AquaMark AM-30V, AM-50V, AM-60V Installation Manual

245 W. Roosevelt Road

1

Building 12, Suite 83

West Chicago, IL 60185

800-323-4498

www.aquamarkboosters.com

Installation, Operation & Maintenance Manual

for

AquaMark models AM-30V, AM-50V, AM-60V

Minimum incoming supply line for AM-30V is 1 ½”

Minimum incoming supply line for AM-50V is 2”

Minimum incoming supply line for AM-60V is 2”

Standard voltage for these systems is 240 Volt Single Phase

THIS PUMP MUST BE PRIMED!

2

Open the city water supply valve to the booster. Open the discharge valve from

the pressure booster system that supplies water to the building. Run water in the

building for a minute. This will force water into the pump housing from the city.

The pump will be primed.

We recommend a bypass valve configuration be installed on ALL booster

pump installations.

In normal operation the bypass valve should be in the closed position.

In normal operation the supply line valve from the city water main MUST

remain open.

In normal operation the discharge valve to the building from the booster

should be open.

There is a relief valve included and installed on this AquaMark pressure

booster system. This relief valve discharge shall be piped to a floor drain.

Yearly inspections should be made to check for leaks or unusual noise and

proper maintenance procedures performed if necessary.

Relief valve discharge outlet shall be piped to floor

drain. Follow local codes pertaining to relief valve

piping and drainage.

Installation

3

Leave 12” of clear space around the pressure booster to allow for service

work to be performed as necessary in the future.

Use the included anti-vibration mat underneath the steel plate the booster is

mounted on. You will find this mat underneath the booster (between the

booster and the skid that the booster is bolted to. This mat is placed on the

jobsite floor beneath the pressure boosting system during the installation

process.

Plumb pressure booster as shown in the diagram included in this manual.

Supply pressure booster with correct incoming minimum supply line size (or

greater) as noted on the first page of this manual:

Minimum incoming supply line for AM-30V is 1 ½”

Minimum incoming supply line for AM-50V is 2”

Minimum incoming supply line for AM-60V is 2”

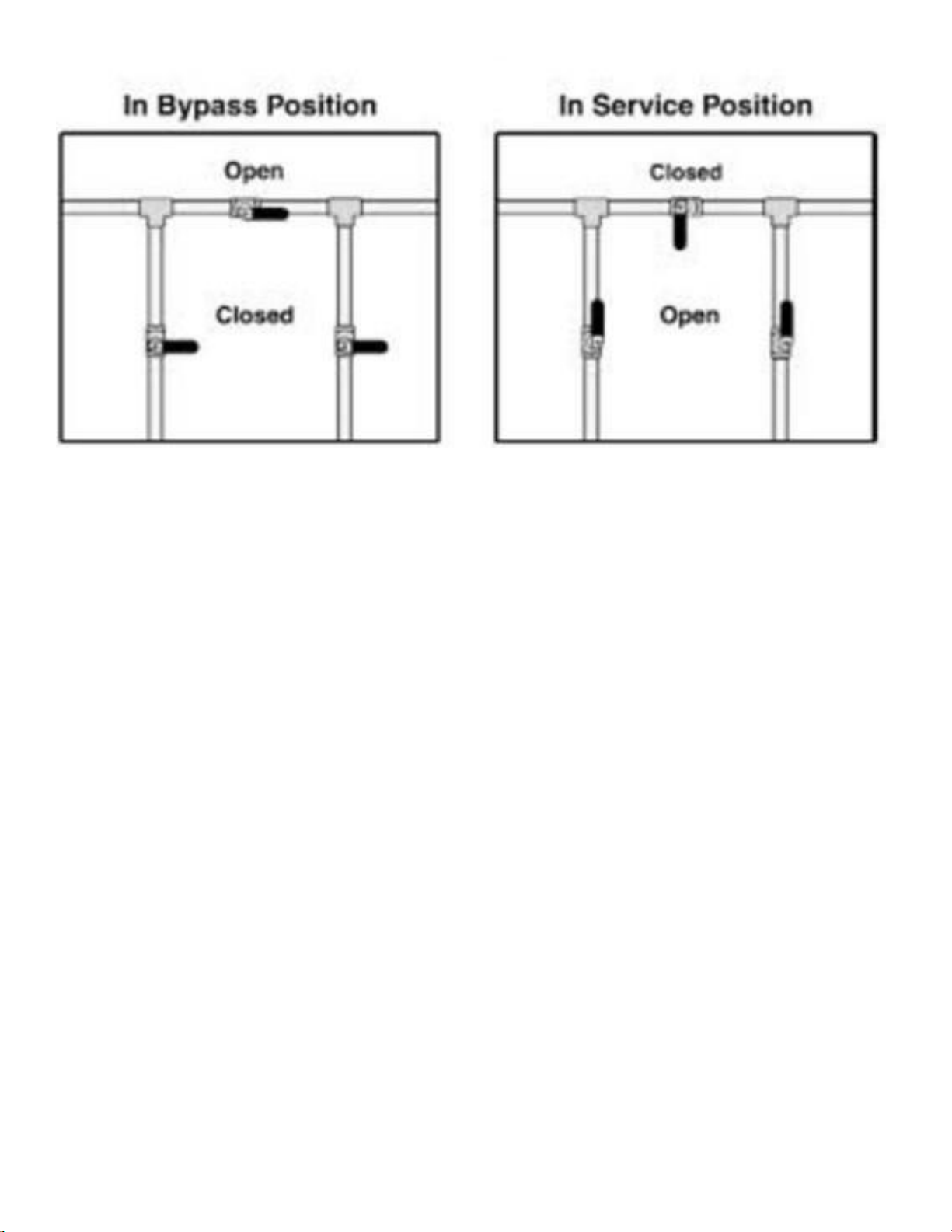

Plumb a three valve bypass system during installation of this pressure

booster. When service needs to be performed this will allow normal city

water pressure to be supplied to the building while servicing/repairing the

pressure booster system.

Unions are recommended when installing this pressure booster system.

Install included vibration isolator in the discharge piping after the connection

point of the bypass loop’s return to the discharge piping. You will find this

zip-tied to the support post of the variable frequency drive unit (blue box).

Have your electrician supply this pressure booster with the correct voltage

and phase electrical power. We recommend a wall mounted cut-off switch

box dedicated to the pressure booster only be mounted on a wall within 6’ of

the pressure booster installation location and should be easily accessible.

Connect the 6’ whip from the pressure booster to the cut-off switch box.

Make sure the breaker used is 20 amps or greater.

Operation

4

Make sure valve from city water supply to the pressure booster is in the full

open position.

Make sure valve on the discharge side of the pressure booster is in the full

open position.

Make sure that the bypass valve line is in the full closed position (if the

bypass valve is in the open position the pressure booster will not shut off.

Supply electrical power to the pressure booster by switching the wall

mounted cut-off switch to the on position.

Pressure booster will turn on and boost pressure to the desired set-point.

Pressure booster will continue to run until the demand has been met.

Pressure booster will enter sleep mode after demand has been met and a

pre-determined amount of time has passed.

Maintenance

This pressure booster has been designed to be maintenance free for many

years.

Do not rest items against switches, gauges, tank drain valves, or pressure

relief valve.

Do not rest items against pump. The pump requires free air space

surrounding it to dissipate heat and take in fresh air for cooling purposes.

Leave 12” of free air space all around the system.

Above is a generic three valve bypass diagram. This will

5

allow service of the pressure booster system when ball

valves are set as shown above in the “Bypass Position”

configuration.

When the ball valves are set as shown in the “In Service

Position” the pressure booster system will be in its normal

mode of operation.

Loading...

Loading...