Page 1

2300 Controller Quick Start Guide, Rev. 1.2 Page 1

AquaMetrix 2300

Multi-Input Controller

Quick Start Guide

Page 2

2300 Controller Quick Start Guide Page 2

Welcome to the Easy Way of Controlling Your Probes

This guide augments the operation manual, showing you how to mount and configure the standard

2300 Controller. Information on using the controller with additional or non-standard I/O cards can be

found in the operation manual, which is available for download on www.Aquametrix.com.

This Quick Start Guide is written for software-preconfigured 2300’s to allow wiring and start of

basic operation of the controller without hooking up to a network first.

1. Installation

WARNING: If this equipment is used in a manner not specified by the manufacturer as per the Users

Manual and this Quick Start Guide, the protection provided by the equipment may be impaired.

1.1. Panel Mounting

Mount the 2300 Controller through the front panel, with the gasket on the outside of the mounting

panel. Hook the sliding mounting blocks on each side of the back of the 2300 Controller enclosure and

tighten the setscrews against the mounting panel with a torque of 4 in-lb as shown in Error!

Reference source not found..

Figure 1 - Mounting hardware attached to panel

with 4 in-lb of torque

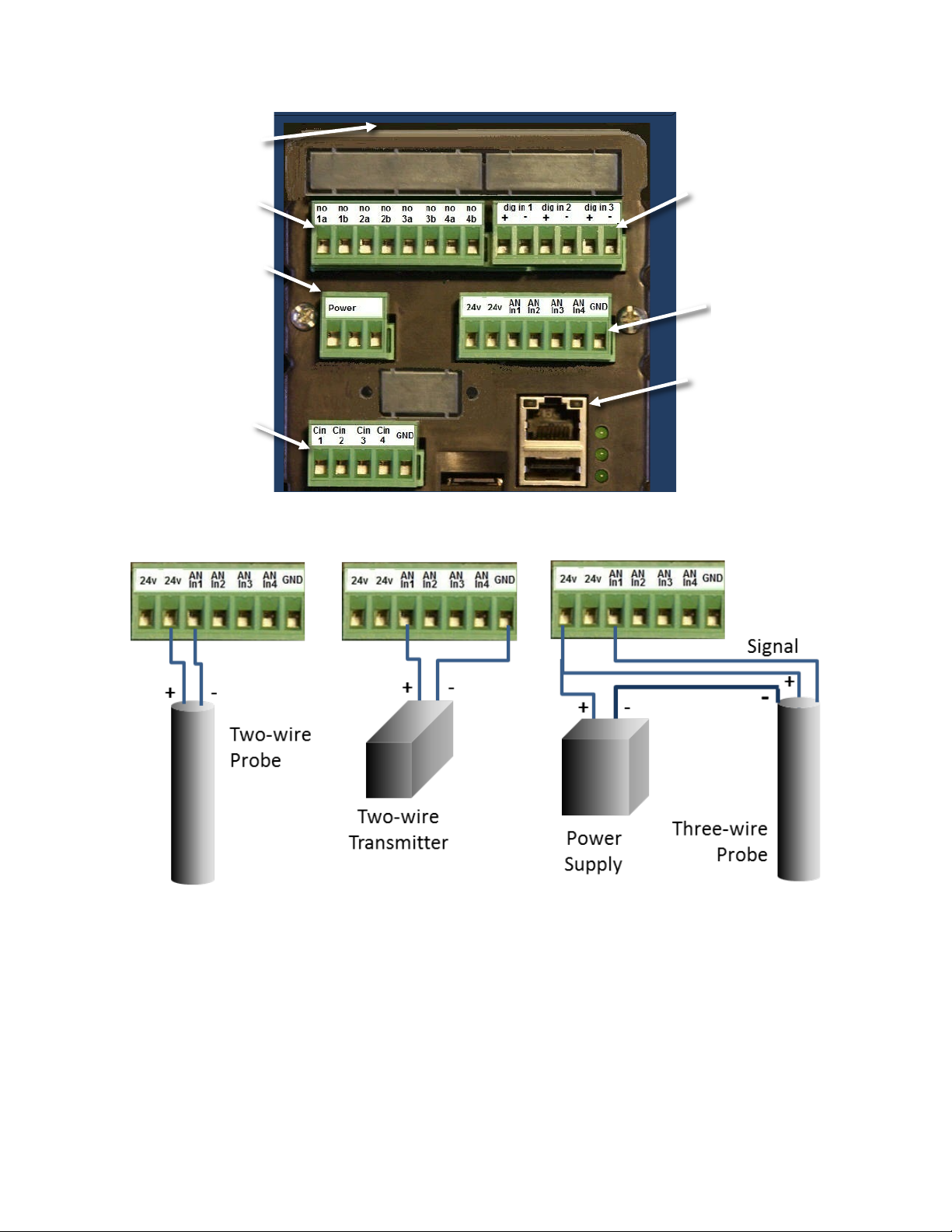

1.2. Power, Probe, and Network Cabling

A picture of the rear of the 2300 is shown below in Figure 2. We recommend removing the Molex

connectors and connecting wires to them and then attaching the connectors to the unit.

Connect the:

• Power cord

• CAT-5 Ethernet cable—to be used later as described in Section 2.

• Probe wires. 2-wire 4-20 mA cables connect to the analog connector. Pulse inputs connect to

the digital inputs.

Probe wiring depends on the type and manufacturer of the probe, and instructions can be found with

each probe. We show examples of the different wiring diagrams in Figure 3 that may be called for by

your analog (4-20 mA) probes, but please look up your individual probe directions. Connections for

flow meters, which output a pulse frequency, such as paddle wheels or magmeters, use the pulse

input connector (“dig in 1” et al).

Page 3

2300 Controller Quick Start Guide Page 3

Figure 2 - 2300 Controller back panel

Figure 3 - Possible analog probe wiring diagrams. There are other possible three-wire probe

setups, so please refer to your specific probe’s instructions for proper hook up.

1.3. Powering Up the 2300

With the probes connected, power up the 2300. If the controller is operating properly, the green LED's

on the back panel indicate proper operation. From top to bottom:

1. The top most LED is the Fault light it should be slowly blinking.

2. The middle LED is the System Operating light and it should be quickly blinking.

3. The bottom LED is the Power On light and it should be on and steady.

Ethernet Connection

Power 120-220 VAC

Pulse Input (digital)

Connector

Relay Connector

Contacts Connector

Analog (4-

20mA) Input

Connector

L N G

Page 4

2300 Controller Quick Start Guide Page 4

The Run screen should appear and display 4 panes. It will show the actual mA reading of the four

analog probes (see Figure 4). Dashes (----) indicate that a probe is either not connected or it is out of

range. Note that the preconfigured software only shows the actual current being read by the 2300. In

order to have probe outputs expressed in the appropriate units (e.g. pH, mV, µS/cm, etc.) you need to

carry out set-up over a network using a web browser. See Section 1.5 or 1.6 of this guide for network

setup, and Section 2 for configuring the 2300 over the network. The main purpose of this initial screen

showing the raw current outputs of the connected probes is simply to reassure you that that

controller is running properly.

To navigate the front panel screens, use the front-panel buttons as follows:

• RUN brings up the quad screen from anywhere

• MENU brings up the front panel menu

• BACK returns the user to the previous screen.

Figure 4 - The RUN screen showing four analog probe inputs. On the left is a display showing

that no probes have been connected. On the right, four analog probes have been connected.

The 2300 is software-preconfigured for six probes, allowing the user to wire up probes and start

operation prior to network hookup. Analog 1 is set up to the analog 1 input on the back of the unit.

The first 4 software channels are shown on the RUN quad screen. If you have more than 4 sensors

connected, press the down arrow to see channels 3 through 6. Channels 5 and 6 are set up as flows

using the pulse inputs 1 and 2 (see Figure 2). The 2300 can be easily reconfigured via a network,

including changing the names, units, order of probes, and just about everything else you can think of.

Use the right arrow on a quad screen to see detailed screens for each channel, addressable by the up

or down arrows. Pressing ENTER on a detailed screen brings up a configuration screen for that

channel. Examples of each are shown below in Figure 5. Press BACK or RUN to move up a level or two

in the front display.

Page 5

2300 Controller Quick Start Guide Page 5

Figure 5 - The channel Detail screen and Configure screen for Channel 1

The detailed screen lists alarm and relay set points, last calibration date, and will flash when the

channel is in alarm mode. The configure screen allows resetting of the alarm and relay set points,

alarm acknowledgement, and zeroing of the totalizer and dispenser functions and other channelspecific functions.

1.4. Front Panel Menu Options

The front panel menu choices are limited as the 2300 is designed to be configured and operated over

a network in a browser. However, there are several key functions available to the user on the front

panel. These include calibration and setting up the network. The main menu is shown in Figure 6.

Figure 6 - Main Menu screen

Use the up or down arrow keys to target an item, and the Enter key to select it. If there are more than

4 choices available, the bottom (or top) corner on the right will be notched.

The menu options are listed in outline form below in Table 1. You may calibrate your probes from the

front panel, but remember that full functionality of the unit is only available via the Ethernet cable

from a network, or browser on a computer, tablet, or phone. Customize your unit via a network to

display proper units, names of probes, and to configure alarms, relays, and notifications.

Page 6

2300 Controller Quick Start Guide Page 6

Table 2 – Front Panel Menu Structure

Menu Item

Description

View System Info

Single screen showing unit Name, IP Address, etc.

Calibrate/Disable Probe

Enable, disable, or calibrate probes

Select Probe

Any defined probe, including virtual probes

Select Action

Calibration is 2-point calibration for the analog inputs, K

Factor scaling for the digital inputs.

Backup/Restore

Saves or Restores a configuration file onto/from the external

micro-SD card, including probe setups and calibrations, alarm

and relay set points, and system configuration.

Reboot System

Closes all open files and restarts system.

Prepare for System Shutdown

Closes all open files.

Advanced Menu

Calibrate Analog In

Password protected for factory calibration only

View Precision

Input

Not Used

Network Setup

Changes from DCHP to Static IP or vice versa, allowing

settings for network type and web server port.

1.5. Setting up an Ethernet Connection to a network switch or router

Connecting the 2300 to an existing network with the Ethernet cable allows the 2300 to be

automatically assigned an IP address. You only need to set the Ethernet connection on your computer

or smart device to configure via DHCP. The IP address is shown on the front panel during power up or

can be seen via the Main Menu under View System Info (hit Menu then Enter from the front panel).

The IP address may look like 192.168.1.7: save this address to access the 2300 from the network in

Section 2. Skip Section 1.6 if you use the DHCP.

1.6. Setting up a Direct Ethernet Connection

A wireless connection between a computer and the 2300 is usually the most convenient method for

controlling the 2300. However one can make a direct connection between the two with an Ethernet

cable. Most current Operating Systems (Mac, Windows and Linux) work with a regular Ethernet cable

but some older OS’s might require a crossover Ethernet cable. Note that, after setting up the 2300

Controller, the tethered laptop may be disconnected for operation.

To configure the connection, switch from DHCP (automatic) IP addressing to manual IP addressing.

Directions are below, but specific instructions for your own computer’s operating system may be

found on the web. Just search using the phrase “setting a manual IP address” in conjunction with your

operating system’s name.

On the computer:

Page 7

2300 Controller Quick Start Guide Page 7

1. Go to its Ethernet settings. On a PC it is in Control Panel > Network. On a Macintosh it is in

System Preferences > Ethernet.

2. Select Manual configuration of IPv4.

You may choose your own IP address. For illustration purposes we will start with the static IP address

that comes as the default for the 2300.

3. Set the IP address to 192.168.7.1.

4. Set the Subnet mask to 255.255.255.0.

Connect the Ethernet (CAT-5) cable into the Ethernet connector, shown in Figure 2, and connect the

other end to a laptop or desktop computer. Connect AC power to the power connector with the

connections on the power connector labeled in Figure 2. Apply power to the 2300 Controller. The

front panel will first display a splash screen with the AquaMetrix logo.

To set a manual IP address:

1. On the front panel go to Menu>Advanced>Network Setup.

2. Select Network Type and, next, Fixed. The Fixed Network Setup screen will appear.

3. There are three fields in which to enter numbers. For illustration purposes we use the

following set of numbers:

IP Address: 192.168.7.7

Subnet Mask: 255.255.255.0.

Default Gateway: 192.168.7.1. (Use the IP address of the connected computer.)

4. When complete, move the cursor down to and press Commit and Restart. A confirmation

screen will appear, move the cursor to Confirm and hit Enter.

2. Configuring the 2300 via a Network or Computer

Enter the unit’s web page address into a web browser connected to the same network as the 2300

Controller or, if not using a network, into the computer’s browser connected to the 2300 Controller via

the Ethernet cable. A web page address will look something like http://192.168.1.7. A login dialog box

will appear, asking for user name and password.

The password here is used on the web to restrict access to administration functions to the system. The

default username is admin, and the default password is aquametrix.

2.1. The Web Menu

Logging into the 2300 via the web as an administrator brings up the Probe Status page, which is

shown in Figure . This displays all enabled probes, their names, values, alarm and relay set points, and

graphs showing the history of values for the previous 15 min. Clicking on a graph enlarges the

history, clicking on a Config button brings up a screen with options including alarm

acknowledgement.

Page 8

2300 Controller Quick Start Guide Page 8

Figure 7 - Probe Status menu showing four analog sensors (pH, ORP, conductivity and Dissolved

Oxygen)

The 2300 and the probes are configured using the five buttons along the top of this screen. Their

functions and their submenus are described below in Table 2. Note that there are two other levels of

password protection, that don’t access everything that the admin level does: these screens are what

an admin-level user sees.

Figure 7 – Probe Status page on web

Table 1 - Menu Items Available to an Administrator

Probe Status

Displays the current values of the sensors along with recent history

and monitor status.

Remote Display

Displays a simulated image of the current front panel of the 2300

with active buttons. Clicking on one of the 8 navigation buttons

changes the screens and moves the cursor just as if these buttons

Page 9

2300 Controller Quick Start Guide Page 9

2.2. Important First-Time Housekeeping Duties

Before configuring the probes, you have some housekeeping tasks to do which, although optional, do

allow you to use the 2300’s full capabilities like emailing.

2.2.1. Password Change

Yes, you get requests for password changes all the time, but if you want security and don’t want all the

other purchasers of 2300’s to know your username and password, now’s the time to change them.

Select Setup, User Maintenance, and then add a user. Make sure that you click on Admin for the

user level, and write down the username and password. You can also add multiple users at the Admin,

Editor, or User levels in order to track via the logs which users have done what to the 2300. Logout,

then log back in under your new admin name, and delete the default name “admin”.

2.2.2. Time Setup

The time of day sets automatically if the 2300 is connected to the web via an NTB time server. To

manually set the time, select Setup, System Configuration > Name > Time Configuration. This

page allows you to customize the name of the 2300, identifying the unit by location or function. Time

zone, date, and time are also set here.

2.2.3. E-Mail Setup

The 2300 is preconfigured with an SMTP server entry suitable for sending emails and alerts along a

network. The email sender is aquametrix2300@juno.com. If you want to set up sending from your

were being pushed on the actual unit. These actions update the

unit accordingly, which in turn updates the simulated display. Try to

remember to leave the Remote Display in RUN mode!

Logs

Data Logs

Brings up the list of daily data logs in memory, allowing data to be

emailed, downloaded, or deleted. Also does setting of the period

for logging

Alarm Logs

Brings up the list of alarm logs in memory, can be saved or deleted

System Logs

Brings up the list of system logs in memory, including errors, jscripts,

and system access. These can be viewed, saved, or deleted

Setup

Probe Configuration

Set up sensors, alarms, relays, and notifications.

User Maintenance

Set up users and passwords.

Data Logging Config

Set up data logging parameters

Network Setup

Set up web server, TFTP server, and emails.

System Config

Miscellaneous configuration options

System Documentation

System doc file

Advanced

Miscellaneous

Logout

Logs the current user out of the system after a confirmation

Page 10

2300 Controller Quick Start Guide Page 10

own email account, talk to your IT department or follow the directions below. Note that the 2300

internal web server does not support SSL security protocol, so you may have to establish a third party

email provider such as juno.com to generate the emails.

To change the email server, select Setup > Network Setup > Email Setup > SMTP Connection

Setup. The two required configuration values are the SMTP server address and the SMTP port. The

SMTP server address can be entered as a DNS name (e.g. SMTP.mycompany.com) or an IP address

(192.168.2.200). The SMTP port is a number that is assigned by your IT department and is normally 25.

You should get both of these values from your IT department. The Global From Address will be used in

all email messages as the sending email address (e.g. myemail@mycompany.com). You also need to

enter email addresses, optionally enter form emails to use later, and send a test email.

2.2.4. Configure Data Logging

If you will be using the data logging feature of the 2300, check that the default settings for the data

file are what you want. Default values are:

1. Data log files will be kept for 15 days

2. Data will be logged every 5 seconds

3. File delivery is by manual download from browser, and

4. Data is stored for configured probes only.

To change these settings, go to Setup > Data Logging Configuration, and follow the Wizard.

2.3. Configuring Probes

The Probe Configuration menu screen is shown in Error! Reference source not found.. It is

accessed from the Setup menu. This screen is used to configure all probes and their outputs, to

enable or disable individual probes, to set up the order that the probes are displayed on both the front

panel and web, to delete old probes, and to add new probes to the controller. There are 8 software

channels, i.e. slots for eight probes, which may be any combination of four analog inputs, three digital

inputs, or several different types of virtual functions that may be set up.

Assuming you have done the housekeeping items in Section 2.2, the next thing you will want to do is

to reconfigure the probes for your specific application. You may delete all the probes and start from

scratch, or edit some or all of the existing probe channels. To reconfigure a defined probe, click on its

name. This will open up a Wizard to change its name, units, and display options, to calibrate or scale

the input current, and then to determine what alarms, relays, or email alerts are attached to that

probe. The Wizard includes instructions, and doesn’t change any probe settings until a final Submit is

clicked. The Wizard also keeps track of the last time a calibration was done on each probe, the date of

which is displayed on the detailed probe screen on the unit’s front panel.

To set up a new probe, click on one of the Click here to add new Probe boxes, and follow the

Wizard’s instructions. Drop down menus are used for multiple choice items, and the Wizards include

pictures of the unit’s rear to facilitate correct wiring (look for Select Input or Select Relay buttons).

Training videos are available from our website at www.Aquamtrix.com. After configuring a sensor,

your inputs are summarized on a single screen and by clicking Submit the data is saved, the sensor is

enabled, and the menu returns to the main Probe Configuration screen.

Page 11

2300 Controller Quick Start Guide Page 11

Figure 8 - Probe Configuration page

3. Go and Explore

Names are self-explanatory and instructions are included on the pages of the various wizards, so feel

free to go out and explore. Most wizards require a Submit to confirm changes, so you can play

around and just hit Cancel when you are done.

After setting up the probes and the monitors, the network connection may be severed if desired,

allowing the 2300 to be used as a stand-alone controller. Keep in mind, however, that email/text

notifications and changes to the 2300’s configuration require a network or computer connection.

We hope you have fun with this new controller, but if you have problems, feel free to call us at (978)

749-9949.

Loading...

Loading...