Page 1

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

For your safety do not store or use gasoline or other flammable vapors or liquids in the

vicinity of this or any other appliance. Keep the area free and clear of combustibles. (See ANZI

Improper installation, operation, service or maintenance can cause property

damage, injury or death. Read and understand these instructions thoroughly before

positioning, installing, maintaining or servicing this equipment.

INSTALLATION AND OPERATING INSTRUCTIONS

UTILITY

Model Numbers:

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES

This equipment has been engineered to provide you with year

according to the instructions in this manual and standard commercial kitchen practices.

APW WYOTT Foodservice Equipment

round dependable service when used

P/N 8893980

+1 (800) 752

www.apwwyott.com

!

!

SPTU

THERMO DRAWER

SPTU-30 , SPTU-30N , SPTU- 50, SPTU-50N

AT ALL TIMES

-

WARNING:

!

Z83.14B, 1991)

WARNING:

!

+1 (307) 634-5801 Phone

+1(307) 637-8071 Fax

Company

P.O. Box 1829

Cheyenne, WY 82003

05/12

-0863 Toll Free

1

Page 2

!

!

!

!

!

!

Improper installation, adjustment, alteration, service or maintenance can cause

!

!

!

APW Wyott takes pride in the design and quality of our products. When used as intended and with

proper care and maintenance, you will experience years of reliable operation from this equipment. To

ensure best results, it is important that you read and follow the instructions in this manual carefully.

Installation and start-up should be performed by a qualified installer who thoroughly read, understands

and follows these instructions.

If you have questions concerning the installation, operation, maintenance or service of this product, write

Technical Service Department APW/Wyott Foodservice Equipment Company, P.O. Box 1829, Cheyenne,

WY 82003.

SAFETY PRECAUTIONS

Before installing and operating this equipment be sure everyone involved in its operation is fully

trained and is aware of all precautions. Accidents and problems can result by a failure to follow

fundamental rules and precautions.

The following words and symbols, found in this manual, alert you to hazards to the operator,

service personnel or the equipment. The words are defined as follows.

DANGER:

death.

!

WARNING:

in serious injury or death.

!

CAUTION:

minor or moderate injury or product or property damage.

!

NOTICE:

understood even though not dangerous.

!

CAUTION:

positioned so the general public can use the equipment make sure that cautions, warnings, and

!

operating instructions are clearly posted near each unit so that anyone using the equipment will

use it correctly and not injure themselves or harm the equipment.

WARNING: - SHOCK HAZARD

!

WARNING:

property damage, injury or death. Read the Installation, Operating and Maintenance Instructions

!

thoroughly before installing or servicing this equipment.

This symbol warns of imminent hazard which will result in serious injury or

This symbol refers to a potential hazard or unsafe practice, which could result

This symbol refers to a potential hazard or unsafe practice, which may result in

This symbol refers to information that needs special attention or must be fully

These models are designed, built, and sold for commercial use. If these models are

Do not open any panels that require the use of tools.

NOTICE:

the absence of local codes, with the national electrical code ANSI/NFPA70- latest edition.

!

Canadian installation must comply with CSA-STANDARD C.22.2 Number 0 M1982 General

Requirements-Canadian Electrical Code Part II, 109-M1981- Commercial Cooking Appliances.

NOTICE:

Fire Protection Association, Inc. states in its NFPA96 latest edition that local codes are “Authority

!

Having Jurisdiction” when it comes to requirement for installation of equipment. Therefore,

installation should comply with all local codes.

The unit when installed, must be electrically grounded and comply with local codes, or in

Local codes regarding installation vary greatly from one area to another. The National

2

Page 3

!

WARNING:

!

!

!

!

and frequency listed on the data plate. Connect only to 1 or 3 phase as listed on the data plate.

Check the data plate on this unit before installation. Connect the unit only to the voltage

WARNING:

!

power plug, indicating that you are working on the circuit.

CAUTION:

!

any maintenance or repair, contact APW Wyott.

NOTICE:

this manual. We strongly recommend having a competent professional install this

equipment. A licensed electrician should make the electrical connections and connect

!

power to the unit. Local codes should always be used when connecting these units to

electrical power. In the absence of local codes, use the latest version of the National

Electrical Code.

Disconnect device from electrical power supply and place a Tag Out-Lockout on the

Maintenance & repair should be handled by a factory authorized agent. Before doing

Install according to the spacing requirements listed in the installation section of

CONTENTS

Description Page Description Page

Safety Precautions………….……….. 2 Exploded Views ………………………… 7

Specifications..............................….... 4 Parts List……….………………………... 9

General Installation Instructions…… 4 Wiring Schematics …………………….. 11

Cleaning .……………………….…….. 5 Notes……………………………………. 12

Troubleshooting / Service ...……….... 5 Warranty………………………………… 13

Operation…………………...……….... 6

LOCATION OF DATA PLATE

The data plate for the SPTU is located on the back of the unit.

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is received damaged, either apparent

or concealed, a claim must be made with the delivering carrier.

A) Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be

signed by the carrier representative (Driver). If this is not done, the carrier may refuse the claim.

The carrier can supply the necessary forms.

B) Concealed damage or loss if not apparent until after equipment is uncrated, a request for

inspection must be made to the carrier within 15 days. The carrier should arrange an inspection.

Be certain to hold all contents and packaging material.

Installation and start-up should be performed by a qualified installer who thoroughly read, understands

and follows these instructions.

3

Page 4

!

!

Do not use ordinary steel wool as any particles left on the surface will rust.

!

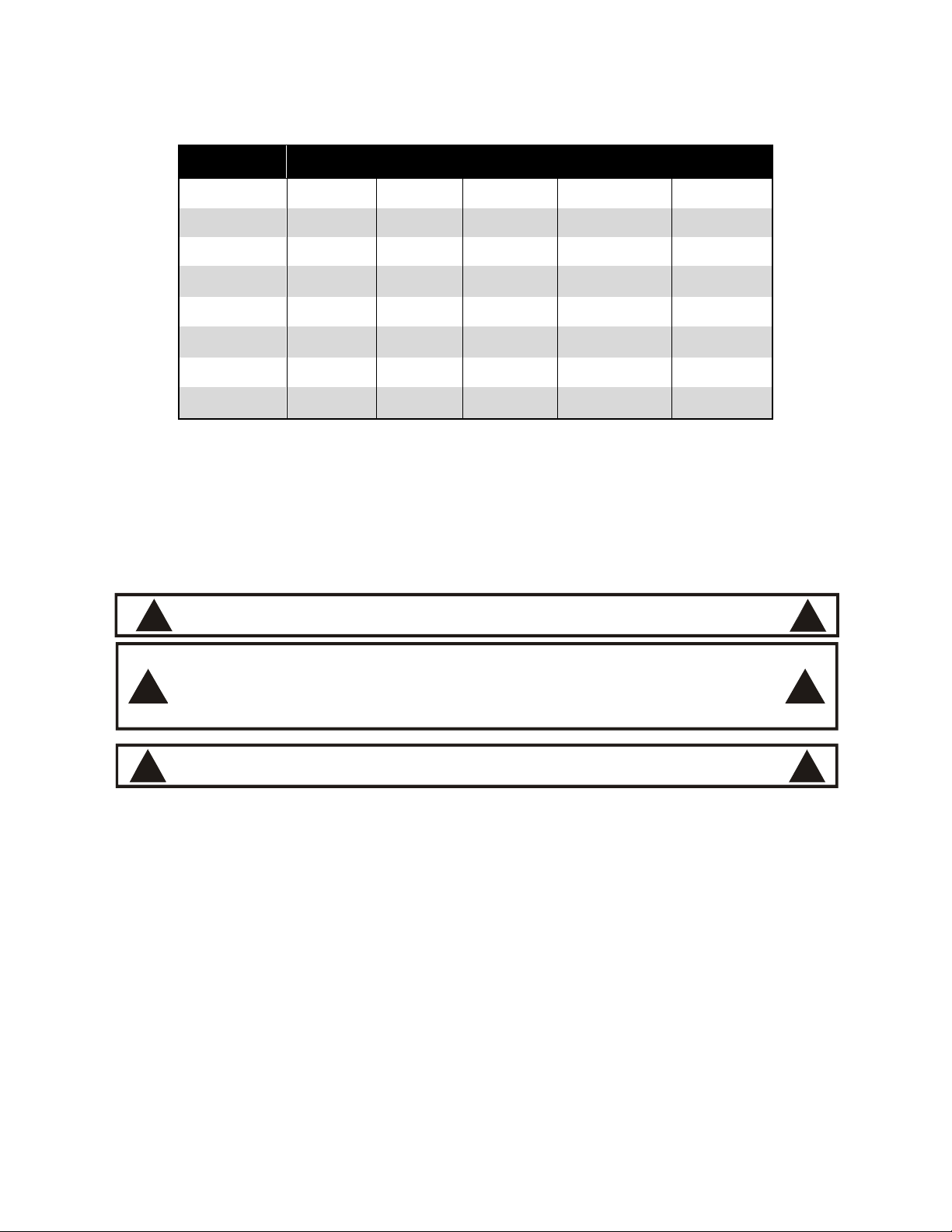

SPECIFICATIONS

MODEL WIDTH DEPTH HEIGHT VOLTAGE AMPS

SPTU-30 23.75” 19.25” 4.625” 120 4.1

SPTU-30 23.75” 19.25” 4.625” 208/240 2.1 / 2.4

SPTU-30N 19.25” 19.25” 4.625” 120 3.0

SPTU-30N 19.25” 19.25” 4.625” 208/240 1.6 / 1.8

SPTU-50 34.75” 19.25” 4.625” 120 7

SPTU-50 34.75” 19.25” 4.625” 208/240 3.6 / 4.2

SPTU-50N 30.25” 19.25” 4.625” 120 5.8

SPTU-50N 30.25” 19.25” 4.625” 208/240 3.0 / 3.5

GENERAL INSTALLATION INSTRUCTIONS

This unit has been inspected and tested at the factory prior to shipment.

Unpack the unit and remove all packing materials. Place on a flat horizontal surface at the desired location.

WARNING:

!

and frequency listed on the data plate. Connect only to 1 or 3 phase as listed on the data plate.

Check the data plate on this unit before installation. Connect the unit only to the voltage

WARNING: IMPROPER GROUNDING COULD RESULT IN ELECTRICAL SHOCK!

appliance is equipped with a three prong (grounded) plug for your protection against electrical

shock hazard and should be plugged directly into a properly grounded three prong receptacle.

!

Do not cut or remove the grounding prong from this plug.

CAUTION:

!

NEVER USE

tools. Surfaces which are marred collect dirt more rapidly and become more difficult to clean. Marring also

increases the possibility of corrosive attack.

NEVER

NEVER

1. Always clean equipment thoroughly before first use. (See general cleaning instructions)

2. Check ratings label for your model designation and electrical ratings.

3. For best results, use stainless steel countertops.

a wire brush, steel or abrasive scouring pads (except stainless), scraper, file or other steel

use any corrosive cleaner. Use only cleaners approved for stainless steel.

use cleaning solvents with a hydrocarbon base.

GENERAL INSTALLATION

This

4

Page 5

GENERAL OPERATION INSTRUCTIONS

1. Trained personnel should operate all food service equipment.

2. Do not allow your customers to come into contact with any surface labeled "CAUTION HOT".

3. Where applicable, never pour cold water into dry heated units.

4. Where applicable, do not cook, warm or hold food directly in liner/well pans. Always use steam table

pans/inserts, etc.

5. NEVER hold food below 140° F.

6. Power Switch appears lighted when unit is on

GENERAL CLEANING INSTRUCTIONS

1. Never clean any electrical unit by immersing it in water. Turn the unit off and allow it to cool before

surface cleaning.

2. Always clean equipment thoroughly before first use. Clean unit daily. Use warm, soapy water. Mild

cleansers and plastic scouring pads may be used to remove baked-on food and water scale on metal

unit.

3. Unplug electrical unit before cleaning or servicing. All service should be performed by an APW Wyott

authorized service agency.

DAILY CLEANING INSTRUCTIONS

1. Allow the unit to cool off.

2. Remove drawer and pan and wash it in hot, soapy water, then rinse. Do not submerge drawer face.

3. If stains are still present add detergent to wash cloth and repeat.

4. Dry with a lint free towel or paper towel.

NOTE: THIS APPLIANCE SHALL NOT BE CLEANED WITH A WATER JET.

GENERAL TROUBLESHOOTING

If the unit fails to operate, check the following:

1. Is the unit connected to a live power source?

2. Check the circuit breaker.

3. Is the power switch on and pilot light glowing?

4. Check the data plate. Are you operating the unit on the proper voltage?

If the above checks out and you still have problems, call an APW Wyott authorized service agency.

NOTICE:

knowledgeable with the operation of commercial gas, electric and steam cooking equipment. Contact the

Authorized Service Agency for reliable service, dependable advice or other assistance and for genuine

factory parts.

Warranty will be void and the manufacturer is relieved of all liability if:

A current listing of all authorized APW Wyott authorized parts/service distributors is included with this

product manual at the time of shipment. In the absence of this list you can call the APW Wyott 24 hour

Service Hot Line which gives access to the nearest Authorized APW Wyott parts/service distributor.

Call 1(800)733-2203.

Service work should be performed only by a qualified technician who is experienced in and

(A) Service work is performed by other than an APW Wyott Authorized Service Agency

Or

(B) Other than Genuine APW Wyott replacement parts are installed.

5

Page 6

SERVICE

Service work should be performed only by a qualified technician who is experienced in and knowledgeable

with the operation of commercial gas, electric and steam cooking equipment. Contact the Authorized Service

Agency for reliable service, dependable advice or other assistance and for genuine factory parts.

IF THE SUPPLY CORD IS DAMAGED, IT MUST BE REPLACED BY THE MANUFACTERER OR ITS

SERVICE AGENT OR A SIMILARLY QUALIFIED PERSON IN ORDER TO AVOID A HAZARD.

OPERATION / GENERAL DESCRIPTION

SPTU operates as a Heat & Hold oven. The product is loaded in the unit by the operator and heated per the

instruction below, insuring the food product has reached the appropriate temperature to meet the depth of

health guidelines. The operator then places it on the roller grill above. This methodology prevents cold food

product that was just placed on the grill from being selected by then customer.

HOLD MODE

- HOLD mode is on when the power switch is turned on and the timer is set to zero.

- This mode will keep product above 150ºF after a HEAT cycle has finished.

HEAT MODE

- HEAT mode is on when the timer is set to an allotted time.

- After the HEAT Cycle ends and the timer hits zero, the unit will automatically enter HOLD mode.

- Some experimentation will be necessary in determining heat times. The quantity and type of product

in the drawer will have an effect on the time it takes to heat to desired temperatures.

OPERATION

1. Open the drawer to expose the controls on the right side of the unit.

2. Turn the unit on using the lighted power switch.

3. Set the timer to 25-30 minutes to preheat the unit.

4. After the preheat period is over, open the drawer and load the roller grill product into the drawer.

5. Set timer for allotted “HEAT” time, the pilot light will come on, signaling the unit is in “HEAT” mode.

6. After product temperature requirements have been met, either remove product from drawer and

place on the roller grill, or leave the timer set at zero to enter the hold mode.

7. The HOLD mode will keep the internal temperature of roller grill product above 150ºF.

6

Page 7

EXPLODED VIEW – SPTU

7

Page 8

EXPLODED VIEW (CONTINUED) – SPTU

8

Page 9

PARTS LIST – SPTU

25000017 /

25000015 /

25000013 /

25000011 /

HEATER, FOIL BLANKET 120V /

RELAY, SPDT, 120V COIL, 30A @

THERMOSTAT, BI

-

MET DISC,

TIMER, 60 MIN TIME SWITCH, HIGH

Item SPTU-50 SPTU-50N SPTU-30 SPTU-30N DESCRIPTION QTY

1 25000157 25000057 25000137 25000037 LINER, INNER 1

2 25000156 25000056 25000136 25000036 LINER, INNER BACK 1

3 25000046 -SAME- -SAME- -SAME- THERMOSTAT BULB BRACKET 1

4 25000155 25000055 25000135 25000035 SKIN, BTM / REAR 1

5 25000064 -SAME- -SAME- - SAME - SUPPORT, SIDE LINER 2

6 25000163 25000063 25000143 25000043 BRACE, FRONT 1

7 25000173 25000073 25000123 25000023 HEAT PLATE, ANODIZED 1

8

9 25000053 - SAME - - SAME - - SAME - CONTROL PANEL 1

10 25000072 - SAME - - SAME - - SAME - COVER, CONTROL PANEL 1

11 25000076 - SAME - - SAME - - SAME - BRACKET, T-STAT & RELAY 1

12 25000154 25000054 25000134 25000034 SKIN, OUTER / SIDES 1

13 25000160 25000060 25000140 25000040 WELDMENT, DRAWER 1

14 25000165 25000065 25000145 25000045 WELDMENT, DRAWER COVER 1

15 25000169 25000069 25000149 25000049 PAN, DRAWER 1

16 8353200 - SAME - - SAME - - SAME - RIVNUT, 1/4-20 THIN HEAD 4

17 8507600 - SAME - - SAME - - SAME - WASHER, FLAT 1/4" 8

18 8641500 - SAME - - SAME - - SAME - BEARING,STAINLESS ROLLER SLIDES 4

19 8354000 - SAME - - SAME - - SAME - RIVET, POP, 1/8, SS 10

20 25000185 25000085 25000195 25000095 INSULATION, TOP 1 1

21 25000186 25000086 25000196 25000096 INSULATION, TOP 2 1

22 25000187 25000087 25000197 25000097 INSULATION, TOP 3 1

23 25000088 - SAME - - SAME - - SAME - INSULATION, SIDE 1 3

24 25000090 - SAME - - SAME - - SAME - INSULATION, SIDE 3 1

25 25000191 25000091 25000198 25000098 INSULATION, REAR 1

27 25000193 25000093 25000199 25000099 INSULATION, FRONT CHANNEL 1

28 1305610 - SAME - - SAME - - SAME - ROCKER SWITCH 1

29 1513903 - SAME - - SAME - - SAME - LIGHT INDICATOR 1

30 1481510 - SAME - - SAME - - SAME - THERMOSTAT, BULB, 200°F 1

25000018

25000016

25000014

25000012

220V

1

31 1475040 - SAME - - SAME - - SAME -

32 1486410 - SAME - - SAME - - SAME -

33 1400185 - SAME - - SAME - - SAME -

9

240V

125/250V 15/10A

TEMP

1

1

1

Page 10

PARTS LIST (CONTINUED) – SPTU

Item SPTU-50 SPTU-50N SPTU-30 SPTU-30N DESCRIPTION QTY

34 8602800 - SAME - - SAME - - SAME - BUSHING, HEYCO B-312-250 NYLON 1

35 8353500 - SAME - - SAME - - SAME - RIVNUT, 8-32 THIN HEAD 1

36 3100742 - SAME - - SAME - - SAME - FEET, BUMPER 1

37 8140800 - SAME - - SAME - - SAME - 8-32 x 1/2 MS 1

38 16218-00 - SAME - - SAME - - SAME - PLUG BEAUTY 1/2" CHROME 1

39 8206615 - SAME - - SAME - - SAME - STUD, PEM #4-40 X 3/8 2

40 8400700 - SAME - - SAME - - SAME - NUT, HEX, 4-40, S/S 2

41 8103400 - SAME - - SAME - - SAME - SCREW, MACH, 6-32 X 1/4" LG. 2

42 8400100 - SAME - - SAME - - SAME - NUT, HEX KEPS, #6-32 4

43 8839110 - SAME - - SAME - - SAME - LABEL, CAUTION HOT SURFACE 2

44 8861000 - SAME - - SAME - - SAME - LABEL, SPEC 1

45 8130000 - SAME - - SAME - - SAME - 8-32 X 3/8 TYPE T 7

46 8506000 - SAME - - SAME - - SAME - LOCKWASHER, EXT TOOTH # 10 1

47 8422400 - SAME - - SAME - - SAME - #10-24 HX NUT GRN 1

48 1196000 - SAME - - SAME - - SAME - CONNECTOR WIRE SETSCREW #11 2

49 8967400 - SAME - - SAME - - SAME - STRAIN RELIEF 1

50 47255900 - SAME - - SAME - - SAME - CORD SET SJTO 16-3 1

51 8206300 - SAME - - SAME - - SAME - BOLT, SHOULDER .312 DIA. 1/2LG 1/4-20 2

52 8431300 - SAME - - SAME - - SAME - 1/4-20 FLANGED HEX LOCKNUT 2

53 25000080 - SAME - - SAME - - SAME - BEARING, LATERAL DRAWER, PTFE 2

10

Page 11

WIRING SCHEMATIC

11

Page 12

NOTES:

12

Page 13

Authorized Service Agency for in-warranty repairs. No mileage or travel charges are allowed on port able units after the first day of use.

APW WYOTT EQUIPMENT LIMITED WARRANTY

APW Wyott Foodservice Equipment Company warrants it's equipment against defects in materials and workmanship, su bject to the

following conditions:

This warranty applies to the original owner only and is not assignable .

Should any product fail to function in its intended ma nner under normal use w ithin the limits defined in this warranty, at the option of

APW Wyott such product will be repaired or replaced by APW Wyott or its Authorized Service Agency. APW Wyott will only be

responsib le for charges incurred or service performed by its Authorized Service Agencies. The use of other than APW Wyott

Authorized Service Agencies will void this war ranty and APW Wyott will not be responsible for such work or any charges associated

with same . The closest APW Wyott Authorized Service Agent must be used.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, metropolitan areas of Alaska and Canada. There

will be no labor coverage for equipment located on any island not connected by roadw ay to the mainland.

Warranty coverage on products used outside the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska and Canada

may vary. Contact the international APW Wyott distributor, dealer, or service agency for details.

Time Period

One year for parts and one year for labor, effective from the date of purchase by the original owner. The Authorized Service Agency

may, at their op tion, require proof of pur chase. Parts replaced und er this warranty are warranted for the un-expired portion of the

original product warranty only.

Exceptions

In all cases, parts covered by extended warranty wil l be ship ped FOB the facto ry after the first year.

Portable Carry In Products

Equipment weighing over 70 pounds or permanently installed will be serviced on-site as per the terms of this wa rranty. Equipment

weighing 70 poun ds or under, and whi ch is not permanently installed, i.e. with co rd and plug, is considered portable and is su bject to

the follow ing warranty handling limitations. If port able equipment fails to operate in its intended manner on the first day of

connection, or use, at APW Wyott's option or its Authorized Service Agency, it will be serviced on site or replaced.

From day two through the conclusi on of this warranty period, portable units mu st be taken to or sent prepaid to the APW Wyott

If the customer wants on-site service, they may receive same by paying the travel and mileage charges. Exceptions to this rule: (1)

countertop warmers and cookers, which are covered under the Enhanced Warranty Program, an d (2) toasters or rollergrills which have

in store service.

Exclusions

The following conditions are not co vered by warranty:

If the equ ipment has been changed, altered, modified or repaired by other than an Authorized Service Agency during or after the

warranty period, then the manufacturer shall not be liable for any damages to any person or to any prop erty, which may result from the

use of the equipm ent thereafter.

This warranty does not cover services performed at overtime or premium labor rates. Should service be required at times which

normally involve overtime or premium lab or rates, the owner shall be charged for the di fference between normal service rat es and such

premium rates. APW Wyott does not assume any liability for extended delays in replacing or repairing any i tems beyond its control.

In all cases, the use of other than APW Wyott Authorized OEM Replacement Parts will void this warranty.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in other than commercial application .

Water Quality Requirements

Water supply int ended for a unit that has in excess of 3.0 grains of hardness per gallon (GPG) must be treated or softened before

being used. Water containing over 3.0 GPG will decrease the efficiency and reduce the operation life of the unit.

Note: Product failure caused by liming or sediment buildup is not covered under warranty.

“THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSES

AND CONSTIT UTES THE E NTIRE LIABILITY OF APW WYOTT. IN NO EVENT DOES THE LIMITED WARRANTY

EXTEND BEYOND THE TERMS STATED HEREIN.”

*Gas/Electric Cookline:

component parts, except switches and thermostats. ( 2 additional years on parts only. No labor on second or third year.)

*Broiler Briquettes,

*Heat Strips:

*Glass Windows, Doors, Seals, Rubber Seals, Light Bulbs:

*Equipment failure relating to improper installation, improper utility connection or supply and problems due to

ventilation.

*Equipment that has not been properly maintained, calibration of controls, adjustments, damage from improper cleaning

and water damage to controls.

*Equipment that has not been used in an appropriate manner, or has been subject to misuse or misapplication, neglect,

abuse, accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot or act of god .

*Equipment that has the model number or serial number removed or altered.

Models FD, FDL, FDD, FDDL. Two (2) Year Warranty on element only. No labor second year.

Models GCB, GCRB, GF, GGM , GGT, CHP-H, EF, EG, EHP. Three (3) Year Warranty on all

Rock Grates, Cooking Grates, Burner Shields, Fireboxes:

90 Day Material Only. No Labor.

90 Day Material Only. No Labor.

9/05

13

Loading...

Loading...