Aquatherm climatherm, greenpipe, lilac Technical Information

Technical Information for

aquatherm greenpipe

pressure pipe system for potable water,

food processing, and hygienically sensitive applications

®

climatherm

pressure pipe system for hydronic, compressed air,

chemical and industrial applications

aquatherm lilac

®

pressure pipe system for

recycled and reclaimed water systems

Table of Contents

Features

Quality Assurance

Planning

Installation Principles

Heat Fusion

Product Range

© 2012 aquatherm GmbH, aquatherm NA, L.c., and Aquatherm CA. All rights reserved.

Heat Fusion

Welding tools

Socket fusion

Fusion outlets

Repairs

Welding jig

Chapter

5

Welding machines

Electrofusion

Butt welding

Aquatherm Advanced

Heat Fusion

Installation training

Installers need to be trained by Aquatherm in heat fusion

techniques in order have their installation covered under

warranty. Training is available from local Aquatherm

trainers and instructors. Failure to follow proper installation

procedures will also invalidate the warranty.

Welding tools: Assembly

1. Use only Aquatherm approved tools and welding irons.

They are designed with the proper temperatures

and dimensions for working with Aquatherm

products. Information on approved tools is available

on Aquatherm’s website or from local Aquatherm

instructors and trainers.

2. Both the welding iron and the welding heads must be

free of residue, dirt, oils, and other impurities before

beginning fusion. Make sure they are clean before

assembly. If necessary, clean the welding tools with

a non-abrasive cleaning wipe. Use rubbing alcohol

or a similar agent. Avoid using corrosive cleaners or

cleaners that will leave a hazardous residue.

Heat Fusion

The assemblies and fusions shown in this chapter are done using the

Aquatherm branded tools. Assembly and operation instructions may vary

for other approved tools. Follow any additional instructions or variations

given by the tool’s manufacturer.

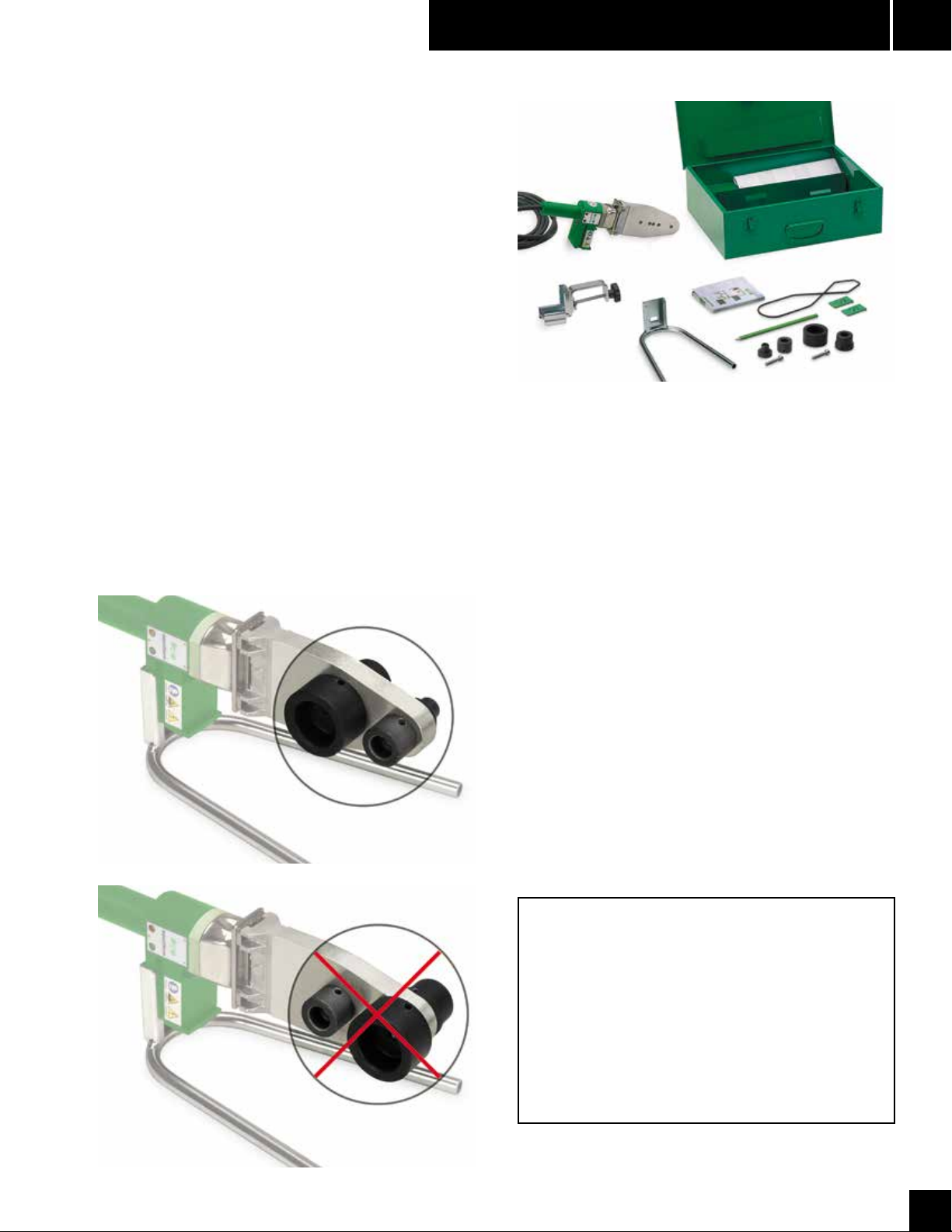

3. Before plugging in the iron, place the welding heads

on the welding iron so that there will be full surface

contact between the welding head and the heating

plate. Welding heads over 1 ¼” (40 mm) must always

be fitted to the rear position of the heating plate. Outlet

welding heads should always be fitted in the rear

position unless there is not enough available space

around the connection.

5

Right

4. Tighten the welding heads until they are almost

touching the heating plate. Do not finish tightening the

welding heads until the heating plate is hot. Tightening

the heads completely before the iron is hot will leave

impressions on the heating plate and reduce its

performance over time.

5. Plug in the welding tool. Depending on the ambient

temperature, it will take 10 - 30 minutes to heat up the

heating plate. The tool gives a signal when it is plugged

in, and gives another signal when it reaches its target

temperature.

Electrical supply:

Make sure that the electrical supply used is fully

compatible with the welding iron being used.

Improper use of any electrical device can cause

harm to both the tool and the operator. Make

sure any extension cords used are compatible

with the power input of the welding tools. Note that

fluctuations in the power supply can cause the tool

to go through longer heating cycles.

Wrong

5.1

5

Heat Fusion

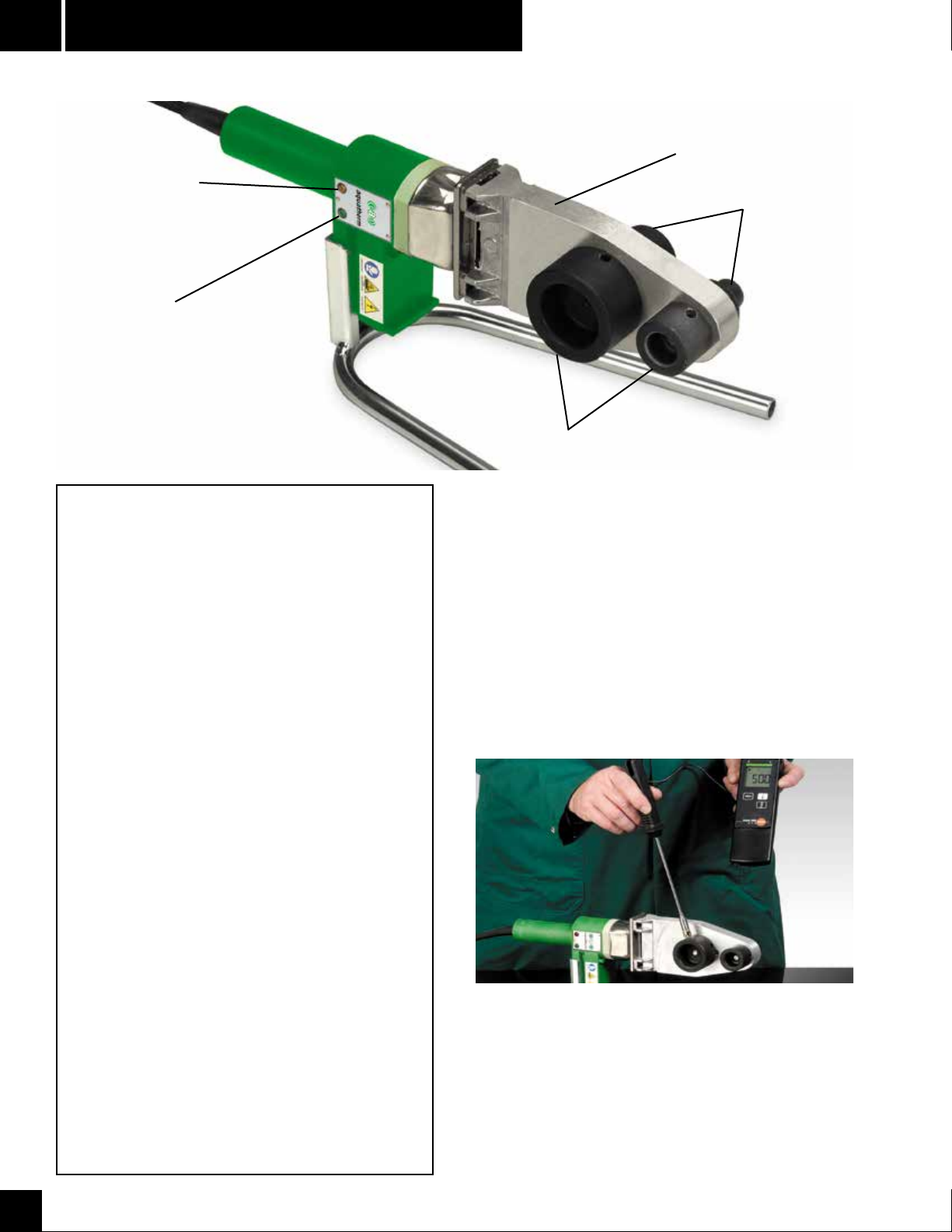

Temperature light

(yellow)

- Cycles on while the iron is heating

- Cycles off when the iron reaches 500 °F

Operating light

(green)

- On whenever the tool is plugged in

Heating plate

Welding head

Welding head

Safety precautions

By using a non-hazardous material and an emissionfree joining process, Aquatherm has eliminated

many of the hazards of installing a piping system.

However, there will always be a certain level of risk

involved in pipe installation, so it is imperative to

always follow the appropriate safety precautions.

The irons are the primary concern. The surface

temperature of the welding iron and heads will

normally be between 450 °F (240 °C) and 500 °F

(260 °C) during operation and may remain at these

temperatures for as long 30 minutes after being

unplugged.

When working with the welding irons, always

wear the appropriate hand and arm protection to

avoid the risk of burns. Protective eyewear is also

recommended.

During operation, always be aware of the location

of the iron. Do not leave the iron hanging loosely or

allow it to brush up against flammable materials.

Make sure to keep the iron clear of other people.

Always post a sign to inform those working nearby

that the iron is hot and could pose a safety risk to

them.

Do not leave the iron unattended while it is plugged

in. After unplugging the iron, protect it with a heatresistant covering or place the iron back in its

container. Do not allow the cord to contact the

welding surfaces.

Welding tools: Heating phase

6. After the iron is hot, tighten the welding heads carefully

with the hex wrench. Do not grab the welding heads with

pliers or other tools that could damage the coatings.

Make sure the welding heads are in complete contact

with the heating plate.

7. The temperature of 500 °F (260 °C) is required for

welding with the Aquatherm piping systems. The

temperature of the welding head must be checked

before starting the welding process. This can be done

with a digital thermometer capable of measuring

temperatures up to 650 °F (340 °C).

Important: If the pipe or the air around it is below 40 °F

(5 °C), heating times are increased by 50%. Remember

to take greater care with the pipe as it can become

brittle in cold temperatures. Using power cutters on cold

pipe can cause cracking and is not recommended. Use

standard ratchet or wheel cutters instead. Never preheat the pipe beyond 100 °F (38 °C).

5.2

Heat Fusion

5

Welding tools: Handling

8. Changing welding heads on a heated iron requires the

installer to check the temperature on the new head

once it heats up.

9. If the tool has been unplugged (e.g. during longer

breaks), the heating process must be restarted (see

item 5).

10. After use, unplug the welding tool and let it cool down.

Never use water to cool the welding device, as this

will destroy the temper of the metal. Always keep the

welding heads dry.

11. Protect Aquatherm welding tools and heads against

impurities. Residue from previous fusions may lead to

an incorrect connection. After cooling, the heads can

be cleaned with a non-abrasive cloth.

12. For a proper fusion, damaged or scratched welding

heads must be replaced, as only undamaged heads

guarantee a perfect connection.

13. Never attempt to open or repair a defective tool. Return

the defective iron to the supplier for repair.

Socket fusion: Preparation

1. Make sure the Aquatherm welding devices and tools

comply with the guidelines in “Welding tools.”

2. All devices and tools must have reached the necessary

operating temperature of 500 °F (260 °C). This should

be checked on the welding head, not the heating plate.

This should be verified with a handheld contact or

digital thermometer.

3. Cut the pipe at right angles to the pipe axis. Only use

Aquatherm cutters or other suitable cutting tools.

Inspect the pipe thoroughly for any cracks.

14. Check the operating temperature of the Aquatherm

welding irons regularly by means of a suitable

measuring device.

Welding tools: Guidelines

15. Fusion welding of joints in Aquatherm piping systems

must be done in accordance with the instructions in

this manual. Additional information is available, and

should be followed where applicable and not in conflict

with these instructions:

• ASTM D 2657 - Standard practice for heat fusion

joining of polyolefin pipe and fittings.

• ASTM F 1290 - Standard practice for electrofusion

joining polyolefin pipe and fittings.

16. Remember to use gloves when handling the iron

while it is plugged in and for at least 30 minutes after

unplugging it. Avoid leaving the iron exposed and

unguarded, as passers-by might accidentally injure

themselves. Always post a sign to inform those working

nearby that the iron is hot and could pose a safety risk

to them.

Always ensure that cutters are sharp. Cutting pipes

with dull or damaged ratchet cutters can cause the

pipe to crack.

Only use the cutters to cut fusiolen® PP-R material.

It is also acceptable to use power saws with plasticappropriate blades. Take care that the pipe surface is

free from burrs or cutting debris and remove where

necessary.

4. Mark the welding depth at the end of the pipe with a

pencil using the Aquatherm marking guide.

5. Mark the desired position of the fitting on the pipe

and/or fitting. The markings on the fitting and the

uninterrupted line on the pipe may be used as a guide

over short distances.

5.3

Loading...

Loading...