Page 1

OWNER’S MANUAL

!!PLEASE NOTE!!

THIS MANUAL MUST BE GIVEN

TO THE HOMEOWNER TO ENSURE

WARRANTY COVERAGE

Aqua Comfort Technologies, LLC - "ACT"

P.O. Box 1520, Sykesville, MD 21784-1520

Tel: (410) 549-6083 / Fax: (410) 549-6082

www.myheatedpool.com

Models: AC-4000 and AC-6000

Page 2

TABLE OF CONTENTS

WELCOME

Safety First................................................................................................................................................ 3

INSTALLATION

General .....................................................................................................................................................

Cell............................................................................................................................................................

Flow Sensor..............................................................................................................................................

Control Box ............................................................................................................................................... 6

Wiring........................................................................................................................................................

STARTUP

**Before Adding Salt/Minerals ..................................................................................................................

Adding Salt ...............................................................................................................................................

How Much Salt to Add .............................................................................................................................

4

5

5

7

10

11

11

**Note: There are many types of acceptable Salts, some which contain other minerals and additives to

improve their quality and performance. Your pool professional will direct you to the right choice for you. For

the purposes of this manual the term salt when used in this manual will refer to any of these choices.

OPERATION

Background & Basic Operation ................................................................................................................

Controls ....................................................................................................................................................

Maintenance / Cleaning............................................................................................................................

Understanding the Chemistry ...................................................................................................................

Saturation Index........................................................................................................................................ 19

TROUBLESHOOTING

Troubleshooting........................................................................................................................................

12

13

15

17

20

WARRANTY

Warranty & Registration ...........................................................................................................................

23

2

Page 3

WELCOME

Congratulations on the purchase of your new Auto-Chlor Chlorine Generator. Your purchase will minimize the

efforts needed to maintain your pool and maximize your enjoyment for many years. Before installation or

operation, please read these instructions carefully. This manual contains easy to follow step-by-step

procedures to properly install and operate your system. A little time spent understanding your system and its

parts will assure successful, trouble-free installation and usage. When working around your pool, please take

care to avoid hazards such as electrical wires and chemicals. CAUTION! Safety comes first!

WARNING SAFETY FIRST

READ AND FOLLOW ALL INSTRUCTIONS

All electrical work must be performed by a licensed electrician and conform to all national, state, and local

codes. When installing and using this electrical equipment, basic safety precautions should always be

followed, including the following:

• DO NOT OPEN THE GENERATOR BOX – NOT A SERVICABLE UNIT

• Disconnect all AC power before installation.

• WARNING – To reduce the risk of injury, do not permit children to use this product.

• The Control Box must be mounted vertically on a flat surface and a minimum of 5 ft (1.5m) horizontal

distance (or more, if local codes require) from the pool/spa.

• In Canada and some other regions, local codes require the unit be connected only to a circuit that is

protected by a ground-fault circuit-interrupter (GFCI). The installer should provide this GFCI

requirement. The GFCI should be tested on a regular basis by pushing the test button. If the GFCI

fails to operate correctly, there is ground current flowing indicating the possibility of an electric shock.

Do not use this unit. Disconnect unit and have a qualified professional correct the problem before

using.

• The power cable must be hardwired to the time clock so that the system cannot operate without the

pump.

• A build-up of flammable fumes can result in a hazardous condition if the Cell is allowed to operate

without flow. This machine must be operated only with an approved in-line flow sensor.

• The Flow Sensor must be installed between the last piece of apparatus and the Cell,

upstream of the cell

• ALWAYS ADD ACID TO WATER, NEVER WATER TO ACID.

• SAVE THESE INSTRUCTIONS.

3

Page 4

INSTALLATION INSTRUCTIONS

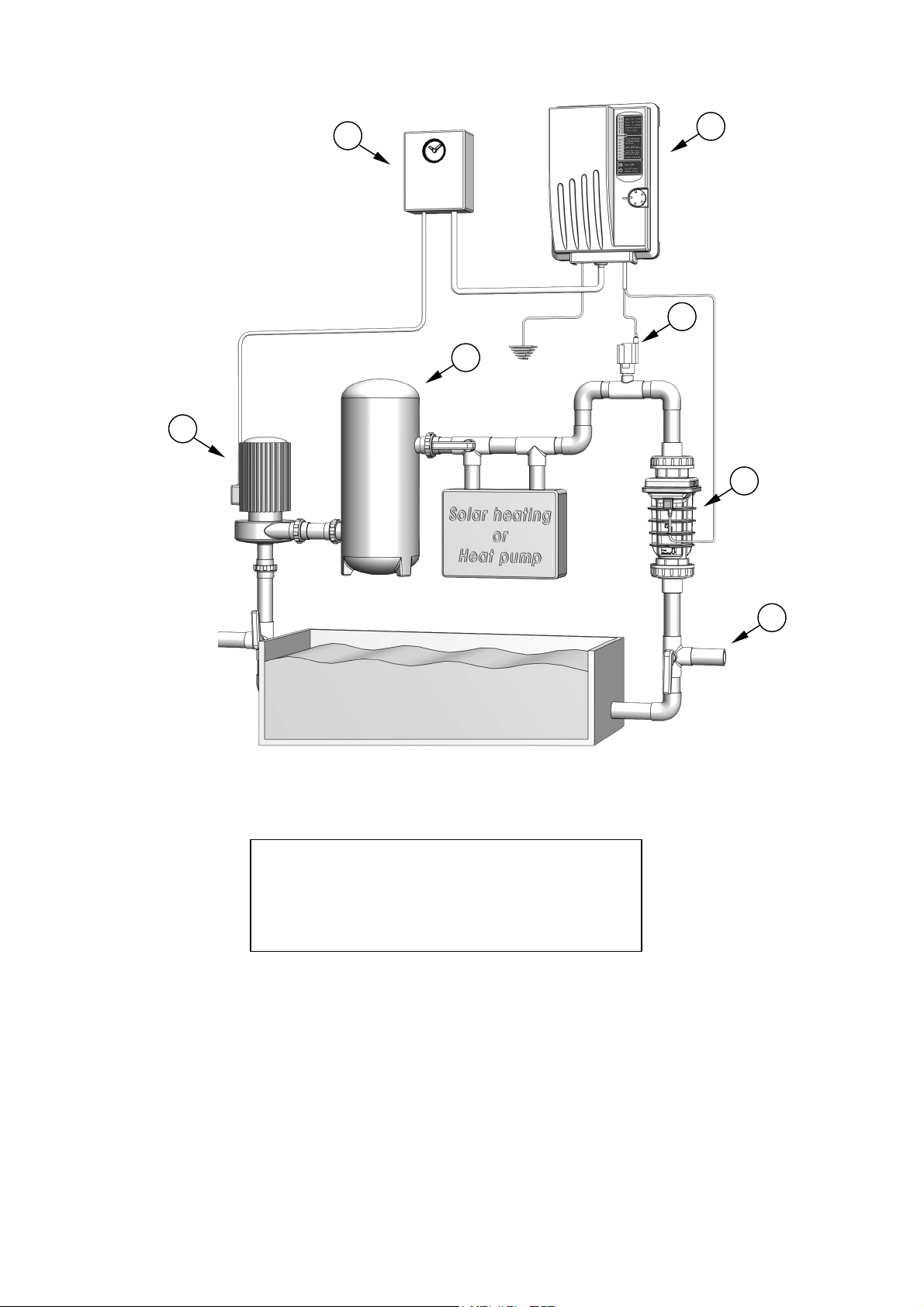

3 56 2

7

4

1

1. Control Box

2. Cell

3. Flow switch

4. Power / Timer

5. Filter

6. Pump

7. Spa line

The system comes in three sections, the Control Box, Cell and Flow Sensor. They are manufactured from the

latest corrosion resistant materials to give you years of trouble free use, and installing them in the most

sheltered position from sun and water will protect them from extreme weather conditions for years to come.

Safety Measures

1. Only operate the system with an approved flow sensor.

2. See safety measures and warnings on page 2 of this manual.

Additional Materials Required

1. PVC solvent cement and priming fluid 6. WD-40

2. Hacksaw or pipe cutters 7. Silicone Sealant (NO NOT USE silicone glue or

3. Screwdrivers petroleum jelly).

4. Drill 8. Pipe adaptors (i.e. reducer couplings) if

5. Teflon Tape (a.k.a. Plumber’s Tape) needed for systems with 1 ½ inch plumbing

4

Page 5

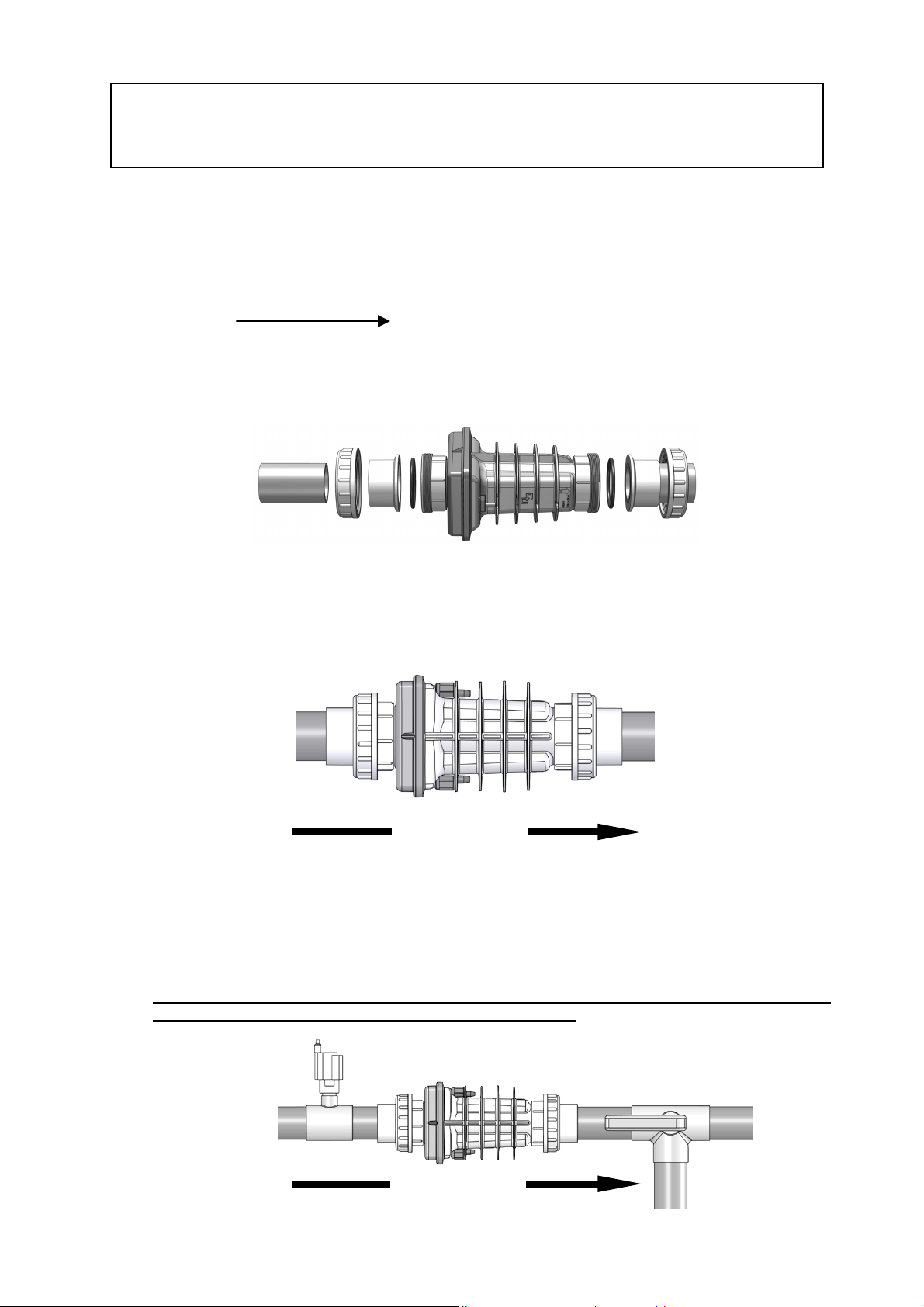

CONFIRM LAYOUT: Lay out equipment pieces to be sure there is enough pipe space

between the last piece of apparatus and the tees in the return line to fit the Flow Sensor and

the Cell. A Vertical installation may be used to save space (see diagrams above).

Install the Cell

1. The Cell and Flow Sensor must be installed downstream from the filter and heating devices but before

any tees in the return line. The Cell may be installed horizontally or vertically so long as the Cell is

pointed in the direction of flow and is installed immediately after the enclosed Flow Sensor (see

diagram above).

2. Approximately 15 inches (~380 mm) of available pipe length will be needed for horizontal installations

of the Flow Sensor and Cell. Vertical installations can be made to take less space.

3. On the pipe where the cell will be installed, mark two lines 11 3/4 inches (300mm) apart and cut out

using hacksaw or pipe cutters.

4. Unscrew and remove the barrel unions (i.e. barrel nuts and slip connections) from either end of the

Cell. Thread one of the barrel nuts over the pipe and glue its slip connection to the cut pipe.

5. Hold up the Cell with the second union to gauge the proper distance before threading the second nut

and gluing the second slip.

6. After the glue had sufficient drying time, place the Cell with the o-rings into the opening between the

two ends of the pipe and tighten the unions making sure that the Cell is installed with the arrow

pointing in the same direction as the flow (i.e. water should enter from the side with the blue cap).

Flow direction

Install the Flow Sensor

1. Install the Flow Sensor between the last piece of apparatus and the Cell (if installed after the Cell,

damage to the sensor may result). When possible, install on a horizontal pipe.

2. Mark two lines on the pipe 3 inches (~76 mm) apart and cut with a hacksaw or pipe cutters.

3. Clean and glue the “T” connector (included) to the pipe making sure that the threaded end with the

sensor is on the topside of the pipe.

4. Be sure the arrow on the top of the Flow Sensor is pointing in the direction of flow, and that no glue

touches the paddle inside the sensor as it may cause it to jam.

Flow direction

5

Page 6

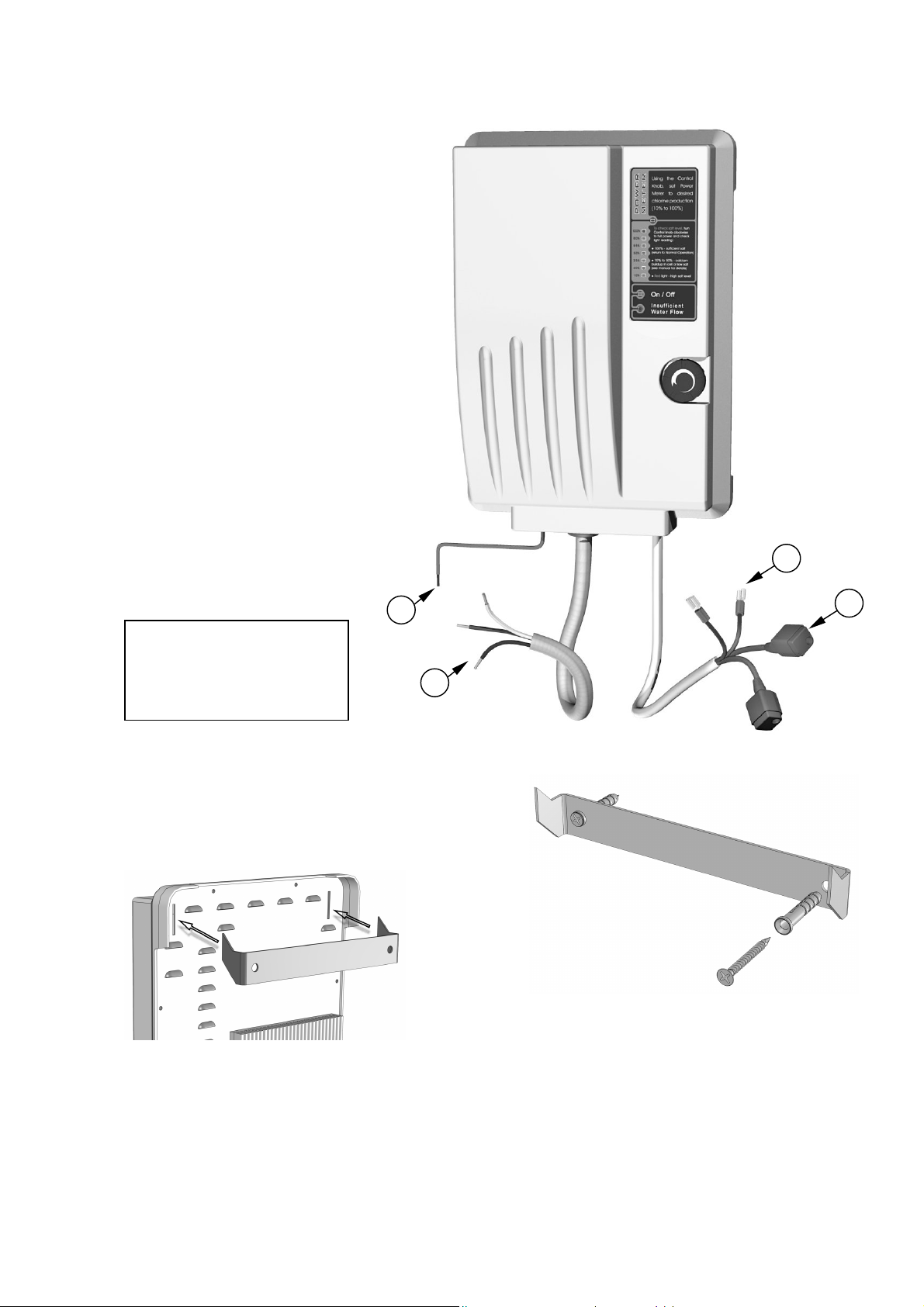

Mount the Control Box

3

2

1. The Control Box must be mounted

vertically on a flat surface and a

minimum of 5 ft (1.5m) horizontal

distance (or more, if local codes

require) from the pool/spa.

2. Locate a position for your Control

Box within 10 ft (3½ meters) of

where the Cell will be installed and

within 2 ft of the power supply to

ensure enough wire is available.

3. Because the box acts as a heat sink

dispersing heat from inside the box,

do not block the four sides of the

Control Box. Do Not mount the

system inside a panel or tight

enclosed area.

1. Flow sensor connectors

2. Cell connectors

3. Bonding

4. Power Cord

4. Secure the hanging rack on the wall

using the enclosed screws and anchors. 1/4” (8mm)

drill bit should be used for the anchor holes.

5. Hang the Control Box on the mounted hanging rack.

4

1

6. Hardwire the power cable to the time clock as indicated in the instructions below. *Check the label on

the side of the Control Box for the proper voltage specification on your system (i.e. 120v or 240v).

7. Do not extend the cable leading to the cell. This decreases the system’s efficiency and will void

warranty coverage. Please contact the manufacturer for installations demanding a longer cell cable.

6

Page 7

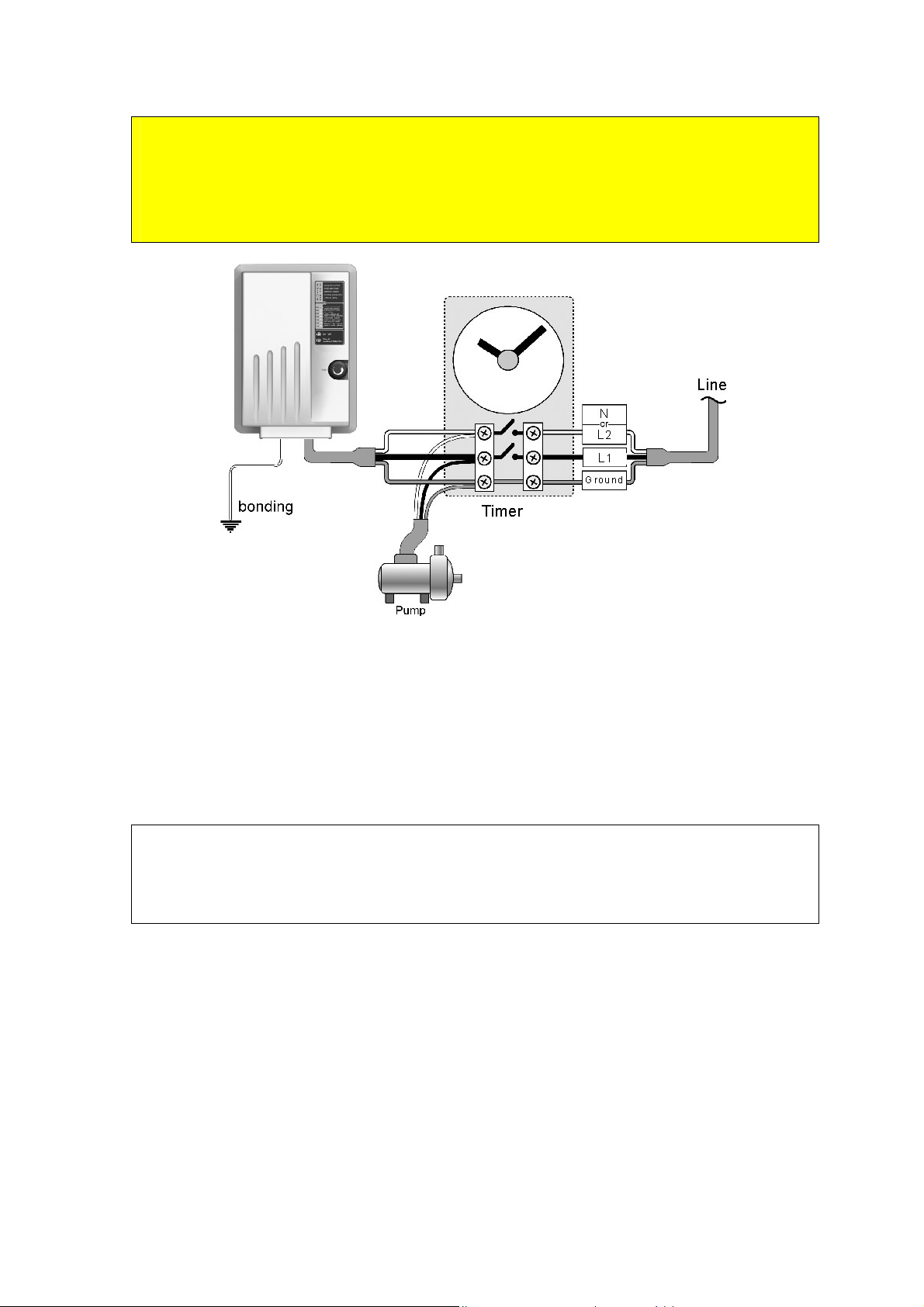

Wiring the Control Box to Standard Timer

CAUTION: Check whether your chlorine generator operates on 120 volts or 240 volts

(see label on the left side of the Control Box), and be sure to wire the system accordingly.

CAUTION: It is critical to wire the chlorine generator in such a way that it can only

operate when the pump is operating (i.e. load side). See instructions below for details.

1. Attach the green ground wire to the grounding lug or bar.

2. Connect the black Load wire from the chlorine generator to Load 1 of the time clock.

3. If wiring a 240 Volt generator, connect the third wire to Load 2 of the time clock. If wiring a 120 Volt

generator, connect the third wire to the Neutral lug or bar on the timer (see label on the left side of the

Control Box to confirm voltage).

4. Bonding is recommended and may be required by local code. The bonding lug is found on the bottom

of the Control Box.

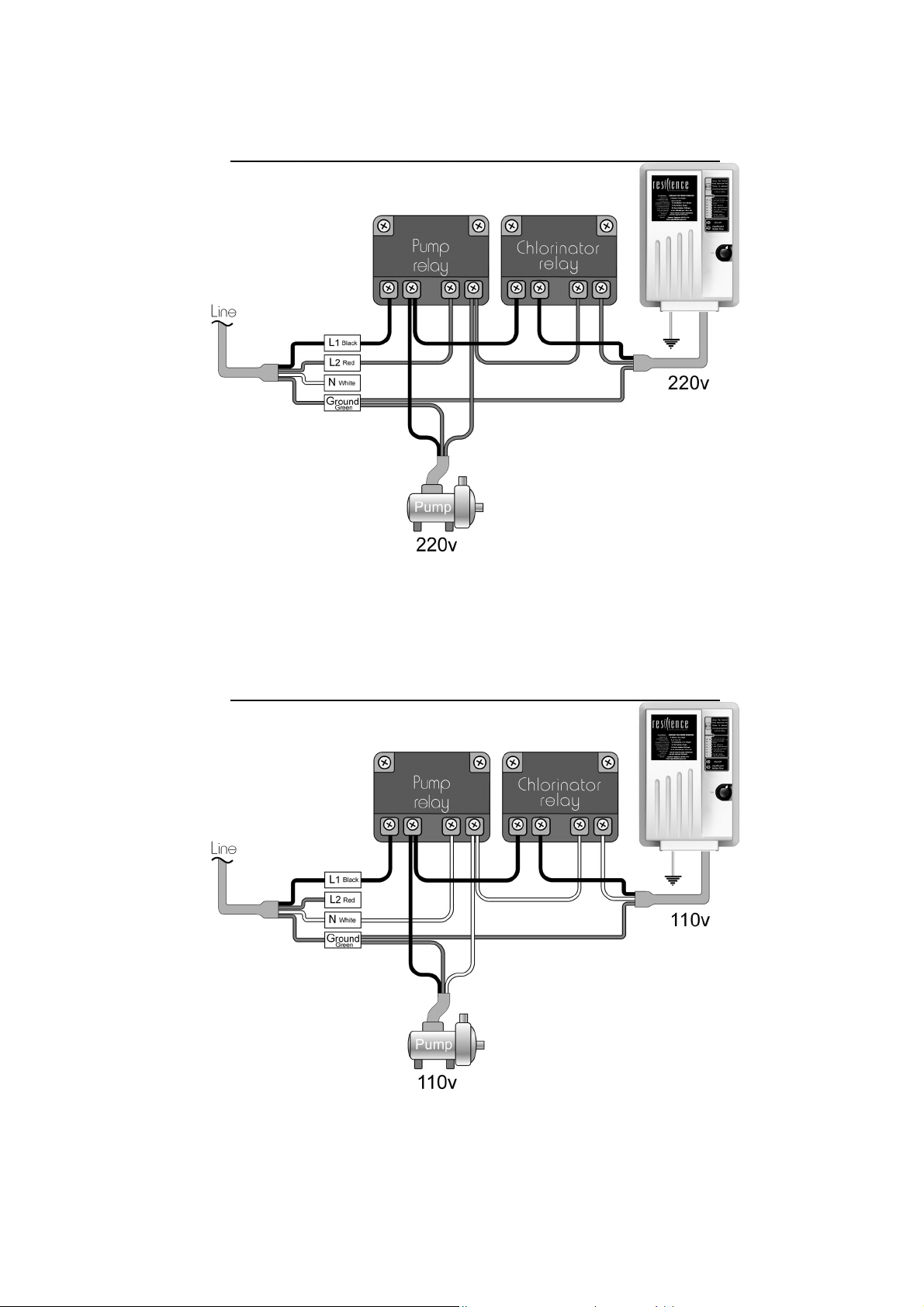

Wiring the Control Box to Automated Systems

CAUTION: Check whether your chlorine generator operates on 120 volts or 240 volts

(see label on the left side of the Control Box), and be sure to wire the system accordingly.

CAUTION: It is critical to wire the chlorine generator in such a way that it can only

operate when the pump is operating (i.e. load side). See instructions below for details.

The Auto-Chlor Chlorine Generator can operate with virtually any automated control system as an auxiliary.

1. Attach the green ground wire to the grounding lug or bar.

2. Connect jumper wires from the Load side of the Circulation Pump Relay to the Line side of an

Auxiliary Relay as depicted in the relevant diagram below (based on the voltage used by the

pump and the chlorine generator) and in accordance with instructions of the automatic

controller manufacturer.

3. Connect the Auto-Chlor Chlorine Generator to the Load 1 & 2 connectors of the Auxiliary

Relay to control the generator’s operation.

4. Bonding is recommended and may be required by local code. The bonding lug is found on

the bottom of the Control Box.

5. Set the chlorine generator to 100% power, and program the Aux Relay to run the chlorine

generator as needed. (e.g. 100%, 50%, 25% of the time the pump is running).

7

Page 8

240Volt Circulation Pump With 240 Volt Chlorine Generator

120Volt Circulation Pump With 120 Volt Chlorine Generator

8

Page 9

220Volt Circulation Pump With 220 Volt Chlorine Generator

120Volt Circulation Pump With 240 Volt Chlorine Generator

A 240 Volt Chlorine Generator may NOT be connected to a system with a 120 Volt circulation pump.

Wiring the Cell

Connect the two black wires from the Control Box to the two metal studs on the sides of the Cell and tighten

firmly with a screwdriver by hand. To avoid damage to the screws, DO NOT use a power screwdriver. Note

these wires are interchangeable. Push the plastic terminal covers up to cover the terminal connection until

they click into place. This will ensure a watertight connection.

Wiring the Flow Sensor

Find the two 18 AWG wires with the ¼” Quick connect terminals from the Cell cable and push them on their

respective connectors on the Flow Sensor. These wires are interchangeable.

9

Page 10

STARTUP

BEFORE ADDING THE SALT

o Balance the chemicals.

balance. Also, add 1 quart of metal remover and 1 quart of non-copper based algaecide to the pool,

according to the manufacturer’s instructions. This will ensure that the transition to the Auto-Chlor

system will be quick and trouble-free.

o Measure existing salt in your pool.

higher due to residual salt.

o New Pools: Wait 10-14 days, or longer if specified by the pool builder, for plaster to cure before

adding salt or operating the Auto-Chlor Chlorine Generator.

o Biguanide Pools: If installing on a pool using Biguanide sanitizers, all Biguanides must be removed

before system startup.

ADDING THE SALT

1. Determine how much salt is needed from the Salinity Demand Table on the following page. This table

is based on a salt concentration of 3500 ppm (approximately 1/3 of 1%). More may be added for

larger pools (e.g. 4000 ppm) and less for very small bodies of water.

2. Keep the pump on to circulate the water.

3. Distribute the determined amount of salt evenly around the pool. To avoid clogging the filter or

damaging the Control Box and pump, do not add salt through the skimmer or surge tank. Brushing

the bottom helps dissolve the salt.

4. The readout on the chlorine generator may fluctuate until the salt is fully dissolved.

UNACCEPTABLE SALTS

Do Not Use:

Iodized Salt

Salts with anti-caking agents of more than 1%

Rock salt because of the dirt mixed with the rock salt

Calcium chloride; it is not a salt.

See the titled “Understanding the Chemistry” for recommended water

Years of liquid chlorine use may cause the salt reading to be

10

Page 11

SALINITY DEMAND TABLE

(in lbs.)

Salt level before addition in PPM

Water volume in thousands of Galloons

Locate the current salt concentration at the top of the chart (e.g. 1000ppm). Then locate the size of your

pool on the left (e.g. 12,000 gallons). Run these figures down and across until they meet. That number is the

number of pounds of salt required for your pool.

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

0 500 1000 1500 2000 2500 3000 3500 4500

How much sat to add – in pounds

117 100

175 150 125 100 75 50 25 0 OK

234 200 167 133 100 67 33 0 OK

292 250 209 167 125 83 42 0 OK

350 300 250 200 150 100 50 0 OK

409 350 292 234 175 117 58 0 OK

467 400 334 267 200 133 67 0 OK

525 450 375 300 225 150 75 0 OK

584 500 417 334 250 167 83 0 OK

642 550 459 367 275 183 92 0 OK

701 600 500 400 300 200 100 0 OK

759 651 542 434 325 217 108 0 OK

817 701 584 467 350 234 117 0 OK

876 751 626 500 375 250 125 0 OK

934 801 667 534 400 267 133 0 OK

992 851 709 567 425 284 142 0 OK

1051 901 751 600 450 300 150 0 OK

1109 951 792 634 475 317 158 0 OK

1168 1001 834 667 500 334 167 0 OK

1226 1051 876 701 525 350 175 0 OK

1284 1101 917 734 550 367 183 0 OK

1343 1151 959 767 575 384 192 0 OK

1401 1201 1001 801 600 400 200 0 OK

1460 1251 1043 834 626 417 209 0 OK

83

67 50 33 17 0 OK

CALCULATING THE SIZE OF THE POOL

Rectangular Length x Width x Average Depth x 7.5 Length x Width x Average Depth x 1000

Round Diameter x Diameter x Average Depth x 5.9 Diameter x Diameter x Average Depth x 785

Oval Length x Width x Average Depth x 6.7 Length x Width x Average Depth x 893

Gallons

(dimensions are in feet)

Liters

(dimensions are in meters)

11

Page 12

OPERATING INSTRUCTIONS

BACKGROUND

Auto-Chlor is a chlorine generator for pool and/or spa sanitation. It is the workhorse of chlorine generators.

The system uses a very low concentration of salt, less than the concentration in a human teardrop, and

converts it into free chlorine that kills algae and bacteria in your pool. After killing the algae and bacteria, the

chlorine reverts back into sodium chloride. This process of purification continues, making the need to add

extra sanitizing chemicals to your pool virtually unnecessary.

The level of necessary chlorine in the pool is affected by a number of factors such as sunlight, bather load,

debris and water temperature, all of which increase sanitation and filtration demand.

Filtration

Proper filtration is critical for maintaining clean healthy water. Filtration increases clarity, and the Auto-Chlor

Chlorine Generator increases sanitation and oxidation. It is customarily required in the pool industry that all

the water in the pool pass through the filter at least one and a half (1 ½) times per day (~ 8 hours on most

pools). During very heavy usage, the filter and chlorine generator may be run continuously.

Inadequate filtration: Inadequate filtration reduces water clarity and makes more work for the generator.

Sanitation/Oxidation

The Auto-Chlor Chlorine Generator has little effect on pH, total alkalinity, or stabilizer levels. These must still

be monitored and adjusted to allow the system to have its greatest effect. If you use a good quality pool test

kit and follow the simple instructions outlined in this manual, your Auto-Chlor Chlorine Generator will help you

maintain a sparkling clean, trouble-free pool for many years with minimal effort. See the section titled

“Understanding the Chemistry” for more information.

BASIC OPERATION

The Auto-Chlor Chlorine Generator produces a pure form of chlorine to sanitize and oxidize your pool water.

The chlorine residual needs to be maintained at 1-3 ppm. This may be tested using a standard kit or by your

local pool store.

To generate more chlorine:

1. Turn the Control Knob to a higher setting as necessary, 10% to 100% chlorine production level. See

“Power Meter” in the next section for more details.

2. Ensure sufficient run time (at least 8 hours / 1 ½ turnovers) up to 24 hours per day.

3. Ensure salt level is correct and the Cell is clean (see “Salinity Indicator” in the next section).

4. Ensure proper water balance including pH and stabilizer levels (see “Understanding the Chemistry”

for recommended levels).

5. Point pool jets down and to the side.

* Summer weather increases demands for chlorine.

To decrease chlorine production:

1. Turn the Control Knob to a lower setting, 10% to 100% chlorine production level. (See “Power Meter”

in the next section)

2. Decrease run time as necessary.

Winterizing

Just like the pool plumbing, freezing may damage the system’s Cell and Flow Sensor. If severe or extended

periods of freezing temperatures are possible, drain all water from the pump, filter, and supply and return lines

before any freezing conditions occur.

Spring Start-up

DO NOT turn on the system until the pool water chemistry has been brought to required levels. See “Startup”

section for more information.

12

Page 13

5

3

2

CONTROLS

Control Knob (1) – The Control Knob is used to adjust chlorine production and to turn the unit on or off. To

increase chlorine production, turn the Control Knob up (clockwise). To decrease chlorine production, turn the

Control Knob down (counterclockwise). To turn the unit off, turn the Control Knob down (counterclockwise)

until it clicks.

NOTE: When changing the power setting, the system takes up to 1 minute to ramp up (i.e. soft start).

During this time, the green On/Off Light (4) will flash.

Power Meter (3) – The Power Meter lights indicate the system’s chlorine output (i.e. 10% to 100% production

rate). The higher lights indicate higher chlorine production.

A Solid Red Light (2) above the Power Meter (2) indicates

that the salt level in the pool is on the high side. This does

not harm the Chlorine Generator, but is provided as a

cautionary notice to the user not to add more salt to the

pool. Operation at very high levels (i.e. above 5500ppm)

is not recommended.

A Flashing Red Light (2) above the Power Meter (2)

indicates that the salt level is exceedingly high (i.e. above

7000ppm), and should be reduced immediately by draining

a significant amount of pool water and refilling the pool.

(Please check with your local pool professional prior to

draining the pool)

Flow Light (5) – This red light should NOT be illuminated

during normal operation. When first turning on the

circulation pump, the red Flow Light (5) may turn on and

off until the air is pushed out of the pump lines and

sufficient water flow is achieved. This is normal and

ensures that the generator automatically shuts off if the

pump fails to prime or a blockage occurs. See

Troubleshooting section if the red Flow Light (5) remains

on.

On/Off Light (4) – When the system is turned on and the

pump is operating, the On/Off Light (4) will illuminate

indicating that power is reaching the Control Box. The

color of the On/Off Light (4) indicates the following:

Solid Green – system is operational.

Solid Red – system is not powering the Cell.

Flashing Green – system is performing a “soft

start”; light will turn solid green within 1 minute.

Flashing Red/Green – reversing polarity; light will

turn solid green within 3 minutes.

Flashing Red – output current is below 0.5A;

check whether the cell cable connections are

completely on and tightened.

4

1

13

Page 14

r

t

Salinity Indicator – To check the salt level, turn the Control Knob clockwise to full power and

check the light reading.

100% reading indicates that the salt level is sufficient.

Return the Control Knob to the desired chlorine

production setting depending on the chlorine level in

your pool (10% to 100% production rate).

Red Light - above the Power Meter indicates that the

salt level in the pool is on the high side. This does not

harm the Chlorine Generator, but is provided as a

cautionary notice to the user not to add more salt to

the pool. Operation at very high levels (i.e. above

5500ppm) is not recommended. Slowly turn down the

Control Knob until the desired Power Meter light

illuminates (i.e. desired chlorine production level).

If Power Meter lights go up & down quickly: The salt

level is high. Slowly turn down the Control Knob

(counterclockwise) until the desired Power Meter light

illuminates. If the lights continue to go up and down

after the Control Knob was turned down, the salt level

is exceedingly high, and should be reduced

immediately by draining a significant amount of pool

water and refilling the pool.

local pool professional prior to draining the pool).

Readings between 10% and 80% indicate a low sal

level, except when the Cell is worn or calcified. Check

the Cell to ensure the blades are in good condition and

not coated with calcium buildup. Cleaning the Cell is

recommended if it is calcified or if the readout seems

questionable. Before adding salt, it is advisable to

have the salt level professionally checked.

(Please check with you

14

Page 15

MAINTENANCE

Maintaining your Auto-Chlor Chlorine Generator requires minimal work but will maximize the

performance and life of the system.

POOL WATER TESTING: Pool water should be tested weekly.

Cell Maintenance

Our clear Cell allows for easy regular inspections for calcium build up. Visually check the Cell periodically,

and clean it as necessary (1 to 2 times per year). Advanced self-cleaning technologies, including reverse

polarization and IBT™ help the cell stay cleaner than other self-cleaning cells.

Cell Cleaning

Do Not use metal or other hard objects to clean the cell as this

could scratch the precious coating on the plates and void the

warranty.

CAUTION: Always add acid to water, NOT water to acid

Diluted muriatic acid solution = 10 parts water to 1 part

acid

Note: Follow the instructions of the acid manufacturer.

Cleaning With Optional Cleaning Cap:

1. Remove the cell from the line by undoing the electrical connections from the Cell and the barrel

unions from the cell ends.

2. Remove the black o-rings on the ends of the Cell.

3. Attach the Cell Cleaning Cap to one end of cell.

4. Pour into Cell, either undiluted white distilled vinegar, or a solution of diluted muriatic acid (10 parts

water to 1 part muriatic acid).

5. Wait for foaming to stop (5-10 minutes when using muriatic acid, vinegar takes longer).

6. If muriatic acid was used, safely dispose of it by pouring it into your pool.

7. Rinse cell with water hose.

8. Put the O-ring back in place and re-install the Cell in the line.

9. Reconnect the electrical wires, being sure to tighten the screws on the electrical wires firmly.

15

Page 16

Cleaning Without Optional Cleaning Cap:

1. Remove the cell from the line by undoing the electrical

connections from the Cell and the barrel unions from the cell ends.

2. Remove the black o-rings on the ends of the Cell.

3. Soak entire cell either in undiluted white distilled vinegar or in a

solution of diluted muriatic acid (10 parts water to 1 part muriatic

acid).

4. Wait for foaming to stop (5-10 minutes when using muriatic acid;

vinegar takes longer)

5. If muriatic acid was used, safely dispose of it by pouring it into

your pool.

6. Rinse cell with water hose.

7. Put the O-ring back in place and re-install the Cell in the line.

8. Reconnect the electrical wires, being sure to tighten the screws on

the electrical wires firmly.

Optional

1. Lubricating the o-rings with a rubber lubricant (e.g. silicone) helps improve the seal of the fittings, but

be sure not to use silicone glue, petroleum jelly (such as Vaseline), or other agents that could

deteriorate the o-rings.

2. Smear the two electrical connections on the outside of the cell with electrical lubricant.

16

Page 17

UNDERSTANDING THE CHEMISTRY

Below is a table showing the recommended balance levels followed by a more detailed explanation of the

factors affecting water chemistry. Maintaining these levels will prevent corrosion and scaling and will ensure

maximum enjoyment of the pool. You should test your water periodically. If the water chemistry needs

adjustment, your authorized dealer or most pool stores can supply you with the appropriate chemicals and

procedures. We recommend you either take a copy of the Water Balance Table to the pool store or notify the

pool store that you are using a salt chlorine generator.

FACTORS IDEAL LEVELS

Salt 3000 to 4000 ppm

Free Chlorine 1 to 3 ppm

PH 7.2 to 7.6

Total Alkalinity 110 to 180 ppm (Depending on the Saturation Index)

Stabilizer (Cyanuric Acid) 40-80 ppm

Nitrates 0 ppm

Metals 0 ppm

Phosphates O ppm

Calcium Hardness Determine level for individual pool surface

Saturation Index -0.3 to 0.3 (0 is ideal)

Salt

Salt is the power source of the Auto-Chlor Chlorine Generator. To ensure maximum benefits with the use of

the system, the ideal salt level is 4000 ppm (parts per million). A low concentration of salt can hinder the

generator’s effectiveness. A concentration of salt above 5500 ppm may cause corrosion damage to the pool

fixtures. See the Adding Salt section for more information.

Total Dissolved Solids (TDS) are different from the salt level of the pool, although TDS levels rise by adding

salt to pool water. This does not harm the pool water chemistry or clarity, but the pool water professional that

is testing for TDS must be aware that salt has been added for the chlorine generator system. The pool

professional doing the TDS test will get the accurate TDS level by subtracting the salinity level.

Free Chlorine v. Combined Chlorine: The unpleasant smells and side effects often associated with chlorine

are actually caused by combined chlorine (i.e. chloramines). Combined chlorine is a chlorine molecule that

attacked a noxious particle in the water but has been unable to destroy that noxious particle. This chlorine

particle remains attached to the noxious particle until one of the two is burned off; hence the term “combined

chlorine” (a.k.a. chloramines). To burn off the noxious particle and free up the chlorine again, pool owners

have had to shock the pool periodically, but with the Auto-Chlor Chlorine Generator, the noxious particles are

burned off within the generator’s Cell and the combined chlorine is continuously converted back to free

chlorine.

The free chlorine level in the pool should be maintained at 1 to 3 ppm. This level of free chlorine is

comfortable to swim in with no unpleasant smells, and it maintains proper sanitizing power.

PH is a measure of how acidic or basic a solution is. A scale of 0 to 14 is used to measure pH. Pure water

has a pH of 7 (neutral), acid solutions have a pH of less than 7, and basic (alkali) solutions have a pH of more

than 7. The recommended range is 7.2 to 7.8; chlorine is more effective within this range and the water is

most comfortable for bathers. Water with very high pH levels can cause scaling in the pool, on the walls and in

pipes. Low pH levels cause the water to be aggressive to the pool walls, equipment, and bathers.

To lower pH, add muriatic acid or dry acid, and to raise pH, add soda ash (sodium carbonate). Be sure to

read and follow the respective manufacturer’s instructions.

Total Alkalinity mitigates changes in pH. It is often referred to as the “big brother of pH.” Keeping proper

levels of total alkalinity will help reduce unwanted fluctuations in pH levels. Total alkalinity is also used to

offset high or low levels of calcium hardness (see Saturation Index below). Add muriatic acid or dry acid to

17

Page 18

lower total alkalinity and add baking soda (sodium bicarbonate) to raise total alkalinity. Be sure to read and

follow the respective manufacturer’s instructions.

Stabilizer (cyanuric acid) is necessary in most outdoor pools to maintain appropriate levels of chlorine.

Chlorine stabilizer helps give an appropriate residual chlorine reading of the pool water. Without stabilizer, UV

radiation from the sun destroys most chlorine within 2 hours, but excessive amounts of stabilizer can decrease

the effectiveness of chlorine. Chlorine stabilizer should be maintained at 40-80 ppm to offset the harmful

effect of the sun while maintaining the effectiveness of the chlorine.

Nitrates and Phosphates, generally associated with fertilizer thrown on nearby grass, can put very high

demands on chlorine; most often nitrates and phosphates will bring the chlorine level down to zero (0). You

can have your water tested for nitrates and phosphates by the local pool professional. No nitrates or

phosphates should be in your pool.

pool professional. To reduce Nitrate levels, the pool must be partially or fully drained. (Please check with your

local pool professional prior to draining the pool)

Metals (certain metals) can cause loss of chlorine and can stain your pool. If a water test reveals the

presence of metals, refer to your local pool professional for recommended methods of removal.

New Pool Water in recently filled or newly refinished pools may contain undesirable matter. The ability of the

Auto-Chlor Chlorine Generator to purify your pool could be hindered by this matter so it is best to balance the

pool chemicals first.

Calcium Hardness, like pH and alkalinity, affects the water’s tendency to be aggressive or scale forming.

Lower levels of calcium hardness improve the chlorine generator’s performance and provide softer silkier

water for the swimmers.

Saturation Index determines whether the pool water is balanced, aggressive, or scale forming by

comprehensively taking into account all the relevant factors, including pH level, alkalinity level, calcium

hardness, and temperature. These factors should be tested periodically then plugged into the worksheet on

the following page to verify the proper balance of the pool and make adjustments as necessary.

To reduce phosphate levels, use a phosphate remover from your local

18

Page 19

SATURATION INDEX

Test the water for pH, Alkalinity, Calcium Hardness, and Temperature, then follow the simple steps below:

1. Write your pool’s pH level here: pH: ________

2. Find your Alkalinity level in the chart below, and write the

corresponding Alkalinity Factor here: Alkalinity Factor: ________

Pool Alkalinity 5 25 50 75 100 150 200 300 400

Factor 0.7 1.4 1.7 1.9 2.0 2.2 2.3 2.5 2.6

3. Find your Calcium level in the chart below, and write the

corresponding Calcium Factor here: Calcium Factor: ________

Pool Calcium

(CaCO

Factor 0.3 1.0 1.3 1.5 1.6 1.8 1.9 2.1 2.2

4. Find your pool temperature in the chart below, and write the

corresponding Temperature Factor here: Temperature Factor: ________

Pool Temp 32 37 46 53 60 66 76 84 94 105

Factor 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

5. Add the results from steps 1 through 4 above and write the result here: Total of above: ________

)

3

5 25 50 75 100 150 200 300 400

- 12.2

6. Subtract 12.2 from step 5 and write the result here: Saturation Index =

If the Saturation Index above is between –0.3 and +0.3, the water is well balanced.

If the Index is more than 0.3, the water will tend to cause scaling or get cloudy. Alkalinity and pH

should be reduced accordingly, but maintained within recommended levels.

If the Index is less than -0.3, the water will tend to be aggressive toward the pool surface, equipment,

and bathers. Alkalinity and pH should be increased accordingly, but maintained within recommended

levels.

19

____

Page 20

TROUBLESHOOTING

Note: evaluating the possible causes for each problem from top to bottom (first to last) will avoid extra labor.

PROBLEM

1. Chlorine

Level Low

2. Green Pool

3. On/Off Light

is OFF: No

power

4. On/Off Light

is Solid Green

5. Red Flow

Light is Off

6. Flow Light is

Turning On

and Off

7. Flow Light is

Solid Red

8. Power Meter

lights do not reach

100%

POSSIBLE CAUSES

System is turned off. Turn Control Knob to the desired setting.

Control Knob is set too low in

relation to chlorination demand

(e.g. higher number of bathers,

warmer weather, increased debris

in pool).

Low Salinity

Pump operation time too short

Low Stabilizer (Cyanuric Acid)

Chemical Imbalance

Chlorine level too low. See “Chlorine Level Low” above.

System is turned off.

Main fuse blew.

Breaker jumped Check the breaker leading to the pool control.

Power wires cut,

disconnected, or incorrectly wired.

Other malfunction in Control

Box.

System is on. This is

normal.

This is normal.

This is normal at initial start-

up or if air bubbles are in pipes.

Insufficient water flow from

pump to Flow Sensor and Cell.

Obstruction or scale

buildup in Cell.

Flow Sensor was not

installed in the correct

direction.

Flow Sensor is not fully

threaded into the “T”

connector.

Cut wires or insufficient

wire connections.

Control Knob set too low

Dirty Cell, Loose Connection,

or Salinity Low.

WHAT TO DO

Turn Control Knob higher (clockwise) and/or

increase pump operation time.

Check the salinity level.

(See “Salinity Indicator” section).

Run pump at least 8 hours per day (1.5

turnovers of all the pool water).

Check water chemistry; stabilizer should be

between 40-80 ppm. If low, add stabilizer (See

“Understanding the Chemistry”).

Check other chemistry and balance

chemicals. (See “Understanding the Chemistry”).

Turn Control Knob clockwise to the desired

setting.

Check main fuse on bottom of Control Box

and replace if necessary with a 6.3 Amp 250VAC

6x32mm Slow Blow fuse. One extra fuse is

supplied on the bottom-side of the Control Box

cover.

Check for correct wiring.

Contact warranty hotline.

Wait a few minutes for air to clear. If

continuous, see troubleshooting section “Flow

Light is Solid Red” below.

This is normal for a few minutes at initial

startup or if air is in the lines.

Clean filters and strainers.

Check for closed valves, faulty pump, etc.

Clean Cell according to instruction

manual. (See “Maintenance” section)

Turn Flow Sensor so arrow faces

direction of water flow.

Fully thread the Flow Sensor into the T

connector being careful not to damage the

wires or sensors.

Check the connection to ensure proper

wire contact.

Turn Control Knob higher (clockwise).

If the red light above the Power Meter

illuminates or if the lights go up and down,

see

Troubleshooting Section “Salinity High” below.

See Troubleshooting Section “Salinity Low”

below.

20

Page 21

TROUBLESHOOTING

Note: evaluating the possible causes for each problem from top to bottom (first to last) will avoid extra labor.

PROBLEM

9. Salinity Low

10. Salinity

High

11. RED light at

the top of the

Power Meter is lit

12. Lights go up &

down quickly

POSSIBLE CAUSES

Dirty Cell

Loose connection with the

Cell’s connection pegs.

Not enough salt due to

heavy rain, initial

miscalculation, etc.

Worn Cell

Salinity High. Enough salt

has been added causing the red

light above the power meter to

light.

Salinity is very high. Too

much salt has been added causing

the Power Meter Lights to go up

quickly, and then shut down.

Salinity far too high. Way too

much salt has been added causing

the Power Meter to completely

shut down.

Salinity high

Salinity is very high.

WHAT TO DO

Check the Cell to ensure the blades are

in good condition and not coated with calcium

buildup. Cleaning the Cell is recommended if

it is calcified or if the readout seems

questionable. (See “Cell Cleaning” under the

“Maintenance” section).

Ensure the connectors are pushed

completely over the pegs and tighten

connections with a screwdriver.

Add salt into the pool. See the “Adding

The Salt” section for more information.

It is also recommended to periodically

test the salt level by a professional and adjust

according to the “Salinity Demand Table” in

this manual.

If none of the above resolutions worked,

the cell may be worn out.

This does no harm to the Natural Generator,

but simply indicates that the salt level is on the

high side for your information. Slowly turn down

the Control Knob (counterclockwise) until the

desired Power Meter light illuminates.

It is also recommended to periodically test the

salt level by a professional. If above 5500 ppm, it

is recommended to drain part of the pool water

and refill with fresh water. (Please check with your

local pool professional prior to draining the pool)

The salt level is very high. Drain part of the

water and refill the pool to bring the salinity down.

It is also recommended to periodically test the

salt level by a professional. If above 5500 ppm, it

is recommended to drain part of the pool water

and refill with fresh water. (Please check with your

local pool professional prior to draining the pool)

The salt level is exceedingly high. Drain part

of the water and refill the pool to bring the salinity

down.

It is also recommended to periodically test the

salt level by a professional. If above 5500 ppm, it

is recommended to drain part of the pool water

and refill with fresh water. (Please check with your

local pool professional prior to draining the pool)

See Troubleshooting Section “Salinity High”

above.

Drain part of the water and refill the pool to

bring the salinity down. See Troubleshooting

Section “Salinity High” above for more information.

It is also recommended to periodically test the

salt level by a professional. If above 5500 ppm, it

is recommended to drain part of the pool water

and refill with fresh water. (Please check with your

local pool professional prior to draining the pool)

21

Page 22

13. Power Meter

not responding,

but On/Off light is

on

build-up inside

Cell

15. White flakes in

the water

16. Cloudy water

17. Colored Water

18. Algae

Control Knob set too low Turn Control Knob up (clockwise).

Improper salt level. The

system automatically shuts down

the Power Meter when the salt

level is extremely low or extremely

high.

Standard occurrence that

needs to be cleaned approximately

twice/year.

Chemical imbalance.

Normal occurrence when Cell

cleans itself.

May be due to chemical

imbalance or low water flow

Metals in the fill water may

have been oxidized.

Algae may be trying to form.

May be due to low chlorine

levels or a chemical imbalance

Check salt level using a test kit or your local

pool professional. The salt level is likely at an

extreme level. Adjust accordingly.

Clean Cell as instructed in the “Maintenance”

section. 14. Scale

Balance chemicals. (Focus mostly on the

“Saturation Index” in the section titled

“Understanding the Chemistry”).

Keeping the water well balanced reduces this

occurrence. (Focus mostly on the “Saturation

Index” in the section titled “Understanding the

Chemistry”).

Make sure your filtration system is working

properly (i.e. clean filter and/or skimmer).

Make sure circulation time is adequate –

increase pump time if not.

Make sure total alkalinity is balanced.

Shock the water to eliminate build up of any

organic matter.

Make sure pool has free chlorine reading of

1.0 to 3.0 ppm

Check with dealer for more information

Have dealer test the pool water. If high in

metals use a Metal out or Sequestering product at

start-up only.

Increase circulation time if needed and clean

the filter.

Check with your dealer for more information.

Have your water tested for chemical balance

including pH, phosphates, and nitrates.

Use a nonmetallic (polyquat) algaecide per

the directions on the bottle and brush the sides of

the pool often.

Clean the filter and shock the pool with

chlorine daily until water clarity returns.

Check with your dealer for more information.

Our contact information is found on the front cover of this manual. For additional information, please visit our website. For

warranty service, questions, or comments, please contact us directly. Technicians are available from 9:00 AM to 4:00 PM

Eastern Standard Time, Monday through Friday. Please have the following information ready:

1. Model and Serial #

2. Date of installation

3. Installing company or dealer

4. Current salt level and chemical levels

5. Proof of Purchase (bill of sale, cancelled check, or some other appropriate payment record)

22

Page 23

Ten (10) Year Limited Warranty

Models: AC-4000 and AC-6000

WARRANTY

This warranty applies to all AC-4000 and AC-6000 chlorine generators and their factory-supplied components (the “System”) when

purchased from an authorized dealer and used for residential swimming pools or spas. Aqua Comfort Technologies, LLC (“ACT”)

warrants the System to be free from defects in materials and workmanship in the manufacturing process for a period of ten (10) years

from the purchase date, when properly installed and operated in accordance with the relevant manuals. For three (3) years after the

System’s original purchase date, should the System exhibit a manufacturing defect, ACT will install comparable replacement parts

without charge for parts or labor. For the subsequent 7 years, if a part with a manufacturing defect is delivered freight prepaid to

ACT, a comparable replacement part will be sent back for a charge of 60% of the latest list price plus the cost of shipping.

EXCEPTIONS & LIABILITY LIMITATIONS

This warranty is not transferable. Labor coverage is applicable only for installations within a 50-mile radius of an authorized dealer.

ACT and their suppliers, dealers, and distributors SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES;

DAMAGE OF ANY SORT OR NATURE RESULTING FROM ABUSE, MISUSE, NEGLIGENCE, LIGHTNING, ABNORMAL WEATHER

CONDITIONS, OR ACT OF GOD; OR DAMAGE CAUSED BY IMPROPER OR UNAUTHORIZED INSTALLATION OR REPAIR. This

warranty applies only to components supplied by the factory and only where such components have been installed and maintained in

compliance with the respective installation and operation manuals and instructions and applicable ordinances and codes. In no event

shall the liability exceed the purchase price of the product. THE CONSUMER SHALL BE LIABLE AT STANDARD RATES FOR ANY

SERVICE VISIT WHERE NO MANUFACTURING DEFECT WAS PRESENT AND FOR ALL SERVICE VISITS REQUESTED AFTER

THE THIRD YEAR FOLLOWING THE ORIGINAL PURCHASE DATE.

PROOF OF PURCHASE

The consumer is responsible for establishing the original purchase date and the purchaser’s identity for warranty purposes. We

recommend that a bill of sale, canceled check, or some other appropriate payment record be kept for that purpose.

The express warranty above constitutes the sole and complete warranty and takes precedence over all other warranties, whether

expressed or implied, including a warranty for fitness for a particular purpose. No sales representative, dealer, distributor, or other

person is authorized to give any warranty on behalf of ACT.

OWNER’S REGISTRATION FORM 10-YEAR LIMITED WARRANTY

Owner’s Name__________________________________________Signature____________________________________

Street Address____________________________________________________City_______________________________

State_________ Zip_________________ Phone # _______________________Date of Purchase__

Authorized Dealer _____________________________ Sales Rep____________________City______________________

State_________ Zip________________ Unit Serial # ______________________

How did you hear about our product? (Please check all that apply)

___ Pool Store Employees ___ Pool Builder ___ Pool Service ___ Direct Mail ___ In-Store Display___ Friend/Relative

___ Magazine ___Newspaper ___ Radio ___ TV ___ Catalog ___ Other:_______________________ ________

Comments: ________________________________________________________________________________________

__________________________________________________________________________________ _______________

* If more space is necessary, please utilize the back of this form.

IN ORDER TO ACTIVATE YOUR WARRANTY Aqua Comfort Technologies, LLC

PLEASE RETURN THIS PORTION TO: P.O. Box 1520 y Sykesville, MD 21784-1520

__/______/ _

23

Page 24

RETURN ADDRESS

______________________________

______________________________

______________________________

AQUA COMFORT TECHNOLOGIES, LLC

ATTN: WARRANTY DEPT. (MBP)

P.O. BOX 1520

SYKESVILLE, MD 21784-1520

24

Loading...

Loading...