Arbonia ENY-S-460, ENY-S-270, ENY-SEL-170, ENY-SEL-36, ENY-SEL-460 Installation, Use And Maintenance Instructions

...Page 1

INSTALLATION, USE AND

MAINTENANCE INSTRUCTIONS

Appliances for residential ventilation

Via Piave, 53 • 20011 Corbetta (MI) • ITALY

Tel. +39.02.97203.1 ric. autom. • Fax +39.02.9777282 - +39.02.9772820

E-mail: info@sabiana.it • Internet: www.sabiana.it

E 11/18

D 11/18

Cod. 4051026

Page 2

Page 3

IT

UK

DE

Gentile cliente,

la ringraziamo per la ducia accordataci con l’acquisto di un nostro prodotto.

Se Lei avrà la costanza di seguire attentamente le indicazioni contenute nel presente manuale, siamo certi

che potrà apprezzare nel tempo e con soddisfazione la qualità della nostra macchina.

La preghiamo di leggere attentamente le indicazioni contenute nel manuale che riguardano l’uso corretto

del nostro prodotto, in conformità alle prescrizioni essenziali di sicurezza.

È possibile scaricare il manuale dal sito www.sabiana.it

We thank you for your custom in the purchase of this product.

By carefully following the instructions contained in this manual you will be sure to appreciate the quality

of our machine.

Please therefore carefully read the instructions of use contained in this manual, which comply with

essential safety regulations.

Sehr geehrter Kunde,

wir danken Ihnen für das uns durch den Erwerb eines unserer Produkte entgegengebrachte Vertrauen.

Wenn Sie die Ausdauer haben, aufmerksam die im vorliegenden Handbuch enthaltenen Hinweise zu

beachten, sind wir gewiß, daß Sie lange und mit Zufriedenheit die Qualität unserer Maschine schätzen

werden können. Wir bitten Sie, aufmerksam die im Handbuch enthaltenen Hinweise bezüglich der richtigen

Verwendung unseres Produktes in Übereinstimmung mit den wesentlichen Sicherheitsvorschriften zu lesen.

FR

Sie können das Handbuch von der Website www.sabiana.it herunterladen

Cher client,

Nous vous remercions de la conance que vous nous avez manifestée en achetant notre produit.

Si vous suivez attentivement les indications contenues dans le présent manuel, nous sommes certains

que vous apprécierez la qualité de notre machine.

Nous vous prions de lire attentivement les indications contenues dans le manuel sur l’utilisation correcte

de notre produit, en conformité avec les prescriptions essentielles de sécurité.

Vous pouvez télécharger le manuel sur le site Web www.sabiana.it

Page 4

Carefully read the following instruction booklet before starting up the machine.

Attention! Carefully turn o the electrical supply before removing the protections

Attention! Carefully turn o the electrical supply before removing the protections

Operations which may be carried out by the user

Interventions to be carried out exclusively by an installer or authorised technician.

Always wear work gloves.

Page 5

English

ESSENTIAL SAFETY

RULES

It is dangerous to touch the appliance with parts of

your body wet and with bare feet.

Do not perform any type of intervention or maintenance without rst having disconnected power to

the appliance.

Do not tamper with or modify the adjustment or

safety devices without being authorised and without

instructions.

Do not twist, detach or pull the power cords coming

out of the appliance even if not plugged in.

Do not pour or spray water on the appliance.

Never insert anything through the lter seat holes.

Do not remove any protection without rst having dis-

connected power to the appliance.

Do not throw or leave any residual packing material

within the reach of children as it is a potential risk of

danger.

Do not install the appliance in explosive or corrosive

atmospheres, in moist areas, outdoors or in extremely

dusty environments.

- SAFETY REQUIREMENTS

The appliance can be used by children no younger

than 8 years old and by persons with reduced physical, sensory or mental capabilities, or lack of necessary

experience and knowledge as long as they are supervised or after they have received instructions regarding

safe use of the appliance and understanding the hazards related to it.

Children must not play with the appliance.

The cleaning and maintenance to be carried out by the

user cannot be done by children without supervision.

Before performing any operation, make sure to:

1 - Disconnect electric power to the appliance.

2 - Close the water supply valve of the coil and let it

cool o (pre-and post-heating coils if installed as

accessories).

3 - Install a circuit breaker switch in an easily accessible position near the appliance or appliances.

RISK OF INJURY!

For safety purposes, during installation, maintenance

and repairs, abide by the following:

• Always wear work gloves.

• Do not be exposed to ammable gases.

RISK OF INJURY/MATERIAL DAMAGE

DAMAGE TO APPLIANCE!

The appliance is very heavy.

Lifting it can cause injuries.

Have another person help you lift it

in order to carry the machine.

Lift it slowly and pay attention that

it does not fall.

The fans can reach a speed of 3000

rpm.

Do not insert objects or your hands into the electric fan.

Do not remove the safety labels inside the appliance. If illeg-

ible, have them replaced.

Make sure to earth the appliance.

Always request original spare parts when replacing compo-

nents.

The installation site must be chosen so that there is sucient

space for the connections of the air pipes and to allow maintenance to be carried out conveniently.

Make sure there is at least 1 m of open space in front of the

appliance to allow for maintenance operations.

If the appliance is hung on a wall, make sure the wall has a

supercial mass of at least 200 kg/m2. Otherwise use a stand

to install it on the oor (optional accessory sold separately).

Do not install the appliance near bedrooms.

To improve environmental comfort, install silencers on the

ambient air input and return piping.

The appliances cannot be installed in environments cooler

than < 12°C.

The residential ventilation systems are designed for con-

stant operation to avoid the formation of condensation and

mould in the environments. The units can only be switched

o for scheduled maintenance.

The appliances cannot be used to dry structures and

masonry of new homes.

ATTENTION! It is strictly forbidden to operate the unit before

having connected the 4 air ducts to the ducting system.

/

5

Page 6

English

USE AND STORAGE

OF THE MANUAL

This instruction manual is intended for the machine

user, owner and technical installer and must always

be available for consultation.

The instruction manual indicates the intended use of

the machine, its technical features and provides indications as to its correct use, cleaning and adjustments.

It also provides important indications for maintenance,

for residual risks and anyhow to carry out operations

with particular attention.

This manual must be considered as a part of the machine and must be KEPT FOR FUTURE REFERENCE

until the nal scrapping of the machine.

The instruction manual must always be available for

consultation and preserved in a dry and protected

area.

Should it be lost or damaged, the user can request a

new manual from the manufacturer or retailer, indicating the model and serial number of the machine

shown on its rating plate.

SCOPE

BEFORE INSTALLING THE APPLIANCE

READ THIS MANUAL CAREFULLY

Residential ventilation appliances convey outdoor air

through the cross-ow heat exchanger and distribute

it to the dierent rooms by means of a duct distribution system.

Moist and stale air is suctioned and then, again

passing through the cross-ow heat exchanger, is

exhausted to the outside of the appliance by residential ventilation.

MACHINE IDENTIFICATION

There is an identication label on each appliance

bearing the data of the manufacturer and the

machine type (See Figure “A”).

Fig. “A”

This manual reects the state of technology at the

moment it was drafted. The manufacturer reserves

the right to update production and following manuals

without being obliged to update previous versions

as well.

The manufacturer will not be held liable in case of:

- improper use or misuse of the machine

- use nonconforming to that expressly specied in

this publication

- serious shortcomings in intended and recommended maintenance

- changes to the machine or any unauthorised intervention

- use of non-original spare parts or not specic for

the model

- total or partial failure to comply with the instructions

- Exceptional events

MADE IN ITALY

SABIANA S.p.A

Via Piave 53 - 20011- Corbetta (MI) - ITALY

ENERGY- S

SIZE

ENY- S - ---

TYPE

MAXIMUM

POWER INPUT

- - - W

MAXIMUN

CURRENT INPUT

- - - A

230V

50Hz

07/03

2017

021B001

WASTE DISPOSAL

Consumables and replaced parts should

be disposed of safely and in accordance

with the environmental protection legislation.

IP21

QUALITY

CONTROL

6

Page 7

RANGE

English

Model

Version

Equip-

ment

- - W

ENY-S-170

ENY-S-270

ENY-S-360

ENY-S-460

ENY-SEL-170

ENY-SEL-270

ENY-SEL-360

ENY-SEL-460

ENY-SER-170

STANDARD - -

STANDARD - -

STANDARD - -

STANDARD X -

STANDARD - X

STANDARD - X

STANDARD - X

STANDARD X X

STANDARD - X

Side

Acoustic

Insulation

Integrated

Modulating

Electric

Resistance

Flow

Conguration

Default LH

Reversible

Default LH

Reversible

Default LH

Reversible

Default LH

Reversible

LH

LH

LH

LH

RH

Integrated

Humidity

Sensor

* ** A -

* ** A -

* ** A -

* ** A -

* ** A 500

* ** A 900

* ** A 1250

* ** A 1600

* ** A 500

Integrated

Automatic

Flow Rate

Control

Energy

Class

Electric

Resistance

Power

ENY-SER-270

ENY-SER-360

ENY-SER-460

ENY-SP-180

ENY-SPM-180 ***

ENY-SP-280

ENY-SPM-280 ***

ENY-SP-370

ENY-SPM-370 ***

ENY-SP-460

ENY-SPM-460 ***

ENY-SPEL-180

ENY-SPMEL-180 ***

ENY-SPEL-280

ENY-SPMEL-280 ***

ENY-SPEL-370

ENY-SPMEL-370 ***

ENY-SPEL-460

ENY-SPMEL-460 ***

ENY-SPER-180

ENY-SPMER-180 ***

ENY-SPER-280

ENY-SPMER-280 ***

ENY-SPER-370

ENY-SPMER-370 ***

ENY-SPER-460

ENY-SPMER-460 ***

STANDARD - X

STANDARD - X

STANDARD X X

PRO X -

PRO X -

PRO X -

PRO X -

PRO X X

PRO X X

PRO X X

PRO X X

PRO X X

PRO X X

PRO X X

PRO X X

RH

RH

RH

Default LH

Reversible

Default LH

Reversible

Default LH

Reversible

Default LH

Reversible

LH

LH

LH

LH

RH

RH

RH

RH

* ** A 900

* ** A 1250

* ** A 1600

X X A+

X X A+

X X A+

X X A

X X A+

X X A+

X X A+

X X A

X X A+

X X A+

X X A+

X X A

-

-

-

-

500

900

1250

1600

500

900

1250

1600

* Humidity sensor available as an accessory

** Pressure transducer for automatic control of ow rates available as an accessory

*** Models tted with enthalpy heat exchangers

7

Page 8

English

DIMENSIONS

8

D

A

D

28

H

42

8

B

E

F

C

Model

A

(mm)

B

(mm)

Ø C

(mm)

D

(mm)

E

(mm)

F

(mm)

H

(mm)

ENY - S - 170 547 505 125 106 93.5 212.5 1041

ENY - S - 270 547 580 160 106 111 240 1041

ENY - S - 360 547 630 160 106 111 290 1041

8

Page 9

DIMENSIONS

English

A

D D

8

28

H

42

8

B

E

A

(mm)

C

B

(mm)

Ø C

(mm)

D

(mm)

E

(mm)

F

(mm)H(mm)

Model

Heat Exchangers Standard

F

Enthalpy Heat Exchangers

ENY - SP - 180 ENY - SPM - 180 600 580 125 132 111 240 1041

ENY - SP - 280 ENY - SPM - 280 600 630 160 132 111 290 1041

ENY - SP - 370 ENY - SPM - 370 660 680 160 147 126 305 980

ENY - SP - 460 ENY - SPM - 460 660 680 180 147 126 305 980

ENY - S - 460 / 660 680 180 147 126 305 980

9

Page 10

English

MACHINE DIMENSIONS WITH PACKAGING

C

B

A

Model

Heat Exchangers Standard

ENY - S - 170 / 670 1200 685 56

ENY - S - 270 / 670 1200 760 64

ENY - S - 360 / 670 1200 810 66

ENY - S - 460 / 780 1140 850 75

ENY - SP - 180 ENY - SPM - 180 720 1200 760 64 69

Enthalpy Heat Exchangers

A

(mm)

B

(mm)

C

(mm)

Heat Exchangers Standard

WEIGHT

(KG)

Enthalpy Heat Exchangers

ENY - SP - 280 ENY - SPM - 280 720 1200 810 66 71

ENY - SP - 370 ENY - SPM - 370 780 1140 850 75 80

ENY - SP - 460 ENY - SPM - 460 780 1140 850 75 80

10

Page 11

TECHNICAL DATA / ENERGY - S

Model ENY-S-170 ENY-S-270 ENY-S-360 ENY-S-460

Length mm 505 580 630 680

Width mm 547 547 547 660

Height mm 1041 1041 1041 980

Diameter of Connections - DN125 DN160 DN160 DN180

Weight kg 47 51 56 59

Maximum Flow Rate m3/h 170 270 360 460

Available Static pressure

at maximum ow rate

Flow rate of reference m3/h 120 190 250 320

Available Static pressure

at ow rate of reference

Minimum Flow Rate m3/h 60 70 90 90

Maximum Available

Static Pressure

Thermal Eciency

at ow rate of reference

EN 13141-7

Filtering Eciency

EN779 - ISO 16890

Fan Type

Maximum power output

(fans and controllers)

Maximum current output

(fans and controllers)

Electric power supply - Single phase -230 V – 50 Hz

Consumption in standby - <1W

Safety Property

Integrated modulating

electric resistance

Preheating resistance

power

Maximum current output

with resistance

Pa 100 100 100 100

Pa 50 50 50 50

Pa 250 250 350 400

% 87% 87% 90% 89%

-

-

W 45 76 125 215

A 0.6 1.1 1.5 2.0

-

-

W 500 900 1250 1600

A 3 5 7 9.2

Centrifugal with EC brushless motor - Blades back - Curves at constant

ENY-SEL-170

ENY-SER-170

F7 supply - M5 exhaust

ePM1 70% - ePM10 50%

speed

Protection: IP21

EC Compliant

ENY-SEL-270

ENY-SER-270

ENY-SEL-360

ENY-SER-360

ENY-SEL-460

ENY-SER-460

English

11

Page 12

English

TECHNICAL DATA / ENERGY - SP

Model ENY-SP-180 ENY-SP-280 ENY-SP-370 ENY-SP-460

Length mm 580 630 680 680

Width mm 600 600 660 660

Height mm 1041 1041 980 980

Diameter of Connections - DN125 DN160 DN160 DN180

Weight kg 47 51 56 59

Maximum Flow Rate m3/h 180 280 370 460

Available Static pressure

at maximum ow rate

Flow rate of reference m3/h 130 200 260 320

Available Static pressure

at ow rate of reference

Minimum Flow Rate m3/h 50 70 50 90

Maximum Available

Static Pressure

Thermal Eciency

at ow rate of reference

EN 13141-7

Filtering Eciency

EN779 - ISO 16890

Fan Type - Centrifugal with EC brushless motor - Blades back - Curves at constant

Maximum power output

(fans and controllers)

Maximum current output

(fans and controllers)

Electric power supply - Single phase -230 V – 50 Hz

Consumption in standby - <1W

Safety Property

Models with integrated

modulating resistance

Preheating resistance

power

Maximum current output

with resistance

Pa 100 100 100 100

Pa 50 50 50 50

Pa 160 240 390 400

% 91% 91% 92% 89%

- F7 supply - M5 exhaust

ePM1 70% - ePM10 50%

speed

W 50 70 120 215

A 0.6 1.0 1.0 2.0

-

ENY-SPEL-180

-

ENY-SPER-180

W 500 900 1250 1600

A 3 5 7 9.2

ENY-SPEL-280

ENY-SPER-280

Protection: IP21

EC Compliant

ENY-SPEL-370

ENY-SPER-370

ENY-SPEL-460

ENY-SPER-460

12

Page 13

TECHNICAL DATA / ENERGY - SPM (Models tted with enthalpy heat exchangers)

Model ENY-SPM-180 ENY-SPM-280 ENY-SPM-370 ENY-SPM-460

Length mm 580 630 680 680

Width mm 600 600 660 660

Height mm 1041 1041 980 980

Diameter of Connections - DN125 DN160 DN160 DN180

Weight kg 52 56 61 64

Maximum Flow Rate m3/h 180 280 370 460

English

Available Static pressure

at maximum ow rate

Flow rate of reference m3/h 130 200 260 320

Available Static pressure

at ow rate of reference

Minimum Flow Rate m3/h 50 70 50 90

Maximum Available

Static Pressure

Thermal Eciency

at ow rate of reference

EN 13141-7

Thermal hygromeric

at ow rate of reference

EN 13141-7

Filtering Eciency

EN779 - ISO 16890

Fan Type -

Maximum power output

(fans and controllers)

Maximum current output

(fans and controllers)

Electric power supply - Single phase -230 V – 50 Hz

Consumption in standby - <1W

Safety Property -

Models with integrated

modulating resistance

Preheating resistance

power

Maximum current output

with resistance

Pa 100 100 100 100

Pa 50 50 50 50

Pa 160 240 390 400

%

%

-

W 50 70 120 215

A 0.6 1.0 1.0 2.0

-

W 500 900 1250 1600

A 3 5 7 9.2

88.6% 84.8% 82.7% 81.5%

72.1% 65.6% 63.4% 58.4%

F7 supply - M5 exhaust

ePM1 70% - ePM10 50%

Centrifugal with EC brushless motor - Blades back - Curves at constant

speed

Protection: IP21

EC Compliant

ENY-SPMEL-180

ENY-SPMER-180

ENY-SPMEL-280

ENY-SPMER-280

ENY-SPMEL-370

ENY-SPMER-370

ENY-SPMEL-460

ENY-SPMER-460

13

Page 14

English

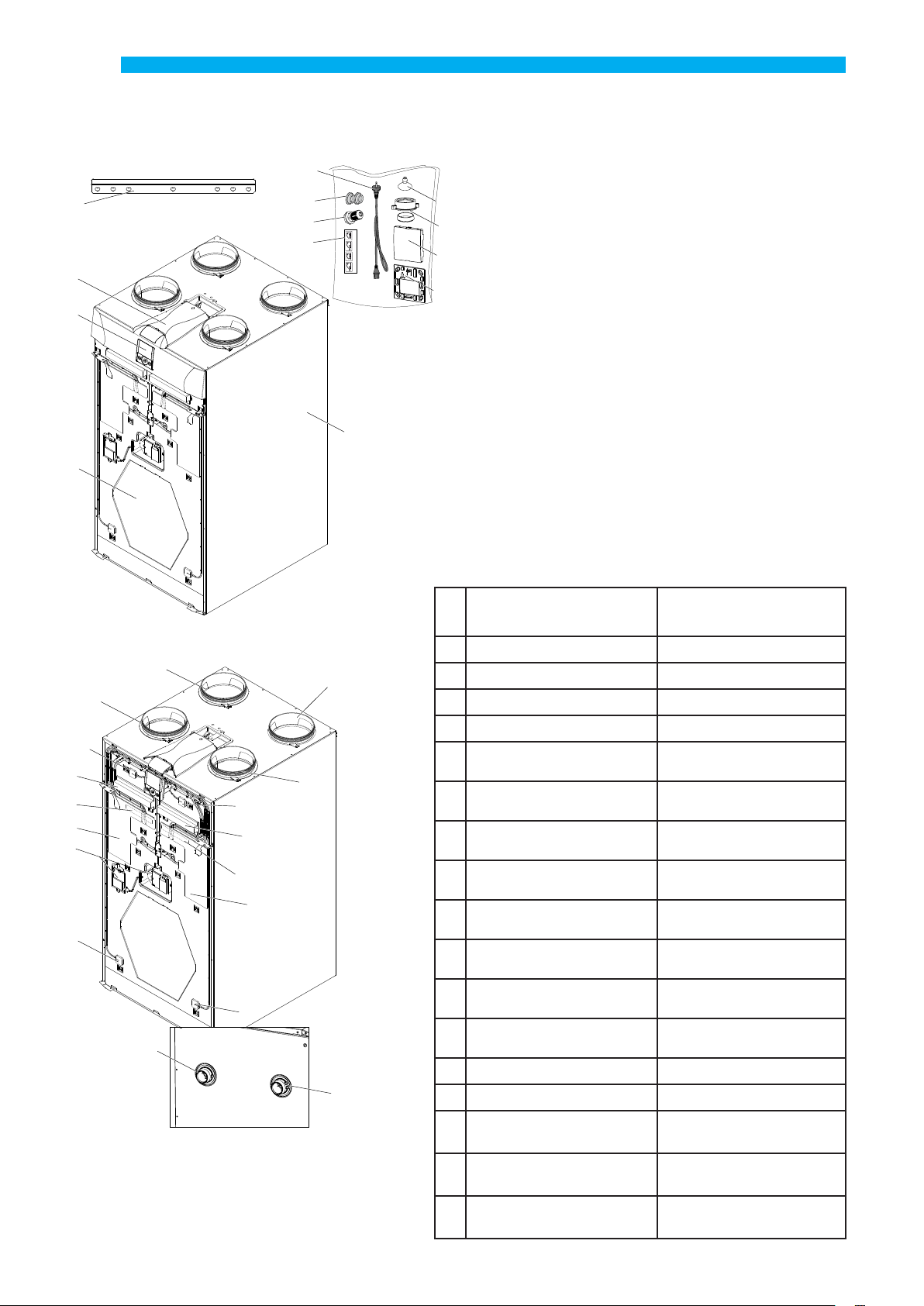

DESCRIPTION OF MACHINE COMPONENTS

6

5

2

3

7

9

10

A B C D

1 - Appliance for residential ventilation

2 - Power board

11

3 - T-EP capacitive touch controller

8

4 - Heat exchanger

12

5 - Hanging bracket

6 - Power cord

30

7 - Spacer foot

8 - Condensate drain plug

9 - Cable gland PG7

10 - Shank label (to use for right side connection)

11 - Suction cup

12 - Front cap (for remote control)

1

4

14

13

15

30 - T-EP support for wall mounting

Left side connection

(Standard Conguration)

13 Outdoor air connection

14 Exhaust air connection Supply air connection

15 Supply air connection Exhaust air connection

Right side connection

(supplementary

Extracted stale air connection

Cong.

)

17

28

19

27

23

21

25

22

29

18

24

20

16

26

16

Extracted stale air connection

17

18

Filter class F7

(outdoor air)

Filter class M5

(extracted stale air)

19 Supply air fan

20

Outdoor air temperature

21

22

temperature probe (T3)

Exhaust air temperature

23

Supply air temperature

24

Stale air

exhaust fan

probe (T1)

Extracted stale air

probe

probe (T2)

Outdoor air connection

Filter class M5

(extracted stale air)

Filter class F7

(outdoor air)

Stale air

exhaust fan

Supply air fan

Extracted stale air

temperature probe (T3)

Outdoor air temperature

probe (T1)

(T4)Supply air temperature

probe (T2)

Exhaust air temperature

probe

25 Condensate drain ------

26 ------ Condensate drain

27

LH Integrated Resistance

28

29

Bypass

Damper System

(if any)

------

RH Integrated Resistance

Bypass

Damper System

------

(if any)

14

Page 15

English

OK

INSTALLATION (OPERATION

CARRIED OUT EXCLUSIVELY BY

QUALIFIED PERSONNEL)

Attention! Installation of the appliance for residential ventilation must only be carried out by

qualied personnel to avoid damage or injury.

Attention! To protect the system against

lth and humidity, all the openings must

remain closed until commissioning, for

example using protective covers.

INSTALLATION INSTRUCTIONS

• The residential ventilation appliance can be

installed in dry environments with the temperature

above 12°C, for example in a utility room.

Installation temperature: from +12 °C to +40 °C.

• Relative humidity (installation environment): max.

60%.

• Storage temperature: -20 ° C to +60 ° C.

PLEASE NOTE: if the temperature in the installation room

drops below 12°C, there could occasionally be condensate

on the external covering of the appliance.

• Position the appliance so that the section up to the

external outlet of the outdoor air and exhaust air

inlet ducts is as short as possible.

• The vibrations produced by the residential ventilation appliance must be dampened. The installed

appliance must be soundproofed.

• The residential ventilation appliance is mounted

with a wall bracket (supplied with the machine).

• The appliance can be mounted on the oor using

optional stands.

• The appliance must be accessible to perform

maintenance and repairs.

• Air flow rates must be set correctly in compliance with standard DIN 1946, part 6.

• The appliance can be commissioned after having

completed installation of the entire residential

ventilation system.

- Fastening the bracket to the wall

Take the bracket and apply it to the wall, making sure that it is

attached in a horizontal position using a spirit level, as described

in the gure below (Fig. 1).

PLEASE NOTE: the screws are not included in the supply.

Choose the screws and relative plugs based on the type

of wall.

WALL INSTALLATION OF APPLIANCE

(Fig. 1)

A

R5

B

5

20

50 50

242,5

485

525

B

50 50

C

H MIN

262,5

MIN 200

1 - Position the bracket and drill the necessary holes

(Fig.1). Make sure the appliance is horizontal.

2 - Secure the bracket by applying the screws.

Model

ENY-S-170

ENY-SEL-170

ENY-SER-170

ENY-S-270

ENY-SEL-270

ENY-SER-270

ENY-S-360

ENY-SEL-360

ENY-SER-360

ENY-S-460

ENY-SEL-460

ENY-SER-460

ENY-SP-180*

ENY-SPEL-180

ENY-SPER-180

ENY-SP-280*

ENY-SPEL-280

ENY-SPER-280

ENY-SP-370*

ENY-SPEL-370

ENY-SPER-370

ENY-SP-460*

ENY-SPEL-460

ENY-SPER-460

* Dimensions are also valid for enthalpy models

H MIN

(mm)A (mm)B (mm)C (mm)

1190 600 11 1000

1190 600 11 1000

1190 600 11 1000

1130 660 67.5 940

1190 600 37.5 1000

1190 600 37.5 1000

1130 660 67.5 940

1130 660 67.5 940

15

Page 16

English

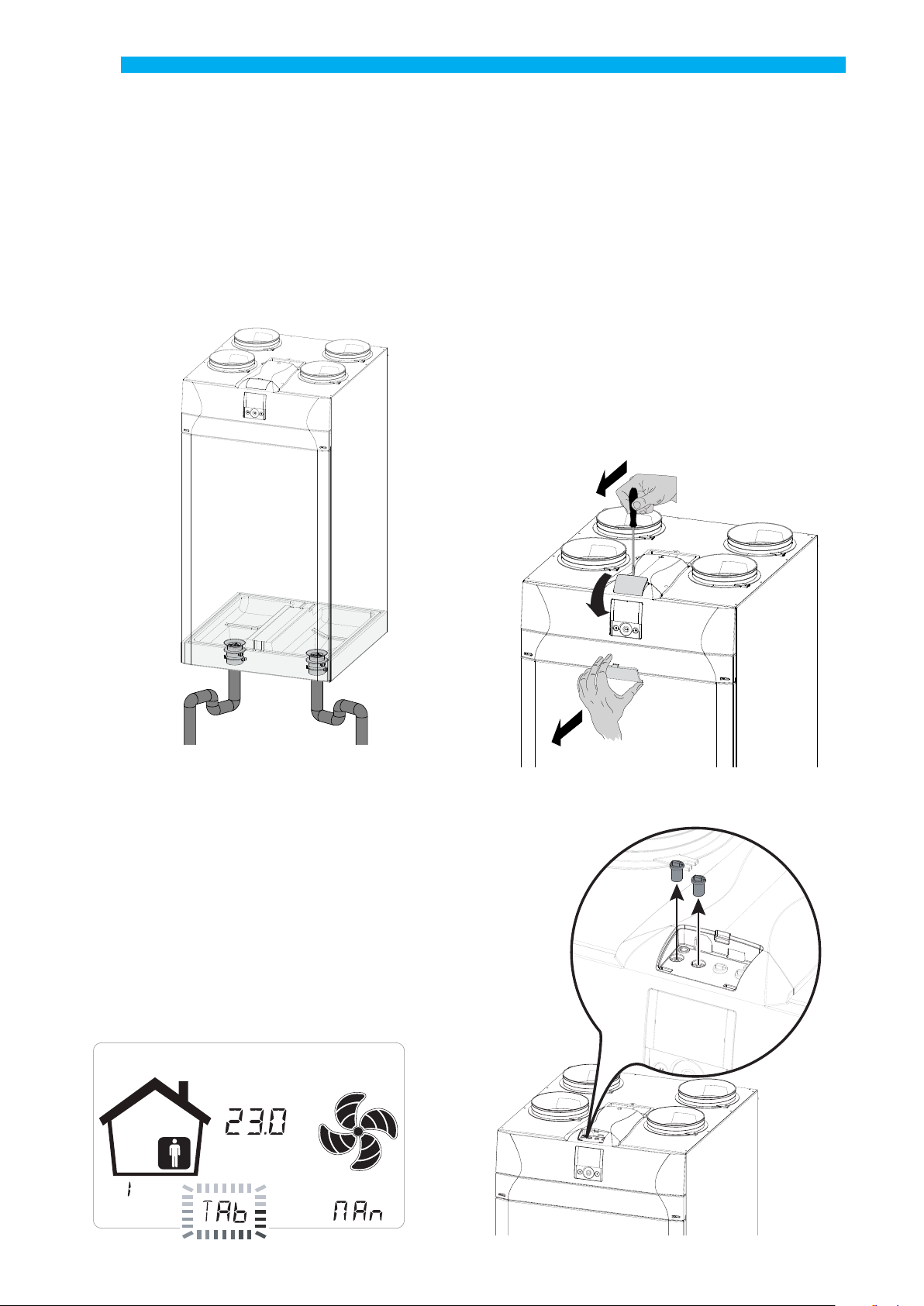

- Positioning the appliance (Fig.2)

1 - Position the appliance by hooking it to the hanging

bracket (1).

2 - Position the supplied spacer foot (2) to guarantee

that the appliance is level.

3 - Secure the appliance to the wall (3).

4 - Mount the condensate drain at the bottom of the

appliance.

PLEASE NOTE: the screws are not included in the supply.

Choose the screws and relative plugs based on the type

of wall.

1

(Fig. 2)

8

1

2

16

2

3

3

Page 17

English

1

2

3

4

5

13

M8 x 20

- Condensate drain connection

The connection for the condensate drain is located

underneath the appliance:

Connect the condensate drain to the domestic sewage

system using a duct or pipe (siphoned).

Condensate must be drained from a minimum height

of 100 mm.

PLEASE NOTE: if you choose the version with right

side connection, invert the condensate drain plug (see

paragraph “

How to change connection”).

FLOOR INSTALLATION OF APPLIANCE

- OPTIONAL ACCESSORY-

As an alternative, the residential ventilation appliance

can be installed using the oor stands.

- Fixing the stands

4

1

5

3

2

13

M8 x 20

1 1/2 " G

min 100

Attention! Make sure that the siphon of the

condensate drain connected to the

domestic sewer system is always full of water.

Y

1 - Fix the stands(1) using the screws (2) and washers

(3),supplied with the accessory, at the bottom of the

appliance (4). Fasten the crossbar (5) to the support (1).

2 - Lift the unit and position it vertically

3 - Use a spirit level to check the position of the appliance.

Attention! Make sure that the end of the

siphon is at least 100 mm below the water

level.

200 ÷ 225

17

Page 18

English

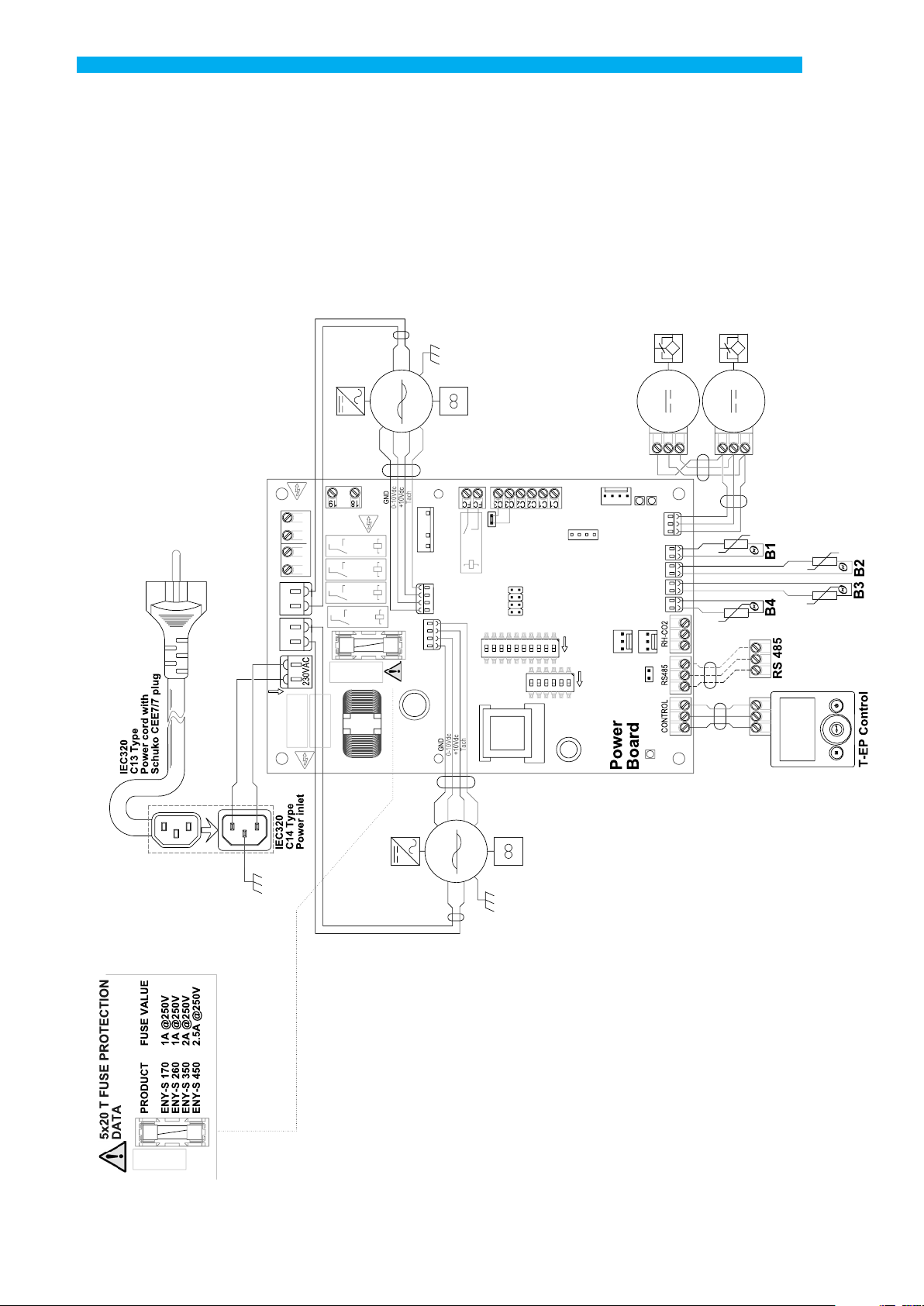

230 V 50 HZ

ELECTRICAL CONNECTIONS

General requirements

• Before installing the appliance, make sure that the

rated supply voltage is 230V - 50 Hz.

• Make sure that the electric system is suitable to

supply, in addition to the operating current required

by the unit, the current necessary to supply the

household appliances and equipment already in use.

• Perform the electrical connections according to

national laws and standards in force.

• Install an omnipolar switch upstream of the unit

with a minimum contact distance of 3.5 mm.

• The unit must always be earthed.

• Check the power cord is in perfect condition. In no

case must you repair a damaged cord with insulation

tape or clamps.

If the power cord is damaged, it must be replaced by

the Technical Assistance Service or anyhow by an individual with a similar qualication to prevent any risk.

• The appliances

the display controller on board the unit.

for residential ventilation

are built with

• When the appliance is connected electrically the

controller is also powered.

- Take the power cord from the accessory bag.

- Couple the cord to the machine.

- Plug in the power cord.

230 V 50 HZ

POWER BOARD

FAN2

FAN1

N1 - L1

F

DIP1

DIP2

BP

KNX

DL2

F1

DL2

MC4

CONTROL

N1

M23

230VAC

L1

FAN1

N

T.Type

F3

M16

FAN2

L L

N

M24

2223

2021

1918

EH2

EH2

EH4 EH3

F2

F1

109876543

6543

KD1

KD2

ON

ON

RS485

321

21

ON

21

ON

BP

KNX

RH-CO2

97

864

5

M12

EH1

F2

FCFC

MC1

FC-FC

C3-C3C2-C2C1-C1

EH1

FC-FC

C3-C3

C2-C2

MC2

C1C1C2C2C3C3

C1-C1

IAQ

IAQ

DL1

DL3

TTL

DL1

DL3

T2T3T4 T1

TTL

BD

18

CONTROL

RS485

RH-CO2

D+

D-

0

T4

T3

T2

T1

BD

Page 19

KEY:

Item Description Notes

English

N1-L1

F

FAN 1

FAN 2

F1

F2

T1 ÷ T4

CONTROL

C1-C1

C2-C2

C3-C3

FC-FC

IAQ

RS485

DIP 1

DIP 2

MC4

BP

BD

TTL

EH1

EH2

DL2

DL3

230 Volt power terminals /

Fuse 5x20 /

230 Volt Power Supply - Fan 1 /

230 Volt Power Supply - Fan 2 /

0-10 Volt Signal - Fan 1 Fan 2 with inverse conguration

0-10 Volt Signal - Fan 2 Fan 1 with inverse conguration

Temperature sensors /

Control Panel T-EP controller supplied with unit

NO potential.free contact (input)

NO potential-free contact (input) Booster function active when the contact is closed

NC potential-free contact (input) (active only if

JUMPER MC1 open)

SPST Potential-Free Contact /

Internal Relative Humidity Sensor /

Modbus Connection /

Conguration Dip Switch See Conguration Dip Switch table

Address Dip Switch for ModBus networks 8 Dip Switches - for max 60 units

Master/slave jumper or Modbus network

Dierential Pressure Sensor Connection for automatic air ow rate control

By-pass damper connection (FreeCooling) /

Connection for additional boards Accessory/Optional

PWM control preheating output /

Pre-Treatment output for controlling 230 Volt ON/

OFF actuators or enabling external modulating

resistance

Power on LED /

Status and alarm LED See alarm table

Remote On/O function – unit O when the contact is

closed

See Fireplace and Boiler functions

The network must be closed on the last unit in case of

RS485 Modbus connection. It is closed by closing Jumper

MC4.

Accessory for ENY-S models

Standard for ENY-SP models

Antifreeze with external systems

19

Page 20

English

CONFIGURATION DIP SWITCH (DIP 1)

DIP NO.

1 OFF

2 OFF

3 OFF

4 OFF

5 OFF

6 OFF

7 OFF

8 OFF

9 OFF

DEFAULT

OFF

LH Fan Cong

(STANDARD CONFIGURATION)

No Pre-Treatment Air Pre-Treatment Air Present

If DIP2 ON

Modulating electric resistance

N/A N/A

N/A N/A

FC-FC transmits error signal

to remote control unit

No Geothermal Hydronic Coil

Contact C3-C3 with function that

prevents

negative ambient pressure in

presence of chimney

If DIP2 ON

Internal modulating

preheating resistance

ON

RH Fan Cong

Right side connection

If DIP2 ON and DIP7 OFF

Electric Resistance ON/OFF

Hot water coil with ON/OFF valve

If DIP2 and DIP3 ON

Geothermal Hydronic Coil Present

Contact C3-C3

with atmospheric boiler start-up booster

If DIP2 ON, DIP3 OFF

External modulating preheating resistance

(supplementary

N/A

Cong.

)

10

OFF

N/A N/A

20

Page 21

English

1

1a

CONTROL

PG7

Connection with remote control

The control is provided by default tted on the appliance, however it can also be remoted by tting it on

the wall.

Always disconnect power

before accessing the unit.

1- Remove the controller from the front panel using

the suction cup accessory.

2- Remove the 3-pole connector coupled to the controller.

3) Unscrew the top cover to access the electric compartment where the power board is located.

3

4) Remove the cable connected to the “

connector (terminals 1-2-3) of the power board.

4

CONTROL

1 2 3

CONTROL

”

2

5) Perform the new connection to position the controller on the wall, respecting the sequence of the

terminal numbers:

a) apply the supplied cable gland as indicated in the

gure;

b) x the cable in the cable gland;

c) connect the cable to terminals1-2-3 from the power

board to the controller respecting the numbers;

21

Page 22

English

Installing controller on the wall

10

9

57

1

3 4

2

8

9

10

60

1

56

2

3

4

22

Page 23

English

T-EP TOUCH CONTROLLER

Introduction

This device was designed for the control of controlled

mechanical ventilation units. It is suitable for ENERGY

SMART units.

The Main Screen on the control panel permits access

to two settings sub-menus:

1. USER Settings Menu where the user can select the

operating mode and set the clock;

2. TECHNICAL Settings Menu where the installer can

calibrate the ow rate, change the standard unit operating parameters and monitor the operating state.

On the main screen, the user can view alarm reports

and main readings of the temperature and humidity.

The USER Settings Menu oers these options:

The MAIN SCREEN features the following options:

1. The preheating icon indicates activation of Antifreeze mode.

2. A timed warning icon blinks to suggest replacing

the lters.

3. A damper bypass icon indicates automatic activation of free-cooling mode.

4. Weekly Program Display 4.

Indoor Air

Temperature

1. Manual selection of the following preset ventilation

modes:

a) Party Mode - Intensive timed ventilation

b) Holiday Mode - Permanent Anti-mould ventilation

2. Automatic Mode, available for units equipped

with air quality sensor (humidity or CO2).

3. Customised selection of desired air ow rate in

manual mode:

a) 100% - Nominal ventilation (standard)

b) 70% - Reduced ventilation (nighttime)

c) 45% - Humidity Control for High Humidity Rate

Environments

d) 25% - Humidity Control for Low Humidity Rate

Environments

4. Weekly Programming.

°C

DAY

The TECHNICAL Menu oers these options:

1. Option of conrming or editing the operating parameters.

2. Monitoring of work conditions.

3. Setting the nominal calibration speed of the fans.

4. Input and Selection of the Weekly Program available

to the user.

4

The four Weekly Programs can be set by the installer and

another 4 weekly programs can be set up according to the

user’s specic requirements.

The User Settings menu allows the user to enable or disable

the Weekly Program congured by the installer.

23

Page 24

English

V

DAY

P

AUTO

°C

°F

T2T1

T4

T3

A

B

C

D

2/2a

1

14

6

7/7a

9

8

4

5

3

15

12

13

11

10

17

16

AUTO

P

P

DAY

Description of the Controller

Keys:

A

B

C

D

_

Display - Functions

1

2

3

4

5

6

7

24

• Start and Stop the machine;

• Access Technical Menu (only authorised sta ): when

the unit is ON, press the keys and at the same

time for 5 seconds to access the menu.

• Access User Menu;

• Access Technical Menu (only authorised sta ): when

the unit is ON, press the keys and at the same

time for 5 seconds to access the menu;

• Exit Menu.

• Conrm.

• Move a nger on the TOUCH PAD to:

+

• Increase/decrease the ventilation speed; or the

setting parameters;

• Scroll between functions.

• Manual Ventilation function.

• Booster function

• Automatic mode.

• Preset ventilation:

Party mode

• Preset ventilation:

Holiday mode

• Time setting

• Current day setting

• Weekly program activation

• Weekly program deactivation

Display - Alerts and alarms

• Display of current time

2a

• Text eld

• Number of current program

7a

• Presence of Person

8

9

• Current day

• Alarm alert

10

• Value alert (Temperature, voltage)

11

°C

• Filter Maintenance/Dirty lter

12

• Bypass in use - Free-cooling mode

13

• Preheating - Antifreeze mode icon

14

15

16

17

• Function lock activated

• User Menu active

• Installer settings menu active

Page 25

1

2

3

5

COMMISSIONING

The connections can be swapped to allow for exible

installation of the appliances for residential ventilation.

The dierence in the connections regards the position

of the air connections, of the lters and of the condensate drain and RH sensor.

English

How to change connection

(For Appliances not equipped with internal modulating electric resistance)

The default appliance is set in the version with left

side connections.

To change the machine to the RIGHT side version,

proceed as follows:

Left side connection (Standard version)

C

A

A - Outdoor air

B - Supply air

C - Exhaust air

D - Extracted stale air

B

D

Always disconnect power

before accessing the unit.

1. Unscrew the top cover.

2. Remove the top cover.

Right side connection (supplementary version)

B

D

A - Outdoor air

B - Supply air

C - Exhaust air

D - Extracted stale air

PLEASE NOTE: Apply the labels, supplied with the

unit, based on the new conguration

C

A

3. Position the DIP n°1 of the power board based on

the desired connection:

DIP 1 = OFF LH installation (default)

DIP 1 = ON RH installation

DIP 1

1

ON

25

Page 26

English

4. Position the lters as in the gure based on the

desired connection:

a - Open the front panel

1

The operations related to the connection

must only be carried out by qualied

personnel to avoid damage or injury.

The units equipped with integrated

electric resistance cannot undergo ow

conguration inversion. The machine

must be purchased with resistance in the left or

right side version depending on the envisaged

installation requirements

b - remove the plugs from the lters

3

2

Standard Conguration

F7

Right Side Conguration

M5

c - extract the lters and insert them based on the

chosen connection.

26

M5

F7

Page 27

Moving the Humidity sensor

for Unit ENY-SP

The sensor is placed by default in the version with left

side connections (standard see picture 5).

To position the sensor for the Right side connection

(supplementary version) you must:

1

English

4

2

3

5

Position of the sensor

STANDARD version

6

Position of the sensor

RIGHT side version (supplementary)

Put all the components back in place and proceed with

the assembly of the condensate drain

In the event of installing the sensor as an accessory,

follow the instructions of the information sheet attached to the accessory pack.

27

Page 28

English

1

Condensate drain connection

Position the condensate drain based on the desired

connection:

Unscrew the plug and fix a drain or siphon as

indicated in the gure.

Condensate must be drained from a minimum

height of 100 mm.

If you choose the version with right side connection,

swap the plug of the condensate drain.

To set the air ow rate based on the number of fan

revolutions, there are two possible types of calibration:

• STANDARD CALIBRATION

• AUTOMATIC CALIBRATION

only with Automatic Flow Rate Control system installed

STANDARD CALIBRATION

– Left Side Configuration –

1. Use a screwdriver to remove the front panel cover.

standard

connection

Y

Y

right

side connection

SETTING THE FLOW RATES

Before setting owrates, fans are run at factory default

speed.

Before setting owrates, Touch Pad is inithbited to

perform any speed modulation. This is communicated

by the message "Tab " blinking in the central eld of

the display.

WARNING!: no speed regulation is possible without

rst owrate setting

2

3

2. Remove the rubber caps of the connections P1 and P2

relative to fan V1.

P

1

P

2

P

3

P

4

28

°C

DAY

Page 29

English

V

V

V

_

V

3. Connect the dierential pressure gauge.

P

1

P

2

P

3

P

4

6. Use the TOUCH PAD to select the installer menu

.

Press the Enter key to conrm .

Select the “V” symbol and conrm .

The message V1 ashes;

Perform the setting of the fan V1;

access the menu by pressing enter, the display shows:

set the nominal design

flow rate (m3/h) using

the TOUCH PAD

V

+

.

_

Press the Enter key to conrm .

Change the voltage value relative to the fan speed

using the TOUCH PAD

+

until the dierential pressure gauge displays a value equal to the value of the

objective pressure drop (Pascal) shown on the display.

4. Turn on the appliance at the ON/OFF key on the

display.

5. Press the ON/OFF and “M” Menu keys at the same

time to access the TECHNICAL MENU.

V1 fan

speed voltage

80 = 8.0 Volt

V

fan rpm

Objective

pressure drop

=

Press the Enter key to conrm .

Before going on to set the fan V2, you must disconnect

the dierential pressure gauge from connections P1

and P2 and put the rubber caps back in place.

29

Page 30

English

1

Now proceed with connection of the dierential

pressure switch to connections P3 and P4

P

1

P

6

2

P

3

P

4

– right Side Configuration –

1. Use a screwdriver to remove the front panel cover.

2

3

“ V1 ” currently ashes on the control display;

use the TOUCH PAD

conrm by pressing enter.

Carry out the procedure described above for V1

also for fan V2.

When fan V2 has been set as well, go back to the

main screen by pressing “M” 3 times.

Disconnect the dierential pressure gauge and put

the rubber caps and the cover of the front panel

back in place.

+

to select fan “ V2 ” and

_

2. Connect the dierential pressure gauge to connections P3 and P4.

P

1

P

6

2

P

3

P

4

30

Page 31

English

V

V

V

_

V

3. Turn on the appliance at the ON/OFF key on the

display.

4. Press the ON/OFF and “M” Menu keys at the same

time to access the TECHNICAL MENU.

5. Use the TOUCH PAD to select the installer menu

.

Press the Enter key to conrm .

Select the “V” symbol and conrm .

The message V1 ashes;

Perform the setting of the fan V1;

access the menu by pressing enter, the display

shows:

set the nominal design ow rate (m3/h)

using the TOUCH

PAD

V

+

.

_

Press the Enter key to conrm .

Change the voltage value relative to the fan speed

+

using the TOUCH PAD

until the dierential

pressure gauge displays a value equal to the value

of the objective pressure drop (Pascal) shown on

the display.

V1 fan

speed voltage

80 = 8.0 Volt

V

fan rpm

Objective

pressure drop

=

Press the Enter key to conrm .

Before going on to set the fan V2, you must disconnect the differential pressure gauge from

connections P3 and P4 and put the rubber caps

back in place.

31

Page 32

English

V

V

V

Now proceed with connection of the dierential

pressure switch to connections P1 and P2

P

1

P

2

P

3

P

4

AUTOMATIC CALIBRATION

onLy with automatiC fLow rate ControL

SyStem inStaLLed

1. Turn on the appliance

by pressing the ON/OFF key on the display.

2. Press the ON/OFF and “M” Menu keys at the same

time to access the TECHNICAL MENU.

“ V1 ” currently ashes on the control display;

use the TOUCH PAD

+

to select fan “ V2 ” and

_

conrm by pressing enter.

Carry out the procedure described above for V1

also for fan V2.

When fan V2 has been set as well, go back to the

main screen by pressing “M” 3 times.

Disconnect the dierential pressure gauge and put

the rubber caps and the cover of the front panel

back in place.

3. Use the TOUCH PAD to select the installer menu

.

Press the Enter key to conrm .

Select the “V” symbol and conrm .

The message V1 ashes;

Perform the setting of the fan V1;

access the menu by pressing enter, the display shows:

set the nominal design

ow rate (m3/h) using

the TOUCH PAD

V

+

.

_

Press the Enter key to conrm .

32

Page 33

English

V

V

V

4. The display will show:

Voltage value

V1fan speed

Air ow m3/h

V

Air ow rate

measured by

the pressure

transducer

target

Air ow rate

Wait for the automatic calibration system to align the

value measured by the transducer to the target value.

Voltage value

V1 fan speed

V

Air ow rate

measured by

the pressure

transducer

=

target

Air ow rate

5. Once fan V1 is calibrated, the system automatically

starts calibrating fan V2.

The display with show:

Voltage value

V2 fan speed

WARNING:!: In case where one fan cannot be run at the

target ow rate, message "Out of Range" is temporarily

displayed.

Then, system steps to next extraction fan balancing or

ends the ow rates setting procedure.

When "Out of Range" is displayed, last ow rate blown

by fan just before the message is the one set by the system, which is the ow rate as close as possible to target.

Setting the clock and day of the week

1. Turn on the appliance at the ON/OFF key on the

display.

2. Press the ON/OFF and “M” Menu keys at the same

time to access the TECHNICAL MENU.

Air ow m3/h

V

Air ow rate

measured by

the pressure

transducer

target

Air ow rate

Wait for the automatic calibration system to align the

value measured by the transducer to the target value.

Once fan V2 is calibrated,

the system automatically goes back to the main

screen of the technical menu (symbol “V” ashes).

NOTE: with pressure transducer mounted, the MENU

“PAr” will show a parameter called “Sprc”; this parameter is the imbalance of the return ow rate compared

to the supply ow rate.

It can be altered with a range from +20 to -20 (%).

Example: if the parameter set is +10, the return is 10%

less than the supply ow rate.

3. Use the TOUCH PAD to select the “clock” icon;

“ ” starts to blink.

Press “enter” to conrm .

Use the TOUCH PAD to set the current hour.

Press “enter” to conrm.

Use the TOUCH PAD to set the current minutes.

33

Page 34

English

+

-

P

P

M

x3

Press “enter” to conrm.

Use the TOUCH PAD to set the current day.

Press “enter” to conrm.

P

V

+

-

DAY

Setting of the weekly program

There is a choice of 8 weekly programs: 4 preset

programs and 4 free programs that can be modied

at will.

Selection of the preset weekly program:

Programs P1-P2-P3-P4

1. Turn on the appliance at the ON/OFF key.

2. Press the ON/OFF and “M” Menu keys at the

same time.

+

-

DAY

3. Use the TOUCH PAD to select the installer

menu .

Press the Enter key to conrm .

4. Select the “P” symbol and conrm .

Now choose the program to be set from P1 - P2 -

P3 and P4 (see the schedules on the next page).

+

-

DAY

Use the TOUCH PAD to increase or de-

+

crease the value.

_

Use the Conrm button to conrm and

move to the next setting.

Set the day of the week as follows:

day 1 = Monday / day 2 = Tuesday

day 3 = Wednesday ... ... day 7 = Sunday

5. Press “M” three times to return to the main

screen.

34

Page 35

DAY

HOUR

SPEED

45%

70%

100%

0 – 1 1 – 2 2 – 3 3 – 4 4 – 5 5 – 6 6 – 7 7 – 8 8 – 9 9 – 10 10 – 11 11 – 12 12 – 13 13 – 14 14 – 15 15 – 16 16 – 17 17 – 18 18 – 19 19 – 20 20 - 21 21 - 22 22 - 23 23 - 24

45%

70%

100%

Monday - Friday

Saturday - Sunday

Tables of settings for the preset weekly program

45%

70%

100%

Monday - Sunday

45%

70%

100%

45%

70%

100%

Monday - Friday

Saturday - Sunday

45%

70%

100%

Monday - Friday

P1

- Weekly program, family with children, both

parents work away from home during the day.

0 – 1 1 – 2 2 – 3 3 – 4 4 – 5 5 – 6 6 – 7 7 – 8 8 – 9 9 – 10 10 – 11 11 – 12 12 – 13 13 – 14 14 – 15 15 – 16 16 – 17 17 – 18 18 – 19 19 – 20 20 - 21 21 - 22 22 - 23 23 - 24

DAY

HOUR

SPEED

P2 - Weekly program, family with steady presence

at home during the day.

DAY

DAY

HOUR

HOUR

SPEED

SPEED

0 – 1 1 – 2 2 – 3 3 – 4 4 – 5 5 – 6 6 – 7 7 – 8 8 – 9 9 – 10 10 – 11 11 – 12 12 – 13 13 – 14 14 – 15 15 – 16 16 – 17 17 – 18 18 – 19 19 – 20 20 - 21 21 - 22 22 - 23 23 - 24

English

P3 - Weekly program, working family who comes

home for lunch.

DAY

HOUR

SPEED

HOUR

SPEED

0 – 1 1 – 2 2 – 3 3 – 4 4 – 5 5 – 6 6 – 7 7 – 8 8 – 9 9 – 10 10 – 11 12 – 13 13 – 14 14 – 15 15 – 16 16 – 17 17 – 18 18 – 19 19 – 20 20 - 21 21 - 22 22 - 24

DAY

0 – 1 1 – 2 2 – 3 3 – 4 4 – 5 5 – 6 6 – 7 7 – 8 8 – 9 9 – 10 10 – 11 11 – 12 12 – 13 13 – 14 14 – 15 15 – 16 16 – 17 17 – 18 18 – 19 19 – 20 20 - 21 21 - 22 22 - 23 23 - 24

P4 - Weekly program, oce used from Monday to

Friday.

DAY

HOUR

SPEED

0 – 1 1 – 2 2 – 3 3 – 4 4 – 5 5 – 6 6 – 7 7 – 8 8 – 9 9 – 10 10 – 11 11 – 12 12 – 13 13 – 14 14 – 15 15 – 16 16 – 17 17 – 18 18 – 19 19 – 20 20 - 21 21 - 22 22 - 23 23 - 24

11 – 12

35

Page 36

English

-

P

Creation of the free weekly program: Programs

P5-P6-P7-P8.

It is possible to create 4 weekly programs at will,

according to your habits and needs.

Proceed as follows:

1. Turn on the appliance at the ON/OFF key.

2. Press the ON/OFF and “M” Menu keys at the same

time.

3. Use the TOUCH PAD to select the installer menu

.

Press enter to conrm .

4. Select the “ P ” symbol and conrm

Now select the rst free program to be created from

among P5 - P6 - P7 or P8.

5. Once the program number is dened, following

scheduling should be done:

- dene the day

- dene fan speed at the rst time step, which starts

by default at 00:00.

Use the TOUCH PAD with the purpose to set 4 avail-

able speeds plus Party Mode speed.

Blades are displayed into fan icon accordingly.

P

+

-

+

DAY

P

DAY

P

-

+

-

- dene hour of rst time step end

- repeat procedure for next time step

- maximum number of time steps is 8

6. After programming the rst day, press “M” to

move to the next day; it is possible to extend the

program created for the rst day to the other days

of the week (Xtend= extend):

DAY

P

+

If you select “YES”the program is automatically copied

to the other days of the week; if instead you select

“no“, you can then use the TOUCH PAD to select a

day and repeat the programming process.

+

DAY

P

DAY

P

DAY

P

-

+

-

+

-

+

PLEASE NOTE: the daily hourly program is set by

default at OFF.

DAY

P

-

36

Page 37

Low

Nominal

Low

Nominal

Monday - Friday

Saturday - Sunday

Low

Nominal

Low

Nominal

Monday - Friday

Saturday - Sunday

P .............................

DAY

HOUR

0 – 1 1 – 2 2 – 3 3 – 4 4 – 5 5 – 6 6 – 7 7 – 8 8 – 9 9 – 10 10 – 11 11 – 12 12 – 13 13 – 14 14 – 15 15 – 16 16 – 17 17 – 18 18 – 19 19 – 20 20 - 21 21 - 22 22 - 23 23 - 24

SPEED

DAY

HOUR

0 – 1 1 – 2 2 – 3 3 – 4 4 – 5 5 – 6 6 – 7 7 – 8 8 – 9 9 – 10 10 – 11 11 – 12 12 – 13 13 – 14 14 – 15 15 – 16 16 – 17 17 – 18 18 – 19 19 – 20 20 - 21 21 - 22 22 - 2 3 23 - 24

SPEED

P .............................

DAY

HOUR

SPEED

0 – 1 1 – 2 2 – 3 3 – 4 4 – 5 5 – 6 6 – 7 7 – 8 8 – 9 9 – 10 10 – 11 11 – 12 12 – 13 13 – 14 14 – 15 15 – 16 16 – 17 17 – 18 18 – 19 19 – 20 20 - 21 21 - 22 22 - 23 23 - 24

English

DAY

HOUR

0 – 1 1 – 2 2 – 3 3 – 4 4 – 5 5 – 6 6 – 7 7 – 8 8 – 9 9 – 10 10 – 11 11 – 12 12 – 13 13 – 14 14 – 15 15 – 16 16 – 17 17 – 18 18 – 19 19 – 20 20 - 21 21 - 22 22 - 2 3 23 - 24

SPEED

IMPORTANT! complete the table(s) with the conguration of the program created.

37

Page 38

English

P

AUTO

P

AUTOPAUTO

AUTO

P

AUTO

P

OPERATIONAL

PROCEDURES USER

START AND STOP

THE HEAT RECOVERY UNIT

To turn the unit on, press the ON/OFF power key as

shown in the gure to the right (Fig. 1).

If this icon is

present, the unit

DAY

SELECTING THE OPERATING MODE

ON THE T-EP CONTROLLER

Press “M” to access the User Settings Menu (Fig. 2).

The following options are available:

is o.

(Fig. 1)

• MANUAL VENTILATION FUNCTION;

• PRESET VENTILATION FUNCTIONS:

- PARTY;

- HOLIDAY;

AUTO

•

AUTOMATIC MODE, available for units

equipped with air quality sensor (humidity or CO2)

• WEEKLY PROGRAM ACTIVATION;

• CURRENT DAY AND TIME SETTING.

(Fig. 2)

AUTO

P

Press “M” to

access the menu.

Use the TOUCH PAD to pass from one function

to another.

To access the desired function, please press the con-

rmation button .

38

Page 39

English

• MANUAL VENTILATION FUNCTION

;

Press "M” and scroll with the TOUCH PAD until the

“Manual ventilation" mode starts ashing.

Then press “Conrm” .

°C

DAY

If this icon is

present, the

operating mode

is MANUAL

With the "Manual ventilation” mode enabled,

the speed of the fan at the various points can

be adjusted by scrolling with the TOUCH PAD.

Rotating the key clockwise on the pad

increases the speed of the fan while

anticlockwise decreases the speed of the fan.

• AUTOMATIC MODE;

Available for units equipped with air quality sensor

(humidity or CO2).

Press "M” and scroll with the TOUCH PAD until the

AUTOMATIC mode starts ashing.

Then press “Conrm” .

If this icon is

present, the

operating mode

is AUTOMATIC

AUTO

°C

DAY

The advanced centralised control systems are

equipped with an RH% humidity sensor or else an

external CO2 sensor.

“Manual ventilation” mode at 100% is the standard

operating mode, corresponding to the nominal air

ow rates set by the installer upon initial conguration.

Speed

No.

4a

_

+

3a

2a

1a

Modulation

(default values)

100%

70%

45%

25%

When” Automatic Mode” is enabled, fan speed is

controlled by an automatic control cycle relative to

internal instantaneous humidity and CO2 variations.

• AUTOMATIC MODE

WITH HUMIDITY SENSOR

The fan speed is set according to the interval relating to

the ambient relative humidity detected by the sensor.

If the ambient humidity is compatible with the

ambient comfort (typically between 25% and 50%),

then a special control for air exchange is not necessary

and the user can control the speed of the fans as in

Manual Mode.

If the ambient humidity temporarily goes beyond the

ambient comfort range, then an automatic variable

ow control mode is engaged, for tracking an ambient

humidity target value.

The target value is continuously calculated by the

system as a daily average of the ambient humidity.

This way the system reacts automatically to restore as

much as possible the comfort conditions lost due to an

extraordinary event, such as steam production caused

by a hot shower or a pot while cooking.

In automatic variable ow control mode, the user can

manually change

the speed of the fans as required at

any time. The automatic mode will be restored at the

next signicant ambient humidity variation.

39

Page 40

English

2000

PPM CO

2

P

AUTO

P

AUTO

If, however, the poor comfort conditions persist, then

it will mean that the low or high humidity is not due

to extraordinary and temporary events, but depends

on harsh weather conditions, such as winter frost or

extreme heat.

In these extreme conditions, the automatic mode sets

the fan at minimum speed, in order to isolate as much

as possible the internal environment from the external

one and at the same time preserve the ambient comfort.

Low humidity emergency speed can be modied by installer by the mean of "ErHs", included into "Par" menu.

Wet climate ventilation mode is eective in case a cooling system with dehumidication is in place. In thic case

it is advisable to eneable the function by operating on

variable HrHis.

• AUTOMATIC MODE WITH

CO2 SENSOR

The variable ow rate control based on the CO2

detected acts according to xed parameters, though

they can be modied by the installer, according to

the following diagram:

FLOW MANAGEMENT LOGIC CHART

Nominal

Velocità nominale

speed

IN RELATION TO PPM CO

2

Incremento

Proportional

proporzionale

increase

“PART Y” mode is a timed function (default 3 hours).

The speed percentage of the “PART Y” mode is set

as a parameter by the installer according to the

customisations requested by the user, starting from

the standard value of 130% compared to the nominal

speed.

• HOLIDAY MODE

Press “M” and scroll with the TOUCH PAD until the

“HOLIDAY” mode starts ashing.

Then press “Conrm” .

+

-

°C

Minimum

speed

Velocità minima

0 200 400 600 800 1000 1200 1400 1600 1800

CO2LO

CO2std CO2HI

• PARTY MODE

Press “M” and scroll with the TOUCH PAD until “PART Y”

mode starts ashing.

Then press “Conrm” .

°C

DAY

“HOLIDAY”

Once

mode speed is the minimum.

“HOLIDAY”

mode is enabled, control device

asks for the period duration in days.

In case where duration is unknow, user can enter

nothing in the eld of duration.

This way permanent

In any case,

“HOLIDAY”

“HOLIDAY”

Mode is enabled.

mode can be stopped by

changing mode within User Menu.

PLEASE NOTE: the operating parameters of

“HOLIDAY”

mode can be changed by the installer

(Parameters Menu section).

DAY

If “PART Y” mode is enabled, fan speed is increased

respect to the nominal speed.

40

Page 41

English

AUTO

P

AUTO

ACTIVATION OF

WEEKLY PROGRAM

Press “M” ; scroll with the TOUCH PAD until

the function “ P ” starts ashing and conrm by

pressing “Conrm” .

When conrmed, the preset program is activated.

The display shows the chosen program number

when the unit is “put into service”.

P

SETTING THE CLOCK

AND THE DAY OF THE WEEK

Press “M”; scroll with the wheel until the “clock” icon

starts ashing “ ”.

Then press “Conrm” .

Scroll with the wheel to set the hour.

Press “Conrm” and scroll

again to set the minutes.

Press “Conrm” and scroll

to set the current date.

°C

DAY

P

If this icon is present, it means that

a scheduled program is active.

The number identies the growth

program chosen when

commissioning the unit.

The activation of the weekly program does not

preclude the user's ability to manually change the

speed of the fans.

In fact, despite a program in time slots is active, the

user can still operate on the TOUCH PAD, increasing

or decreasing the speed as desired.

The manual override applied to the weekly program

will remain operational until the next time slot,

when automatic programming will become active

again.

+

-

DAY

+

-

DAY

+

-

DAY

+

Use the TOUCH PAD to increase or

decrease the value.

_

Use the Conrm button to conrm and

move to the next setting.

Set the day of the week as follows:

day 1 = Monday / day 2 = Tuesday

day 3 = Wednesday ... ... day 7 = Sunday

41

Page 42

English

P

AUTO

SUPPLEMENTARY FUNCTIONS

• BOOSTER MODE

This is enabled by a remote control normally located

in a bathroom or kitchen.

The power board of the centralised unit receives the

pulse from the outside and enables the “Booster Mode”.

In this case the “Boost” icon appears as a notication

on the screen of the unit’s control panel.

°C

DAY

Like for “Party Mode”, “ Booster Mode” determines an

increase in the timed speed respect to the nominal

speed.

The percentage of the duration and of the speed

increase of the ventilation unit can be congured

by the installer upon a specic request of the user.

The standard duration is 3 hours (default) and the

standard percentage is 130% beyond the nominal

speed.

Before standard duration ends, user can stop Booster

mode by repeating the command on the remote

switch.

• ANTIFREEZE FUNCTION

• With Integrated Modulating Electric Resistance

In the event that the unit is installed in a cold climate,

we recommend the use of versions with an electric

antifreeze resistance on the external air intake circuit

(

MODELS ENY - SER/SEL/SPER/SPEL).

The electric resistances available for units preheat

the air entering the heat exchanger in order to avoid

freezing of the humid air extracted and discharged

by the heat exchanger in the opposite circuit.

In fact, when the external air drops below the

critical temperature, posing the risk of freezing of

the discharged air, the resistance is activated and

modulates the heat output to keep the temperature

of the discharged air within the desired uctuation

range (set point 4°C).

The electric resistances are selected in order to

maintain the minimum conditions of indoor comfort at outdoor temperatures down to -10°C, and in

order to avoid the degenerative formation of ice at

discharge down to -15°C outside.

The electric resistance is tted with a safety thermostat

that turns o the unit in case of uncontrolled heating.

In case the resistance does not start up, instead, the

unit will turn o if the intake air temperature falls

below 5°C.

Activation of the resistance as a result of the anti-

• FIREPLACE FUNCTION

If the unit is interfaced with an negative pressure

ambient pressure switch and is set in the DIP-SWITCH

conguration recommended in presence of a natural

draught chimney, the unit is automatically turned o

when the ignition of the replace causes negative

pressure in the room.

This occurs in order to prevent the ambient pressure

induced by the action of the dual ow ventilation

unit from counteracting the natural draught of the

replace and releasing smoke into the room.

• BOILER FUNCTION

If the unit is interfaced with a remote switch and

set in the DIP-SWITCH conguration recommended

presence of an atmospheric boiler, the unit is forced

into a strong imbalance supply mode in order to

facilitate the ignition of the boiler.

The mode remains active as long as the switch stays

in the activation position.

is

in

freeze function is represented by the icon .

°C

DAY

42

Page 43

English

For units not equipped with integrated electric

resistance, a duct modulating electric resistance is

available as a preheating accessory.

• Without Electric Resistance

In case the unit is without an electric antifreeze resistance, the unit has preventive operation logic which,

below -5°C, automatically sets running of the intake

fan at minimum for 10 minutes every hour.

Also, in case the temperature falls below -10° C, the

unit stops automatically and an alert appears on the

display of the controller: “

When the Frost alarm is triggered, the unit switches

OFF and restarts automatically when the critical

climatic condition disappears. The Frost alert remains

until the next time the unit is switched o and back on.

FROST ”.

• With preheating Hydronic Coil or ON/OFF

resistance

As an alternative to the use of versions with the

electric preheating resistance, a hot water or ON/OFF

resistance pre-treatment coil can be used to perform

the antifreeze function, mounted on the outdoor air

inlet duct.

The hydronic coil or ON/OFF resistance is not available

as an accessory. However if the conguration DIP

SWITCHES 2 and 3 are activated, the power board

is capable of managing the opening of an on/o

valve or an ON/OFF electric resistance stage for the

preheating function.

The valve opening and closing logic is shown in the

table below.

The opening of the water supply valve of the coil is or

of the ON/OFF electric resistance stage is represented

on the display with the icon

.

Antifreeze protective circuit chart

Antifreeze electric resistance switch on

Setpoint t4=4°C

Electric resistance shutdown

UNITS

EQUIPPED

WITH

ANTIFREEZE

SYSTEM

UNITS WITHOUT

ANTIFREEZE

SYSTEM

ALL

UNITS

Activation of preheating water coil valve

or ON/OFF resistance

Valve closure or ON/OFF resistance shutdown

Speed reduction of both fans

with proportional law with decreasing t4.

Electric resistance malfunctioning alarm

Unit switch o with “Frost” alarm

the input fan is brought to minimum speed for 10min an hour

Unit switch o with “Frost” alarm

Input air low temperature alarm

Unit switch o with “Frost” alarm

Defrost cycles:

External

air t

1

<-3°C – <4°C

– – <1°C

>0°C – –

<-3°C – <3°C

– – <1°C

– – >6°C

<-3°C – <3.5°C

<-3°C – <1°C

<-20°C – –

<-5°C – –

<-10°C – –

– <10°C –

– <5°C –

Supply

air t

Exhaust

2

air t

4

When the Frost alarm is triggered, the unit switches OFF and restarts automatically when the critical climatic condition disappears.

The Frost alert remains until the next time the unit is switched o and back on.

43

Page 44

English

• FREE COOLING FUNCTION

There can be climatic conditions during the year

that make it impractical to recover heat from

extracted air for treating fresh air from outside.

For example, in midseason, the outdoor air temperature can be lower than the indoor air temperature

due to solar and internal factors, and this tends to

occur when the indoor temperature is between

22 and 26°C so there is more of a need for cooling

than for heating. In this case it is advisable to use

free-cooling, i.e. fresh air from outdoors to cool for

free, bypassing the heat recovery unit. Conversely,

it is possible to use fresh air for heating during a

change in season, in which case the process is known

as free-heating.

The units are equipped with a bypass damper system that totally disables use of the recovery heat

exchanger to permit free-cooling (or free-heating).

The system is controlled on the basis of a logic subject to the feedback of the integrated temperature

probes.

The logic is as follows:

The indoor air temperature setpoints of the air con-

ditioning system in winter and summer are dened

in order to maintain conditions of comfort:

t

normally t

heating

t

normally t

cooling

heating

cooling

= 20°C

= 26°C

• Pre-Treatment Function with Geothermal Coil

If a hydronic circuit with geothermal or ground water

probes is available, it is possible to feed a hydronic

pre-treatment coil, which can be used in both seasons.

A dedicated function for using the geothermal source

is available.

In winter, the coil valve is controlled to carry out the

antifreeze function. It opens if the exhaust temperature falls below 3°C and closes above 6°C.

Depending on the available water temperatures, the

coil must be sized to ensure the antifreeze function.

In summer, the coil valve is controlled to carry out

the pre-cooling function.

It opens when the outside temperature rises above

24°C.

There is a provisional closure mode if the intake

temperature is too cold, to ensure the ambient comfort conditions and a permanent closure when the

outside climate starts returning to winter conditions.

Pre-cooling, or geothermal water free-cooling, is

compatible with ventilation free-cooling and extends

the periods of use.

(temperatures can be modied by the installer according

to the actual settings of the plant)

The following are also dened:

ti = indoor air temperature (return air)

EAT = External air temperature

FREE-COOLING CONDITION

EAT > t

and simultaneously ti>EAT

heating

FREE-HEATING CONDITION

EAT < t

and simultaneously ti<EAT

cooling

• SUMMER MODE

Summer mode is a strong air change cycle, which is

enabled when "Flush" parameter is switched on into

"Par Menu".

NOTE: Summer mode is performed 4 times a day,

except when it would imply high ventilation heat

loss..

+

-

44

Page 45

English

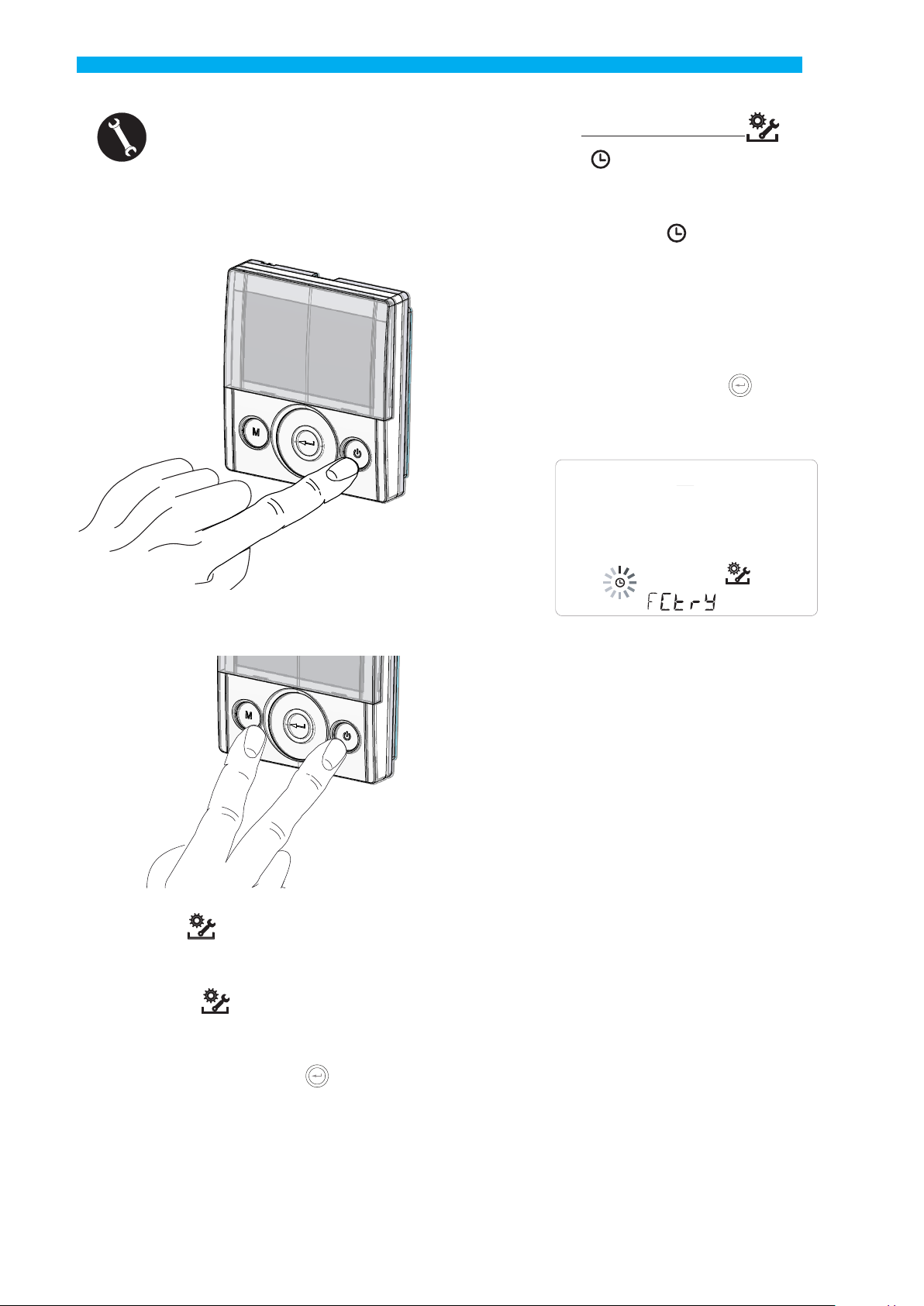

TECHNICAL MENU

1. Turn on the appliance at the ON/OFF key.

• Installer Menu

The symbol ashes on the display when the

installer menu is opened. Use the TOUCH PAD to

choose the desired function between:

- day and time setting ;

- initial setting/conguration of fans “V”(see section “COMMISSIONING”);

- Selection/Setting of the chosen weekly program

“P”(see section “COMMISSIONING”);

- FCtry (FACTORY) menu;

Press the Enter key to conrm .

2. Press the ON/OFF and “M” Menu keys at the

same time.

3. The symbol ashes on the display;

Use the TOUCH PAD to choose the desired function

between:

- Installer menu (initial setting menu);

- “PAr” parameters;

- rEAd menu;

P

V

NOTE: the FACTORY (“FCtry”) menu is for the

exclusive use of the manufacturer.

Password-protected menu

Press the“M” button once to return to parameter

selection; to exit the menu, press the “M” button

3 times.

Press the Enter key to conrm .

45

Page 46

English

• “PAr” Parameters Menu

This menu allows you to modify the operating parameters of the appliance. With the controller “ON”,

press “M” and On/O simultaneously for 3 seconds.

Select the “PAr”menu using the TOUCH PAD and

conrm by pressing “Enter”. Select the parameter to

be modied by using the TOUCH PAD and conrm by

pressing Enter”. Once the parameter is selected, the

value will be displayed. The value can be modied

using the TOUCH PAD. Press the“M” button once to

return to parameter selection; to exit the menu, press

the “M” button 3 times.

Table 1

“PAr” DESCRIPTION RANGE DEFAULT

CO2hi

CO2lo

CO2st

CO2Sr

VLO

Minimum control voltage in calibration -10% ÷ +10% See table 2

VHI

nLO

nHI

Pstd

Pbst

Percentage of standard modulation of nominal speed 100% ÷ 110% 100%

Percentage of boost/party modulation 110% ÷ 130% 130%

PnGt

Pmed

Phol

Percentage of intermediate modulation 35% ÷ 70% 45%

Percentage of minimum - holiday modulation 0 ÷ 35% 25%

Tbst

TCOOL

THEAT

Test

Tinv

SPrc

RHnSP

Cooling setpoint temperature for freeheating management 10 ÷ 30°C 26

Heating setpoint temperature for freecooling management 10 ÷ 30°C 20

Summer season transition temperature for pre-cooling management

Winter season transition temperature for antifreeze management

Percentage imbalance between ow rates -20% ÷ +20% 0%

Number of samples to calculate dynamic humidity setpoint 1 ÷ 96 96 (15 min)

Flife

HrLO

Hrst

HrHiF Shows the HrHi parameter* On ÷ O O

HrHi

Relative humidity for Minimum Humidity mode activation

Relative humidity lower limit in the comfort range *

Relative humidity upper limit in the comfort range * 40 ÷ 50 45

Relative humidity for Maximum Humidity mode activation* 60 ÷ 80 65

FLUSH

ErHs

Func

FUNCTIONS blocking operation (see dedicated paragraph)

Maximum CO2 level * 1500 ÷ 2000 ppm

Minimum CO2 level * 400 ÷ 600 ppm

Nominal CO2 level * 900 ÷1100 ppm

Full-scale CO2 * 2000 ÷ 30000 ppm

Maximum control voltage -10% ÷ +10% See table 2

Minimum speed in operation -10% ÷ +10% See table 2

Maximum speed -10% ÷ +10% See table 2

Percentage of night modulation 45% ÷ 100% 70%

Boost/Party Time 60 ÷ 240 min 180

geothermal coil

geothermal coil

Filter service life 30 ÷ 400 days 180 days

Summer Mode activation On ÷ O

Speed of

Low humidity

10 ÷ 30°C 18

10 ÷ 30°C 24

20 ÷ 45 25

1 ÷ 4 speeds

- -

1500

500

1000

2000

OFF

2 speed

* Available only if the functions feature air quality sensors

46

Page 47

Table 2

English

Model

nMAX

(rpm)

nMIN

(rpm)

Vmax

(Volt)

Vmin

(Volt)

ENY-S-170

ENY-SEL-170

ENY-SER-170

3450 588 9 4

ENY-S-270

ENY-SEL-270

ENY-SER-270

2470 220 8 3.5

ENY-S-360

ENY-SEL-360

ENY-SER-360

2850 220 7 4

ENY-S-460

ENY-SEL-460

ENY-SER-460

3200 434 7 3.22

• FUNCTIONS

BLOCK SCREEN ("Func")