Page 1

R

INSTALLATION

XWAV 1422

AND

OPERATING

INSTRUCTIONS

XWAV 1829EZ

Models: XWAV-1422, -1829, -1422EZ & -1829EZ

PASS THROUGH OVEN

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this equipment.

Initial heating of unit may generate smoke or fumes and must be done in a well ventilated area.

Overexposure to smoke or fumes may cause nausea or dizziness.

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

ANSI/NSF4

P/N 96000079 9/06

Phone: +1

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

(214) 421-7366

APW WYOTT

729 Third Avenue

Dallas, TX 75226

!!

!!

1

Page 2

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information isrequired.

Model Number Serial Number Date Purchased

TABLE OF CONTENTS

SECTION ITEM PAGE SECTION ITEM PAGE

1 Owner's Information 2

2 Safety Information 2

3 Specifications 3

4 Installation Instructions 4

5 Operation 6

6 Cleaning 14

WARNING: In Europe, appliance must be connected by an earthing cable to all other units

in the complete installation and thence to an independent earth connection in compliance

!

with EN 60335-1 and/or local codes

WARNING: An earthing cable must connect the appliance to all other units in the complete

installation and from there toan independent earth connection.

!

7 Troubleshooting 14

8 Preventative Maintenance 15

9 Wiring Diagrams 15

10 Parts List & Exploded View 24

11 Warranty 27

1. OWNER’S INFORMATION

General Information:

1. Always clean equipment thoroughly before first use. (See general cleaning instructions).

2. Check rating label for your model designation and electrical rating.

3. For best results, use stainless steel counter tops.

General Operation Instructions:

1. All food-service equipment should be operated by trained personnel.

2. Do not allow your customers to come in contact with any surface labeled “CAUTION HOT”.

3. Never touch ceramic or steel heaters.

!

!

Warranty Information:

Reliability Backed By APW Wyott’s Warranty:

All APW Wyott Pass Through Ovens are backed by a one year parts and labor warranty, including On-Site

Service calls within 50 miles of authorized service technicians.

Service Information:

Service Hotline (800) 733-2203

2. SAFETY INFORMATION

APW Wyott equipment is designed, built and sold for commercial use and should be operated by trained

personnel only. Clearly post all CAUTIONS, WARNINGS and OPERATING INSTRUCTIONS near each

unit to insure proper operation and to reduce the chance of personal injury and/or equipment damage. This

product is used for the cooking, defrosting or re-thermalization of food products only.

Always disconnect power before servicing the unit. Surfaces will remain hot after power has been turned

off. Allow unit to cool before cleaning or servicing. Never clean the unit by immersing it in water. The unit is

not protected against water jets; DO NOT CLEAN PASS THROUGH OVEN WITH A WATER JET. Always

clean equipment properly before first use.

2

Page 3

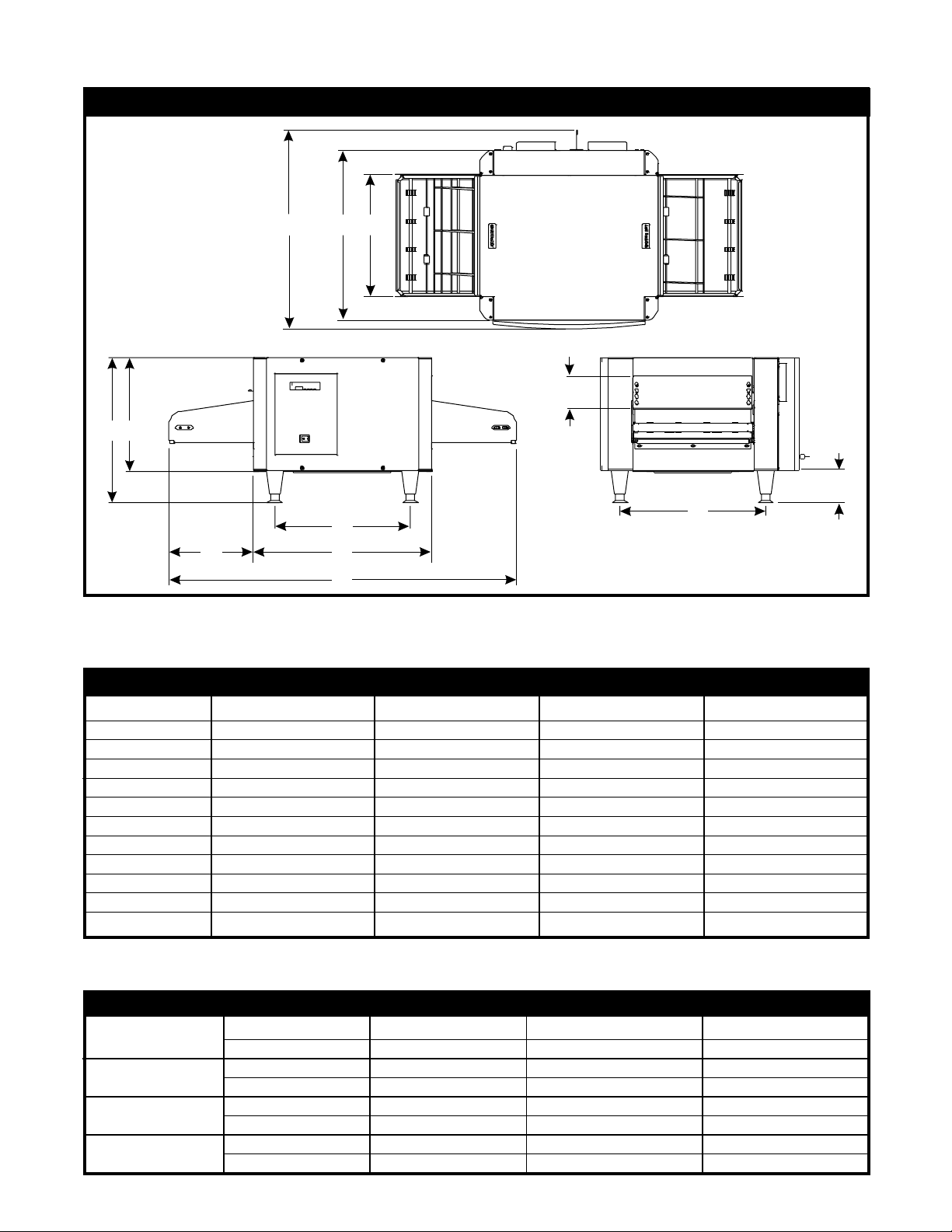

3. SPECIFICATIONS

OVERALL DIMENSIONS - XWAV-1422, -1829, -1422EZ & -1829EZ

B

A

C

J

E

D

L

F

K

G

H

I

Dimensions: INCHES (mm)

DIMENSION XWAV1422 XWAV 1829 XWAV1422EZ XWAV1829EZ

28.0 (711)

25.0 (635)

19.1 (486)

18.0 (457)

14.0 (356)

24.1 (611)

10.5 (267)

29.5 (749)

50.5 (1283)

3.8 (97)

22.0 (559)

4.0 (102)

24.5 (622)

21.0 (533)

15.1 (385)

18.0 (457)

14.0 (356)

16.8 (425)

10.5 (267)

22.0 (559)

43.0 (1092)

3.8 (97)

18.0 (457)

4.0 (102)

28.0 (711)

25.0 (635)

19.1 (486)

18.0 (457)

14.0 (356)

24.1 (611)

10.5 (267)

29.5 (749)

50.5 (1283)

3.8 (97)

22.0 (559)

4.0 (102)

C

D

E

F

G

H

K

A

B

I

J

L

24.5 (622)

21.0 (533)

15.1 (385)

18.0 (457)

14.0 (356)

16.8 (425)

10.5 (267)

22.0 (559)

43.0 (1092)

3.8 (97)

18.0 (457)

4.00 (102)

Electrical Rating:

MODEL WATTS VOLTS AMPS (1 Phase) NEMA PLUG

XWAV1422

XWAV1829

XWAV 1422EZ

XWAV 1829EZ

5400

5400

7200

7200

5500

5500

7000

7000

208

240

208

240

208

240

208

240

3

26.0

22.5

34.6

30.0

26.4

22.9

33.7

29.2

6-30P

6-30P

6-50P

6-50P

6-30P

6-30P

6-50P

6-50P

Page 4

Power Cord:

Six (6) foot, 3 wire grounded cord. If the supply cord is damaged, the manufacturer, or an authorized

service agent, must replace it in order to avoid a hazard and warranty. Please contact the factory by

calling the 800 # located on the unit.

Shipping Weights:

XWAV1422 XWAV 1829 XWAV1422EZ XWAV1829EZ

115 lbs. (52.2 kg.)

149 lbs. (67.6 kg.)

115 lbs. (52.2 kg.)

149 lbs. (67.6 kg.)

4. INSTALLATION INSTRUCTIONS

If the carton appears damaged, or damage is discovered once the carton is opened, stop

immediately and contact the freight company to file a damage claim.

CAUTION: The Pass Through Oven is shipped assembled. The unit is shipped with

urethane supports between the top heaters and the conveyor assembly. Please remove

all urethane supports and packaging materials before operating the unit. Failure to

!

remove all packaging materials may leadto a fire and / or damage to the appliance.

1. Remove allexternal packaging that is protecting top portion of unit.

2. Remove unit from shipping container while in the upright position. The unit can be lifted out of the

carton by grasping under the conveyor on each side of the appliance. Please remove the plastic

bag.

3. Remove all internal packaging to the unit.

inside the tunnel oven between the top heaters and the conveyor.

conveyor trays. Remove tape from extrusion corners. Remove tape from deflecting curtains

located just above entrance and exit of conveyor.

4. Visually inspect all external and internal portions of unit for damage.

top white ceramic elements located inside the oven tunnel after removal of urethane

supports.

detect cracks.

To inspect these white ceramic elements, use a small mirror held under each element to

Important: The Ceramic elements are fragile and will break under

stress. Do not twist, pull, push, or otherwise subject the white ceramic elements to

stress.

5. Wipe down the exterior of the unit using a cloth with warm water. Do not use abrasive pads or

cleaners as they will damage the stainless steel surface and high temperature plastic.

NOTE: DO NOT USE CLEANERS OF ANY KIND ON THE WHITECERAMIC HEATERS.

6.

Remove four feet from box and install into threaded nuts located at the four corners underside of the

left and right housings; Also remove conveyor extension tray(s). Conveyor extensions should be

hung off end of conveyor frame. Model XWAV 1422EZ and XWAV 1829EZ will have two conveyor

extensions for loading and exit ends.

7. Place unit in operating location.

: Make sure that the operating location is in an area where the

Note

ambient temperature is held constant (minimum 70°F). Please avoid areas such as near

exhaust fans and air conditioning ducts.

Warning

Ensure that operation location is at a reasonable distance from combustible walls and materials

otherwise combustion or discoloration could occur.

important in maintaining proper division of inlet and exhaust air flow - If removed it could result in

improper functioning of unit and cause personal injuryand void your warranty.

Ambient Conditions -

:

Operating environment

MAY WILL

Important: Remove urethane supports located

Remove tape from

Important: Inspect the

damp

Stand-off/Air-divider located on rear panel is

!

4

Page 5

Caution

Operating environment

:

Place unit on a stable, level counter at a convenient height for use. Turn the adjustable feet so

that unit is level to counter top. The top of the unit is not intended for use a shelf. Materials

placed there are at risk for fire.

8. Before plugging unit into wall, make sure that the switch is in the off position.

9. Ensure no hands, tools or parts or other unintended items are located on the conveyor

Warning:

as injury will result when unit is turned on.

10. Plug unitinto grounded electrical outlet with correct voltage, and plug configuration.

Warning:

personal injury and void your warranty.

Using any receptacle that is not designed to match the attached cord and plug cause

WILL Please attach the XWAV1422/Medium Size unit,

MAY

208V, 5400W only, to an individual branch circuit.

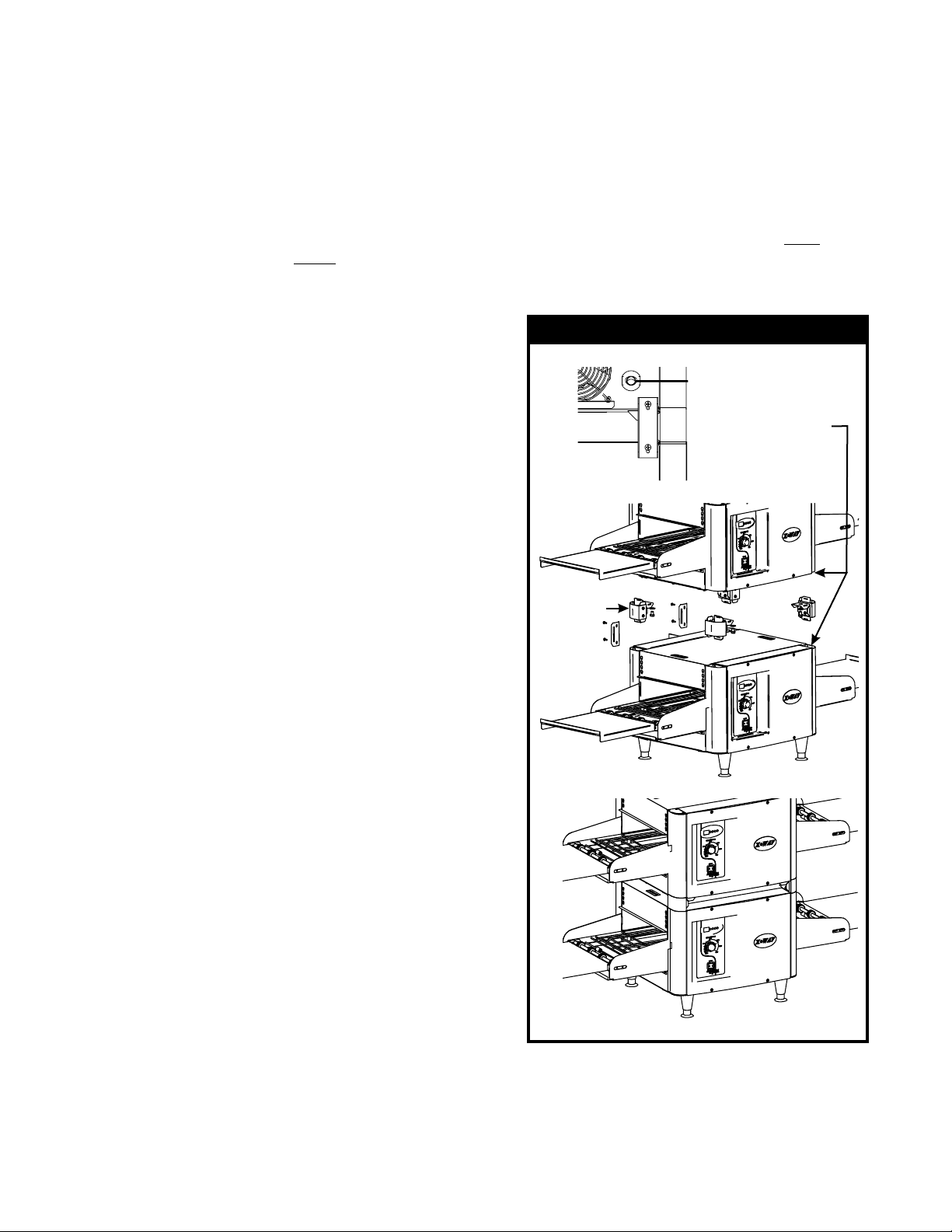

Oven Stacking

The stacking kit willconsist of 4 cornerposts to be inserted

between stacked units.

Warning:

When stacking, unit must have proper

stacking kit installed. This will prevent overheating

and damaging of electrical components.

Warning:

Do not stack more than three units tall or do

not use more than two stacking kits.

Warning:

Standoff on rear panel of unit is important to

allow proper inlet and exhaust fan airflow. Do not

cover inlet or exhaust fan openings as this could

damage electrical components.

1. Ensure bottom unit is mounted on secure

surface, with feet installed.

2. Remove respective corner end caps and

screws. This will allow each of the stacking

spacer retaining fingers to slide into the

extrusions.

3. Remove the feet from the top unit as shown.

4. Secure each stacking spacer to the bottom of

the unit as shown by using the bolts and

washers provided. You should have four total

of each.

5. Once the stacking kit spacers are secure, place

top unit onto bottom unit. The stacking kit

spacers each have tapered guides to allow the

unit to lock into position.

6. Refer to Figure 1. Install rear support bracket

and screws as shown. Each stacking kit

requires that two brackets be mounted on the

backside only. One bracket near the strain

relief and one at the opposite end.

7. Refer to Cleaning Instructions for cleaning of

stacking spacers and cleaning between units.

FIGURE 1

Remove End

Caps & Screws

Before Installing Kit

Stacking Kit

#94000189

5

Page 6

5. OPERATION

1. The controls that operate the belt conveyor and the heaters are locatedon the front ofthe unit.

2. A. (NON-EZ MODELS)

The On/Off switch is used to turn the unit on or off. Once the unit is turned on the

1.

conveyor will automatically run. Warning: Ensure no hands, tools or parts are

located on the conveyor as injury will result when unit is turned on.

2. The control display (oval keypad) is used to control top and bottom heat only. The control

settings allow for separate upper and lower zone control. The settings for upper and lower

zones are 1 through 15; 1 being coolest and 15 being hottest setting. (See control operation

below)

B. (EZ MODELS)

1.

The direction of the belt conveyor travel is controlled by a hidden rocker switch located

beneath the left side conveyor extension, behind a removable cover attached to the base

housing panel. To change belt direction, remove this cover, flip the rocker switch to the

opposite setting, and replace the cover. This operation can be performed while the belt is

moving.

3. Note: Before moving the On / Off switch to the “On” position, please read the following statements:

4. A. The exterior metal surfaces of the unit will get hot enough to

5. Two adjustable deflector shields are located at the inlet/outlet of the unit, above the conveyor belt.

Control Operation (NON-EZ MODELS):

6. This oven has 3 heating zones, 2 on top, and a bottom one. The 2 top zones share the same

CAUTION: HOT SURFACES!

cause burns. Avoid touching these surfacesto prevent injury.

WARNING: SEVERE BURN HAZARD CERAMIC HEATERS

B. (top heaters). The white ceramic

heaters located in the top of the unit operate at very high temperatures.

HEATERS AFTER UNIT IS TURNED ON.

These shields are designed to keep maximum heat inside the unit. Position the shields as needed

for product flow.

parameters (set point, probe offsets, etc.) The bottom zone is completely independent of the top

one.

CAUTION HOT SURFACE!

DO NOT TOUCH

6

Page 7

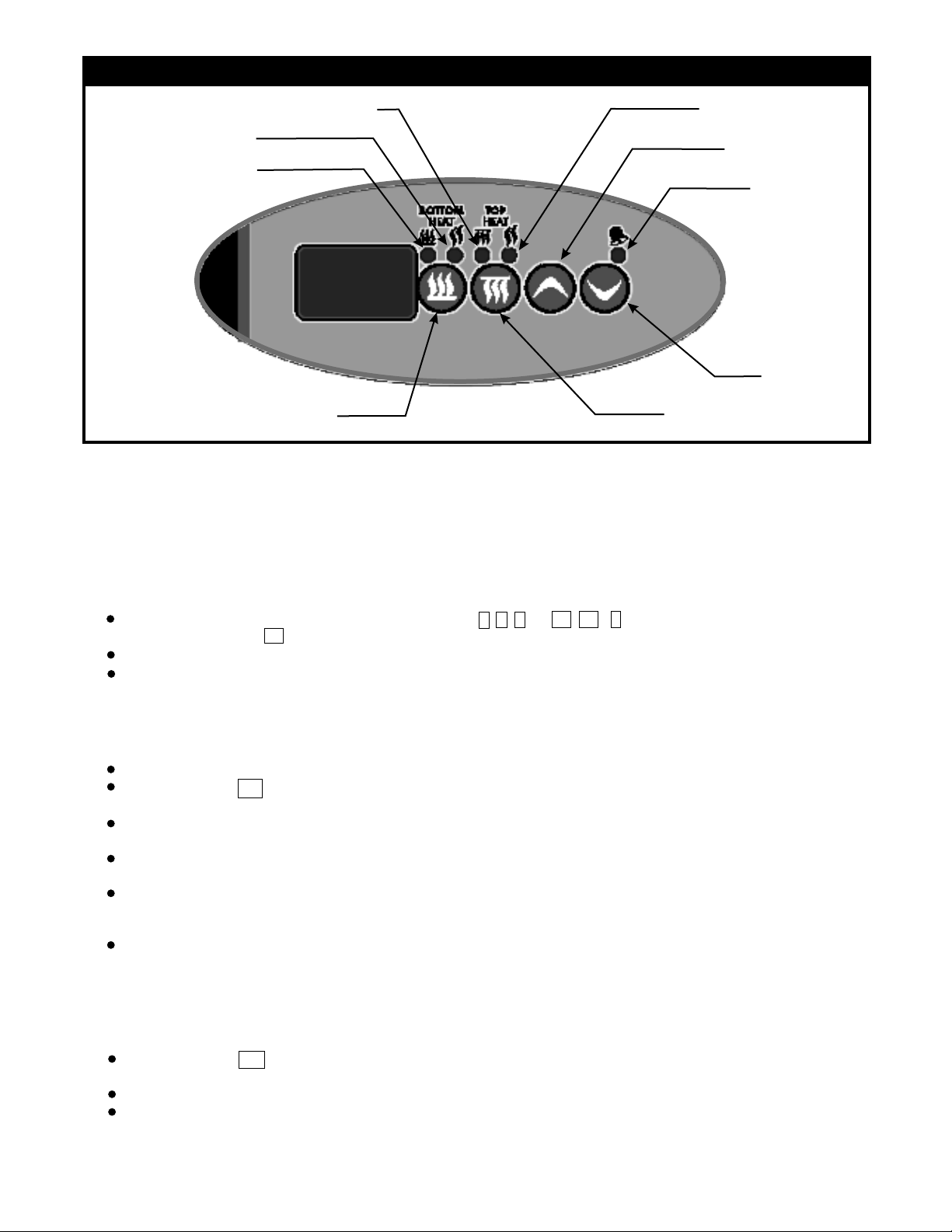

USER INTERFACE

Top Zone Selected

Active Bottom Zone

Bottom Zone Selected

Bottom Zone

There are 4 keys: Bottom Zone, Top Zone, Up, and Down. There are also 5 status LEDs: 2 that indicate the

currently selected Zone; and 2 that indicate the zone Heater output state; and 1 for theAlarm conditions.

7. Operating Modes

Active Top Zone

Up

Alarm

Down

Top Zone

A. Display

Set point temperature is displayed as a range: 1, 2, 3,..., 14, 15. 1 corresponds to the lowest sensor

temperature and 15 corresponds to the highest sensor temperature.

The factory default setting is 8.

Once the settings are changed and the unit is turned off, these new settings will remain in memory

and appear in the display once the unit is turned on.

B. Preheat Mode

· Unit powers up in this state

· Unit displays Lo and the active bottom and active top LEDs are on whenever the corresponding

zone output is active.

· A normal press of Bottom Zone key selects this zone (its LED lights up) and display shows its current

set point for 5 seconds

· A normal press ofTop Zone key selects this zone (its LED lights up) and display shows its current set

point for 5 seconds

· Up and Down keys are used to change setpoint of current zone. Set point is displayed for 5 seconds

after last Up or Down key press, then normal display resumes. Default set points are definedin Lowlevel parameters.

· Preheat state ends when top and bottom zones are within the Low Temperature threshold

defined in Low-level programming.

C. Ready Mode

both

· Unit displays rdy and the LEDs are on whenever the corresponding

zone output is active.

· All keys work in the same fashion as for thePreheat mode

· Ready state ends when one of the top bottom zones fall below the Low Temperature threshold

defined in Low-level programming (unit then goes back to Preheat mode)

active bottom and active top

or

7

Page 8

8. Special Features/Alarms

A. Zone Probe Error

· Heater probe is disconnected or defective

· Normal user interface operation applies, but heater output remains inoperative

· Display flashes Alarm LED as well as an Alarm ID:

o AL1 for Zone 1(Bottom probe)

o AL2 for Zone 2 (Top, probeA)

o AL3 for Zone 3 (Top, probe B)

· Alarm shuts down all outputs

· Probe must be replaced or re-connected to allow normal use

B. High Temperature Error

· Heater elementis too hot, most likely due to external SSR that failed short

· Display flashes Alarm LED as well as an Alarm ID:

o AL4 for Zone 1(Bottom probe)

o AL5 for Zone 2 (Top, probeA)

o AL6 for Zone 3 (Top, probe B)

· Alarm shuts down heaterregulation.

· The alarm threshold temperature is Low-level programmable

· Algorithm:

o In normal use, if temperature ever goes above (set point + threshold), High Temperature

Error is immediately triggered.

o If set point is changed (lowered) by the user, the unit will look at the current temperature for 2

minutes and display HI. The peak temperature reached during this time is recorded.

o Thereafter, unit monitors the temperature until it reaches set point. During this cooldown

time, standard HI message is still displayed. User may change set point again, but 2-minute

timer is restarted (and oldPeak value still applies.)

· During the cooldown time, if ever the temperature rises the previously recorded peak

not

above

temperature, High TemperatureError is triggered.

· Once set point is reached, rdy is displayed again.

· HI is displayed only if other zone is rdy or also HI. If other zone is Lo, then LH (low-high) is displayed

instead of HI.

8

Page 9

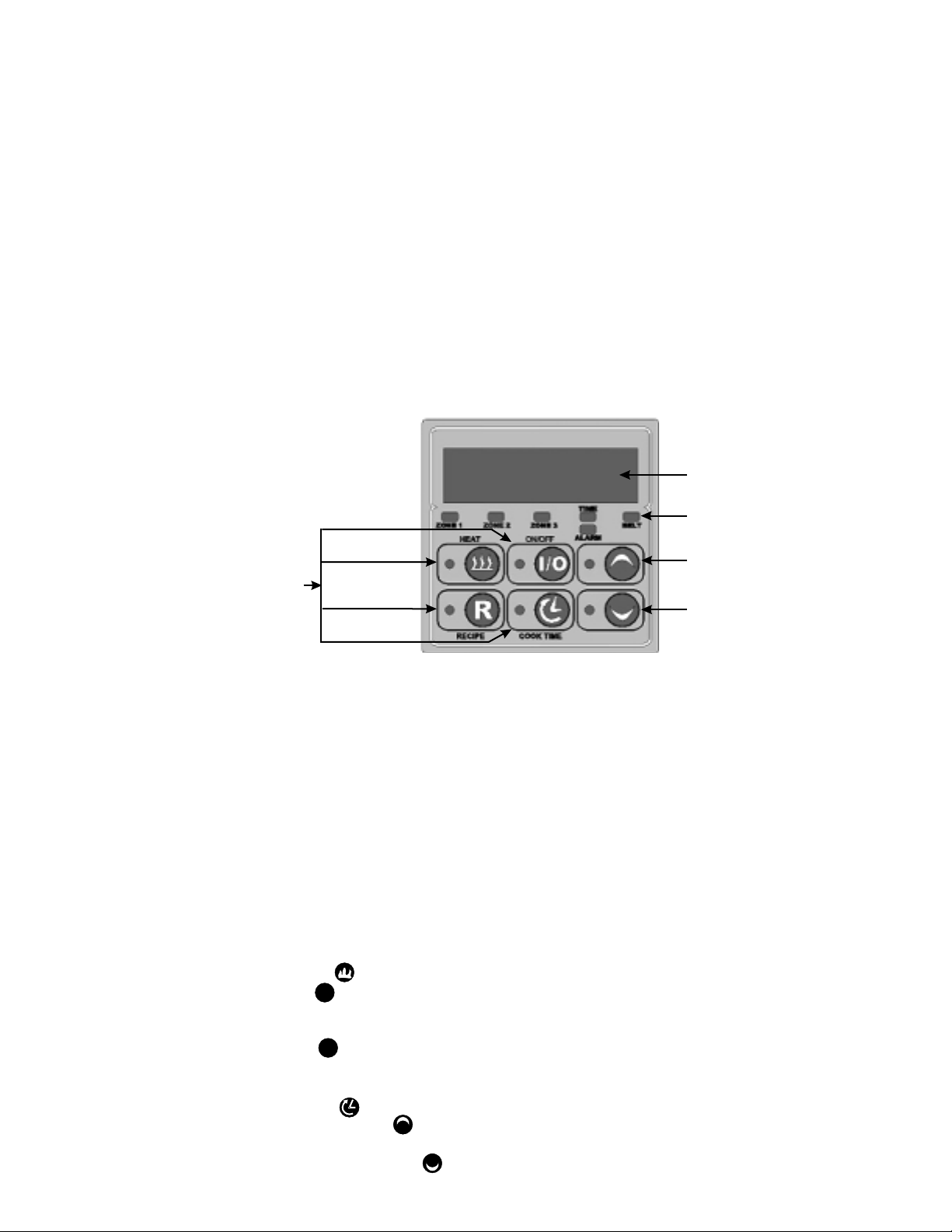

Control Operation (EZ MODELS):

6. The Main ON/OFF rocker switch controls electric power to the electronic controller.

NOTE

: If theALARM BUZZER should sound when the switch is turned ON, PRESS the I/0button to

MUTE the ALARM. The alarm conditionstill exists, but the buzzer is turned OFF.

a. In the OFF position ( 0 ), the digital display is blank, all functions are OFF. The rear

exhaust/cooling fans may run because they are controlled by thermostats.

b. In the ON position ( I ), the digital display will showthe current state of operation:

1. OFF belt and heaters are OFF, or

2. REC “X” unit operating according to user-defined recipe settings: belt speed (cooktime), and heat values (top & bottom); or

3. Scrolling message of importance, stating action needed to continue proper

operation.

7. The Control Panel of the controller is shown below, and consists of a large 5-digit display, 6

rectangular status lights, and 6 control buttons with indicatorlights

5 - DIGIT DISPLAY

ON/OFF

HEAT

STATUS LIGHTS

UP (INCREASE)

CONTROL BUTTONS

RECIPE

DOWN (DECREASE)

COOK TIME

a. The 5-digit display shows both letters and numbers, and is capable of scrolling messages.

In the Recipe Programming Mode (Section 6.3), a flashing arrow appears on the left side

pointing to the value being modified.

b. The status lights indicate what is happening to various areas of the unit:

1. Three “Heat Zone” lights show when heat is being added, Zone 1 being the bottom,

Zones 2 & 3 being the top. These lights also come on when pressing the “Heat”

button to see the current temperature of the zones.

2. The “Time” status light comeson when the cook-time is being viewed or modified.

3. The “Alarm” light indicates when an alarm condition exists.

4. The “Belt” light indicates if the belt is moving or not.

c. The Control buttons are used to make changes to various settings needed for recipes. They

also are used to view present settings of the current recipe being run.

1. The “Heat” button controls the heat values for top and bottom heaters.

2. The “R” (Recipe) is used to access the Recipe Programming Mode where

R

individual recipe parameters are entered, including belt speed, top heat, and bottom

heat.

3. The “I/0” button turns the controller ON/OFF. In the ON mode, the unit operates

I/O

according to the current recipe desired. In the OFF mode, the “Low-Level

Programming Mode” may be accessed. This is forAdvanced Users Only.

4. The “Clock” button indicates cooktime, and controls thebelt speed.

5. The “UP ARROW” button is used to INCREASE various settings, whether recipe

selections, belt speed, or heat.

6. The “DOWN ARROW” button is used to DECREASE the same settings.

9

Page 10

8. Control Operating Modes

There are 4 Modes of operation with this appliance:

1. OFF

2. HEAT (normal Mode)

3. RECIPE PROGRAMMING

4. ALARM

Because each Mode is capable of several functions, careful study should be given to their details to

maximize appliance utility. The Programming Mode should only be accessed by an

LOW-LEVEL

authorized, advanced user or Service Professional.

1. Off Mode (display Reads Off)

This Mode allows three (3) functions:

a. LOCKing / UNLOCKing of the control buttons (keypad). When the keypad is LOCKED, the

temperature set points, cook-time, and recipe changes are no longer accessible to the user.

All other functions operate normally, including recipe selection.

1. To change the current state to the other, PRESS the UP button for 5 seconds. The current

state will be displayed.

2. PRESS the UPbutton immediately a second time for 5 or more seconds. This will changethe

state to the oppositevalue.

3. If the secondPRESS is not done properly, the original state will remain.

b. LANGUAGE Selection

1. PRESS the HEAT button for 5 seconds to view the present Language setting: ENGLISH or

ESPANOL.

2. Use the UPor DOWN arrow to select the desired language.

3. DO NOT press anything for 5 seconds and the new selection is retained.

4. The following messagesare available in both languages:

OFF

a. (APAGADO)

LOCKED

b. (BLOQUEADO)

UNLOCKED (DESBLOQUEADO)

c.

ZONE OVERHEAT CALL FOR SERVICE

d.

(SOBRECALENTAMIENTO ZONA LLAMADA DE SERVICIO)

PROBE FAILURE CALL FOR SERVICE

e.

(FALLA SENSOR LLAMADA DE SERVICIO)

2. Heat Mode(normal Mode of Operation)

IF the display reads OFF, PRESS the I/0 button to Enter this Mode. PRESS the I/0 button again to Exit

this Mode.

This Mode allows seven (7) functions:

a. Recipe Selection. Use the UP/DOWN buttons to toggle to the next recipe. The display will show

the current recipe selection as “REC 1”, “REC 2”, etc. (NOTE: This is the Default display setting.)

b. Heat Regulation. As the recipe requirements dictate, the controller supplies power to the

various heat zones. When there is a Call For Heat in any Heat Zone, the status light of the

respective Zone will be illuminated. NOTE: Top heaters are regulated independently of the

Bottom heater.

c. Temperature Setting Viewing. PRESS and HOLD the HEAT button repeatedly to see the current

temperature of Zones 1,2,3 in succession. (Zone 1 = Bottom, Zone 2 = Top Left, Zone 3 = Top

Right).

10

Page 11

d. Temperature Setting “Tweaking”. This feature allows “1-time” adjustments to temperature

settings that will be lost when a new recipe is selected.

PRESS HOLD

1. and HEAT button for 10 seconds. A flashing arrow appears on the left side of

the display, pointing to the value that is now available for “tweaking”.

2. Use the UP & DOWNARROWs toadjust the values to new settings.

3. Successive PRESSes of the HEAT button jumps to the next Temperature Zone, where these

settings may now be “tweaked”.

NOTE:

“Tweaked” temperature settings remain good as long as the recipe is unchanged.

When a new recipe is selected, “tweaked” settings are lost.

e. Cook-time Regulation. As the recipe requirements dictate, the controller monitors and adjusts

the belt speed to achieve the desired cook-time.

NOTE: COOK-TIME is defined as: “The time required for the product Leading Edge to

Enter and Exit the Cook Zone”. COOK-TIME leading Edge IN to Trailing

DOES NOT MEAN

Edge OUT. There isan important difference and shouldbe understood by theoperator.

f. Cook-time Viewing. PRESS and HOLD the Clock button to see the current cook-time setting

(belt speed).

NOTE:

NOTE:

0.30 = 30 seconds; 3:45 =3 minutes, 45 seconds,etc.

Factory default minimum and maximum cook-times are set at 30 seconds (1422), 38

seconds (1829) and 10:00 minutes (both 1422 and 1829).

g. Cook-time “Tweaking”. This feature allows “1-time” adjustments to cook-time settings that will

be lost when anew recipe is selected.

PRESS HOLD CLOCK

1. and button for 10 seconds. A flashing arrow appears on the left side

of the display, pointing at the value that is now available for “tweaking”.

2. Use the UP & DOWNARROWs toadjust the values to a new setting.

NOTE:

“Tweaked”cook-time settings remain good as long as the recipe is unchanged. When a

new recipe is selected, “tweaked' settings are lost.

3. Recipe Programming Mode

This Mode allows the user to set the temperature and cook-time valuesfor every recipe thatis desired.

There are a maximum of 20 recipes that can be programmed by the user. Recipe are not

NAMES

programmable.

All values entered into recipes remain saved in memory and when the unit is turned

OFF

.

ARE NOT LOST

The controller starts at Recipe 1 every time the unit is turned . This cannot be modified.

ON

This Mode allows three (3) functions:

a. Bottom Heat (Zone 1) temperature setting.

PRESS HOLD R

1. and the (Recipe) button for 5 seconds. A flashing arrow appears

on the left side of thedisplay, pointing at the value that is now ready for programming.

2. Use the to adjust the values to the new temperature setting.

For accelerated scrolling, the button down.

DO NOTHING

3. for 5 seconds and the new value is saved in memory.

UP & DOWN ARROWs

HOLD ARROW

11

Page 12

b. Top Heat Zones [2 (left side, top) & 3 (right side, top)] temperature setting. Duplicate steps

for Bottom Heat setting.

NOTE:

Zones 2 & 3 are tied together (internal software coding) and CANNOT be set at different

values.

c. Cook-time setting.

PRESS HOLD CLOCK

1. and button for 5 seconds, until a flashing arrow appears on

the left side ofthe display,pointing at the value that is now ready for programming.

2. Use the s to adjust the value to the new cook-time setting.

DO NOTHING

3. for 5 seconds and the new value issaved in memory.

NOTE: UP & DOWNARROW PRESS

UP & DOWN ARROW

If the s are not ed within 15 seconds of when the flashing

arrow appears, the controller jumps out of Recipe Programming Mode and retains the previous

recipe values.

NOTE

: These same steps must be repeated for each recipe. After each recipe is programmed,

the display returns to display . Use the arrow to jump to the next recipe

REC “X” UP & DOWN

and repeat the process as described above.

4. Alarm Mode

This Mode alerts the operator to situations that the controller has detected as faulty operation that

needs attention.

ALARM BUZZER PRESS

An starts beeping loudly when such a situation is detected. the I/0 button to

MUTE BUZZER

the . The alarm condition still exists, theALARM status light continues to flash, but the

buzzer is cancelled.

Alarm conditions are in two (2) categories: (a) Temperature Probe Failure; (b) Overheat Conditions.

a. Temperature Probe Failure.

Whenever any of the three temperature probes fail (2-top, 1-bottom), the controller alerts the

operator (loud buzzer beeping). Only when the alarm condition has been fixed will the

buzzer not sound when the unit is turned ON via the I/0 button.

A qualified service

professional should replace the faulty probe for proper operation toresume.

The controller automatically responds to such conditions, depending on which type of failure

has occurred. Responses are as follows:

1. Scrolling message on the display:

PROBE FAILURE CALL FOR SERVICE.

2. The affected zone status light flashes.

3. If either of the Top probes has failed, the controller continues to regulate top heat as if

nothing had happened. This is because each probe is a redundant item for the other. With

one probe input invalid, the controller reads the other input as valid.

4. If both Top probes should fail, the controller reverts to a preset “duty cycle” program

that allows a reduced amount of top heat to be generated. Since there is no reliable

top probe input, the controller controls power to the heaters on an

percentage basis, such as 66% time , 33% time . This is done to prevent a

ON OFF

“ON/OFF”

possible “Overheat” condition, since there is now no reliable means to sense an Top

overheat condition.

5. If the Bottom probe should fail, the controller reverts to a preset “duty cycle” program

similar to the dual-Top probe failure mentioned above.

12

Page 13

NOTE: In either case where the unit is in a “duty cycle” mode, the operator can still use the

NOTE: In either case where the unit is in a “duty cycle” mode, the operator can still use

the unit until service is performed to correct the failure. However, the reduced

unit until service is performed to correct the failure. However, the reduced heat

value will affect the output capacity of theunit.

heat value will affect the output capacity of the unit.

NOTE:

1. the I/0 button to the buzzer.

2. The scrolling message goes away.

3. The status light stays illuminated.

Anormal operator response maybe as such:

PRESS MUTE

PROBE FAILURE

ALARM

4. All other functions continue as normal:

a. Display shows current recipe selection. Recipe selection is still

possible.

b. Belt moves and belt status light is illuminated.

c. Heat Zonestatus lights will be dark.

5. If the button is pressed to view current temperatures, the unaffected zones will

HEAT

display their current temperature, but the affected zone(s) will scroll the

FAILURE

message, without any beeping buzzer.

b. Overheat Conditions.

NOTE: If unexpected smoke should appear around the unit during an Overheat Alarm

condition, turn the Main Switch OFF.

Overheat conditions result from excessive power being applied to the heaters. Such situations

usually arise froma solid-state relay that has failed , of whichthere is one for each heat

CLOSED

zone (three total). However, over-voltage conditions can also cause excess heat, even though

the relays are OK. Therefore, it is necessary to properly trouble-shoot such conditions to

correctly identify the problem.

A qualified technician should make any needed repairs.

PROBE

The maximum allowable temperature is programmable in the

LOW-LEVEL PROGRAMMING

Mode, and is factory set at 1100°F (593°C).

The controller automatically responds to such conditions as follows:

1. Scrolling message on the display:

TEMPERATURE ZONE OVERHEAT - CALL FOR

SERVICE.

2. Alarm status light isilluminated.

3. By shutting power to heaters until Overheat condition resolved.

NOTE:

Anormal operator response maybe as such:

1. the I/0 button to the buzzer.

PRESS MUTE

2. The scrolling message goes away.

3. The status light stays illuminated.

OFF ALL ALL

OVERHEAT

ALARM

4. All other functions continue as normal:

a. Display shows current recipe. Recipe selectionis still possible.

b. Belt moves and belt status light is illuminated.

c. Heat Zone status lights will be dark.

5. If the button is pressed to view current temperatures, the unaffected

HEAT

zones will display their current temperatures, but the affected zone(s) will scroll the

OVERHEAT

message, without any beeping buzzer. (Since there is no power going

to the heaters, the temperatures should be lower than normal, a failed

relay is continuing to power the heater(s).

UNLESS

13

Page 14

6. CLEANING

Insure the appliance has been turned off and has had sufficient time for all surfaces to cool down before

cleaning. Use only mild soap and water to clean this appliance. Appliance cleaning should be performed

daily.

NOTE:

Daily Cleaning

!

!

!

!

!

!

DO NOT USE ABRASIVE PADS OR CLEANING SOLUTIONS ON THIS APPLIANCE.

Remove the crumb pans and wipeout debris with a damp rag and mild soap solution.

Remove the deflector panels located at the entrance and exit of the oven tunnel. Wipe down the

area under the deflector panels, and the deflector panels, with a damp rag and mild soap. Reinstall

the deflector panels by reversing theprocedure used to remove them.

Using a damp rag with mild soap and water, wipe down the exterior surfaces of the appliance.

Using a damp rag with mild soap solution, wipe down all areas of the conveyor. DO NOT ATTEMPT

TO CLEAN THE UPPER WHITE CERAMIC, OR LOWER METALHEATERS.

When units are in the stacked configuration, it is still necessary to clean between the units. Using a

damp rag with mild soap and water, wipe down the tops and undersides of all units. Ensure there

are no foreign objects between theunits that could catch fire.

Using a damp rag with mild soap and water, wipe the surfaces of the stacking spacers on all four

corners.

7. TROUBLESHOOTING

Always ask and check the following:

Not getting power:

1. Is the unit connectedto a live power source of the proper voltage?

2. Check the rating label. Is the unit connected to the correct power source?

3. Check the circuit breaker.

4. Is power switch“ON” and led displaying information?

If the above checks out, and you still have problems, call your local serviceagent.

5.

Conveyor not working (NON-EZ MODELS):

1. Please refer to “Not getting power” section.

2. Is the knob turnedto correct setting per desired speed?

3. Note: At slower settings the conveyor moves very slow and may appear stalled, which is not the

case.

4. If the abovechecks out and you still have problems, call your local service agent.

Conveyor not working (EZ MODELS):

1. Please refer to “Not getting power” section.

2. Check belt for obstructions. Belt may be jammed.

3. Reverse belt direction to check for belt jam - locate Reversing Switch on left side, beneath conveyor

frame, hidden by removable cover. Remove cover, flip switch, and note if belt begins to move

backwards. Does belt move backwards?

4. If , then clear belt jam and resetbelt direction via ReversingSwitch.

YES

5. If , thencall your local service agent.

NO

6. Note: At slower settings the conveyor moves very slow and may appear stalled, which is not the

case.

7. If the above checks out, and you still have problems, call your local service agent.

14

Page 15

Food not cooking properly:

1. Please refer to “Not getting power” section.

2. Are the controller and speed control adjusted to the desired setting?

3. Are the deflector curtains in the proper position?

4. If the above checks out, and you still have problems, call your local service agent.

8. PREVENTATIVE MAINTENANCE SCHEDULE

!

!

!

!

!

!

!

Please follow the cleaning section for the daily preventative maintenance schedule.

DO NOT USE ABRASIVES OR CLEANING SOLUTIONS ON THIS APPLIANCE.

Routinely check before every operation that adequate distance is allowed between fans and

anything that would possibly allow foreign debris or substances to be taken in by inlet fan.

Clean fan guards on a daily basis to ensure proper inlet cooling to electrical components and

efficient hot air exhaust.

On a daily basis make sure side walls of tunnel oven remain clean to assist in maintaining even

cooking around product. Be careful not to bump or hit the upper ceramic heaters when wiping

down.

Ensure belt is properly tensioned as to prevent slippage or binding, which causes strain on

motor.

DO NOT ATTEMPT TO MAINTENANCE, SERVICE OR CLEAN THE UPPER CERAMIC AND

LOWER METALHEATERS.

9. WIRING DIAGRAMS/SCHEMATICS

OVERHEAD XWAV1422

(NON-EZ MODELS)

To: Relay

To: Terminal Block

RTD 3 To: Controller AN3

OVERHEAD XWAV1829

(NON-EZ MODELS)

RTD 2 To: Controller AN2

To: Terminal Block

RTD 3 To: Controller AN3

RTD 3

11

12

REAR HEATERS ZONE 3

13

14

FRONT HEATERS ZONE 2

RTD 2 To: Controller AN2

11

12

RTD 2

13

14

To: Relay

To: Terminal Block

0

1

9

15

16

16

9

RTD 2

11

12

REAR HEATERS ZONE 3

13

14

FRONT HEATERS ZONE 2

16

10

15

To: Terminal Block

RTD 3

13

14

RTD 2

To: Relay

To: Relay

11

10

9

2

1

15

16

10

RTD 2

16

15

9

15

Page 16

UNDER CARRIAGE (NON-EZ MODELS)

Motor wiring for left to right configuration of

conveyor belt non-reversable switch

LEFT SIDE HOUSING

(NON-EZ MODELS)

16

TO 3 POLE TERMINAL BLOCK

TO 3 POLE TERMINAL BLOCK

FEMALE TER MINAL

MALE TERMINAL

24

7

OR

GR

OR

GR

BLUE

MOTOR SPEED

POT

BLACK ( -)

ORANGE (+)

GREEN (-)

94100134

5/24V DC

OUTPUT

208 V

RED (+)

RED

BLACK

TO: P OWER S WITCH

2

2

5

2

TO: POWER

SWITCH

L2

26

5

26

POWER CORD

L1= BLACK

L2= WHITE

T.STAT

1

1

L2

L1

L1

L1

L2

.STAT

T

GR

RIGHT SIDE HOUSING

1. ORANGE

1. OPEN

2. WHITE

2. WHITE

3. BLUE

3. BLUE

4. RED

4. RED

5. OPEN

5. GREEN

6. BLACK

BL

94200093

6. BLACK

MOTOR

CONTACTOR

A2 A1

24

T1/2

7

T2/4

T3/6

14

22

22 21/NC

94000172

3/L2

5/L3

13/NO

28

29

5

1/L1

2

28

RED

29

TO: POWERSWITCH

TO 2 POL E TERMIN AL B LOCK

TO 2 POLE TERMINAL BLOCK

(NON-EZ MODELS)

TO SPEED

MOTOR-ORANGE

TO SPEED

MOTOR-GREEN

BL

G

MOTOR SPEED POT.

TO SPEED

MOTOR-BLUE

OR

R

TO CONTACTOR "A1 "

29

POWER SWITCH

TO POWER SUPPLY

6PIN-RED

30

ESCUTCHEON

Page 17

XWAV LADDER SCHEMATIC (NON-EZ MODELS)

C1

TEMPERATURE SWITCHES

POWER SUPPLY

85 - 265 VAC INPUT, 1

~

24 VDC / 5 VDC OUTPUT

MAIN SWITCH

ORANGE

L1

+

L2

BLUE

TO REVERSE DIRECTION

OF CONVEYOR BELT,

CONNECT / DISCONNECT

WHITE WIRE TO TERMINAL

“A2” ON CONTACTOR.

-

CONTACTOR COIL

C1

C1

GREEN

M1

BRUSHLESS

MOTOR

TOP FAN

EXHAUST

BOTTOM FAN

COOLING

A2A1

WHITE

C1

SSR1

SSR2

SSR3

ZONE 1

RTD BTM

INPUTS

OUTPUTS

ZONE 2

RTD TOP

ECM-3 DIGITAL

TEMP CONTROL

+++

R1

R2

R3

CONVEYOR

SPEED POT

ZONE 3

RTD TOP

---

SOLIDSTAT E

RELAYS

(1) BOTTOM ELEMENT

17

TOP ELEMENTS

Note: 1417 = (5) Top Elements

1422 = (6) Top Elements

1829 = (8) Top Elements

Page 18

XWAV 1422EZ POWER SUPPLY WIRING DIAGRAM 208 or 240VAC, 1 PH, 50/60 HZ

18

26

3

29

326816899

29

MAIN

ON / OFF

ZONE 1 - BOTTOM HEAT

USER INTERFACE

KEYPAD

SWITCH

CABLE

ECM-3 CONTROLLER

P16 YEL

TIME

BELT

ALARM

23

28

CONTAC TOR

24VDC COIL

P20 +

RED

RED

SELECT

VOLTA GE

JUMPER

120

208

240

MOTOR

SIGNAL

PROCES SOR

P16 -

YEL

18

17

5

2

5

WH

YEL

P20 +

RED

YEL

YEL

24

7

RED

WH

BLK

BLU

RED

14 6T3 4T2 2T1

N.O.

CONTA CTOR

13

N.O. 5L 3 3 L2 1 L1

17

A2-

28

BLK

17

BLK

24

7

5

COIL

23

A1+

18

5

2

TOP TOP

HEAT HEAT

ZONE 2 ZONE 3

14 13 12

15

3

26

15

E

B

O

R

P

D

T

R

16

PRODUCT FLOW

ZONE 1 SSR ZONE 2 SSR ZONE 3 SSR

-DC+ -DC+ -DC+

19 20 21 22

28

4

RTD PROBE

11

16

10

10

9

BELT

REVERSE

SWITCH

1

2

3

4

9

4

-24VDC BLK

-24VDC WH ITE

29

26

BLACK RED

L1

5

23

23

24 VDC OUT

--- +++

RED +

BLK -

208240

VAC I N

10

15

3

7

6

24

+24VDC RED

L2

25

ZONE1 ZONE2 ZONE3

HEAT O N / OFF

RTD PROBE

RECIPE COOKTIME

29

30

25

MOTOR POWER SUPPLY

6

BLACK

RED

WH

30

25

24

7

6

WH

L2/N

L1

21 _

22 +

19 -

20 +

COM

AN1

AN2

AN3

+

AC

N.O.

RELAY

NOTE: Top & Bottom

Heaters are either

208V or 240V, and

must match power

supply voltage.

L1-BLACK

6-30P

L2-WHITE

G

208 or 240VAC, 1 PH, 50/60 Hz

Power Supply, 5500 Watts

REAR

FANS

1

FAN T HERMOSTA T

27

2

FAN THERMOSTAT

2

CONVEYOR MOTOR

24VBLDC

Page 19

XWAV 1422EZ LADDER WIRING SCHEMATIC

L1 L2

TOP FA N

THE RMOSTATS

POWER SUPPLY

85 - 265 VAC, 1~ INPUT

24 VDC OUTPUT

MAIN SWITCH

5

C1

24

18

+

23

17

P20 + RED

-

CONTACTOR COIL

A1 + A2 -

C1

R

YEL BLU

BLK

C1

WH

M1

BLK

BRUSHLESS

MOTOR

BELT

REVERSING

SWITCH

MSP

P16 - YEL

ZONE 1

RTD BTM

ZONE 2

RTD TOP

+5VDC

ZONE 3

RTD TOP

EXHAUST

BOT TOM F A N

COOLIN G

2

C1

7

6

SSR 1

329

16

26

SSR 2

SSR 3

9

8

ECM-3

ELECTRONIC

CONTROLLER

ANALOG INPUTS

HI-VOLT AC IN

R

LOW-VOLTAGE DC I/O

+

+++

20

( 6 ) TOP ELE MENTS

HI-VOLT AC OUT

R3

R2

R1

---

21

19

4

13

13

11

11

22

-

SOLIDSTATE

RELAYS

16

9

MOTOR SIGNAL

28

25

(1)BOTTOMELEMENT

30

14

15

14

12

10

12

19

Page 20

XWAV 1829EZ POWER SUPPLY WIRING DIAGRAM 208 or 240VAC, 1 PH, 50/60 HZ

20

26

3

TOP TOP

HEAT HEAT

ZONE 2 ZONE 3

RTD PROBE

14

13

15

3

26

15

PRODUCT FLOW

NOTE: Top & Bottom

Heaters are either

208V or 240V, and

must match power

supply voltage.

30

326816899

ZONE 1 SSR ZONE 2 SSR ZONE 3 SSR

-DC+ -DC+ -DC+

4

28

16

19 20 21 22

12

11

10

10

208 or 240VAC, 1 PH, 50/60 Hz

Power Supply, 7000 Watts

16

9

6-50P

RTD PROBE

REVERSE

SWITC H

BELT

L1

L2

G

1

2

3

28

4

-24VDC BLK

-24VDC WHITE

30

30

9

26

MAIN

ON / OFF

SWITCH

24 VDC OUT

--- +++

BLK -

208240

VAC IN

L1

24

5

27

2

29

29

RED +

10

15

3

7

6

1

FAN T HERMOST AT

30

+24VD C RE D

L2

25

ZONE 1 - BOTTOM HEAT

USE INTERFACE

KEYPAD

CABLE

ECM-3 CONTROLLER

P16 YEL

TIME

BELT

ALARM

29

28

CONTA CTOR

24VDC COIL

P20 +

RED

RED

SELECT

VOLTAGE

JUMPER

120

208

240

MOTOR

SIGNAL

PROCESSOR

P16 -

YEL

18

17

5

2

5

WH

YEL

P20 +

RED

YEL

YEL

24

7

RED

WH

BLK

BLU

CONVEYOR MOTOR

2

RED

14 6T3 4T2 2T1

N.O.

CONTACTOR

13

N.O. 5L3 3L2 1L1

17

A2-

2

8

BLK

17

BLK

24VBLDC

24

7

5

COIL

29

A1+

18

5

2

ZONE 1 Z ONE 2 ZONE 3

HEAT ON/ OFF

RTD PROBE

32

SPLICES

23

31

23

21 _

22 +

19 -

20 +

25

6

L2/N

L1

RECIPE COOKTIME

AN1

AN2

AN3

-

+

MOTOR POWER SUPPLY

COM

AC

N.O.

WH

23

25

24

7

6

WH

REAR

FANS

FAN TH ERMOST AT

RELAY

Page 21

XWAV 1829EZ LADDER WIRING SCHEMATIC

L1 L2

THE RMO STATS

TOP F AN

EXHAUST

BOTTOM FAN

COOLIN G

5

24

4

POWER SUPPLY

85 - 265 VAC, 1~ INPUT

24 VDC OUTPUT

MAIN SWITCH

C1

35

30

+

29

34

P20 + RED

-

CONTACTOR CO IL

A1 + A2 -

C1

R

YEL BLU

BLK

28

C1

WH

M1

BRUSHLESS

MOTOR

REVERSING

BLK

23

BELT

SWITCH

2

C1

7

MSP

P16 - YEL

ZONE 1

RTD BTM

ZONE 2

RTD TOP

+5VDC

ANALOG INPUTS

6

HI-VOLT AC IN

ZONE 3

RTD TOP

MOTO R SIGNAL

25

SSR 1

332

SSR 2

SSR 3

8

16

9

26

ECM-3

ELECTRONIC

CONTROLLER

R

LOW-VOLTAGE DC I/O

+

+++

20 19

18

( 8 ) TOP ELEMENTS

HI-VOLT AC OUT

R3

R2

R1

21

---

21

17

13

13

16

13

11

11

9

11

22

-

SOLIDSTATE

RELAYS

(1)BOTTOMELEMENT

33

14

14

15

14

12

12

10

12

Page 22

XWAV 1829 POWER SUPPLY WIRING DIAGRAM 208VAC

22

DETAIL A

240 V

JUMPER

SETUP

DETAIL B

11 11

12 12

REAR HEATE RS ZONE 3

13 13

14

RTD 2

FRONT HEATERS ZONE 2

OVERHEAD

208 V

JUMPER

SETUP

RTD 3

10

9

15

14

16

LOWERHEATERZONE1

4200 WATTS

2800 WATTS

RTD 2

RTD 3

30

15

UNDER CARRIAGE

ESCUTCHEON

LEFT SIDE HOUSING

RTD 2

24

7

7

7

RTD 3

(P6 "-")

(P9"+")

(P11 "-")

(P15 "+")

(P16 "-")

(P20"+")

24

FEMALETERMINAL

MALE TERM INAL

24

RTD 1

AN1

AN2

AN3AN3AN3

21

22

M. CTL.

19

20

I/O2 I/O3

17

18

I/O 1

25

6

A

L2/N

B

SEE

L1

DETAIL

VIEW

OR

GR

BL

94000172

OR

BL

GR

MOTOR SPEED POT.

ORANGE(+)

GREEN (-)

94100134

3

2

1

34

1.ORANGE

1.OPEN

2.W HITE

2.W HITE

3.BLUE

3. BLUE

4.RED

4.R ED

5.GREEN

5.O PEN

6. BLACK

6.B LACK

94200093

34

CONTACTOR

A2 A1

24

T1/2

7

T2/4

T3/6

14

22

22 21/N C

ESCUTCHEON

1/L1

3/L2

5/L3

28

13/NO

2829

5

2

RED

POWER SWITCH

7000 WATTS @ 208V = 33.6 A

7000 WATTS @ 208V = 29.1 A

5/24VDC

OUTPUT

29

208 V

BLACK(-)

RED (+)

RED

BLACK

MOTOR

2

2

1

L2

27

5

L1

27

POWER CORD

L1= BLACK

L2= WHITE

1

T.STAT

L2

L1

GR

T.STAT

L1

L2

15

7

10

L2

30

6

24

7

25

L1

RTD 1

6

ZONE 3

9

+

T1

A1

-

A2

L1

8

RTD 1

ZONE 2

16

+

T1

A1

-

8

A2

L1

26

NATURAL

ZONE 1

31

+

T1

A1

3

-

A2

RTD 1

30

33

NATUR AL

32

33

L1

RIGHT SIDE

HOUSING

BROWN

3

26

21

22

20

17

18

22

21

3

20

19

18

17

3

3

BROWN

32

31

SHEET 1 OF 6

Page 23

23

XWAV 1829 LADDER WIRING SCHEMATIC

L1

L2

TEMPERATURE SWITCHES

POWER SUPPLY

85 - 265 VAC INPUT, 1~

24 VDC / 5VDC OUTPUT

ZONE 2

RTD TOP

R1

R2

BLUE

-

CONTACTORCOIL

A1

C1

GREEN

CONVEYO R

SPEED POT

ZONE 3

RTD TOP

---

C1

M1

SOLIDSTATE

RELAYS

A2

BRUSHLESS

MOTOR

WHITE

+

MAIN SWITCH

C1

INPUTS

OUTPUTS

ORANGE

ZONE 1

RTD BTM

ECM-3 DIGITAL

TEMP CONTROL

+++

TOP FAN

EXHAUST

BOTTOM F AN

COOLIN G

TO REVERSE DIRECTION

OF CONVEYORBELT,

CONNECT / DISCONNECT

WHITEWIRETOTERMINAL

"A2" ON CONTACTOR

NOTE: 1417= (5) TOP ELEMENTS

1422= (6) TOP ELEMENTS

1829= (8) TOP ELEMENTS

XWAV 1829 REVERSE SWITCH

Merkle-Korff Motor With Reverse Switch

ORANGE(+)

GREEN (-)

94100134

1. ORANGE

1. OPEN

2.WHITE

2. WHITE

3. BLUE

CONTACTOR

A2 A1

T1/2

T2/4

T3/6

14

22

22 21/NC

GREEN

ORANGE

3. BLUE

4.RED

4. RED

5.GREEN

5. OPEN

6. BLACK

6. BLACK

28

29

5

1/L1

2

3/L2

5/L3

28

13/NO

RED

ORANGE

GREEN

POTENTIOMETER

BLUE

94200093

24

7

94000172

BLUE

C1

FEMALE T ERMINAL

MALE TERMINAL

TO 3 POLE TERMINAL BLOCK

TO 3 POLE TERMINAL BLOCK

BLACK (-)

RED(+)

5/24V DC

OUTPUT

208 V

RED

BLACK

MOTOR

TO POWER SWITCH

BLACK (-)

123

WHITE

TO POWERSWITCH

TO 2 POLE TERMINAL BLOCK

TO 2 POLE TERMINAL BLOCK

SSR 1

SSR 2

SSR 3

R3

(1)BOTTOMELEMENT

TOP ELEMENTS

Page 24

10. PARTS LIST & EXPLODED VIEW

EXPLODED VIEW

XWAV

Installation

peration

O

M

23

20

16

&

anual

8

2

15

18

24

36

12

14

1

28

27

6

7

3

30

32

33

31

5

22

34

9

10

21

35

26

17

11

29

4

Non-EZ

25

41

13

19

39

37

Stacking Kit

43

40

42

38

24

Page 25

ITEM

PART NUMBER

DESCRIPTION

QUANTITY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

96000034

96300004

96000033

96300003

96000064

96200006

96800064

96900006

96000001

96000007

96200001

93000067

96000070

82914

94100043

94200045

94200089

94100140

95000033

69148

85283

85287

85284

30201

30203

86295

94000105

96000075

94000108

94000109

94200057

96000079

89488

89408

94000056

94200029

94100045

94200055

94100108

94000189

38125

96000010

94000211

96000077

96000002

94000099

88705

89488

94000027

94000121

94000122

94000172

94100015

ELEMENT, CERAMIC, 208V

ELEMENT, CERAMIC, 240V

ELEMENT, CERAMIC W/RTD, 208V

ELEMENT, CERAMIC W/RTD, 240V

ASSY, CALROD ELEMENT, XWAV1422, 208V

ASSY, CALROD ELEMENT, XWAV 1829, 208V

ASSY, CALROD ELEMENT, XWAV 1422, 240V

ASSY, CALROD ELEMENT, XWAV 1829, 240V

ESCUTCHEON, ECM-2, XWAV 1422EZ & 1829EZ

W/ASSY, CONVEYOR, XWAV 1422EZ

W/ASSY, CONVEYOR, XWAV 1829EZ

END, CAP, F/L & B/R

END, CAP, B/L & FIR

CHAIN, CONVEYOR DRIVE, XWAV 1422EZ & 1829EZ

WIREBELT, XWAV 1422EZ (NOT SHOWN)

WIREBELT, XWAV 1829EZ (NOT SHOWN)

GEARMOTOR, MERKLE-KORFF

POWER SUPPLY, 5V/24DC OUTPUT

TERMINAL BLOCK, CERAMIC

RELAY, SOLID STATE

FAN, CORD

FAN, GUARD

FAN, COOLING

TERMINAL BLOCK, 3 POLE

TERMINAL BLOCK, 2 POLE

LEG, BLACK

THERMOSTAT FAN

CONTROLLER, ECM-3, XWAV II

RTD, 3/16" DIA, BOTTOM ELEMENT

POWER CORD, 10/3, 6-30P

POWER CORD, 8/3, 6-50P

INSTALLATION & OPERATION MANUAL, XWAV EZ

ROCKER, SWITCH

SWITCH, LIGHTED ROCKER (BELT REVERSING)

TRAY, CONVEYOR, XWAV 1422EZ

TRAY, CONVEYOR, XWAV 1829EZ

CONVEYOR, EXTENSION, XWAV 1422EZ

CONVEYOR, EXTENSION, XWAV 1829EZ

CONTACTOR, 24V DC 15KW/400V 20HP/460V

STACKING BRACKING KIT (OPTIONAL)

BEARING, FLANGED POLYMER

ASSY, CLIP BEARING

SPROCKET, 12 TOOTH, 42X50

MOTOR SIGNAL PROCESSOR

LED DISPLAY, GECKO, ECM-2

TUNNEL, GUARD

KNOB 039-266 8A BLACK

SWITCH, ROCKER DPST 16A

TCS INTERFACE, LED DISPLAY, GECKO

LABEL, ESCUTCHEON, CONTROL AREA

LABEL, ESCUTCHEON, LOGO

10K OHM POTENTIOMETER

ESCUTCHEON, FRONT

AS R'QD

AS R'QD

AS R'QD

AS R'QD

1

1

1

1

1

1

1

4

4

1

1

1

1

1

AS R'QD

3

2

2

2

1

1

4

2

1

1

1

1

1

1

1

2

2

AS R'QD

2

1

1

4

4

AS R'QD

1

1

2

1

1

1

1

1

1

1

25

Page 26

Notes:

26

Page 27

11.APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies to the original owner only and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized Service Agencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated

with same. The closestAPW WyottAuthorized ServiceAgent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas ofAlaska and Canada. There

will be no labor coverage for equipment located on any island not connected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary. Contact the international APW Wyott distributor,dealer, or service agency for details.

TimePeriod

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency

may, at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

Inall cases, parts covered by extended warranty will be shipped FOB the factory after the first year.

Portable Carry InProducts

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to

the following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of

connection, or use, at APW Wyott'soption or itsAuthorized Service Agency, it will be serviced on site orreplaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized ServiceAgency for in-warranty repairs. No mileage or travel charges are allowed on portable units after the first day of use.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers, which are covered under the Enhanced Warranty Program, and (2) toasters or rollergrills which have

instore service.

Exclusions

The following conditions arenot covered by warranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or to any property, which may result from the

use of the equipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime or premium labor rates, the owner shall be charged for the difference between normal service rates and such

premium rates.APW Wyott does not assume any liability for extended delays in replacing orrepairing any items beyond its control.

Inall cases, the use ofother than APW WyottAuthorized OEM Replacement Parts will void this warranty.

This equipment isintended for commercial use only.Warrantyis void if equipment is installed in other than commercial application.

WaterQuality Requirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OFAPW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THETERMS STATEDHEREIN.

*Gas/Electric Cookline:

component parts, except switches and thermostats. (2additional years on parts only.No labor onsecond or third year.)

*BroilerBriquettes,

*Heat Strips:

*GlassWindows, Doors, Seals, Rubber Seals, Light Bulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot or act of god.

*Equipment that has the model number or serial number removed or altered.

Models FD, FDL, FDD, FDDL. Two(2)YearWarranty on element only. No labor second year.

Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP.Three (3) Year Warranty on all

RockGrates, Cooking Grates, Burner Shields, Fireboxes:

90Day Material Only. No Labor.

90Day Material Only.NoLabor.

9/05

27

Page 28

R

Phone: +1

(214) 421-7366

Fax: +1 (214) 565-0976

Toll Free: +1 (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

APW WYOTT

729 Third Avenue

Dallas, TX 75226

28

Loading...

Loading...