aquarea dhw PAWDHWM120ZNT, PAWDHWM80ZNT User Manual

PAW-DHWM 80-120 ZNT

EN

DE

IT

ES

DA

NO

SV

HR

CS

HU

Instructions for Use 3

Gebrauchsanweisung 27

Istruzioni per l'uso 51

Manual del Usuario y del Instalador 75

Brugsanvisning 99

Bruksanvisning 123

Bruksanvisning 147

BIH

Upute za upotrebu 171

Návod k obsluze 195

Használati útmutató 219

PL

2

Instrukcja obsługi 243

WARNINGS!

The appliance may be used by children older than 8 years old, elderly

persons and persons with physical, sensory or mental disabilities or lacking

experience and knowledge, if they are under supervision or taught about safe

use of the appliance and if they are aware of the potential dangers.

Children should not play with the appliance.

Children should not clean or maintain the appliance without supervision.

Always transport the heat pump in an upright position; exceptionally, it

may be tilted by 35° in all directions. Be careful not to damage the housing or

the vital component parts of the heat pump during transport.

The heat pump is not intended for industrial use and use in premises

where corrosive and explosive substances are present.

The connection of the heat pump to the mains should be performed in

accordance with standards for electrical appliances. An all-poles disconnect

switch should be installed between the heat pump and the mains in accordance

with the national installation standards.

The heat pump should not be in operation without water in the hot water

tank, because of danger of destruction of the compressor!

The installation should be performed in accordance with the valid

regulations and the instructions of the manufacturer. It should be performed by

a professionally trained installation expert.

It is necessary to install a safety valve with a rated pressure to the inlet

pipe of the heat pump, to prevent the pressure in the boiler from rising for more

than 0.1 MPa (1 bar).

Water may drip from the outlet opening of the safety valve, so the outlet

opening should be set to atmospheric pressure.

The outlet of the safety valve should be installed facing downwards and in

a non-freezing area.

To ensure proper functioning of the safety valve, the user should perform

regular controls to remove limescale and make sure the safety valve is not

blocked.

Do not install a stop valve between the heat pump and the safety valve,

because it will impair the functioning of the safety valve!

Before the beginning of the operation two 90° elbows must be installed to

the top of the appliance (ø125 mm), each facing in the opposite direction. The

premises must be properly ventilated.

The elements in the electronic control unit are live even after pressing the

off field (9) on the heat pump.

If you disconnect the heat pump from the power supply, please drain any

water from the pump to prevent freezing.

Water can be drained from the pump through the boiler inlet pipe. For this

purpose it is advisable to install a special element or outlet valve between the

inlet pipe and safety valve.

Please do not try to fix any defects of the heat pump on your own. Call the

nearest authorised service provider.

EN

3

INTRODUCTION

EN

Dear Customer,

Thank you for purchasing this Aquarea product. This heat pump for heating sanitary

water is one of the most advanced appliances in its class. Its material, design and

testing were made in compliance with related applicable standards.

Power, capacity and safety systems were thoroughly tested. Tests were made

individually for each component part, as well as for the finished product, according to

international quality standards.

Please read these Instructions for Installation and Use carefully before use in order to

prevent eventual problems that may cause damage to the product.

Keep this Manual for future reference, as a source of information on the details of the

heat pump operation or its maintenance.

Of course, you can always contact any of our experienced authorised servicing

technicians for occasional maintenance.

4

USE

This unit is designed for production of sanitary water in households and at premises

where daily consumption of hot water (40 °C) does not exceed 150 l to 250 l. The

appliance must be connected to water supply mains and to the power supply grid.

The air intake and air exhaust may also be provided by designing the inlet and outlet

drain from and to the adjacent room.

In case of installing the unit in a room with a bathtub or shower tub, take into account

the requirements defined in the IEC 60364-7-701 standard (VDE 0100, Teil 701). To

mount the unit on the wall, use special wall bolts with a nominal diameter of minimum

8 mm and always mount the unit in an upright position. Make sure the mounting

location on the wall is adequately reinforced if the wall is not strong enough. We

recommend leaving enough space between the floor and unit as to provide easy

access to the Mg anode (for maintenance or replacement purposes – Fig. 4). If not,

the unit will need to be dismounted from the wall before servicing.

The heat pump may not be used for purposes other than those defined in these

Instructions. The unit is not designed for industrial use or use in rooms where

corrosive or explosive substances are present.

The manufacturer shall not assume any liability for damages caused by incorrect

installation or misuse that are not in compliance with the Instructions for installation

and use.

The instructions for use are a component and important part of this product and must

be delivered to the customer. Read the warnings carefully, as they contain important

directions related to safety during operation, use and maintenance.

Keep these Instructions for later use.

The marking of the heat pump is stated on the nameplate located on the bottom side

of the unit, between both inlet pipes for sanitary water.

Once the packaging is removed, check the contents. When in doubt, contact your

dealer. Never let children play with the packaging parts (clamping, plastic bags,

expanded polystyrol, etc.) – potential risk. Make sure to remove and dispose of the

packaging safely and in an environmentally friendly way.

STORAGE AND TRANSPORT

Store the heat pump in an upright position, in a clean and dry place.

EN

5

A

264

B

589

C

294

350

350

D

E

324

506

533

285

170

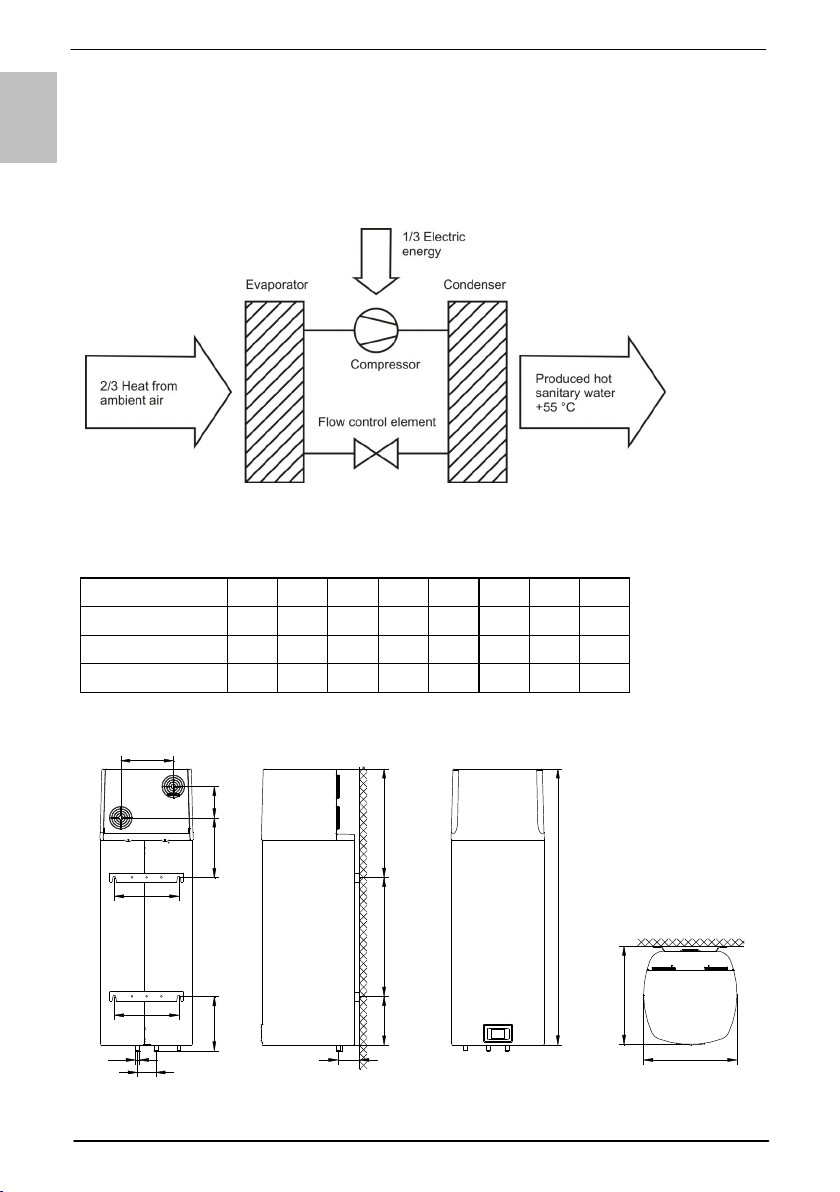

THE PRINCIPLE OF OPERATION

EN

The heat pump is in fact a thermodynamic heat generator, drawing heat from a low

temperature level (e.g.: heat from the ambient air) to a higher temperature level (e.g.:

hot sanitary water).

The heat drawn from the ambient air, along with the electric energy, generates

heating energy, which is available for heating the sanitary water.

DIMENSIONS

PAW-DHWM80ZNT

PAW-DHWM100ZNT

PAW-DHWM120ZNT

* - DIN norm

** - NF norm

Fig. 1: Chart of energy flow through the heat pump unit

A B C * C ** D * D ** E * E **

1197 345 100 175 100 230 G 1/2 G 3/4

1342 490 100 175 100 230 G 1/2 G 3/4

1497 645 100 175 100 230 G 1/2 G 3/4

Fig. 2: Connection and installation dimensions of the heat pump [mm]

6

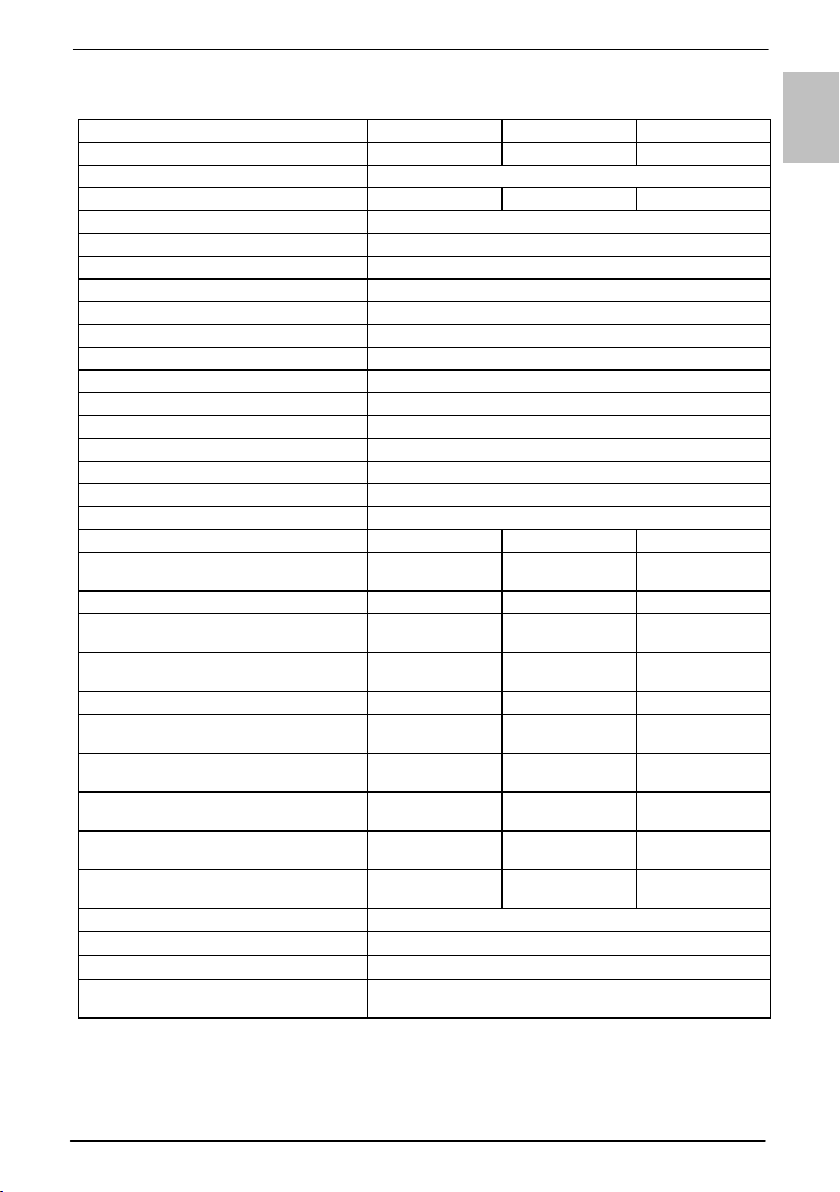

TECHNICAL CHARACTERISTICS

Type

Volume [l] 80 100 120

Rated pressure [MPa (bar)] up to 1,0 (10)

Weight / Filled with water [kg] 58 / 138 62 / 162 68 / 188

Anti-corrosion protection of tank Enamelled / MG Anode

Insulation thickness [mm] 40 - 85

Degree of protection IP24

Max connected load [W] 2350

Voltage 230 V / 50 Hz

Number and power of heating elements [W] 2 x 1000

Electricity protection [A] 16

Adjusted water temperature [°C] 55

Maximum temperature (HP / el. heater) [°C] 55 / 75

Legionella control programme [°C] 70

Temperature range of installation [°C] 2 to 35

Operation zone – air [°C] -7 to 35

Refrigerating agent R 134a

Quantity of coolant [g] 540

*Heating time A15 / W10-55 [h:min] 4:40 5:40 6:40

*Energy consumption during heating

A15 / W10-55 [kWh]

Type of measured cycle of emissions M M M

*Energy consumption in the selected cycle

of emissions A15 / W10-55 [kWh]

*COP

in the selected cycle of emissions

DHW

A15 / W10-55

**Heating time A7 / W10-55 [h:min] 5:20 6:50 8:41

**Energy consumption during heating

A7 / W10-55 [kWh]

**Energy consumption in the selected cycle

of emissions A7 / W10-55 [kWh]

**COP

A7 / W10-55

Max quantity of usable water

(min 40 °C) [l]

Power in standby mode

according to EN16147 [W]

Sound power / Sound pressure at 1m [dB(A)] 51 / 39,5

Air connections [mm/m]

Working Air Flow [m3/h] 100-230

Max acceptable pressure drop in the pipeline

(volumetric flow rate of air 100 m3/h) [Pa]

(*) Heating of water to 55 °C at inlet air temperature of 15 °C, 74% humidity and inlet temperature of water of

10 °C; in accordance with the EN16147 standard.

(**) Heating of water to 55 °C at inlet air temperature of 7 °C, 89% humidity and inlet temperature of water of

10 °C; in accordance with the EN16147 standard.

in the selected cycle of emissions

DHW

PAW-DHWM80ZNT PAW-DHWM100ZNT PAW-DHWM120ZNT

0,99 1,19 1,41

2,04 2,05 2,08

3,10 3,10 3,10

1,12 1,43 1,78

2,45 2,35 2,51

2,65 2,63 2,61

90 130 142

19 20 27

ø125 (□150x70) / 15

95

EN

7

INSTALLATION OF THE HEAT PUMP

EN

The heat pump can be used using the ambient air or air from other premises. The

heat pump must be installed in a frost-free room. When selecting a place for

installation, particular attention should be paid that the selected air intake location is

dust free, because dust has adverse effects on the heat pump performance. When

selecting the place of installation, pay attention to the solidity of the wall – can it take

the weight of the heat pump together with the weight of the water inside the boiler?

Take all the necessary precautions to prevent the operation noise and vibrations from

transferring through the walls to the premises where this would be disturbing

(bedrooms, rest areas). Do not install the heat pump and its air intake in premises

with other air consumption appliances (gas boilers, solid-fuel fireplaces, dust

extraction appliances etc.) During installation, please bear in mind the minimum

distances from the wall, ground and ceiling. The condensate outlet from the heat

pump is placed on the bottom left side in the form of a plastic tube with an external

diameter of ø18 mm. This tube should be connected to the external condensate

outlet pipe and led to the sewage system or a container. The quantity of condensate

depends on air temperature and humidity when the heat pump is in operation.

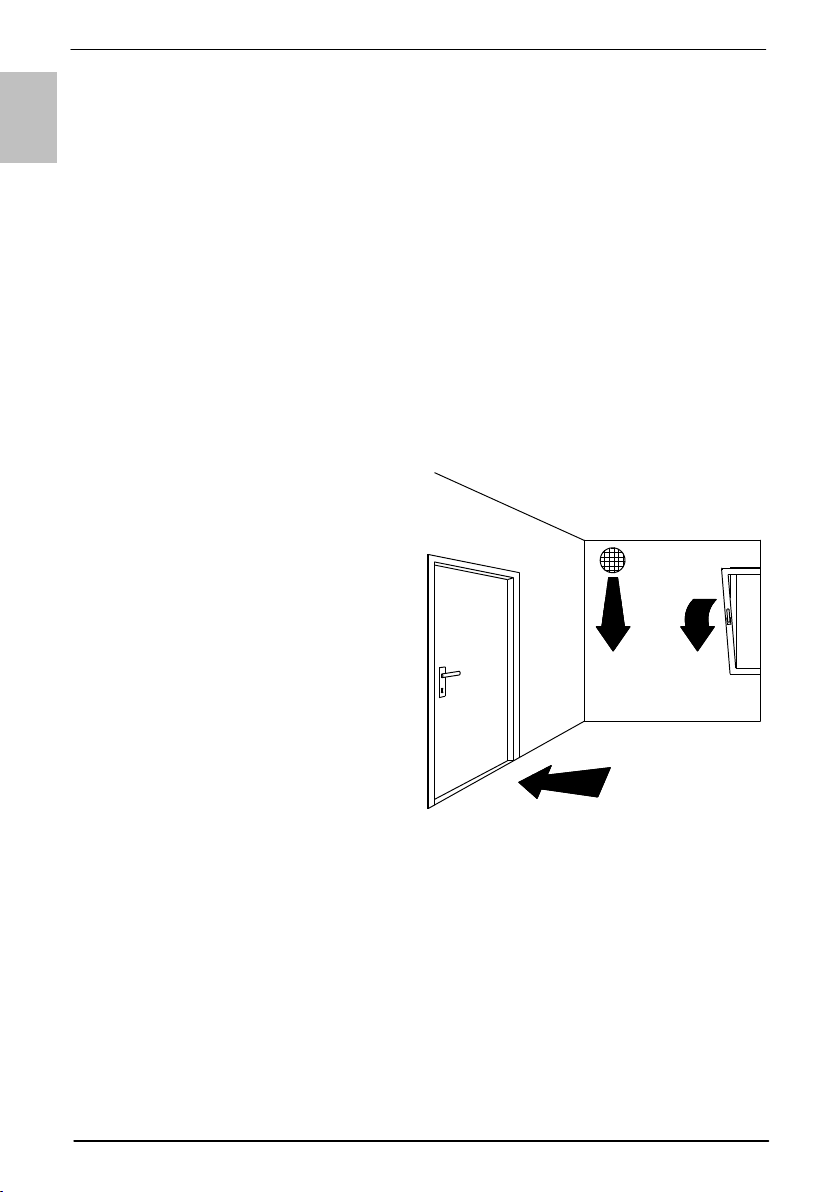

To prevent pressure depression in the

building, fresh air must be regularly

supplied to the premises. The desired

rate of air exchange for a residential

building is 0.5. This means that the

entire quantity of air in the building is

exchanged every two hours.

Connecting the heat pump to the same

pipeline as the kitchen extractor fan or

taking air out of several smaller

apartments or suites is not allowed.

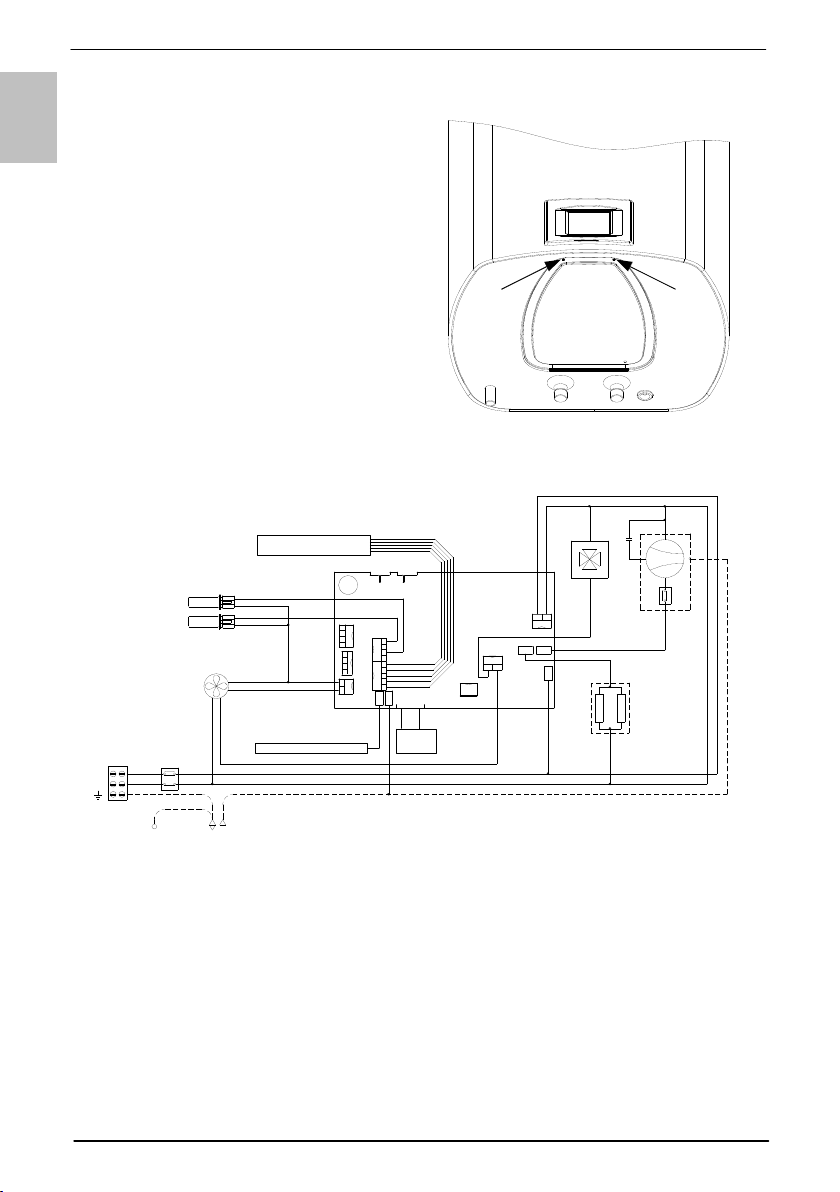

Fig. 3: Ventilation

To minimize the transfer of noise and vibrations through walls into the premises

where this would be disturbing (bedrooms, rest areas), please take the following

measures:

- install flexible joints for hydraulic connections

- install a flexible tube for the pipeline of inlet/outlet air

- plan vibration insulation for wall openings

- plan noise dampers for inlet/outlet air

- pipelines for inlet/outlet air should be attached using noise dampers

- plan vibration insulation against the wall

8

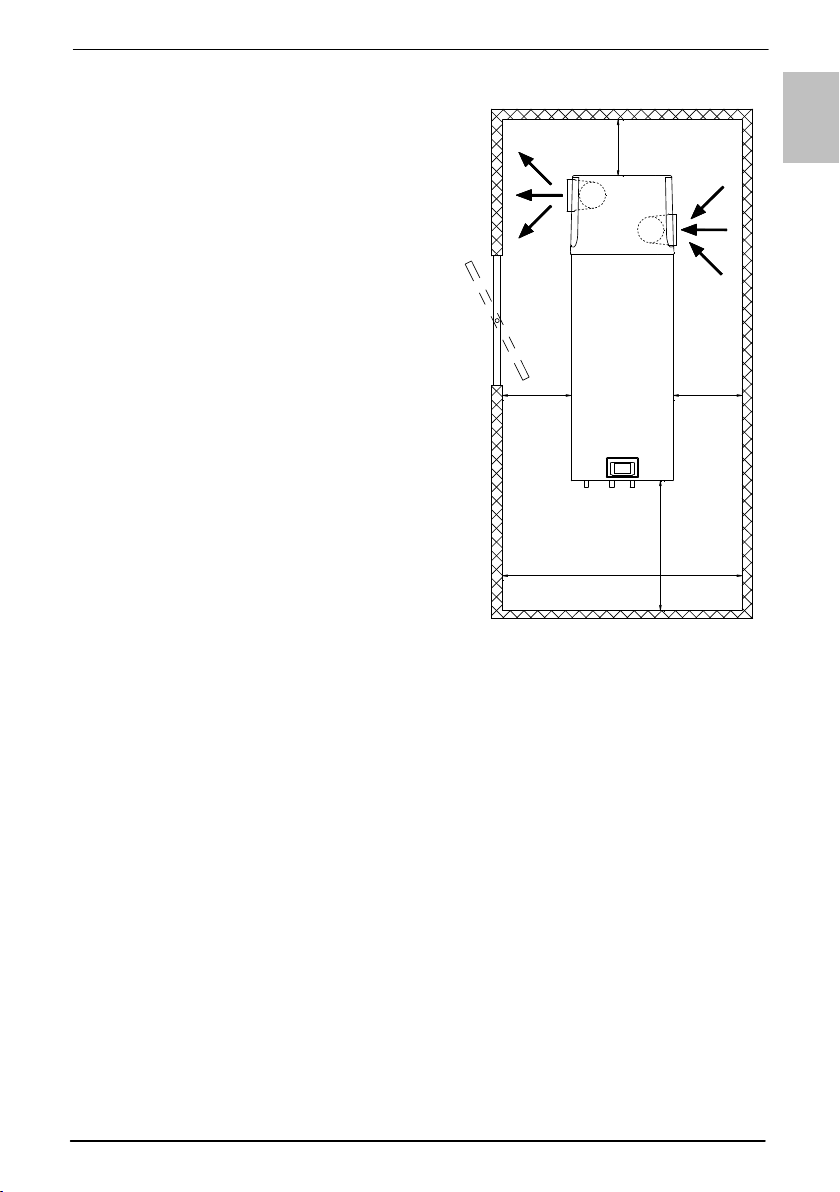

min 25 cmmin 25 cm

min 150 cm

min 20 cm

min 75 cm

a) Operation using ambient air

In this type of operation, the device heats

domestic water using only the amount of

energy generated by the air from the room

where the device is installed. The heat pump

must be installed in a ventilated, frost-free

room, possibly in the vicinity of other heating

sources. For optimal performance of the heat

pump, we recommend a sufficiently large and

well ventilated room with the temperature

ranging between 15 °C and 25 °C. It is vital to

ensure sufficient intake of air in the room.

Elbows must be installed on the heat pump

and turned so that they prevent the mixing of

air. Heat losses are greater in premises with

colder air.

If the heat pump is installed in a frost-free

room and the temperature is under 7 °C, the

heat pump operates in the normal mode of

operation.

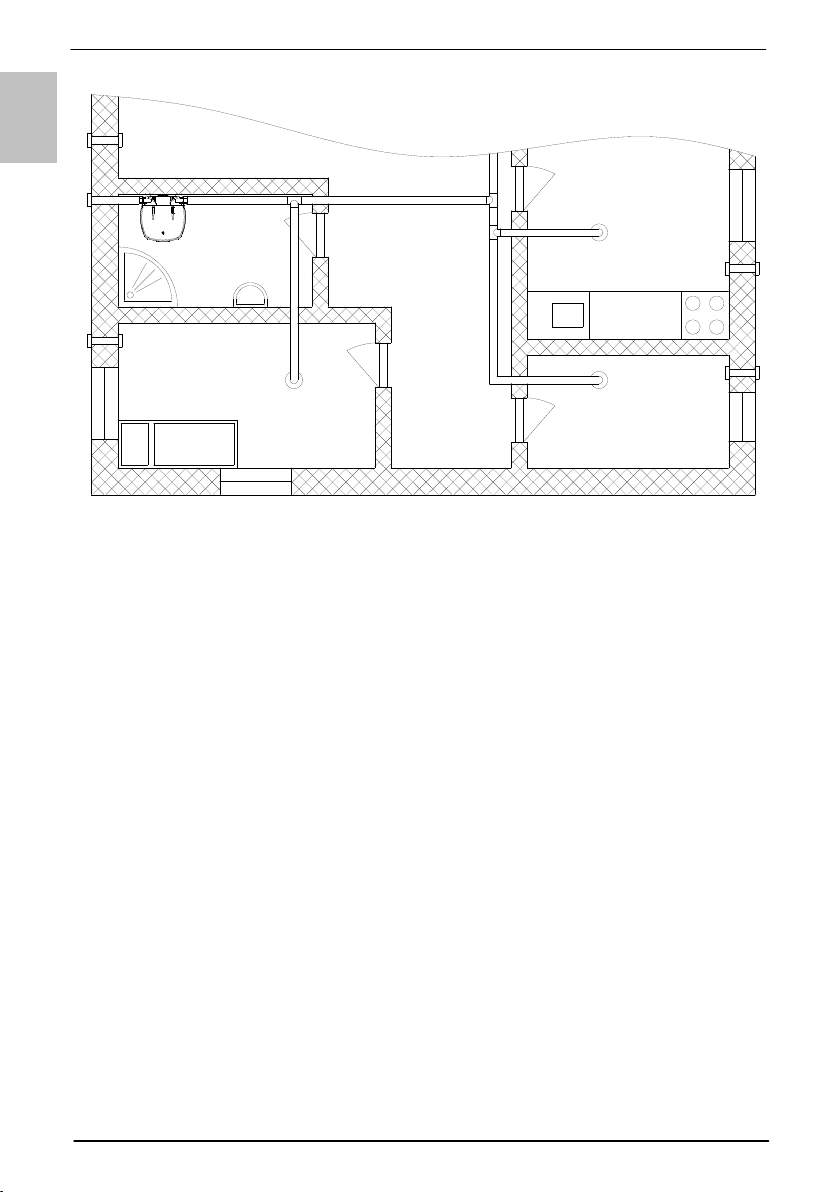

b) Operation using air from other premises

In this type of operation, the heat pump uses air from other premises via a pipeline

system. It is advisable to insulate the pipeline system to prevent the formation of

condensate. In case of using air from outside, the external part must be covered so

as to prevent the intrusion of dust or snow into the appliance.

Besides the drag in the pipes and elbows, the user should be aware that increased

drag also increases noise levels.

In case of using air from outside, the user should adhere to the minimum diameter of

the pipes ø125 mm or □150x70.

To make sure the operation of the pump is effective at all times, you can install

dampers to take air from the premises and then return it either to the premises or

outside. If the temperature of air is under -7 °C, heaters for the heating of domestic

water are switched on. The heat pump operates in reserve mode.

Fig. 4: Minimum requirements

for the installation of HP

EN

9

EN

Fig. 5: Possible installation of a heat pump

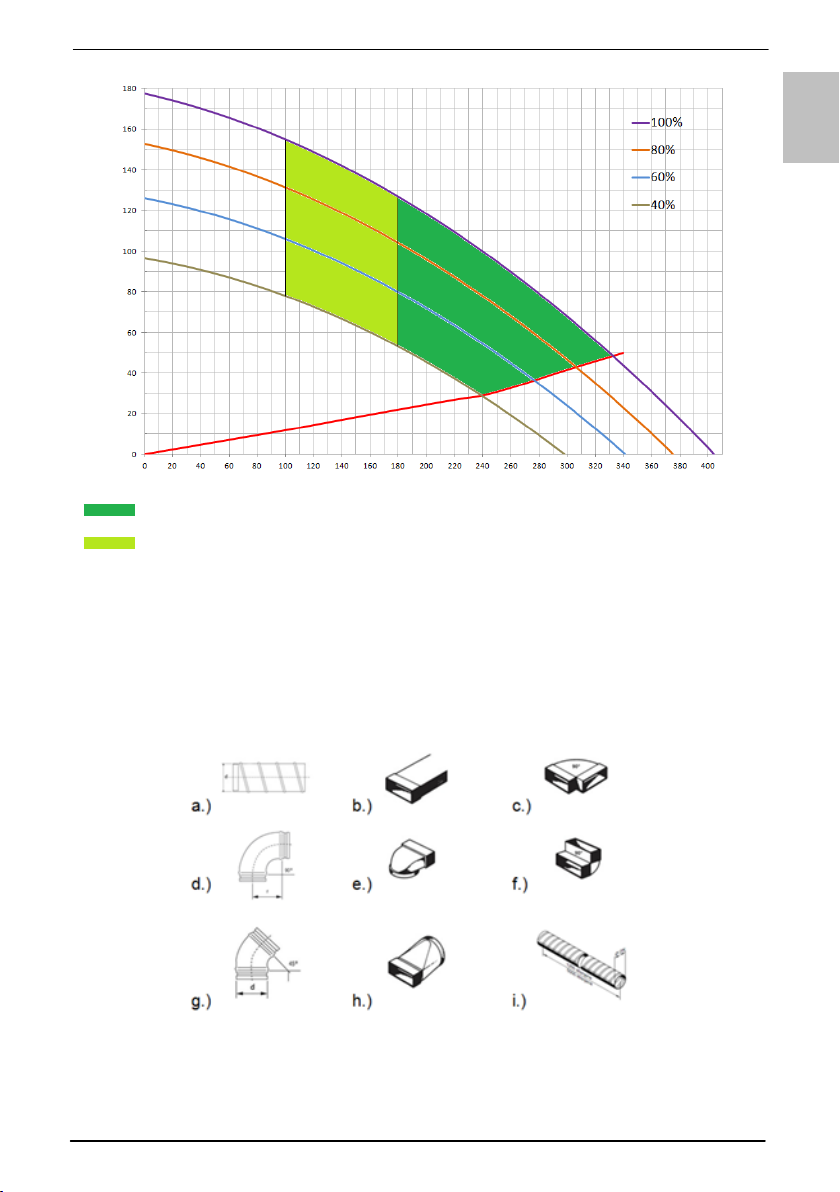

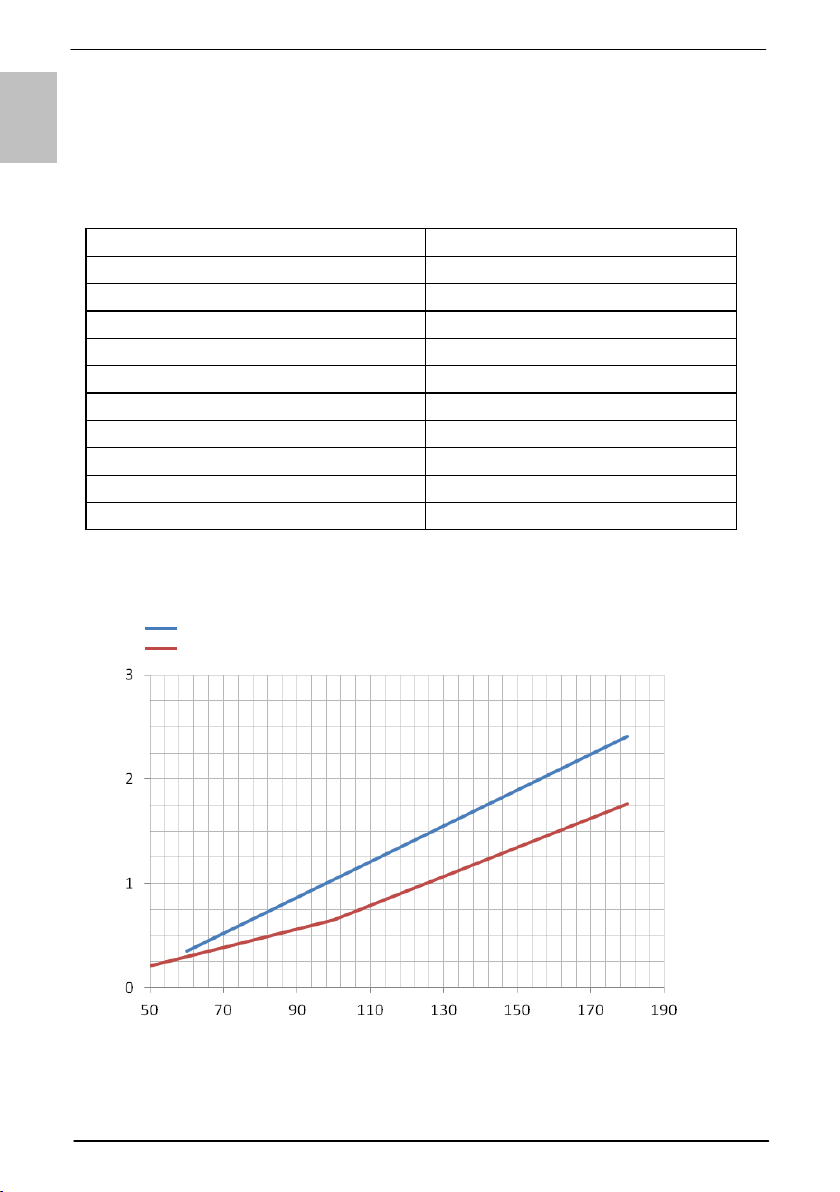

PRESSURE LOSS IN CASE OF USING THE PIPELINE SYSTEM

In planning the pipeline system for the inlet and outlet of air to and from the heat

pump, the key element is to take into account the aerodynamic character of the fan

which also causes the loss of static pressure.

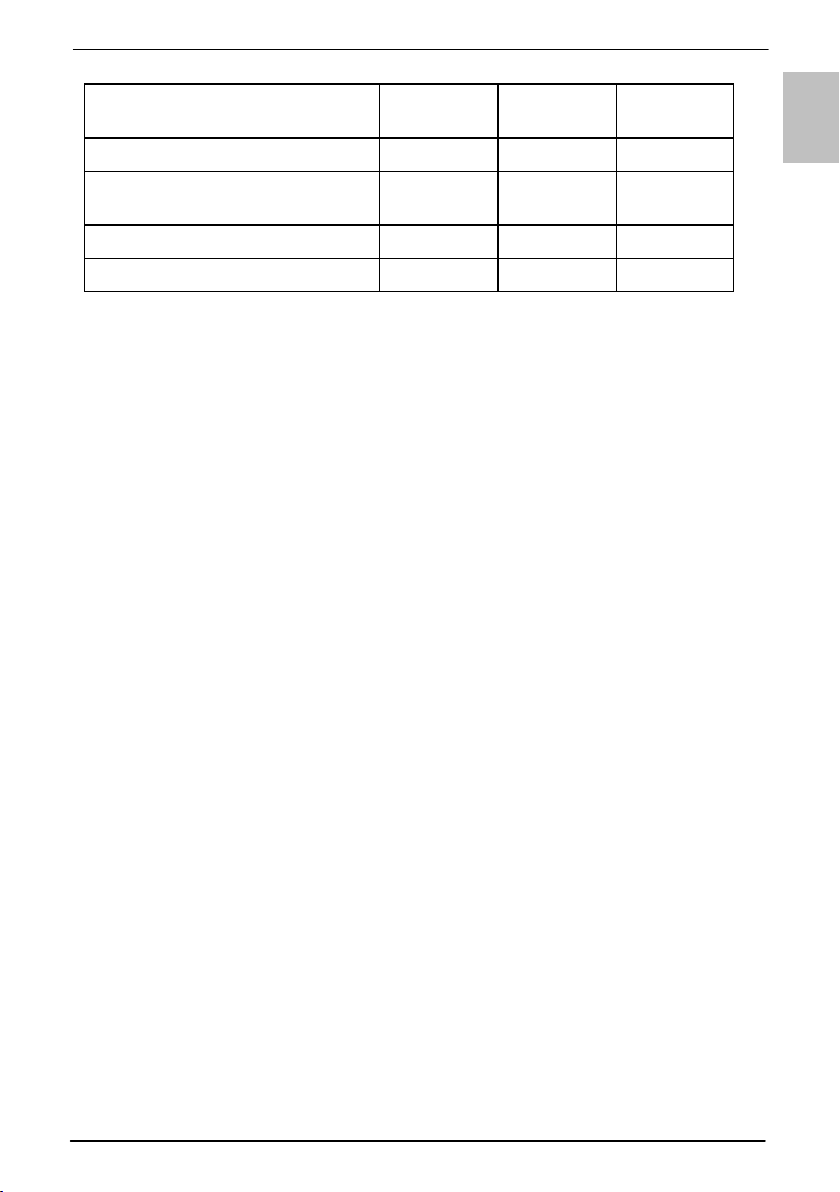

Presentation of the diagram of aerodynamic characteristics for different speeds

of the fan

The diagram (Diagram 1) includes aerodynamic characteristics of the operation of

the fan. The top (purple) line represents the curve of air flow depending on the

pressure drop at maximum speed of the fan (100 %). The bottom (brown) line

represents the operation of the fan at minimum speed (40 %). The curves between

(60 %, 80 %) represent the aerodynamic characteristics at lowered revolutions of the

fan. The bottom (red) line that lies between points (0,0) and (340,50) represents the

internal drop of static pressure created by the evaporator alone, without overloading

the pipeline system. This pressure drop cannot be eliminated.

10

EN

Pressure difference [Pa]

Air flow [m³/h]

- Area of more efficient use – volumetric flow of air is higher here, which requires a lower pressure

drop (channel system with minimum pressure drop). Fan is set to higher speeds.

- Operating area with a normal air flow with respect to the pressure drop and fan setting.

Diagram 1: Aerodynamic characteristics

Air inlet and outlet pipeline system

When connecting the sanitary heat pump to an existing pipeline system, we use the

basic pipe elements that we connect into a pipeline system for air inlet and outlet.

The air pipeline should consist of round pipes with an inner diameter of ø125 mm, or

rectangular pipes with a cross section of □150x70 mm.

Fig. 6: Schematic demonstration of the basic elements in a pipeline system for inlet

and outlet of air

11

Calculation of pressure drops

The values of total static pressure drop can be calculated by adding up the losses

EN

from individual elements built into the air pipeline system and the internal static

pressure. The values of static pressure drops of individual elements (static pressure

drops of elements relate to the internal diameter ø125mm or □150x70mm) are shown

in Table no. 2.

Type of element

a.) Spiral ribbed pipe

b.) Rectangular pipe □150x70 mm

c.) Rectangular elbow - horizontal 90° 5 Pa

d.) Elbow 90° 4 Pa

e.) Angular reducer ø125 to □150x70 5 Pa

f.) Rectangular elbow - vertical 90° 5 Pa

g.) Elbow 45° 3 Pa

h.) Reducer ø125 to □150x70 3 Pa

i.) Flexible tube

j.) Air intake grid 25 Pa

Table no. 2: Types of elements and corresponding pressure loss values

Flexible pipe according to DN 125

Spiral ribbed pipe DN 125

Value of static pressure loss

Diagram 2

Diagram 2 (according to DN 125)

Diagram 2

12

Pressure drop [Pa/m]

Volumetric air flow [m³/h]

Diagram 2: Value of the static pressure drop for selected pipes

Rectangular elbow horizontal 90° 4 5 20

Flexible tube (DN125) 13.5 1.85

Air intake grid 1 25 25

Total: 70

Table 3: Example of pressure drop calculation

Note:

As mentioned above, the total loss of static pressure, which can be calculated by

adding up the losses of individual elements built into the pipeline system, may not

exceed 95 Pa. If they do, the values of COP start dropping more dramatically.

DETERMINING THE FAN SETTING

When pressure drop is determined, select the mode in which the fan will operate.

This determines the speed of the fan. The mode is selected using Diagram no. 1,

which shows the aerodynamic characteristics of the fan depending on the air flow and

pressure drop in the pipeline*.

Note:

*Pressure drop in the pipeline – in diagram 1 this is marked as pressure difference.

Zone of operation of the sanitary heat pump

On diagram 1 there are two zones of operation of the sanitary heat pump among the

curves:

Number of

elements

p (Pa) p (Pa)

25

(at 150 m3/h)

The dark green zone represents the area of use with higher efficiency. The

volumetric air flow is higher in this zone, which requires a lower pressure drop

(channel system version with minimum pressure drop).

The light green zone represents the area of use with lower air flow in relation to the

pressure drop and fan setting.

Noise

Like the aerodynamic characteristics rise from the lowest to the highest, the noise

increases as well. Between the aerodynamic characteristics 80% and 100 % there is

a zone with increased noise.

Checking the calculation of pressure drop

Determining the aerodynamic characteristics based on the calculation of pressure

drop while taking into account individual elements of the pipeline and air flow is an

iteration. Once the aerodynamic characteristic has been determined and set, we must

measure the air flow in the pipeline. If the air flow does not correspond to the

ventilation system, we select the next higher or lower aerodynamic characteristic that

corresponds to the ventilation system.

EN

13

Selecting the operating point of the fan for the ventilation system

EN

When determining the speed of the fan, we must know the maximum air flow for

ventilation and pressure drop caused by the pipeline. In Diagram 1, find the desired

air flow and draw a vertical line, then draw a horizontal line at the pressure drop that

you have calculated (based on the existing pipeline). Select the fan characteristic

curve that lies the closest to the point where the lines cross.

Example of selecting the aerodynamic characteristic

In diagram 3 at air flow of 150 m³/h draw a vertical line. The pipeline represents 70

Pa of pressure drop, which is added to the below (red) line**. Total pressure drop is

thus 90 Pa. Draw a horizontal line at the pressure drop of 90 Pa. The point where the

lines meet lies on the curve that corresponds to 60% speed of the fan. This is the

standard setting of the fan that has also been preset by the manufacturer.

Note:

**Line, represents the internal static pressure drop created by the evaporator.

14

Pressure difference [Pa]

Air flow [m³/h]

Diagram 3: Example of determining aerodynamic characteristic

3 4 78765ba21 9

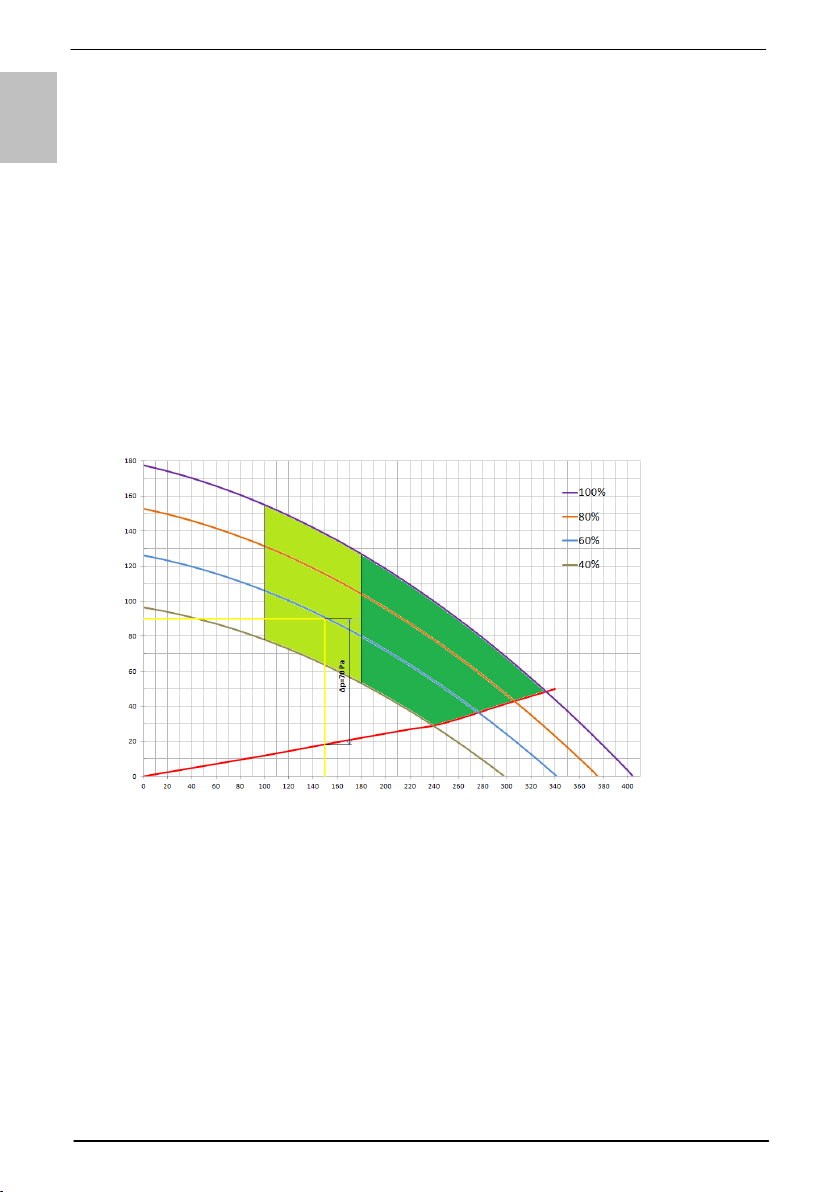

CONNECTION TO WATER SUPPLY MAINS

Water inlet and outlet on the heat pump are marked with colours. Cold water inlet is

marked with blue, and warm water outlet is marked with red. The heat pump is

designed for connection to indoor water supply mains without using the relief valve if

the pressure in the supply mains is lower than 0.6 MPa (6 bar). If the pressure is

higher, a relief valve needs to be installed so as to provide that the pressure at the

inlet to the hot water tank does not exceed the nominal pressure.

Installing a safety valve is mandatory in order to assure safe operation. The valve

prevents an increase of the pressure in the boiler by any more than 0.1 MPa (1 bar)

above the rated pressure. The outflow nozzle on the safety valve must have an outlet

into the atmosphere. To assure correct operation of the safety valve, the valve must

be regularly checked.

When checking the valve, push the lever or unscrew the nut of the valve (depending

on the type of the valve) and open the drain from the safety valve. Water must flow

from the valve nozzle, showing that the valve operation is faultless. During the

heating of water, the water pressure in the hot water tank is increased up to the level

preset in the safety valve. Since the system prevents backflow of water into the water

supply mains, water may be dripping from the outlet opening on the safety valve. The

dripping water may be drained via trap into the drains; the trap is mounted under the

safety valve. The outlet pipe, which is mounted under the safety valve, must be

directed downwards, in a place with a temperature above freezing.

If the installation does not allow draining of the water from the safety valve into the

drains, dripping can be avoided by installing an expansion vessel onto the heat pump

inlet pipe. The volume of the expansion vessel must be ca. 3% of the hot water tank

volume.

EN

Fig. 7: Closed (pressure) system Fig. 8: Open (non-pressure) system

Legend:

1 - Pressure mixer taps

2 - Expansion tank

3 - Safety valve

a - Test valve

b - Non-return valve

4 - Funnel with outlet connection

5 - Checking fitting

6 - Pressure reduction valve

7 - Closing valve

8 - Non-return valve

9 - Low pressure mixer tap

H - Cold water

T - Hot water

15

QUART

PROG.

BUZZ1

K4

K9

K6

K5

K1

K11

K3

K10

K7

FAS5

FAS4

FAS1

FAS3 FAS2

8

7

4

T1

1000 W

6

1000 W

T2

T3

1

2

3

4

1

2

3

4

5

2

1

1

2 1

2

1 2

L

N

5

10

9

C

R

S

1

2

3

4

4

3

2

1

CONNECTING THE HEAT PUMP TO THE POWER SUPPLY NETWORK

EN

Before connecting to the power supply

network, install a power supply cord in

the heat pump, with a min. diameter of

1.5 mm2 (H05VV-F 3G 1.5 mm2). To do

this, remove the protective cover from the

heat pump. The cover is attached using

two screws (Fig. 9). Connecting the heat

pump to the power supply network must

take place in accordance with the

standards for electric appliances. To

comply with the national installation

regulations, an all poles disconnect

switch must be installed between the heat

pump and the power supply network.

Fig. 9: Protective cover

Legend:

T1 - Bar with sensors

T2 - Evaporator – temp. sensor

T3 - Air temperature sensor

1 - 4-way valve

2 - Compressor

4 - Fan

5 - Electric heating element

(2 x 1000 W)

Fig. 10: Electrical circuit diagram

6 - Thermal cut-out

7 - Magnesium anode

8 - LCD touch screen

9 - Boiler - ground

10 - Housing - ground

16

HEAT PUMP OPERATION

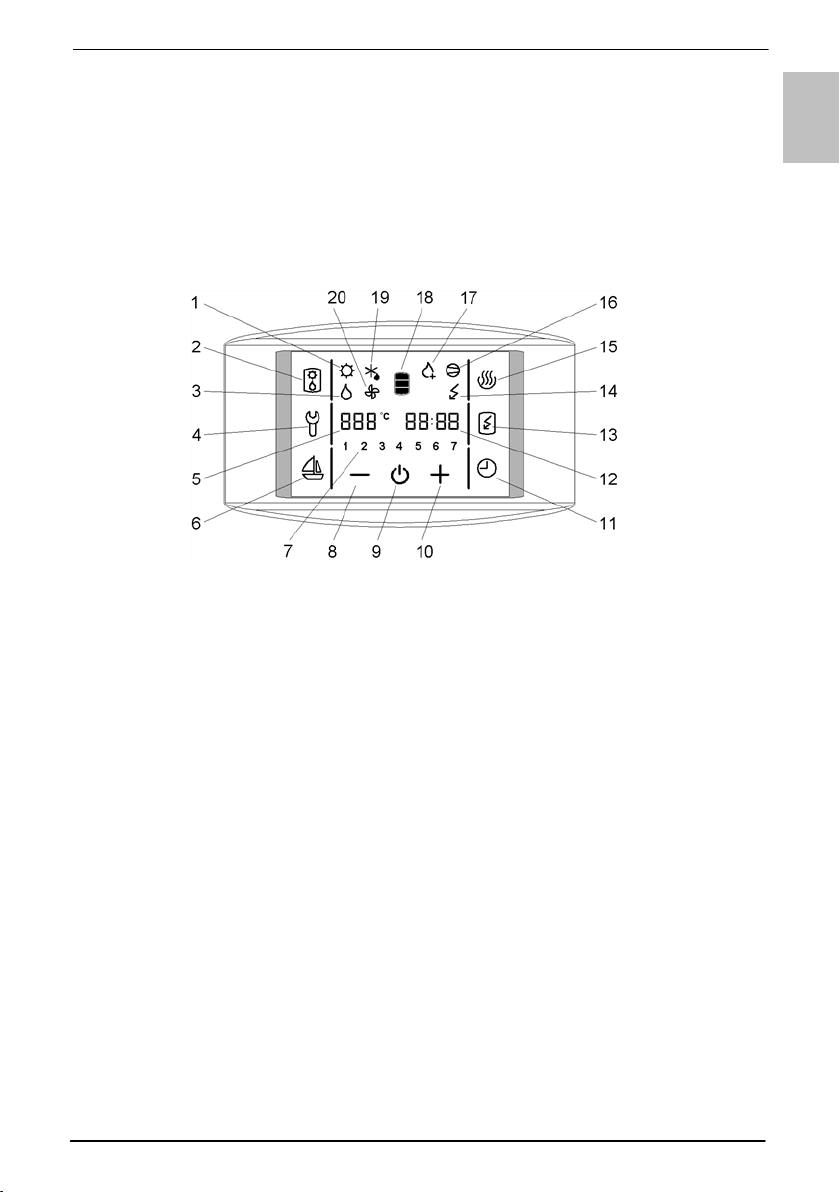

The heat pump can be operated using an LCD touch screen (Fig. 11). If you press

anywhere on the screen, the screen lights up. When the screen is lit up, the operation

fields are active.

When the heat pump is connected to the water and power supply mains and the

boiler is filled with water, the heat pump is ready to be used. The heat pump heats

the water in the range 10 °C - 55 °C. From 55 °C - 75 °C the water is heated by

electrical heaters.

EN

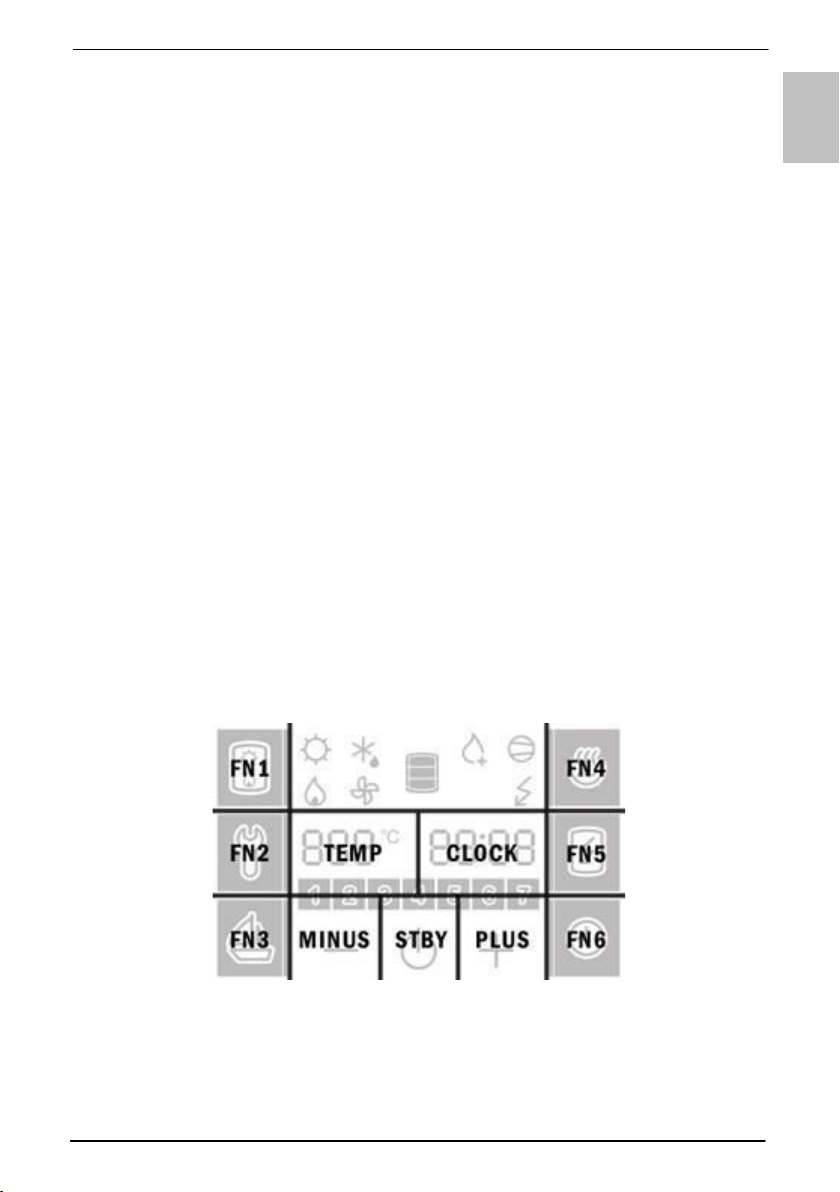

Fig.11: LCD touch screen

Legend:

1 - Signalization of the operation of solar

collectors**

2 - alternative source of heating turned on

(heaters)

3 - Signalization of the operation of the oil

boiler**

4 - Indication, overview of operation

errors, entrance into the service menu

5 - Display and setup of temperature in

°C

6 - Start and setup of the VACATION

programme

7 - Day of the week

(1 .. Monday, …, 7 .. Sunday)

8 - Reducing the value

9 - Heat pump on/off switch

10 - Increasing the value

Starting/stopping the heat pump

11 - TIMER start and setup

12 - Time setup and display

13 - Start-up of quick heating "TURBO"

14 - Indicator of the heating element

operation

15 - Start-up of heating to the maximum

temperature level

16 - Signalization of compressor

operation

17 - Signalization of anti-legionella

programme operation

18 - Warm water quantity display

19 - Signalization of defrosting

20 - Signalization of fan operation

** function is not used in versions

TC-ZNT

To start the heat pump hold field no. 9.

When the appliance is switched on, the fan starts first and operates for one minute

(symbol no. 20 is displayed). If the temperature of inlet air is appropriate, the

controlling unit switches on the compressor and the heat pump operates in normal

17

mode (symbols 16 and 20 are displayed). The heat pump is on, the screen remains

unlit and inactive.

EN

In 60 seconds after the last touch of the screen, the illumination and activity of the

screen are turned off, but that does not affect the operation of the heat pump.

Pressing anywhere on the screen re-activates the screen and its illumination.

If trying to start up at a lower temperature, please see chapter "Operation at lower

temperatures".

By holding field no. 9, the heat pump is switched off. The appliance stops

functioning and the only field visible on the screen is field no. 9. (If you switch off

the heat pump for a longer period of time, the water must be drained from the pump

if there is any danger of freezing).

Power failure protection

In case of power failure, the settings remain stored for up to 23 hours.

After restarting, the heat pump operates in the same mode it was operating in before

the power failure.

Operation at lower temperatures

When the appliance is switched on, the fan starts first and operates for one minute

(symbol no. 20 is displayed). If the temperature of inlet air is lower than -7 °C, the fan

is turned off. Domestic water is heated with heaters. The heat pump operates in the

reserve mode (symbol no. 14 is displayed). The possibility of switching to normal

mode is checked every 2 hours by switching on the fan for one minute. If the

temperature of inlet air is higher than -7 °C, the heat pump switches to normal mode

of operation (symbols 16 and 20 are displayed). The heaters switch off. The heat

pump is on, the screen remains unlit and inactive.

At lower air temperatures, the evaporator defrosting cycle is started if necessary.

Symbol no. 19 is displayed on the screen. The fields 2, 4, 6, 11, 13 and 15 remain

inactive. Defrosting takes place until the conditions for normal operation of the heat

pump are achieved.

After successful defrosting, the heat pump returns to normal operation (symbols 16

and 20 are displayed).

If defrosting is unsuccessful after two consecutive attempts, the controlling unit

displays an error message. Field no. 4 starts flashing, accompanied by warning

beeps. By pressing field no. 4 the warning beeps can be turned off. Error code E247

appears in field no. 12 and the pump switches automatically to heating with electric

heaters. The screen displays symbol no. 14. The error code can be deleted at any

time by pressing field no. 4. Field no. 12 resumes to displaying time.

Setting the clock and day of the week

Hold field no. 12, until field no. 7 shows a flashing number of the day of the week.

By pressing + or – you can set the number of the day of the week

(1 – Monday, …, 7 – Sunday).

Press field no. 12 again (flashing hour setting is displayed).

By pressing + or – set the hour (by holding + or – you can speed up the setting).

Press field no. 12 again.

Flashing minute setting is displayed.

18

By pressing + or – set the minutes (by holding + or – you can speed up the setting).

The setting is stored when you press field no. 12, or when the field stops flashing.

Setting the temperature

Press field no. 5 (the set temperature starts blinking).

By pressing + or – you can change the temperature setting from 10 °C to 75 °C

(preset to economic temperature of 55 °C).

The setting is stored by pressing field no. 5 again, or when field no. 5 stops

flashing. After a few seconds, the display shows the actual temperature.

In case of power failure, the last stored value is restored.

Switching on the "TURBO" mode

If you need more warm water than the heat pump can heat up in a short period of

time, press field no. 13 (switches on the "TURBO" mode). The heat pump and

heater work simultaneously. The screen shows symbols no. 14, 16 in 20. When the

temperature reaches 55 °C the heat pump returns to the mode used before the

"TURBO" mode.

Switching on the "HOT" mode

If you want to heat the water to the maximum temperature of 75 °C, press field no.

15. The heat pump will heat water to 55 °C. The screen displays symbols no. 16 in

20. When the temperature in the boiler reaches 55 °C the electric heater turns on to

heat the temperature up to 75 °C. The screen displays the symbol no. 14. When the

temperature reaches 75 °C the heat pump returns to the mode used before the

"HOT" mode.

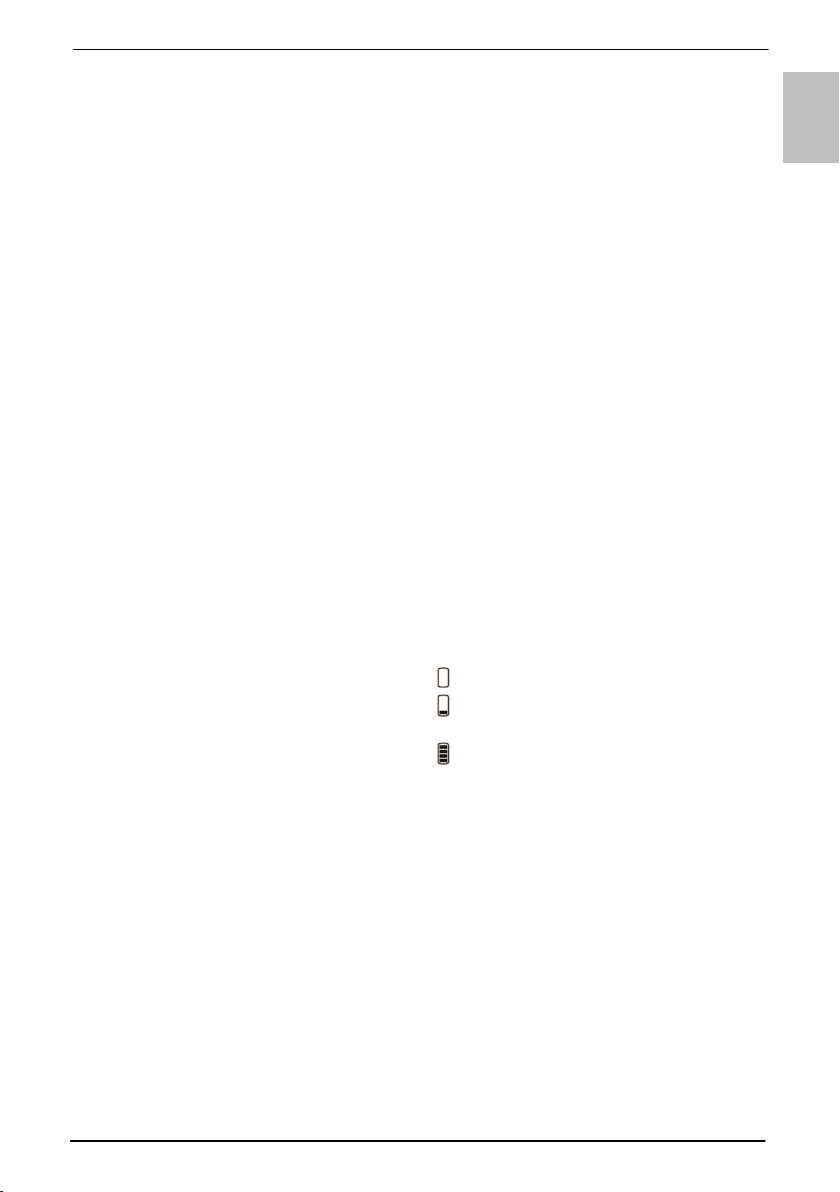

Display of the quantity of water in the heat pump

Field no. 18 shows the following symbol : - no warm water

- low quantity of warm water

- high quantity of warm water

Setting the vacation mode

In the vacation mode, you can set the number of days (maximally 100), when the

heat pump shall maintain the minimal temperature of water (approximately 10 °C).

Hold field no. 6 for a while (fields 5 and 6 start to flash).

By pressing fields + or – you can set the number of vacation days shown in field no.

5.

By pressing field no. 6 again, or when field no. 6 stops flashing, the set number of

days is stored.

If you set the value to 0, then the heat pump will resume its normal operating mode

after confirming the setting, and illumination of field no. 6 will turn off.

After the set number of days has elapsed, the heat pump returns to the normal

mode and illumination of field no. 6 turns off.

EN

19

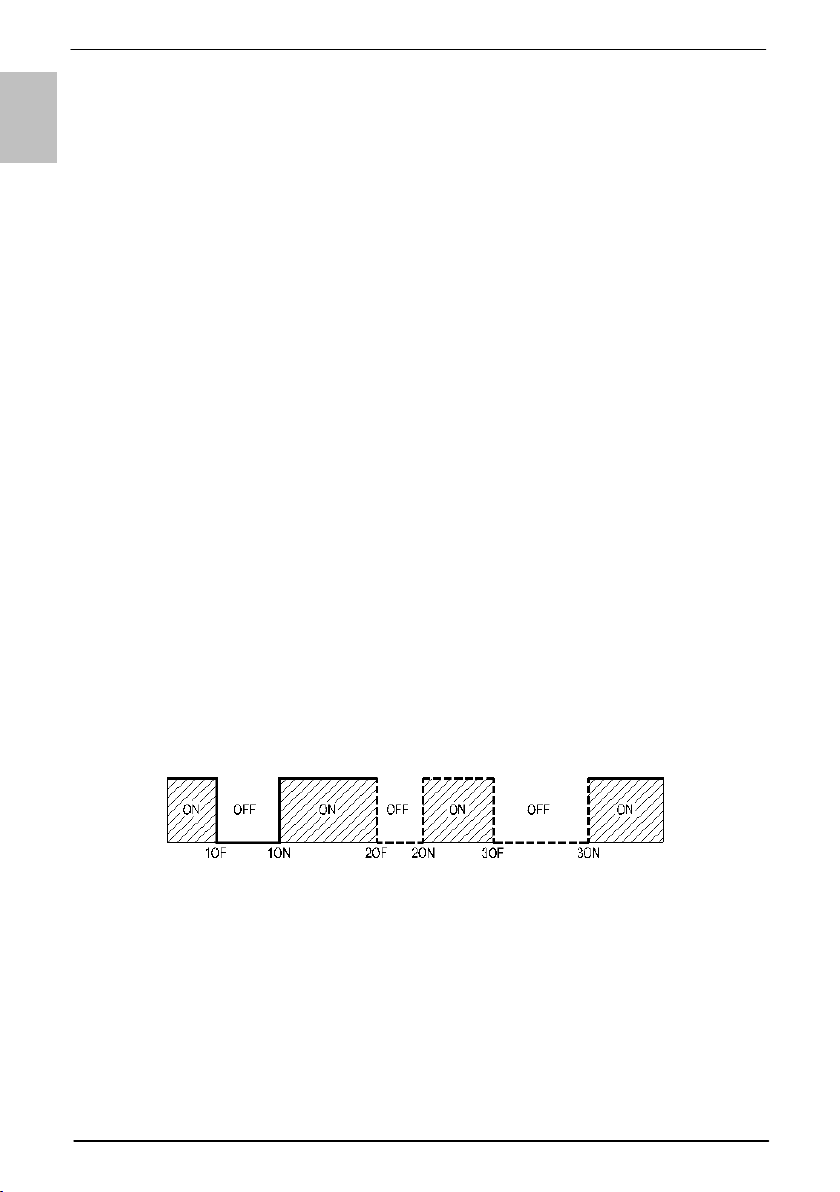

Setting the TIMER mode

In the TIMER operating mode, you can set the times when the heat pump will start

EN

and stop. For each timer combination you can set up to three time periods in which

the heat pump will not heat the water.

a) Setting the timer combinations

Hold field no. 11 for a while (fields 7 and 11 start to flash).

By pressing fields + or – choose among three timer modes of operation:

- Timer mode of operation of the heat pump for the entire week (numbers 1-7 flash

in field no. 7),

- Timer mode of operation of the heat pump for Monday to Friday and Saturday to

Sunday (numbers 1-5 and then 6 and 7 flash in field no. 7),

- Timer mode of operation of the heat pump for each day at a time (individual

numbers 1-7 flash in field no. 7).

To set the time, press field no. 12.

On the field no. 5, the text 1OF appears and field no. 12 starts to blink.

By pressing fields + or – set the time of shutdown.

Press field no. 12 again.

On the field no. 5, the text 1ON appears and field no. 12 starts to blink.

By pressing fields + or – set the time of start-up.

By pressing field no. 12 again, you can use the above procedure to set the second

and third period.

By pressing field no. 12 again, or when field no. 6 stops flashing the set number of

days is stored. Again, press field no. 12.

b) Activation, deactivation of timer

By pressing field no. 11, you can activate the set timer mode.

The heat pump heats the water in the ON periods (to the set temperature) and in

the OFF periods, it does not heat the water.

By pressing field no. 11 again, you can deactivate the set time mode of operation.

Fig. 12: Time periods

Anti-legionella function

Works only when the heat pump is switched on. When activated, symbol no. 17 is

displayed.

Automatic activation: every 2 weeks of operation of the heat pump, if the

temperature of water did not exceed 65 °C for one straight our or more in the

previous two-week period.

Anti-legionella programme can be activated manually by pressing field no. 15

(heating of water to the temperature of 75 °C).

20

Operation signalization:

Anti-legionella programme:

Programme on – control field no. 17 is displayed

Programme off – control field no. 17 is not displayed

electric heaters:

heaters on – control field no. 14 is displayed

heaters off – control field no. 14 is not displayed

heat pump:

heat pump is heating water – control field no. 16 is displayed

heat pump is not heating water – control field no. 16 is not displayed

on/off:

heat pump is on – next to field no. 9 other fields are also visible on the screen

heat pump is off – only field no. 9 is visible on the screen

defrosting:

heat pump is in the defrosting mode – control field no. 19 is displayed

heat pump is not in the defrosting mode – control field no. 19 is not displayed

fan on/off:

fan is on – control field no. 20 is displayed

fan is off – control field no. 20 is not displayed

alternative source of heat – electric heaters: (field no. 2)

switched to the electric heaters - control field no. 14 is displayed

fields 1 and 3 are not active in these versions of the heat pump

Access to the service level

By holding field no. 4 on the display (figure 11), the function "service mode" is

turned on.

The introductory menu appears with code written in the CLOCK field; the service

code can be entered using the keys FN1, FN2, FN3, FN4, FN5 and FN6, which

correspond to numbers 1,2,3,4,5,6.

EN

Fig. 13: Fields on the display

If none of the fields are pressed for 10 s the menu automatically returns to normal

functioning.

If the code is entered incorrectly, the programme automatically exits the

21

introductory menu.

When the code is entered correctly, the first parameter appears. The number on the

EN

right consecutive number of the parameter and the number on the left is its value.

The first parameter :00 is the version of the programme code that is purely of

informative nature.

By pressing the right number (the CLOCK field on Figure 13) the next parameter is

displayed.

Installation menu: CODE 1166:

After the installation menu code is entered correctly, the following parameters can be

accessed:

00 programme code version (informative parameter)

21 setting the speed of fan

27 setting low-temperature mode

Setting the speed of the fan (parameter :21)

When the parameter (:21) is selected, press (+) or (-) to set the desired fan speed (40

-100%). On the left side (field 5) the numeric value of the setting is displayed. When

the desired speed of the fan is set, it is stored after a short delay or after pressing

field no. 4.

Setting the low-temperature mode of operation of the heat pump (parameter :27)

When parameter :27 is selected, press (+) or (-) to determine the temperature mode

of operation of the heat pump, which depends on the version of the heat pump. The

low-temperature mode can only be set if the heat pump version allows it!**** On the

left side (TEMP field) the set mode is displayed:

Yes – heat pump version TC ZNT, heat pump operation mode (up to -7°C), the

system includes a 4-way valve

No – heat pump version TC Z, heat pump operation mode 7°C, the system does not

include a 4-way valve

Note:

****The low-temperature mode of operation of the heat pump is a setting that the

installer can only set if the version of the heat pump is appropriate. When replacing

the electronic module, the mode of operation must be selected in such a way that it

suits the version of the heat pump!

22

SERVICE AND MAINTENANCE

If installed and used correctly, the heat pump will last for years without service.

The exterior of the heat pump should be cleaned with a mild detergent solution. Do

not use solvents or abrasive cleaning agents.

If the heat pump was exposed to dust, evaporator lamellas might become blocked,

which can have a detrimental effect on the functioning of the heat pump. In this case

the evaporator should be cleaned. The cleaning of the evaporator must be carried out

by an authorised service provider.

By performing regular service inspections you can ensure faultless operation and a

long life span of the heat pump. The tank corrosion warranty applies only if the

prescribed regular anode inspections have been performed. The interval between

individual inspections should not be longer than 36 months. Inspections must be

carried out by an authorised service provider that logs each inspection on the

product’s warranty sheet. The service provider inspects the wear and tear of the anticorrosion protective anode and cleans the limescale that accumulates inside the tank,

depending on the quality, quantity and temperature of the water used. Service

providers will also provide you with the following inspection date, depending on the

state of the heat pump.

Before calling your service provider, check the following:

Is everything OK with the power supply network?

Is the air outlet obstructed?

Is ambient temperature too low?

Can you hear the operation of the compressor and fan?

Pipeline system pressure drop

Do not try to eliminate malfunctions by yourself, call your nearest authorized

service provider!

EN

23

EN

24

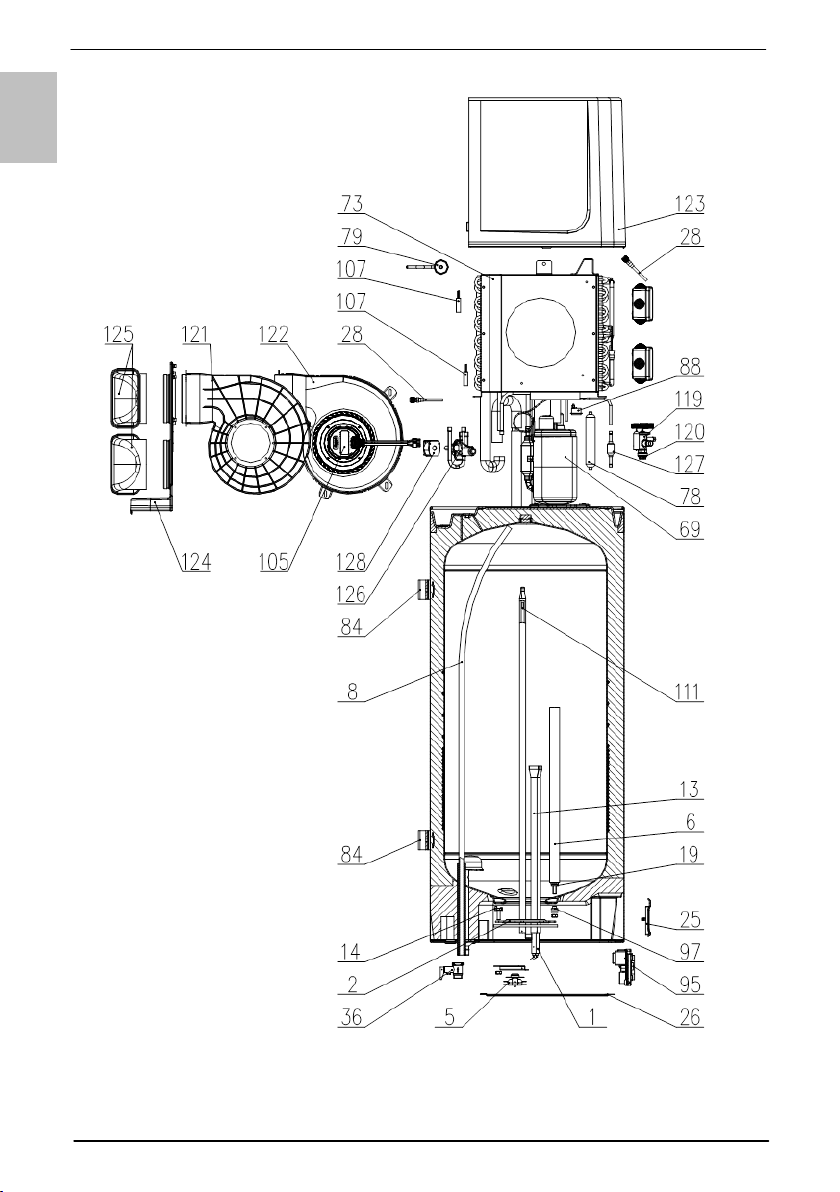

Position Ident Spare part description Quantity Validity

1 458697 Heating Element 1000W 2

2 482939 Gasket 160/94X8 1

5 482993 Bimetal Safety 1

6 268069 Mg Anode D25,5X340-M8 1

6 269182 Mg Anode D25,5X450-M8 1 PAW-DHWM120ZNT

8 321302 Outlet Tube 865mm 1 PAW-DHWM80ZNT

8 321287 Outlet Tube 1015mm 1 PAW-DHWM100ZNT

8 321289 Outlet Tube 1185mm 1 PAW-DHWM120ZNT

13 404077 Heater Flange 80L 1 PAW-DHWM80ZNT

13 404053 Heater Flange 100L 1 PAW-DHWM100ZNT

13 404046 Heater Flange 120L 1 PAW-DHWM120ZNT

14 482940 Screw Holder 6

19 482950 Gasket D18,8/D7,6X3 1

25 478222 Control Panel 1

26 757132 Bottom Cover 1

28 321732 Filling Valve Assy 2

69 405139 Compressor 1

88 419383 Thermal Cutout 1

73 392473 Evaporator 1

78 364934 Drying Filter 30 g 1

79 404919

84 757137 Wall Bracket 2

95 405088 Electronics 1

97 487074 Insulating Bush D17/D8X5 1

105 404083 Centrifugal Fan 1

107 334192 Temperature Sensor 2

111 345664 Sensor Strip 80L 1 PAW-DHWM80ZNT

111 345665 Sensor Strip 100L 1 PAW-DHWM100ZNT

111 345666 Sensor Strip 120L 1 PAW-DHWM120ZNT

119 451724

121 404081 Air Duct Left 1

122 404082 Air Duct Right 1

123 439625 Front Protection Cap 1

124 364941 Back Protection Cap 1

125 429797 Connection Elbow D125/150X70 2

126 392462 4-Way Valve 1

127 451725 Check Valve 1

128 443882 4-Way Valve Coil 1

Capacitor 10 F

Thermal Expansion Valve TUBR134

PAW-DHWM80ZNT

PAW-DHWM120ZNT

1

1

EN

25

OPERATION ERRORS

EN

Despite careful production and control, the heat pump can produce errors that must

be solved by an authorised service provider.

Indicator of errors

In case of an error on the appliance, the beeper starts beeping and field no. 4 starts

flashing. When you press field no. 4 the error code is displayed in field no. 12.

Error Description of error Solution

E004 Freezing. The error appears if the

temperature in the heat pump is below 4 °C.

Call the service.

E005 Overheating (temperature > 85 °C,

electronic regulator failure).

E006 Mg anode error. Call the service (heat pump

E007 Volume and/or temperature sensors error. Call the service.

E042 Anti-legionella function error. Press field no. 4 to restart.

E247 Defrosting error. Automatically turns on heating with

E361 External air sensor error. Call the service (automatically

E363 Defrosting sensor error. Call the service (automatically

Unplug the heat pump from the

power supply. Call the service.

functions normally).

the electric heater. When the error

is deleted, the aggregate resumes

its normal operation.

switches to the electric heater).

switches to the electric heater).

26

HINWEISE!

Das Gerät kann von 8-jährigen und älteren Kindern und Personen mit

begrenzten physischen, sinnlichen und psychischen Fähigkeiten oder mit

ungenügend Erfahrungen bzw. Kenntnis benutzt werden, falls sie dabei kontrolliert

werden oder über die sichere Anwendung des Gerätes belehrt worden sind und

dass sie die eventuelle damit verbundene Gefahr verstehen.

Kinder dürfen mit dem Gerät nicht spielen.

Kinder dürfen das Gerät nicht reinigen oder warten, wenn sie dabei nicht von

einer befähigten Person kontrolliert werden.

Die Wärmepumpe darf nur in senkrechter Lage transportiert werden,

ausnahmsweise darf sie um 35° in jede Richtung geneigt werden.

Die Wärmepumpe ist nicht für die industrielle Anwendung und Anwendung in

den Räumen mit vorhandenen Korrosions- und Explosionsstoffe bestimmt.

Der Anschluss der Wärmepumpe ans Stromnetz ist im Einklang mit den

Standards für elektrische Installation auszuführen. Zwischen Wärmepumpe und

Dauerinstallation ist ein Pole-Trennelement nach nationalen

Installationsvorschriften einzubauen.

Die Wärmepumpe darf bei leerem Kessel (kein Wasser im Kessel) nicht im

Betrieb sein, damit kein Schaden am Aggregat entstehen kann!

Die Installation ist nach den gültigen Vorschriften und nach Anweisungen des

Herstellers auszuführen. Die Installation darf nur ein fachlich ausgebildeter

Installateur ausführen.

Auf das Zuflussrohr der Wärmepumpe ist unbedingt ein Sicherheitsventil mit

Nenndruck zu installieren, um die Druckerhöhung im Kessel um mehr als 0,1 MPa

(1 bar) über den Nenndruck zu verhindern.

Das Wasser kann aus der Abflussöffnung des Sicherheitsventils tropfen,

deshalb muss die Zuflussöffnung auf Atmosphärendruck geöffnet sein.

Der nach unten gerichtete Auslass des Sicherheitsventils darf in keiner

Frostumgebung installieren werden.

Die einwandfreie Funktion des Sicherheitsventils müssen Sie selber

regelmäßig kontrollieren. Sie müssen den Kalk entfernen und das Sicherheitsventil

auf Blockade zu prüfen.

Zwischen Wärmepumpe und Sicherheitsventil darf kein Schliessventil

installiert werden, so dass die Funktion des Sicherheitsventils nicht blockiert wird!

Vor dem Betrieb sind auf die Kappe des Gerätes unbedingt zwei Bögen 90°

(ø125 mm), jeder in eigene Richtung, anzubringen. Der Raum muss gut gelüftet

werden.

Die Elemente in der elektronischen Steuerungseinheit sind auch nach der

Betätigung des Ausschaltfeldes (9) der Wärmepumpe unter Spannung.

Falls Sie die Wärmepumpe ausschalten (vom Stromnetz nehmen), müssen Sie

das Wasser wegen Frostgefahr aus der Wärmepumpe ablassen.

Das Wasser aus der Pumpe wird durch das Zuflussrohr des Kessels

abgelassen. Es ist sinnvoll zwischen Sicherheitsventil und Zuflussrohr ein

Spezialteil oder ein Auslassventil zu installieren.

Wir bitten Sie, eventuelle Störungen an der Wärmepumpe nicht selber zu

reparieren, sondern nehmen Sie beim nächsten beauftragten Kundendienst

Kontakt auf.

DE

27

VORSTELLUNG

DE

Verehrte Kundin, verehrter Kunde!

Wir danken Ihnen, dass Sie sich für den Kauf unserer Brauchwasser-Wärmepumpe

Aquarea entschieden haben. Damit haben Sie Ihr Vertrauen einem der technisch

ausgeklügelten Geräte erwiesen. Werkstoffe, Konstruktion und Prüfungen sind mit

den Normen abgestimmt, die diesen Bereich betreffen.

Leistung, Kapazität und Sicherheitsvorrichtungen wurden in unseren Labors geprüft.

Alle Prüfungen an den Bauteilen und am Endprodukt wurden in Einklang mit den

internationalen Normen des Qualitätsstandards durchgeführt.

Lesen Sie bitte sorgfältig die Bedienungsanleitung, die Informationen über die

Funktion sowie die Hinweise zur Instandhaltung; dadurch können Sie

Unannehmlichkeiten und Schäden am Gerät verhindern.

Bewahren Sie dieses Handbuch sorgfältig auf, damit Sie es zur Hand nehmen

können, wenn Sie Zweifel bezüglich der Funktion oder Instandhaltung haben sollten.

Sie können auch jederzeit den autorisierten Kundendienst für gelegentliche

Instandhaltungsarbeiten anrufen. Unsere Kundendienst-Fachleute stehen Ihnen

gerne mit Ihren Erfahrungen zur Verfügung.

28

ANWENDUNGSGEBIET

Dieses Gerät ist zur Warmwasserbereitung im Haushalt und bei anderen

Verbrauchern mit einem täglichen Warmwasserverbrauch (40 °C) von 150 l bis 250 l

bestimmt. Das Gerät ist an die hauseigene Installation des warmen Brauchwassers

und ans elektrische Versorgungsnetz angeschlossen. Die zur Funktion des Geräts

notwendige Luftansaugung und -abgabe kann auch aus einem anderen Raum

ausgeführt werden.

Falls Sie die Wärmepumpe in einem Raum aufstellen, in dem sich eine Badewanne

oder Duschkabine befindet, sind unbedingt die Anforderungen des Standards IEC

60364-7-701 (VDE 0100, Teil 701) zu berücksichtigen. Das Gerät ist ausschließlich

für die senkrechte Wandmontage mit Wandschrauben, Nominaldurchmesser

Minimum 8 mm bestimmt. Eine Wand mit schlechter Tragfähigkeit muss an der

Montagestelle entsprechend verstärkt werden. Zur leichten Kontrolle und zum

Wechseln der Mg-Schutzanode ist es sinnvoll, genügend Raum zwischen Gerät und

Boden zu lassen, sonst muss das Gerät beim Serviceeingriff von der Wand

demontiert werden (Bild 4).

Ein andersartiger Gebrauch des Geräts als der angeführte ist nicht erlaubt. Das

Gerät ist nicht zum Gebrauch in der Industrie oder in Räumen bestimmt, in welchen

korrosive und explosive Stoffe vorhanden sind.

Der Hersteller haftet nicht für Schäden, die wegen unsachgemäßem Einbau und

Gebrauch entstehen und nicht in Einklang mit der Montage- und

Bedienungsanleitung sind.

Die Bedienungsanleitung ist ein wichtiger Bestandteil des Produkts und muss dem

Käufer ausgehändigt werden. Der Käufer sollte die Hinweise in der

Bedienungsanleitung sorgfältig lesen, weil darin wichtige Hinweise über die

Sicherheit bei Installation, Gebrauch und Instandhaltung angeführt sind.

Die Bedienungsanleitung ist sorgfältig für eventuelle künftige Verwendung

aufzubewahren.

Der Typ Ihrer Wärmepumpe ist auf dem Typenschild angegeben, das an der

Unterseite des Geräts zwischen den Anschlussrohren für Brauchwasser angebracht

ist.

Überprüfen Sie nach der Entfernung der Verpackung deren Inhalt. Wenden Sie sich

im Zweifelsfall an Ihren Lieferanten. Lassen Sie Verpackungsteile (Klammern, PVCSäcke, Styropor u.Ä.) nicht im Zugriffsbereich von Kindern liegen, weil diese

potentielle Gefahrenquellen darstellen. Sorgen Sie für eine umweltgerechte

Entsorgung der Verpackung.

LAGERUNG UND TRANSPORT

Die Wärmepumpe darf nur in senkrechter Lage gelagert werden und zwar in einem

trockenen und sauberen Raum.

DE

29

A

264

B

589

C

294

350

350

D

E

324

506

533

285

170

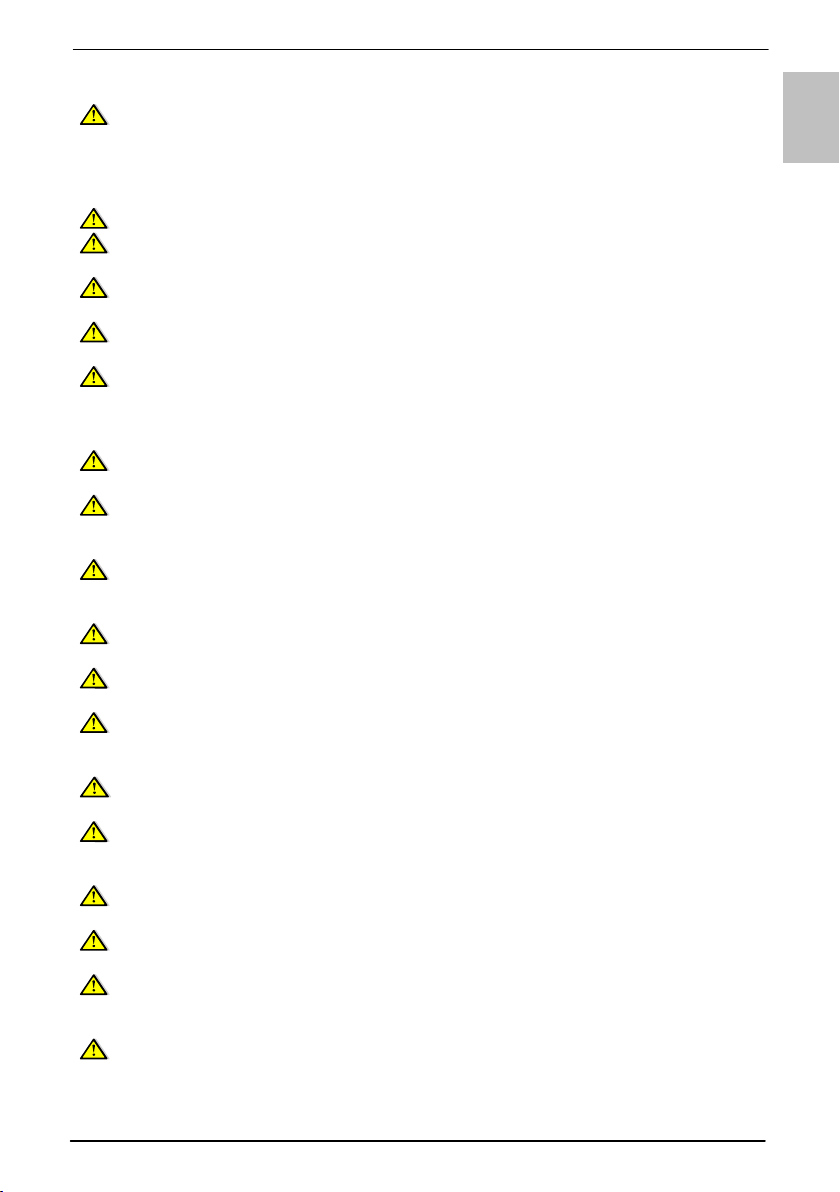

FUNKTIONSPRINZIP DER WÄRMEPUMPE

DE

Die Wärmepumpe ist ein thermodynamischer Wärmegenerator, der die Wärme aus

dem niedrigeren Temperaturniveau (z.B. Wärme der Raumluft) auf ein höheres

Temperaturniveau anhebt (z.B. warmes Brauchwasser).

Diese, der Raumluft entzogene Wärme, schafft zusammen mit der Antriebsenergie

(elektrische Energie) Wärmeenergie, die zum Erwärmen des Brauchwassers zur

Verfügung steht.

Bild 1: Schematische Darstellung des Energieflusses durch das Aggregat der Wärmepumpe

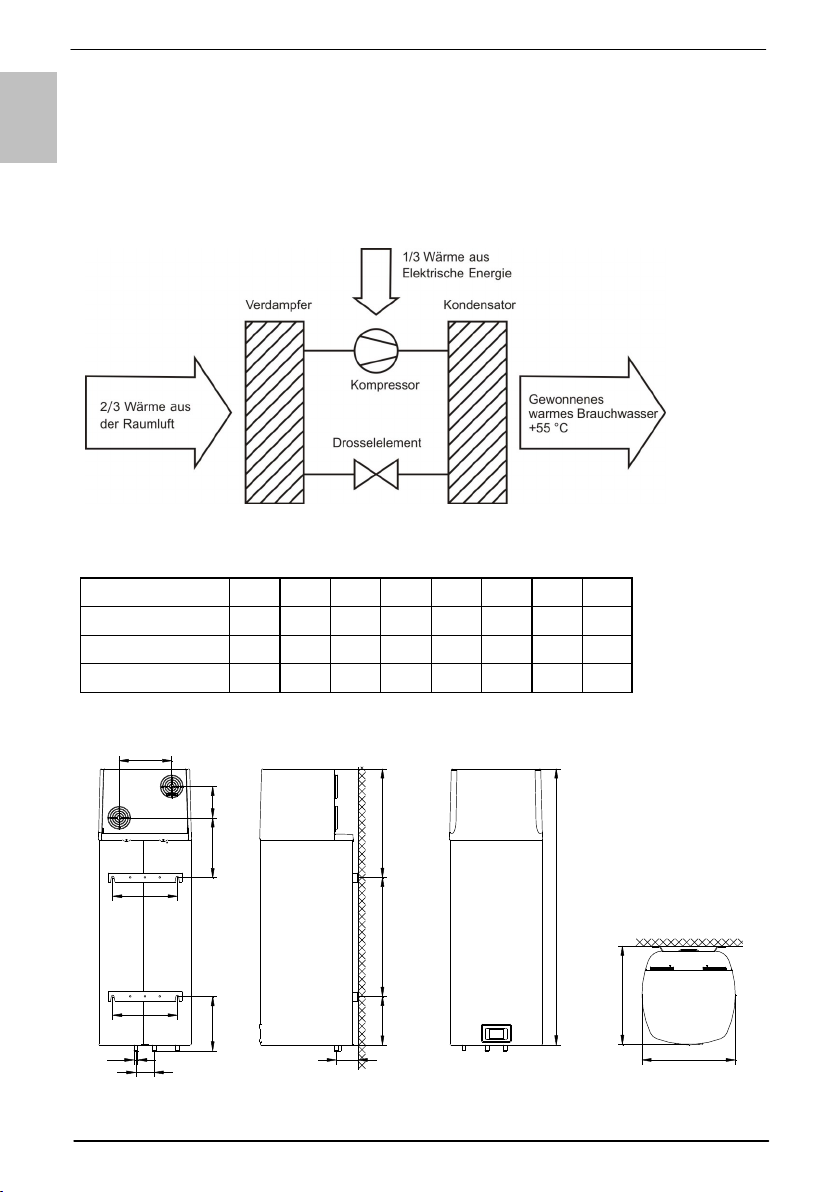

DIMENSIONEN

PAW-DHWM80ZNT

PAW-DHWM100ZNT

PAW-DHWM120ZNT

A B C * C ** D * D ** E * E **

1197 345 100 175 100 230 G 1/2 G 3/4

1342 490 100 175 100 230 G 1/2 G 3/4

1497 645 100 175 100 230 G 1/2 G 3/4

* - DIN Norm

** - NF Norm

Bild 2: Anschluss- und Installationsmaße der Wärmepumpe (mm)

30

Loading...

Loading...