Page 1

Acrylic Pan - Roll-In Shower - ADA Compliant

p

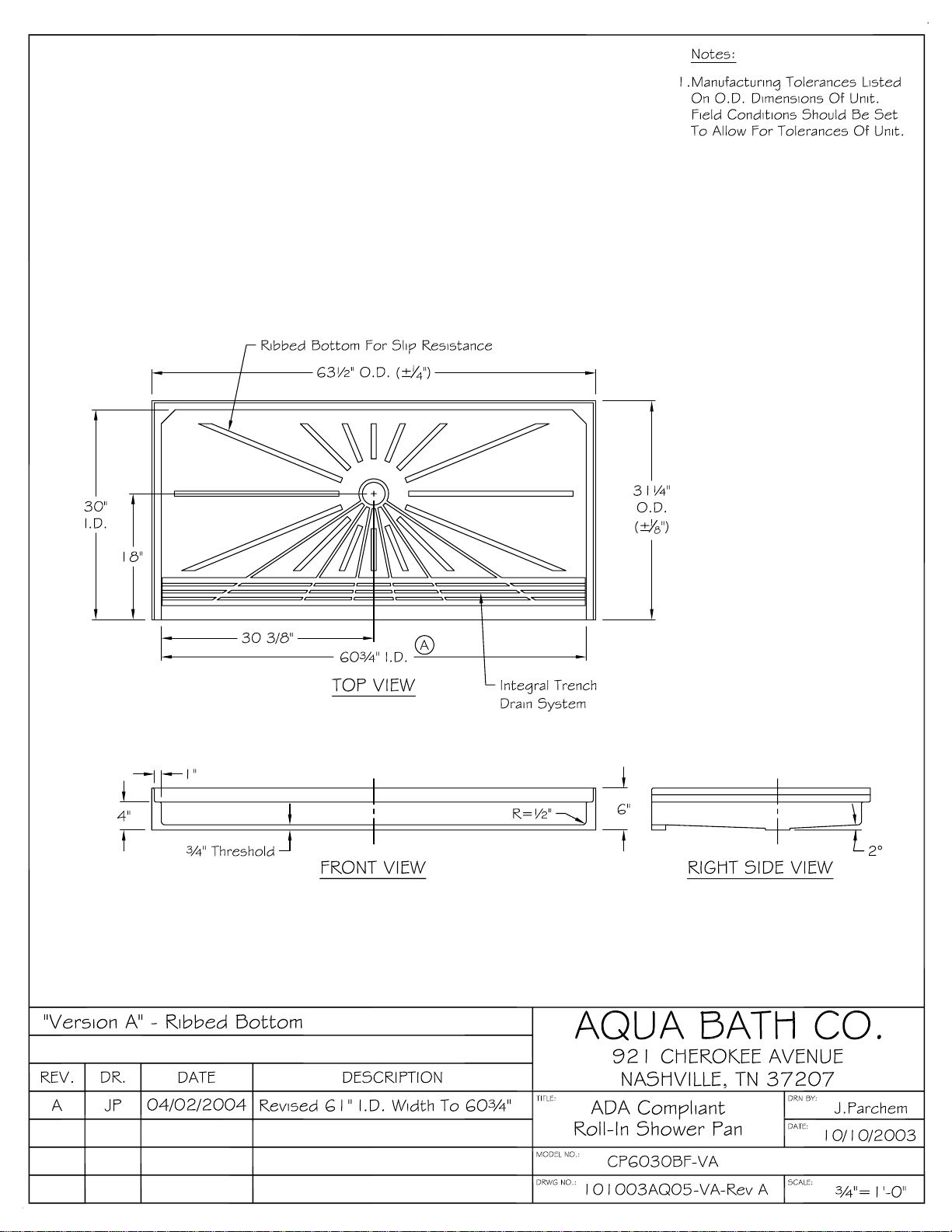

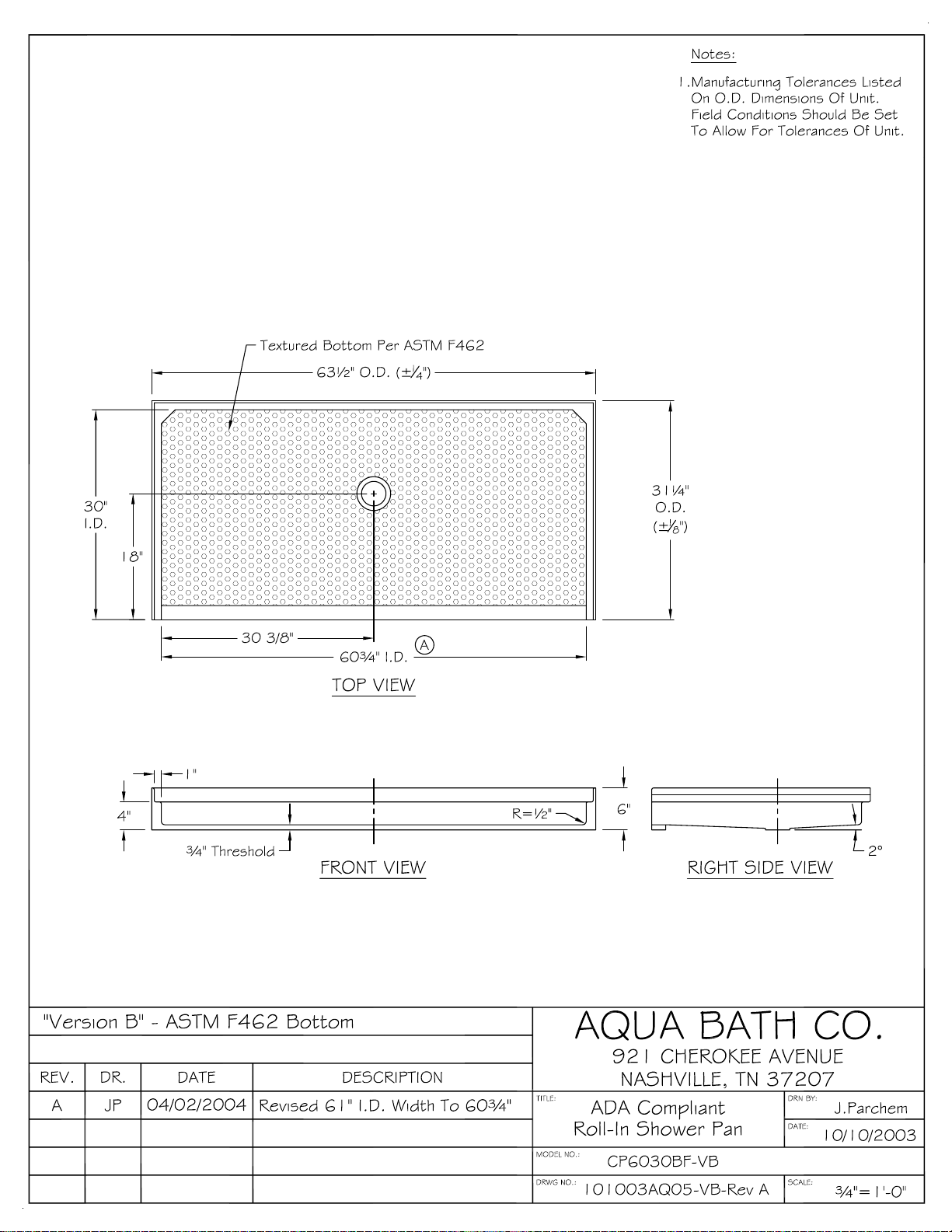

• Model CP6030BF

• Acrylic pans designed for new build and renova t ions of

existing hospitals, nursing homes, rehabilitation centers,

hotels, motels, dormitories and residential applications.

• Meets ANSI A117.1, ADA Guidelines and other standards

for accessibility

• Acrylic one-piece molded construction simplifies installation

with a lightweight durable base.

• Inside dimensions: 60 3/4" W x 30" D x 4" H.

• 3/4" threshold height for top of slab installation.

• Patented integral molded in "Trench Drain System" to help

channel water from the front of the unit to the center drain location.

For additional information, call the

Aqua Bath Customer Service

Department At 1-800-232-2284

Please check with your local city and

state for code compliancy. Aqua Bath's

advertised ADA compliant units are

based on our interpretation of the

Americans with Disabilities Act 1991

Guidelines. Field alterations or improper

installation could take the units out of

compliance. Aqua Bath accepts no

onsibility for final code compliance.

res

ROLL-IN SHOWER PAN

Aqua Bath Rol l-In Shower Pan CP6030BF is molded from a single sheet of cast acrylic so as not to have any

joints or seams. Shall meet ANSI Z124.2. Shall meet ADA guidelines and other standards for accessibility.

Unit shall have a backside flame spread of less than 30 (Class B). Shall be designed to be ADA COMPLIANT

and NAHB LISTED. The enclosure shall have inside dimensions of 60¾" W x 30" D x 4" H and outside

dimensions of 63½" W x 31¼" D x 6" H. The unit shall be molded with a patented integral recessed "Trench

Drain System" so as to direct water to the center drain location. The approximate weight of the unit shall be 55lbs.

ADA states that the threshold must be flush with the finished floor.

The roll-in shower pan shall be equipped with the following factory installed accessory: 1) Self-caulking brass drain

with stainless steel strainer (not installed). 2) Ribbed bottom for slip resistance (standard).

AVAILABLE OPTIONS

1) Available in model CP6030TD - This unit is the same as the above stated unit except it will have a center front

trench drain located approximately 4" inside of the front flange.

2) ASTM F462 non-slip bottom (see drawing CP6036BF-VB).

(*) When the ASTM F462 bottom is specified with the center drain location, it will re-configure the trench

drain system. A signed off approval is required for the bottom re-configuration.

Modifications: Received and / or approved by:

CP6030BF Acrylic Pan - Roll-In Shower Unit - ADA Compliant

05/04

AQUA BATH COMPANY INC.921 Cherokee Ave.Nashville, TN 372071-800-232-2284Fax (615) 227-9446

www.aquabath.com

Page 2

Page 3

Page 4

CP6030BF Acrylic Roll-In Shower Pan Installation Guidelines

T

Installation Requirements

• Check to make sure that rough in dimensions of framing studs matches the outside dimensions (OD) of the

acrylic pan (31 1/4" x 63 1/2", reference "top view" in illustration box below) See Figures #1 and #2 on Page 2

• Pre-Drill holes in acrylic pan top flanges (matching location of stud supports) for connection of acrylic pan to

stud supports. The diameter of holes drilled should be the proper size for diameter of fasteners to be used (reference

"detail at top flange" in illustration box below) See Figure #3 on Page 2

• Check to make sure that area where pan is to be installed is level, free of debris, and that the area where the drain

is placed has been chipped out (1/2" deep x 10" diameter). See Figure #4 on Page 2

Steps For The Installation Process

• Dry fit acrylic pan into its installation position to ensure proper dimensional fit, that chipped out area at drain

location is in correct location and that acrylic pan sits level. See Figure #5 on Page 2

• After dry fit is complete, you may grout acrylic pan into place. Be sure to use a Non-Shrink Grout and mix it

extra wet. After grout is place, make sure pan is level left to right and front to back along top flanges (do not level

at floor of unit as it is angled to direct water to the drain). All acrylic pans have a 2-degree angle built into them

to help direct water to the drain (reference "side view" in illustration box below). See Figure #6 on Page 2

• Place a 100lb weight at drain location and additional weights on floor of acrylic pan to help pan adhere to grout.

• Attach acrylic pan to stud supports through pre-drilled holes with fasteners.

• Apply a bead of construction adhesive (1/8") at front flange of acrylic pan to attach front of unit to floor.

30" I.D.

Pre-drilled hole for

connection of acrylic

Ribbed Bottom For Slip Resistance

63½" O.D.

18"

30½"

¼"

1"

4"

61" I.D.

OP VIEW

R=½"

¾"

FRONT VIEW

pan to stud supports.

31¼" O.D.

31"

Integral Trench

Drain System

6"

RIGHT SIDE VIEW

2" Top

Flange

Stud Support

Detail At Top Flange

2°

CP6030BF Acrylic Roll-In Shower Pan Installation Guidelines

02/04

AQUA BATH COMPANY INC.921 Cherokee Ave.Nashville, TN 372071-800-232-2284Fax (615) 227-9446

Page 1

Page 5

CP6030BF Acrylic Roll-In Shower Pan Installation Guidelines

Figure #1 Figure #2

Figure #3 Figure #4

Figure #5 Figure #6

CP6030BF Acrylic Roll-In Shower Pan Installation Guidelines

AQUA BATH COMPANY INC.921 Cherokee Ave.Nashville, TN 372071-800-232-2284Fax (615) 227-9446

Page 2

02/04

Page 6

1. Product Name

QUIKRETEª Non-Shrink Precision Grout #1585-00

2. Manufacturer

The QUIKRETE Companies

One Securities Centre

3490 Piedmont Rd., NE, Suite 1300

Atlanta, GA 30305

(404) 634-9100

Fax: (404) 842-1424

www.quikrete.com

3. Product Description

BASIC USE

Typical applications for QUIKRETE Non-Shrink

Precision Grout include grouting of:

• All types of machinery

• Steel columns

• Bearing plates

• Precast concrete

• Other anchoring conditions that require

high in-service strength

The nonshrink characteristics of Non-Shrink

Precision Grout make it stable and capable of

handling high load transfers.

COMPOSITION & MATERIALS

QUIKRETE Non-Shrink Precision Grout is a non-

metallic Portland cement based material.

Non-Shrink Precision Grout is a preblended

product including expansi

ve additives, requiring

only the addition of water to obtain flowable

properties and high strengths.

SIZES

• 50 lb (22.7 kg) bags

COLORS

• Gray

YIELD

A 50 lb (22.7 kg) bag of QUIKRETE Non-Shrink

Precision Grout will yield 0.45 cu ft (12.7 L) at

flowable consistency.

LIMITATIONS

The proper cleaning and wetting of surfaces to

be grouted is vital to maximum performance.

Hot and cold temperature precautions, as they

apply to concrete, should also be followed.

4. Technical Data

APPLICABLE STANDARDS

ASTM International

• ASTM C109/C109M Standard Test Method for

Compressive Strength of Hydraulic Cement

Mortars (Using 2-in. or [50-mm] Cube

Specimens)

• ASTM C939 Standard Test Method for Flow of

Grout for Preplaced-Aggregate Concrete

(Flow Cone Method)

• ASTM C1090 Standard Test Method for

Measuring Changes in Height of Cylindrical

Specimens from Hydraulic-Cement Grout

• ASTM C1107 Standard Specification for

Packaged Dry, Hydraulic-Cement Grout

(Nonshrink)

• ASTM E488 Standard Test Methods for

Strength of Anchors in Concrete and

Masonry Elements

U.S. Army Corps of Engineers (USACE) - CRD 621

PHYSICAL/CHEMICAL PROPERTIES

QUIKRETE Non-Shrink Precision Grout complies

with all properties of ASTM C1107 and CRD 621

producing the results shown in Table 1.

5. Installation

MIXING

QUIKRETE Non-Shrink Precision Grout should be

mechanically mixed for a minimum of 5 minutes.

PRECAUTIONS

A

dd the minimum

amount of wa

ter necessary

to produce the desired flow characteristics as

indicated in Table 2. Do not exceed a flow of

20 seconds per ASTM C939.

METHODS

Surfaces to receive the grout must be clean

and free of any type of foreign matter, grease,

paint, oil, dust or efflorescence. In some cases it

may be necessary to roughen smooth surfaces

or etch old ones with acid. The area should be

flushed and soaked with clean water prior to

grouting leaving no standing water. Place the

GROUTS 03600

The QUIKRETE Companies

SPEC-DATAªand MANU-SPECªare registered trademarks of Reed Elsevier Inc. The ten part SPEC-DATA format conforms to the editorial style

of The Construction Specifications Institute and is used with their permission. The manufacturer is responsible for technical accuracy. ©2005 Reed Construction Data. All Rights Reserved.

TM

TABLE 1 TYPICAL PHYSICAL PROPERTIES AT 73°F (23°C)

Compressive strength, ASTM C109 modified per

ASTM C1107

Plastic consistency

1 day 3000 psi (20.7 MPa)

3 days 9500 psi (65.5 MPa)

7 days 10,000 psi (68.9 MPa)

28 days 14,000 psi (96.5 MPa)

Height change, ASTM C1090

1, 3, 7 and 28 days 0 - 0.2%

Flowable consistency

1 day 3000 psi (20.7 MPa)

3 days 9000 psi (62.1 MPa)

7 days 9500 psi (65.5 MPa)

28 days 12,500 psi (86.2 MPa)

Height change, ASTM C1090

1, 3, 7 and 28 days 0 - 0.2%

Fluid consistency

1 day 2500 psi (17.2 MPa)

3 days 5000 psi (34.5 MPa)

7 days 6000 psi (41.4 MPa)

28 days 8000 psi (55.2 MPa)

Height change, ASTM C1090

1, 3, 7 and 28 days 0 - 0.2%

Pull-out strength, 35,000 psi (241 MPa)

ASTM E488

1

1

1 1/4" (31 mm) bolts embedded 9" (225 mm) deep in 3" (75 mm)

hole in 2000 psi (13.8 MPa) concrete.

TABLE 2 APPROXIMATE WATER REQUIRED FOR 50 LB

(22.7 KG) OF GROUT

Plastic 1 gal (3.8 L)

Flowable 1 gal + 1 pt (4.3 L)

Fluid 1 gal + 3 pt (5.2 L)

TABLE 3 WORKING TIME

Temperature Working time

50°F (10°C) 25 min

73°F (23°C) 25 min

90°F (32°C) 15 min

QUIKRETEª Non-Shrink Precision Grout #1585-00

®

Page 7

SPEC-DATAªand MANU-SPECªare registered trademarks of Reed Elsevier Inc. The ten part SPEC-DATA format conforms to the editorial style

of The Construction Specifications Institute and is used with their permission. The manufacturer is responsible for technical accuracy. ©2005 Reed Construction Data. All Rights Reserved.

TM

grout quickly and continuously using light rodding to eliminate air bubbles.

WORKING TIME

When properly mixed to a fluid consistency

QUIKRETE Non-Shrink Precision Grout will comply with all portions of ASTM C1107 and CRD

621 and retain a fluid consistency for the maximum usable working times stated in Table 3.

TEMPERATURE

Grout temperature should be maintained from

50 - 90 degrees F (10 - 32 degrees C) to achieve

specified results. Use cold water in hot weather

or hot water in cold weather to achieve desired

grout temperature. Do not pour grout if temperature is expected to go below 32 degrees F

(0 degrees C) within a 12 hour period.

CURING

A damp cure of at least 3 days is necessary to

control the nonshrink characteristics and

maintain strength levels.

6. Availability

QUIKRETE Non-Shrink Precision Grout is available at leading concrete construction supply

houses and distributors. Contact QUIKRETE

Construction Products for the name of the

nearest dealer.

7. Warranty

The QUIKRETE Companies warrant this product

to be of merchantable quality when used or

applied in accordance with the instructions

herein. The product is not warranted as suitable for any purpose or use other than the

general purpose for which it is intended.

Liability under this warranty is limited to the

replacement of its product (as purchased)

found to be defective, or at the shipping

companies’ option, to refund the purchase

price. In the event of a claim under this warranty, notice must be given to The QUIKRETE

Companies in writing. This limited warranty is

issued and accepted in lieu of all other

express warranties and expressly excludes

liability for consequential damages.

8. Maintenance

None required.

9. Technical Services

The QUIKRETE Companies maintain technical

field representatives throughout the country.

Contact a local distributor for the name and

number of the nearest representative, or call

QUIKRETE Construction Products.

10. Filing Systems

• First Source«

• Additional product information is available

from the manufacturer.

GROUTS 03600

The QUIKRETE Companies

6943-09

®

Loading...

Loading...