Page 1

R

C

A

U

T

IO

N

H

O

T

T

O

H

N

IO

T

U

A

C

INSTALLATION

AND

OPERATING

INSTRUCTIONS

5

6

0

Model: VCG

VERTICAL CONTACT BUN GRILL TOASTER

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

TOASTER MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

!!

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this equipment.

!!

Initial heating of toaster may generate smoke or fumes and must be done in a well ventilated area.

Overexposure to smoke or fumes may cause nausea or dizziness.

This equipment has been engineered to provide you with year-round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

ANSI/NSF4

P/N 81600289 9/05

Phone:

(214) 421-7366

Fax: (214) 565-0976

Toll Free: (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

APW / WYOTT

729 Third Avenue

Dallas, TX 75226

1

Page 2

Notes:

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

2

Page 3

TABLE OF CONTENTS

SECTION ITEM PAGE

1 Owner’s Information

2 Important! Safety Information

3 Specifications

4 Operation

5 Cleaning

6 Troubleshooting

7 Preventative Maintenance Schedule

8 Wiring Diagram

9 Parts List

10 Procedure: Silicone Belt Tracking

Procedure: Belt Adjustment

11 Procedure: Changing a belt

12 Warranty

........

3

General Info. 3

Warranty Info. 3

4

4

Electrical 4

Dimensions 5

..

Operating Instructions 6

Temperature Adjustments 6

....

Cleaning Instructions 7

Cleaning Instructions (En Espa ol) 8

Figure 1 Diagram 7, 8

Release Sheet Replacement 9

Release Sheet Kit Removal 9

Manual Reset Thermostat 11

ñ

6

7

9

12

15

16

17

18

18

19

1. OWNER’S INFORMATION

General Information:

The APW Wyott Vertical Contact Bun Grill Toaster (VCG) is designed to toast two buns (crown and a heel) at

the same time. Toasting is accomplished through contact of the flat side of the buns with an aluminum

griddle plate. The user places both buns into the top of the toaster and two perfectly caramelized, warm

buns (4 halves) will slide out of the bun chute. The VCG will toast two buns, crown and heel, in 8 seconds.

The Manual includes information for proper procedures on safety, installation and operation of the Vertical

Contact Bun Grill Toaster (VCG). It is of extreme importance that this manual be read in its entirety before

installing and operating this unit.

This Vertical Contact Bun Grill Toaster (VCG) is manufactured of the highest quality materials available and

is built to the stringent quality standards of APW Wyott. Quality Assurance testing is one of the standards

that we adhere to.

Please keep this manual for future reference. It contains important instructions for the proper installation,

operation and service of this unit. If this unit changes ownership, it is important that this manual accompany

the equipment.

WarrantyInformation:

Reliability backed byAPW Wyott’s Warranty:

All APW Wyott Bun Grill Toasters are backed by a 1-year Parts and Labor warranty, including On-Site

Service calls within 50 miles of authorized service technicians.

Service Information:

Service Hotline (800) 733-2203

3

Page 4

2. SAFETY INFORMATION

APW Wyott toasters are designed, built, and sold for commercial use and should be operated by trained

personnel only. Clearly post all CAUTIONS, WARNINGS and operating instructions near each unit to

insure proper operation and to reduce the chance of personal injury and/or equipment damage.

Always disconnect power before servicing the toaster. Surfaces will remain hot after power has been

turned off. Allow unit to cool before cleaning or servicing. Never clean the toaster by immersing it in water.

The toaster is not protected against water jets; DO NOT CLEAN TOASTER WITH A WATER JET. Always

clean equipment before first use.

Operating toaster withoutlegs will void the warranty. Insureall accessories and exterior panels are properly

installed and adjusted before applying power and operating.

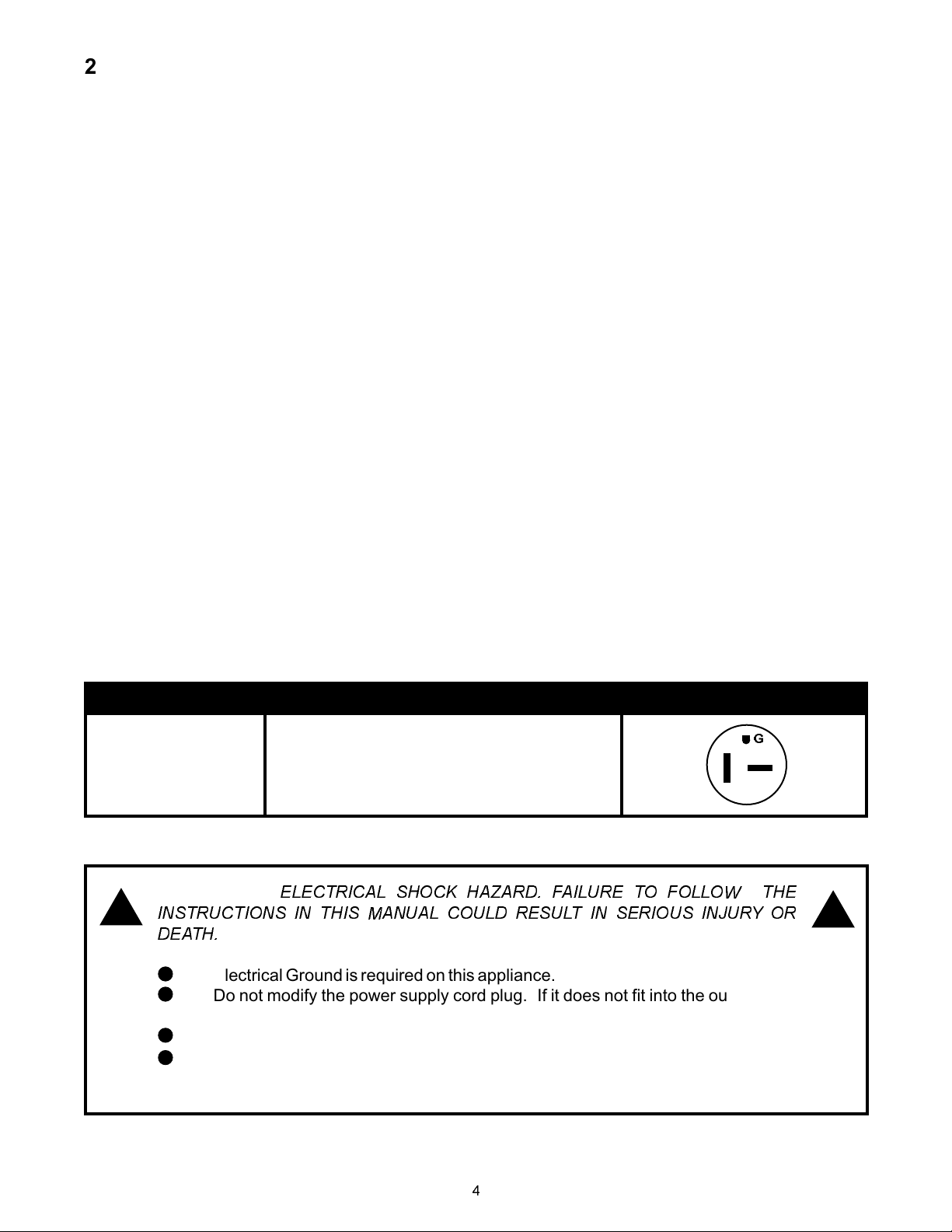

3. SPECIFICATIONS

Cordset Configuration:

208/240V: NEMA6-20P plug, 3 foot, 3 wire grounded cord.

208/240V: NEMA6-20P plug (90° angle), 5 foot, 3 wire grounded cord.

If the supply cord is damaged, the manufacturer or an authorized service agent or a similarly qualified

person must replace it to avoid a hazard or voiding the warranty.

Overall Dimensions:

VCG: 24”H x 21 3/4”W x 10 5/8” D (61 cm x 55 cm x 27 cm)

Electrical Ratings:

VCG: 208V - 2570W, 12.5 Amps 60HZ

VCG: 240V - 3420W, 14.5 Amps 60HZ

NEMA NUMBER

6

WARNING:

INSTRUCTIONS IN THIS MANUAL COULD RESULT IN SERIOUS INJURY OR

!

DEATH.

Electrical Ground is required on this appliance.

Do not modify the power supply cord plug. If it does not fit into the outlet, have

the proper outlet installed by a qualified electrician

Do not use an extension cord with this appliance.

Check with a qualified electrician if you are unsure as to whether the appliance

is properly grounded.

ELECTRICAL SHOCK HAZARD. FAILURE TO FOLLOW THE

DESCRIPTION

NEMA-6-20P

20 Amp, 250 VAC

CONFIGURATION

G

!

4

Page 5

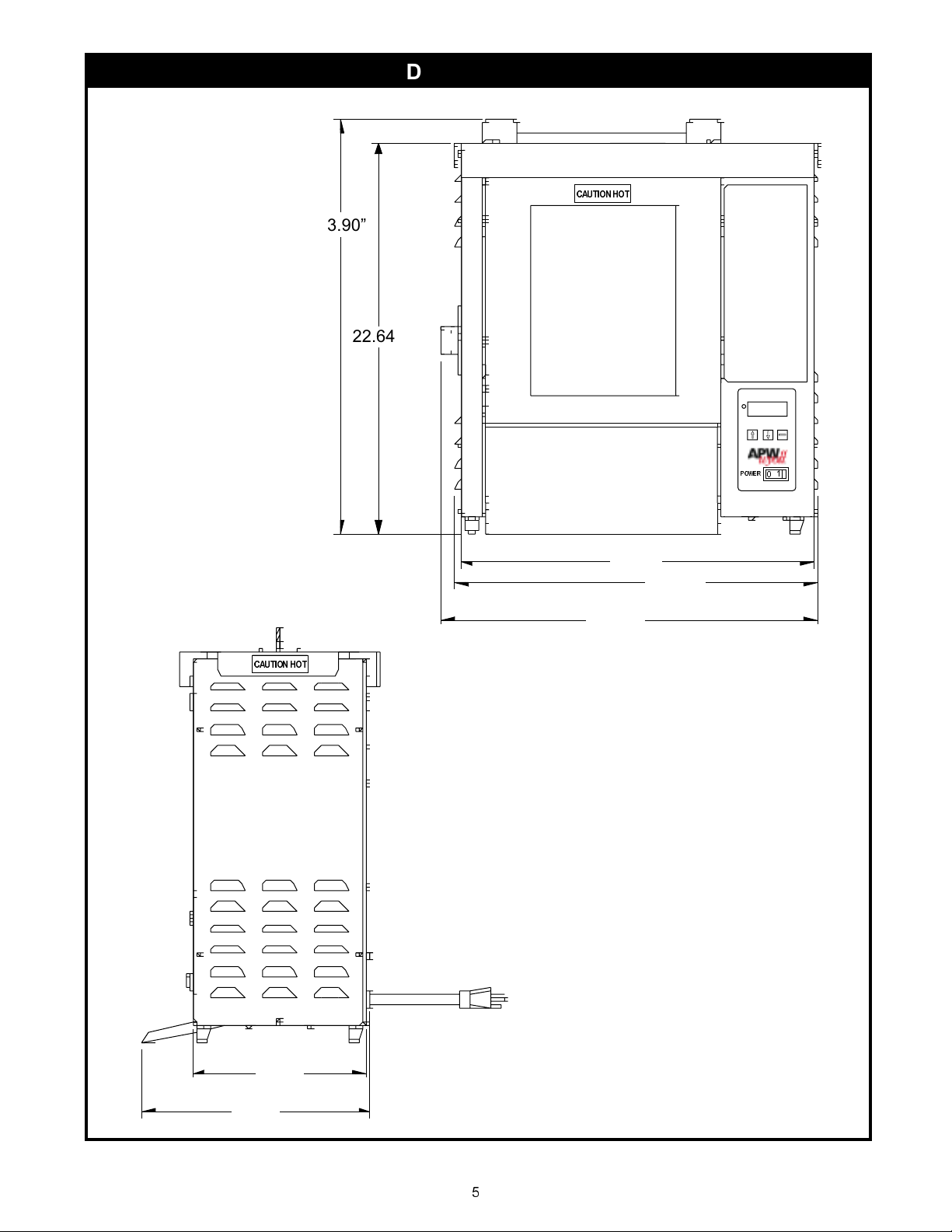

23.90”

22.644”

DIMENSIONS

CAUTION HOT

POWER

560

0

1

CAUTION HOT

20.44”

20.88”

21.77”

10.05”

13.20”

5

Page 6

4. OPERATION

Operating Instructions

Dry operation onlyThis toaster is for (no oil). Do not put buttered bread products in the toaster.

!

Ensure Release sheets are properly installed. (See page 9.)

!

Turn Main Power Switch on. Set Temperature Control to desired temperature. (Temperature is factory

set at 600°F.) Allow Pilot Light to cycle at least two times (on/off). When the light is on, the grill is heating.

Heat up time is about 15 minutes.

!

Place bun halves on feeder cut side down (facing grill surface). Toast time is approximately 8, 20 or 30

seconds depending on bun height, diameter and model purchased. Increase or decrease temperature

setting to achieve desired brownness and temperature.

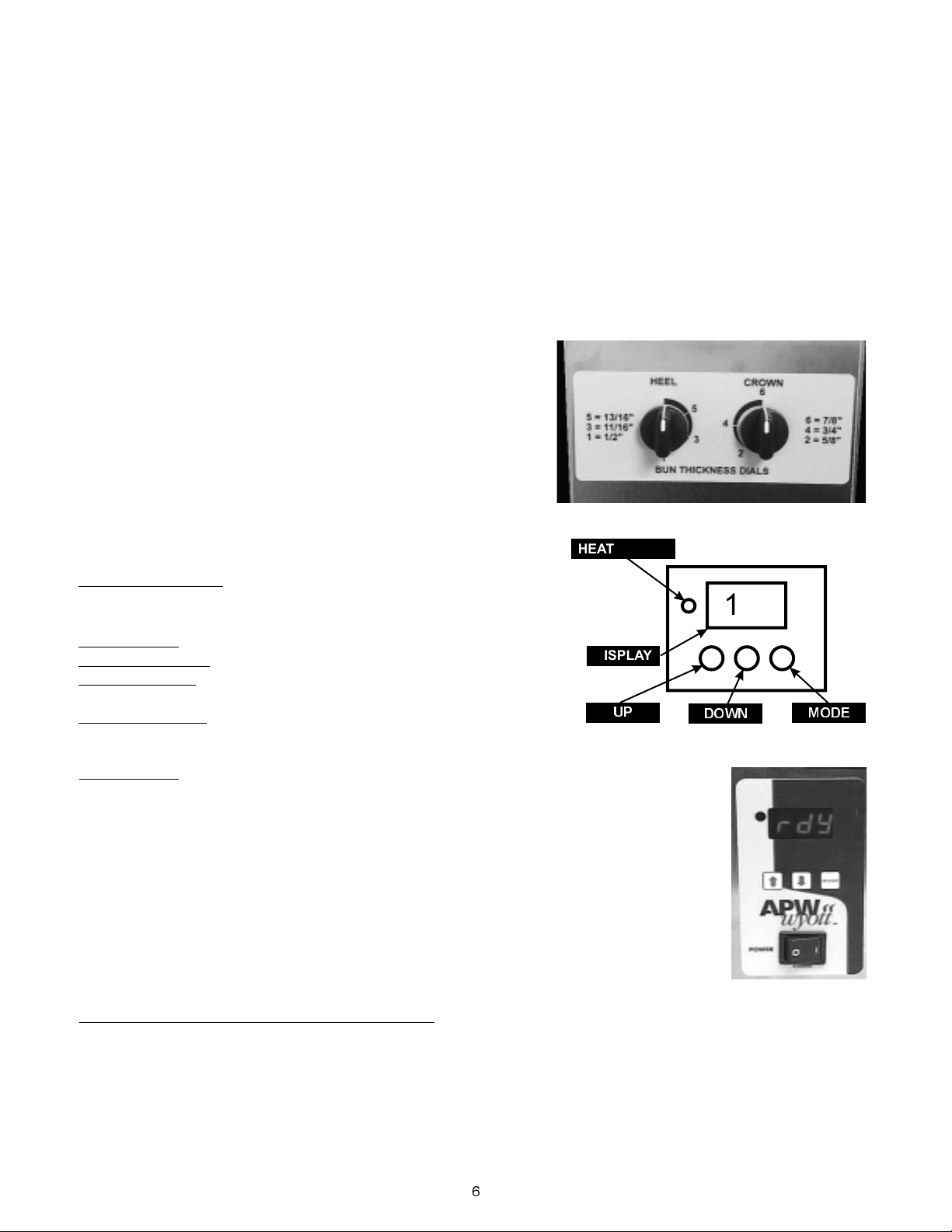

Bun Thickness Adjustment

The VSX is designed to accommodate a variety of

different products. Adjust for product thickness by

setting the Bun Adjustment Knobs on the side of the

toaster to the appropriate setting. Settings for

different thicknesses are indicated on the label

adjacent to the adjusting knobs. See photo.

Temperature Control

DIGITAL DISPLAY:

UP SWITCH:

DOWN SWITCH:

HEAT ON LED:

MODE SWITCH:

OPERATION

1. When power is applied, the digital display will initially show the software version

then change to “Lo”.

2. Press appropriate UP or DOWN switch and then press and hold until desired

setpoint is displayed. Holding the UP or DOWN switch will cause the

setpoint to increment by 1 degree for the first 5 degrees and after that the display

will increment by 5 degrees at a time.

3. Heat On LED will be illuminated until temperature reaches setpoint. Once the

toaster reaches setpoint, the display will change to “rdy” and the Heat on LED will

turn off. The heat on LED will then cycle on andoff to maintain temperature.

Shows setpoint, actual

temperature and error / status

messages.

Increase / view setpoint.

Decrease / view setpoint.

Illuminated when power is

being applied to heater.

View actual temperature.

HEAT ON LED

DISPLAY

UP

185

DOWN

MODE

STATUS, ALARM, AND ERROR MESSAGES

rdy

lo

Hi

Prb

HIE

Control has reached setpoint and the toaster is ready for operation.

Actual temperature is 50 degrees (or more) below setpoint.

Actual temperature is 50 degrees (or more) above setpoint.

Defective or disconnected temperature probe (sensor).

Appears if relay is defective or inoperable.

6

Page 7

5. CLEANING

Cleaning Instructions

Toaster is for DRY BUNS ONLY. Do not

put buttered bread products in the

toaster.

Note: To save time at closing (it will take

15 minutes for toaster to cool down), you

might want to have the day shift clean the

toaster.

1. Turn off (7) Main Power Switch (See

Fig. 1). Allow toaster tocool down.

2. Remove (6) Bun Slide and (1) Top

Cover (See Fig. 1.) and wash in

sink.

3. For ease of cleaning, rotate toaster.

4. Lift up and lower (5) Front Panel (See

Fig. 1).

5. Depress (9) Conveyor Button (See

Fig. 1). Using a damp

cloth or sponge, wipe (4) belting back

and forth removing bread crumbs

and debris. Continue until belting is

clean.

6. Close (5) Front Panel (See Fig. 1).

7. Lift up and lower (8) Back Panel (See

Fig. 1).

8. Repeat step six.

9. Close (8) Back Panel (See Fig. 1).

10. Rotate (3) BunThickness Dials to the

vertical position.

11. Remove (2) Release Sheet (See Fig.

1) and place on flat surface. Using a

damp cloth or sponge, wipe (2)

Release Sheet (See Fig. 1.)

Removing bread crumbs and debris.

12. Rotate and replace (2) Release

Sheet (See Fig. 1).

13. Replace (1) Top Cover (See Fig. 1).

14. Rotate (3) Bun Thickness Dials to

their original position.

15. Turn on (7) Main Power Switch (See

Fig. 1).

Figure 1 Diagram

7

Page 8

CLEANING (EN ESPAÑOL)

El Procedimiento de Limpieza

Tostador es SOLO PARA LOS BOLLOS SECOS.

No ponga los productos de pan unta dos con

mantequilla en la tostadora.

!

Tostador con Parrilla de Contacto Vertical

Instrucciones Para Limpiar el Tostador

!

Solamente Ponga Bollos Secos en el Tostador

!

En el Tostador no se Debe Poner Pan u Otro Tipo

!

deAlimentos Untados con Mantequilla

Figure 1 Diagram

Nota:

Para ahorrar tiempo al cerrar (Hay que esperar

15 minutos para que el tostador se pueda enfriar)

usted puede decirle al los trabajadores del horario

diurno que deben limpiar el tostador.

1. Apagar usando (7) el interruptor principal (mirar

ra

la 1 figura). Darle un tiempo al tostador de

enfriarce.

2. Quitar (6) el deslizador de los bollos y (1) la tapa

superior (mirar la 1 figura) y l a v a r e n e l

ra

fregadero.

3. Para limpiar con más facilidad debe girar el

tostador.

4. Levantar y bajar (5) el panel delantero de el

tostador (mirar la 1 figura).

5. Deprimir (9) el botón de la correa transportadora

(mirar la 1 figura). Usando un t r a p o

ra

ra

humedo o esponja, limpiar (4) la correa adelante

y atras quitando las migajas de pan y

otros escombros. Continuar hasta que la correa

este limpia.

6. Cerrar (5) el panel delantero.

7. Levantar y bajar (8) el panel trasero de el

tostador (mirar la 1 figura).

ra

8. Repetir el paso número seis.

9. Cerrar (8) el panel trasero

10. Girar (3) los diales que específica el gueso de los

bollos a la posición vertical

11. Quitar (2) la hoja de salida (mirar la 1 figura) y

ra

pongase en una superficie plana. Usando un

trapo humedo o esponja, limpiar la (2) la hoja de

salid(mirar la1 figura) quitando las

ra

migajas de pan y otros escombros.

12. Girar y reemplazar (2) la hoja de salida (mirar la

ra

1 figura).

13. Reemplazar (1) la tapa superior (mirar la 1

figura).

14. Girar (3) los diales que específica el gueso de los

bollos a su posición original.

15. Poner en marcha usando (7) el interruptor

principal (mirar la 1 figura).

ra

ra

8

Page 9

Release Sheet Replacement

1

6

2

7

1. Turntoaster off.

2. Remove the top cover.

3. Remove old release sheet from the toaster

platen (grill).!!! CAUTION !!! TOASTER

PLATEN MAY BE HOT.

4. If the reverse side of the release sheet is still

good, then fold the release sheet the opposite

way and use the other side. Skip to step 6.

5. If using a new release sheet, fold the release

sheet in half (length-wise) and crease it.

6. Turn toaster on. (Conveyors will not run

because top cover is removed.)

firmly

3

8

7. Move theconveyors out full. (The bun thickness

dials point straight up.)

111

8. Drape the release sheet over the toaster platen

and go about 5” down.

9. While holding the release sheet with one hand,

press the conveyor button on top to start the

conveyors. As the conveyors turn, they will

help the release sheet to go down. !!!

CAUTION !!! BUTTON MAYBE HOT.

10. When the crease reaches the top of the platen,

release the conveyor button.

4/5

9/10

Release Sheet Kit

11

12

13

6. TROUBLESHOOTING GUIDE

Always ask and check the following:

1. Is the unit connected to a live power source of the proper voltage?

2. Check the circuit breaker.

3. Is power switch “ON” and pilot light glowing?

4. Check the rating label. Is the unit connected to the correct power

source?

11. Replace the top

cover to the toaster.

(Conveyor starts to

move.)

12. Let the toaster run

for about 30

minutes to warm up

the release sheet.

13.Re-adjust the

conveyors to their

proper settings

using the bun

thickness dials.

Service Hotline (800) 733-2203

Removing Release Sheet

9

Page 10

Problem

No heat and conveyor

belts don’t move.

Possible Cause Corrective Action

Toaster is installed incorrectly. Review and perform installation and operation

procedures.

Lid not placed on top securely. Install or adjust lid so that the push button

plunger on the top of the toaster is depressed.

Manual High Limit switch tripped open. Reset high limit switch according to the

instructions contained in this manual.

Defective components or wiring problem Check all connections

No heat and conveyor

belts move.

Temperature Controller

Check Temperature Controller for an Alarm

Message or erroneous reading. Contact an

authorized APW service technician.

Solid-state relay failure

Contact an authorized APW service

technician.

Inoperative Platen or Wiring Problem

Set-point is too low

Contact an authorized APW service agent.

Adjust Temperature Control to desired

setpoint. (See page 6)

Platen is hot and

conveyor belts don’t

move

Product or silicone belt jammed Turn unit off, disconnect from power, allow to

cool, and and remove silicone belt. Clean

thoroughly according to the instructions in this

manual and re-install the silicone belt.

Wiring problems, loose of broken drive

chains.

Conveyor hung up.

Contact an authorized APW service

technician.

Turn toaster off, wait 5 seconds, and turn

toaster back on. If this happens often, contact

an authorized APW service agent.

Product is over toasted

or heat is too high, or

Bun adjustment controls set incorrectly. Measure bun thickness and set the bun

controls accordingly.

drop time is too slow,

product is getting stuck

or conveyor belts stop

when

Buns sticking to release sheet. Clean or replace release sheet or

silicone belt according to the instructions in

this manual.

product is toasting. Temperature controller set point too high. Verify thermostat is cycling at the desired

temperature set point and lower if necessary.

Voltage too high. Verify the line voltage matches the toaster’s

rated voltage identified on the serial number

data plate.

Product is under toasted

or platen heat is too low

Wiring problems or defective

components.

Bun adjustment controls set incorrectly. Measure bun thickness and set the bun

Contact an authorized APW service

technician.

controls correctly.

or drop time is too fast

Temperature controller set point too low. Verify that the thermostat is cycling at the

desired temperature and raise if necessary.

Voltage too low. Verify that the line voltage matches the

toaster’s rated voltage identified on the serial

number data plate

Wiring problem or defective components. Contact an authorized APW service

technician.

Conveyor belts are

jumping or snapping

Buns getting stuck on

discharge.

Toaster is installed incorrectly Review and perform installation and operation

instructions.

Conveyor drive belts skipping, loose,

worn, or broken.

Buns not being removed from discharge

Contact an authorized APW service

technician.

Remove buns from bun chute faster.

chute fast enough. Several buns are

being allowed to collect on the bun chute.

Discharge chute has been lifted up and a pan

placed under it (to catch crumbs).

Remove the pan or purchase APW / Wyott

#81699001 BUN CATCHER ACCESSORY KIT.

This part has a pan built in to the bun chute to

catch crumbs.

10

Page 11

Problem

Crown and / or heel must

be forced into the toaster.

Toaster is overheating or

cooling fan is not turning

properly.

Toaster making noise or

unusual sounds. (Note that

some noise is inherent to

the normal operation of the

toaster and does not requi

field service. If unsure, call

the APW Wyott technical

service department.)

Possible Cause Corrective Action

Release sheet and / or silicone belt need

cleaning.

Bun Chute improperly installed.

Dirt and build-up on the fan blades or in the fan

motor.

Drop down side panels rattle.

Lid Rattles

re

Chains emit squeaking or skipping noise or any

noise indicating metal is rubbing on metal.

Clean or replace release sheet or silicone belt

according to the instructions in this manual.

Review installation instructions and relocate bun chute.

Verify that the bottom of the bun chute is level and

setting flat on the counter or table.

Turn the unit off, disconnect from power, allow to cool,

and clean the cooling fan blades.

Verify that the door is undamaged, closed and properly

seated on the top cross rods. Verify the silicone belt is

properly installed.

Verify the lid is undamaged, and re-secure it to the top

of the toaster.

Contact an authorized APW technical service

technician.

Temperature Co ntrol

Display Error Code – High

Temperature (rly)

Temperature Control

Display Error Code – Probe

or Sensor (prb)

No Temperature Control

Display, or erratic display,

or displays ’---‘

Belt wrap pin rubbing on metal housing.

Silicone belt wrap is installed incorrectly.

Failed solid-state relay, heating platen, or

temperature control board.

Loose or “open” sensor, failed sensor.

Unit not plugged in.

Circuit Breakers turned off or tripped.

Wire problem, failed circuit board, or damaged

electrical components

Cooling Fan not turning properly. Control

compartment temperature is above 150° F.

Center the pin in the belt wrap zipper.

Re-install the silicone belt according to the instructions

in this manual.

Contact an authorized APW service technician.

Contact an authorized APW service technician.

Plug unit in to proper electrical outlet.

Reset breakers. If they trip again, contact your local

electrician or authorized APW service technician.

Contact an authorized APW service technician.

Turn unit off, disconnect power, allow to cool, clean

cooling fan. If toaster continues to overheat, contact an

authorized APW service technician.

Manual Reset Thermostat

The manual reset is a device that provides thermal protection for the platen. In the event that the main

controller or power relay fails to regulate the heat on the platen, the manual reset thermostat will break the

electrical connection to the platen. The control, the motors, the conveyors, and the fans may all continue to

operate, but no more heat will go to the platen. The manual reset thermostat will prevent any power from

going to the platen until a person resets it.

If the manual reset thermostat trips (disallows heat to the platen), this may indicate an extreme failure of

another device. If this thermostat trips more than once, it is important that you contact an authorized APW /

Wyott technical service technician.

To reset the thermostat, locate the thermostat at the rear of the toaster. There is a blackknob near the power

cord and the rating label. Unscrew the black cover (you may need a screwdriver). Push in the button that it

is covering. Replace the black cover(hand tight).

11

Page 12

7. PREVENTATIVE MAINTENANCE SCHEDULE

Tools required: Heat Resistant Gloves, Standard Cleaner, Standard Sanitizer, Soft Towels.

1) Preventative Maintenance -

A. Exterior. Everyday you should clean the outside of the toaster by wiping it down with a

B. Cooling Fan. Check air intake. The cooling fan grille on the side of the toaster must be

C. Additional cleaning according to the instructions described on page 7 & 8.

D. Remove the top cover and bun chute and clean in a sink.

E. Remove the release sheet and wipe clean with a damp cloth. Be careful not to crinkle it

Daily:

Monthly:

Yearly:

WARNING!

when removing the top cover,cleaning the Release Sheet,and cleaning the silicone belt.

soft cloth and detergent.

cleaned daily clean grille with a stiff nylon type brush. The cooling fan operates when

the power switch is turned to on. It must operate to keep the electrical control compartment

below 140°F (60°C).

WARNING!

motor shaft, do not operate toaster. Serious damage could be done to the blower motor and /

or the solid-state electrical components if the toaster is operated while the cooling fan is not

running or if the cooling intake is blocked.

or rip it at the crease. Be careful when removing it since it might still be hot.

Needle Nose Pliers, Soft Brush

Phillips Screwdriver, Standard Lubricating Oil

Daily

Toaster may be hot. Allow to cool before cleaning. Use heat resistant gloves

If the fan blade is not rotating, or fan assembly is missing from main blower

2) Preventative Maintenance -

WARNING!

when removing the top cover, cleaning the release sheet,

and cleaning the silicone belt.

A. Clean Silicon Belts. In addition to the daily cleaning

described above, remove the top cover. Open one side

(front or rear) of the toaster and clean the orange silicone

belt. Using a standard cleaner, wipe across and down.

Clean both sides of each silicone belt. To rotate the belt,

depress the safety interlock switchlocated on the top of the

toaster.

WARNING!

fingers, or any foreign objects from being caught in the

rotating conveyor belt. To stop the conveyor from turning,

release the safety interlock switch.

Follow cleaning by wiping down both sides of each silicone

belt with a standard sanitizer. Turn the toaster on the

counter to access the other silicone belt, and repeat the

cleaning instructions.

Toaster may be hot. Allow to cool before cleaning. Use heat resistant gloves

Do not allow articles of clothing, hands,

Weekly

Cleaning Silicone Belt

Cleaning Release Sheets

B. Clean Release Sheets. Carefully remove the Release

Sheet, laying it flat on a clean surface. Using a standard

cleaner, wipe down both sides of the sheet until clean.

Follow cleaning by wiping down both sides of the sheet

with a standard sanitizer. If the Release Sheet appears to

be overly worn, replace it.

12

Page 13

3) Preventative Maintenance -

Monthly

WARNING!

Toaster may be hot. Allow to cool before cleaning. Use heat resistant gloves

when removing the top cover,cleaning the Release Sheet,and cleaning the silicone belt.

A. In addition to the daily cleaning described above, remove and

clean silicone belt. Remove the top cover and bun chute and

clean with detergent in a sink. Open one of the side panels (front

or rear) exposing the orange silicone belt. By depressing the

safety interlock switch at the top of the toaster, rotate the

conveyor so that the “flap” is in the front of the conveyor.

WARNING!

Do not allow articles of clothing, hands, fingers, or

any foreign objects from being caught in the rotating conveyor

belt. To stop the conveyor from turning, release the safety

interlock switch.

Slide the pin that runs through the zipper under the

flap of the belt by grasping it with a pair of needle

nose pliers and pulling sideways. DO NOT

DISCARD THE PIN. Once the belt is removed, lay

it out flat on a clean surface. Using a standard

cleaner, wipe down both sides of the belt until clean.

Follow cleaning by wiping down both sides of the

belt with a standard sanitizer.

B. Brush out the conveyor chain and sprockets. Using a soft brush, remove any

food particles that may have built up under the silicone belt. Visually inspect the drive

sprockets to verify that food particles have been cleared away. Wipe down the metal chain

with a soft cloth and standard cleaner. Follow cleaning by wiping again with a standard

sanitizer.

C. Clean the release sheet tensioning roller. Wipe down the roller with a standard cleaner.

Follow cleaning by wiping down again with a standard sanitizer. Spin the roller to make sure

that it turns freely.

D. Replace the silicone belt. Wrap the silicone belt around the metal conveyor chain, with the

top flap located at the top of the conveyor. THE TOP FLAP MUST BE POSITIONED

PROPERLY THE OPENING THAT EXPOSES THE ZIPPER SHOULD BE IN FRONT OF

AND ACCESSIBLE TO YOU, ROTATING UP AND TOWARD THE PLATEN AS THE

CONVEYOR TURNS. (See diagram)

With one hand, hold the zipper together on one edge of the belt. With the other hand, start to

slide the pin through the zipper, securing the belt to the conveyor. You may have to use the

needle nose pliers to slide the pin all the way through the zipper. MAKE SURE ALL OF THE

TEETH ON THE ZIPPERARE LINED UPAND OPPOSITE EACH OTHER, AND THE PIN IS

STICKING OUT EQUALLY ON EITHER SIDE OF THE SILICONEBELT.

4) Preventative Maintenance -

3 to 6 Months

WARNING!

Toaster may be hot. Allow to cool before cleaning. Use heat resistant gloves

when removing the top cover,cleaning the Release Sheet, and cleaning the silicone belt.

A. In addition to the daily cleaning described above, remove and inspect the silicone belt. If

worn, brittle, or damaged, replace thebelt with a new one according to section12, Procedure

for Changing a Belt (see page 18).

13

Page 14

5) Preventative Maintenance

A. In addition to the daily cleaning described above, remove the silicone belts according to the

instructions described in (3), and inspect the metal conveyor chain. Check the tension to

make sure that drive sprockets are engaging all the wires in the metal conveyor chain. If the

sprockets are not engaging all the wires, if the metal belt is too loose, making noise, or

exhibits any other indication of being unusually loose, call an authorized APW Wyott Service

Technician.

Yearly

CAUTION.

AN ANNUAL PREVENTATIVE MAINTENANCE INSPECTION OF THE

INTERNAL COMPONENTS IN YOUR TOASTER WILL EXTEND THE PRODUCT'S LIFE

AND ASSURE PROPER LONG TERM PERFORMANCE. PREVENTATIVE

MAINTENANCE OF THE INTERNAL COMPONENTS IS A RECOMMENDED

PROCEDURE THAT MUST BE COMPLETED BY A KNOWLEDGEABLE TECHNICIAN,

SUCH AS AN APW WYOTT AUTHORIZED SERVICE TECHNICIAN. PREVENTATIVE

MAINTENANCE IS THE RESPONSIBILITY OF THE OWNER, AND IS NOT COVERED

UNDER THE WARRANTYAGREEMENT PROVIDED WITH THE TOASTER.

B. Open the right side panel by removing the Phillips screws with a screwdriver, and

inspect the drive chain and motor. DO NOT DISCARD THE SCREWS.

WARNING! Electrical hazards are present inside the toaster's right side panel. THE

TOASTER MUST BE UNPLUGGED BEFORE THE SIDE PANEL IS REMOVED. ONLY

AN EXPERIENCED / AUTHORIZED EMPLOYEE OR SERVICE AGENT PROPERLY

TRAINED IN MAINTAINING ELECTRICAL EQUIPMENT SHOULD BE REMOVING THE

RIGHT SIDE PANEL.

Inspect the drive chain. Lubricate the chain by applying a few drops of standard lubricant to

the chain and internal idler sprocket.

Inspect the drive motor. Lubricate the motor by applying a few drops of standard lubricant to

the hole in the outer metal flange thatcontains the motor's drive shaft.

14

Page 15

8. WIRING DIAGRAM - VCG TOASTER

15

SSR

Relay

Temperature

Control

-

+

Yellow “K” T/C

J3

Red

J2

Out Com

J1

2

3

Output

AC Input

1

4

From 81600321

4

Manual

Limit Sw.

N.C.

(+)

(-)

5

8

Cooling Fan

Element

Limit Sw.

N.C.

6

Orange or Red

Black

18

From 81600321

Sensor

Blue

Blue-Yellow

Blue

Transformer

17

Black-White

Black-Red

Black-Yellow

Black

Brown

Terminal

Momentary

Push Button

16

Blue

6 Places

Block

Switch

Main

Power

1

White or Blue Wire From Cord

Black or Brown Wire From Cord

Green Wire From Cord

66935 Scotch-Lok

Connector

7

Unused Wire

240V 60Hz Orange

208V 60Hz Red

Orange or Red

Black

Conveyor Motor

Page 16

29

11

9. PARTS LIST (EXPLODED VIEW) - VCG TOASTER

28

20

12

18

12

11

30

25

4

38

39

27

26

14

13

8

40

15

42

41

17

16

37

34

33

1

32

2

3

5

6

7

21

35

36

10

23

22

4

9

24

21

Page 17

PARTS LIST - VCG TOASTER

ITEM NUMBER PART NUMBER DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Not Shown

20

21

22

23

24

25

26

27

28

29

30

Not Shown

32

33

34

35

36

37

38

39

40

41

42

85640

89111

81600204

81600223

81600284

81600025

81600282

81600214

81600226

81600227

81600249

81600266

81600100

89488

81600296

85281

81600101

81600065

81600294

81600220

81600295

81600235

81600277

81600210

81600212

83267

81600105

81600255

81600103

81600050

81600321

86285

69146

69147

30218

81600311

81600322

81600248

81600337

81600340

81600323

81600350

Cordset

Strain Releif bushing

Motor Mount Assy'

Bearing

Bearing idler sprocket housing

Bushing

Sprocket 14 tooth

Platten

Conveyor Shaft, Lower

Conveyor Shaft, Upper

Sprocket 14 tooth

Retainer Ring

Controller, toaster microprocessor

Rocker Switch

Switch

Cooling fan motor

Probe

Belting

Sprocket (on drive motor)

Middle Cover

Sprocket 20 t

Chain

Motor

Right Side Cover

Left Side Cover

Legs

Bun Chute

Lid Weld Assy

Release Sheet

Knob

Control harness

High limit thermostat (Auto Reset)

Relay

Thermal Pad

Terminal Block

Transformer

High Limit Thermostat (Manual Reset)

Silicone Belt

Roller, Idler Belt Trainer 1 1/2”

Roller, Idler Belt Trainer 2 1/2”

Nut, Lock 3/8-32 UNEF

Knob w/Screw

10. Procedure: Orange Silicone Belt Tracking

Conveyor belt tracking is checked at the factory. New toasters

should not need adjusting. If, after replacing the orange silicone

belt as described under the periodic maintenance procedure, it

begins to "walk" toward one end of the conveyor or another, use the

Belt Tracking Knob to align the belt to the center of the conveyor.

Keeping the belt centered, along with regular cleaning, helps

preserve the life of this belt. Turn the knob in the direction the belt

appears to be "walking", to bring it back to the center of the

conveyor.After adjusting, check the tracking periodically for the first

hour to verify the belt is still centered. Over-adjusting may cause

the belt to begin to "walk" in the opposite direction. If this occurs, readjust by turning the knob again in the opposite direction, once

again, in the direction the belt is walking. Two to three rotations of

the knob should be enough to center the belt on the conveyor.Also

see the flow diagram on page 16 for belt tracking instructions.

Silicone Belt Tracking Adjustment

Belt Tracking Knob

Page 18

Start

PROCEDURE FOR BELT ADJUSTMENT (TRACKING)

Position yourself so that you face the conveyor with the access cover

between you and the conveyor. The platen should be on the other side

of the conveyorfrom you.This putsthe adjustmentscrew on yourright.

No

18

Continue to monitor the

conveyor from time-totime for a couple of days

to see if it walks over a

sprocket.

END

No

Did the conveyor

belt walk after a

few hours?

Yes

No

Has the belt

walked over

one of the

sprockets

within 10

minutes?

Yes

To which

sprocket did

the belt walk

over?

Left

Did thebelt walk

off the sprocket

in 5 minutes?

No

Turn the screw counter clock-wise about a half turn. If the belt has walked over the right

sprocket, you will need to put it in the center of the sprockets by hand. CAUTION!!! THE

BELTMAYBE EXTREMELY HOT. YOU COULDBURN YOURSELF.

Right

Yes

While conveyor

belt is still

between the

sprockets, turn the

screw 2 times

clock-wise.

Did thebelt walk

off the sprocket

in 5 minutes?

Within about 5

minutes, which

sprocket is the

conveyor walking

toward?

Neither. It stays

in center.

Yes

Left

While conveyor

belt is still

between the

sprockets, turn

the screw 2

times counter

clock-wise.

Right

Turn the screw clockwise about a half turn. If

the belt has walked over

the right sprocket, you

will need to put it in the

center of the sprockets

by hand. CAUTION!!!

THE BELT MAY BE

EXTREMELY HOT. YOU

COULD BURN

YOURSELF.

11. PROCEDURE FOR CHANGING A BELT

TOOLS NEEDED: Needle-nose pliers, phillips-head screwdriver.

1. Turn off toaster. Let coolfor 30 minutes.

2. Remove top lid and openfront cover.

3. Turn toaster on and depress top lid switch button until the belt splice

(flap) is at aboutthe center of the conveyor. Turn toaster off.

4. Remove the pin from thesplice using the needle-nose pliers.

5. Remove the old belt from the toaster. (CAREFUL!!! MAY BE HOT! YOU

COULD BURN YOURSELF!)

6. Put the new belt on. Feed the belt through the conveyor using the end

of the belt without the flaps. (CAREFUL!!! MAY BE HOT! YOU

COULD BURN YOURSELF!)

7. Put pin in splice. Make sure sides of belt are aligned and that belt is

routed over the plasticroller. Make surebelt is in center of conveyor.

8. Closethe front coverand turnto the rear conveyor.

9. Repeatsteps 3-7 forrear conveyor.

10. Close the rearcover and replacethe lid.

11. Turn toaster onand turn knobs to theirnormal settings.

12. Watch the conveyors to see if belts ride over the sprockets. If they do,

follow procedure for traininga belt (see section 10,pages 17-18).

Page 19

12. APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, subject to the

following conditions:

This warranty applies tothe original owner only and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsible for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized Service Agencies will void this warranty and APW Wyott will not be responsible for such work or any charges associated

with same.The closest APWWyottAuthorized Service Agent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas of Alaska and Canada. There

will be no labor coverage for equipment located on any island not connected by roadway to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary.Contact the internationalAPW Wyottdistributor, dealer, orservice agency for details.

TimePeriod

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency

may, at their option, require proof of purchase. Parts replaced under this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

Inall cases, parts covered by extended warranty will be shipped FOB the factory after the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this warranty. Equipment

weighing 70 pounds or under, and which is not permanently installed, i.e. with cord and plug, is considered portable and is subject to

the following warranty handling limitations. If portable equipment fails to operate in its intended manner on the first day of

connection, or use, atAPWWyott's option or its Authorized ServiceAgency, it willbe serviced on site or replaced.

From day two through the conclusion of this warranty period, portable units must be taken to or sent prepaid to the APW Wyott

Authorized ServiceAgency for in-warranty repairs. No mileage or travel charges are allowed on portable units after the first day of use.

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers, which are covered under the Enhanced WarrantyProgram, and (2) toasters or rollergrills which have

instore service.

Exclusions

The following conditions are not covered by warranty:

If the equipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person orto any property,which may result from the

use of the equipment thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime or premium labor rates, the owner shall be charged for the difference between normal service ratesand such

premium rates.APW Wyottdoes not assume any liability for extended delays in replacing orrepairing any items beyond its control.

Inall cases, the use of other thanAPW WyottAuthorized OEM Replacement Partswill void this warranty.

This equipment is intended forcommercial use only.Warranty isvoid if equipment is installed in other than commercial application.

WaterQuality Requirements

Water supply intended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTITUTES THE ENTIRE LIABILITY OFAPW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THE TERMS STATED HEREIN.

*Gas/Electric Cookline:

component parts, except switches and thermostats. (2 additional years on parts only.No labor on second or third year.)

*BroilerBriquettes,

*Heat Strips:

*GlassWindows, Doors, Seals, Rubber Seals, Light Bulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot or act ofgod.

*Equipment that has the model number or serial number removed or altered.

Models FD, FDL, FDD, FDDL. Two(2)YearWarrantyon element only. No labor second year.

Models GCB, GCRB, GF, GGM, GGT, CHP-H, EF, EG, EHP.Three (3) Year Warranty on all

RockGrates, Cooking Grates, BurnerShields, Fireboxes:

90Day Material Only. No Labor.

90Day Material Only.No Labor.

9/05

19

Page 20

Phone:

Fax: (214) 565-0976

Toll Free: (800) 527-2100

Website: www.apwwyott.com

E-mail: info@apwwyott.com

(214) 421-7366

APW / WYOTT

729 Third Avenue

Dallas, TX 75226

20

Loading...

Loading...