APW Wyott XWAV-1417 Installation Manual

Models: XWAV1417 / XWAV1422 / XWAV1829

PASS THROUGH OVEN

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE UNIT

MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

Initial heating of unit may generate smoke or fumes and must be done in a well ventilated area.

Overexposure to smoke or fumes may cause nausea or dizziness.

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

Phone: (214)421-7366

Fax: (214) 565-0976

Toll Free: (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

APWWYOTT

729 Third Avenue

Dallas, TX 75226

TABLE OF CONTENTS

SECTION

ITEM PAGE

1

2

3

4

5

6

7

8

9

10

11

Owner's Information 3

Safety Information 3

Specifications 4

Installation Instructions 5

Operation 6

Cleaning 9

Troubleshooting 9

Preventative Maintenance Schedule 9

Wiring Diagrams 10

Parts List and Exploded View 12

Warranty 14

1. OWNER'S INFORMATION

General Information:

1. Always clean equipment thoroughly before first use. (See general cleaning instructions).

2. Check rating label for your model designation and electrical rating.

3. For best results, use stainless steel countertops.

General Operation Instructions:

1. All foodservice equipment should be operated by trained personnel.

2. Do not allow your customers to come in contact with any surface labeled "CAUTION HOT".

3. Never touch ceramic or steel heaters.

Warranty Information:

Reliability Backed By APW Wyott's Warranty:

All APW Wyott Pass Through Ovens are backed by a one year parts and labor warranty, including On-Site

Service calls within 50 miles of authorized service technicians.

Service Information:

Service Hotline (800) 733-2203

2. SAFETY INFORMATION

APW Wyott equipment is designed, built and sold for commercial use and should be operated by trained

personnel only. Clearly post all CAUTIONS, WARNINGS and OPERATING INSTRUCTIONS near each

unit to insure proper operation and to reduce the chance of personal injury and/or equipment damage. This

product is used for the cooking, defrosting or re-thermalization of food products only.

Always disconnect power before servicing the unit. Surfaces will remain hot after power has been turned

off. Allow unit to cool before cleaning or servicing. Never clean the unit by immersing it in water. The unit is

not protected against water jets; DO NOT CLEAN PASS THROUGH OVEN WITH A WATER JET. Always

clean equipment properly before first use.

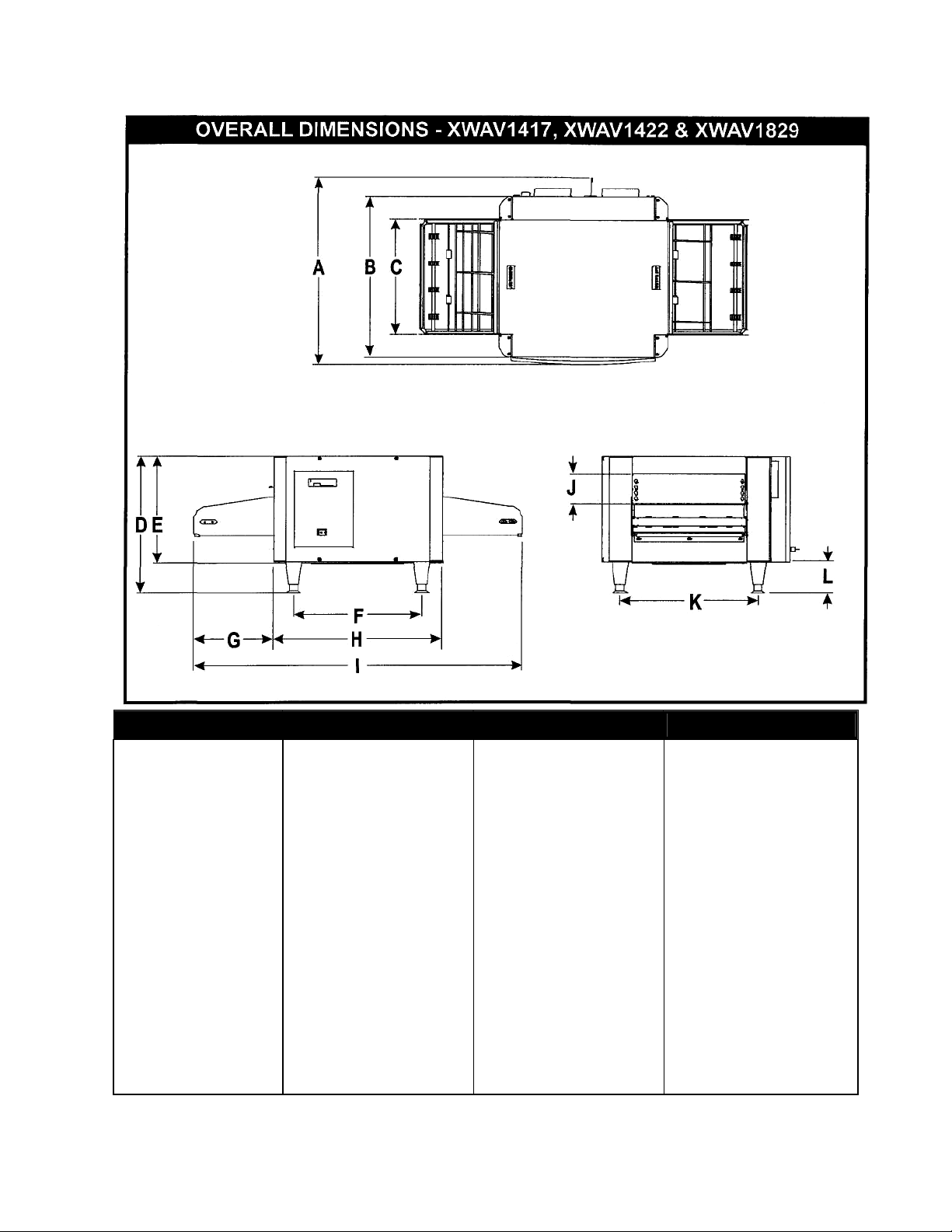

3. SPECIFICATIONS

DIMENSION

XWAV1417

XWAV1422

XWAV1829

A 24.49 24.49 28.00

B 21.00 21.00 25.00

C 15.14 15.14 19.14

D 18.00 18.00 18.00

E 14.00 14.00 14.00

F 11.80 16.75 24.05

G 10.50 10.50 10.50

H 17.25 22.00 29.50

1 38.25 43.00 50.50

J 3.84 3.84 3.84

K 18.00 18.00 22.00

L 4.00 4.00 4.00

Electrical ratings:

MODEL

XWAV1417

XWAV1499 5400 208 26.0 6-30P

XWAV1829

Power Cord:

Six (6) foot, 3 wire grounded cord. If the supply cord is damaged, the manufacturer, or an authorized

service agent, must replace it in order to avoid a hazard and warranty. Please contact the factory by

calling the 800 # located on the unit.

Shipping Weight:

XWAV1417 98lbs.(44.5kg.);XWAV1422 115lbs. (52.2kg.);XWAV1$29 149 lbs. (67.6 kg.)

WATTS VOLTS AMPS (1 Phase) NEMA PLUG

4100 208 19.7

4100 240 17.1 6-30P

5400 240 22.5 6-30P

7200 208 34.6 6-50P

7200 240 30.0 6-50P

6-30P

4. INSTALLATION INSTRUCTIONS

If the carton appears damaged, or damage is discovered once the carton is opened, stop

immediately and contact the freight company to file a damage claim.

1. Remove all external packaging that is protecting top portion of unit.

2. Remove unit from snipping container while in the upright position. The unit can be lifted out of the

carton by grasping under the conveyor on each side of the appliance. Please remove the plastic

bag.

3.

Remove all internal packaging to the unit.

inside the tunnel oven between the top heaters and the conveyor.

conveyor trays. Remove tape from extrusion corners. Remove tape from deflecting curtains

located just above entrance and exit of conveyor.

4. Visually inspect all external and internal portions of unit for damage. Important: Inspect the

top white ceramic elements located inside the oven tunnel after removal of urethane

supports. To inspect these white ceramic elements, use a small mirror held under each element to

Important: Remove urethane supports located

Remove tape from

detect cracks. Important: The Ceramic elements are fragile and will break under

stress. Do not twist, pull, push, or otherwise subject the white ceramic elements to

stress.

5. Wipe down the exterior of the unit using a damp cloth with warm water. Do not use abrasive pads or

cleaners as they will damage the stainless steel surface and high temperature plastic.

NOTE: DO NOT USE CLEANERS OF ANY KIND ON THE WHITE CERAMIC HEATERS.

6. Remove four feet from box and install into threaded nuts located at the four corners underside of the

left and right housings; Also remove conveyor extension tray(s). Conveyor extensions should be

hung off end of conveyor frame. As our standard, Model XWAV1417 will only have one extension

intended for the exit end; Model XWAV1422 and XWAV1829 will have two for loading and exit ends.

7. Place unit in operating location.

Note. Ambient Conditions - Make sure that the operating location is in an area where the

ambient temperature is held constant (minimum 70°F). Please avoid areas such as near

exhaust fans and air conditioning ducts.

Warning: Operating environment

Ensure that operation location is at a reasonable distance from combustible walls and materials

otherwise combustion or discoloration could occur. Stand-off/Air-divider located on rear panel is

important in maintaining proper division of inlet and exhaust air flow - If removed it could result in

improper functioninq of unit and MAY cause personal injury and WILL void your warranty.

Caution. Operating environment

Place unit on a stable, level counter at a convenient height for use. Turn the adjustable feet so

that unit is level to countertop. The top of the unit is not intended for use a shelf. Materials

placed there are at risk for fire.

8. Before plugging unit into wall, make sure that the switch is in the off position.

9. Warning: Ensure no hands, tools or parts or other unintended items are located on the conveyor

as injury will result when unit is turned on.

10. Plug unit into grounded electrical outlet with correct voltage, and plug configuration.

Warning: Using any receptacle that is not designed to match the attached cord and plug MAY cause

personal injury and WILL void your warranty. Please attach the XWAV1422/Medium Size unit,

208V, 5400Wonly, to an individual branch circuit.

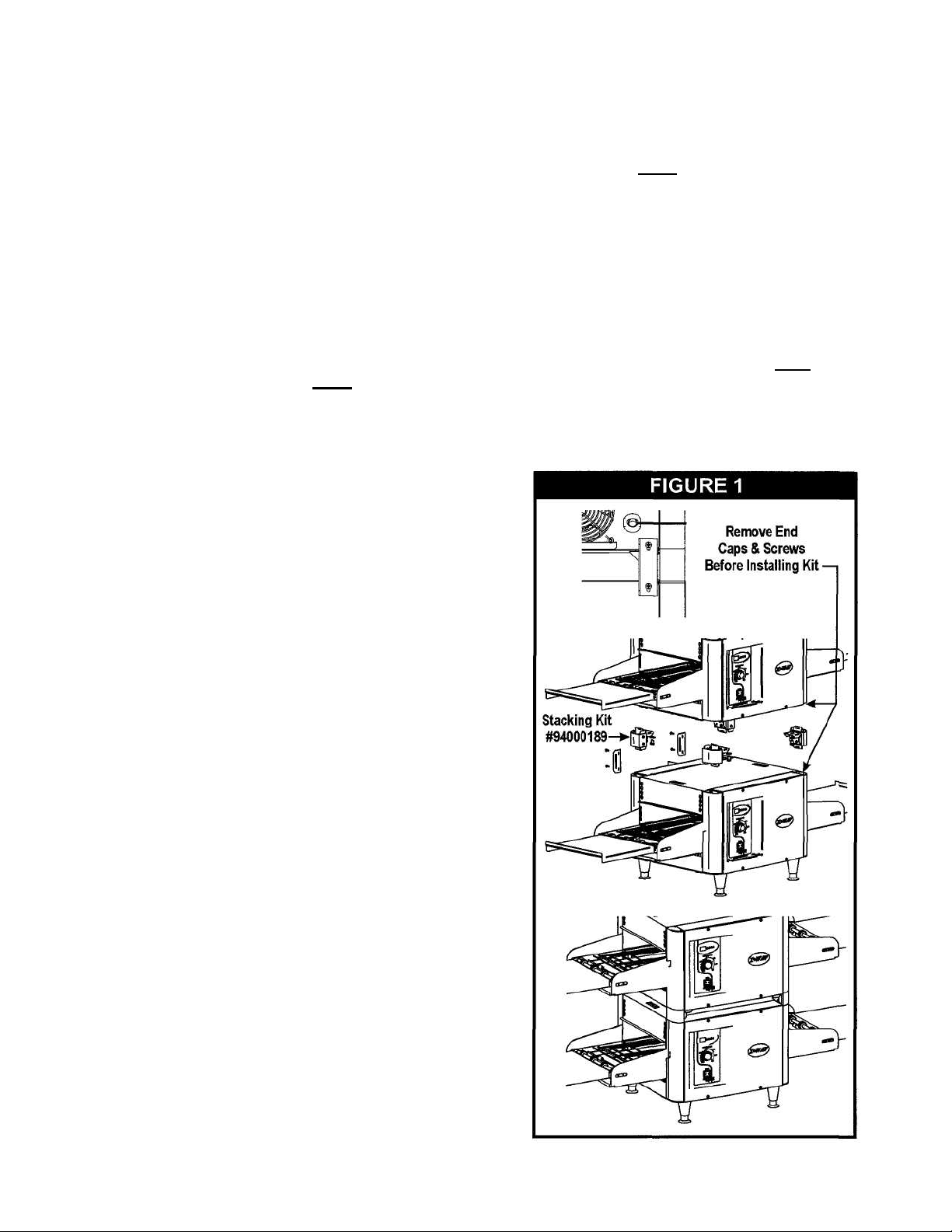

Oven Stacking

The stacking kit will consist of 4 corner posts to be inserted

between stacked units.

Warning: When stacking, unit must have proper

stacking kit installed. This will prevent overheating

and damaging of electrical components.

Warning: Do not stack more than three units tall or do

not use more than two stacking kits.

Warning: Standoff on rear panel of unit is important to

allow proper inlet and exhaust fan airflow. Do not

cover inlet or exhaust fan openings as this could

damage electrical components.

1. Ensure bottom unit is mounted on secure

surface, with feet installed.

2. Remove respective corner end caps and

screws. This will allow each of the stacking

spacer retaining fingers to slide into the

extrusions.

3. Remove the feet from the top unit as shown.

4. Secure each stacking spacer to the bottom of

the unit as shown by using the bolts and

washers provided. You should have four total

of each.

5. Once the stacking kit spacers are secure, place

top unit onto bottom unit. The stacking kit

spacers each have tapered guides to allow the

unit to lock into position.

6. Refer to Figure 1. Install rear support bracket

and screws as shown. Each stacking kit

requires that two brackets be mounted on the

backside only. One bracket near the strain

relief and one at the opposite end.

7. Refer to Cleaning Instructions for cleaning of

stacking spacers and cleaning between units.

Loading...

Loading...