AquaCheck ACPROBE R Users Manual

AquaCheck ACPROBE-R

Instruction Manual

Feb 2015

www.aquacheck.co.za

2

AquaCheck (Pty) Ltd

All rights reserved

Neither whole nor any part of the information contained in this publication

may be reproduced, transcribed or translated in a ny form, writ ten or elect ronic

for any purpose whatsoever without prior written consent of AquaCheck (Pty)

Ltd.

This publication is intended only to assist the read er in the use of t he product .

AquaCheck (Pty) Ltd shall not be liable for any loss or damage arising from

the use of any information contained in this publication, or any error or

omission in such information, or any incorrect use of the product.

Version 1.1 FEB 2015.

3

STATEMENT OF COMPLIANCY

ELECTRO-MAGNETIC COMPLIANCE

The ACPROBE-R wireless probe has been tested and found to comply with the

limits for this Class digital device, pursuant to the requirements of the CE rules.

These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause interference to other radio communications.

EMC APPROVALS

The ACPROBE-R, Analogue and MobiCheck versions of the AquaCheck probe have

been tested and found to comply with the following EMC guidelines:

IMMUNITY TESTING: IEC 61000-6-1 and IEC 61000-6-2

Electrical Fast Transients (EFT) - IEC 61000-4-4

Electrostatic Discharge (ESD) - IEC 61000-4-2

Surges - IEC 61000-4-5

Radiated Susceptibility - IEC 801 –3

Voltage Dips and Interruptions - IEC 61000-4-11

Conducted Susceptibility - IEC 61000-4-6

EMISSIONS AND HARMONICS: CISPR 11/14/15/22 IEC 61000-3-3 and IEC 61000-3-2

Radiated Emissions

Conducted Emissions

Flicker

Harmonics

4

NOTICE:

Changes or modifications made to this equipment not expressly approved by

AquaCheck (Pty) Ltd. could void the user's authority to operate the equipment.

Use only AquaCheck (Pty) Ltd approved acces sories.

This device complies with part 15 of the FCC Rules. Operation is subject to the following

two conditions: 1) This device may not cause harmful interference, and 2) This device

must accept any interference received, including interference that may cause undesired

operation

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenn a.

• Increase the separation between the eq uipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/T V t ec hnician for help

This device complies with Industry Canada licence-exempt RSS standard(s). Operation

is subject to the following two conditions: (1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause

undesired operation of the device.

Under Industry Canada regulations, this radio transmitter may only operate using an

antenna of a type and maximum (or lesser) gain approved for the transmitter by Industry

Canada. To reduce potential radio interference to other users, the antenna type and its

gain should be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not

more than that necessary for successful communication.

This radio transmitter (identify the device by certification number, or model number if

Category II) has been approved by Industry Canada to operate with the antenna types

listed below with the maximum permissible gain and required antenna impedance for

each antenna type indicated. Antenna types not included in this list, having a gain

greater than the maximum gain indicated for that type, are strictly prohibited for use with

this device.

5

Antenna

Gain (dBi)

Whip

5.25

Wideband Omni

2.0

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils

radio exempts de licence. L'exploitation est autorisée aux deux conditions suivantes : (1)

l'appareil ne doit pas produire de brouillage, et (2) l'appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d'en compromettre le

fonctionnement.

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio peut

fonctionner avec une antenne d'un type et d'un gain maximal (ou inférieur) approuvé

pour l'émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage

radioélectrique à l'intention des autres utilisateurs, il faut choisir le type d'antenne et son

gain de sorte que la puissance isotrope rayonnée équivalente (p.i.r.e.) ne dépasse pas

l'intensité nécessaire à l'établissement d'une communication satisfaisante.

Le présent émetteur radio (identifier le dispositif par son numéro de certification ou son

numéro de modèle s'il fait partie du matériel de catégorie I) a été approuvé par Industrie

Canada pour fonctionner avec les types d'antenne énumérés ci-dessous et ayant un

gain admissible maximal et l'impédance requise pour chaque type d'antenne. Les types

d'antenne non inclus dans cette liste, ou dont le gain est supérieur au gain maximal

indiqué, sont strictement interdits pour l'exploitation de l'émetteur.

List of antennas

6

“...then anyone who leaves behind him a written

manual, and likewise anyone who receives it, in the

belief that such writing will be clear and certain,

must be exceedingly simple-minded...”

Plato

(423-347 BC).

7

CONTENTS

LIST OF FIGURES .................................................................................................................9

1 Introduction ....................................................................................................................10

2 ACPROBE-R Wireless System Components ..............................................................11

3 Probe construction .........................................................................................................13

4 General Statistics ...........................................................................................................14

5 Sensor Configuration .....................................................................................................14

6 Probe Settings .................................................................................................................14

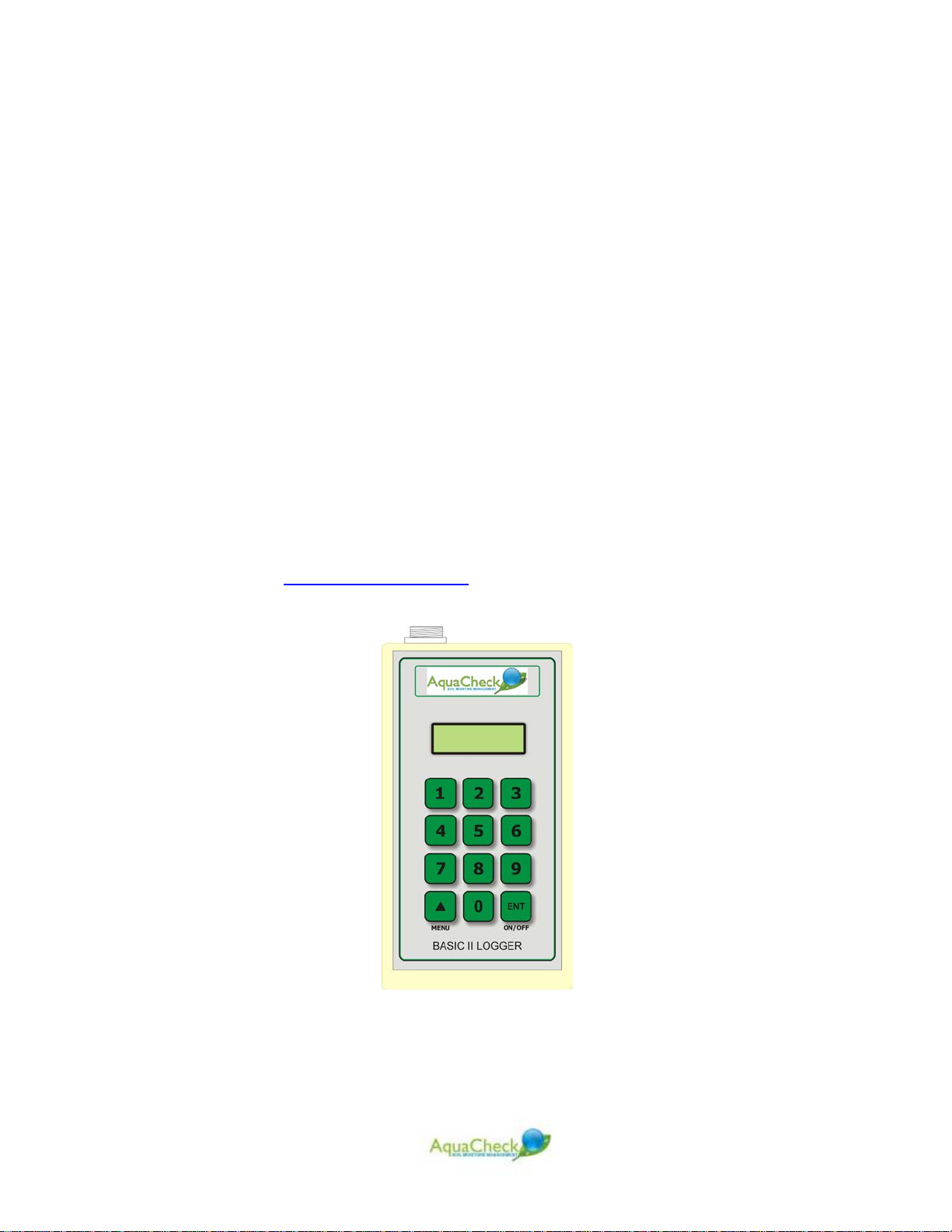

7 Hand-held wireless logger .............................................................................................15

7.1 Introduction ..............................................................................................................15

7.2 Menu Functions .......................................................................................................17

7.3 THE STEPS OF COMMISSIONING .....................................................................20

8 COMMISSIONING STEPS IN DETAIL ....................................................................20

8.1 Charge the logger’s battery. .....................................................................................20

8.2 Record the unique ID of each Basic II probe PRO II. .............................................21

8.3 Program the ID’s into the Logger ............................................................................21

8.4 Program the current Time and Date into the Logger ...............................................22

8.5 Perform a Profile Log on all Programmed Profiles .................................................23

9 ADDITIONAL FEATURES .........................................................................................24

9.1 Single Log ................................................................................................................24

9.2 9.2 Clear All Logs ....................................................................................................24

9.2 9.2 Clear All Logs ....................................................................................................25

9.3 9.3 View Stats ..........................................................................................................25

9.3 9.3 View Stats ..........................................................................................................26

10 Trouble shooting ............................................................................................................27

11 Taking a reading ............................................................................................................28

11.1 Adding a probe as a profile ......................................................................................28

11.2 Download readings ..................................................................................................28

11.2.1 Profile Log .......................................................................................................28

11.2.2 Single Log ........................................................................................................29

12 Add-on’s ..........................................................................................................................29

13 Maintenance ...................................................................................................................29

14 INSTALLATION OF THE PROBE ............................................................................30

14.1 Installation in sandy soils .........................................................................................30

14.2 Using the “Slurry Technique” ..................................................................................32

15 REFILL LIMITS ...........................................................................................................35

8

16 Getting Started ...............................................................................................................37

16.1 STEP 1 – Setup logger .............................................................................................37

16.2 STEP 2 - Activate probe (s) .....................................................................................37

16.3 STEP 3 – Installing the Software .............................................................................37

16.4 STEP 4 – Setting up blocks .....................................................................................39

16.5 STEP 5 – Connecting the logger to the CropGraph software ..................................39

16.6 STEP 6 – Setting up groups on the logger ...............................................................39

16.7 STEP 7 – Taking the first reading ............................................................................39

9

LIST OF FIGURES

Figure 1: Hand-held wireless logger ................................................................................... 11

Figure 3: AquaCheck probe ................................................................................................ 12

Figure 4: Probe Construction ............................................................................................. 13

Figure 5: RF Utility Software............................................................................................... 15

Figure 6: Drilling a hole with the hand-held auger .......................................................... 30

Figure 7: Collecting sand from the augured hole ............................................................ 31

Figure 8: A good fitting access tube .................................................................................. 31

Figure 9: Wetting the profile ............................................................................................... 32

Figure 10: Pouring slurry from the augured hole back into the hole ............................ 33

Figure 11: Increasing the viscosity of the slurry .............................................................. 33

Figure 12: An installed MobiCheck access tube ............................................................. 34

Figure 13: A typical hand-auger bit ............................................................................... 34

Figure 14: A typical hand-auger T-handle bar ................................................................. 34

Figure 15: A typical separate level graph showing a depletion cycle .......................... 35

Figure 16: A typical summed graph showing a depletion cycle .................................... 36

Figure 17: ProductKey Menu .............................................................................................. 38

Figure 18: Software registration form ................................................................................ 38

10

1 Introduction

Capacitance based soil moisture probes have been used for irrigation scheduling

purposes for the past 15 years around the world.

Global market trends have however necessitated a revised point of departure for

affordable and practical irrigation scheduling technology and instruments.

AquaCheck (Pty) Ltd, has recognized the shift in global trends. The AquaCheck

probe was therefore specifically developed to address these needs. Its design and

construction is not only flexible enough to interface with the most advanced irrigation

system, but also has the ability to function as a very basic tool for entry level

irrigators.

Five versions of the AquaCheck II probe are available:

o A BASIC II wireless continuous logging version using a wireless hand-held

logger for data transfer to a PC;

o An ANALOGUE version compatible to third party analogue loggers.

o A SDI-12 version compatible to third party SDI-12 loggers.

o A MODBUS version compatible to third party MODBUS loggers.

o An AquaGREEN probe (SDI-12 or MODBUS) for greenhouse and turf

applications.

Capacitance sensors measure the dielectric constant of the soil by applying a

voltage between two electric plates (sensor rings). The frequency measured by the

rings varies with the dielectric constant, and this is used to calculate the soil

moisture content of the soil. The sensors are typically positioned at various depths

on a column 32mm in diameter. The current AquaCheck probe range offers six

standard length options varying from 200mm to 1200m m. The 400mm typically has

4 sensors and the 1200mm offers 6 sensor depths (see page 10 – configuration).

The column with attached sensors is posit ioned in the probe shaft and is sea led with

a water resistant resin. After assembly, the sensors are individually calibrated or

normalized to set the default air and water counts for each sensor. The probe also

takes a soil temperature reading at each depth. Each sensor has a built-in

temperature variation compensation factor. Readings from each sensor are

therefore corrected for possible inherent electronic temperature v ar iations.

The probe can be set to take readings at variable time intervals but typically a

reading every 30 minutes (on all 6 sensors) would allow f or up to 42 days on-board

storage capacity.

This manual covers the BASIC II wireless version.

11

1 ACPROBE-R Wireless System Components

Figure 1: Hand-held wireless logger

The ACPROBE-R wireless system consists of the following components:

A. A continuous logging soil moisture probe

B. Hand-held wireless logger unit & CropGraph software

C. Accessories:

a. Charger & Download cable

b. Manual & Installation CD

c. RF Utility Module

d. Installation Kit

The AquaCheck Basic II wireless probe is also offered in a sub-surface

configuration for turf and pasture applications. For this applicat ion the probe head

and shaft are separate units joined by a 0.5m cable. The shaft is equipped with a

hardened top cap, which if viewed from the top, looks like a standard popup

sprinkler head once installed.

The probe head is embedded in a separate sleeve with a screw-on lid allowing

access to the probe head. The lid can be opened and probe head removed to

replace the battery pack. (For more detail on the subs urface version please visit

our website at www.aquacheck.co.za and browse the products section)

12

Figure 2: AquaCheck probe ACPROBE-R

Loading...

Loading...