Page 1

by

Water Analytics

Aqua

by

Water Analytics

Aqua

Metrix

Metrix

Description

The model 2200D Dissolved Oxygen analyzer/controller is a rugged and dependable industrial grade microprocessor-based

instrument that is extremely easy to use.

Its large, bright LED digital display is clearly

visible even in direct sunlight. It’s speedy calibration and simple operator interface makes

this analyzer/controller a favorite with instrumentation departments in a wide variety of demanding industrial and municipal application.

Frequently used functions are accessed through

an intuitive step-through menu which is printed

directly on the front panel for ease of navigation. By pressing the MENU key the operator

scrolls through the menu, illuminating an LED

beside the selected item and displaying the

stored value. Arrow keys are used to change the

value. Seldom used or set-once adjustments,

such as password activation are located on DIP

switches on the back of the swing-out front panel.

INPUTS

The 2200D accepts a sensor input from the P91

sensor. The P91 sensor consists of a probe that

is tted with a cartridge (P91D) containing a pre cisely stretched permeable membrane, electrodes

and electrolyte. The inexpensive and easy to

change cartridge will provide continuous service

for years and is then easily replaced in minutes.

The cartridge is hermetically sealed for long shelf

life. Optional mounting hardware include submersion, ow through and “ball oat” assemblies.

Aquametrix Model 2200D

Dissolved Oxygen Anayzer / Controller

Features

• Dissolved Oxygen

level displayed in PPM

or Percent Saturation

• Intuitive step-through menu

design for quick and easy setup

• Bidirectional control

through two control relays

with independent setpoints

for Relay On and Relay Off

• High/low alarm relay

• ALARM LED on front panel

• Membrane perforation alarm

• Output signal is eld-scalable

meter; in a clean water sample to a lab meter;

in a saturated process; in saturated clean water and in air. To Calibrate, press the MENU key

until the CALIBRATION LED illuminates. Use

the arrow keys to set the value determined using a calibration method described above. Press

The Enter key twice. The unit is now calibrated.

OUTPUTS

The 2200D provides three analog outputs, including a 4-20 mA, 0-5 VDC and 0-1 mA. The instrument also provides control of external devices using its two independent control relays. An alarm

relay has both high and low set points with a xed

dead band. When this relay is energized, the Alarm

LED on the front panel also illuminates to clearly

indicate an alarm condition. Factory set for bidirectional control, both control relays can be set to

control either a rising or falling process, with easily

programmed Relay On and Relay Off set points.

DIAGNOSTICS

A self-diagnostics program clearly indicates any

system errors or faults by turning the STATUS LED

on the front panel from green to red. The operator

then scrolls through the menu to STATUS to determine the fault code. The Operator’s Manual indicates the source and likely remedy for the fault.

When the status fault is corrected the STATUS

LED will turn back to green.

for maximum resolution

• Altitude compensation

for maximum accuracy

• STATUS errors illumi-

nate LED on front panel

• Test feature allows simula-

tion of DO readings to test relay

setpoints and analog settings

• Password protection

and watchdog timer

Applications

• Industrial and Municipal

Waste Treatment

• Aeration basin monitoring

• Aquariums

• Fish Hatcheries

CALIBRATION

Calibration can be accomplished by using one

of seven different calibration techniques: in the

process to a portable meter; in clean water to

a portable meter; in a process sample to a lab

ENCLOSURE

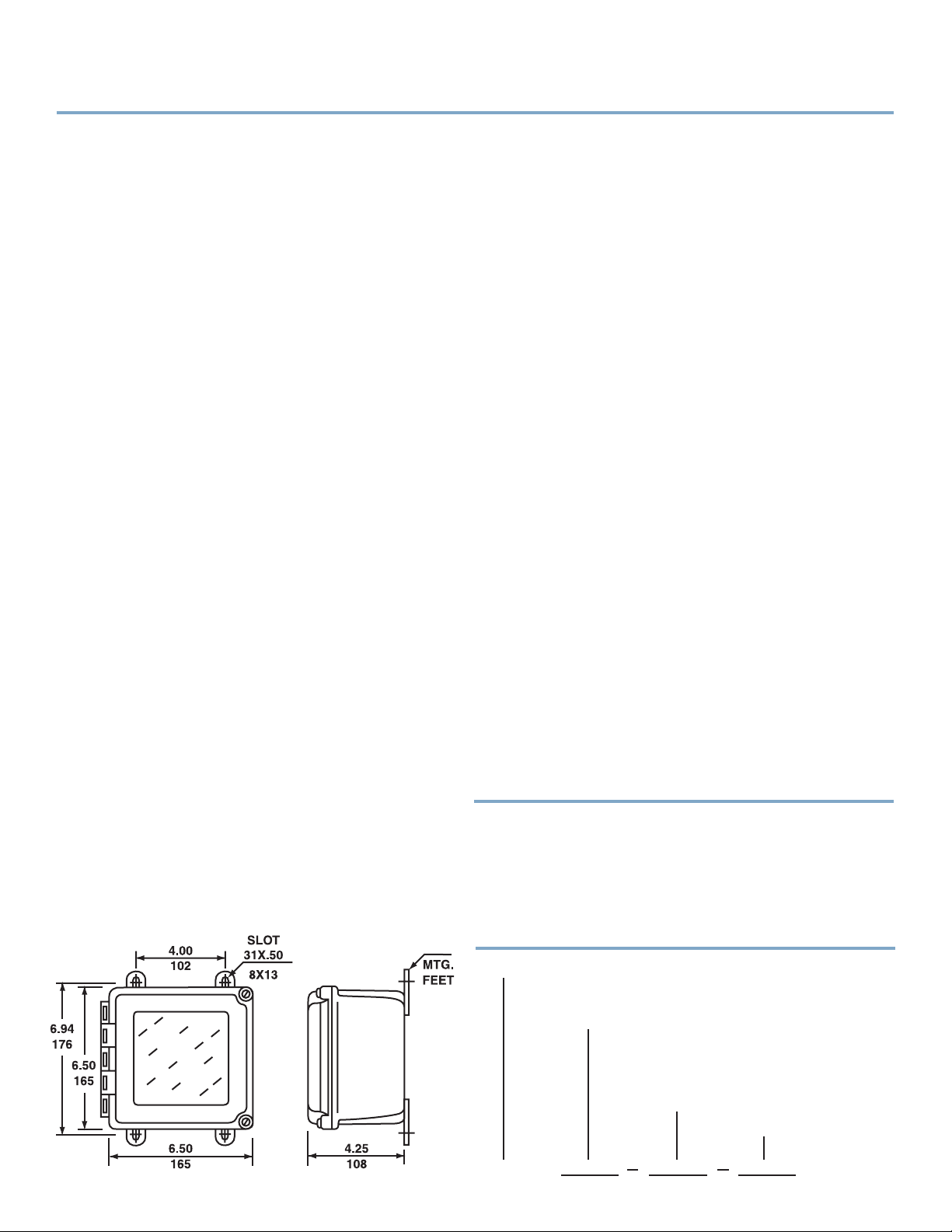

Model 2200D is packaged in a rugged NEMA 4X

berglass reinforced polyester enclosure. It is ideally suited for heavy-duty outdoor applications

such as municipal and industrial wastewater applications.

100 School Street

Andover, MA 01810

978-749-9949

Toll free - 855-747-7623

www.WaterAnalytics.net

Page 2

Model 2200D Dissolved Oxygen Analyzer / Controller

Technical Data

Display 4 x 7 segment 1/2” LED Display

Indicator Lights 4 LED indicators: Status, Alarm, Relay A,

Relay B

Measuring Range

D.O. 0 to 20.00 ppm

Temperature 0 to 400C (32 to 1040 F)

Power Requirements

Standard 98-132 VAC 50/60 Hz, (less than 10 VA)

Optional 196-26 4 VAC 50/60 Hz (less than 10 VA)

23-26 VDC (nominal current: 150 mA)

Ambient Conditions

Temperature -30 to 50°C (-22 to 122°F)

Humidity 0 to 90% RH non-condensing

Control Relays

Number Two Control Relays: Relay A, Relay B

Rating 5A 115/230Vac, 5A 30Vdc, SPDT

Bidirectional Relays factory preset for bidirectional con-

trol, can be individually eld set for rising or

falling process

On/ Off Setpoints Field selectable full scale

Fail-safe Normal or fail safe operation

Relay Indicators Three individual LED’s indicate status of

two control relays and alarm relay.

Analog Outputs

Non-isolated 0-1 mA, 100 W maximum load

Non-isolated 0-5 VDC, 1000 W minimum load

Isolated 4-20 mA, 800 W maximum load Output

is isolated from the input, the ground, line

power and all other outputs.

Range Expand Outputs can be scaled to represent any

segment of the instrument scale to a minimum of 10% of full scale.

Output Holds The analog outputs are automatically

placed on hold when the instrument is

placed in the menu mode

Temperature The 0-1 mA and 0- 5 V dc output can be se-

lected to track either the dissolved oxygen

level of the process or the temperature of

the process.

Temperature Compensation

Automatic 0-40°C (32 to 104°F)

Diagnostics

Invalid Entries Identied by ashing LEDs.

System Error Two color STATUS LED indicates system sta-

tus: Green no fault, Red system fault. Status

menu value indicates system problem and

likely solution.

Alarm LED Illuminates red when Alarm Relay is energized,

indicating high/low process value or memory

loss.

Test Display value and analog outputs can be man-

ually set to any value for testing and diagnostic

purposes.

Safety & Security

Operator Password protected (activated by DIP switch)

Memory Nonvolatile memory (EPROM)

Microprocessor Watchdog timer monitors microprocessor. In-

strument automatically returns to online operation if left in menu mode for more than 10 minutes and no key is pressed.

Sensitivity 0.1% of span

Stability 0.1% of span per 24 hours non-cumulative

Temperature Drift Zero - 0.01% of span per °C

Span - 0.01% of span per °C

Response Time 0.5 second to 90% of value upon step change

Enclosure NEMA 4X molded berglass reinforced polyes-

ter enclosure with four 1/2” conduit holes and

mounting feet for surface mount. A NEMA 4X

plug is provided for one hole.

Mounting

Standard Surface Mount

Optional Panel Mount kit P/N C35 -68

Pipe Mount kit P/N C35-69

Weight 3.5 lbs. (1.6 kg)

Related Products

P91 Dissolved Oxygen probe, for use with P91D cartridge

P91D Replaceable cartridge for P91 probe; thick membrane

MHDS Submersion Mounting Hardware

MHBF Ball Float Hardware

FTA2 Inline Mounting Hardware

Ordering Information

2200D Dissolved Oxygen Analyzer/Controller

1 120 Vac, 50/60 Hz Powe

2 240 Vac, 50/60 Hz Power

A Surface Mount

B Panel Mount

C Pipe Mount

1 Reserved

2200D

www.WaterAnalytics.net 978-749-9949 Toll free - 855-747-7623 (855-pHProbe)

Loading...

Loading...