Aqua-Pure APPM150 User Manual

INSTALLATION AND OPERATING

INSTRUCTIONS

APPM SERIES IRON REDUCTION FILTRATION SYSTEMS

MODELS:

APPM100 APPM100M APPM100DM APPM100MDM

APPM150 APPM150M APPM150DM APPM150MDM

APPM200 APPM200M APPM200DM APPM200MDM

Installer, please leave with homeowner.

Homeowner, retain for future reference.

SAFETY INFORMATION

Read, understand, and follow all safety information contained in these instructions prior to installation and use of the APPM Series Iron Reduction Filtration System. Retain

these instructions for future reference. Failure to follow installation, operation and maintenance instructions may result in property damage and will void warranty.

This product includes a GAST

contact your Dealer/Installer or our Customer Service Department at 1-800-222-7880.

Intended use:

The APPM Iron Reduction Filtration System is intended for use in reducing iron, manganese, and hydrogen sulfi de, as well as elevating low pH in water in homes and

has not been evaluated for other uses. The system must be installed indoors near the point of entry of a home water line, and be installed by qualifi ed professional

installers according to these installation instructions.

WARNING

CAUTION

CAUTION

To reduce the risk associated with choking:

• Do not allow children under 3 years of age to have access to small parts during the installation of this product.

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

To reduce the risk of physical injury:

• Shut off inlet water supply and depressurize system as shown in manual prior to service.

• Do not operate system with air release valve (ARVTA-1X) in the closed position.

To reduce the risk associated with a hazardous voltage:

• If the home electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient ground connection across the

fi lter installation piping — refer installation to qualifi ed personnel.

• Do not use the system if the power cord is damaged — contact qualifi ed service personnel for repair.

To reduce the risk associated with back strain due to the heavy weight of the various system components:

• Follow safe lifting procedures.

®

component. Please refer to GAST website at www.gastmfg.com for detailed information on GAST LOA-P109-AA compressor or

EXPLANATION OF SIGNAL WORD CONSEQUENCES

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury and/or property damage.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury and/or property damage.

Indicates a potentially hazardous situation, which, if not avoided, may result in property damage.

WARNING

CAUTION

To reduce the risk associated skin, eye, and respiratory tract irritation from gravel and fi lter media during installation:

• Gravel and several types of fi lter media may be used in this product, depending upon the application. During installation, dust may cause irritation to skin, eyes, and respiratory tract.

• Utilize a NIOSH-approved dust fi lter mask, protective gloves, and appropriate eye protection when handling and pouring gravel and fi lter media.

• To request an MSDS relating to this product, call 203-238-8965 or go to www.3M.com, select country, and use the search engine to search MSDS. For emergencies, call

800-364-3577 or 651-737-6501 (24 hours).

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use instructions before installation and use of this water treatment system.

• Installation and use MUST comply with existing state or local plumbing codes.

• Protect from freezing, relieve pressure and drain system when temperatures are expected to drop below 33°F (0.6°C).

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 110°F (43.3°C).

• Do not install if water pressure exceeds 50 psi. If your water pressure exceeds 50 psi (345 kPa), you must install a pressure limiting valve. Contact a plumbing professional

if you are uncertain how to check your water pressure.

• Do not install where water hammer conditions may occur. If water hammer conditions exist you must install a water hammer arrester. Contact a plumbing professional if

you are uncertain how to check for this condition.

• Where a backfl ow prevention device is installed on a water system, a device for controlling pressure due to thermal expansion must be installed.

• Do not use a torch or other high temperature sources near fi lter system, cartridges, plastic fi ttings or plastic plumbing.

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic.

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

• Do not install in direct sunlight or outdoors.

• Install system in such a position as to prevent it from being struck by other items used in the area of installation.

• Ensure all tubing and fi ttings are secure and free of leaks.

• SHUT OFF FUEL OR ELECTRIC POWER SUPPLY TO WATER HEATER after water is shut off.

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum prevention.

• Do not apply heat to any fi tting connected to bypass or control valve as damage may result to internal parts or connecting adapters.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment equipment

products will vary depending on the control valve brand used.

• Failure to follow instructions will void warranty.

IMPORTANT NOTES

IMPORTANT NOTE

IMPORTANT NOTE

TABLE OF CONTENTS

SECTION DESCRIPTION

1 GENERAL INFORMATION

2 BEFORE INSTALLATION

3 INSTALLATION

4 BACKWASHING INSTRUCTIONS

5 TROUBLESHOOTING

6 SPECIFICATIONS AND OPERATING DATA

7 MAINTENANCE

8 LIMITED WARRANTY

SECTION 1: GENERAL INFORMATION

This APPM Series Iron Reduction Filtration System reduces dissolved, precipitated and bacterial iron from your water supply. In addition, the system reduces

manganese and hydrogen sulfi de, as well as elevating low pH. Contrary to conventional methods, the APPM Series Iron Reduction Filtration System requires

NO chemicals (either added to the water supply or the fi lter). The unique process requires ONLY periodic backwashing for a few minutes to fl ush out entrapped iron that has accumulated in the media tank.

The APPM Series Iron Reduction Filtration System was designed to be used primarily on jet pump applications where the operating pressures do not exceed

50 psi, as well as with variable speed constant pressure pumps and in split stream water system designs. The MAXIMUM PRESSURE for proper operation of

the aeration tank is 50 psi. If you have a private water system, refer to page 2-1 to determine your system’s capability. If your system produces the required

fl ow rate at 50 psi or higher, contact your Dealer/Installer or our Customer Service Department at 1-800-222-7880.

When properly installed, the APPM Series Iron Reduction Filtration System will provide years of dependable service. Read this manual all the way through

fi rst, and then follow the instruction steps in the proper sequence.

DESCRIPTION AND OPERATION OF THE SYSTEM:

The APPM Series Iron Reduction Filtration System consists of two major components which are:

1) An aeration tank, with GAST LOA-P109-AA compressor, installed after the existing pressure tank. Every time the well pump runs, the compressor injects

air into the iron laden water.

2) A backwashing type fi lter containing a special media that causes the iron to precipitate throughout the fi lter bed (rather than on the surface as in chemical oxidizing fi lters). This process produces an iron reduction capacity from 30,000 to 50,000 parts per million (ppm) compared to 6,000 to 8,000 ppm

for chemical oxidation processes. The media DOES NOT require a chemical regenerant (such as potassium permanganate) for oxygen enrichment, salt,

chlorine or any other chemicals.

The APPM Series Iron Reduction Filtration System automatically adjusts the pH to neutral or higher on acid water WITHOUT an acid neutralizer (a required piece

of equipment with chemical oxidation fi lters whenever the pH is less than 6.7). The ability to raise pH when it is below neutral (7 or less) greatly enhances

the fi ltration system’s ability to reduce iron effi ciently.

IMPORTANT NOTE

Replenishment of the component of the fi lter media that adjusts pH, “pH Plus”, may be required periodically, the frequency of which is dependent on the

raw water pH, the manganese (Mn) concentration in the water (if any) and the water consumption rate.

Periodic backwashing of the fi lter bed fl ushes the precipitated iron to the drain and readies the fi lter for use again. The duration of the backwash procedure is

approximately ten (10) minutes. The frequency of backwashing depends on iron concentration and water usage, and ranges from daily to once every twelve

(12) days.

IMPORTANT NOTE

Due to the aeration process, the water will probably appear milky when drawn from the tap. Allow the water to stand and the air will dissipate.

• Professional Installation Required: Installation requires shutting water off to home, cutting home water supply pipe and using a welding torch

to add piping and fittings. Specialized tools and skills are required.

1-1

IMPORTANT NOTE

SECTION 2: BEFORE INSTALLATION

INSPECTING AND HANDLING YOUR FILTRATION SYSTEM:

Inspect the equipment for shipping damage. If damaged, notify the transportation company and request a damage inspection.

Handle the fi lter unit with care. Damage can result if dropped or if set on sharp, uneven projections on the fl oor. Do not turn the fi lter unit upside down.

MAKE SURE YOUR WATER HAS BEEN THOROUGHLY TESTED:

An analysis of your water should be made prior to the selection of your water conditioning equipment and fi lter media. Enter your water analysis results below

for a permanent record.

IMPORTANT NOTE

Hydrogen sulfi de (H2S) must be tested for at the well site. For accuracy, the sample must be drawn with the pump RUNNING, and the test be completed

within ONE minute after the sample is drawn.

Analysis Of Your Water

Hardness gpg Tannins (Humic Acid) ppm

Iron (Fe) ppm Hydrogen Sulfi de (H2S) ppm

Manganese (Mn) ppm Other ppm

pH ppm

Iron concentrations as low as 0.3 ppm (0.1 ppm under some conditions) will cause staining. The iron concentration, together with the fl ow rate demand and

the consumption rate of the water determines the basic size fi lter system. The higher these factors are, the larger the required system. The APPM Series

Iron Reduction Filtration System is capable of reducing the three main types of iron found in water supplies; Dissolved iron (also known as “clear water” or

ferrous iron), precipitated iron (also known as “red water” or ferric iron) and bacterial iron (also known as iron bacteria). Special care must be taken when

selecting a fi lter model if your water has a combination of high iron, very low pH and/or manganese levels above 0.2 ppm. The MAXIMUM CONCENTRATION

of iron which can be treated with this system is 10 ppm or less. If your water contains higher concentrations, contact your Dealer/Installer or our Customer

Service Department at 1-800-222-7880.

The APPM Series Iron Reduction Filtration System is not bactericidal, i.e. it does not remove or kill “bacterial iron”. It reduces the iron and slime deposits in

your plumbing line and fi xtures upon which the bacteria may live, thus minimizing its effects.

Other ppm

IRON (Fe)

pH

The pH of water is a measurement of Hydrogen Ion concentration in water. Water with a pH of less than 7.0 is acidic, above 7.0 it is base, and a pH of 7.0 is

neutral. The lower the pH value the greater the acidity, and the higher the pH value the more base. Acidic water (pH less than 7.0) is corrosive to pipes, appliances, etc. A pH of 7.0 or higher facilitates iron reduction – which is why the APPM Series Iron Reduction Filtration System is designed to increase the pH

when it is less than 7.0.

The pH increasing component of the media is “sacrifi cial,” that is, it slowly dissolves during the process of increasing pH. The rate this occurs is proportional

to the degree of the pH increase and the water consumption rate (i.e., the greater the pH increase and water consumption, the greater the sacrifi cial rate).

Thus, when the pH is increased to 8.2 or more, as is necessary when manganese is present, the sacrifi cial rate is even greater. Under the most severe conditions, the MpH component of the media may have to be replenished two to four times per year. On the other hand, if the raw water pH is 7.0 or above and no

manganese is present, the sacrifi cial rate is very slight.

HYDROGEN SULFIDE (H2S)

Hydrogen sulfi de (often referred to as “sulfur”), is easily detectable by its objectionable “rotten egg” odor. Sulfur corrodes iron, brass, copper and silver. While the

APPM Iron Reduction Filtration System is not intended to be used as a sulfur fi lter, it is capable of reducing sulfur in concentrations of up to 2 or 3 ppm. Whenever

hydrogen sulfi de is present, backwashing must be performed at more frequent intervals.

CHECK YOUR WATER PRESSURE AND PUMPING RATE:

To avoid unsatisfactory operation or equipment damage, the following system condition must be carefully checked.

WATER PRESSURE

Low _____ psi High _____ psi

The pumping rate of your well pump must be suffi cient to BACKWASH the fi lter. To measure the pumping rate of your pump, follow these instructions:

1. Make certain no water is being drawn. Open spigot nearest pressure tank. When pump starts, close spigot and measure time (in seconds) to refi ll pres-

2-1

sure tank (when pump shuts off). This fi gure represents CYCLE TIME.

IMPORTANT NOTE

IMPORTANT NOTE

2. With the pressure tank full, draw water into a container of known volume, measure the number of gallons drawn until the pump starts again. This is

DRAW-DOWN. Divide this fi gure by CYCLE TIME and multiply the result by 60 to arrive at the PUMPING RATE in gallons per minute (gpm). To aid in your

calculation, insert the data in the following formula:

DRAW-DOWN _____ ÷ CYCLE TIME _____ x 60 = PUMPING RATE _____

(gals.) (secs.) (gpm)

EXAMPLE: CYCLE TIME is 63 secs.; DRAW-DOWN is 8 gals.; then PUMPING RATE equals: 8 gals. ÷ 63 secs. x 60 = 7.6 gpm

IMPORTANT NOTE

The addition of other water treatment devices (such as an acid neutralizer) may reduce the fl ow rate at the fi lter drain to an inadequate level to properly

backwash the fi lter. If you are uncertain whether your fl ow rate is adequate, contact your Dealer/Installer or our Customer Service Department at 1-800222-7880 BEFORE installing the APPM Series Iron Reduction Filtration System, so that corrective action, if required, may be taken.

LOCATE WATER CONDITIONING EQUIPMENT CORRECTLY:

Select the location of your media tank with care. Various conditions which contribute to proper location are as follows:

1) Locate as close as possible to water supply source.

2) Locate as close as possible to a fl oor or laundry tub drain.

3) Locate in correct relationship to other water conditioning equipment (See Figure 1, in Section 3).

4) Filtration systems and softeners (if applicable) should be located in the supply line BEFORE the water heater. Temperatures above 110°F (43.3°C) damage

fi lters and softeners and will void the factory warranty.

5) Do NOT install a fi ltration system or softener (if applicable) in a location where freezing temperatures occur. Freezing may cause permanent damage to

this type of equipment and will also void the factory warranty.

6) Allow suffi cient space around the unit for easy servicing.

7) If your water source is a community water supply, a public water supply, OR you wish to bypass water used for a geothermal heat pump, lawn sprinkling, out

buildings or other high demand applications, the purchase of an FS1 Flow Switch is suggested. Instructions accompanying the fl ow switch will describe the

proper installation for these types of applications.

THE IMPORTANCE OF YOUR PRESSURE TANK:

The APPM Series Iron Reduction Filtration System will perform satisfactorily with either a captive-air (“bladder”) type pressure tank or a standard air-to-water

type with an air volume control (air-relief valve).

A PROPERLY SIZED PRESSURE TANK OF EITHER STYLE WILL REQUIRE A MINIMUM PUMP CYCLE OF 60 SECONDS TO REFILL FROM THE WELL PUMP ON-TO-OFF

PRESSURE SETTINGS.

IMPORTANT NOTE

If your pressure tank (or any part of your water system) is not functioning properly, corrective action MUST be taken BEFORE installation of the APPM

Series Iron Reduction Filtration System.

FACTS TO REMEMBER WHILE PLANNING THE INSTALLATION:

WARNING

To reduce the risk associated with a hazardous voltage:

• If the home electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient ground connection across the fi lter installation piping — refer installation to qualifi ed personnel.

• Do not use the system if the power cord is damaged — contact qualifi ed service personnel for repair.

If lawn sprinkling, geothermal heating/cooling or water for other devices/activities are to be treated by the fi lter, a larger model fi lter MUST be selected to

accommodate the higher demands of these items. The pumping rate of the well pump must be suffi cient to accommodate these items plus the backwashing

requirement of the softener. Consult your Dealer/Installer or our Customer Service Department at 1-800-222-7880 for alternative instructions if the pumping

rate is insuffi cient.

Remember that the fi lter INLET is attached to the pipe that supplies water (i.e. runs to the pump) and OUTLET is the line that runs toward the water heater

or other water treatment equipment device.

Before commencing the installation, it is advisable to study the existing piping system and to determine the size, number and type of fi ttings required. Typical

system schematics shown in Figure 1 will be of assistance (page 3-1).

2-2

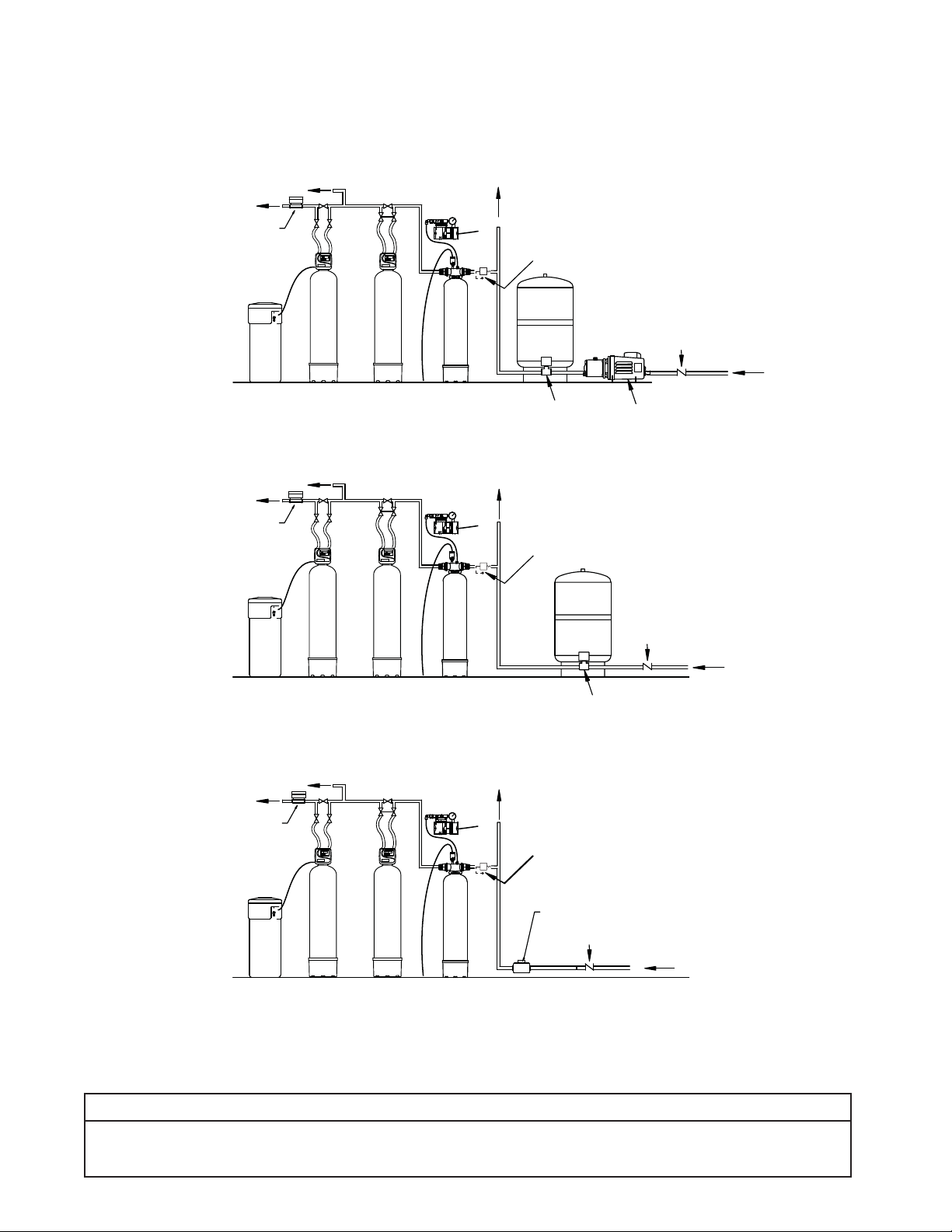

FILTERED WATER

CAUTION

FILTERED

SOFT WATER

FS1 FLOW SWITCH

BRINE

TANK

FILTERED WATER

FILTERED

SOFT WATER

FS1 FLOW SWITCH

SECTION 3: INSTALLATION

Proper installation sequence of water conditioning equipment is very important.

Refer to the diagram following for your particular water supply.

TYPICAL INSTALLATION

UNTREATED

WATER

PRESSURE

REGULATOR

(NOT SUPPLIED)

PRESSURE

TANK

AERATION

TANK

PRESSURE

SWITCH

SPLIT STREAM INSTALLATION

UNTREATED

WATER

PRESSURE

REGULATOR

(NOT SUPPLIED)

CHECK VALVE

PUMP

RAW

WATER

BRINE

TANK

FILTERED WATER

FILTERED

SOFT WATER

FS1 FLOW SWITCH

BRINE

TANK

SOFTENER

(OPTIONAL)

SOFTENER

(OPTIONAL)

PRESSURE

TANK

IRON

REDUCTION

FILTRATION

SYSTEM

AERATION

TANK

PUBLIC WATER SUPPLY INSTALLATION

UNTREATED

WATER

PRESSURE

REGULATOR

(NOT SUPPLIED)

METER

CHECK VALVE

IRON

REDUCTION

FILTRATION

SYSTEM

AERATION

TANK

CHECK VALVE

PRESSURE

SWITCH

RAW

WATER

RAW

WATER

FIGURE 1

CAUTION

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water

treatment equipment products will vary depending on the control valve brand used.

3-1

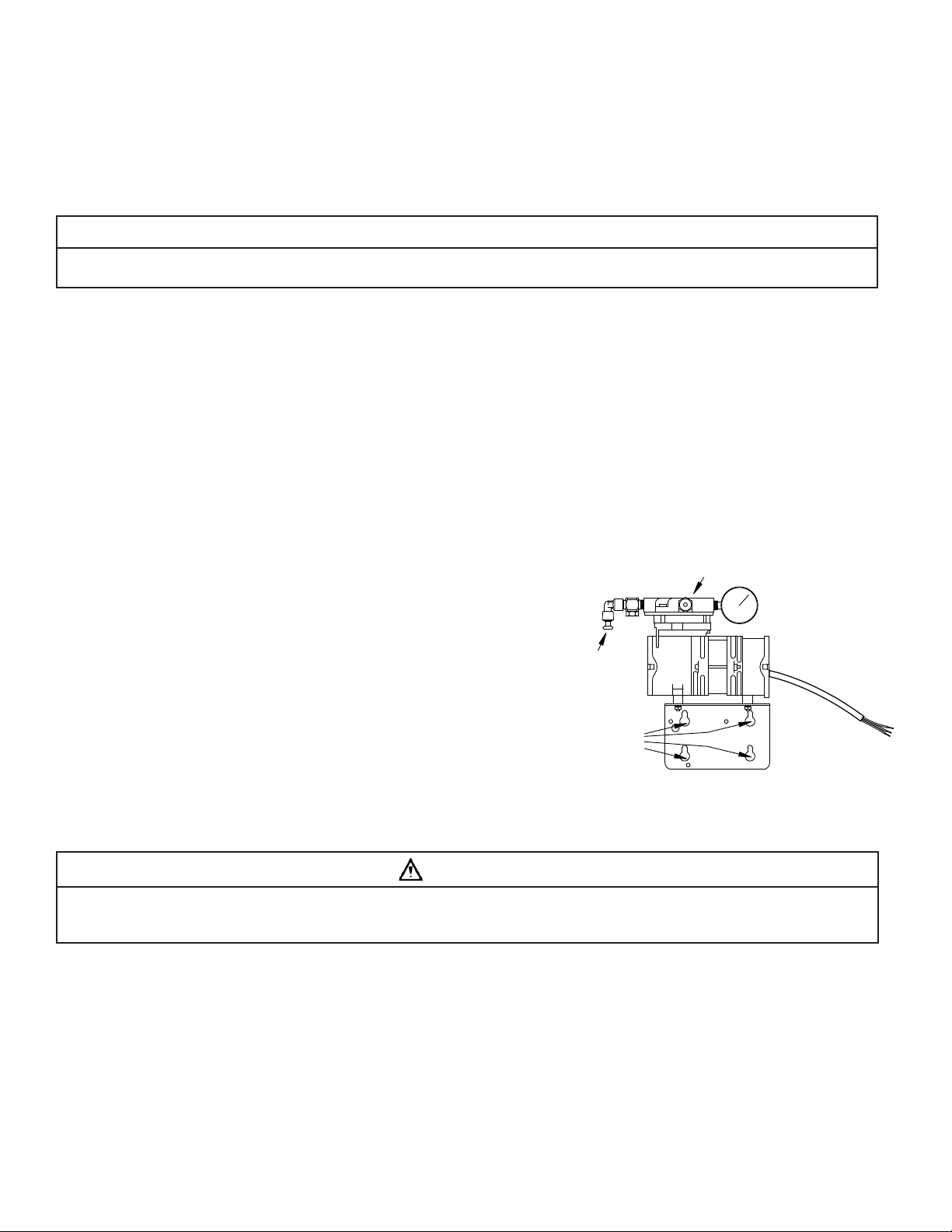

MOUNTING & SET-UP INSTRUCTIONS FOR GAST LOA-P109-AA COMPRESSOR UNIT

Prior to using the system, some assembly and adjustments are required. Please locate these parts and ensure all items are present. These items are required to

mount and set-up the GAST LOA-P109-AA Compressor assembly as well as to connect the tubing to the GAST LOA-P109-AA Compressor and aeration tank.

• GAST LOA-P109-AA Compressor/Bracket Assembly

• RETROFIT KIT

• 1/4” Polyethylene Tubing (10 feet)

• A4FE4-MG (1/4” NPT x 1/4” Quick Connect Elbow)

IMPORTANT NOTE

This product includes a GAST® component. Refer to the GAST’s website @ www.gastmfg.com for their instruction and operation manual for detailed

instructions and safety information related to Model # LOA-P109-AA Oil-less Compressor.

How It Works:

When the GAST LOA-P109-AA Compressor is running, it injects air into the water which causes iron to precipitate. The precipitated iron is then fi ltered as it

passes through the APPM Iron Reduction Filtration System. There are two ways to turn the GAST LOA-P109-AA Compressor on.

1. For Private Water Well Systems — The GAST LOA-P109-AA Compressor can be wired to either a pressure switch in the water well system or a fl ow switch

installed in the service side of the iron reduction fi ltration system. The GAST LOA-P109-AA Compressor is activated on a standard well pump system by

a pressure switch that senses pressure in the water line. When the preset low pressure side of the switch is met, the GAST LOA-P109-AA Compressor is

turned on and will continue to run until the high pressure setting is reached, at which time the GAST LOA-P109-AA Compressor is turned off. On a fl ow

switch application the GAST LOA-P109-AA Compressor is wired into the fl ow switch and is energized when water fl ows through the fl ow switch and turns

on the GAST LOA-P109-AA Compressor. The GAST LOA-P109-AA Compressor will continue to run until water fl ow in no longer detected.

2. For Split Stream or Public Water Supply – An FS1 Flow Switch (sold separately) is installed in the service line and turns on the GAST LOA-P109-AA

Compressor when water fl ow exceeds 0.5 gpm. See Page 3-1 for installation diagram.

GAST LOA-P109-AA Compressor Mounting Instructions:

1. Locate the GAST LOA-P109-AA Compressor/Bracket Assembly within six (6) feet of the aeration tank.

2. Thread A4FE4-MG onto the brass check valve located on the compressor. The

quick connect end of the elbow should already be plugged with a Plug00007.

Keep the plug installed to set the air release fi tting. Fitting should point to the

fl oor as shown in Figure 2.

3. The mounting bracket should be mounted on a surface that will support vibration, preferably to studs or a concrete wall. The installer must choose and

supply the appropriate fastener for mounting the bracket to the wall.

4. When using the FS1 Flow Switch, the power supply must be connected to a

dedicated 110 VAC, minimum 15 amps, 60 Hz. Power supply. Follow NEC and/

or all relevant codes for your area.

5. If the system is being serviced, insert the Plug00007 plug found in the RETROFIT KIT into the quick connect fi tting on top of the air release tank head

to set the air release fi tting. This is the only component of the RETROFIT KIT

you will use.

A4FE4-MG

MOUNTING HOLES

LOCATE CORRESPONDING

HOLES ON VALVE

AIR RELEASE FITTING

Figure 2

GAST LOA-P109-AA

Compressor

Wiring Instructions:

WARNING

To reduce the risk associated with hazardous voltage:

• Disconnect line circuit power before wiring the switch and compressor. Consult a licensed electrician for correct and safe connection of the fl ow

switch and GAST LOA-P109-AA Compressor to the home electrical system.

1. For Well Systems – The GAST LOA-P109-AA Compressor can be wired to run in parallel to the well pump pressure switch. The air compressor runs on

110 VAC and has a standard 3 wire connection (black, white, and green wires). The leads of the GAST LOA-P109-AA Compressor must be made on the

well pump motor contacts. All contacts must be made in accordance with NEC and local codes and standards. Use a licensed electrician to perform this

task to ensure safety and correctness.

2. For Use With A Flow Switch – An FS1 Flow Switch should be installed in the service line after all water treatment equipment (e.g. APPM Iron Reduction

Filtration System, etc.). The FS1 plumbing connection is 1” PVC socket (solvent weld) and must be installed horizontally and the top in an upright position

or it will not function correctly. Make sure the direction of water fl ow matches the arrows on the FS1 Flow Switch..

The FS1 comes with a power cord installed, but the GAST LOA-P109-AA Compressor power cord must be connected to the fl ow switch in order to operate.

The GAST LOA-P109-AA Compressor must be wired to run when water fl ow is detected in the treated water line. The electrical leads must be fed through

the strain relief on the fl ow switch and attached to the wire leads provided on the micro switch under the cover of the fl ow switch. Follow the instructions

provided by the manufacturer of the fl ow switch. The fl ow switched power cord must be plugged into a 110 volt, 60 hertz circuit with a minimum 15 amp

rating on a non-switched electrical outlet. A licensed electrician must perform the wiring needs for this application to ensure the electrical connections

are made in accordance with the NEC and local codes and standards.

3-2

IMPORTANT NOTE

It is suggested that a licensed electrician perform the wiring needs for this application to ensure the electrical connections are made in accordance

with the NEC and local codes and standards.

FS1 Specifi cations: Compressor Specifi cations

a. 15 Amp Max @ 110 VAC a. 120 VAC

b. 0.5 gpm minimum actuation fl ow b. 1/16 HP

c. 110˚ F maximum temperature c. 0.05 KW

d. 1575 RPM (@ 60Hz)

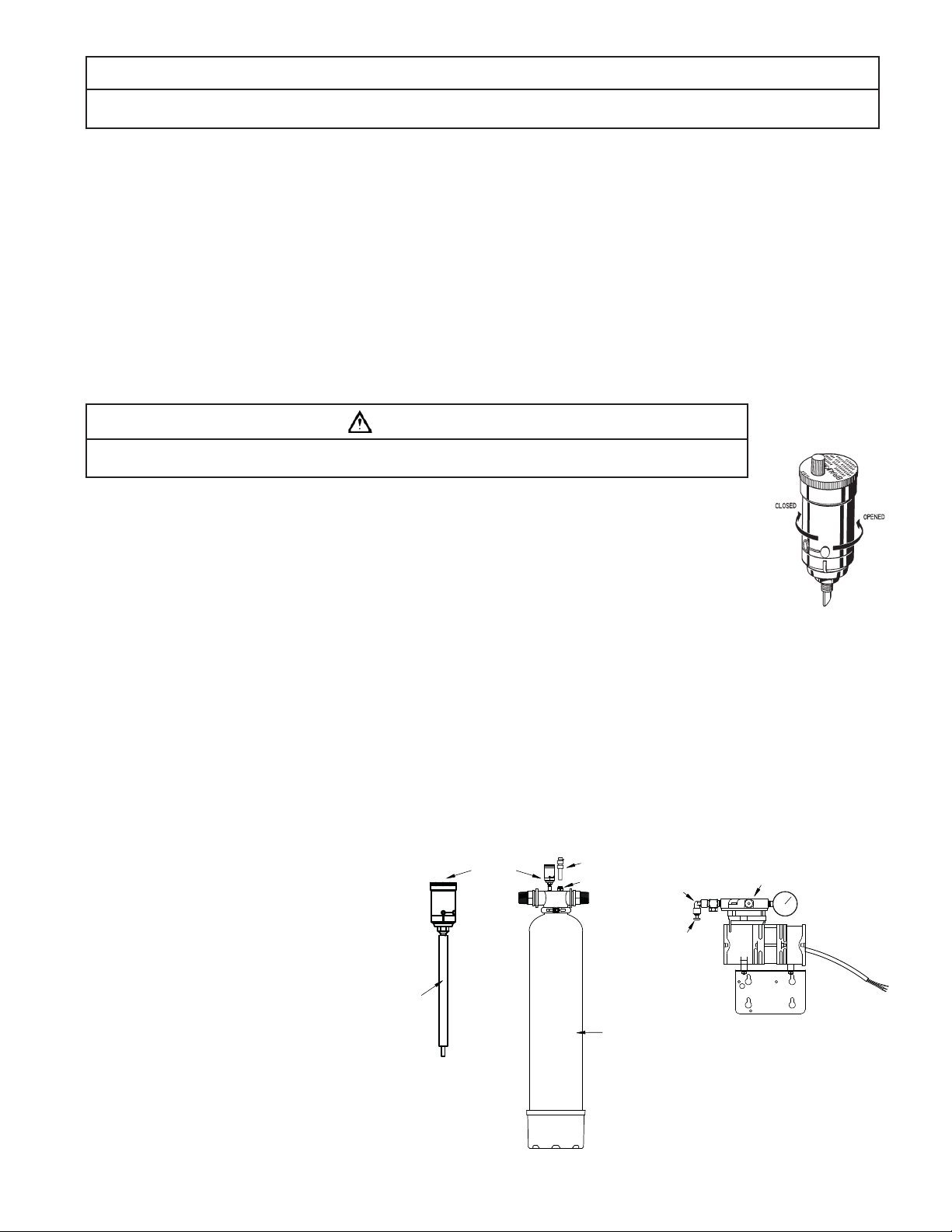

GAST LOA-P109-AA Compressor Set-Up:

1. Screw assembly ARVTA-1X into the 1/4” threaded hole on top of air release tank in the tank head. Attach the 3/8” polyethylene tubing to the top of the

air release valve. To be able to do so remove the red cap and slip tubing over the threaded boss of the air release valve. The ARTVA-1X assembly can be

found in its own box in the aeration tank shipping box. This tubing needs to be run to a waste drain to accommodate water that may be expelled during

the venting cycles. It is recommended to keep the tubing as short as possible to ensure proper performance in venting air and water correctly. Ensure the

air release valve is open by examining the side of the air release valve (see Figure 3). It should always remain open.

WARNING

To reduce the risk of physical injury:

• Do not operate system with air release valve (ARVTA-1X) in the closed position.

2. The air release fi tting requires adjustment before the system is operational. Your water system operating pressure range

needs to be determined to allow for adjustment of the air release valve. This can be performed by observing the pressure

gauge on your pressure tank while the well pump is running. If you are on a municipal, community or constant pressure /

variable speed pump observe the pressure in the water system on the water line.

3. Locate and install the MAXRETRO kit into the quick connect check valve on the air release tank prior to adjusting the air

release valve mounted on the air compressor, see Figure 4. If you’re replacing the compressor on an older style system with

threaded nut fi ttings, cut the 1/4” polyethylene tubing about 2 inches above the nut. Care needs to be taken to ensure the

tubing is cut square and clean. Remove the 1/4” polyethylene from the MAXRETRO kit and slide the union connector onto the

1/4” polyethylene tubing left in the threaded nut, see Figure 4. NOTE: Relive any pressure from the aeration tank before cutting the tubing.

4. Connect the GAST LOA-P109-AA Compressor to either the pressure switch or fl ow switch; please note the compressor is rated for 110 VAC, minimum

15 amps, 60 cycles. Be sure the plug is installed in the Compressor Assembly as shown in Figure 4 during this step. Start the GAST LOA-P109-AA

Compressor. by running water down stream of the pressure tank or fl ow switch. Open the brass air release mechanism on the side of the compressor.

Control the setting by turning the adjustment nut in or out to set the operating pressure of the GAST LOA-P109-AA Compressor. The correct adjustment

would be when the pressure gauge maintains a pressure of 10 to 15 pounds less than the shut off pressure of the water system. Once the adjustment

is correct, lock the setting by tightening the second nut on the air release mechanism to secure the setting.

5. Once the air release mechanism is adjusted, turn off the GAST LOA-P109-AA Compressor, relieve pressure on the air release tank by opening the air

release valve. Remove the plug from the quick release elbow on the air compressor and the MAXRETRO fi tting on air release tank. Connect the 1/4”

polyethylene tubing between the two quick connect fi ttings. Ensure the tubing is seated correctly into the quick connect fi ttings. The MAXRETRO will

need to stay in place if you are replacing the compressor on an older style system. In this case, just remove the plug from the MAXRETRO kit.

6. Pressurize the water system and check for leaks, correct

as needed.

Please visit GAST’s website @ www.gastmfg.com for their instruction manual and additional information

(http://www.gastmfg.com/pdf/OM/saa_soa_RP_OM.pdf)

AIR RELEASE VALVE

MAXRETRO

QUICK CONNECT

CHECK VALVE

QUICK CONNECT

FITTING

PLUG

AIR RELEASE FITTING

Figure 3

ARVTA-1X

AERATION TANK

Figure 4

3-3

SYSTEM AND PLUMBING SET-UP INSTRUCTIONS

CAUTION

IMPORTANT NOTES

CAUTION

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Installation must comply with existing state or local plumbing codes, even if they are contrary to our instructions.

• Do not use a torch or other high temperature sources near fi lter system, cartridges, plastic fi ttings or plastic plumbing.

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic.

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

IMPORTANT NOTES

• Damage due to heat is not covered under the manufacturer’s warranty and will void the warranty.

• The use of fl exible drain lines are prohibited in some states, check with your local code offi cer for requirements. Distance and height affects the

performance of the drain line to discharge at the proper rate to effectively backwash the fi lter media. The following are guidelines for drain line size

installation. Do not bend the drain line too sharply if using fl exible tubing. Secure the drain line over the discharge line to prevent splashing or blow

out during regeneration. Do not use garden hose or vinyl tubing as a drain line as this may cause a failure to regenerate properly.

Step 1

Inspect and open factory sealed box to ensure all components required for installation are present. If media was ordered, verify the amount and type of

fi lter media (ordered separately) is correct. (See Section 6, page 6-2.)

Step 2

Remove fi ltration system from shipping carton and inspect to ensure there is no damage to product from shipping. Inspect any packing for components that

have been attached for shipping before discarding. If any items intended for installation are missing at this time contact your Dealer/Installer or our Customer

Service Department at 1-800-222-7880 to notify them of this situation. Provide the model number and serial number when contacting Customer Service.

Step 3

Threaded Tank Models: APPM100, APPM150, APPM200, APPM100M, APPM150M, APPM200M: Follow the steps to center the distributor tube and load the

fi lter media into the media tank for successful installation of the APPM Iron Reduction Filtration System.

a. Remove the control valve from the media tank by rotating the valve head assembly to the left (counter-clockwise) and set aside to reassemble after

media is loaded into tank.

b. Tilt media tank to a 45 degree angle until gravel shifts to the side of the tank and dimple at bottom of media tank is visible. This will allow you to

place the distributor tube basket assembly in the dimple on the bottom of the media tank.

c. Place media tank back in upright position and ensure gravel at the bottom of the media tank is level. Place red plastic cap on the distributor tube

that is provided in the parts bag.

d. Locate the fi lter media that will be used in the iron reduction fi lter and load into the media tank. Note: fi ll only to the labeled line on the outside of

the media tank. Refer to Section 6 Specifi cation and Operating Data, page 6-1, for the correct quantity for your fi lter system. Use a clean rag to wipe

the opening of the media tank to remove any dust or sediment before moving to the next step.

Dome Hole Tank Models: APPM100DM, APPM100MDM, APPM150DM, APPM150MDM, APPM200DM, APPM200MDM:

a. Add media through fi llport cap located on tank using funnel (See FILLING MEDIA TANK below). Fillport cap can be removed by turning a quarter turn

counter clockwise.

CAUTION

To reduce the risk associated with skin, eye, and respiratory tract irritation from dust

from fi lter media during installation:

• Gravel and several types of fi lter media may be used in this product, depending upon the

application. During installation, dust may cause irritation to skin, eyes, and respiratory tract,

and may affect lungs.

• Utilize a NIOSH-approved dust fi lter mask and appropriate eye protection when handling and

pouring gravel and fi lter media.

• To request an MSDS relating to this product, call 203-238-8965 or go to www.3M.com ,

select country, and use the search engine to search MSDS. For emergencies, call 800-364-

3577 or 651-737-6501 (24 hours).

b. Reinstall fi llport cap by turning a quarter turn clockwise.

c. If bypass valve assembly is not factory pre-installed, attach using clips and screws.

d. Using a clean dry rag, wipe the opening of the media tank to remove any dust or residue from the opening to receive the control valve. Attach the

valve head to the media tank by rotating the valve head assembly to the right (clockwise).

3-4

FILLING MEDIA TANK

Loading...

Loading...