factory. Normally, no adjustment is necessary as long as neither

the drive clutch nor the driven pulley

is removed or disassembled. However,

if premature drive belt wear is experienced or if the drive belt turns over,

the drive clutch/driven pulley alignment must be checked. Take the snowmobile to an authorized Arctic Cat

Snowmobile dealer for this service. If

not under warranty, this service is at

the discretion and expense of the

snowmobile owner.

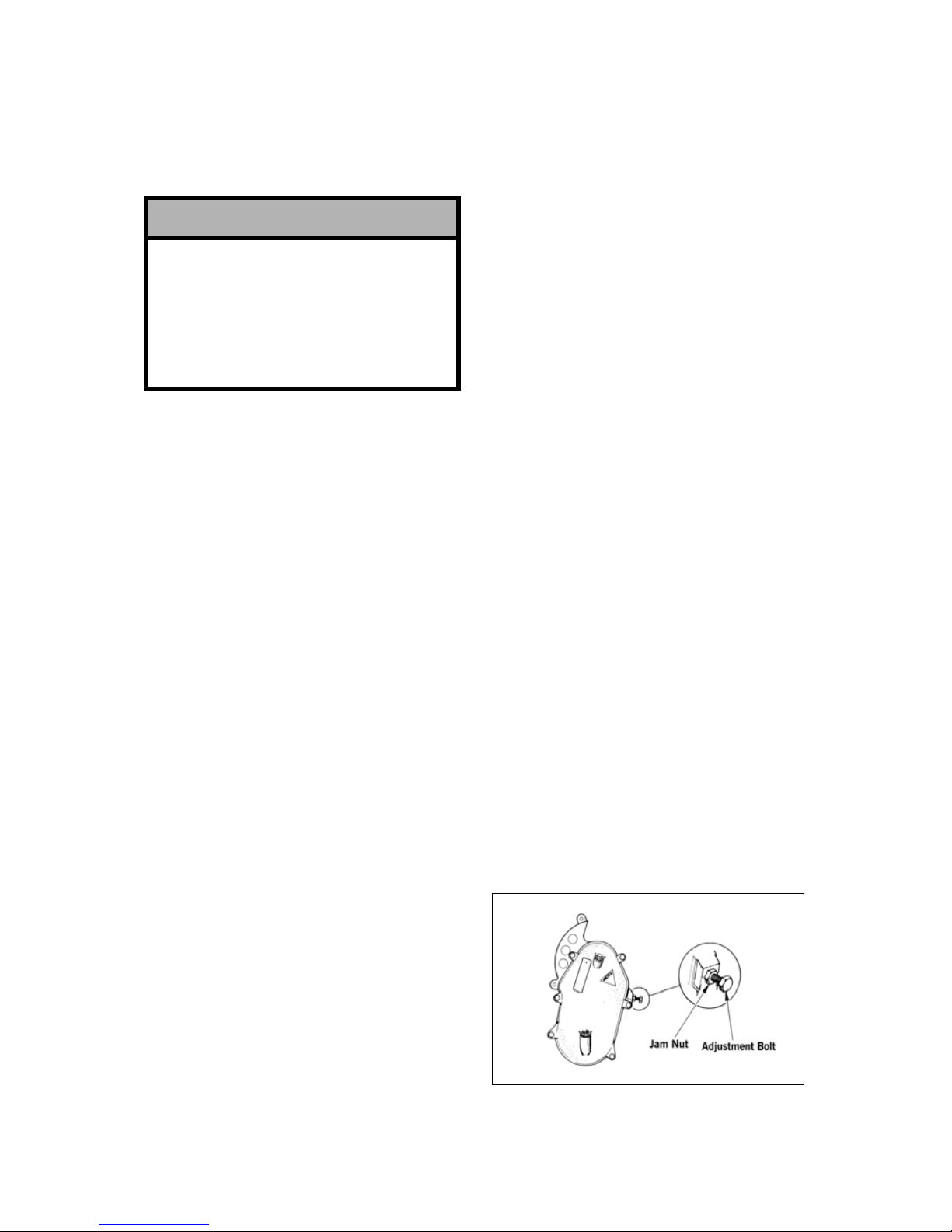

DRIVE CHAIN

TENSION

The drive chain must be properly tensioned for proper operation to prevent

“ratcheting” and unnecessary chain/

sprocket wear. On these snowmobiles, there are two different chain tensioners in the chain case. One chain

tensioner is automatic and one is man ual. The automatic chain tensioner

will take up the slack in the chain

under most operating conditions; however, every 500 miles or whenever

repeated hard accelerations will occur,

the manual chain tensioner should be

adjusted. Arctic Cat recommends that

the chain, sprockets, and chain tensioner be checked for wear and proper

alignment and adjustment every year,

1000 miles, or whenever a drive chain

related problem is suspected. Take the

snowmobile to an authorized Arctic

Cat Snowmobile dealer for this service. If not under warranty, this service is at the discretion and expense of

the snowmobile owner. To adjust the

manual drive chain tensioner, use the

following procedure:

1. Loosen the jam nut on the chain

tensioner adjustment bolt.

2. Tighten the adjustment bolt finger-tight.

0730-323

! CAUTION

DO NOT attempt to service the

drive clutch and driven pulley.

The drive clutch and driven pulley must be serviced by an

authorized Arctic Cat Snowmobile dealer only.

22 GENERAL INFORMATION

NOTE: If the adjustment bolt

will not turn using the fingers

(because of dirty threads), use a

wrench to loosen the bolt; then

using the fingers, adjust the bolt

until it is finger-tight. Once the

adjustment bolt becomes difficult to turn by hand, the drive

chain is properly tensioned.

3. Lock the adjustment by bottoming the jam nut against the chain

case.

NOTE: When the head of the

adjustment bolt bottoms on the

jam nut, the drive chain is in

need of being replaced. See an

authorized Arctic Cat Snowmobile dealer for this service.

FUEL PUMP

The fuel pump is designed to provide

adequate amount of gas to the carburetors (on carbureted models) or to the

injectors (on EFI models) at all throttle settings. If a fuel delivery problem

is suspected, take the snowmobile to

an authorized Arctic Cat Snowmobile

dealer. If not under warranty, this service is at the discretion and expense of

the snowmobile owner.

GAS TANK SHUT-OFF

VALVE

On certain models, a shut-off valve is

incorporated into the gas hose coming

from the gas tank. The valve should be

turned to the CLOSED position when

trailering or storing the snowmobile.

Turn the valve to the OPEN position

before attempting to start the engine.

NOTE: On all remaining models, there is an automatic shutoff valve incorporated into the

fuel pump which prevents gasoline flow when the engine is off.

SHOCK ABSORBERS

(Standard Gas)

Each shock absorber should be visibly

checked weekly for fluid leakage,

cracks or breaks in the lower case, or a

bent plunger. If any one of these conditions is detected, replacement is necessary. Take the snowmobile to an

authorized Arctic Cat Snowmobile

dealer for this service. If not under

warranty, this service is at the discretion and expense of the snowmobile

owner.

NOTE: When the snowmobile

is operated in extremely cold

weather (-23° C/-10° F or colder),

a small amount of leakage may

be present. Unless the leakage

is excessive, replacement is not

necessary.

SHOCK ABSORBERS

(Rebuildable Gas)

NOTE: The presence of an A CT

identifier (decal or embossed)

on a shock absorber body indicates a “rebuildable” shock

absorber.

GENERAL INFORMATION 23

NOTE: The frequency of servicing rebuildable shock absorbers will vary according to the

types of conditions and terrain

the snowmobile has been subjected to. If riding quality deteriorates (or seems to be deteriorating), take the snowmobile to

an authorized Arctic Cat Snowmobile dealer for shock

absorber evaluation and/or servicing. This service is at the discretion and expense of the

snowmobile owner.

Servicing rebuildable shock absorbers

is considered normal maintenance and

is the responsibility of the owner. Take

the snowmobile to an authorized Arctic Cat Snowmobile dealer for this service. This service is at the discretion

and expense of the snowmobile owner.

Kits are available to either stiffen or

soften gas shock valving. If changes in

shock valving are desired, see an

authorized Arctic Cat Snowmobile

dealer. This service is at the discretion

and expense of the snowmobile owner.

Each shock absorber should be visibly

checked weekly for fluid leakage,

cracks or breaks in the lower case, or a

bent plunger. If any one of these conditions is detected, replacement is necessary. Take the snowmobile to an

authorized Arctic Cat Snowmobile

dealer for this service. If not under

warranty, this service is at the discretion and expense of the snowmobile

owner.

NOTE: When the snowmobile

is operated in extremely cold

weather (-23° C/-10° F or colder),

a small amount of leakage may

be present. Unless the leakage

is excessive, replacement is not

necessary.

DEEP-LUG TRACK

Some models are equipped with a

deep-lug track which is specially

designed for use in powder snow riding conditions. When the deep-lug

track is operated in hard-packed snow

conditions, it will run slightly slower

than a standard-lug track and it will

accelerate wear strip wear. To

decrease the amount of wear strip

wear, slower speeds must be maintained when operating on hard-p acked

trails. Accelerated wear strip wear

caused by operating a deep-lug track

on hard-packed snow conditions is

NOT covered under Arctic Cat Inc.

warranty policy.

HACKSAW TRACK

Accelerated wear strip wear caused by

operating a Hacksaw Track on hardpacked snow conditions is NOT covered under Arctic Cat Inc. warranty

policy.

TRACK STUDS

NOTE: Stud or hooker plate

installation will void track and

tunnel warranty.

24 GENERAL INFORMATION

NOTE: Stud ins tallation can be

performed by the snowmobile

owner if qualified to do so. If the

owner does not feel qualified,

take the snowmobile to an

authorized Arctic Cat Snowmobile dealer for this service. Thi s

service is at the discretion and

expense of the snowmobile

owner.

For proper installation, use the following procedure:

1. Using Stud Template (p/n 2639-

903), mark the desired stud pattern to be used.

2. Using the proper-sized stud hole

drill bit, drill out the stud holes.

3. Push the stud through the hole

from inside the track; then place

the domed support plate and lock

nut on the exposed stud.

4. Using a wrench to secure the stud,

tighten the lock nut on the

exposed stud.

It is also recommended that whenever

studs are installed on a track, carbide

wear bars should be installed on the

skis. Carbide wear bars complement

the track studs to balance steering control under these conditions. The length

of the carbide on the wear bars should

be proportionate to the number of

track studs (i.e. small number of track

studs — short length of carbide...many

track studs — long length of carbide).

The proper proportion between the

number of studs and carbide length on

the wear bar will maintain steering

balance.

REVERSE

TRANSMISSION

The reverse transmission offers the

operator the convenience of being able

to back up the snowmobile rather than

having to turn the snowmobile around

by hand. This feature, under most situations, should not be used to free a

stuck snowmobile as it will tend to dig

the skis deeper into the snow. Before

starting the snowmobile, be sure the

shift lever is in the desired position for

either forward or reverse operation.

! WARNING

Always balance the snowmobile

with the proper proportion

between the number of studs

and carbide length on the wear

bars. Do not “over drive” conditions; use common sense in all

operating conditions.

! CAUTION

Do not use studs that are more

than 9.525 mm (0.375 in.) longer

than the track lug height.

! WARNING

Do not operate a snowmobile

with loose studs as they may be

thrown from the track. Always

use a shielded safety stand

whenever performing any maintenance or adjustments.

! WARNING

DO NOT stand behind the snowmobile or near the rotating track.

NEVER run the track at high

speed when the track is suspended.

GENERAL INFORMATION 25

Always use minimal speed when operating in reverse and come to a complete stop before shifting from either

forward to reverse or reverse to forward. Once you have shifted to a new

gear, apply slight throttle until positive

engagement of the shift has been

observed. To shift the reverse transmission, use the following procedure:

1. Come to a complete stop.

2. Either push or pull the shift lever

to the desired position; then apply

slight throttle until positive

engagement of the shift has been

observed.

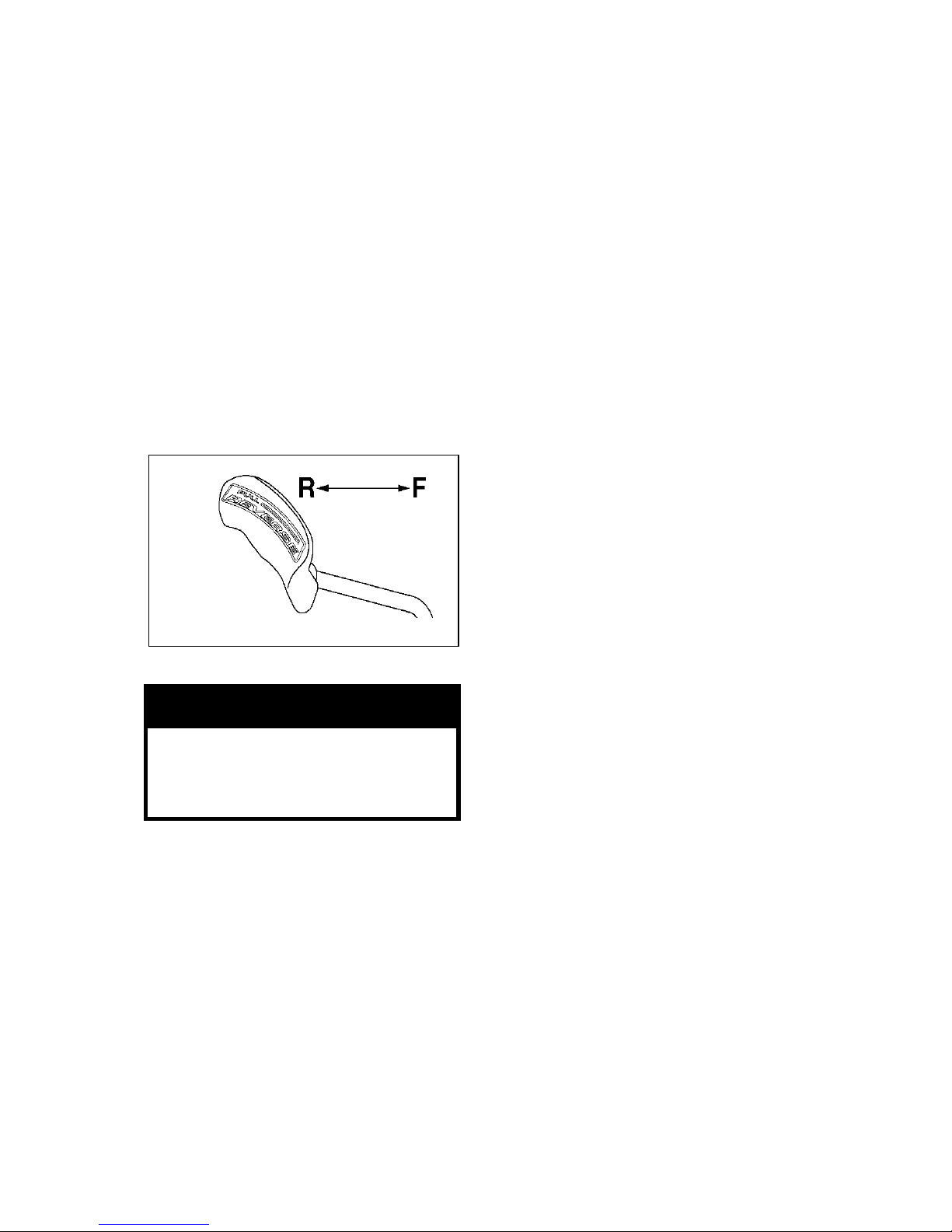

737-831A

No special maintenance is required for

the reverse transmission; however, if

chattering is experienced when the

transmission is shifted into reverse,

the linkage may have to be adjusted.

Arctic Cat recommends taking the

snowmobile to an authorized Arctic

Cat Snowmobile dealer for this service. If not under warranty, this service is at the discretion and expense of

the snowmobile owner.

NOTE: A warning buzzer will

sound when the transmission is

in the reverse position; however,

always check the position of the

shift lever before accelerating.

REVERSE

TRANSMISSION

(Crossfire/F-Series/

Jaguar Z1/M-Series

Models)

The reverse transmission offers the

operator the convenience of being able

to back up the snowmobile rather than

having to turn the snowmobile around

by hand. This feature, under most situations, should not be used to free a

stuck snowmobile as it will tend to dig

the skis deeper into the snow. Always

use minimal speed when operating in

reverse and come to a complete stop

before shifting from either forward to

reverse or reverse to forward. To shift

the reverse transmission, use the following procedure:

1. Come to a complete stop.

NOTE: The snowmobile must

be at a complete stop and the

engine at idle before the system

will allow shifting.

2. With the engine at idle, press the

reverse switch button; then release

the button. The reverse selection

will be complete.

! WARNING

Use caution and minimal speed

when operating the snowmobile

in reverse. Be sure the shift lever

is in the desired lever position.

26 GENERAL INFORMATION

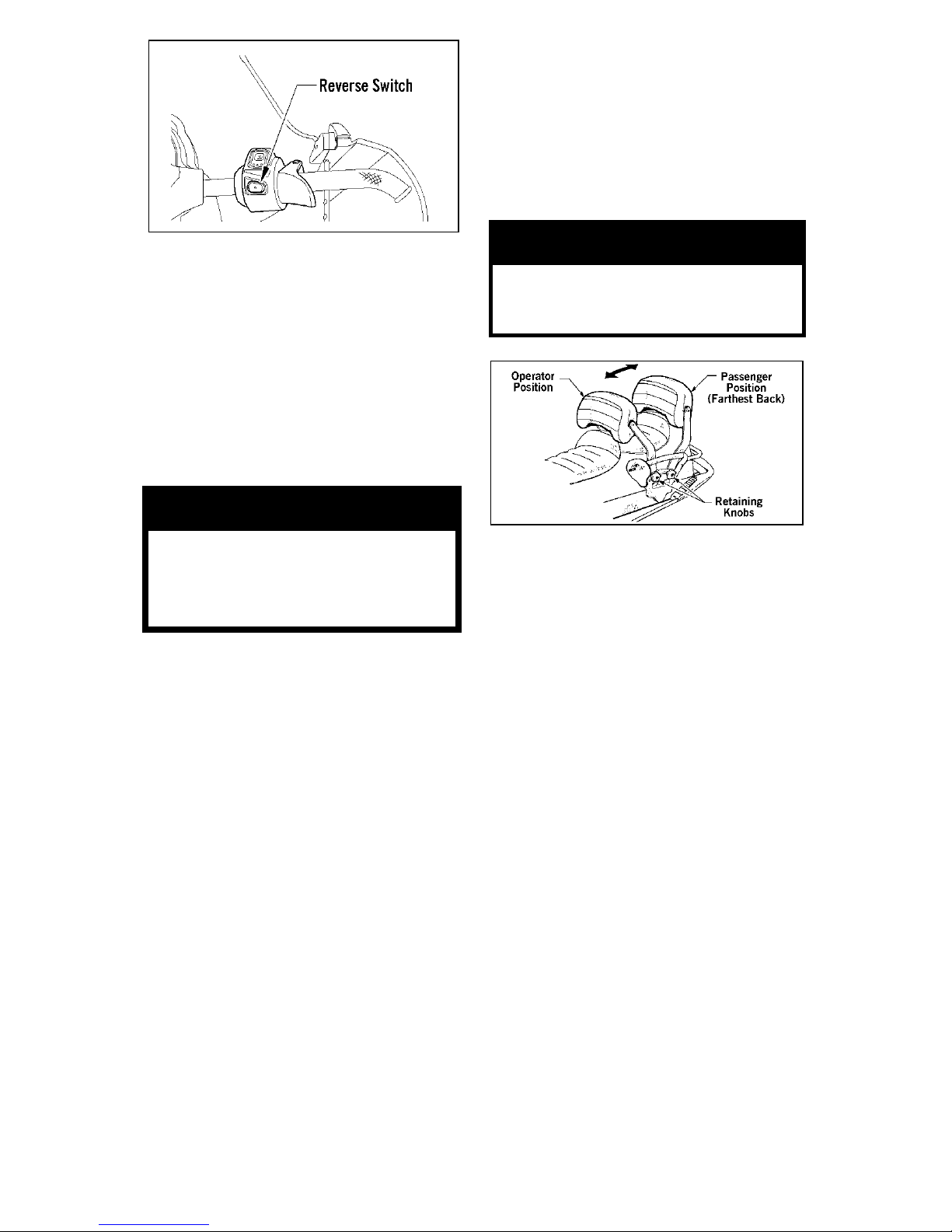

0741-438

NOTE: The system will not

shift until the button is released.

3. To shift into forward, stop the

snowmobile and allow the engine

to idle; then press the button and

release. The forward selection will

be complete.

NOTE: A warning buzzer will

sound when the transmission is

in the reverse position.

TOWING

If the snowmobile is to be towed by

another snowmobile, do not tow u sing

the loops in the skis. The tow rope

should be attached to the spindles.

ADJUSTABLE

BACKREST

The adjustable backrest is designed

for maximum comfort and safety.

When riding double, the backrest must

be adjusted to the most rearward position.

When riding single, the backrest

should be moved forward to a positi on

comfortable to the operator. Be sure to

maintain the backrest pad in a vertical

position in all locations. Also, be sure

to tighten all retaining knobs securely

after adjusting the backrest.

0734-425

REMOVABLE REAR

SEAT

Some snowmobiles are equipped with

a removable rear seat to allow for

additional cargo space when no passenger is being carried. To remove the

rear seat, use the following procedure:

1. Move and lock the adjustable

backrest in the forward position.

2. Pull back on the seat latch handle

located at the bottom rear of the

seat.

3. Lift on the back of the seat and

move it rearward to remove it

from the tunnel.

! WARNING

Use caution and minimal speed

when operating the snowmobile in reverse. Be sure the button is in the desired position.

! WARNING

Moving the backrest forward limits the seating capacity to one

person only.

Loading...

Loading...